oil capacity FORD FESTIVA 1991 Service Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1991, Model line: FESTIVA, Model: FORD FESTIVA 1991Pages: 454, PDF Size: 9.53 MB

Page 102 of 454

levels to proper level.

Removal (1.6L & 1.6L Turbo)

1. Relieve fuel pressure and discharge air conditioning system (if equipped). See FUEL PRESSURE RELEASE under REMOVAL &

INSTALLATION. Disconnect and remove battery, battery tray and battery tray support bracket.

2. Release wiring harness retaining straps from battery support tray. Disconnect windshield washer supply hose between fluid reservoir and

hood. Mark hinge locations and remove hood.

3. Disconnect intake air tube and wiring to ignition coil and vane airflow meter. Remove air cleaner/vane airflow meter assembly. Remove

air cleaner assembly support brackets. Disconnect intercooler hoses from turbocharger (if equipped).

4. Drain engine coolant and remove radiator. Disconnect accelerator cable, and remove retaining bracket from cam cover. Position cable to

one side.

5. Disconnect and plug fuel lines at fuel filter and pressure regulator. Disconnect power brake booster manifold vacuum hose from

manifold. Disconnect heater hoses at heater core tubes. Label and remove vacuum hoses located at throttle body.

6. For manual transaxle turbocharged vehicles, disconnect clutch cable and remove support bracket and cable from transmission. On non-

turbo vehicles, disconnect clutch slave hydraulic line. For automatic transaxle, remove transaxle cooler lines.

7. Disconnect starter wiring at starter. Remove harness from locating strap on bracket. Disconnect alternator wiring. Disconnect wiring

from engine coolant sensors located on rear of engine block. Remove ground connection at bracket on thermostat cover. Disconnect O2

sensor wire, main wiring harness connector, TPS connector (turbocharged only), knock sensor connector, distributor wiring and

transaxle wiring. Disconnect ground wire and strap at front of engine, and reinstall lifting eye.

8. Remove engine oil dipstick and retaining clip. Remove power steering pump from mounting bracket. Remove power steering pump

mounting bracket. With hoses attached, position pump aside. Remove upper air conditioning compressor retaining bolts (if equipped).

9. Raise vehicle on hoist. Drain engine oil and cooling system. On vehicles with air conditioning, remove lower air conditioning

compressor mounting bolts, and position compressor out of way.

10. Remove front wheels and tires. Remove front ball joints-to-ste e r in g kn u c kl e s r e t a in in g b o l t s. R e mo ve sp l a sh gu a r d s. Dr a in t ransmission

oil and remove half shafts from differential. Remove front exhaust pipe bracket located on lower side of engine. Disconnect front

exhaust pipe from exhaust manifold, or turbocharger (if equipped).

11. Remove frame support bar-to-engine support bolt. Loosen right control arm bolt and, pivot support bar downward. Disengage rubber

exhaust hangers located directly behind catalytic converter. Allow exhaust system to hang down 6 inches, and support system with

mechanic's wire. Unbolt shift linkage and stabilizer bar at transaxle. Remove nuts from front and rear engine mounts, and lower vehicle.

12. Attach chains onto lift eyes at ends of cylinder head, and support engine with hoist. Remove RH engine mount through bolt. Raise

engine off mounts and slightly pivot engine/transaxle assembly. Disconnect oil pressure sensor and route starter/alternator wiring

harness from engine. Carefully lift engine/transaxle assembly, turn assembly while raising to clear brake master cylinder, shift linkage

universal joint, radiator support and air conditioning lines (if equipped).

13. Remove intake manifold support bracket. Remove gusset plate(s) (if equipped). Remove starter. Remove transaxle-to-engine retaining

bolts. Identify bolts to ensure correct installation. Separate transaxle from engine. On manual transaxle, remove pressure plate, clutch

disc and flywheel. On automatic transaxle, remove flexplate.

Installation (1.6L & 1.6L Turbo)

1. Install transaxle to engine in reverse order of removal. Attach hoist to engine/transaxle assembly and position assembly in vehicle.

Before engine contacts mounts, route starter, alternator and oil pressure sensor wiring, and connect oil pressure sensor. Lower engine

until front mount seats on crossmember. Install through bolt on RH engine mount. DO NOT tighten bolt.

2. Remove hoist. Raise vehicle and support with jackstands. Align rear engine mount to crossmember, and install retaining nuts to front

and rear engine mounts. Tighten nuts to specification. See TORQUE SPECIFICATIONS

table at end of article.

3. On manual transaxles, connect shift coupling and stabilizer. Tighten to specification. On automatic transaxles, connect shift linkage and

oil cooler lines. Tighten linkage retaining bolt, shift cable pivot and oil cooler hose clamps to specification. Connect front exhaust pipe

to manifold (or turbocharger). Install exhaust pipe to support bracket. Tighten bolts to specification. Tighten manifold (or turbocharger)

to specification. Attach rubber exhaust hangers. Position cross brace. Tighten retaining nut and bolt and right control arm front bolt.

4. Install drive axles. Install ball joint retaining bolts and tighten to specification. Mount A/C Compressor to engine (if equipped). Tighten

lower retaining bolts to specification. Install splash guards. Install tire and wheel assemblies. Tighten retaining nuts to specification.

5. Lower vehicle. Install upper A/C compressor retaining bolts (if equipped). Tighten bolts to specification. Tighten RH engine mo u n t

through bolt to specification. Connect alternator wiring.

6. Position power steering pump bracket on stud. Lower pump into engine compartment. Install power steering pump bracket retaining

bolts and nut. Tighten to specification. Install power steering pump and belt. Tighten adjustment nut and pivot bolt to specification.

7. Install engine oil dipstick and retaining clip. Install ground strap and ground wire to cylinder head. Install clutch cable (if equipped).

Connect clutch hydraulic line if equipped with manual transaxle or naturally aspirated. Connect transmission electrical connectors.

Connect fuel lines to fuel filter and pressure regulator. Install intake air tube to throttle body.

8. Install intercooler hoses on turbocharged models. Install air cleaner assembly brackets. Install air cleaner assembly with airflow meter

attached. Install intake air tube. Install coil and airflow meter connectors. Connect coolant crankcase and air bypass hoses. Install

vacuum hoses as noted in disassembly.

9. Connect accelerator cable. Install retaining bracket. Install power brake booster hose. Remove speedometer cable from transaxle. Fill

transaxle to specification. See CAPACITIES in SERVICE & ADJUSTMENT SPECIFICATIONS article. Install speedometer cable.

Connect speedometer cable connector. Fill engine oil to capacity.

10. Install radiator/fan assembly. Tighten bracket retaining bolts to specification. Connect coolant hoses and fan electrical connector. Fill

coolant to specification.

11. Install hood and connect washer hose. Install battery tray support, battery tray, battery and battery hold-down. Connect battery

terminal. Evacuate and charge air conditioning system (if equipped). Road test vehicle and inspect for leaks.

INTAKE MANIFOLD

Removal (1.3L)

CAUT ION: DO NOT allow com pressor to hang by hoses. T ie up com pressor with m echanic's wire.

Page 2 of 19 MITCHELL 1 ARTICLE - ENGINE OVERHAUL 1991-92 FORD MOTOR CO. ENGINES 1.3L & 1.6L 4-Cylinder

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 114 of 454

2. Remove main bearing cap bolts. Remove cap and lower bearing insert. Use bearing remover or fabricated cotter key to remove upper

bearing insert. Insert bearing remover in journal lubrication hole. Rotate crankshaft in normal direction of operation only. Repeat

procedure for remaining main bearings.

3. Check bearings for abnormal wear. Check crankshaft for grooves, scratches and pitting. Using Plastigage method, check clearance of

main bearing-to-crankshaft. Always keep at least 2 bearings and caps tight during clearance check. See, at end of article,

CRANKSHAFT MAIN & CONNECTING ROD BEARINGS

table under ENGINE SPECIFICATIONS.

4. Lubricate and install new bearings in cap and block. Match bearing tangs with notch in cap and block. Position cap in its proper

location and position. Install cap bolts and tighten to specification. See TORQUE SPECIFICATIONS

table at end of article. Repeat

procedure for remaining main bearings.

CRANKSHAFT END PLAY

Check crankshaft end play with dial indicator. End play should be .0031-.0111" (.08-.282 mm). Service limit is .012" (.30 mm). If end play is

not within specification, replace thrust bearings as necessary.

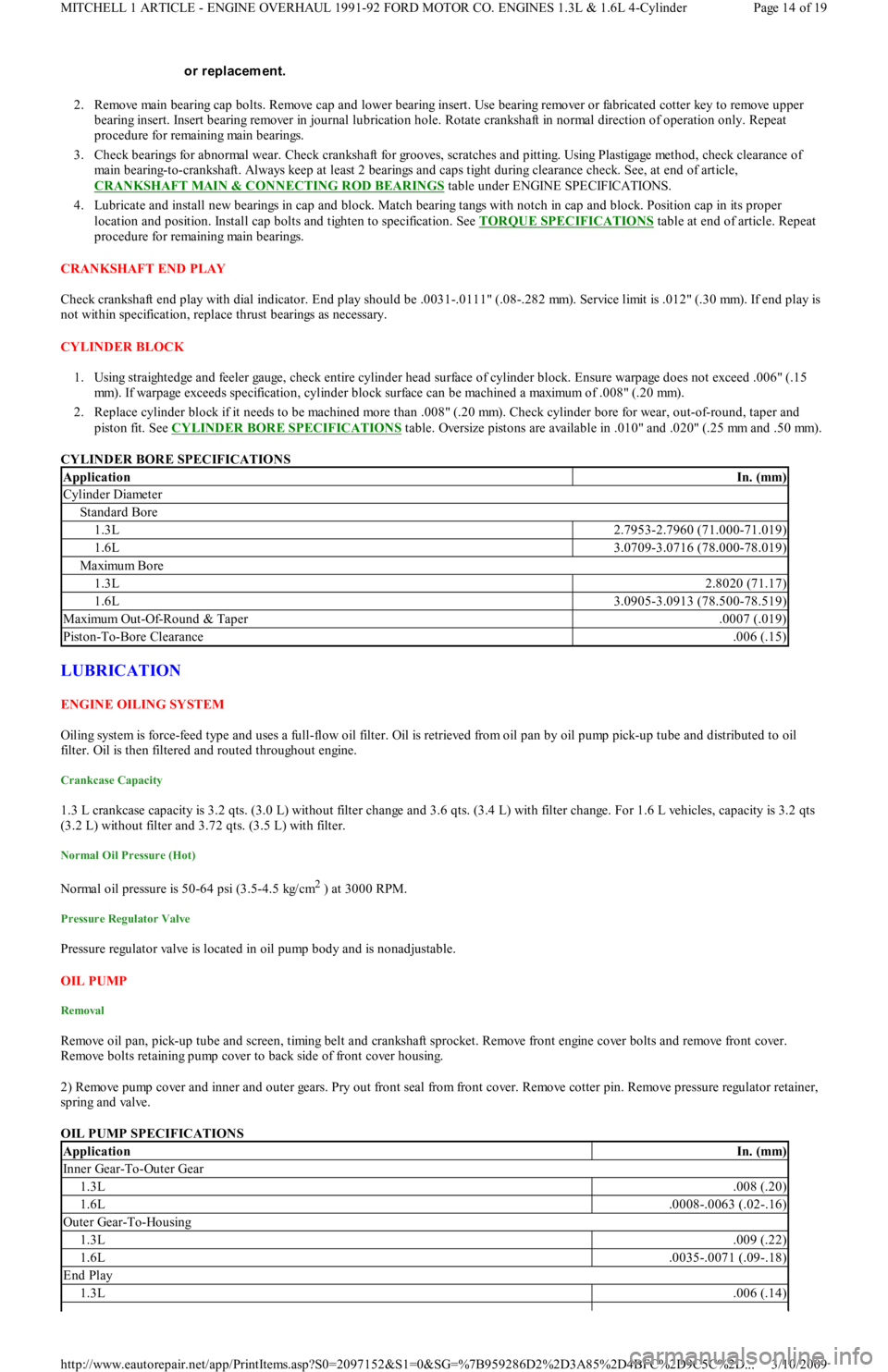

CYLINDER BLOCK

1. Using straightedge and feeler gauge, check entire cylinder head surface of cylinder block. Ensure warpage does not exceed .006" (.15

mm). If warpage exceeds specification, cylinder block surface can be machined a maximum of .008" (.20 mm).

2. Replace cylinder block if it needs to be machined more than .008" (.20 mm). Check cylinder bore for wear, out-of-round, taper and

piston fit. See CYLINDER BORE SPECIFICATIONS

table. Oversize pistons are available in .010" and .020" (.25 mm and .50 mm).

CYLINDER BORE SPECIFICATIONS

LUBRICATION

ENGINE OILING SYSTEM

Oiling system is force-feed type and uses a full-flow oil filter. Oil is retrieved from oil pan by oil pump pick-up tube and distributed to oil

filter. Oil is then filtered and routed throughout engine.

Crankcase Capacity

1.3 L crankcase capacity is 3.2 qts. (3.0 L) without filter change and 3.6 qts. (3.4 L) with filter change. For 1.6 L vehicles, capacity is 3.2 qts

(3.2 L) without filter and 3.72 qts. (3.5 L) with filter.

Normal Oil Pressure (Hot)

Normal oil pressure is 50-64 psi (3.5-4.5 kg/cm2 ) at 3000 RPM.

Pressure Regulator Valve

Pressure regulator valve is located in oil pump body and is nonadjustable.

OIL PUMP

Removal

Remove oil pan, pick-up tube and screen, timing belt and crankshaft sprocket. Remove front engine cover bolts and remove front cover.

R e mo ve b o l t s r e t a in in g p u mp c o ve r t o b a c k sid e o f fr o n t c o ve r h o u sin g.

2) Remove pump cover and inner and outer gears. Pry out front seal from front cover. Remove cotter pin. Remove pressure regulator retainer,

spring and valve.

OIL PUMP SPECIFICATIONS or replacem ent.

ApplicationIn. (mm)

Cylinder Diameter

Standard Bore

1.3L2.7953-2.7960 (71.000-71.019)

1.6L3.0709-3.0716 (78.000-78.019)

Maximu m Bo re

1.3L2.8020 (71.17)

1.6L3.0905-3.0913 (78.500-78.519)

Maximu m Ou t -Of-Ro u n d & Tap er.0007 (.019)

Piston-To-Bore Clearance.006 (.15)

ApplicationIn. (mm)

Inner Gear-To-Outer Gear

1.3L.008 (.20)

1.6L.0008-.0063 (.02-.16)

Outer Gear-To-Housing

1.3L.009 (.22)

1.6L.0035-.0071 (.09-.18)

End Play

1.3L.006 (.14)

Page 14 of 19 MITCHELL 1 ARTICLE - ENGINE OVERHAUL 1991-92 FORD MOTOR CO. ENGINES 1.3L & 1.6L 4-Cylinder

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 219 of 454

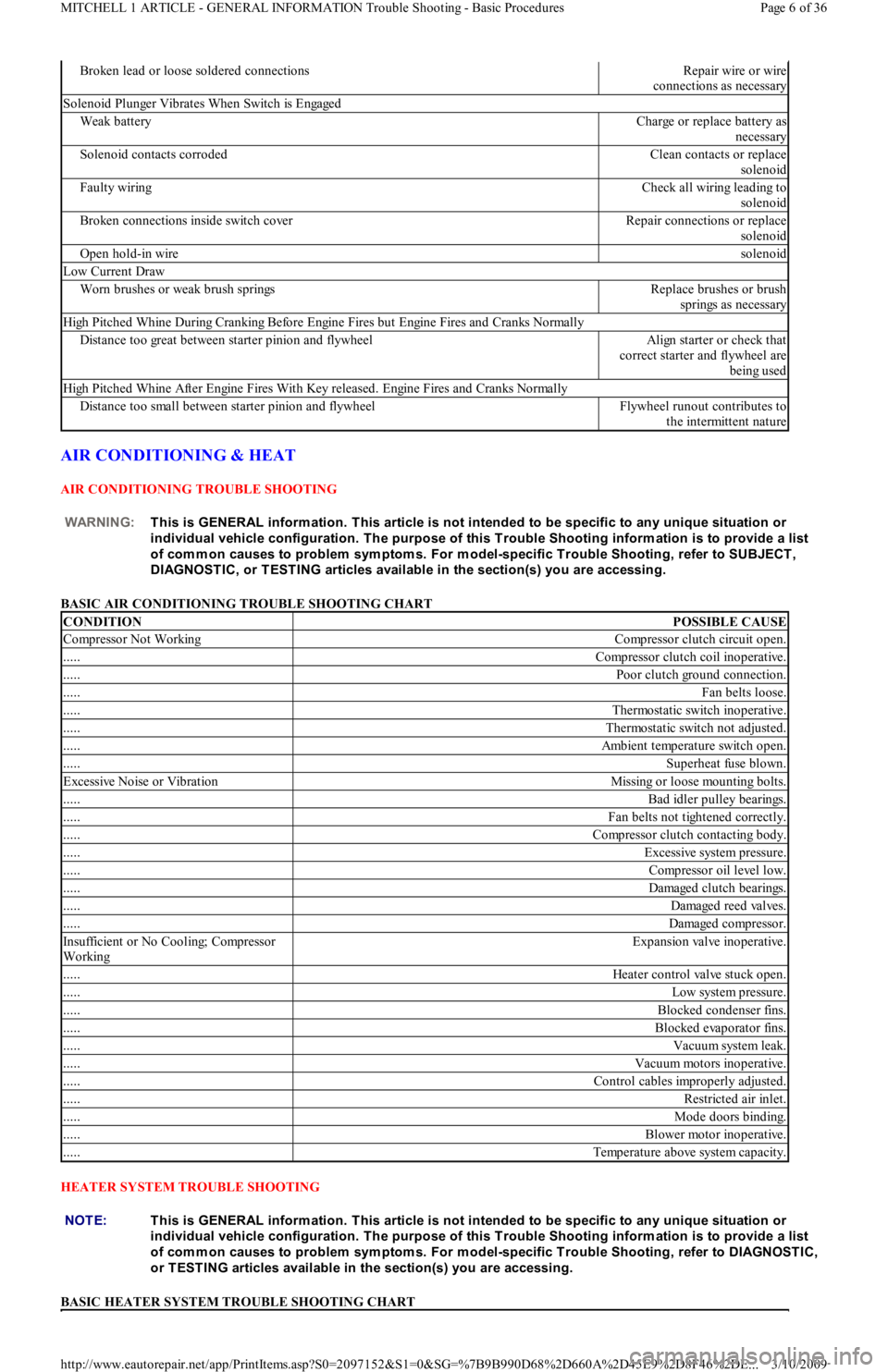

AIR CONDITIONING & HEAT

AIR CONDITIONING TROUBLE SHOOTING

BASIC AIR CONDITIONING TROUBLE SHOOTING CHART

HEATER SYSTEM TROUBLE SHOOTING

BASIC HEATER SYSTEM TROUBLE SHOOTING CHART

Broken lead or loose soldered connectionsRepair wire or wire

connections as necessary

Solenoid Plunger Vibrates When Switch is Engaged

Weak batteryCharge or replace battery as

necessary

Solenoid contacts corrodedClean contacts or replace

solenoid

Faulty wiringCheck all wiring leading to

solenoid

Broken connections inside switch coverRepair connections or replace

solenoid

Open hold-in wiresolenoid

Low Current Draw

Worn brushes or weak brush springsReplace brushes or brush

springs as necessary

High Pitched Whine During Cranking Before Engine Fires but Engine Fires and Cranks Normally

Distance too great between starter pinion and flywheelAlign starter or check that

correct starter and flywheel are

being used

High Pitched Whine After Engine Fires With Key released. Engine Fires and Cranks Normally

Distance too small between starter pinion and flywheelFlywheel runout contributes to

the intermittent nature

WARNING:This is GENERAL inform ation. This article is not intended to be specific to any unique situation or

individual vehicle configuration. T he purpose of this T rouble Shooting inform ation is to provide a list

of com m on causes to problem sym ptom s. For m odel-specific T rouble Shooting, refer to SUBJECT ,

DIAGNOST IC, or T EST ING articles available in the section(s) you are accessing.

CONDITIONPOSSIBLE CAUSE

Compressor Not WorkingCompressor clutch circuit open.

.....Compressor clutch coil inoperative.

.....Poor clutch ground connection.

.....Fan belts loose.

.....Thermostatic switch inoperative.

.....Thermostatic switch not adjusted.

.....Ambient temperature switch open.

.....Superheat fuse blown.

Excessive Noise or VibrationMissing or loose mounting bolts.

.....Bad idler pulley bearings.

.....Fan belts not tightened correctly.

.....Compressor clutch contacting body.

.....Excessive system pressure.

.....Compressor oil level low.

.....Damaged clutch bearings.

.....Damaged reed valves.

.....Damaged compressor.

In su fficien t o r No Co o l in g; Co mp resso r

WorkingExpansion valve inoperative.

.....Heater control valve stuck open.

.....Low system pressure.

.....Blocked condenser fins.

.....Blocked evaporator fins.

.....Vacuum system leak.

.....Vacuum motors inoperative.

.....Control cables improperly adjusted.

.....Restricted air inlet.

.....Mode doors binding.

.....Blower motor inoperative.

.....Temperature above system capacity.

NOTE:This is GENERAL inform ation. This article is not intended to be specific to any unique situation or

individual vehicle configuration. T he purpose of this T rouble Shooting inform ation is to provide a list

of com m on causes to problem sym ptom s. For m odel-specific T rouble Shooting, refer to DIAGNOST IC,

or T EST ING articles available in the section(s) you are accessing.

Page 6 of 36 MITCHELL 1 ARTICLE - GENERAL INFORMATION Trouble Shooting - Basic Procedures

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 342 of 454

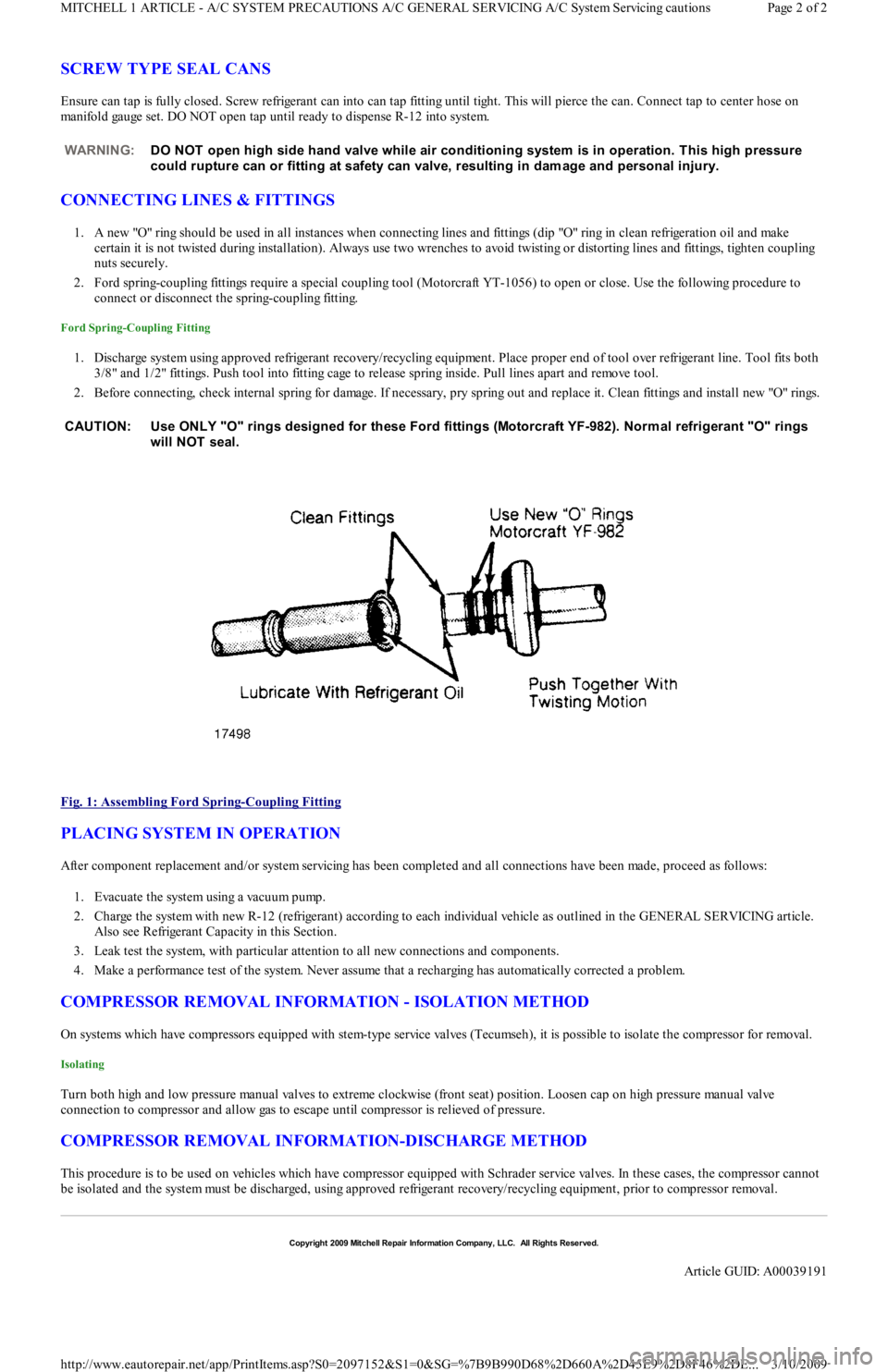

SCREW TYPE SEAL CANS

Ensure can tap is fully closed. Screw refrigerant can into can tap fitting until tight. This will pierce the can. Connect tap to center hose on

manifold gauge set. DO NOT open tap until ready to dispense R-12 into system.

CONNECTING LINES & FITTINGS

1. A new "O" ring should be used in all instances when connecting lines and fittings (dip "O" ring in clean refrigeration oil and make

certain it is not twisted during installation). Always use two wrenches to avoid twisting or distorting lines and fittings, tighten coupling

nuts securely.

2. Ford spring-coupling fittings require a special coupling tool (Motorcraft YT-1056) to open or close. Use the following procedure to

connect or disconnect the spring-coupling fitting.

Ford Spring-Coupling Fitting

1. Discharge system using approved refrigerant recovery/recycling equipment. Place proper end of tool over refrigerant line. Tool fits both

3/8" and 1/2" fittings. Push tool into fitting cage to release spring inside. Pull lines apart and remove tool.

2. Before connecting, check internal spring for damage. If necessary, pry spring out and replace it. Clean fittings and install new "O" rings.

Fig. 1: Assembling Ford Spring

-Coupling Fitting

PLACING SYSTEM IN OPERATION

After component replacement and/or system servicing has been completed and all connections have been made, proceed as follows:

1. Evacuate the system using a vacuum pump.

2. Charge the system with new R-12 (refrigerant) according to each individual vehicle as outlined in the GENERAL SERVICING article.

Also see Refrigerant Capacity in this Section.

3. Leak test the system, with particular attention to all new connections and components.

4. Make a performance test of the system. Never assume that a recharging has automatically corrected a problem.

COMPRESSOR REMOVAL INFORMATION - ISOLATION METHOD

On systems which have compressors equipped with stem-type service valves (Tecumseh), it is possible to isolate the compressor for removal.

Isolating

Turn both high and low pressure manual valves to extreme clockwise (front seat) position. Loosen cap on high pressure manual valve

connection to compressor and allow gas to escape until compressor is relieved of pressure.

COMPRESSOR REMOVAL INFORMATION-DISCHARGE METHOD

This procedure is to be used on vehicles which have compressor equipped with Schrader service valves. In these cases, the compressor cannot

be isolated and the system must be discharged, using approved refrigerant recovery/recycling equipment, prior to compressor removal. WARNING:DO NOT open high side hand valve while air conditioning system is in operation. T his high pressure

could rupture can or fitting at safety can valve, resulting in dam age and personal injury.

CAUT ION: Use ONLY "O" rings designed for these Ford fittings (Motorcraft YF-982). Norm al refrigerant "O" rings

will NOT seal.

Copyr ight 2009 Mitchell Repair Information Company, LLC. All Rights Reserved.

Article GUID: A00039191

Page 2 of 2 MITCHELL 1 ARTICLE - A/C SYSTEM PRECAUTIONS A/C GENERAL SERVICING A/C System Servicing cautions

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 343 of 454

Back To Article

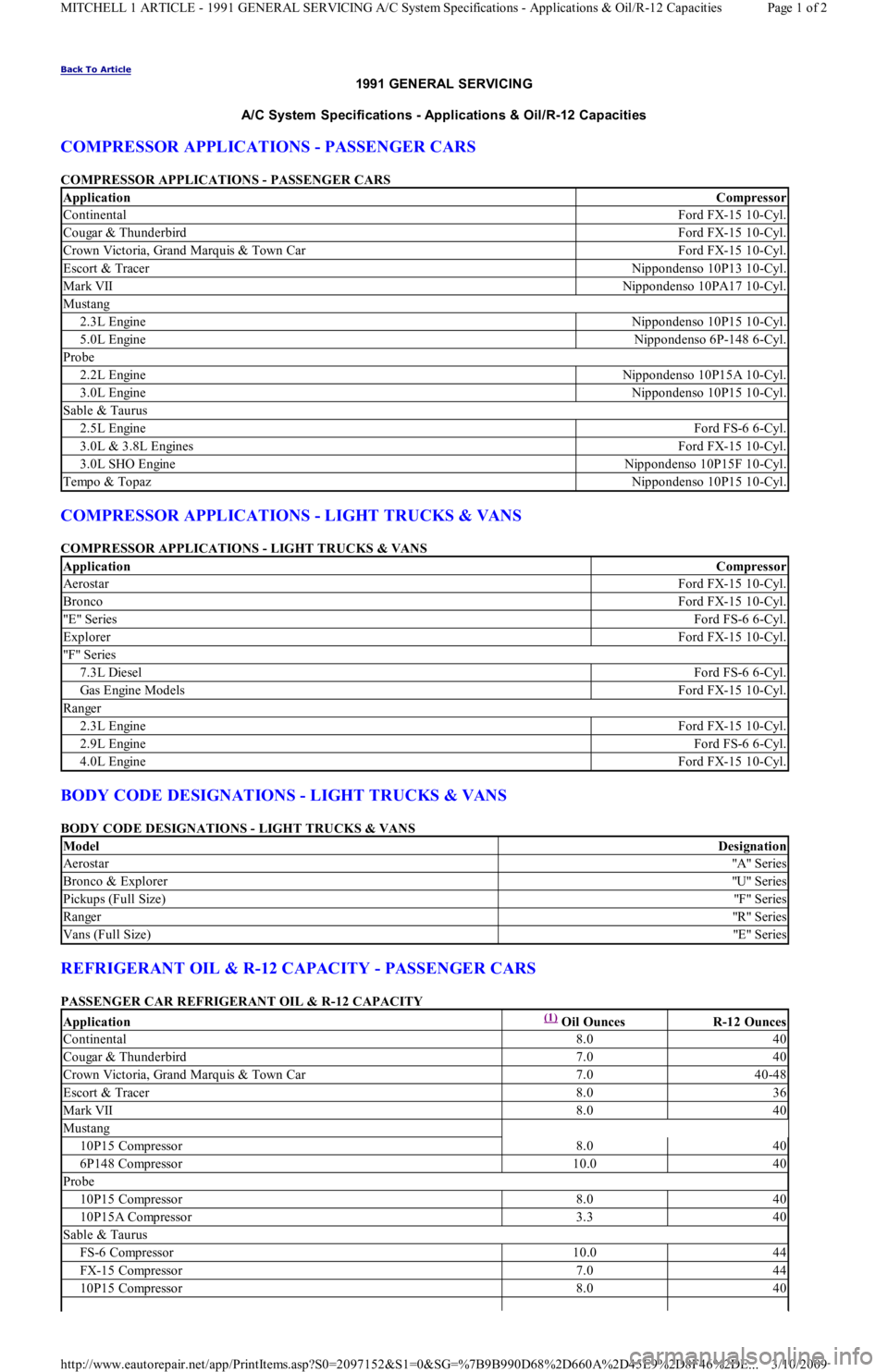

1991 GENERAL SERVICING

A/C System Specifications - Applications & Oil/R-12 Capacities

COMPRESSOR APPLICATIONS - PASSENGER CARS

COMPRESSOR APPLICATIONS - PASSENGER CARS

COMPRESSOR APPLICATIONS - LIGHT TRUCKS & VANS

COMPRESSOR APPLICATIONS - LIGHT TRUCKS & VANS

BODY CODE DESIGNATIONS - LIGHT TRUCKS & VANS

BODY CODE DESIGNATIONS - LIGHT TRUCKS & VANS

REFRIGERANT OIL & R-12 CAPACITY - PASSENGER CARS

PASSENGER CAR REFRIGERANT OIL & R-12 CAPACITY

ApplicationCompressor

ContinentalFord FX-15 10-Cyl.

Cougar & ThunderbirdFord FX-15 10-Cyl.

Crown Victoria, Grand Marquis & Town CarFord FX-15 10-Cyl.

Escort & TracerNippondenso 10P13 10-Cyl.

Mark VIINippondenso 10PA17 10-Cyl.

Mustang

2.3L EngineNippondenso 10P15 10-Cyl.

5.0L EngineNippondenso 6P-148 6-Cyl.

Probe

2.2L EngineNippondenso 10P15A 10-Cyl.

3.0L EngineNippondenso 10P15 10-Cyl.

Sable & Taurus

2.5L EngineFord FS-6 6-Cyl.

3.0L & 3.8L EnginesFord FX-15 10-Cyl.

3.0L SHO EngineNippondenso 10P15F 10-Cyl.

Tempo & TopazNippondenso 10P15 10-Cyl.

ApplicationCompressor

AerostarFord FX-15 10-Cyl.

BroncoFord FX-15 10-Cyl.

"E " SeriesFord FS-6 6-Cyl.

ExplorerFord FX-15 10-Cyl.

"F" Series

7.3L DieselFord FS-6 6-Cyl.

Gas Engine ModelsFord FX-15 10-Cyl.

Ranger

2.3L EngineFord FX-15 10-Cyl.

2.9L EngineFord FS-6 6-Cyl.

4.0L EngineFord FX-15 10-Cyl.

ModelDesignation

Aerostar"A" Series

Bronco & Explorer"U" Series

Pickups (Full Size)"F" Series

Ranger"R" Series

Vans (Full Size)"E " Series

Application(1) Oil OuncesR-12 Ounces

Continental8.040

Cougar & Thunderbird7.040

Crown Victoria, Grand Marquis & Town Car7.040-48

Escort & Tracer8.036

Mark VII8.040

Mustang

10P15 Compressor8.040

6P148 Compressor10.040

Probe

10P15 Compressor8.040

10P15A Compressor3.340

Sable & Taurus

FS-6 Compressor10.044

FX-15 Compressor7.044

10P15 Compressor8.040

Page 1 of 2 MITCHELL 1 ARTICLE - 1991 GENERAL SERVICING A/C System Specifications - Applications & Oil/R-12 Capacities

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 344 of 454

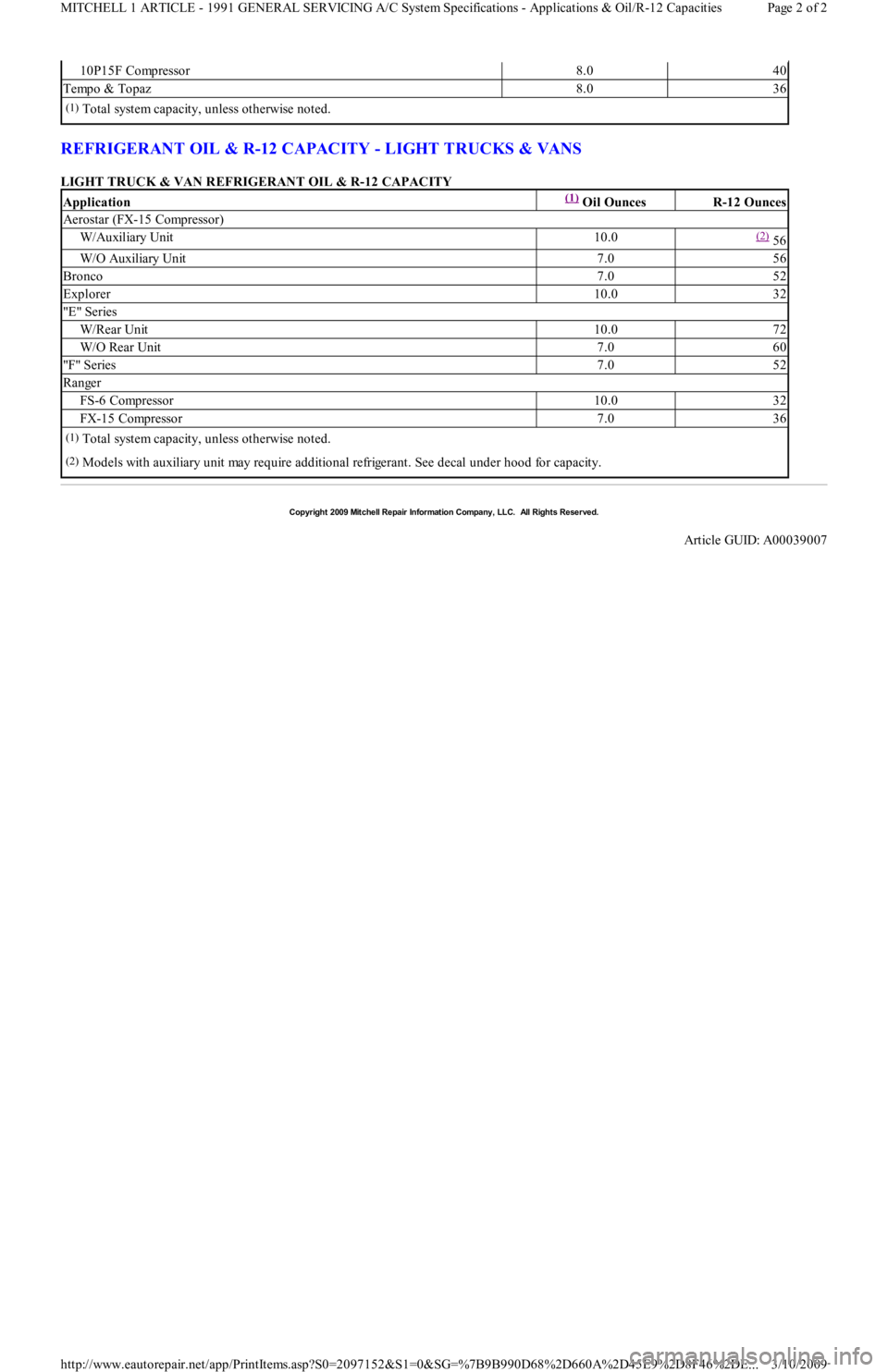

REFRIGERANT OIL & R-12 CAPACITY - LIGHT TRUCKS & VANS

LIGHT TRUCK & VAN REFRIGERANT OIL & R-12 CAPACITY

10P15F Compressor8.040

Tempo & Topaz8.036

(1)Total system capacity, unless otherwise noted.

Application(1) Oil OuncesR-12 Ounces

Aerostar (FX-15 Compressor)

W/Auxiliary Unit10.0(2) 56

W/O Auxiliary Unit7.056

Bronco7.052

Explorer10.032

"E " Series

W/Rear Unit10.072

W/O Rear Unit7.060

"F" Series7.052

Ranger

FS-6 Compressor10.032

FX-15 Compressor7.036

(1)Total system capacity, unless otherwise noted.

(2)Models with auxiliary unit may require additional refrigerant. See decal under hood for capacity.

Copyr ight 2009 Mitchell Repair Information Company, LLC. All Rights Reserved.

Article GUID: A00039007

Page 2 of 2 MITCHELL 1 ARTICLE - 1991 GENERAL SERVICING A/C System Specifications - Applications & Oil/R-12 Capacities

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 349 of 454

Back To Article

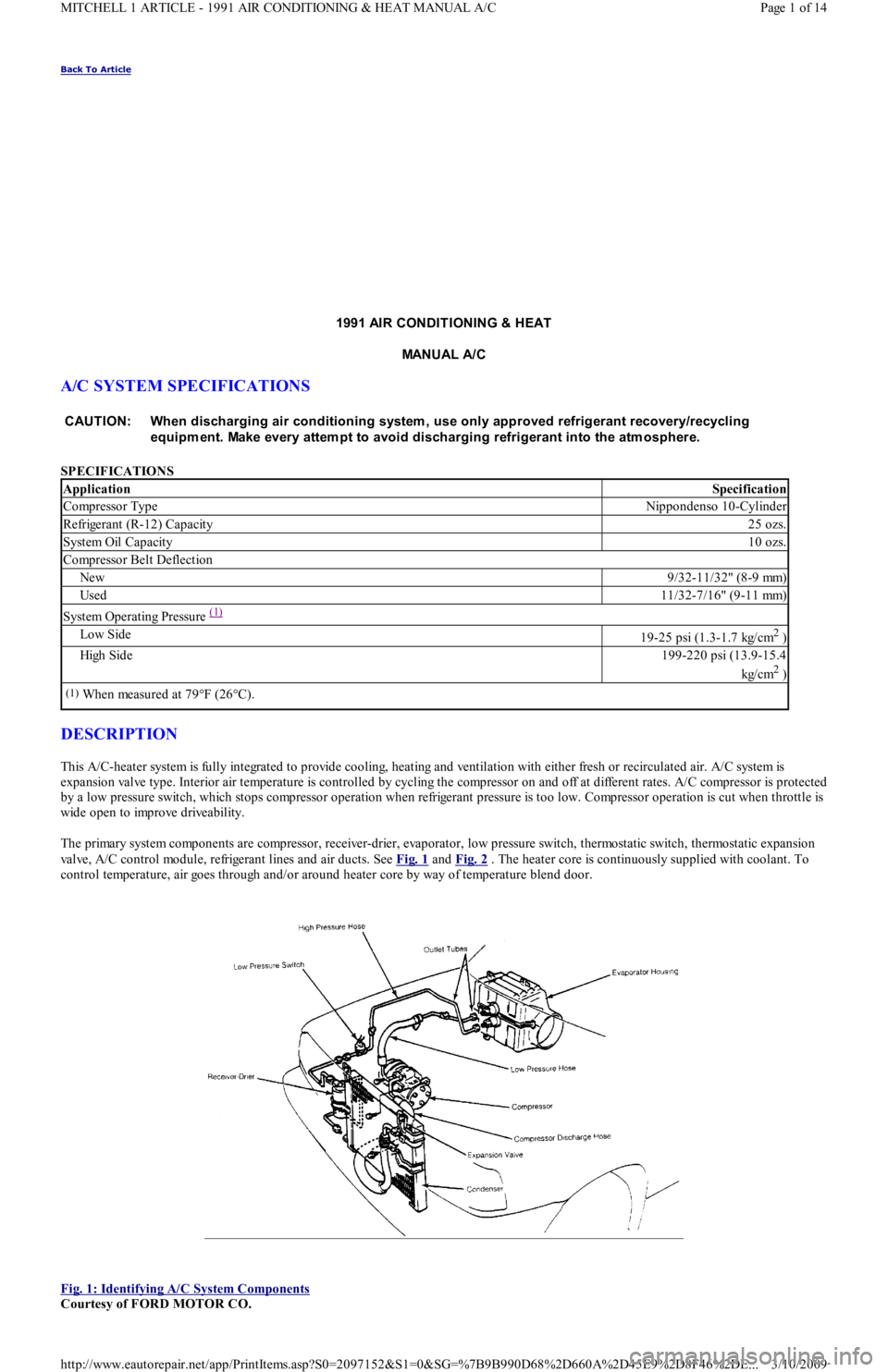

1991 AIR CONDIT IONING & HEAT

MANUAL A/C

A/C SYSTEM SPECIFICATIONS

SPECIFICATIONS

DESCRIPTION

This A/C-heater system is fully integrated to provide cooling, heating and ventilation with either fresh or recirculated air. A/C system is

expansion valve type. Interior air temperature is controlled by cycling the compressor on and off at different rates. A/C compressor is protected

by a low pressure switch, which stops compressor operation when refrigerant pressure is too low. Compressor operation is cut when throttle is

wide open to improve driveability.

The primary system components are compressor, receiver-drier, evaporator, low pressure switch, thermostatic switch, thermostatic expansion

valve, A/C control module, refrigerant lines and air ducts. See Fig. 1

and Fig. 2 . The heater core is continuously supplied with coolant. To

control temperature, air goes through and/or around heater core by way of temperature blend door.

Fig. 1: Identifying A/C System Components

Courtesy of FORD MOTOR CO. CAUT ION: When discharging air conditioning system , use only approved refrigerant recovery/recycling

equipm ent. Make every attem pt to avoid discharging refrigerant into the atm osphere.

ApplicationSpecification

Compressor TypeNippondenso 10-Cylinder

Refrigerant (R-12) Capacity25 ozs.

System Oil Capacity10 ozs.

Compressor Belt Deflection

New9/32-11/32" (8-9 mm)

Used11/32-7/16" (9-11 mm)

System Operating Pressure (1)

Low Side19-25 psi (1.3-1.7 kg/cm2 )

High Side199-220 psi (13.9-15.4

kg/cm

2 )

(1)When measured at 79°F (26°C).

Page 1 of 14 MITCHELL 1 ARTICLE - 1991 AIR CONDITIONING & HEAT MANUAL A/C

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 378 of 454

Back To Article

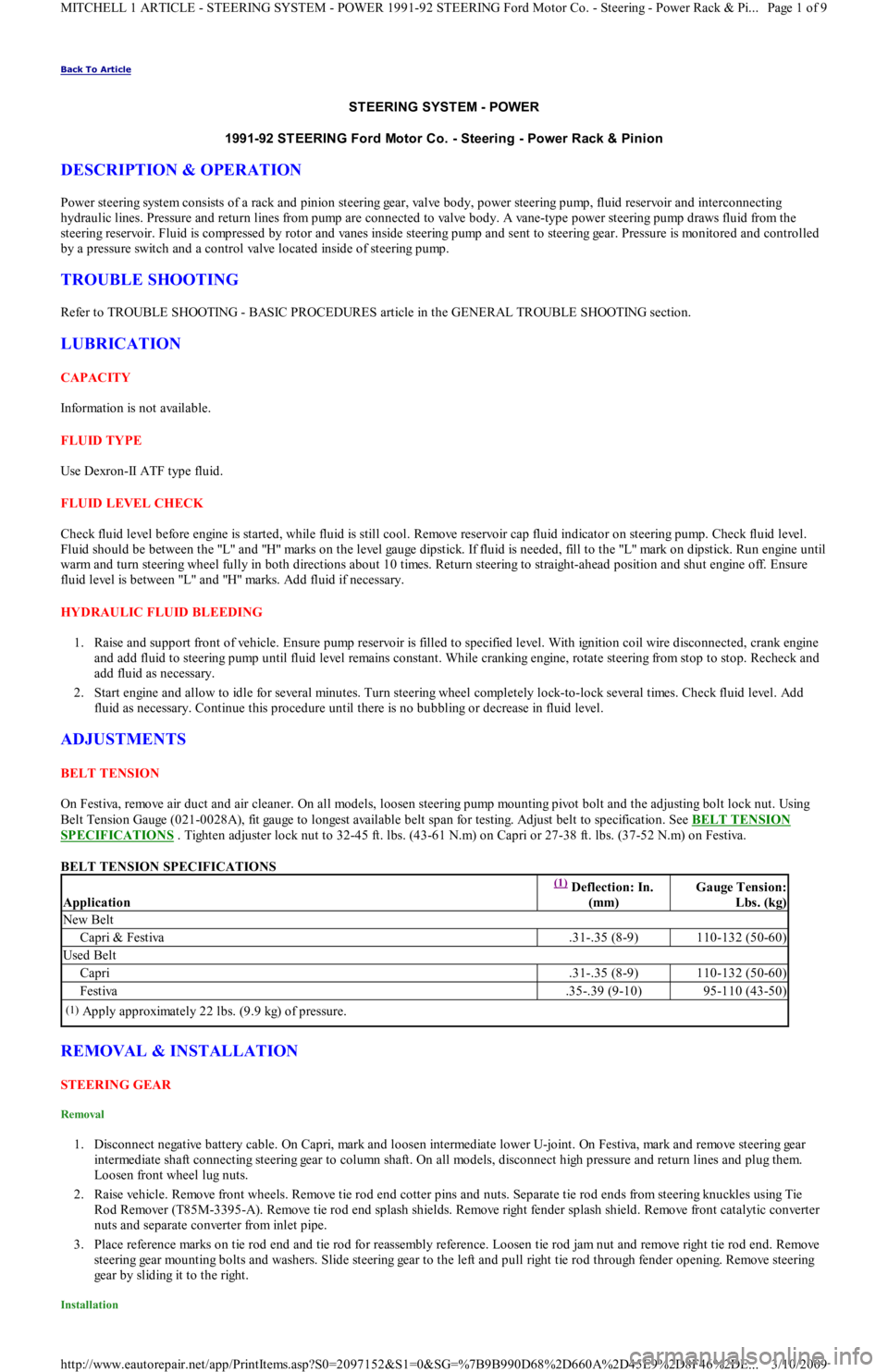

ST EERING SYST EM - POWER

1991-92 ST EERING Ford Motor Co. - Steering - Power Rack & Pinion

DESCRIPTION & OPERATION

Power steering system consists of a rack and pinion steering gear, valve body, power steering pump, fluid reservoir and interconnecting

hydraulic lines. Pressure and return lines from pump are connected to valve body. A vane-type power steering pump draws fluid from the

steering reservoir. Fluid is compressed by rotor and vanes inside steering pump and sent to steering gear. Pressure is monitored and controlled

by a pressure switch and a control valve located inside of steering pump.

TROUBLE SHOOTING

Refer to TROUBLE SHOOTING - BASIC PROCEDURES article in the GENERAL TROUBLE SHOOTING section.

LUBRICATION

CAPACITY

Information is not available.

FLUID TYPE

Use Dexron-II ATF type fluid.

FLUID LEVEL CHECK

Check fluid level before engine is started, while fluid is still cool. Remove reservoir cap fluid indicator on steering pump. Check fluid level.

Fluid should be between the "L" and "H" marks on the level gauge dipstick. If fluid is needed, fill to the "L" mark on dipstick. Run engine until

warm and turn steering wheel fully in both directions about 10 times. Return steering to straight-ahead position and shut engine off. Ensure

fluid level is between "L" and "H" marks. Add fluid if necessary.

HYDRAULIC FLUID BLEEDING

1. Raise and support front of vehicle. Ensure pump reservoir is filled to specified level. With ignition coil wire disconnected, crank engine

and add fluid to steering pump until fluid level remains constant. While cranking engine, rotate steering from stop to stop. Recheck and

add fluid as necessary.

2. Start engine and allow to idle for several minutes. Turn steering wheel completely lock-to-lock several times. Check fluid level. Add

fluid as necessary. Continue this procedure until there is no bubbling or decrease in fluid level.

ADJUSTMENTS

BELT TENSION

On Festiva, remove air duct and air cleaner. On all models, loosen steering pump mounting pivot bolt and the adjusting bolt lock nut. Using

Belt Tension Gauge (021-0028A), fit gauge to longest available belt span for testing. Adjust belt to specification. See BELT TENSION

SPECIFICATIONS . Tighten adjuster lock nut to 32-45 ft. lbs. (43-61 N.m) on Capri or 27-38 ft. lbs. (37-52 N.m) on Festiva.

BELT TENSION SPECIFICATIONS

REMOVAL & INSTALLATION

STEERING GEAR

Removal

1. Disconnect negative battery cable. On Capri, mark and loosen intermediate lower U-joint. On Festiva, mark and remove steering gear

intermediate shaft connecting steering gear to column shaft. On all models, disconnect high pressure and return lines and plug them.

Loosen front wheel lug nuts.

2. Raise vehicle. Remove front wheels. Remove tie rod end cotter pins and nuts. Separate tie rod ends from steering knuckles using Tie

Rod Remover (T85M-3395-A). Remove tie rod end splash shields. Remove right fender splash shield. Remove front catalytic converter

nuts and separate converter from inlet pipe.

3. Place reference marks on tie rod end and tie rod for reassembly reference. Loosen tie rod jam nut and remove right tie rod end. Remove

steering gear mounting bolts and washers. Slide steering gear to the left and pull right tie rod through fender opening. Remove steering

gear by sliding it to the right.

Installation

Application

(1) Deflection: In.

(mm)Gauge Tension:

Lbs. (kg)

New Belt

Capri & Festiva.31-.35 (8-9)110-132 (50-60)

Used Belt

Capri.31-.35 (8-9)110-132 (50-60)

Festiva.35-.39 (9-10)95-110 (43-50)

(1)Apply approximately 22 lbs. (9.9 kg) of pressure.

Page 1 of 9 MITCHELL 1 ARTICLE - STEERING SYSTEM - POWER 1991-92 STEERING Ford Motor Co. - Steering - Power Rack & Pi

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...