FORD F750 2017 13.G Owners Manual

Manufacturer: FORD, Model Year: 2017, Model line: F750, Model: FORD F750 2017 13.GPages: 382, PDF Size: 5.18 MB

Page 121 of 382

WARNING

Sudden accelerations on slippery

surfaces could cause the wheels to

spin, the vehicle to turn sideways on

a crowned road surface or in a turn,

possibly resulting in loss of vehicle control

and personal injury. Activating the Locking Differential

You can lock and unlock the differential

when your vehicle is moving at a constant

speed of less than 25 mph (40 km/h) and

while the wheels are not slipping. Do not

lock the differential when your vehicle is

traveling down steep grades and when

traction is minimal.

The differential lock and differential lock

light automatically disengage at speeds

above 25 mph (40 km/h). The differential

lock remains off until either you restart your

vehicle or you turn the differential lock

switch off then back on.

Servicing a Vehicle with a Locking

Differential

Turn the engine off and raise all drive

wheels of the locker differential axle in

order to prevent your vehicle from moving

when servicing the wheels, tires or brakes.

Axles equipped with a driver-controlled

differential deliver power to both wheels

even when only one wheel is on the ground. WARNING

Failure to raise all drive wheels with

this type of differential could cause

the vehicle to move unexpectedly,

resulting in property damage, personal

injury or death. 2-SPEED REAR AXLE

(If Equipped)

WARNING

Never shift a two-speed axle when

descending a steep grade as this

may cause loss of vehicle control and

result in personal injury. Note:

Do not shift between ranges when

the speed control is on.

A two-speed rear axle allows the driver to

select a low range for greater pulling power

and a high range for greater road speed

and fuel economy. You can also use these

ranges to provide extra steps between

transmission shifts when driving on steep

grades or fuel economy may be factors.

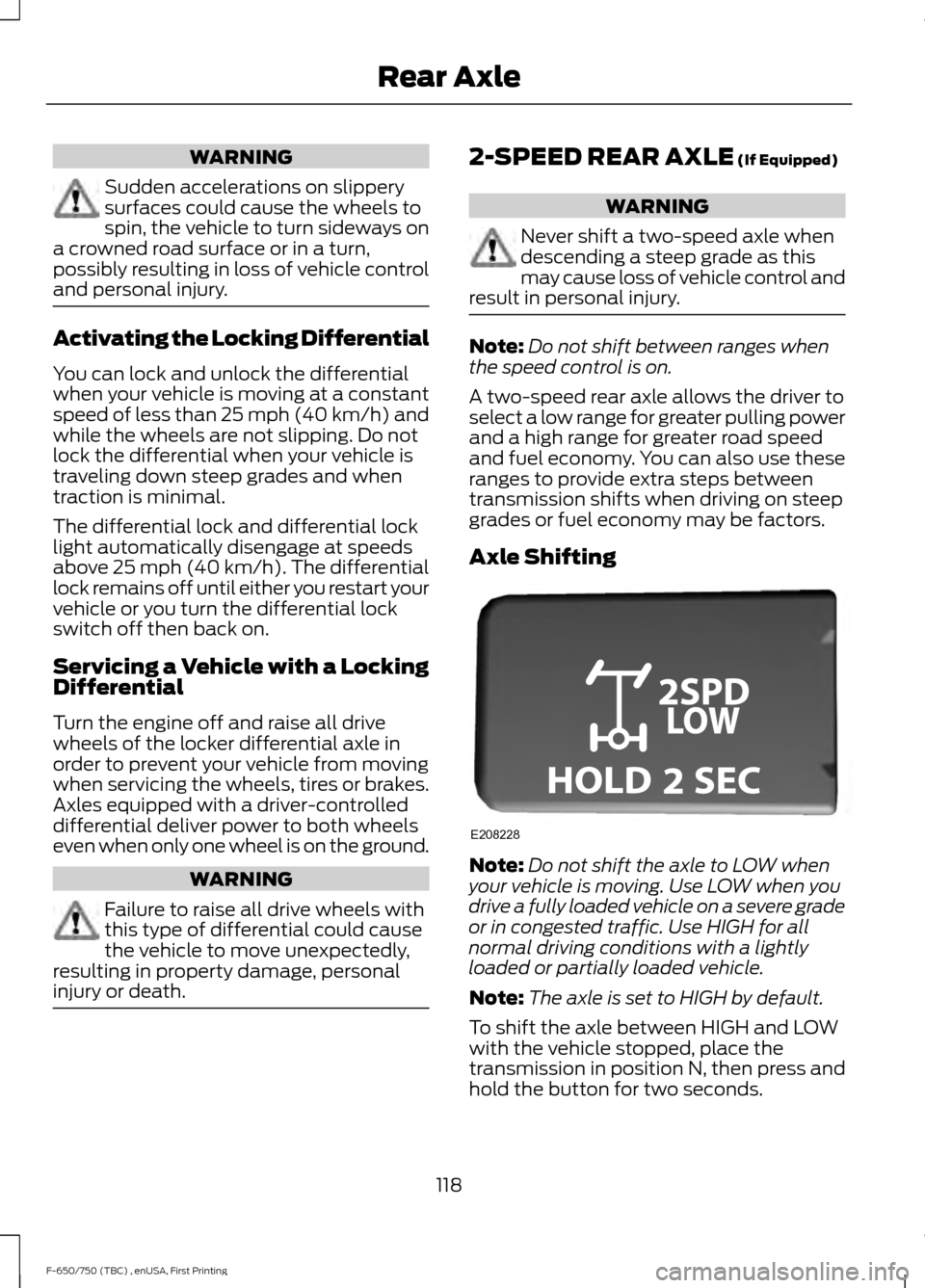

Axle Shifting Note:

Do not shift the axle to LOW when

your vehicle is moving. Use LOW when you

drive a fully loaded vehicle on a severe grade

or in congested traffic. Use HIGH for all

normal driving conditions with a lightly

loaded or partially loaded vehicle.

Note: The axle is set to HIGH by default.

To shift the axle between HIGH and LOW

with the vehicle stopped, place the

transmission in position N, then press and

hold the button for two seconds.

118

F-650/750 (TBC) , enUSA, First Printing Rear AxleE208228

Page 122 of 382

GENERAL INFORMATION

WARNINGS

Do not drive with your foot resting on

the brake pedal. This results in

abnormally high brake temperatures,

excessive lining wear and increased

stopping distance. Continuous application of the brakes

causes the brakes to overheat,

resulting in temporary loss of braking.

Note:

Occasional brake noise is normal. If

a metal-to-metal, continuous grinding or

continuous squeal sound is present, the

brake linings may be worn-out. Have the

system checked by an authorized dealer. If

your vehicle has continuous vibration or

shudder in the steering wheel while braking,

have it checked by an authorized dealer.

All standard equipment brakes are

self-adjusting. Automatic adjustment,

when required, occurs whenever you apply

and release the brakes during forward or

reverse operation.

Know the required stopping distances for

all driving conditions you may encounter.

For longer brake lining life, take full

advantage of engine braking power when

coming to a stop. See Warning Lamps and

Indicators (page 58).

Wet brakes result in reduced braking

efficiency. Gently press the brake pedal a

few times when driving from a car wash or

standing water to dry the brakes.

If brakes do not grip well:

• Check brake adjustment.

• Check brake linings for excessive wear.

• Check system air pressure on vehicle

equipped with air brakes. •

Let the brakes cool if you have been

using them excessively, as in mountain

driving or after several fast, high-speed

stops.

• If you have been driving through deep

water, gently apply the brakes several

times while your vehicle is moving

slowly.

Brake Over Accelerator

In the event the accelerator pedal

becomes stuck or entrapped, apply steady

and firm pressure to the brake pedal to

slow the vehicle and reduce engine power.

If you experience this condition, apply the

brakes and bring your vehicle to a safe

stop. Move the transmission to park (P),

switch the engine off and apply the parking

brake. Inspect the accelerator pedal for

any interference. If none are found and the

condition persists, have your vehicle towed

to the nearest authorized dealer

Anti-lock Brake System

This system helps you maintain steering

control during emergency stops by keeping

the brakes from locking. This lamp momentarily

illuminates when you turn the

ignition on. If the light does not

illuminate during start up, remains on or

flashes, the system may be disabled. Have

the system checked by an authorized

dealer. If the system is disabled, normal

braking is still effective. If the

brake warning lamp illuminates

when you release the parking brake, have

the system checked by an authorized

dealer.

119

F-650/750 (TBC) , enUSA, First Printing BrakesE209041 E209041

Page 123 of 382

If you connect a PLC trailer with

the ignition on, the trailer ABS

light also illuminates. If the light

fails to illuminate, if it remains on after you

start the vehicle or continues to flash, have

the system serviced immediately.

HINTS ON DRIVING WITH

ANTI-LOCK BRAKES

Note: When the system is operating, the

brake pedal may pulse and may travel

further. Maintain pressure on the brake

pedal. You may also hear a noise from the

system. This is normal.

The anti-lock braking system will not

eliminate the risks when:

• You drive too closely to the vehicle in

front of you.

• Your vehicle is hydroplaning.

• You take corners too fast.

• The road surface is poor.

PARKING BRAKE

Hydraulic Brakes WARNINGS

Always set the parking brake and

leave your vehicle with the

transmission in park (P).

When doing this procedure, you need

to take the transmission out of park

(P) which means your vehicle can

roll freely. To avoid unwanted vehicle

movement, always fully set the parking

brake prior to doing this procedure. Use

wheels chocks if appropriate. Unexpected and possibly sudden

vehicle movement may occur if you

do not take these precautions. WARNINGS

If the parking brake is fully released,

but the brake warning lamp remains

illuminated, the brakes may not be

working properly. Have your vehicle

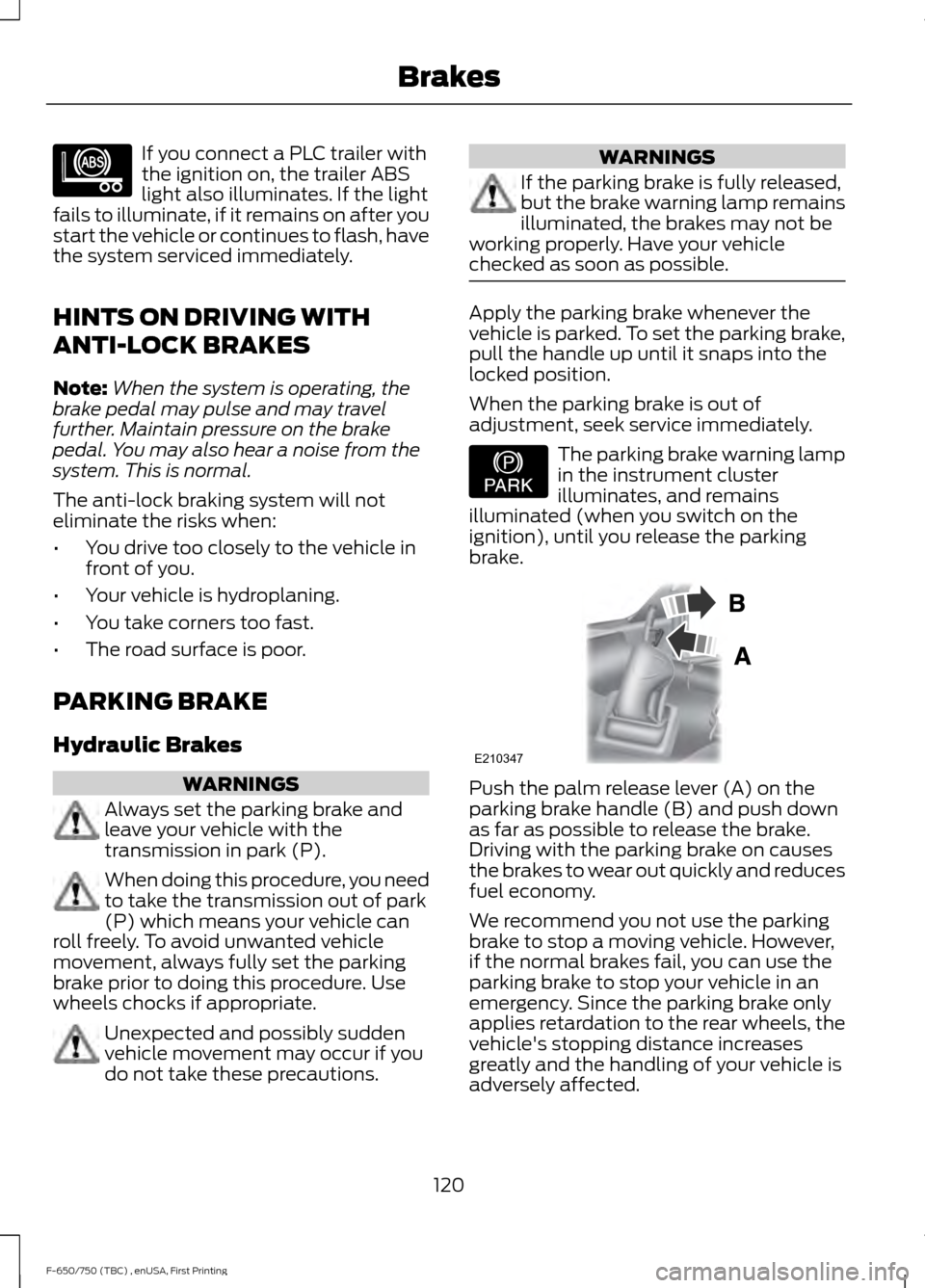

checked as soon as possible. Apply the parking brake whenever the

vehicle is parked. To set the parking brake,

pull the handle up until it snaps into the

locked position.

When the parking brake is out of

adjustment, seek service immediately.

The parking brake warning lamp

in the instrument cluster

illuminates, and remains

illuminated (when you switch on the

ignition), until you release the parking

brake. Push the palm release lever (A) on the

parking brake handle (B) and push down

as far as possible to release the brake.

Driving with the parking brake on causes

the brakes to wear out quickly and reduces

fuel economy.

We recommend you not use the parking

brake to stop a moving vehicle. However,

if the normal brakes fail, you can use the

parking brake to stop your vehicle in an

emergency. Since the parking brake only

applies retardation to the rear wheels, the

vehicle's stopping distance increases

greatly and the handling of your vehicle is

adversely affected.

120

F-650/750 (TBC) , enUSA, First Printing BrakesE210335 E208810 E210347

Page 124 of 382

Releasing Spring Manually

WARNINGS

Do not attempt to disassemble the

parking brake air chamber under any

circumstances as this may cause

serious injury. Block the wheels to help prevent the

vehicle from moving.

Unexpected and possibly sudden

vehicle movement may occur if you

do not take these precautions.

If you release hydraulic pressure from the

spring brake chamber, the power spring

applies the brake. If the hydraulic pressure

can be re-established, you must release

the spring brake in order to move your

vehicle.

Air Brakes

WARNING

This control is for parking only. Do

not leave the vehicle unattended

after setting the parking brake

without placing the transmission in park

(P). We recommend using wheel chocks

for hilly or off-road circumstances. If the service brakes fail to operate while

your vehicle is moving, you can make an

emergency stop with the parking brake.

Since the parking brake only applies

stopping power to the rear wheels, your

vehicle

’s stopping distance greatly

increases and the handling of your vehicle

is adversely affected. Make repairs

immediately to an inoperative air brake

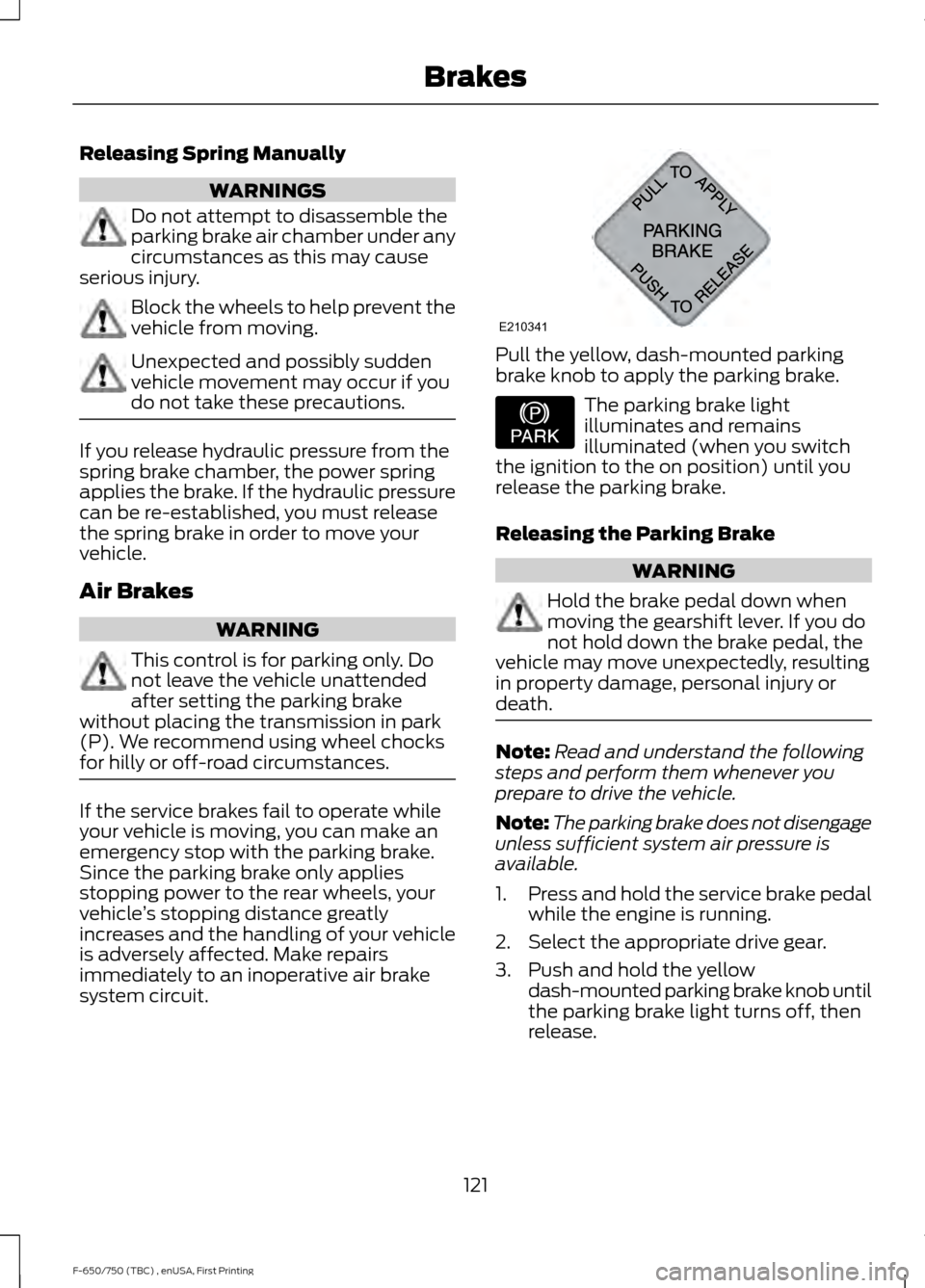

system circuit. Pull the yellow, dash-mounted parking

brake knob to apply the parking brake.

The parking brake light

illuminates and remains

illuminated (when you switch

the ignition to the on position) until you

release the parking brake.

Releasing the Parking Brake WARNING

Hold the brake pedal down when

moving the gearshift lever. If you do

not hold down the brake pedal, the

vehicle may move unexpectedly, resulting

in property damage, personal injury or

death. Note:

Read and understand the following

steps and perform them whenever you

prepare to drive the vehicle.

Note: The parking brake does not disengage

unless sufficient system air pressure is

available.

1. Press and hold the service brake pedal

while the engine is running.

2. Select the appropriate drive gear.

3. Push and hold the yellow dash-mounted parking brake knob until

the parking brake light turns off, then

release.

121

F-650/750 (TBC) , enUSA, First Printing BrakesE210341 E208810

Page 125 of 382

Parking Brake Light Illumination Due

to Low Air Pressure

If the air pressure becomes too low at any

time during vehicle operation, the parking

brake may apply and the parking brake

light turns on.

If the parking brake applies due to low air

pressure, immediate service is required to

the parking brake system.

Releasing Spring Brake with Air

Pressure

The air system in all vehicles with

spring-actuated rear wheel parking brakes

has a valve on the governor for connection

to an outside air supply. The valve lets you

recharge the system with air from an

outside source, releasing the

spring-actuated parking brakes. Your

vehicle is now ready to tow in an

emergency.

You can only use an outside air source if

the protected system is in operating

condition. If you cannot restore air pressure

in the protected air system, you must

release the spring-actuated brakes

manually.

Releasing Spring Manually

Do not use impact wrenches as they may

damage the piston and prevent proper

caging of the spring. Do not apply more

than 50 lb.ft (68 Nm) to the release bolt

nut.

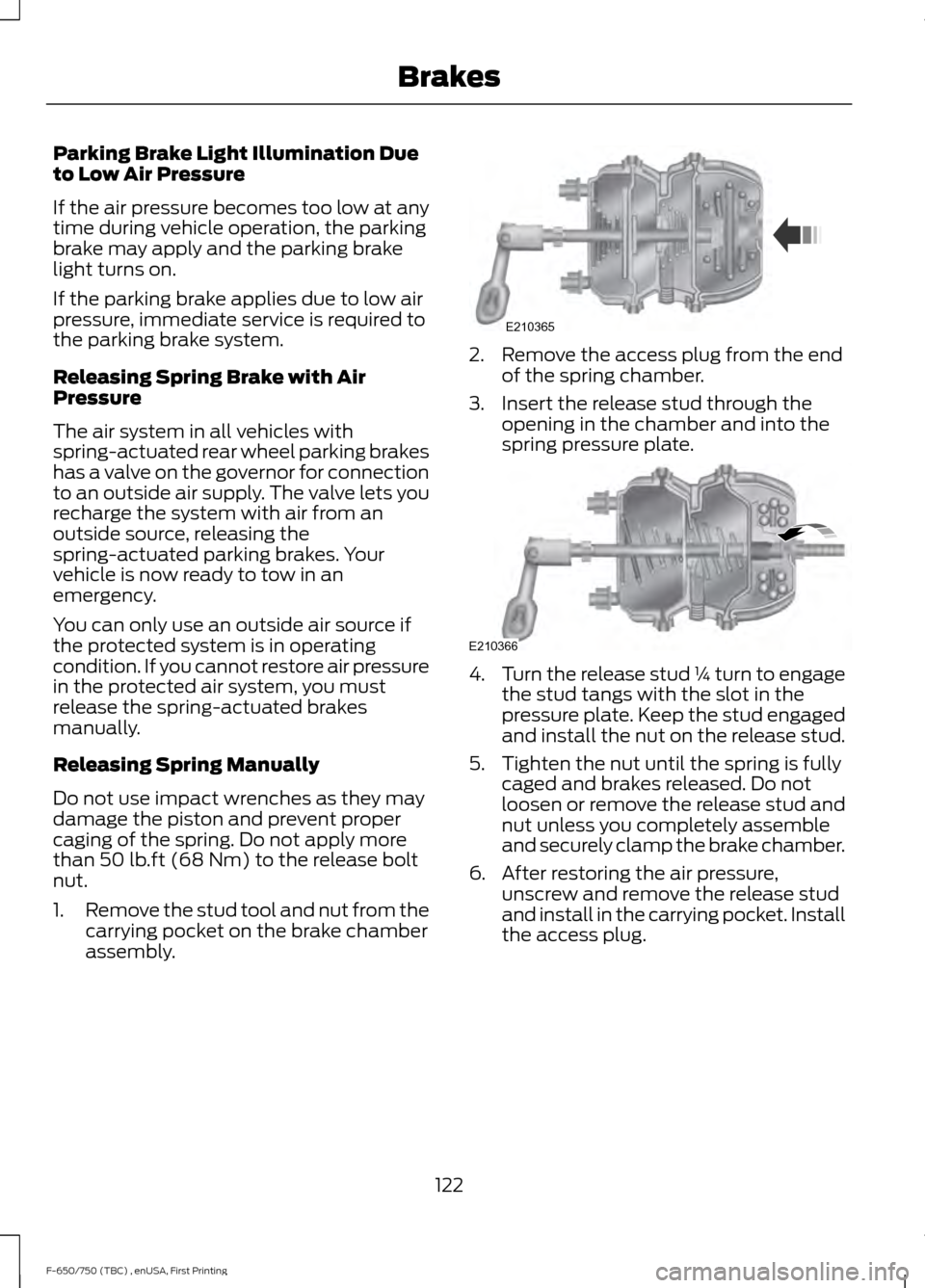

1. Remove the stud tool and nut from the

carrying pocket on the brake chamber

assembly. 2. Remove the access plug from the end

of the spring chamber.

3. Insert the release stud through the opening in the chamber and into the

spring pressure plate. 4.

Turn the release stud ¼ turn to engage

the stud tangs with the slot in the

pressure plate. Keep the stud engaged

and install the nut on the release stud.

5. Tighten the nut until the spring is fully caged and brakes released. Do not

loosen or remove the release stud and

nut unless you completely assemble

and securely clamp the brake chamber.

6. After restoring the air pressure, unscrew and remove the release stud

and install in the carrying pocket. Install

the access plug.

122

F-650/750 (TBC) , enUSA, First Printing BrakesE210365 E210366

Page 126 of 382

FULL POWER BRAKE

WARNING

If the brake warning lamp in the

instrument cluster remains

illuminated after engine start up, this

indicates a system failure in the Full Power

Brake system. Stop the vehicle safely as

soon as possible and seek service

immediately. This system incorporates standard braking,

an anti-lock braking system (ABS) and

optional Power Park Brake into one fully

integrated hydraulic brake system. With

the Full Power Brake system, braking

energy is stored, similar to an air brake

system, resulting in faster response times

and shorter stopping distances. This is

accomplished using motor and pump

assemblies that pressurize the system by

pumping brake fluid into accumulators.

This is similar to the air compressor of an

air brake system pressurizing the air tanks.

The system includes a master cylinder that

provides the normal pedal feel and

transfers the pedal force, via brake fluid,

to the main components of the system.

Note:

The motor and pumps run

momentarily with the ignition switch in the

on or run position, or in the off position with

the brake pedal pressed.

Note: During normal driving, you may hear

the pump and motors replenishing the

accumulators. This is a normal function of

the system. AIR BRAKES WARNINGS

Do not drive or continue to drive if the

low air pressure buzzer is sounding

or the brake warning light is lit. These

warnings indicate that air pressure is not

to normal operating level. Continued use

of the vehicle could result in loss of braking

ability. Avoid repeated light application of

the brake pedal. This depletes air

pressure faster and could result in

loss of braking capability. Do not move the vehicle when the

air pressure is insufficient because

the brake system may be inoperative.

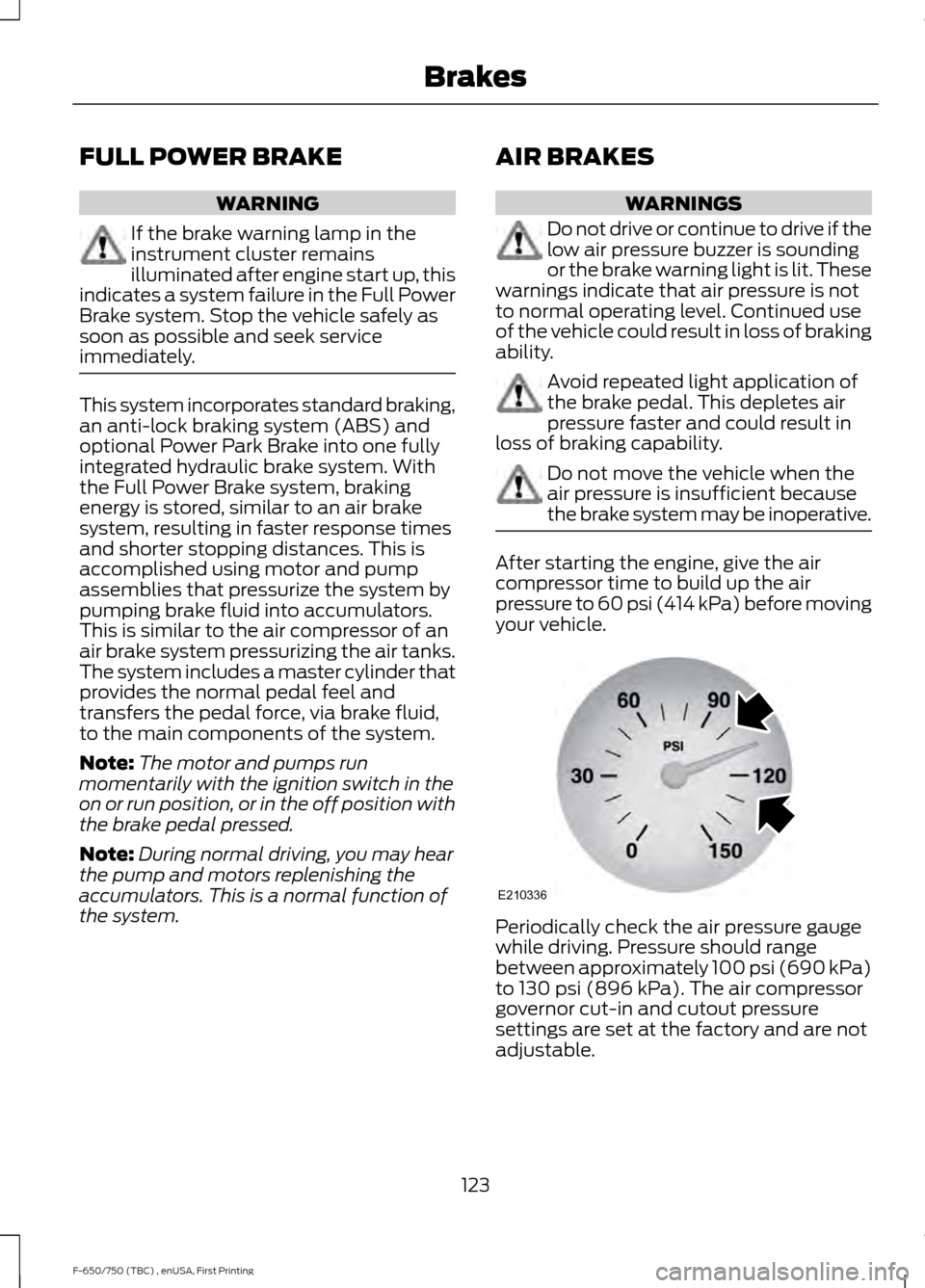

After starting the engine, give the air

compressor time to build up the air

pressure to 60 psi (414 kPa) before moving

your vehicle. Periodically check the air pressure gauge

while driving. Pressure should range

between approximately 100 psi (690 kPa)

to

130 psi (896 kPa). The air compressor

governor cut-in and cutout pressure

settings are set at the factory and are not

adjustable.

123

F-650/750 (TBC) , enUSA, First Printing BrakesE210336

Page 127 of 382

When air pressure is insufficient

(below 60 psi (414 kPa)), a

warning light illuminates and a

buzzer sounds when the ignition is in the

on position. This may happen because

excessive brake applications are depleting

the system air pressure. If this condition

occurs, stop driving your vehicle until the

compressor has fully recharged the air

system.

Select a gear ratio to help slow your vehicle

before descending grades. Supplementing

with brakes, as required, help to safely slow

the vehicle and avoids overspeeding the

engine.

Air Chamber Stroke Indication

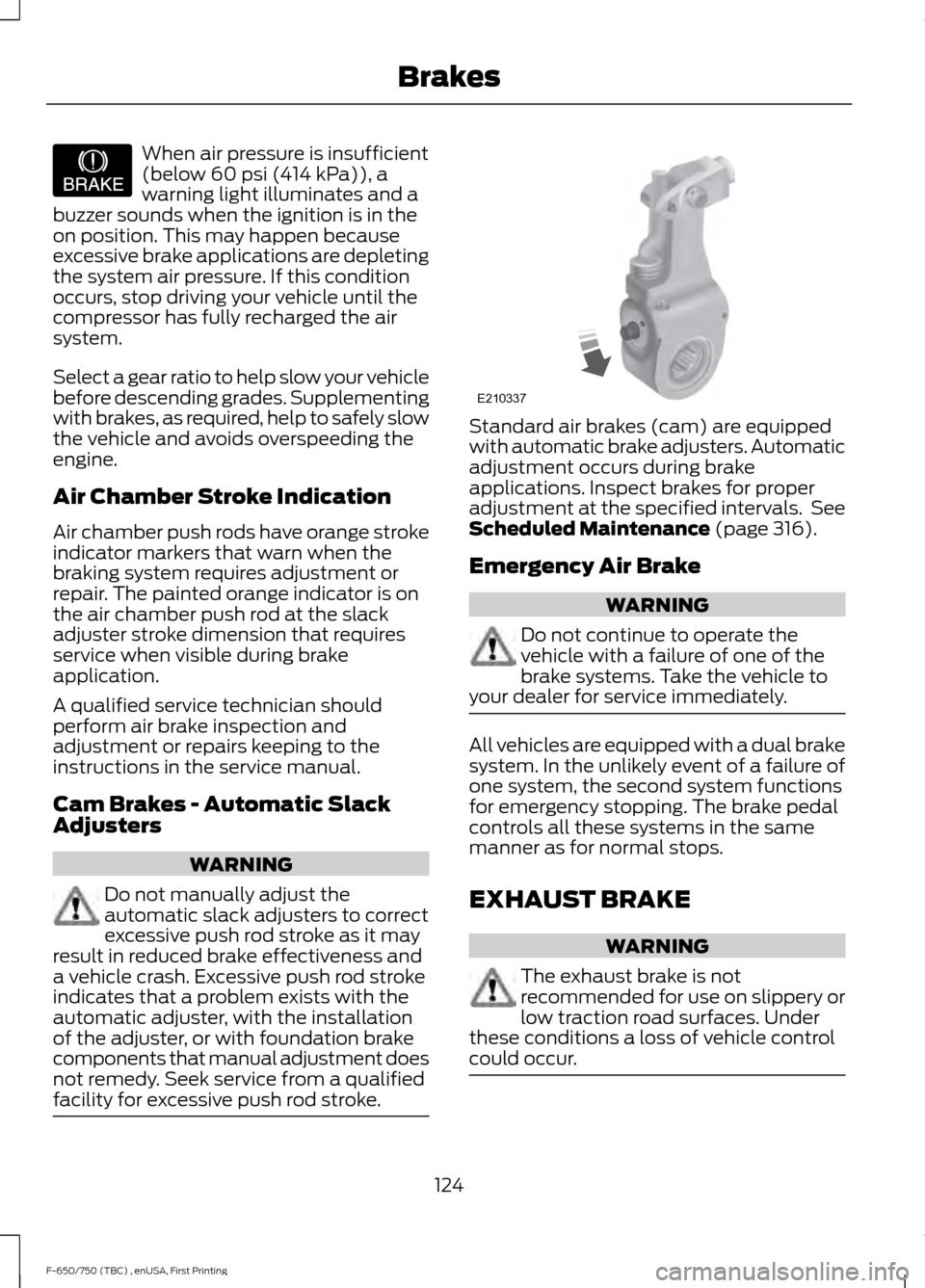

Air chamber push rods have orange stroke

indicator markers that warn when the

braking system requires adjustment or

repair. The painted orange indicator is on

the air chamber push rod at the slack

adjuster stroke dimension that requires

service when visible during brake

application.

A qualified service technician should

perform air brake inspection and

adjustment or repairs keeping to the

instructions in the service manual.

Cam Brakes - Automatic Slack

Adjusters WARNING

Do not manually adjust the

automatic slack adjusters to correct

excessive push rod stroke as it may

result in reduced brake effectiveness and

a vehicle crash. Excessive push rod stroke

indicates that a problem exists with the

automatic adjuster, with the installation

of the adjuster, or with foundation brake

components that manual adjustment does

not remedy. Seek service from a qualified

facility for excessive push rod stroke. Standard air brakes (cam) are equipped

with automatic brake adjusters. Automatic

adjustment occurs during brake

applications. Inspect brakes for proper

adjustment at the specified intervals. See

Scheduled Maintenance

(page 316).

Emergency Air Brake WARNING

Do not continue to operate the

vehicle with a failure of one of the

brake systems. Take the vehicle to

your dealer for service immediately. All vehicles are equipped with a dual brake

system. In the unlikely event of a failure of

one system, the second system functions

for emergency stopping. The brake pedal

controls all these systems in the same

manner as for normal stops.

EXHAUST BRAKE

WARNING

The exhaust brake is not

recommended for use on slippery or

low traction road surfaces. Under

these conditions a loss of vehicle control

could occur. 124

F-650/750 (TBC) , enUSA, First Printing BrakesE206772 E210337

Page 128 of 382

Note:

Installing an exhaust or auxiliary

brake does not necessarily protect the

engine from exceeding maximum governed

speed. Use the primary brakes to make sure

the engine never exceeds maximum

governed speed under any circumstance.

Note: Before starting the engine, make sure

that the exhaust brake switch is in the off

position. Do not turn the exhaust brake on

until the engine has reached normal

operating temperature.

Note: Maximum exhaust brake

performance relates to the type of

transmission your vehicle has.

Note: Engine speed has a major influence

of retarding performance. When engine

speed stays at the maximum allowable

level, the exhaust brake operates at peak

performance.

Note: Exhaust brakes operate effectively

with automatic transmissions, but

performance varies with engine speed and

the gear selected by the transmission.

An exhaust brake is an auxiliary braking

system that assists, but does not replace,

the primary service brake system. It helps

control vehicle speed; it is not a

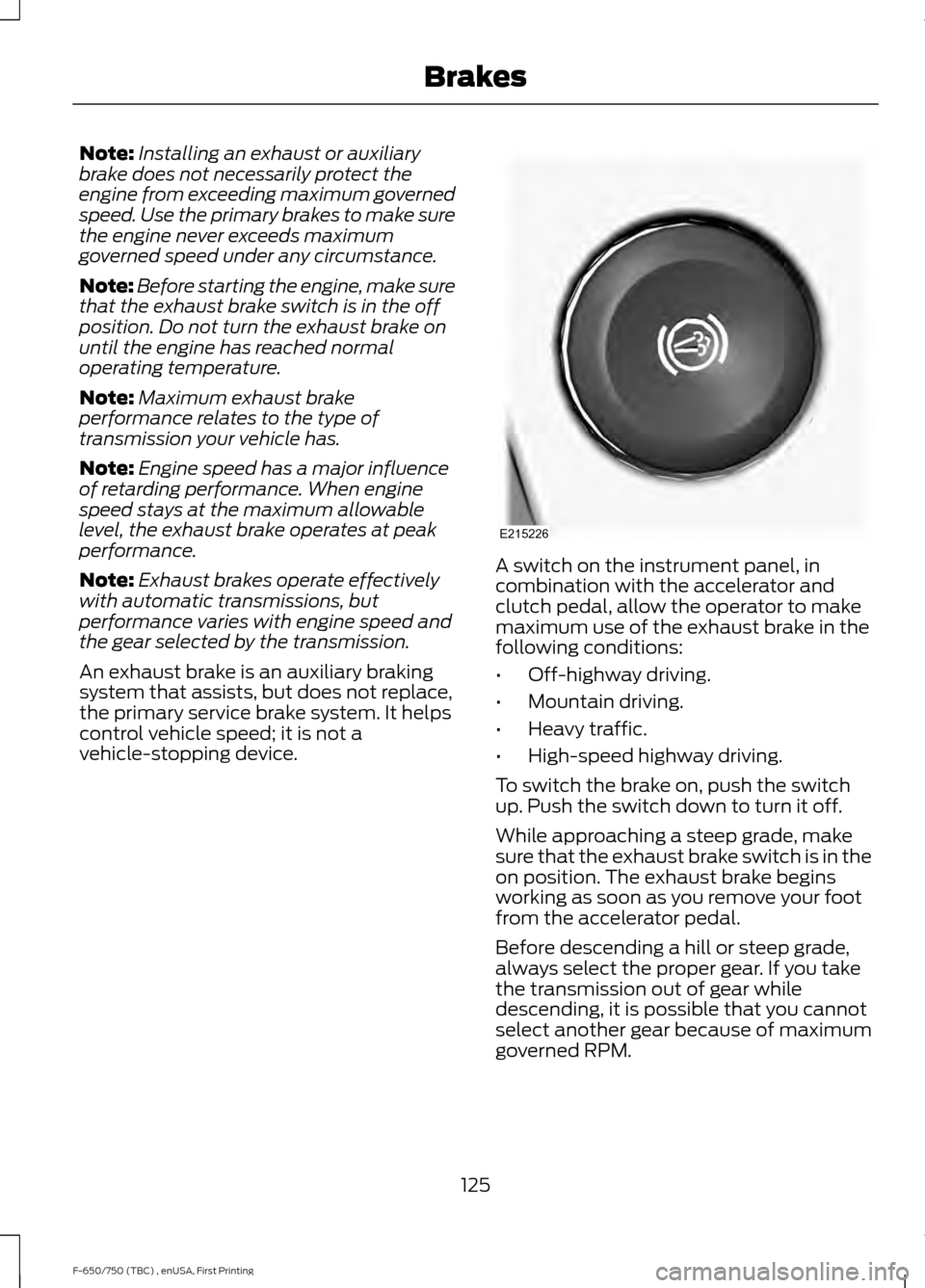

vehicle-stopping device. A switch on the instrument panel, in

combination with the accelerator and

clutch pedal, allow the operator to make

maximum use of the exhaust brake in the

following conditions:

•

Off-highway driving.

• Mountain driving.

• Heavy traffic.

• High-speed highway driving.

To switch the brake on, push the switch

up. Push the switch down to turn it off.

While approaching a steep grade, make

sure that the exhaust brake switch is in the

on position. The exhaust brake begins

working as soon as you remove your foot

from the accelerator pedal.

Before descending a hill or steep grade,

always select the proper gear. If you take

the transmission out of gear while

descending, it is possible that you cannot

select another gear because of maximum

governed RPM.

125

F-650/750 (TBC) , enUSA, First Printing BrakesE215226

Page 129 of 382

Make sure the engine speed does not

exceed the maximum allowable engine

RPM. Exceeding the maximum allowable

engine RPM can result in damage to the

engine. Apply the service brakes to reduce

the engine RPM or make a slower descent

by using a lower gear.

While going down the grade, use a low

enough gear to descend safely with a

minimum application of the service brakes.

As a general guideline, use the same gear

as you use to ascend the hill.

Exhaust Brake Operating

Characteristics

The exhaust brake turns on when you

remove your feet from both the accelerator

and clutch pedals and the exhaust brake

switch is in the on position. The following

conditions exist if the brake is operating

properly:

•

A slight change in engine sound when

the exhaust brake turns on.

• A smooth braking effect. Do not expect

a retarding effect similar to sudden,

hard application of the service brakes.

• The retarding force possibly felt acting

against your body during brake

application (depending on the grade

and vehicle load). This force is actually

preventing the vehicle from going much

faster.

• Engine temperature remaining in the

normal operating range.

• The tachometer showing a drop in

engine RPM (depending on grade and

vehicle load) during a descent.

• A decrease in road speed when

applying the exhaust brake during a

descent, except when your vehicle is

carrying a heavy load or the grade is

extremely steep. In these instances,

you may need to apply the service

brakes occasionally. TRAILER BRAKES

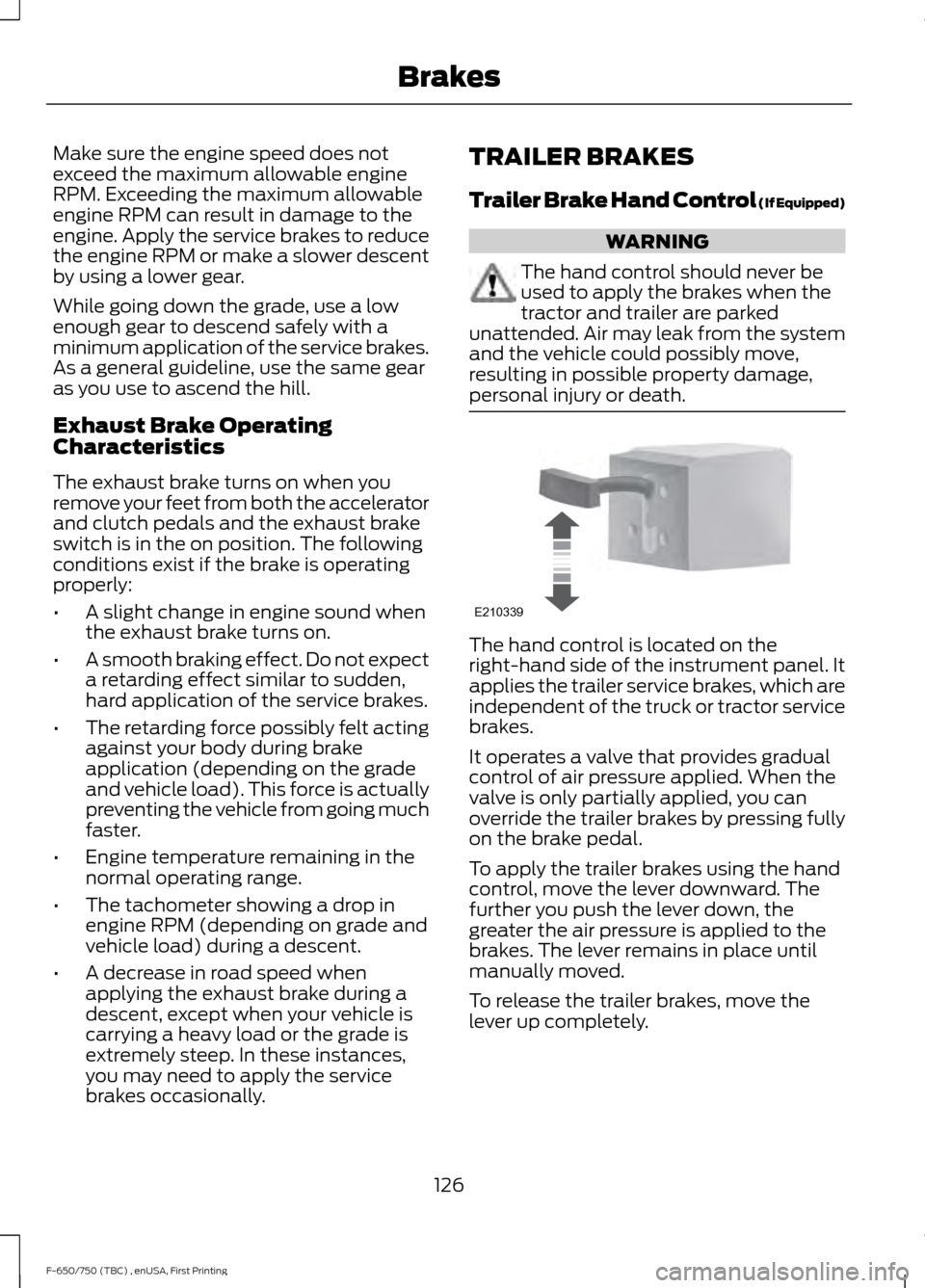

Trailer Brake Hand Control (If Equipped) WARNING

The hand control should never be

used to apply the brakes when the

tractor and trailer are parked

unattended. Air may leak from the system

and the vehicle could possibly move,

resulting in possible property damage,

personal injury or death. The hand control is located on the

right-hand side of the instrument panel. It

applies the trailer service brakes, which are

independent of the truck or tractor service

brakes.

It operates a valve that provides gradual

control of air pressure applied. When the

valve is only partially applied, you can

override the trailer brakes by pressing fully

on the brake pedal.

To apply the trailer brakes using the hand

control, move the lever downward. The

further you push the lever down, the

greater the air pressure is applied to the

brakes. The lever remains in place until

manually moved.

To release the trailer brakes, move the

lever up completely.

126

F-650/750 (TBC) , enUSA, First Printing BrakesE210339

Page 130 of 382

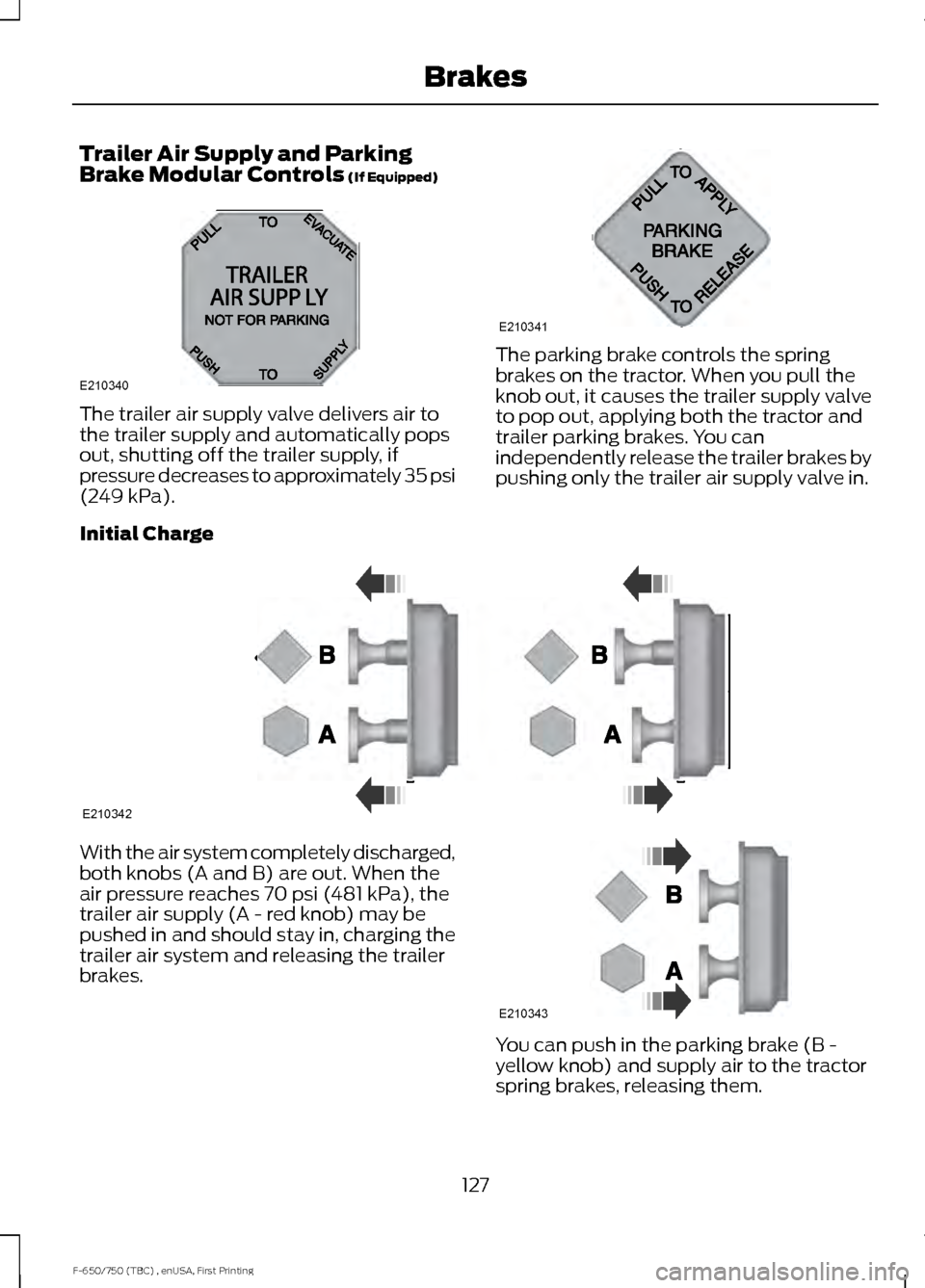

Trailer Air Supply and Parking

Brake Modular Controls (If Equipped)

The trailer air supply valve delivers air to

the trailer supply and automatically pops

out, shutting off the trailer supply, if

pressure decreases to approximately 35 psi

(249 kPa)

. The parking brake controls the spring

brakes on the tractor. When you pull the

knob out, it causes the trailer supply valve

to pop out, applying both the tractor and

trailer parking brakes. You can

independently release the trailer brakes by

pushing only the trailer air supply valve in.

Initial Charge With the air system completely discharged,

both knobs (A and B) are out. When the

air pressure reaches

70 psi (481 kPa), the

trailer air supply (A - red knob) may be

pushed in and should stay in, charging the

trailer air system and releasing the trailer

brakes. You can push in the parking brake (B -

yellow knob) and supply air to the tractor

spring brakes, releasing them.

127

F-650/750 (TBC) , enUSA, First Printing BrakesE210340

A

B

12

A320

A E210341 E210342 E210343