power steering fluid FORD F750 2017 13.G Owners Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2017, Model line: F750, Model: FORD F750 2017 13.GPages: 382, PDF Size: 5.18 MB

Page 6 of 382

Using Traction Control - Vehicles With:

Hydraulic Brakes.......................................130

Cruise Control

Principle of Operation.................................132

Using Cruise Control....................................132

Driving Aids

Steering............................................................134

Load Carrying

Load Limit

........................................................135

Air Suspension

...............................................136

Towing

Towing a Trailer.............................................138

Recommended Towing Weights............139

Essential Towing Checks...........................140

Fifth Wheel Operation

.................................141

Driving Hints

Breaking-In......................................................143

General Driving Points

................................143

Economical Driving......................................144

Cold Weather Precautions........................145

Driving Through Water................................147

Roadside Emergencies

Roadside Assistance

...................................148

Hazard Warning Flashers

..........................149

Fuel Shutoff

...................................................149

Jump Starting the Vehicle.........................150

Transporting the Vehicle

............................153

Customer Assistance

Getting the Services You Need................155

In California (U.S. Only).............................156

The Better Business Bureau (BBB) Auto Line Program (U.S. Only).......................157 Utilizing the Mediation/Arbitration

Program (Canada Only).........................157

Getting Assistance Outside the U.S. and Canada.........................................................158

Ordering Additional Owner's Literature.....................................................159

Reporting Safety Defects (U.S. Only).............................................................159

Reporting Safety Defects (Canada Only).............................................................160

Fuses

Fuse Specification Chart

............................161

Changing a Fuse...........................................169

Vehicle Inspection Guide

Vehicle Inspection Information.................171

Maintenance

General Information....................................180

Opening and Closing the Hood................181

Under Hood Overview - 6.8L...................183

Under Hood Overview - 6.7L Diesel......184

Engine Oil Dipstick - 6.8L..........................185

Engine Oil Dipstick - 6.7L Diesel.............185

Engine Oil Check - 6.8L

..............................185

Engine Oil Check - 6.7L Diesel.................186

Changing the Engine Oil and Oil Filter...............................................................187

Changing the Coalescer Filter Element.......................................................188

Oil Change Indicator Reset.......................189

Engine Coolant Check - 6.8L...................189

Engine Coolant Check - 6.7L Diesel......194

Automatic Transmission Fluid Check............................................................198

Brake Fluid Check.......................................200

Power Steering Fluid Check

.....................201

Washer Fluid Check

.....................................201

Draining the Fuel Filter Water Trap - 6.7L Diesel...........................................................202

3

F-650/750 (TBC) , enUSA, First Printing Table of Contents

Page 15 of 382

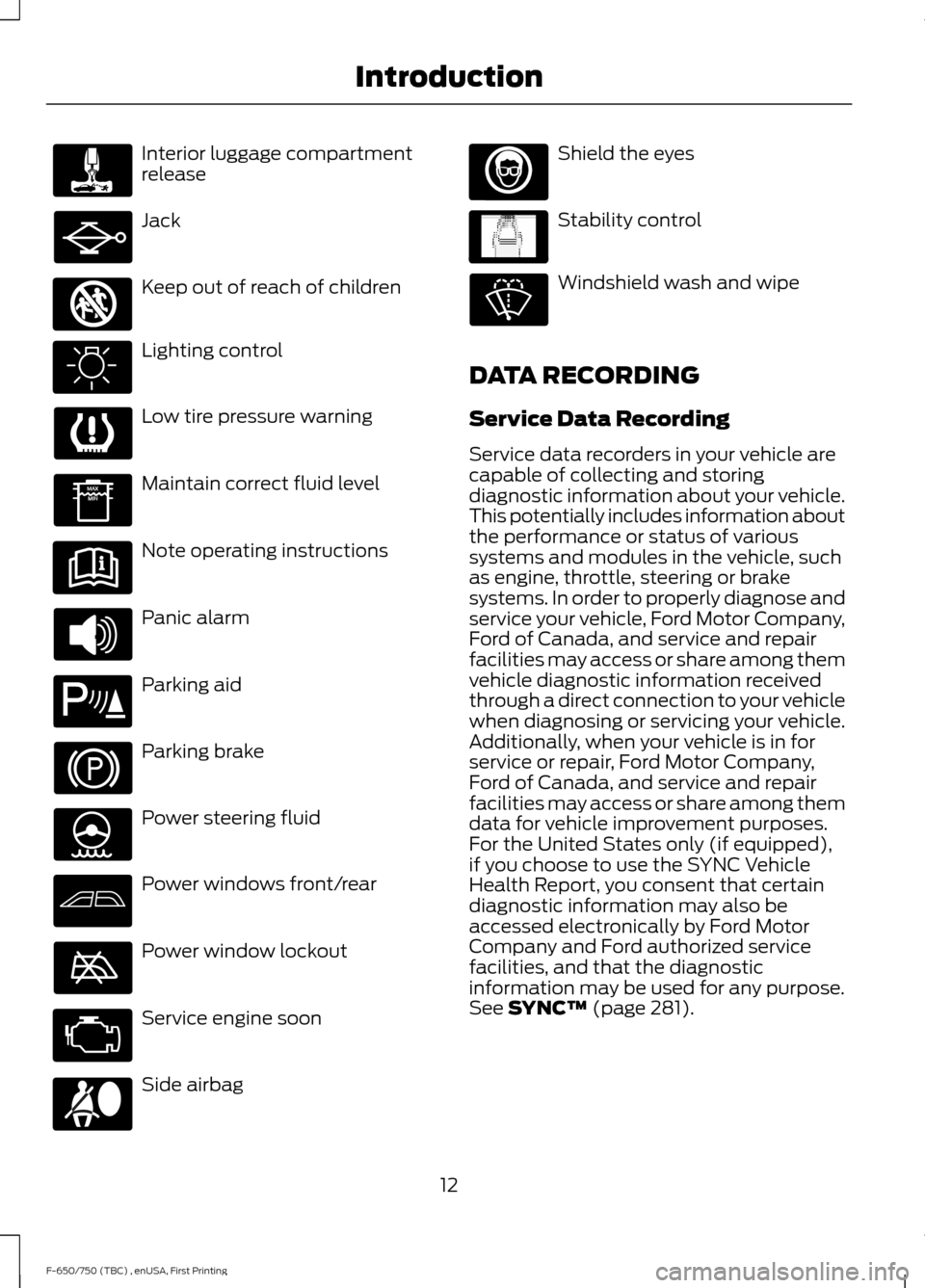

Interior luggage compartment

release

Jack

Keep out of reach of children

Lighting control

Low tire pressure warning

Maintain correct fluid level

Note operating instructions

Panic alarm

Parking aid

Parking brake

Power steering fluid

Power windows front/rear

Power window lockout

Service engine soon

Side airbag Shield the eyes

Stability control

Windshield wash and wipe

DATA RECORDING

Service Data Recording

Service data recorders in your vehicle are

capable of collecting and storing

diagnostic information about your vehicle.

This potentially includes information about

the performance or status of various

systems and modules in the vehicle, such

as engine, throttle, steering or brake

systems. In order to properly diagnose and

service your vehicle, Ford Motor Company,

Ford of Canada, and service and repair

facilities may access or share among them

vehicle diagnostic information received

through a direct connection to your vehicle

when diagnosing or servicing your vehicle.

Additionally, when your vehicle is in for

service or repair, Ford Motor Company,

Ford of Canada, and service and repair

facilities may access or share among them

data for vehicle improvement purposes.

For the United States only (if equipped),

if you choose to use the SYNC Vehicle

Health Report, you consent that certain

diagnostic information may also be

accessed electronically by Ford Motor

Company and Ford authorized service

facilities, and that the diagnostic

information may be used for any purpose.

See SYNC™ (page 281).

12

F-650/750 (TBC) , enUSA, First Printing Introduction E161353 E139213 E167012 E138639

Page 120 of 382

GENERAL INFORMATION

WARNING

Exceeding these ratings by

overloading can cause component

failure resulting in property damage,

personal injury or death. Fluid Temperature

If the operating temperature exceeds

250°F (121°C), the rate of axle lubrication

oxidation increases and shortens the life

of the lubricant and seals, requiring axle

lubrication changes to become more

frequent to preserve the axle. Do not

consistently run extreme pressure (EP)

lubricants above

250°F (121°C).

Axle Conversions WARNING

When operating a loaded vehicle, the

driver must keep all adjustable axles

on the ground at all times, supporting

their share of the vehicle ’s load. Failure to

do so can overload other axles, tires,

wheels, springs, steering components,

brakes and frames, resulting in early

component failure, loss of vehicle control,

possible property damage and personal

injury. We do not recommend, or approve,

performing axle conversions. However, we

understand that, on occasion, others install

aftermarket add-on axles on the truck

chassis that allow operator control for

weight transfer from other axles (such as

air lift axles). LIMITED SLIP DIFFERENTIAL

(If Equipped) WARNING

If both wheels are not raised off the

ground, the one wheel that is not

raised may pull the vehicle off its

support, possibly resulting in personal

injury. This axle provides added traction on

slippery surfaces, particularly when one

wheel is on a poor traction surface. Under

normal conditions, the limited-slip axle

functions like a standard rear axle. The axle

may exhibit a slight noise or vibration

during tight turns with low vehicle speed.

This is normal behavior and indicates the

axle is working.

Both wheels must be raised off the ground

should it be necessary to operate one

wheel with your vehicle stationary.

ELECTRONIC LOCKING

DIFFERENTIAL

(If Equipped)

Driver-Controlled Locking

Differential

Note: Never use the differential lock at

vehicle speeds above

25 mph (40 km/h).

Some drive axles have a driver-controlled

differential lock. The differential lock can

lock or unlock the differential when your

vehicle is moving or stopped. When extra

traction is required, the differential lock

provides full power to both wheels.

When you lock the differential, your

vehicle ’s turning radius increases

(under-steer).

Take care to avoid sudden accelerations

when both drive wheels are on a slippery

surface.

117

F-650/750 (TBC) , enUSA, First Printing Rear Axle

Page 137 of 382

STEERING

To help prevent damage to the power

steering system:

•

Never hold the steering wheel at its

furthest turning points (until it stops)

for more than three to five seconds

when the engine is running.

• Do not operate the vehicle with a low

power steering pump fluid level (below

the MIN mark on the reservoir).

• Some noise is normal during operation.

If excessive, check for low power

steering pump fluid level before

seeking service by your dealer.

• Heavy or uneven efforts may be caused

by low power steering fluid. Check for

low power steering pump fluid level

before seeking service by your dealer.

• Do not fill the power steering pump

reservoir above the MAX mark on the

reservoir, as this may result in leaks

from the reservoir.

If the power steering system breaks down

(or if the engine is turned off), you can

steer the vehicle manually, but it takes

more effort.

Operating the steering system excessively

at an elevated engine RPM (>1200 rpm)

for more than 2 minutes can result in

steering system damage from overheating.

Move the steering wheel to the full left

position then full right position at idle

speed, or stop using the system for 2

minutes to allow the system to cool down.

If the power steering system exhibits heavy

or uneven efforts, check for the following

before seeking service from your dealer:

• An improperly inflated tire.

• Overloading of front suspension.

• Uneven vehicle loading.

• Binding suspension components. If the power steering system wanders or

pulls, check for:

•

An improperly inflated tire.

• Uneven vehicle loading.

• Uneven tire wear.

• Loose or worn suspension

components.

• Loose or worn steering components.

• Improper vehicle alignment.

• High crosswinds.

If any steering components are serviced or

replaced, install new fasteners (many are

coated with thread adhesive or have

prevailing torque features which may not

be re-used). Never re-use a bolt or nut.

Torque fasteners to specifications.

A high crown in the road or high crosswinds

may also make the steering seem to

wander or pull.

134

F-650/750 (TBC) , enUSA, First Printing Driving Aids

Page 174 of 382

VEHICLE INSPECTION

INFORMATION

To make sure your vehicle is ready to

operate, conduct a pre-trip inspection at

the beginning of each work period. Follow

the steps listed in this section to verify a

proper vehicle inspection procedure.

WARNINGS

Exercise great caution when working

on a vehicle equipped with an

automatic fan clutch. The fan starts

in motion only after the engine coolant

reaches a predetermined temperature or

the refrigerant pressure (if equipped with

air conditioning) reaches a predetermined

setting. The fan starts at this point with no

advance warning. Never reach near, or

permit objects to protrude into, the fan

blade radius while the engine is running as

this could result in vehicle damage,

personal injury or death. WARNINGS

Do not operate the vehicle if any

suspension conditions listed in the

following charts are evident. Loss of

steering or suspension could result in

property damage, personal injury or death. If a wheel must be changed, obtain

expert tire service help. Mounting and

un-mounting of tires should only be

performed by a qualified technician using

necessary safety procedures and

equipment, otherwise the result could be

property damage, personal injury or death. Note:

Always make sure you apply the

parking brake before starting the engine. Engine compartment (with engine off)

Use the dipstick to verify the oil level is in the proper operating

range. See Engine Oil Dipstick (page 185).

Engine oil

Look through the plastic reservoir and verify the coolant level

is within the proper operating range. Do not remove the

pressure cap until the coolant has cooled. See

Engine

Coolant Check (page 189).

Engine coolant

Verify that the fluid level is in the proper operating range. See

Power Steering Fluid Check

(page 201).

Power steering fluid

Remove the master cylinder caps and inspect the fluid level.

See

Brake Fluid Check (page 200).

Brake fluid

171

F-650/750 (TBC) , enUSA, First Printing Vehicle Inspection Guide

Page 177 of 382

Front of vehicle

Verify running lights are clean and unbroken.

Inspect for any missing or loose fasteners, power steering

fluid leaks and damage to power steering hoses.

Steering gear

Verify connecting links, arms and rods are not worn or cracked.

Steering linkage

Verify joints, sockets and boot seals are not worn or loose.

Verify cotter keys, nuts and bolts are not loose or missing.

Inspect front and rear tow hooks for damage or loose

mounting. This is particularly important on vehicles that use

them frequently.

Tow hooks Front suspension

Inspect for missing, broken or shifted leaves, or leaves that

may be in contact with (or nearly contacting) a tire, rim, brake

drum, frame or body component.

Springs

Note: Never apply grease to spring pads.

Make sure there the following items are properly tightened

and that there are no cracks, breaks, wear, damage to spring

hangers, bolts, bushings, axle mounting bolts, and nuts.

Spring mounts

Inspect for any cracks, leaks, or missing or broken bolts or

bushings.

Shock absorbers

174

F-650/750 (TBC) , enUSA, First Printing Vehicle Inspection Guide

Page 186 of 382

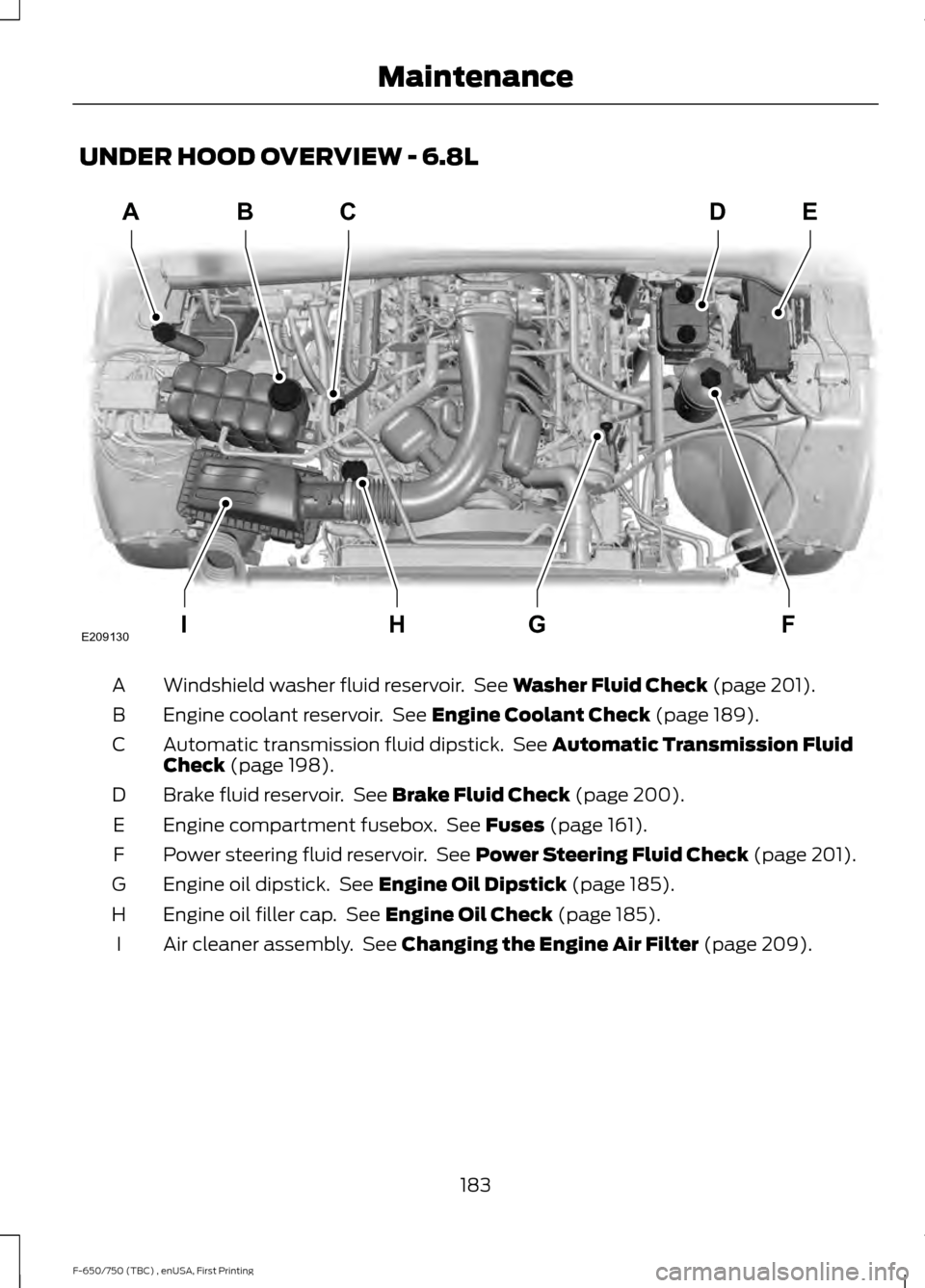

UNDER HOOD OVERVIEW - 6.8L

Windshield washer fluid reservoir. See Washer Fluid Check (page 201).

A

Engine coolant reservoir. See

Engine Coolant Check (page 189).

B

Automatic transmission fluid dipstick. See

Automatic Transmission Fluid

Check (page 198).

C

Brake fluid reservoir. See

Brake Fluid Check (page 200).

D

Engine compartment fusebox. See

Fuses (page 161).

E

Power steering fluid reservoir. See

Power Steering Fluid Check (page 201).

F

Engine oil dipstick. See

Engine Oil Dipstick (page 185).

G

Engine oil filler cap. See

Engine Oil Check (page 185).

H

Air cleaner assembly. See

Changing the Engine Air Filter (page 209).

I

183

F-650/750 (TBC) , enUSA, First Printing MaintenanceABC

FGHI

DE

E209130

Page 187 of 382

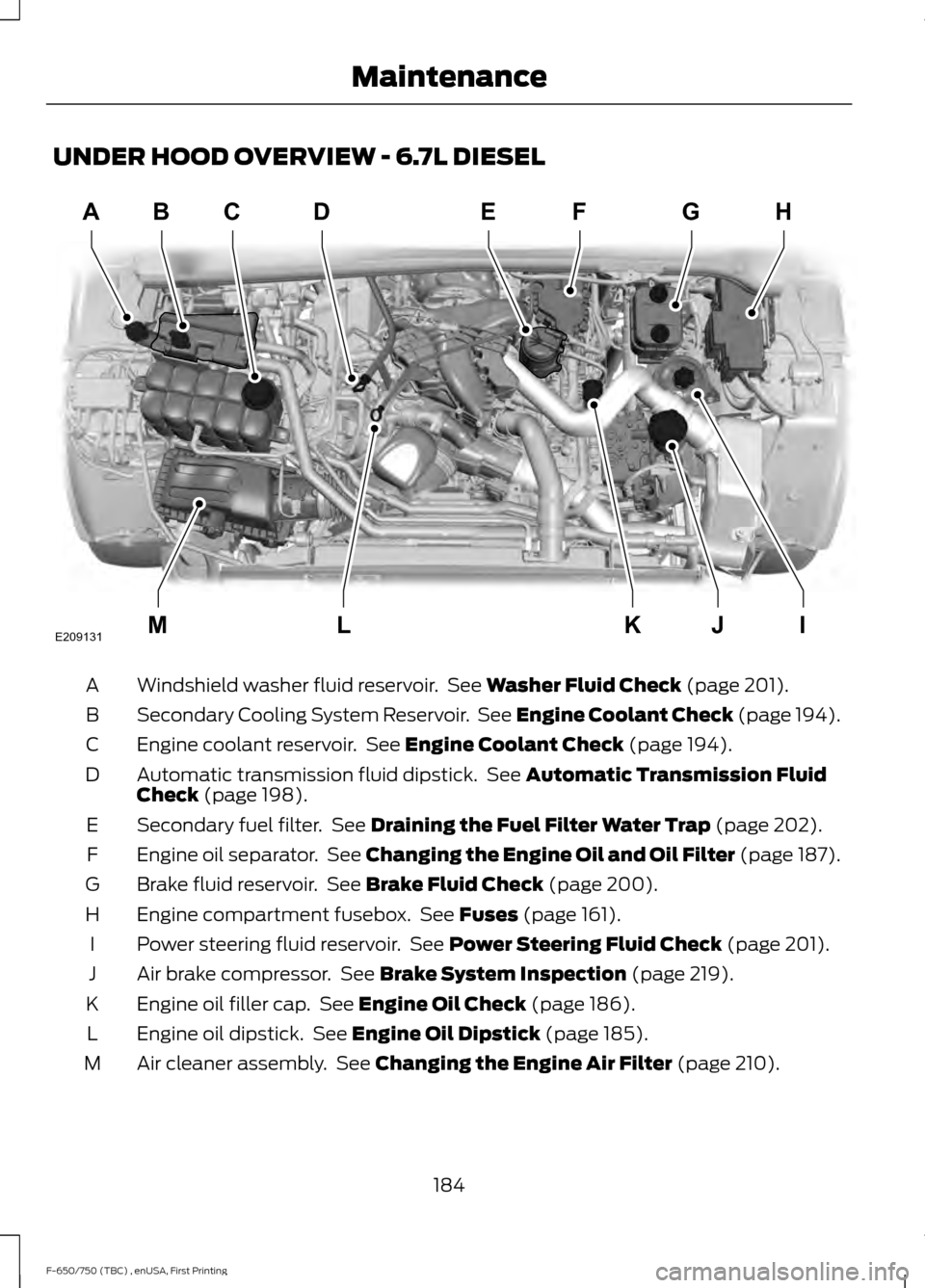

UNDER HOOD OVERVIEW - 6.7L DIESEL

Windshield washer fluid reservoir. See Washer Fluid Check (page 201).

A

Secondary Cooling System Reservoir. See Engine Coolant Check (page 194).

B

Engine coolant reservoir. See

Engine Coolant Check (page 194).

C

Automatic transmission fluid dipstick. See

Automatic Transmission Fluid

Check (page 198).

D

Secondary fuel filter. See

Draining the Fuel Filter Water Trap (page 202).

E

Engine oil separator. See Changing the Engine Oil and Oil Filter (page 187).

F

Brake fluid reservoir. See

Brake Fluid Check (page 200).

G

Engine compartment fusebox. See

Fuses (page 161).

H

Power steering fluid reservoir. See

Power Steering Fluid Check (page 201).

I

Air brake compressor. See

Brake System Inspection (page 219).

J

Engine oil filler cap. See

Engine Oil Check (page 186).

K

Engine oil dipstick. See

Engine Oil Dipstick (page 185).

L

Air cleaner assembly. See

Changing the Engine Air Filter (page 210).

M

184

F-650/750 (TBC) , enUSA, First Printing MaintenanceABD

IJKLM

FEGH

E209131C

Page 204 of 382

To avoid fluid contamination, the reservoir

cap must remain in place and fully tight,

unless you are adding fluid.

Only use fluid that meets Ford

specifications. See Capacities and

Specifications (page 252).

POWER STEERING FLUID

CHECK

Check the power steering fluid. See

Scheduled Maintenance

(page 316). If

adding fluid is necessary, use only

MERCON LV ATF

Check the fluid level when it is at ambient

temperature.

1. Check the fluid level in the reservoir. It should be between the MIN and MAX

range. Do not add fluid if the level is

within this range.

2. If the fluid level is low, add fluid to bring

the fluid level up to between the MIN

and MAX range.

3. Switch the engine on. 4.

While the engine idles, turn the steering

wheel left and right several times.

5. Switch the engine off.

6. Recheck the fluid level in the reservoir. Do not add fluid if the level is between

the MIN and MAX range.

7. If the fluid is low, add the proper type of fluid in small amounts, continuously

checking the level until it is between

the MIN and MAX range. See

Capacities and Specifications (page

258). Be sure to put the cap back on the

reservoir.

WASHER FLUID CHECK WARNING

If you operate your vehicle in

temperatures below 40°F (5°C), use

washer fluid with antifreeze

protection. Failure to use washer fluid with

antifreeze protection in cold weather could

result in impaired windshield vision and

increase the risk of injury or accident. Add fluid to fill the reservoir if the level is

low. Only use a washer fluid that meets

Ford specifications. See

Capacities and

Specifications (page 252).

State or local regulations on volatile

organic compounds may restrict the use

of methanol, a common windshield washer

antifreeze additive. Washer fluids

containing non-methanol antifreeze

agents should be used only if they provide

cold weather protection without damaging

the vehicle ’s paint finish, wiper blades or

washer system.

201

F-650/750 (TBC) , enUSA, First Printing MaintenanceE170684

Page 226 of 382

•

Maintaining proper steering gear and

power steering pump lubricant levels.

• Checking steering column joint bolts

and steering linkage, particularly for

body-to-chassis clearance.

Steering Column Joint Bolts

As a good maintenance practice, check

steering column joint bolt tightness every

60,000 mi (96,000 km) or annually,

whichever occurs first. Do not overtighten

the bolts.

Hydraulic System

Whenever draining and refilling the power

steering's hydraulic system for any reason,

bleed air from the system before returning

the vehicle to service. Failure to bleed the

hydraulic system properly can result in

degradation of power system performance.

Consult an authorized dealer who is aware

of the proper procedures for filling and

bleeding the system.

SUSPENSION SYSTEM

INSPECTION

Note: Do not adjust air suspension height

to any setting other than the specified

setting. Altering the height setting changes

the driveline angle and may result in

unwarrantable component damage, such

as transmission component damage.

Verify drive axle air suspension height and

height control valve performance at engine

oil change intervals.

Periodically check:

• Condition of spring leaves for evidence

of fatigue, bending or breakage.

• Condition of suspension mounting

brackets and bushings.

• Torque rod mounting fasteners for

tightness. •

For proper suspension alignment.

Maintain proper alignment at all times.

• U-bolts. After the chassis has been

operating under load for

1,000 mi

(1,600 km) or six months (whichever

comes first), the U-bolt nuts must be

re-torqued. Re-torque the U-bolt nuts

every

37,000 mi (60,000 km)

thereafter. Clean and lubricate the

U-bolt and nut threads and seats to

make sure a like new condition when

re-torqueing. See

Spring U-Bolt

Check (page 224).

FRAME AND TOW HOOK

INSPECTION

Your vehicle's chassis is manufactured

with frame rails of either HSLA steel or

heat-treated steel. Handle each in a

specific manner to make sure maximum

service life. Consult the service manual or

an authorized dealer before attempting

frame repair or modification.

It is important, particularly on vehicles that

use tow hooks frequently, to inspect the

front and rear tow hooks for damage or a

loose mounting.

REAR AXLE FLUID CHECK

Your rear axle may have an optional

synthetic lubricant that allows the use of

extended service intervals. A tag on the

filler plug identifies the use of the synthetic

lubricant.

Only use a lubricant that meets

manufacturer specifications. Only use a

lubricant that meets manufacturer

specifications. Use of a non-approved rear

axle lubricant may cause internal axle

component damage. See Capacities and

Specifications

(page 258).

223

F-650/750 (TBC) , enUSA, First Printing Maintenance