ABS FORD F750 2012 12.G Owners Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2012, Model line: F750, Model: FORD F750 2012 12.GPages: 306, PDF Size: 1.74 MB

Page 14 of 306

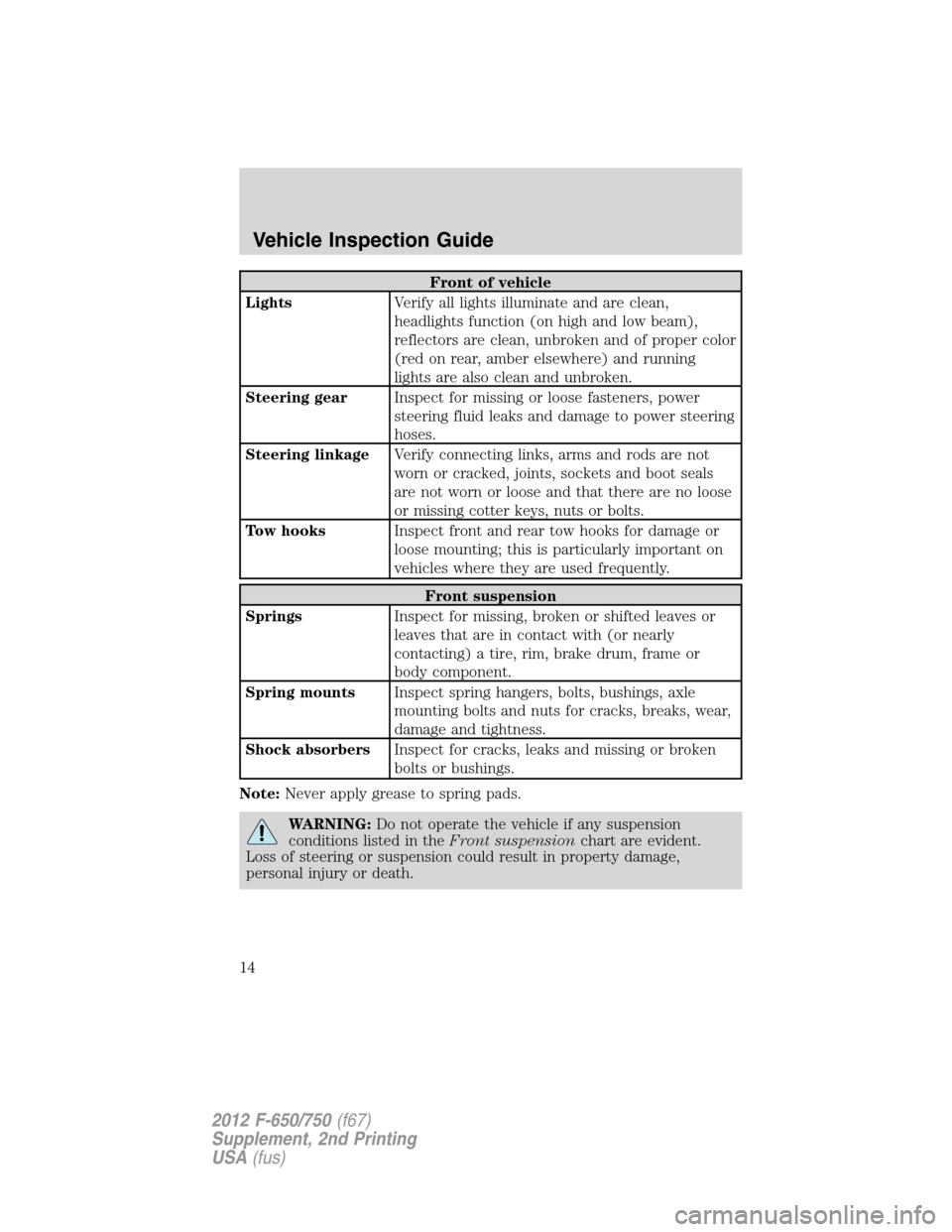

Front of vehicle

LightsVerify all lights illuminate and are clean,

headlights function (on high and low beam),

reflectors are clean, unbroken and of proper color

(red on rear, amber elsewhere) and running

lights are also clean and unbroken.

Steering gearInspect for missing or loose fasteners, power

steering fluid leaks and damage to power steering

hoses.

Steering linkageVerify connecting links, arms and rods are not

worn or cracked, joints, sockets and boot seals

are not worn or loose and that there are no loose

or missing cotter keys, nuts or bolts.

Tow hooksInspect front and rear tow hooks for damage or

loose mounting; this is particularly important on

vehicles where they are used frequently.

Front suspension

SpringsInspect for missing, broken or shifted leaves or

leaves that are in contact with (or nearly

contacting) a tire, rim, brake drum, frame or

body component.

Spring mountsInspect spring hangers, bolts, bushings, axle

mounting bolts and nuts for cracks, breaks, wear,

damage and tightness.

Shock absorbersInspect for cracks, leaks and missing or broken

bolts or bushings.

Note:Never apply grease to spring pads.

WARNING:Do not operate the vehicle if any suspension

conditions listed in theFront suspensionchart are evident.

Loss of steering or suspension could result in property damage,

personal injury or death.

Vehicle Inspection Guide

14

2012 F-650/750(f67)

Supplement, 2nd Printing

USA(fus)

Page 18 of 306

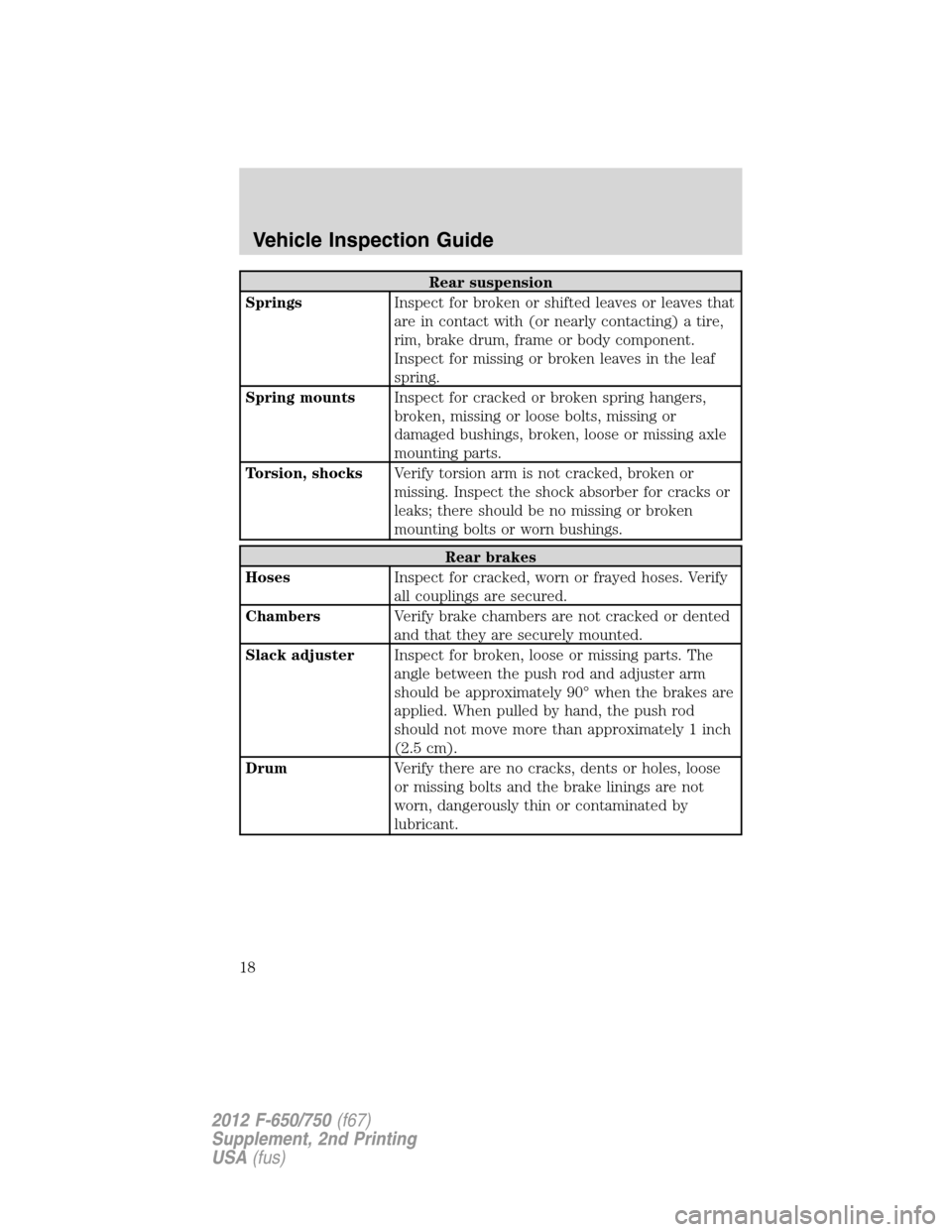

Rear suspension

SpringsInspect for broken or shifted leaves or leaves that

are in contact with (or nearly contacting) a tire,

rim, brake drum, frame or body component.

Inspect for missing or broken leaves in the leaf

spring.

Spring mountsInspect for cracked or broken spring hangers,

broken, missing or loose bolts, missing or

damaged bushings, broken, loose or missing axle

mounting parts.

Torsion, shocksVerify torsion arm is not cracked, broken or

missing. Inspect the shock absorber for cracks or

leaks; there should be no missing or broken

mounting bolts or worn bushings.

Rear brakes

HosesInspect for cracked, worn or frayed hoses. Verify

all couplings are secured.

ChambersVerify brake chambers are not cracked or dented

and that they are securely mounted.

Slack adjusterInspect for broken, loose or missing parts. The

angle between the push rod and adjuster arm

should be approximately 90° when the brakes are

applied. When pulled by hand, the push rod

should not move more than approximately 1 inch

(2.5 cm).

DrumVerify there are no cracks, dents or holes, loose

or missing bolts and the brake linings are not

worn, dangerously thin or contaminated by

lubricant.

Vehicle Inspection Guide

18

2012 F-650/750(f67)

Supplement, 2nd Printing

USA(fus)

Page 21 of 306

when you start your vehicle to make sure the bulb works. If any light

remains on after starting the vehicle, refer to the respective system

warning light for additional information.

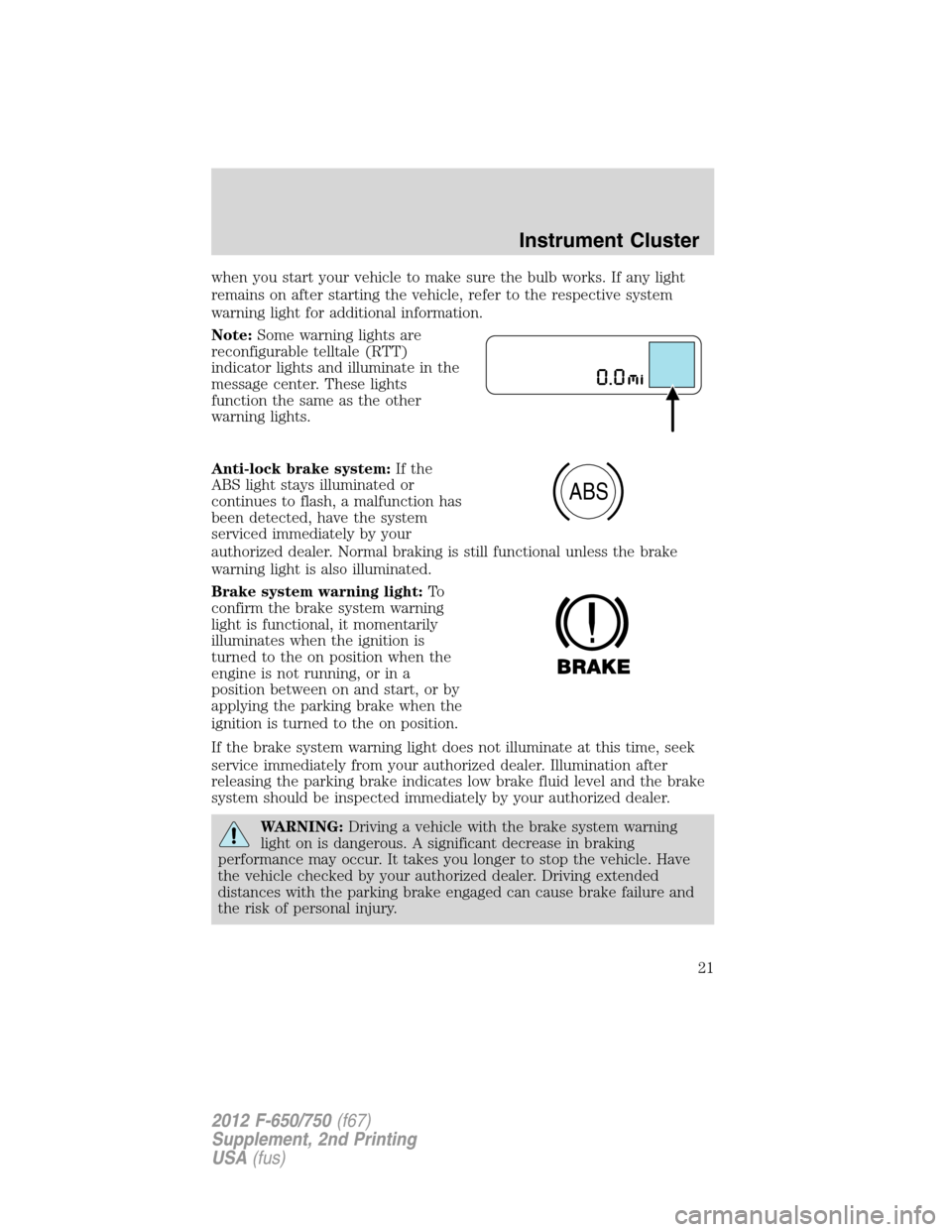

Note:Some warning lights are

reconfigurable telltale (RTT)

indicator lights and illuminate in the

message center. These lights

function the same as the other

warning lights.

Anti-lock brake system:If the

ABS light stays illuminated or

continues to flash, a malfunction has

been detected, have the system

serviced immediately by your

authorized dealer. Normal braking is still functional unless the brake

warning light is also illuminated.

Brake system warning light:To

confirm the brake system warning

light is functional, it momentarily

illuminates when the ignition is

turned to the on position when the

engine is not running, or in a

position between on and start, or by

applying the parking brake when the

ignition is turned to the on position.

If the brake system warning light does not illuminate at this time, seek

service immediately from your authorized dealer. Illumination after

releasing the parking brake indicates low brake fluid level and the brake

system should be inspected immediately by your authorized dealer.

WARNING:Driving a vehicle with the brake system warning

light on is dangerous. A significant decrease in braking

performance may occur. It takes you longer to stop the vehicle. Have

the vehicle checked by your authorized dealer. Driving extended

distances with the parking brake engaged can cause brake failure and

the risk of personal injury.

ABS

Instrument Cluster

21

2012 F-650/750(f67)

Supplement, 2nd Printing

USA(fus)

Page 26 of 306

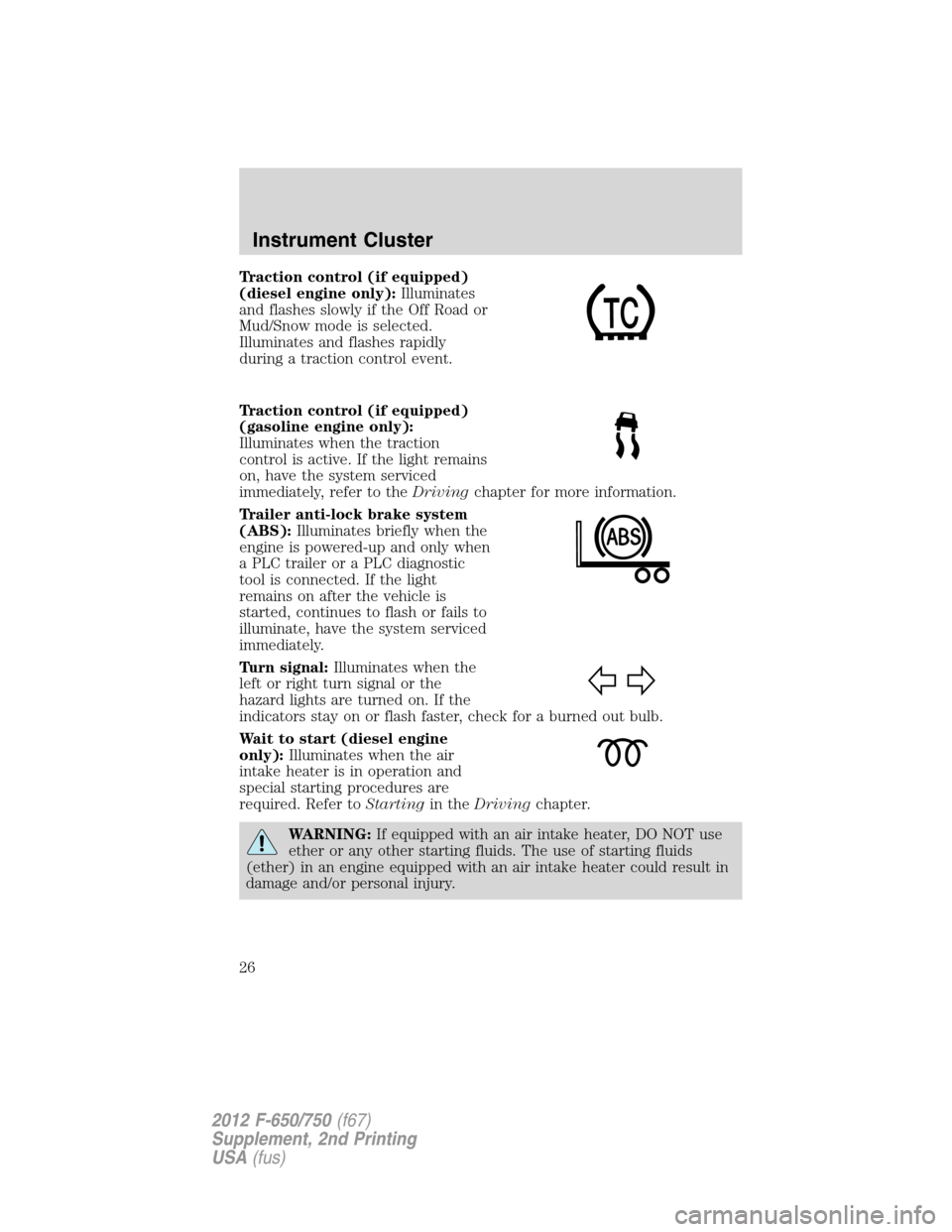

Traction control (if equipped)

(diesel engine only):Illuminates

and flashes slowly if the Off Road or

Mud/Snow mode is selected.

Illuminates and flashes rapidly

during a traction control event.

Traction control (if equipped)

(gasoline engine only):

Illuminates when the traction

control is active. If the light remains

on, have the system serviced

immediately, refer to theDrivingchapter for more information.

Trailer anti-lock brake system

(ABS):Illuminates briefly when the

engine is powered-up and only when

a PLC trailer or a PLC diagnostic

tool is connected. If the light

remains on after the vehicle is

started, continues to flash or fails to

illuminate, have the system serviced

immediately.

Turn signal:Illuminates when the

left or right turn signal or the

hazard lights are turned on. If the

indicators stay on or flash faster, check for a burned out bulb.

Wait to start (diesel engine

only):Illuminates when the air

intake heater is in operation and

special starting procedures are

required. Refer toStartingin theDrivingchapter.

WARNING:If equipped with an air intake heater, DO NOT use

ether or any other starting fluids. The use of starting fluids

(ether) in an engine equipped with an air intake heater could result in

damage and/or personal injury.

Instrument Cluster

26

2012 F-650/750(f67)

Supplement, 2nd Printing

USA(fus)

Page 33 of 306

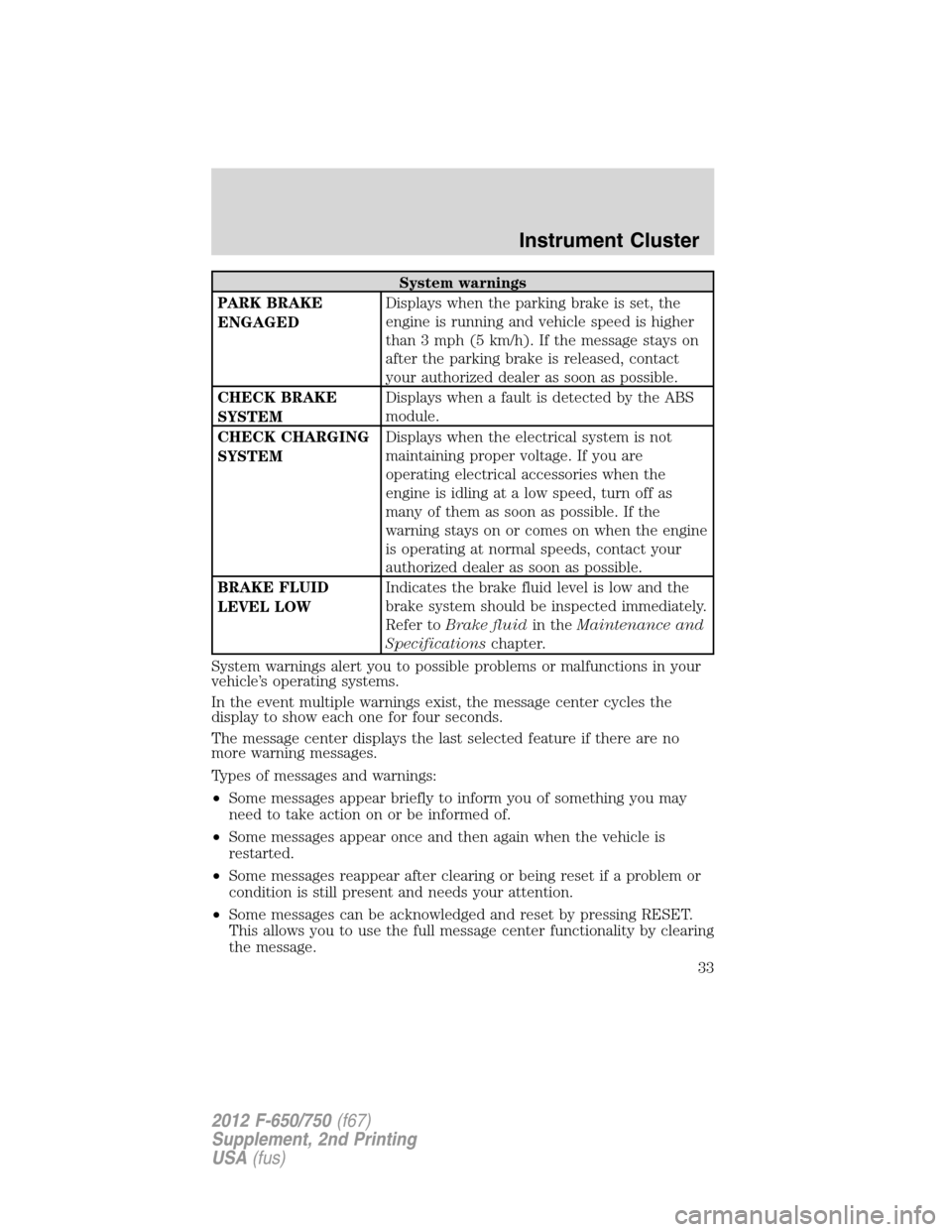

System warnings

PARK BRAKE

ENGAGEDDisplays when the parking brake is set, the

engine is running and vehicle speed is higher

than 3 mph (5 km/h). If the message stays on

after the parking brake is released, contact

your authorized dealer as soon as possible.

CHECK BRAKE

SYSTEMDisplays when a fault is detected by the ABS

module.

CHECK CHARGING

SYSTEMDisplays when the electrical system is not

maintaining proper voltage. If you are

operating electrical accessories when the

engine is idling at a low speed, turn off as

many of them as soon as possible. If the

warning stays on or comes on when the engine

is operating at normal speeds, contact your

authorized dealer as soon as possible.

BRAKE FLUID

LEVEL LOWIndicates the brake fluid level is low and the

brake system should be inspected immediately.

Refer toBrake fluidin theMaintenance and

Specificationschapter.

System warnings alert you to possible problems or malfunctions in your

vehicle’s operating systems.

In the event multiple warnings exist, the message center cycles the

display to show each one for four seconds.

The message center displays the last selected feature if there are no

more warning messages.

Types of messages and warnings:

•Some messages appear briefly to inform you of something you may

need to take action on or be informed of.

•Some messages appear once and then again when the vehicle is

restarted.

•Some messages reappear after clearing or being reset if a problem or

condition is still present and needs your attention.

•Some messages can be acknowledged and reset by pressing RESET.

This allows you to use the full message center functionality by clearing

the message.

Instrument Cluster

33

2012 F-650/750(f67)

Supplement, 2nd Printing

USA(fus)

Page 70 of 306

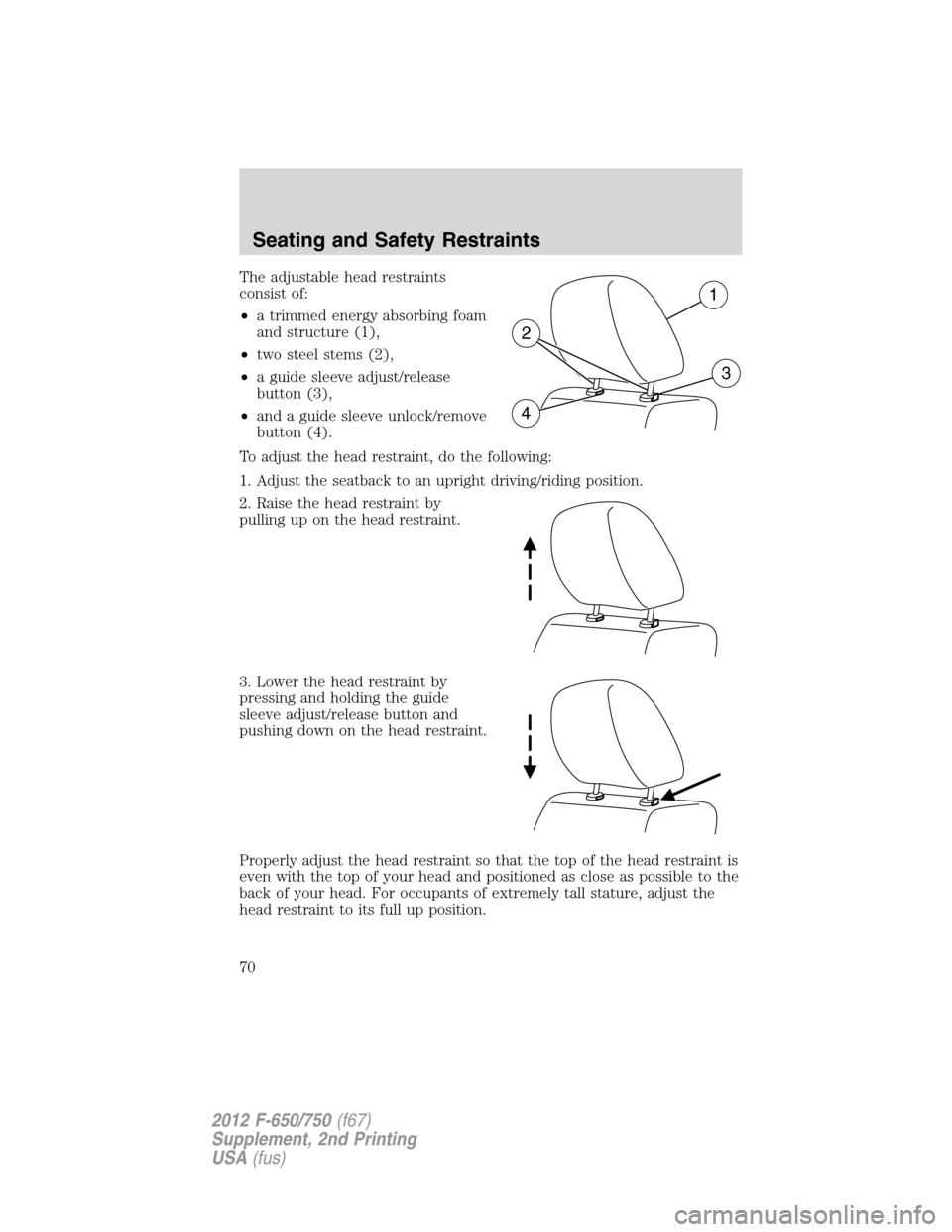

The adjustable head restraints

consist of:

•a trimmed energy absorbing foam

and structure (1),

•two steel stems (2),

•a guide sleeve adjust/release

button (3),

•and a guide sleeve unlock/remove

button (4).

To adjust the head restraint, do the following:

1. Adjust the seatback to an upright driving/riding position.

2. Raise the head restraint by

pulling up on the head restraint.

3. Lower the head restraint by

pressing and holding the guide

sleeve adjust/release button and

pushing down on the head restraint.

Properly adjust the head restraint so that the top of the head restraint is

even with the top of your head and positioned as close as possible to the

back of your head. For occupants of extremely tall stature, adjust the

head restraint to its full up position.

3

1

2

4

Seating and Safety Restraints

70

2012 F-650/750(f67)

Supplement, 2nd Printing

USA(fus)

Page 72 of 306

Properly adjust the head restraint so that the top of the head restraint is

even with the top of your head and positioned as close as possible to the

back of your head. For occupants of extremely tall stature, adjust the

head restraint to its full up position.

WARNING:To minimize the risk of neck injury in the event of a

crash, head restraints must be installed properly.

Front row center non-adjustable head restraint (if equipped)

Vehicles equipped with a front center seat have a head restraint that is

non-adjustable.

The non-adjustable head restraint

consists of:

•a trimmed energy absorbing foam

and structure (1),

•two steel stems (2),

•and two guide sleeve

unlock/remove buttons (3).

To remove the non-adjustable head restraint, do the following:

Simultaneously press and hold both

unlock/remove buttons, then pull up

on the head restraint.

12

3

Seating and Safety Restraints

72

2012 F-650/750(f67)

Supplement, 2nd Printing

USA(fus)

Page 78 of 306

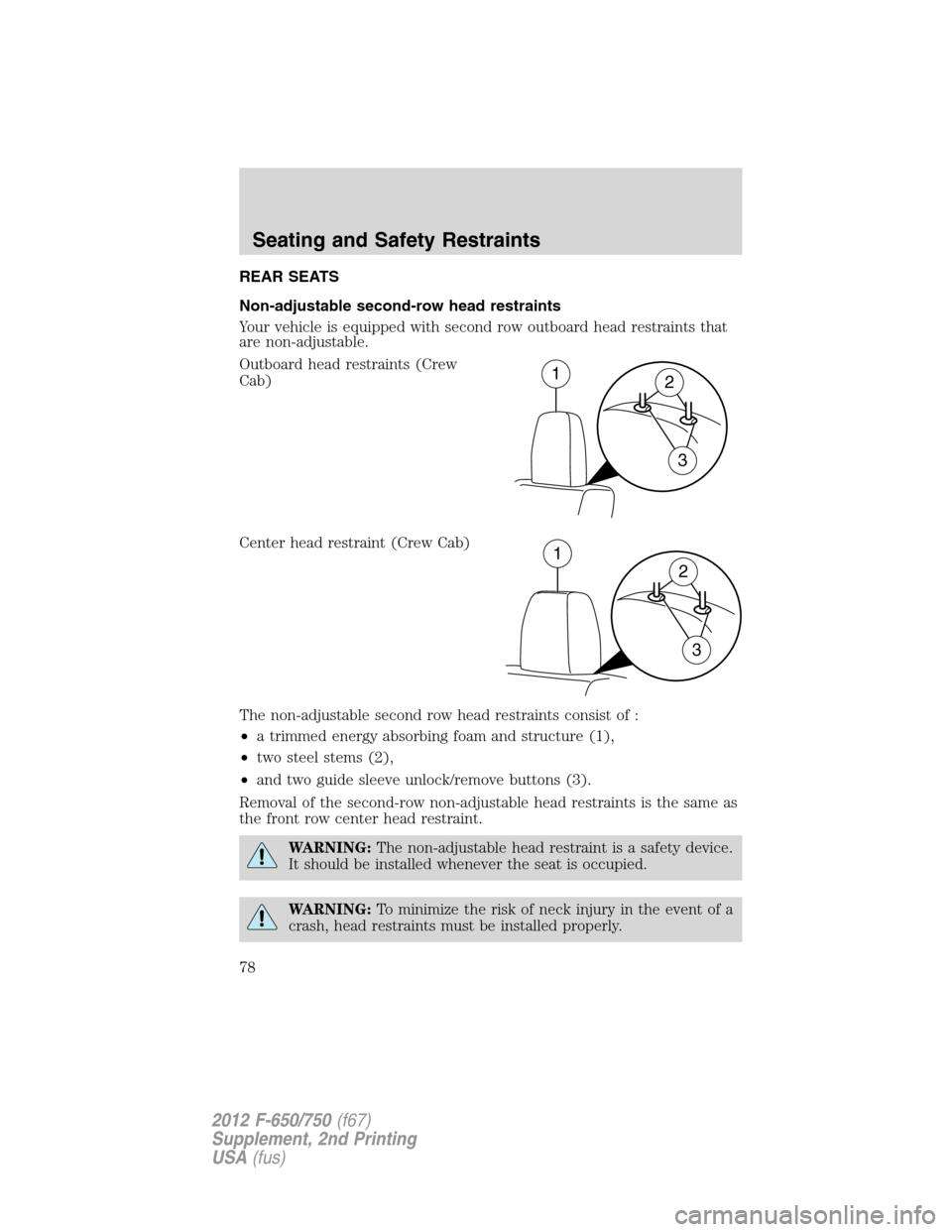

REAR SEATS

Non-adjustable second-row head restraints

Your vehicle is equipped with second row outboard head restraints that

are non-adjustable.

Outboard head restraints (Crew

Cab)

Center head restraint (Crew Cab)

The non-adjustable second row head restraints consist of :

•a trimmed energy absorbing foam and structure (1),

•two steel stems (2),

•and two guide sleeve unlock/remove buttons (3).

Removal of the second-row non-adjustable head restraints is the same as

the front row center head restraint.

WARNING:The non-adjustable head restraint is a safety device.

It should be installed whenever the seat is occupied.

WARNING:To minimize the risk of neck injury in the event of a

crash, head restraints must be installed properly.

12

3

1

2

3

Seating and Safety Restraints

78

2012 F-650/750(f67)

Supplement, 2nd Printing

USA(fus)

Page 110 of 306

WARNING:Do not drive with your foot resting on the brake

pedal. This results in abnormally high brake temperatures,

excessive lining wear and increased stopping distances.

Before descending a long or steep hill, shift to a lower gear and avoid

continuous application of the brakes. Normally, choose the same gear to

descend the hill that you use to ascend the hill.

WARNING:Continuous application of the brakes causes the

brakes to overheat, resulting in a temporary loss of braking.

If brakes do not grip well

•If you have been driving through deep water, gently apply the brakes

several times while the vehicle is moving slowly.

•Let the brakes cool if you have been using them excessively, as in

mountain driving or after several fast, high-speed stops.

•Check brake adjustment.

•Check brake linings for excessive wear.

•Check system air pressure on vehicles equipped with air brakes.

HYDRAULIC BRAKES (IF EQUIPPED)

Full Power Brake System

This system incorporates standard braking, an anti-lock braking system

(ABS) and optional Power Park Brake into one fully-integrated hydraulic

brake system. With the Full Power Brake System, braking energy is

stored, similar to an air brake system, resulting in faster response times

and shorter stopping distances. This is accomplished using motor/pump

assemblies that pressurized the system by pumping brake fluid into

accumulators. This is similar to the air compressor of an air brake system

pressurizing the air tanks. The system includes a master cylinder that

provides the normal pedal “feel” and transfers the pedal force, via brake

fluid, to the main components of the system.

Note:The motor/pumps run momentarily with the ignition switch in the

on or run positions or the switch is in the off position and the brake

pedal is pressed.

Driving

110

2012 F-650/750(f67)

Supplement, 2nd Printing

USA(fus)

Page 127 of 306

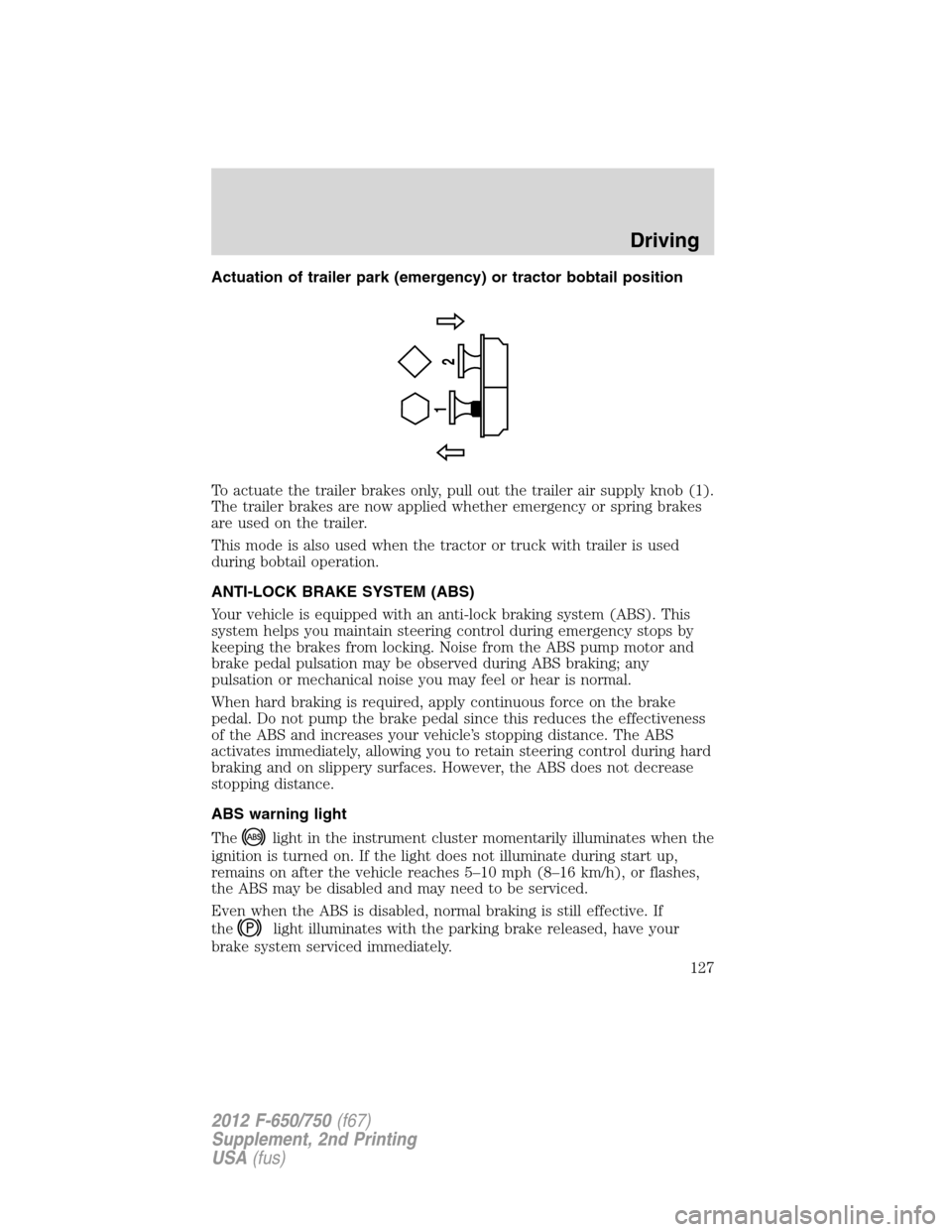

Actuation of trailer park (emergency) or tractor bobtail position

To actuate the trailer brakes only, pull out the trailer air supply knob (1).

The trailer brakes are now applied whether emergency or spring brakes

are used on the trailer.

This mode is also used when the tractor or truck with trailer is used

during bobtail operation.

ANTI-LOCK BRAKE SYSTEM (ABS)

Your vehicle is equipped with an anti-lock braking system (ABS). This

system helps you maintain steering control during emergency stops by

keeping the brakes from locking. Noise from the ABS pump motor and

brake pedal pulsation may be observed during ABS braking; any

pulsation or mechanical noise you may feel or hear is normal.

When hard braking is required, apply continuous force on the brake

pedal. Do not pump the brake pedal since this reduces the effectiveness

of the ABS and increases your vehicle’s stopping distance. The ABS

activates immediately, allowing you to retain steering control during hard

braking and on slippery surfaces. However, the ABS does not decrease

stopping distance.

ABS warning light

The

light in the instrument cluster momentarily illuminates when the

ignition is turned on. If the light does not illuminate during start up,

remains on after the vehicle reaches 5–10 mph (8–16 km/h), or flashes,

the ABS may be disabled and may need to be serviced.

Even when the ABS is disabled, normal braking is still effective. If

the

light illuminates with the parking brake released, have your

brake system serviced immediately.

1

2

Driving

127

2012 F-650/750(f67)

Supplement, 2nd Printing

USA(fus)