check engine light FORD FESTIVA 1991 Service Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1991, Model line: FESTIVA, Model: FORD FESTIVA 1991Pages: 454, PDF Size: 9.53 MB

Page 2 of 454

Back To Article

INST RUMENT PANEL

1991 ACCESSORIES & SAFET Y EQUIPMENT Ford Motor Co. Switches & Instrum ent Panels - Standard

DESCRIPTION & OPERATION

Instrument panel on Capri contains a speedometer, tachometer, fuel, water temperature, oil pressure and voltmeter gauges. A boost gauge is

incorporated into the tachometer on turbo models. Instrument panel is equipped with indicator/warning lights for charging system, air b ag,

manual shift, seat belt, turn signals, high beam and brakes. A CHECK ENGINE light, located on instrument panel, illuminates if a

computerized engine control fault occurs with engine running.

Instrument panel on Festiva contains a speedometer, fuel and water temperature gauges. Instrument panel is equipped with indicator/warning

lights for charging system, oil pressure, seat belt, rear defogger, turn signals, high beam and brakes. A CHECK ENGINE light, located on

instrument panel, illuminates if a computerized engine control fault occurs with engine running.

TROUBLE SHOOTING

FUEL GAUGE

Fuel Gauge Always Reads Empty

If fuel gauge always reads empty, check these items:

Check fuel gauge for open or damaged wires.

Check for open ground at fuel gauge sending unit.

Check for defective fuel sending unit.

Check for defective fuel gauge.

Check for defective instrument panel voltage regulator (Festiva).

Check for blown 10-amp METER fuse in fuse panel.

Check for open in Black/Yellow power feed wire from fuse panel instrument panel.

Check for fuel tank float full of fuel (sunk).

Fuel Gauge Always Reads Full

If fuel gauge always reads full, check these items:

Check for fuel gauge Yellow wire shorted to ground.

Check for defective fuel sending unit.

Check for defective fuel gauge.

Check for defective instrument panel voltage regulator (Festiva).

Fuel Gauge Inaccurate

If fuel gauge is inaccurate, check these items:

Check for faulty (loose or corroded) wire connections.

Check for defective fuel sending unit.

Check for defective instrument panel voltage regulator (Festiva).

TEMPERATURE GAUGE

Temperature Gauge Always Reads Cold

If temperature gauge always reads cold, check these items:

Check temperature gauge for open wire.

Check for defective temperature sender.

Check for defective temperature gauge.

Check for defective instrument panel voltage regulator (Festiva).

Check for blown 10-amp METER fuse in fuse panel.

Check for open in Black/Yellow power feed wire from fuse panel to instrument panel.

Temperature Gauge Always Reads Hot

CAUT ION: On m odels with Supplem ental Restraint System (SRS), observe safety precautions. T he air bag system

is powered directly from the battery and back-up power supply. Before any repairs are perform ed,

disconnect and shield battery ground cable. Disconnect the back-up power supply BEFORE servicing

ANY air bag com ponent. Use caution when working near steering colum n. Air bag could accidentally

deploy at any tim e.

NOTE:Ensure continuity exists between chassis ground and Black wire of instrum ent panel connector,

especially if fault exists in m ultiple gauge circuits. See appropriate chassis wiring diagram in the

WIRING DIAGRAMS Section.

Page 1 of 5 MITCHELL 1 ARTICLE - INSTRUMENT PANEL 1991 ACCESSORIES & SAFETY EQUIPMENT Ford Motor Co. Switches

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 4 of 454

Turbo Boost Gauge Always Reads High

If turbo boost gauge always reads high, check these items:

Check for damaged White/Black signal wire.

Check for defective boost sensing unit.

Check for defective boost gauge.

Turbo Boost Gauge Inaccurate

If turbo boost gauge is inaccurate, check these items:

Check for loose or corroded connections.

Check for defective boost sensing unit.

Check for defective boost gauge.

TESTING

FUEL GAUGE SENDING UNIT

Capri

Remove rear seat cushion. Disconnect fuel pump/fuel gauge sending unit electrical connector at access cover. Turn ignition on. Fuel gauge

should read empty. Using a jumper wire, connect Yellow fuel gauge wire of vehicle harness connector to ground. Fuel gauge should read full.

If fuel gauge operates as specified, replace fuel gauge sending unit.

Festiva

Remove fuel gauge sending unit from tank. See FUEL SENDING UNIT under REMOVAL & INSTALLATION. Connect an ohmmeter and

check sending unit resistance as indicated in FUEL GAUGE SENDING UNIT RESISTANCE (FESTIVA)

table. Replace sending unit if

resistance is drastically different than specification.

FUEL GAUGE SENDING UNIT RESISTANCE (FESTIVA)

OIL PRESSURE GAUGE (CAPRI)

1. Remove electrical connector from oil pressure sending unit located on right side of engine block. Turn ignition switch on. Oil pressure

gauge should read low. Install a jumper wire between Yellow/Red wire of oil pressure sending unit vehicle harness connector and

ground. Oil pressure gauge should read high.

2. If oil pressure gauge operates as specified, replace sending unit. If gauge does not operate as specified, check instrument panel power

and ground circuits.

OIL PRESSURE WARNING LIGHT (FESTIVA)

Light Stays On With Engine Running

1. Turn ignition on (DO NOT start engine). Disconnect Yellow/Red wire from oil pressure switch connector. Light should go off.

2. If light stays on, repair short in Yellow/Red wire between oil indicator light and oil pressure switch. Reconnect wire to switch. Light

should be on with ignition on. If light does not go off when engine is started, check switch or engine for low oil pressure.

Oil Light Will Not Go On With Ignition On

1. Ground Yellow/Red wire at instrument panel connector. If light goes on, repair Yellow/Red wire between oil pressure switch and

indicator light or replace defective oil pressure switch.

2. If light does not illuminate, check bulb or check instrument panel ground circuit.

TEMPERATURE GAUGE (CAPRI)

1. Remove electrical connector from temperature sending unit located at front of cylinder head. Connect one lead of Gauge System Tester

(021-00055) to connector and other tester lead to ground. Set tester to 18 ohms, turn ignition switch on and observe temperature gauge.

Gauge should read 250°F.

2. Turn tester to 60 ohms. Gauge should read 175°F. Turn tester to 223 ohms. Gauge should read 100°F. If all readings are within twice

the needle width of correct reading, gauge is functioning properly. If readings are not as specified, replace gauge.

TEMPERATURE GAUGE (FESTIVA)

See TROUBLE SHOOTING for possible service areas.

TEMPERATURE SENDING UNIT (CAPRI)

Remove sending unit from engine and place in container of water. Heat water to 176°F (80°C). Measure resistance between sending unit

connector and case. Resistance should be 49.3-57.7 ohms. If resistance is not as specified, replace sending unit. NOTE:Inspect fuel tank for distortion or dam age. If distorted or dam aged, repair or replace tank before testing.

Float PositionOhms

Full Position (Up)Approximately 7

Half-Full Position (Middle)Approximately 33

Empty Position (Down)Approximately 95

Page 3 of 5 MITCHELL 1 ARTICLE - INSTRUMENT PANEL 1991 ACCESSORIES & SAFETY EQUIPMENT Ford Motor Co. Switches

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 30 of 454

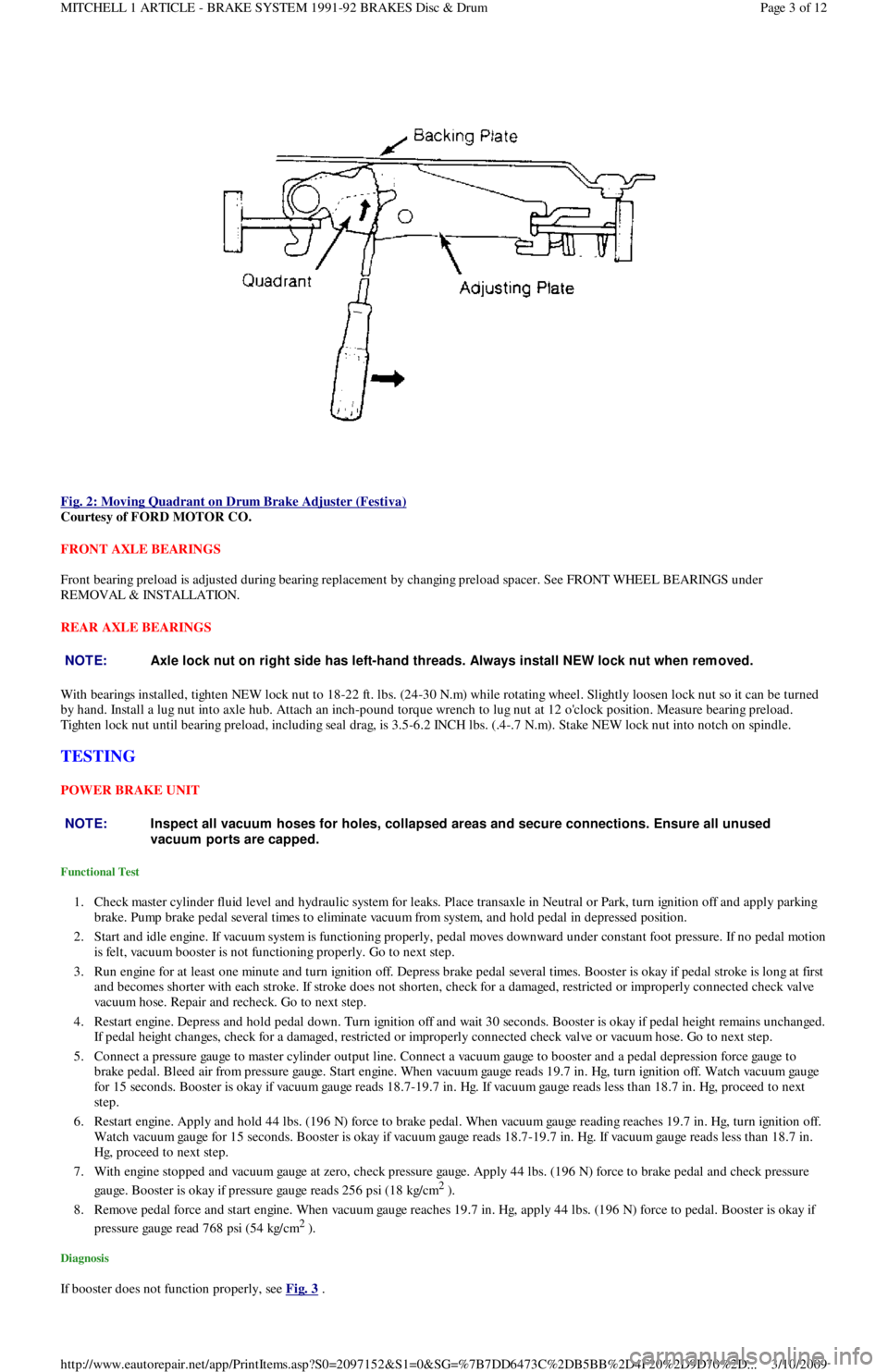

Fig. 2: Moving Quadrant on Drum Brake Adjuster (Festiva)

Courtesy of FORD MOTOR CO.

FRONT AXLE BEARINGS

Front bearing preload is adjusted during bearing replacement by changing preload spacer. See FRONT WHEEL BEARINGS under

REMOVAL & INSTALLATION.

REAR AXLE BEARINGS

With bearings installed, tighten NEW lock nut to 18-22 ft. lbs. (24-30 N.m) while rotating wheel. Slightly loosen lock nut so it can be turned

by hand. Install a lug nut into axle hub. Attach an inch-pound torque wrench to lug nut at 12 o'clock position. Measure bearing preload.

Tighten lock nut until bearing preload, including seal drag, is 3.5-6.2 INCH lbs. (.4-.7 N.m). Stake NEW lock nut into notch on spindle.

TESTING

POWER BRAKE UNIT

Functional Test

1. Check master cylinder fluid level and hydraulic system for leaks. Place transaxle in Neutral or Park, turn ignition off and apply parking

brake. Pump brake pedal several times to eliminate vacuum from system, and hold pedal in depressed position.

2. Start and idle engine. If vacuum system is functioning properly, pedal moves downward under constant foot pressure. If no pedal motion

is felt, vacuum booster is not functioning properly. Go to next step.

3. Run engine for at least one minute and turn ignition off. Depress brake pedal several times. Booster is okay if pedal stroke is long at first

and becomes shorter with each stroke. If stroke does not shorten, check for a damaged, restricted or improperly connected check va l ve

vacuum hose. Repair and recheck. Go to next step.

4. Restart engine. Depress and hold pedal down. Turn ignition off and wait 30 seconds. Booster is okay if pedal height remains unchanged.

If pedal height changes, check for a damaged, restricted or improperly connected check valve or vacuum hose. Go to next step.

5. Connect a pressure gauge to master cylinder output line. Connect a vacuum gauge to booster and a pedal depression force gauge to

brake pedal. Bleed air from pressure gauge. Start engine. When vacuum gauge reads 19.7 in. Hg, turn ignition off. Watch vacuum ga u ge

for 15 seconds. Booster is okay if vacuum gauge reads 18.7-19.7 in. Hg. If vacuum gauge reads less than 18.7 in. Hg, proceed to next

step.

6. Restart engine. Apply and hold 44 lbs. (196 N) force to brake pedal. When vacuum gauge reading reaches 19.7 in. Hg, turn ignition off.

Watch vacuum gauge for 15 seconds. Booster is okay if vacuum gauge reads 18.7-19.7 in. Hg. If vacuum gauge reads less than 18.7 in.

Hg, proceed to next step.

7. With engine stopped and vacuum gauge at zero, check pressure gauge. Apply 44 lbs. (196 N) force to brake pedal and check pressure

gauge. Booster is okay if pressure gauge reads 256 psi (18 kg/cm

2 ).

8. Remove pedal force and start engine. When vacuum gauge reaches 19.7 in. Hg, apply 44 lbs. (196 N) force to pedal. Booster is okay if

pressure gauge read 768 psi (54 kg/cm

2 ).

Diagnosis

If booster does not function properly, see Fig. 3 .

NOTE:Axle lock nut on right side has left-hand threads. Always install NEW lock nut when rem oved.

NOTE:Inspect all vacuum hoses for holes, collapsed areas and secure connections. Ensure all unused

vacuum ports are capped.

Page 3 of 12 MITCHELL 1 ARTICLE - BRAKE SYSTEM 1991-92 BRAKES Disc & Drum

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 43 of 454

Back To Article

ALTERNATOR & REGULATOR

1991 ELECT RICAL Alternators & Regulators

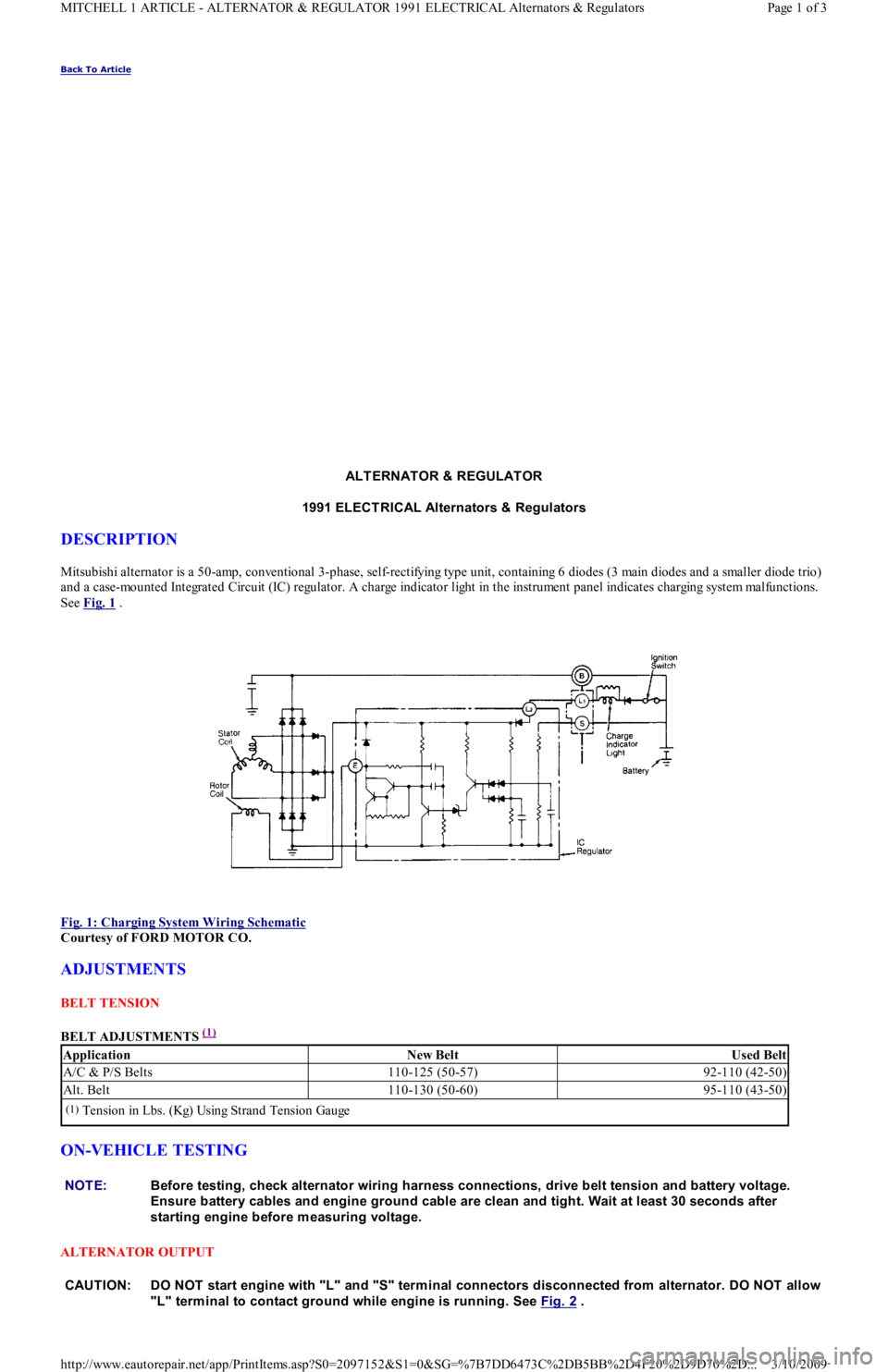

DESCRIPTION

Mitsubishi alternator is a 50-amp, conventional 3-phase, self-rectifying type unit, containing 6 diodes (3 main diodes and a smaller diode trio)

and a case-mounted Integrated Circuit (IC) regulator. A charge indicator light in the instrument panel indicates charging system mal fu n ct io n s.

See Fig. 1

.

Fig. 1: Charging System Wiring Schematic

Courtesy of FORD MOTOR CO.

ADJUSTMENTS

BELT TENSION

BELT ADJUSTMENTS

(1)

ON-VEHICLE TESTING

ALTERNATOR OUTPUT

ApplicationNew BeltUsed Belt

A/C & P/S Belts110-125 (50-57)92-110 (42-50)

Alt. Belt110-130 (50-60)95-110 (43-50)

(1)Tension in Lbs. (Kg) Using Strand Tension Gauge

NOTE:Before testing, check alternator wiring harness connections, drive belt tension and battery voltage.

Ensure battery cables and engine ground cable are clean and tight. Wait at least 30 seconds after

starting engine before m easuring voltage.

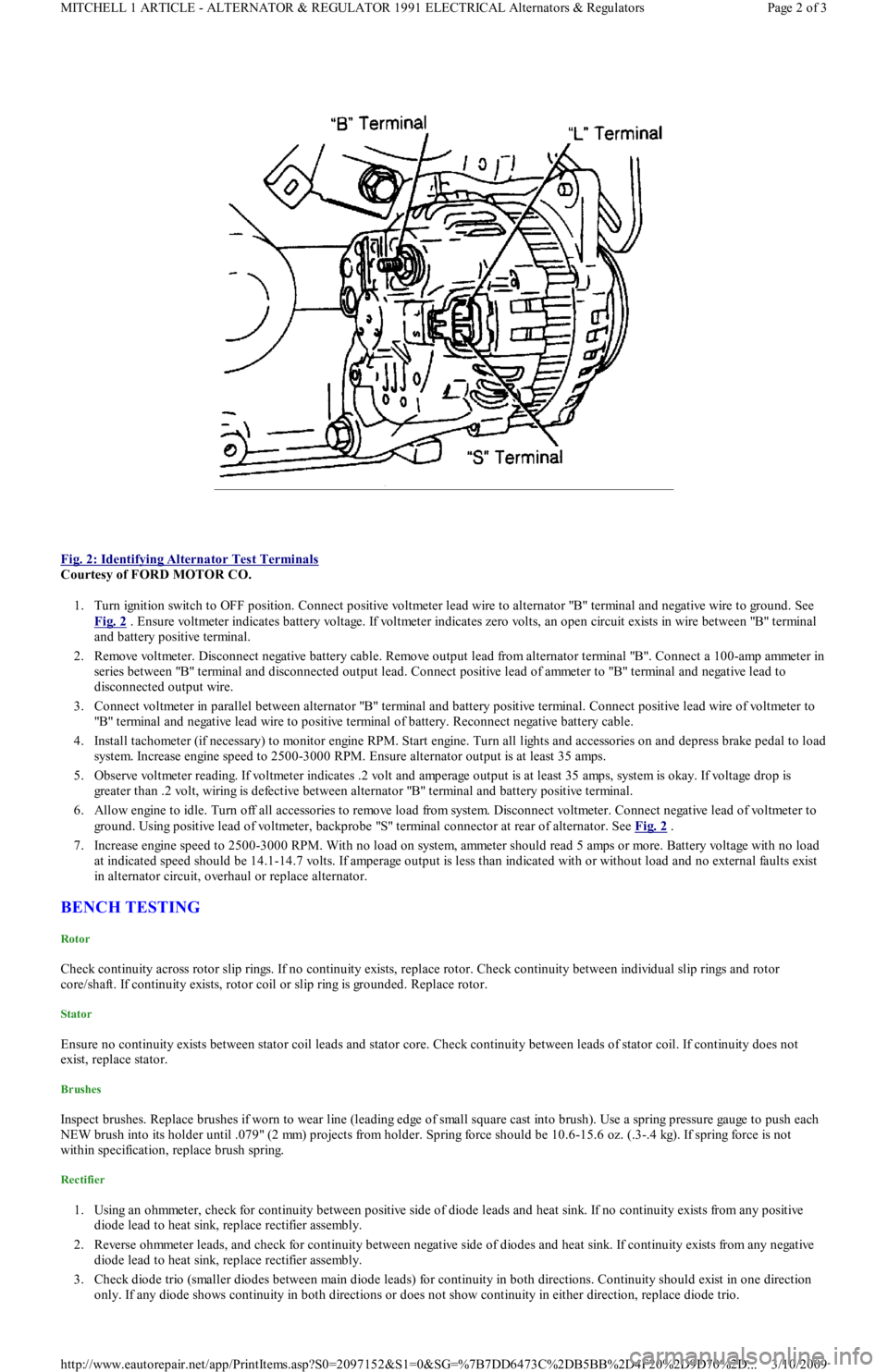

CAUT ION: DO NOT start engine with "L" and "S" term inal connectors disconnected from alternator. DO NOT allow

"L" term inal to contact ground while engine is running. See Fig. 2

.

Page 1 of 3 MITCHELL 1 ARTICLE - ALTERNATOR & REGULATOR 1991 ELECTRICAL Alternators & Regulators

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 44 of 454

Fig. 2: Identifying Alternator Test Terminals

Courtesy of FORD MOTOR CO.

1. Turn ignition switch to OFF position. Connect positive voltmeter lead wire to alternator "B" terminal and negative wire to ground. See

Fig. 2

. Ensure voltmeter indicates battery voltage. If voltmeter indicates zero volts, an open circuit exists in wire between "B" terminal

and battery positive terminal.

2. Remove voltmeter. Disconnect negative battery cable. Remove output lead from alternator terminal "B". Connect a 100-amp ammeter in

series between "B" terminal and disconnected output lead. Connect positive lead of ammeter to "B" terminal and negative lead to

disconnected output wire.

3. Connect voltmeter in parallel between alternator "B" terminal and battery positive terminal. Connect positive lead wire of voltmeter to

"B" terminal and negative lead wire to positive terminal of battery. Reconnect negative battery cable.

4. Install tachometer (if necessary) to monitor engine RPM. Start engine. Turn all lights and accessories on and depress brake pedal to load

system. Increase engine speed to 2500-3000 RPM. Ensure alternator output is at least 35 amps.

5. Observe voltmeter reading. If voltmeter indicates .2 volt and amperage output is at least 35 amps, system is okay. If voltage drop is

greater than .2 volt, wiring is defective between alternator "B" terminal and battery positive terminal.

6. Allow engine to idle. Turn off all accessories to remove load from system. Disconnect voltmeter. Connect negative lead of voltmeter to

ground. Using positive lead of voltmeter, backprobe "S" terminal connector at rear of alternator. See Fig. 2

.

7. Increase engine speed to 2500-3000 RPM. With no load on system, ammeter should read 5 amps or more. Battery voltage with no load

at indicated speed should be 14.1-14.7 volts. If amperage output is less than indicated with or without load and no external faults exist

in alternator circuit, overhaul or replace alternator.

BENCH TESTING

Rotor

Check continuity across rotor slip rings. If no continuity exists, replace rotor. Check continuity between individual slip rings and rotor

core/shaft. If continuity exists, rotor coil or slip ring is grounded. Replace rotor.

Stator

Ensure no continuity exists between stator coil leads and stator core. Check continuity between leads of stator coil. If continuity does not

exist, replace stator.

Brushes

Inspect brushes. Replace brushes if worn to wear line (leading edge of small square cast into brush). Use a spring pressure gauge to push each

NEW brush into its holder until .079" (2 mm) projects from holder. Spring force should be 10.6-15.6 oz. (.3-.4 kg). If spring force is not

within specification, replace brush spring.

Rectifier

1. Using an ohmmeter, check for continuity between positive side of diode leads and heat sink. If no continuity exists from any positive

diode lead to heat sink, replace rectifier assembly.

2. Reverse ohmmeter leads, and check for continuity between negative side of diodes and heat sink. If continuity exists from any n e ga t ive

diode lead to heat sink, replace rectifier assembly.

3. Check diode trio (smaller diodes between main diode leads) for continuity in both directions. Continuity should exist in one direction

only. If any diode shows continuity in both directions or does not show continuity in either direction, replace diode trio.

Page 2 of 3 MITCHELL 1 ARTICLE - ALTERNATOR & REGULATOR 1991 ELECTRICAL Alternators & Regulators

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 53 of 454

3. If voltage is not present or is less than 8 volts at starter solenoid terminal "S", malfunction in circuit to terminal "S" is indicated. Proceed

to the following tests.

IGNITION SWITCH TEST

1. Locate ignition switch connector under dash. Using a 12-volt test light or voltmeter, ensure voltage is present on Black/Yellow wire

when ignition switch is turned to RUN or ON position. This will verify proper operation of ignition switch.

2. If there is no voltage on Black/Yellow wire, the problem is either ignition switch or circuit between battery and ignition switch.

CLUTCH ENGAGE SWITCH (M/T) TEST

Unplug clutch engage switch from main wiring harness. Using an ohmmeter, check for continuity across switch terminals. Continuity should

exist when switch plunger is pushed in and should not exist when switch plunger is released. If clutch engage switch does not operate as

specified, replace switch.

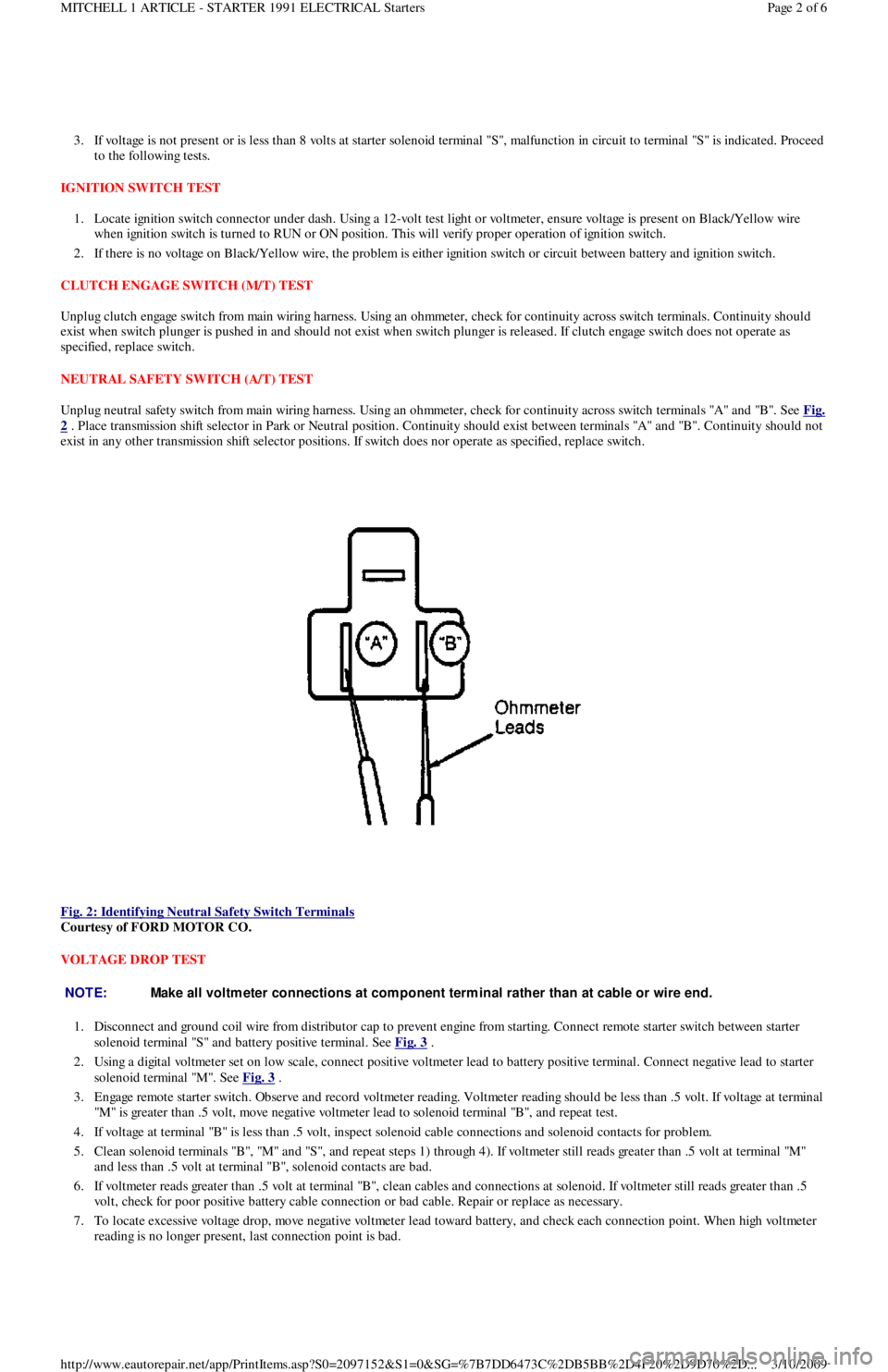

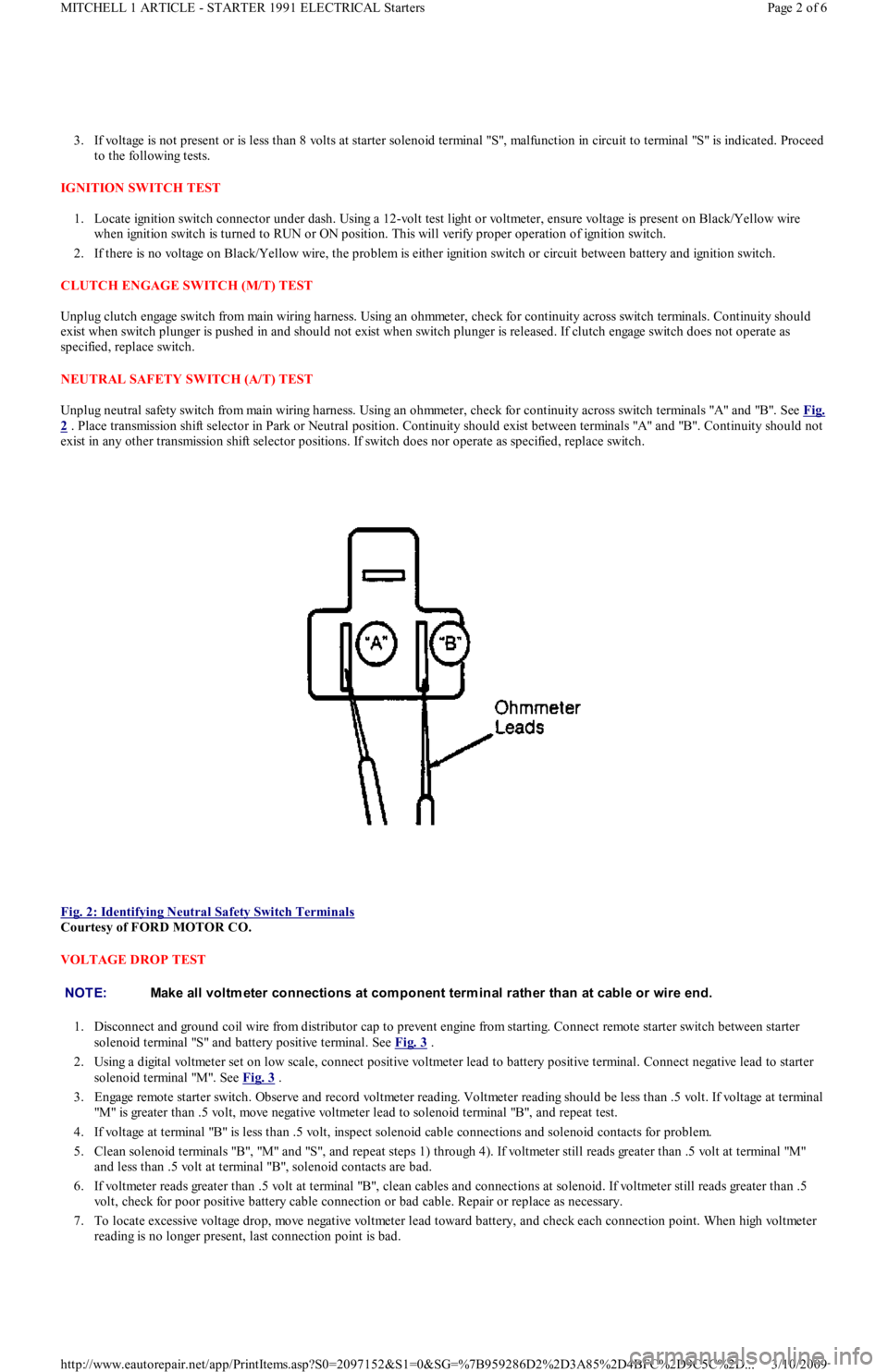

NEUTRAL SAFETY SWITCH (A/T) TEST

Unplug neutral safety switch from main wiring harness. Using an ohmmeter, check for continuity across switch terminals "A" and "B". See Fig.

2 . Place transmission shift selector in Park or Neutral position. Continuity should exist between terminals "A" and "B". Continuity should not

exist in any other transmission shift selector positions. If switch does nor operate as specified, replace switch.

Fig. 2: Identifying Neutral Safety Switch Terminals

Courtesy of FORD MOTOR CO.

VOLTAGE DROP TEST

1. Disconnect and ground coil wire from distributor cap to prevent engine from starting. Connect remote starter switch between starter

solenoid terminal "S" and battery positive terminal. See Fig. 3

.

2. Using a digital voltmeter set on low scale, connect positive voltmeter lead to battery positive terminal. Connect negative lead to starter

solenoid terminal "M". See Fig. 3

.

3. Engage remote starter switch. Observe and record voltmeter reading. Voltmeter reading should be less than .5 volt. If voltage at terminal

"M" is greater than .5 volt, move negative voltmeter lead to solenoid terminal "B", and repeat test.

4. If voltage at terminal "B" is less than .5 volt, inspect solenoid cable connections and solenoid contacts for problem.

5 . Cl ean so l en o id t ermin al s "B", "M" an d "S", an d rep eat st ep s 1 ) through 4). If voltmeter still reads greater than .5 volt at termin al "M"

and less than .5 volt at terminal "B", solenoid contacts are bad.

6. If voltmeter reads greater than .5 volt at terminal "B", clean cables and connections at solenoid. If voltmeter still reads greater than .5

volt, check for poor positive battery cable connection or bad cable. Repair or replace as necessary.

7. To locate excessive voltage drop, move negative voltmeter lead toward battery, and check each connection point. When high voltmeter

reading is no longer present, last connection point is bad.

NOTE:Make all voltm eter connections at com ponent term inal rather than at cable or wire end.

Page 2 of 6 MITCHELL 1 ARTICLE - STARTER 1991 ELECTRICAL Starters

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 63 of 454

Back To Article

GENERAL INFORMATION

Using Mitchell1's Wiring Diagram s

INTRODUCTION

Mitchell1(R) obtains wiring diagrams and technical service bulletins, containing wiring diagram changes, from the domestic and import

manufacturers. These are checked for accuracy and are all redrawn into a consistent format for easy use. All system wiring diagrams are

available in color format and may be viewed and or printed in color or black and white, depending on your program settings and available

printer hardware.

In the past, when cars were simpler, diagrams were simpler. All components were connected by wires, and diagrams seldom exceeded 4 pages

in length. Today, some wiring diagrams require more than 16 pages. It would be impractical to expect a service technician to trace a wire from

page 1 across every page to page 16.

Removing some of the wiring maze reduces eyestrain and time wasted searching across several pages. Today, the majority of Mitchell1(R)

diagrams follow a much improved format, which permits space for internal switch details, and component and ground locations.

Components shown with a dashed line instead of a solid line indicate not all circuits are shown in this particular diagram (circuits shown in

system diagrams are typically applicable to that system only). The remaining circuits connected to that component will be shown in the

appropriate system that they apply to.

Today, the wiring diagram necessary to support a given repair procedure is included within that article or a link is provided to the appropriate

SYSTEM WIRING DIAGRAM article. For example, the wiring diagram for a Ford EEC-IV system may be included in ENGINE

PERFORMANCE and WIRING DIAGRAMS articles for Ford Motor Co. The wiring diagram for a cruise control system may be included in

ACCESSORIES & EQUIPMENT section for the specific vehicle manufacturer, and the wiring diagram for an anti-lock brake system may be

included in BRAKES and WIRING DIAGRAMS for the specific manufacturer.

WIRING DIAGRAMS contains all wiring diagrams not included in STARTING & CHARGING SYSTEMS and ACCESSORIES &

EQUIPMENT. This includes: Data Link Connectors, Ground Distribution, Power Distribution, Engine Performance, Electric Cooling Fans,

Anti-Lock Brakes, Electronic Suspension and Electronic Steering wiring diagrams. The Data Link Connectors wiring diagrams show the

circuits by which the various on-board computers exchange information, and the diagnostic connectors used for diagnosis and their location.

The Ground Distribution wiring diagrams show all vehicle ground points, their location, and the components common to those ground points.

The Power Distribution wiring diagrams show the power feed circuits and the components common to those power feeds.

Wiring diagrams used to support the information in ACCESSORIES & EQUIPMENT are drawn in a "top-down" format. The diagrams are

drawn with the power source at the top of the diagram and the ground point at the bottom of the diagram. Component locations are identified

on the wiring diagrams. Any wires that do not connect directly to a component are identified on the diagram to indicate where they go.

WIRING DIAGRAM COLOR ABBREVIATIONS

COLOR ABBREVIATIONS

WIRING DIAGRAM SYMBOLS

ColorNormalOptional

BlackBLKBK

BlueBLUBU

BrownBRNBN

ClearCLRCR

Dark BlueDK BLUDK BU

Dark GreenDK GRNDK GN

GreenGRNGN

GrayGRYGY

Light BlueLT BLULT BU

Light GreenLT GRNLT GN

OrangeORGOG

PinkPNKPK

PurplePPLPL

RedREDRD

TanTANTN

VioletVIOVI

WhiteWHTWT

YellowYELYL

Page 1 of 6 MITCHELL 1 ARTICLE - GENERAL INFORMATION Using Mitchell1's Wiring Diagrams

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 103 of 454

Disconnect negative battery cable. Drain cooling system. Remove air cleaner. Remove intake manifold bracket. Disconnect throttle cable.

Mark and disconnect vacuum hoses, fuel hoses and wiring. Remove intake manifold bolts. Remove intake manifold and gasket.

Installation (1.3L)

Clean all gasket mating surfaces. Ensure surface is free of burrs, scratches and cracks. Replace all gaskets. Position gasket and manifold to

cylinder head. Install bolts and tighten to specification. To complete installation, reverse removal procedure.

Removal (1.6L)

1. Disconnect negative battery terminal. Relieve fuel pressure. See FUEL PRESSURE RELEASE under REMOVAL &

INSTALLATION. Drain cooling system. Disconnect intercooler tube and/or air intake tube. Disconnect air by-pass hoses. Disconnect

main engine harness electrical connection and TPS connector. Disconnect vacuum hoses from throttle body.

2. Disconnect fuel lines from fuel filter and pressure regulator. Disconnect throttle cable. Disconnect hoses from By-pass Air Control valve

( B AC ) . R e mo ve B AC va l ve r e t a in in g n u t a n d b o l t . R e mo ve in t a ke manifold retaining nuts and bolts from support bracket and cylinder

head. Remove intake manifold and throttle body assembly.

Installation (1.6L)

1. Install new intake manifold gasket, ensuring coolant passage openings align with openings in cylinder head and manifold. Install intake

manifold. Tighten retaining nut and bolts and support bracket bolts to specification. See TORQUE SPECIFICATIONS

table at end of

article.

2. Install BAC valve and connect air hoses. Connect throttle cable. Connect fuel lines to fuel filters and pressure regulator. Connect main

engine harness connector and TPS connector. Connect vacuum lines to throttle body. Install intake air tube. Connect intercooler tube

and/or intake air tube. Connect air by-pass hoses. Fill cooling system. Connect negative battery terminal. Start engine and check for

fluid leaks and correct operation.

EXHAUST MANIFOLD

Removal (1.3L)

1. Raise vehicle. Remove catalytic converter inlet pipe at exhaust manifold. Remove pulse air tube nuts at inlet pipe. Remove inlet pipe

support bracket bolts. Lower vehicle. Remove air intake duct. Remove exhaust manifold heat shroud bolts and remove shroud.

2. Disconnect oxygen sensor connector. Remove exhaust manifold nuts and remove exhaust manifold. Remove gasket from inlet pipe and

cylinder head.

Installation

Position new gasket on cylinder head and inlet pipe. Install exhaust manifold and nuts. Tighten nuts to specification. See, at end of article,

TORQUE SPECIFICATIONS

table. To complete installation, reverse removal procedure. Tighten all bolts and nuts to specification.

Removal (1.6L Non-Turbo)

Remove intake air tube. Remove front exhaust pipe to exhaust manifold retaining nuts. Remove exhaust support bracket (if equipped). Remove

heat shield. Disconnect O2 sensor electrical connector. Remove exhaust manifold.

Installation (1.6L Non-Turbo)

Install exhaust manifold gaskets. Install heavier gasket first. Install exhaust manifold and tighten retaining nuts to specification. See TORQUE

SPECIFICATIONS table at end of article. Connect O2 sensor electrical connector. Install manifold heat shield. Install intake air tube.

Connect front exhaust pipe to intake manifold and tighten retaining nuts to specification. Install exhaust support bracket, if removed, and

tighten engine mount bolt to specification. Start engine and check for leaks.

Removal (1.6L Turbo)

1. Disconnect negative battery cable. Drain cooling system. Remove throttle body air intake tube. Disconnect intercooler hose from

turbocharger assembly and position both intercooler hoses out of the way. Remove O2 sensor connector from its retaining clip, and

disconnect O2 sensor. Remove lower heat shield and then upper heat shield. Remove turbocharger side heat shield.

2. Remove power steering pump (leave hoses attached) and lay aside. Disconnect lower radiator hose from water pump. Position power

steering pump to access mounting bracket retaining bolts and nut. Remove both bolts and one nut, and remove bracket from engine.

Remove 2 screws retaining air cleaner duct tube, loosen clamp at turbocharger and position duct tube out of the way. Disconnect

coolant return hose at turbocharger. Remove bolt and brass sealing washers from oil supply line at engine block.

3. Raise vehicle. Remove retaining nuts and washers from exhaust pipe flange. Remove 2 bolts retaining exhaust hangers to engine block.

Slide off two rubber exhaust hangers at catalytic converter. Pull exhaust pipe downward and to LH side of vehicle. Disconnect oil return

hose at turbocharger. Disconnect coolant return hose at turbocharger. Remove 2 retaining bolts from turbocharger support bracket.

Remove 2 bolts retaining coolant by-pass tube outlet to water pump. Lower vehicle.

4. Loosen retaining clamp bolt on coolant by-pass tube at rear of cylinder head. Remove 11 retaining nuts from exhaust manifold. Pull

coolant by-pass tube bracket from exhaust stud, and position tube out of way. Grasp manifold, pull off studs and move assembly slightly

to RH side of engine compartment to clear cooling fan, and remove assembly from vehicle.

5. Working on bench, remove 4 nuts retaining turbocharger to exhaust manifold, separate assembly and discard gasket.

Installation (1.6L Turbo)

NOTE:Feed O2 sensor wire and guide through upper heat shield.

NOTE:When reinstalling turbocharger, thoroughly rem ove all gaskets and sealant. Use new gaskets. Add .85

oz. (25 cc) of engine oil in the oil passage of the turbocharger.

Page 3 of 19 MITCHELL 1 ARTICLE - ENGINE OVERHAUL 1991-92 FORD MOTOR CO. ENGINES 1.3L & 1.6L 4-Cylinder

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 111 of 454

bearing oil seal. To complete installation, reverse removal procedure.

WATER PUMP

Removal & Installation (1.3L)

Remove timing belt. Drain cooling system. Remove lower radiator hose and heater return hose from water pump. Remove water pump

retaining bolts and water pump. Clean gasket mounting surface and replace gasket. To install, reverse removal procedure.

Removal (1.6L)

1. Remove timing belt. See TIMING BELT . Drain cooling system. Remove timing belt tensioner and idler pulleys. Remove oil dipstick

bracket retaining bolt.

2. Remove power steering pump from retaining bracket, leaving hoses attached. Remove power steering bracket and position power

steering pump to one side. Remove water pump outlet. Remove water pump retaining bolts and water pump.

Installation (1.6L)

1. Clean all gasket surfaces. Transfer rubber belt cover seal to new water pump (if required). Position water pump with new gasket and

install retaining bolts. Install pump outlet with new gasket and "O" ring. See TORQUE SPECIFICATIONS

table at end of article.

2. Install oil dipstick retaining bolt. Install timing belt tensioner and idler pulleys. Install power steering pump bracket. Install power

steering pump. Tighten all bolts and nuts to specification. See TORQUE SPECIFICATIONS

table at end of article.

3. Install timing belt. Fill cooling system. Start engine and check for leaks and proper system function.

OIL PAN

Removal (1.3L)

Disconnect battery ground cable. Raise vehicle and drain engine oil. Remove flywheel housing dust cover. Remove oil pan retaining bolts,

nuts and stiffeners. Rotate crankshaft while removing oil pan. Remove baffle plate from oil pan. Clean gasket mating surfaces thoroughly.

Installation (1.3L)

Ensure gasket surfaces are clean. Apply oil resistant sealer to front and rear engine covers and across joint line of cylinder block.

Removal (1.6L)

1. Raise vehicle and drain engine oil. Remove frame brace retaining bolt. Loosen RH "A" arm front bolt, and pivot brace downward.

Disconnect front exhaust pipe from exhaust manifold (or turbocharger). Remove exhaust pipe bracket retaining bolts. Loosen rubber

exhaust hangers at catalytic converter.

2. Allow exhaust to hang supported by mechanic's wire. Disconnect turbocharger oil return hose (if equipped). Remove oil pan retaining

bolts. Carefully pry oil pan loose from cylinder block.

Installation (1.6L)

1. Clean pan and block gasket surfaces. Apply Gasket Sealant (E3AZ-19562-A) to new front and rear pan seals. Install seals to cylinder

block. Apply Gasket Sealant (E3AZ-19562-A) to oil pan gasket surface. See Fig. 8

. Install oil pan and tighten pan retaining bolts to

specification. See TORQUE SPECIFICATIONS

table at end of article.

2. Connect turbocharger oil return hose (if equipped). Install rubber exhaust hanger to brackets. Install new gasket and connect fro n t

exhaust pipe to exhaust manifold (or turbocharger). Install front exhaust pipe bracket. Tighten nuts and bolts to specification.

3. Pivot frame brace into position. Tighten retaining bolt to crossmember and RH "A" arm front retaining bolt to specification. Lower

vehicle, fill with oil and start engine. Check for oil leaks and system operation. NOTE:Raise engine slightly with floor jack, if required, to gain clearance for water pum p rem oval.

CAUT ION: DO NOT force a pry tool between cylinder block and oil pan.

Page 11 of 19 MITCHELL 1 ARTICLE - ENGINE OVERHAUL 1991-92 FORD MOTOR CO. ENGINES 1.3L & 1.6L 4-Cylinder

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 121 of 454

3. If voltage is not present or is less than 8 volts at starter solenoid terminal "S", malfunction in circuit to terminal "S" is indicated. Proceed

to the following tests.

IGNITION SWITCH TEST

1. Locate ignition switch connector under dash. Using a 12-volt test light or voltmeter, ensure voltage is present on Black/Yellow wire

when ignition switch is turned to RUN or ON position. This will verify proper operation of ignition switch.

2. If there is no voltage on Black/Yellow wire, the problem is either ignition switch or circuit between battery and ignition switch.

CLUTCH ENGAGE SWITCH (M/T) TEST

Unplug clutch engage switch from main wiring harness. Using an ohmmeter, check for continuity across switch terminals. Continuity should

exist when switch plunger is pushed in and should not exist when switch plunger is released. If clutch engage switch does not operate as

specified, replace switch.

NEUTRAL SAFETY SWITCH (A/T) TEST

Unplug neutral safety switch from main wiring harness. Using an ohmmeter, check for continuity across switch terminals "A" and "B". See Fig.

2 . Place transmission shift selector in Park or Neutral position. Continuity should exist between terminals "A" and "B". Continuity should not

exist in any other transmission shift selector positions. If switch does nor operate as specified, replace switch.

Fig. 2: Identifying Neutral Safety Switch Terminals

Courtesy of FORD MOTOR CO.

VOLTAGE DROP TEST

1. Disconnect and ground coil wire from distributor cap to prevent engine from starting. Connect remote starter switch between starter

solenoid terminal "S" and battery positive terminal. See Fig. 3

.

2. Using a digital voltmeter set on low scale, connect positive voltmeter lead to battery positive terminal. Connect negative lead to starter

solenoid terminal "M". See Fig. 3

.

3. Engage remote starter switch. Observe and record voltmeter reading. Voltmeter reading should be less than .5 volt. If voltage at terminal

"M" is greater than .5 volt, move negative voltmeter lead to solenoid terminal "B", and repeat test.

4. If voltage at terminal "B" is less than .5 volt, inspect solenoid cable connections and solenoid contacts for problem.

5 . Cl ean so l en o id t ermin al s "B", "M" an d "S", an d rep eat st ep s 1 ) through 4). If voltmeter still reads greater than .5 volt at termin al "M"

and less than .5 volt at terminal "B", solenoid contacts are bad.

6. If voltmeter reads greater than .5 volt at terminal "B", clean cables and connections at solenoid. If voltmeter still reads greater than .5

volt, check for poor positive battery cable connection or bad cable. Repair or replace as necessary.

7. To locate excessive voltage drop, move negative voltmeter lead toward battery, and check each connection point. When high voltmeter

reading is no longer present, last connection point is bad.

NOTE:Make all voltm eter connections at com ponent term inal rather than at cable or wire end.

Page 2 of 6 MITCHELL 1 ARTICLE - STARTER 1991 ELECTRICAL Starters

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...