Compressor FORD F750 2015 13.G Owners Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2015, Model line: F750, Model: FORD F750 2015 13.GPages: 384, PDF Size: 4.95 MB

Page 15 of 384

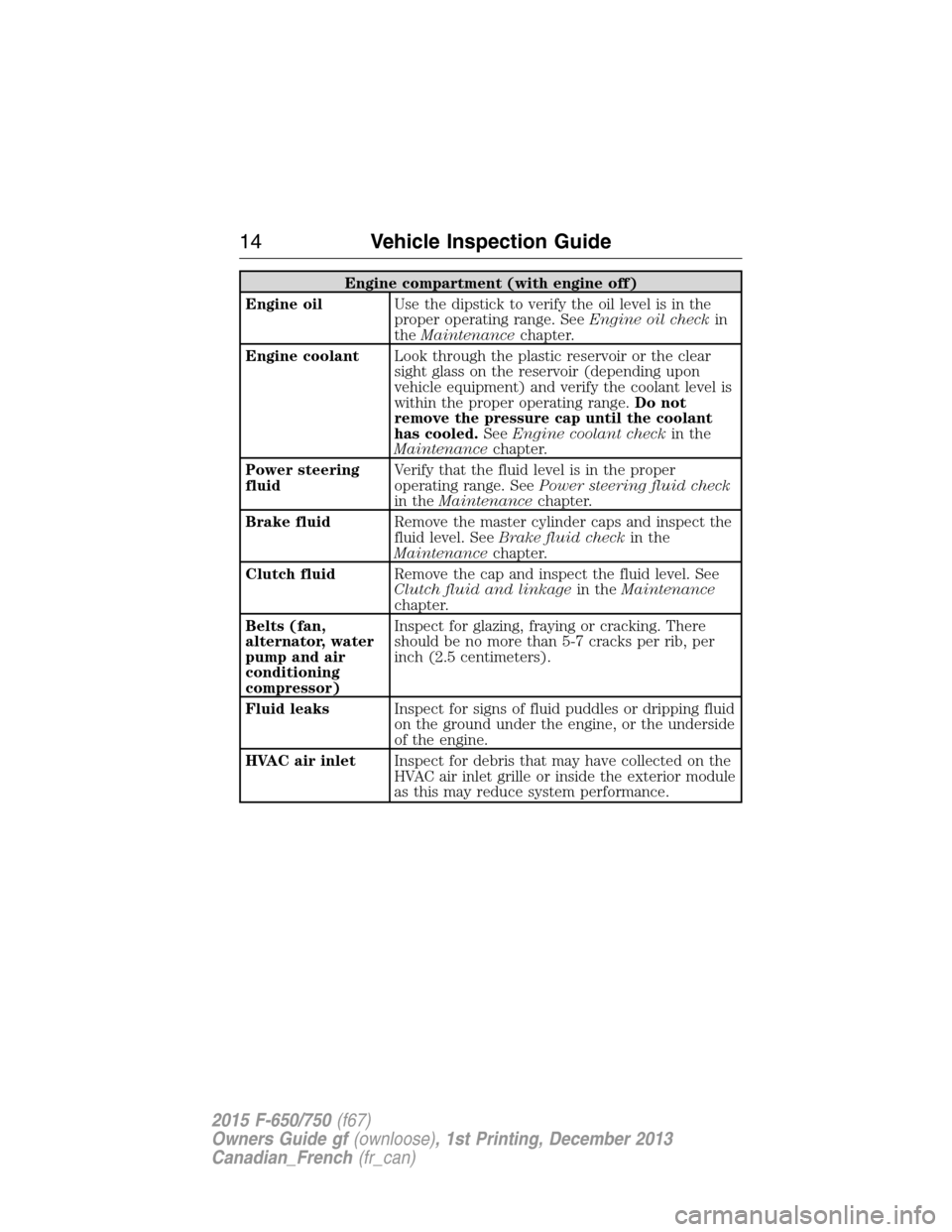

Engine compartment (with engine off)

Engine oilUse the dipstick to verify the oil level is in the

proper operating range. SeeEngine oil checkin

theMaintenancechapter.

Engine coolantLook through the plastic reservoir or the clear

sight glass on the reservoir (depending upon

vehicle equipment) and verify the coolant level is

within the proper operating range.Do not

remove the pressure cap until the coolant

has cooled.SeeEngine coolant checkin the

Maintenancechapter.

Power steering

fluidVerify that the fluid level is in the proper

operating range. SeePower steering fluid check

in theMaintenancechapter.

Brake fluidRemove the master cylinder caps and inspect the

fluid level. SeeBrake fluid checkin the

Maintenancechapter.

Clutch fluidRemove the cap and inspect the fluid level. See

Clutch fluid and linkagein theMaintenance

chapter.

Belts (fan,

alternator, water

pump and air

conditioning

compressor)Inspect for glazing, fraying or cracking. There

should be no more than 5-7 cracks per rib, per

inch (2.5 centimeters).

Fluid leaksInspect for signs of fluid puddles or dripping fluid

on the ground under the engine, or the underside

of the engine.

HVAC air inletInspect for debris that may have collected on the

HVAC air inlet grille or inside the exterior module

as this may reduce system performance.

14Vehicle Inspection Guide

2015 F-650/750(f67)

Owners Guide gf(ownloose), 1st Printing, December 2013

Canadian_French(fr_can)

Page 16 of 384

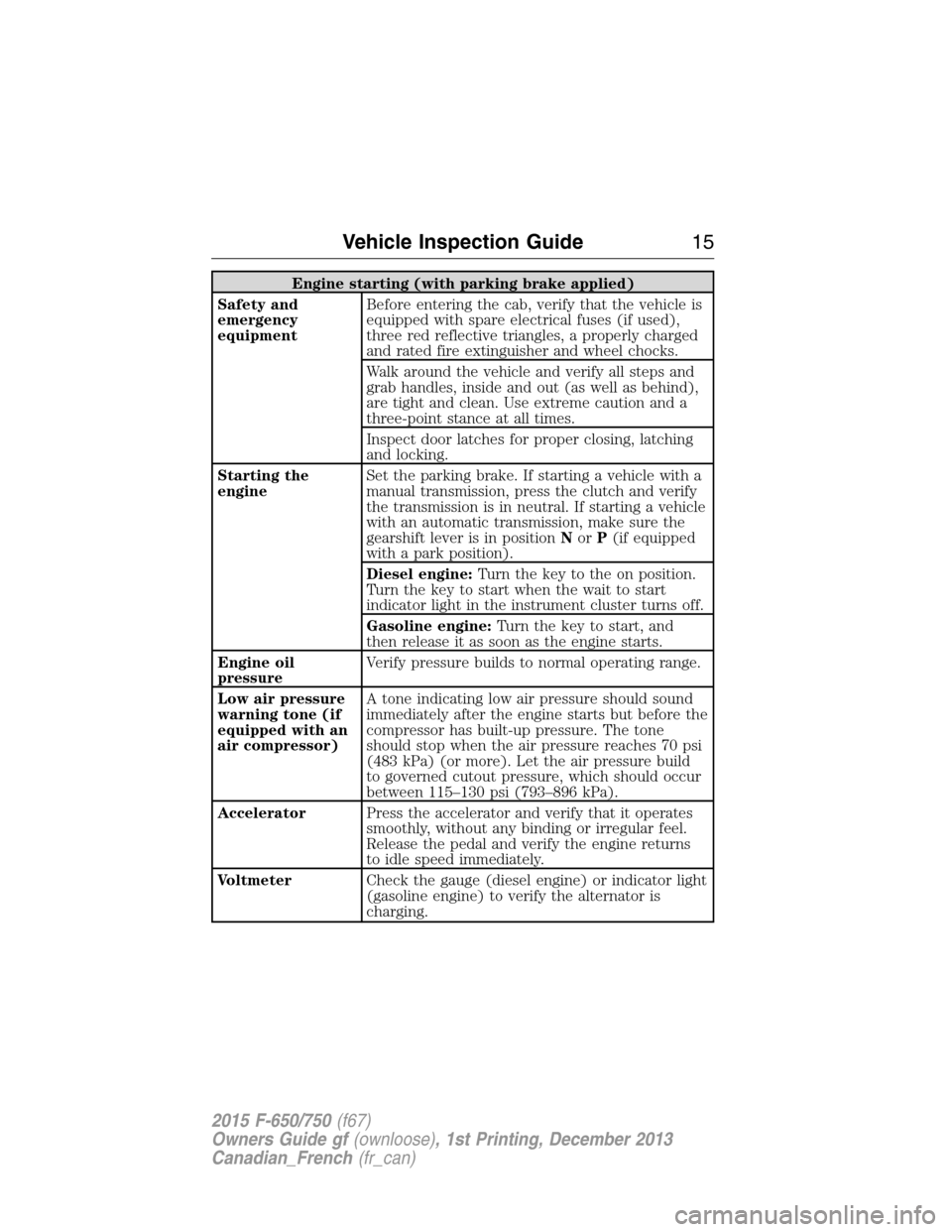

Engine starting (with parking brake applied)

Safety and

emergency

equipmentBefore entering the cab, verify that the vehicle is

equipped with spare electrical fuses (if used),

three red reflective triangles, a properly charged

and rated fire extinguisher and wheel chocks.

Walk around the vehicle and verify all steps and

grab handles, inside and out (as well as behind),

are tight and clean. Use extreme caution and a

three-point stance at all times.

Inspect door latches for proper closing, latching

and locking.

Starting the

engineSet the parking brake. If starting a vehicle with a

manual transmission, press the clutch and verify

the transmission is in neutral. If starting a vehicle

with an automatic transmission, make sure the

gearshift lever is in positionNorP(if equipped

with a park position).

Diesel engine:Turn the key to the on position.

Turn the key to start when the wait to start

indicator light in the instrument cluster turns off.

Gasoline engine:Turn the key to start, and

then release it as soon as the engine starts.

Engine oil

pressureVerify pressure builds to normal operating range.

Low air pressure

warning tone (if

equipped with an

air compressor)A tone indicating low air pressure should sound

immediately after the engine starts but before the

compressor has built-up pressure. The tone

should stop when the air pressure reaches 70 psi

(483 kPa) (or more). Let the air pressure build

to governed cutout pressure, which should occur

between 115–130 psi (793–896 kPa).

AcceleratorPress the accelerator and verify that it operates

smoothly, without any binding or irregular feel.

Release the pedal and verify the engine returns

to idle speed immediately.

VoltmeterCheck the gauge (diesel engine) or indicator light

(gasoline engine) to verify the alternator is

charging.

Vehicle Inspection Guide15

2015 F-650/750(f67)

Owners Guide gf(ownloose), 1st Printing, December 2013

Canadian_French(fr_can)

Page 17 of 384

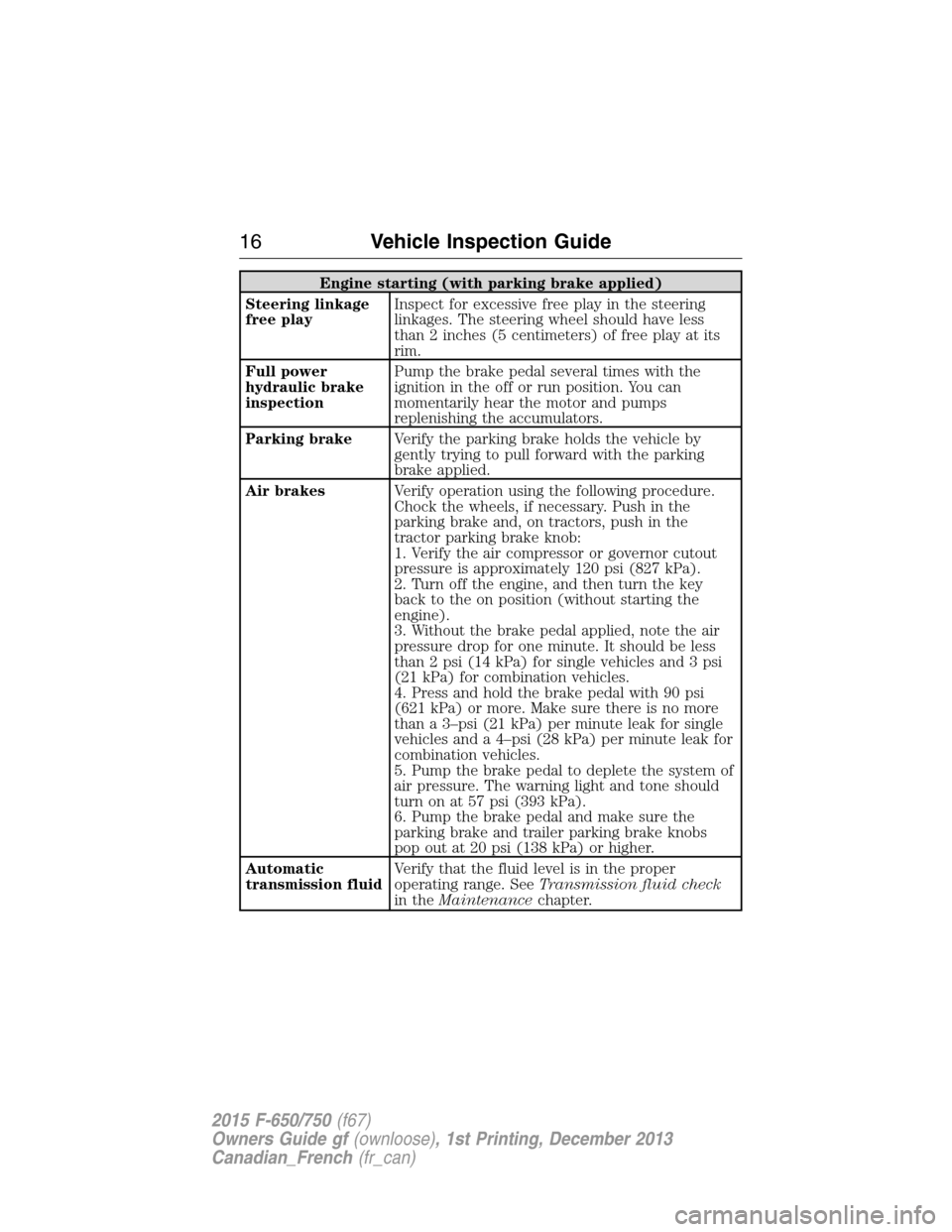

Engine starting (with parking brake applied)

Steering linkage

free playInspect for excessive free play in the steering

linkages. The steering wheel should have less

than 2 inches (5 centimeters) of free play at its

rim.

Full power

hydraulic brake

inspectionPump the brake pedal several times with the

ignition in the off or run position. You can

momentarily hear the motor and pumps

replenishing the accumulators.

Parking brakeVerify the parking brake holds the vehicle by

gently trying to pull forward with the parking

brake applied.

Air brakesVerify operation using the following procedure.

Chock the wheels, if necessary. Push in the

parking brake and, on tractors, push in the

tractor parking brake knob:

1. Verify the air compressor or governor cutout

pressure is approximately 120 psi (827 kPa).

2. Turn off the engine, and then turn the key

back to the on position (without starting the

engine).

3. Without the brake pedal applied, note the air

pressure drop for one minute. It should be less

than 2 psi (14 kPa) for single vehicles and 3 psi

(21 kPa) for combination vehicles.

4. Press and hold the brake pedal with 90 psi

(621 kPa) or more. Make sure there is no more

than a 3–psi (21 kPa) per minute leak for single

vehicles and a 4–psi (28 kPa) per minute leak for

combination vehicles.

5. Pump the brake pedal to deplete the system of

air pressure. The warning light and tone should

turn on at 57 psi (393 kPa).

6. Pump the brake pedal and make sure the

parking brake and trailer parking brake knobs

pop out at 20 psi (138 kPa) or higher.

Automatic

transmission fluidVerify that the fluid level is in the proper

operating range. SeeTransmission fluid check

in theMaintenancechapter.

16Vehicle Inspection Guide

2015 F-650/750(f67)

Owners Guide gf(ownloose), 1st Printing, December 2013

Canadian_French(fr_can)

Page 79 of 384

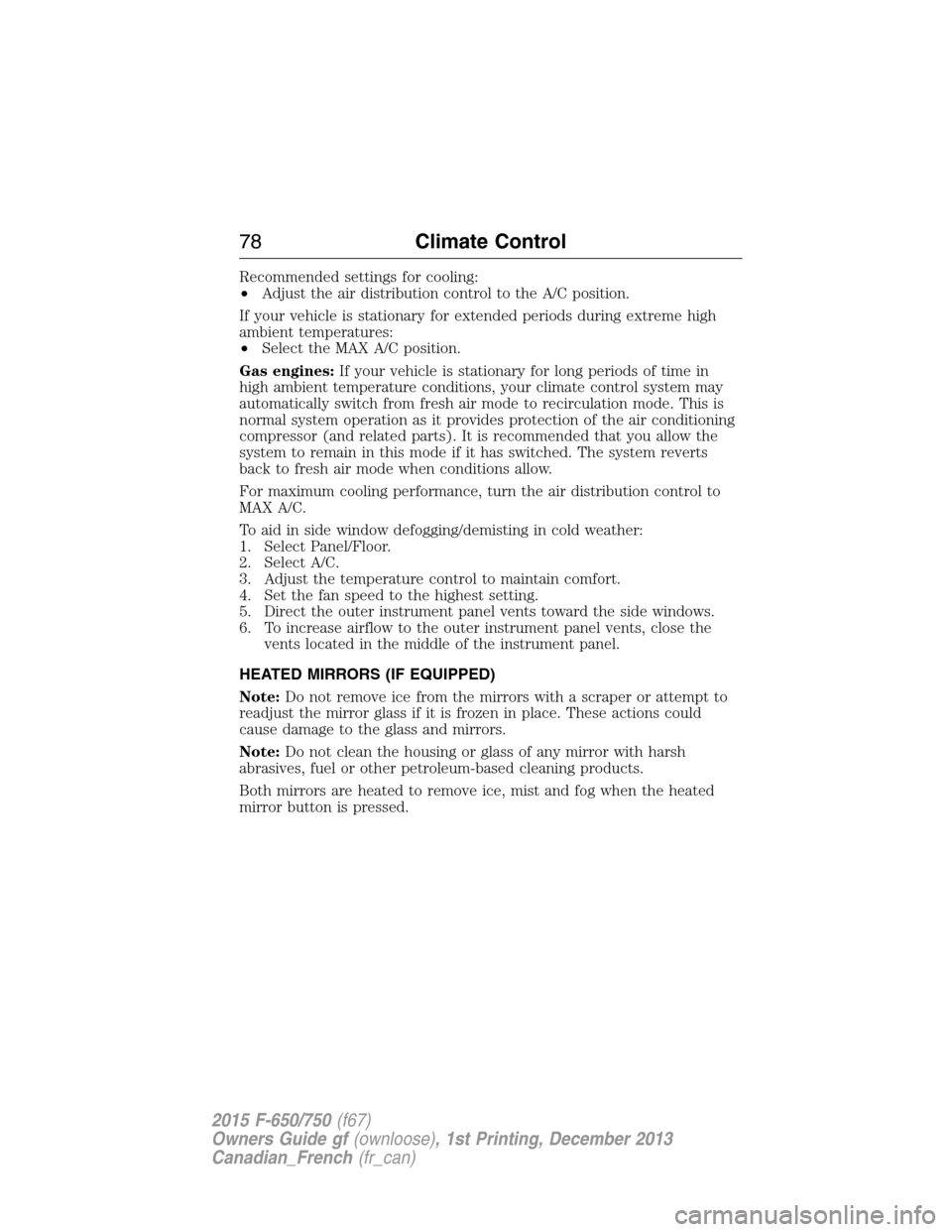

Recommended settings for cooling:

•Adjust the air distribution control to the A/C position.

If your vehicle is stationary for extended periods during extreme high

ambient temperatures:

•Select the MAX A/C position.

Gas engines:If your vehicle is stationary for long periods of time in

high ambient temperature conditions, your climate control system may

automatically switch from fresh air mode to recirculation mode. This is

normal system operation as it provides protection of the air conditioning

compressor (and related parts). It is recommended that you allow the

system to remain in this mode if it has switched. The system reverts

back to fresh air mode when conditions allow.

For maximum cooling performance, turn the air distribution control to

MAX A/C.

To aid in side window defogging/demisting in cold weather:

1. Select Panel/Floor.

2. Select A/C.

3. Adjust the temperature control to maintain comfort.

4. Set the fan speed to the highest setting.

5. Direct the outer instrument panel vents toward the side windows.

6. To increase airflow to the outer instrument panel vents, close the

vents located in the middle of the instrument panel.

HEATED MIRRORS (IF EQUIPPED)

Note:Do not remove ice from the mirrors with a scraper or attempt to

readjust the mirror glass if it is frozen in place. These actions could

cause damage to the glass and mirrors.

Note:Do not clean the housing or glass of any mirror with harsh

abrasives, fuel or other petroleum-based cleaning products.

Both mirrors are heated to remove ice, mist and fog when the heated

mirror button is pressed.

78Climate Control

2015 F-650/750(f67)

Owners Guide gf(ownloose), 1st Printing, December 2013

Canadian_French(fr_can)

Page 140 of 384

Anti-lock Brake System (ABS)

This system helps you maintain steering control during emergency stops

by keeping the brakes from locking.

The ABS lamp momentarily illuminates when you switch on the

ignition. If the light does not illuminate during start-up, if it

remains on or flashes, the ABS may not be working and

requires servicing.

If the ABS is disabled, normal braking is still effective. If the

brake warning lamp illuminates, have your brake system

serviced immediately.

If you connect a PLC trailer with the ignition on, the trailer

ABS light also illuminates. If the light fails to illuminate, if it

remains on after you start the vehicle or continues to flash,

have the system serviced immediately.

FULL POWER BRAKE SYSTEM

WARNING:If the red BRAKE warning lamp in the instrument

cluster remains illuminated after engine start up, this indicates a

system failure in the Full Power Brake System. Stop the vehicle safely

as soon as possible and seek service immediately.

This system incorporates standard braking, an anti-lock braking system

(ABS) and optional Power Park Brake into one fully integrated hydraulic

brake system. With the Full Power Brake System, braking energy is

stored, similar to an air brake system, resulting in faster response times

and shorter stopping distances. This is accomplished using motor and

pump assemblies that pressurize the system by pumping brake fluid into

accumulators. This is similar to the air compressor of an air brake system

pressurizing the air tanks. The system includes a master cylinder that

provides the normal pedal feel and transfers the pedal force, via brake

fluid, to the main components of the system.

Note:The motor and pumps run momentarily with the ignition switch in

the on or run position, or in the off position with the brake pedal

pressed.

Note:During normal driving, you may hear the pump and motors

replenishing the accumulators. This is a normal function of the system.

AIR BRAKES

After starting the engine, give the air compressor time to build up the air

pressure to 60 psi (414 kPa) before moving your vehicle.

Brakes139

2015 F-650/750(f67)

Owners Guide gf(ownloose), 1st Printing, December 2013

Canadian_French(fr_can)

Page 141 of 384

WARNING:Do not drive or continue to drive if the low air

pressure buzzer is sounding or the brake warning light is lit.

These warnings indicate that air pressure is not to normal operating

level. Continued use of the vehicle could result in loss of braking ability.

WARNING:Avoid repeated light application of the brake pedal.

This depletes air pressure faster and could result in loss of

braking capability.

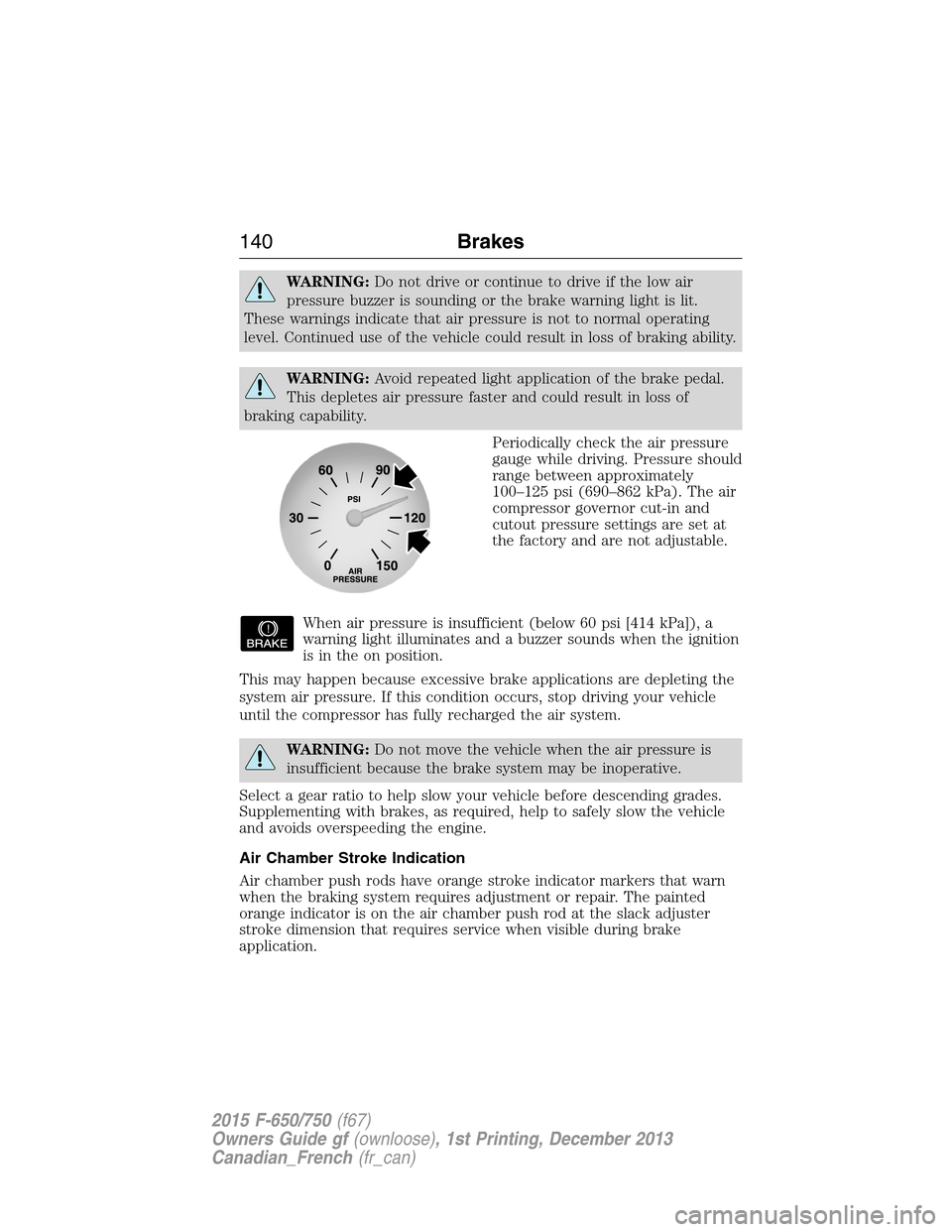

Periodically check the air pressure

gauge while driving. Pressure should

range between approximately

100–125 psi (690–862 kPa). The air

compressor governor cut-in and

cutout pressure settings are set at

the factory and are not adjustable.

When air pressure is insufficient (below 60 psi [414 kPa]), a

warning light illuminates and a buzzer sounds when the ignition

is in the on position.

This may happen because excessive brake applications are depleting the

system air pressure. If this condition occurs, stop driving your vehicle

until the compressor has fully recharged the air system.

WARNING:Do not move the vehicle when the air pressure is

insufficient because the brake system may be inoperative.

Select a gear ratio to help slow your vehicle before descending grades.

Supplementing with brakes, as required, help to safely slow the vehicle

and avoids overspeeding the engine.

Air Chamber Stroke Indication

Air chamber push rods have orange stroke indicator markers that warn

when the braking system requires adjustment or repair. The painted

orange indicator is on the air chamber push rod at the slack adjuster

stroke dimension that requires service when visible during brake

application.

140Brakes

2015 F-650/750(f67)

Owners Guide gf(ownloose), 1st Printing, December 2013

Canadian_French(fr_can)

Page 195 of 384

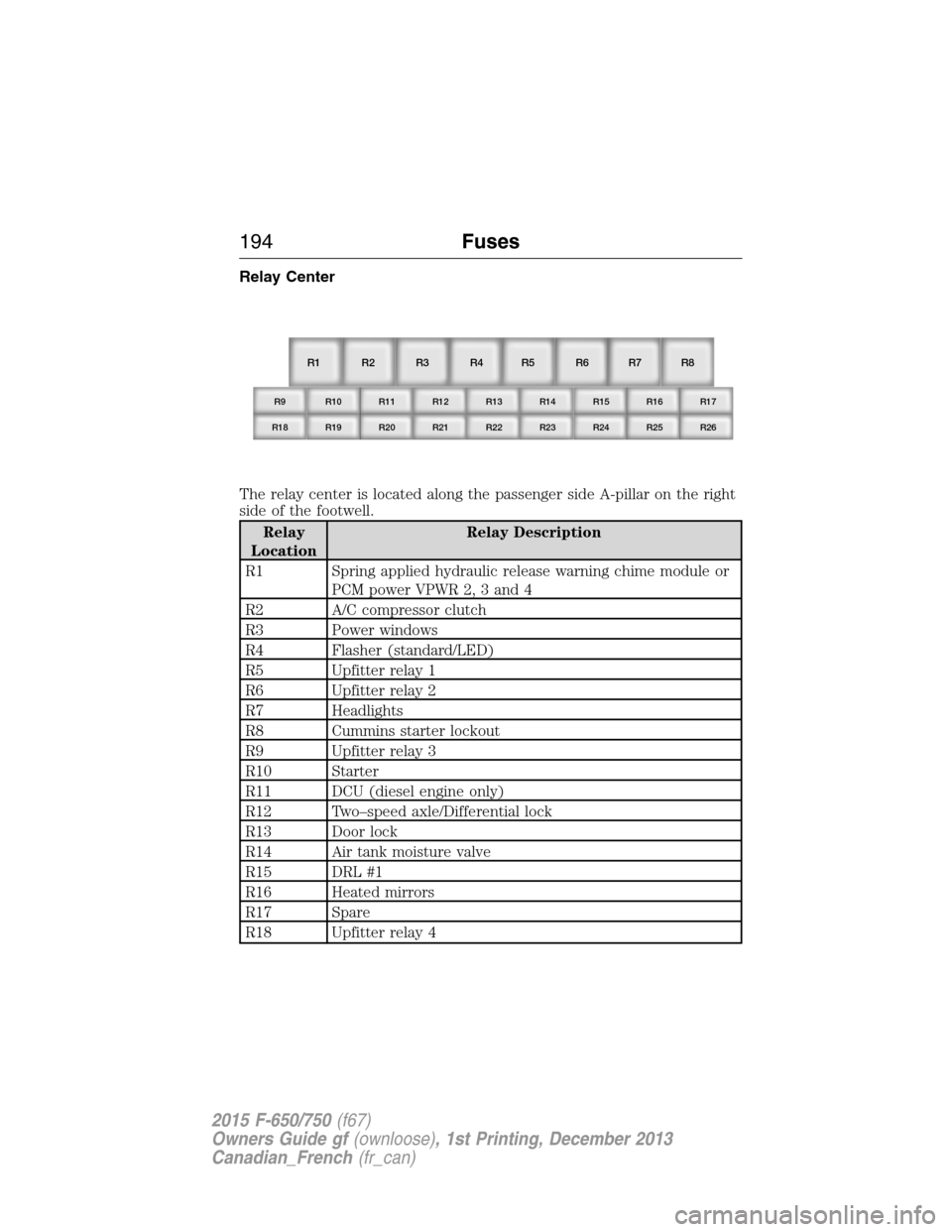

Relay Center

The relay center is located along the passenger side A-pillar on the right

side of the footwell.

Relay

LocationRelay Description

R1 Spring applied hydraulic release warning chime module or

PCM power VPWR 2, 3 and 4

R2 A/C compressor clutch

R3 Power windows

R4 Flasher (standard/LED)

R5 Upfitter relay 1

R6 Upfitter relay 2

R7 Headlights

R8 Cummins starter lockout

R9 Upfitter relay 3

R10 Starter

R11 DCU (diesel engine only)

R12 Two–speed axle/Differential lock

R13 Door lock

R14 Air tank moisture valve

R15 DRL #1

R16 Heated mirrors

R17 Spare

R18 Upfitter relay 4

R1

R9 R10 R11 R12 R13 R14 R15 R16 R17

R18 R19 R20 R21 R22 R23 R24 R25 R26

R2 R3 R4 R5 R6 R7 R8

194Fuses

2015 F-650/750(f67)

Owners Guide gf(ownloose), 1st Printing, December 2013

Canadian_French(fr_can)

Page 203 of 384

Inspection and adjustment:Establish a regular schedule for periodic

cleaning, lubrication and adjustment inspection based on vehicle use.

Exact maintenance intervals are difficult to predetermine due to vehicle

applications and operating conditions. If you are uncertain of the proper

schedule for your vehicle, contact an authorized dealer.

Regular inspections should include:

•Periodic checking (every service interval) of push rod travel or brake

adjustment. This is essential for effective braking. Brake chamber

push rods on original equipment chambers now incorporate an orange

paint marker near the base of the push rod as a stroke indicator to

aid in adjustment checks. If the push rod is clean and the brakes are

out of adjustment, you can see the orange marker protruding from

the chamber when the brakes are applied.

•Checking the brake lining (every service interval). When brake lining

or blocks wear within 1/16th inch (1.6 millimeters) of rivets, replace

the brake linings. A qualified technician should perform this

inspection and keep to instructions provided by the service manual.

Do not back off or disconnect the front brakes so that they are less

effective, letting the rear brakes do all the stopping of your vehicle. Do

not overlook the brakes on the trailer either. Brake condition on the

trailer is just as important as the tractor. Proper brake balance on trucks

and tractor-trailers is essential for effective braking.

Once a year, inspect the entire brake system:

•Rubber components for deterioration. A qualified technician should

inspect these components and replace them as necessary.

Replacement intervals vary according to the severity and length of

vehicle service.

•Condition of brake drums, brake chambers and slack adjusters.

•System for air leaks.

•Hose or pipes for rust, damage and deterioration.

•Operation of service and parking brakes.

Periodically inspect parts such as air brake chamber diaphragm, air

compressor and air cleaner. Replace any parts if you can consider them

unserviceable.

Air dryer:Climactic conditions affect performance of desiccant or

after-cooler type air dryers. You must establish a maintenance schedule

for each specific operation.

The use of an air dryer on a vehicle does not eliminate the need to drain

the air reservoirs periodically.

202Maintenance

2015 F-650/750(f67)

Owners Guide gf(ownloose), 1st Printing, December 2013

Canadian_French(fr_can)

Page 206 of 384

•Checking that the pitman arm (steering arm at steering gear)

mounting is tight and locked. Check system for leaks or hose chafing.

Repair immediately, if necessary.

•Maintaining proper steering gear and power steering pump lubricant

levels.

•Checking steering column joint bolts and steering linkage, particularly

for body-to-chassis clearance.

Steering Column Joint Bolts

As a good maintenance practice, check steering column joint bolt

tightness every 60000 miles (96000 kilometers) or annually, whichever

occurs first. Do not overtighten the bolts.

Hydraulic System

Whenever draining and refilling the power steering’s hydraulic system for

any reason, bleed air from the system before returning the vehicle to

service. Failure to bleed the hydraulic system properly can result in

degradation of power system performance.

Consult an authorized dealer who is aware of the proper procedures for

filling and bleeding the system.

Catalytic Converter (Diesel Engine)

Note:If your vehicle is equipped with a catalytic converter or muffler,

do not blend waste oil with diesel fuel. Operate only on ultra-low sulfur

(less than 15 parts per million sulfur) diesel fuel with a cetane value of

45 or higher.

If your diesel engine is equipped with a catalytic converter, it is

important to review the maintenance schedule to make sure proper

functioning of the catalytic converter. Also, take precautions not to

damage the catalytic converter when servicing your engine or storing

your vehicle.

Diesel Exhaust Fluid (DEF), Diesel Particulate Filter (DPF) and

Select Catalyst Reduction (SCR) System

See your engine operator’s manual for information about DEF, DPF and

SCR system service

Air Induction System

WARNING:When performing maintenance to any turbocharged

engine with engine air inlet piping disconnected, keep loose

clothing, jewelry and long hair away from the engine air inlet piping. A

turbocharger compressor air inlet protective shield should be installed

over the turbocharger air inlet to reduce the risk of personal injury or

death.

Maintenance205

2015 F-650/750(f67)

Owners Guide gf(ownloose), 1st Printing, December 2013

Canadian_French(fr_can)

Page 247 of 384

Checking Tire Pressure

Always check inflation pressure when tires are cold. Never bleed air from

hot tires to relieve normal pressure build-up. Normal increase in pressure

due to service conditions is 10–15 psi (69–103 kPa), which is allowable

in truck tires.

Tires should be properly inflated to manufacturers’ recommended

pressure for the size and service load in which the vehicle is being used.

See the specific tire manufacturer with which your vehicle is equipped

with for the latest information concerning service load and inflation

pressure.

It is particularly important to keep moisture from the inside of tires, and

proper selection of air compressor equipment, proper air line routing,

and the use of shop air dryers is strongly recommended to avoid

moisture in the high pressure air used for tire inflation.

Under-inflation

Do not allow tires to become under-inflated; increased flexing due to

under-inflation causes heat build-up within the tire components. This

leads to reduced strength, breakdown of the rubber compounds, and

possible separation of the tire components (such as ply and tread

separation and reduced retreadability).

Under-inflation is the primary cause of premature tire concerns including

sudden loss of air. In addition, low inflation causes an increase in rolling

resistance. This results in reduced fuel mileage, a loss in tread mileage,

and uneven wear due to increased tread movement. To determine proper

inflation, see the tire manufacturer load and inflation guide, which you

can find on the tire manufacturer website or at your local truck tire

dealer.

Tire Inspection

Check the tires for abnormal wear patterns and proper inflation

pressures. Repair or replace cut or broken tire casings.

Inspect tires for the following conditions. If any are present, remove and

repair, retread, or scrap the tire as the condition dictates.

•Any blister, bump or raised portion anywhere on the surface of the

tire tread or sidewall (other than a bump made by a repair). These

indicate the start of internal separation.

•Any cut that reaches to the belt or ply cords, or any cut that is large

enough to grow in size and depth.

•Any nail or puncturing object.

•If a tread groove is holding a stone or object that is starting to drill

into the tread base, remove the object.

246Wheels and Tires

2015 F-650/750(f67)

Owners Guide gf(ownloose), 1st Printing, December 2013

Canadian_French(fr_can)