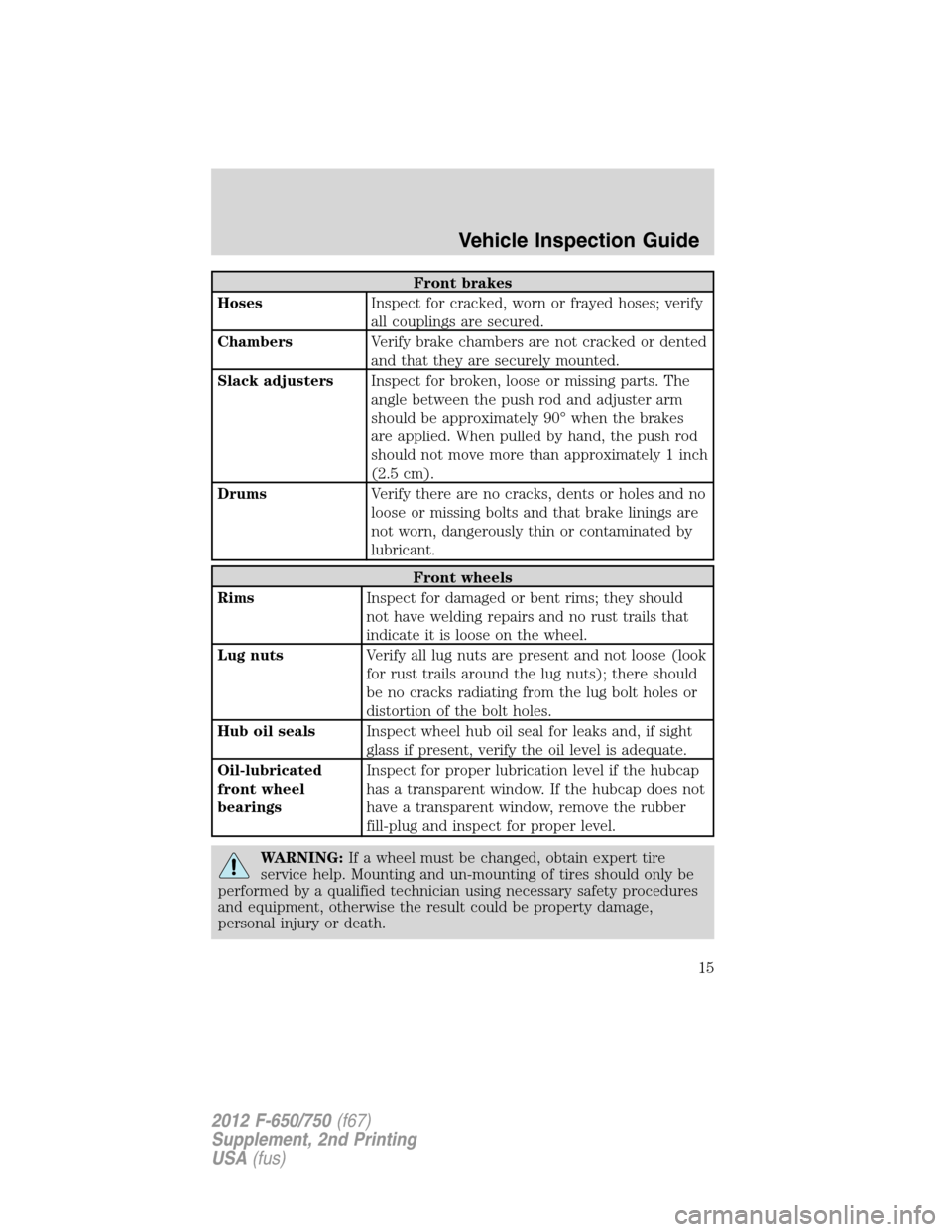

Front brakes

HosesInspect for cracked, worn or frayed hoses; verify

all couplings are secured.

ChambersVerify brake chambers are not cracked or dented

and that they are securely mounted.

Slack adjustersInspect for broken, loose or missing parts. The

angle between the push rod and adjuster arm

should be approximately 90° when the brakes

are applied. When pulled by hand, the push rod

should not move more than approximately 1 inch

(2.5 cm).

DrumsVerify there are no cracks, dents or holes and no

loose or missing bolts and that brake linings are

not worn, dangerously thin or contaminated by

lubricant.

Front wheels

RimsInspect for damaged or bent rims; they should

not have welding repairs and no rust trails that

indicate it is loose on the wheel.

Lug nutsVerify all lug nuts are present and not loose (look

for rust trails around the lug nuts); there should

be no cracks radiating from the lug bolt holes or

distortion of the bolt holes.

Hub oil sealsInspect wheel hub oil seal for leaks and, if sight

glass if present, verify the oil level is adequate.

Oil-lubricated

front wheel

bearingsInspect for proper lubrication level if the hubcap

has a transparent window. If the hubcap does not

have a transparent window, remove the rubber

fill-plug and inspect for proper level.

WARNING:If a wheel must be changed, obtain expert tire

service help. Mounting and un-mounting of tires should only be

performed by a qualified technician using necessary safety procedures

and equipment, otherwise the result could be property damage,

personal injury or death.

Vehicle Inspection Guide

15

2012 F-650/750(f67)

Supplement, 2nd Printing

USA(fus)