instrument panel FORD FESTIVA 1991 Owner's Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1991, Model line: FESTIVA, Model: FORD FESTIVA 1991Pages: 454, PDF Size: 9.53 MB

Page 147 of 454

ELECTRONIC CONTROL ASSEMBLY (ECA)

REMOVAL & INSTALLATION

Disconnect negative battery cable. On Festiva, from under instrument panel, remove heater duct. On Capri, disengage push-pin retainers by

pulling back on front edges of both center carpet panels. Remove carpet panel retaining screws and panels. Disconnect ECA wire harness

connector. Remove ECA bolts and ECA. To install, reverse removal procedure. On Festiva, ensure mounting clip is inserted into bulkhead

recess.

FUEL SYSTEM

FUEL SYSTEM PRESSURE RELEASE

Remove rear seat assembly. With engine running, disconnect fuel pump connector. Run engine until it stalls to relieve fuel line pressure.

FUEL INJECTORS

Removal

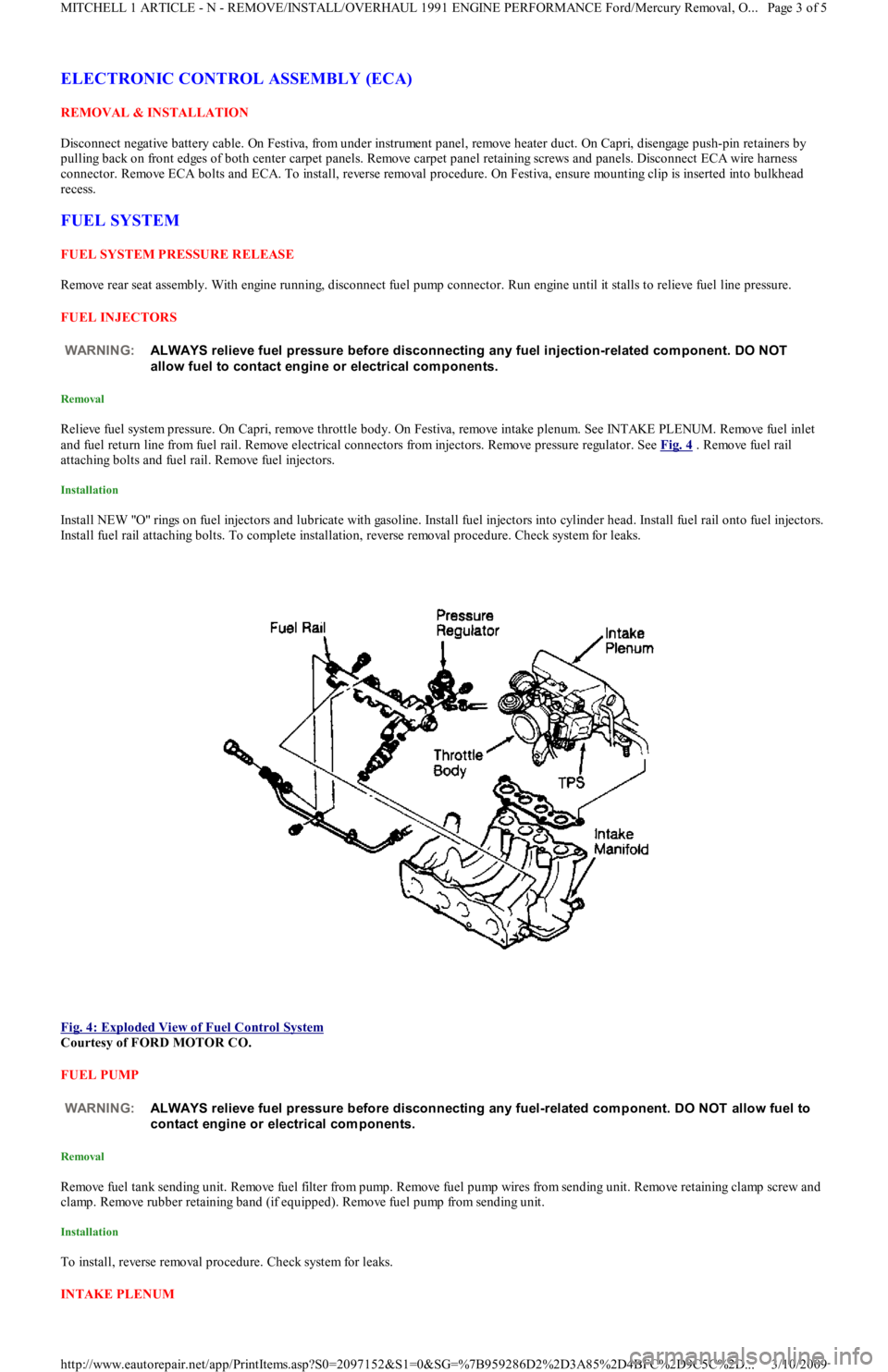

Relieve fuel system pressure. On Capri, remove throttle body. On Festiva, remove intake plenum. See INTAKE PLENUM. Remove fuel inlet

and fuel return line from fuel rail. Remove electrical connectors from injectors. Remove pressure regulator. See Fig. 4

. Remove fuel rail

attaching bolts and fuel rail. Remove fuel injectors.

Installation

Install NEW "O" rings on fuel injectors and lubricate with gasoline. Install fuel injectors into cylinder head. Install fuel rail onto fuel injectors.

Install fuel rail attaching bolts. To complete installation, reverse removal procedure. Check system for leaks.

Fig. 4: Exploded View of Fuel Control System

Courtesy of FORD MOTOR CO.

FUEL PUMP

Removal

Remove fuel tank sending unit. Remove fuel filter from pump. Remove fuel pump wires from sending unit. Remove retaining clamp screw and

clamp. Remove rubber retaining band (if equipped). Remove fuel pump from sending unit.

Installation

To install, reverse removal procedure. Check system for leaks.

INTAKE PLENUM WARNING:ALWAYS relieve fuel pressure before disconnecting any fuel injection-related com ponent. DO NOT

allow fuel to contact engine or electrical com ponents.

WARNING:ALWAYS relieve fuel pressure before disconnecting any fuel-related com ponent. DO NOT allow fuel to

contact engine or electrical com ponents.

Page 3 of 5 MITCHELL 1 ARTICLE - N - REMOVE/INSTALL/OVERHAUL 1991 ENGINE PERFORMANCE Ford/Mercury Removal, O

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 171 of 454

CLEARING CODES

Clearing Codes Procedure

Disconnect negative battery cable. Press brake pedal for 5-10 seconds. Turn off VOM or Super Star II tester. Reconnect battery.

ECA LOCATION

ECA is located on center console behind kick panel on Capri, and under instrument panel on driver side of Festiva.

QUICK TESTS

KEY ON, ENGINE OFF (KOEO) SELF-TEST

KOEO

1. This is a test of electronic engine control system, conducted with power (voltage) applied and engine not running. Activate self-test, and

record all codes displayed.

2. Erase codes, and repeat self-test. Diagnose only codes occurring during repeat self-test. See TROUBLE CODE DEFINITION

table. If

no codes are present, proceed to KEY ON, ENGINE RUNNING (KOER) SELF

-TEST .

KEY ON, ENGINE RUNNING (KOER) SELF-TEST

KOER

1. Deactivate self-test. Start and run engine at 2000 RPM for 2 minutes to warm up EGO sensor. Turn off engine and wait 10 seconds.

2. Restart engine, and activate self-test. Record all service codes displayed. See TROUBLE CODE DEFINITION

table. If no codes are

present, proceed to SWITCH MONITOR TEST

.

SWITCH MONITOR TEST

This test procedure checks input signals received by ECA from individual switches. Use following procedure to perform switch monitor test:

Turn engine off and allow it to cool.

Ensure all accessories are turned off.

Deactivate self-test.

Ensure transmission is in Neutral or Park.

Turn ignition on.

SUPER STAR II Tester

Connect Super Star II tester adapter cable. Turn on tester. Latch center button. Operate each switch listed in SWITCH MONITOR TEST

table. Note output of LED on adapter cable as each switch operates. Record test results.

VOM

1. Ground STI connector. Connect VOM positive lead to SML terminal on self-test connector. Connect negative lead to ground. See Fig.

1 .

2. Operate each switch listed in SWITCH MONITOR TEST

table. Note output on VOM as each switch is operated. Go to specified

PINPOINT TEST if any switch does not meet specification.

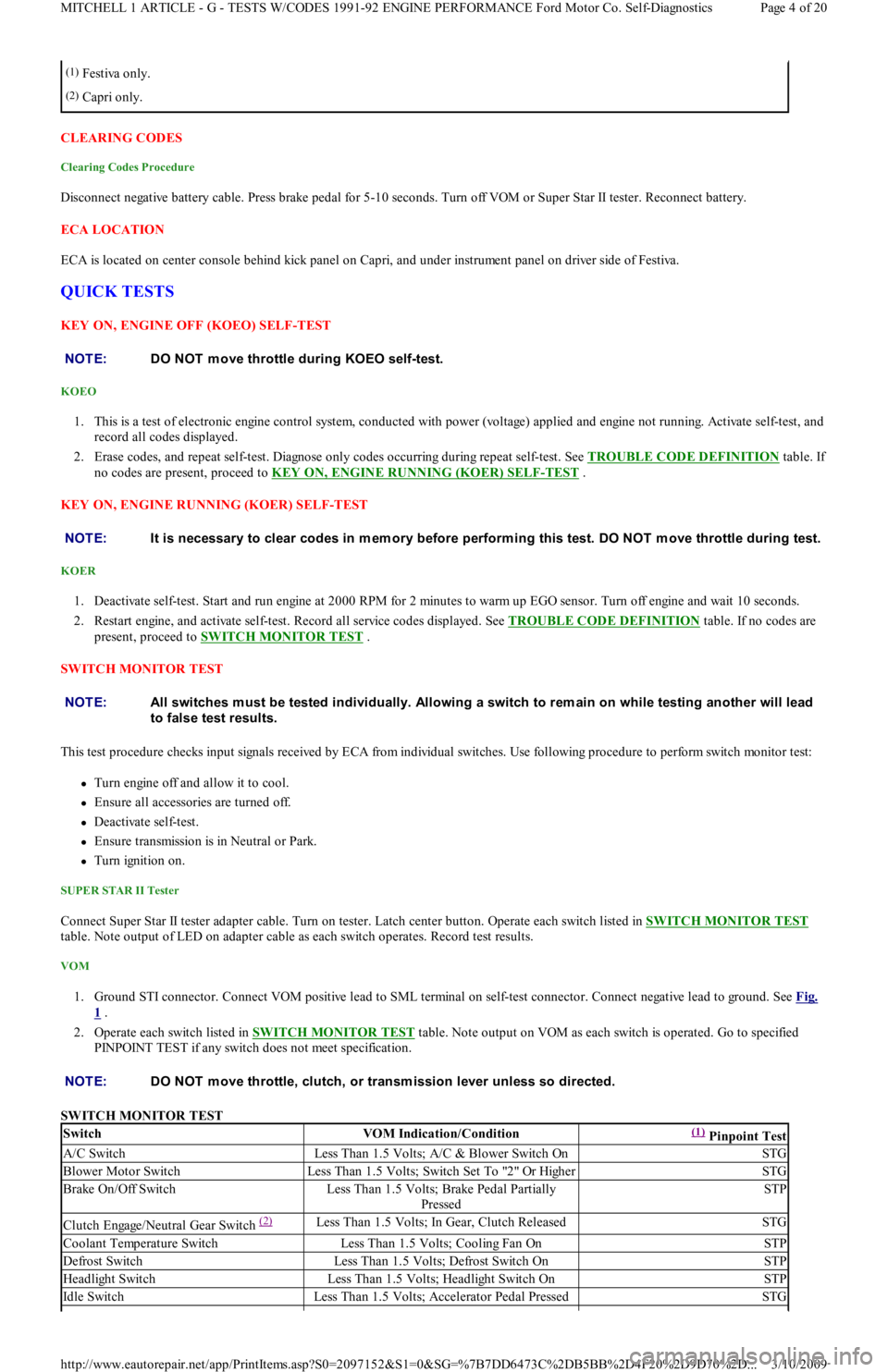

SWITCH MONITOR TEST

(1)Festiva only.

(2)Capri only.

NOTE:DO NOT m ove throttle during KOEO self-test.

NOTE:It is necessary to clear codes in m em ory before perform ing this test. DO NOT m ove throttle during test.

NOTE:All switches m ust be tested individually. Allowing a switch to rem ain on while testing another will lead

to false test results.

NOTE:DO NOT m ove throttle, clutch, or transm ission lever unless so directed.

SwitchVOM Indication/Condition(1) Pinpoint Test

A/C SwitchLess Than 1.5 Volts; A/C & Blower Switch OnSTG

Blower Motor SwitchLess Than 1.5 Volts; Switch Set To "2" Or HigherSTG

Brake On/Off SwitchLess Than 1.5 Volts; Brake Pedal Partially

PressedSTP

Clutch Engage/Neutral Gear Switch (2) Less Than 1.5 Volts; In Gear, Clutch ReleasedSTG

Coolant Temperature SwitchLess Than 1.5 Volts; Cooling Fan OnSTP

Defrost SwitchLess Than 1.5 Volts; Defrost Switch OnSTP

Headlight SwitchLess Than 1.5 Volts; Headlight Switch OnSTP

Id l e Swit chLess Than 1.5 Volts; Accelerator Pedal PressedSTG

Page 4 of 20 MITCHELL 1 ARTICLE - G - TESTS W/CODES 1991-92 ENGINE PERFORMANCE Ford Motor Co. Self-Diagnostics

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 191 of 454

Back To Article

E - T HEORY/OPERAT ION

1991 ENGINE PERFORMANCE Ford/Mercury T heory & Operation

INTRODUCTION

This article covers basic description and operation of engine performance-related systems and components. Read this article before attempting

to diagnose systems with which you are not completely familiar.

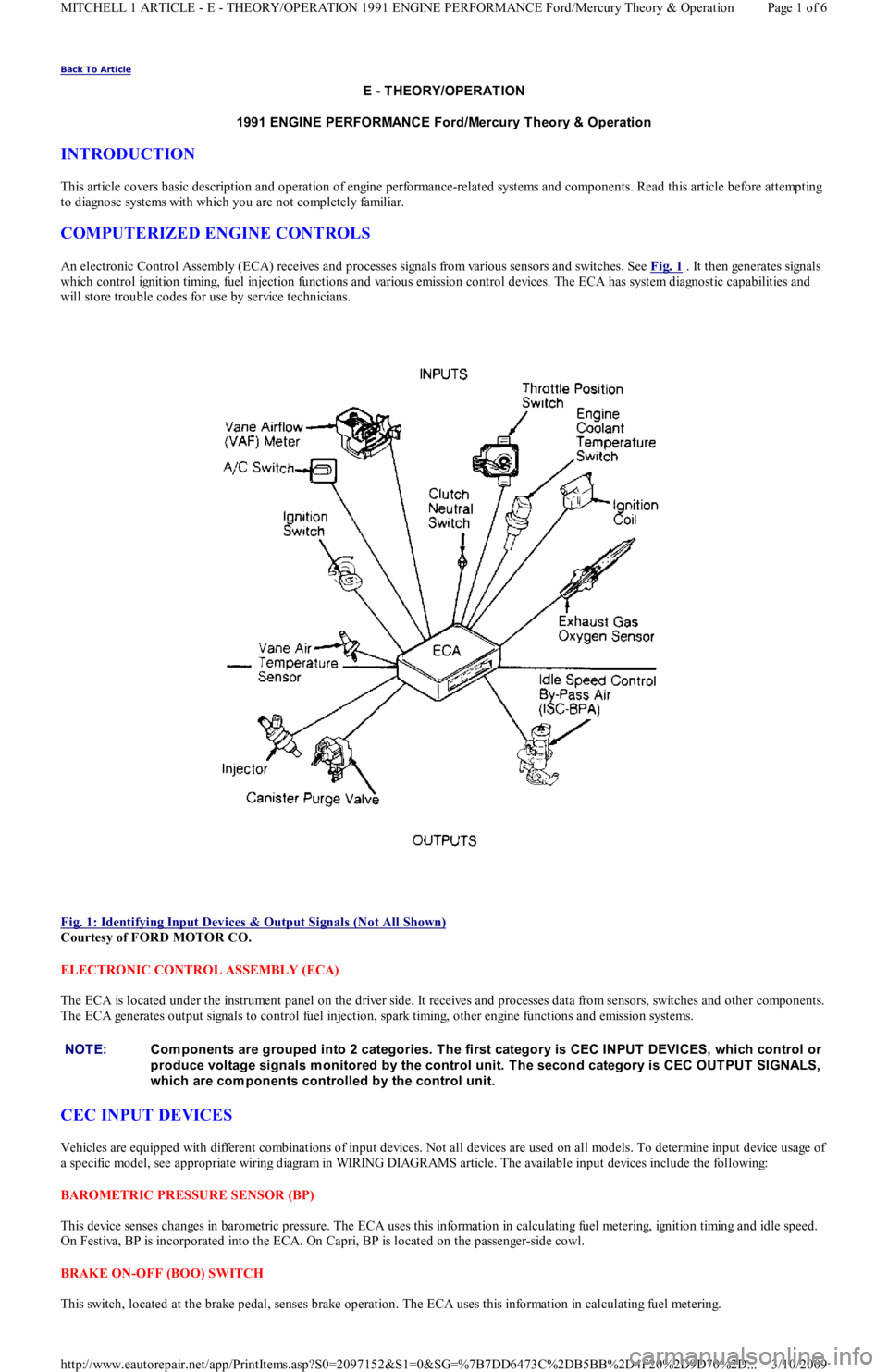

COMPUTERIZED ENGINE CONTROLS

An electronic Control Assembly (ECA) receives and processes signals from various sensors and switches. See Fig. 1 . It then generates signals

which control ignition timing, fuel injection functions and various emission control devices. The ECA has system diagnostic capabilities and

will store trouble codes for use by service technicians.

Fig. 1: Identifying Input Devices & Output Signals (Not All Shown)

Courtesy of FORD MOTOR CO.

ELECTRONIC CONTROL ASSEMBLY (ECA)

The ECA is located under the instrument panel on the driver side. It receives and processes data from sensors, switches and other components.

The ECA generates output signals to control fuel injection, spark timing, other engine functions and emission systems.

CEC INPUT DEVICES

Vehicles are equipped with different combinations of input devices. Not all devices are used on all models. To determine input device usage of

a specific model, see appropriate wiring diagram in WIRING DIAGRAMS article. The available input devices include the following:

BAROMETRIC PRESSURE SENSOR (BP)

This device senses changes in barometric pressure. The ECA uses this information in calculating fuel metering, ignition timing and idle speed.

On Festiva, BP is incorporated into the ECA. On Capri, BP is located on the passenger-side cowl.

BRAKE ON-OFF (BOO) SWITCH

This switch, located at the brake pedal, senses brake operation. The ECA uses this information in calculating fuel metering.

NOTE:Com ponents are grouped into 2 categories. T he first category is CEC INPUT DEVICES, which control or

produce voltage signals m onitored by the control unit. T he second category is CEC OUT PUT SIGNALS,

which are com ponents controlled by the control unit.

Page 1 of 6 MITCHELL 1 ARTICLE - E - THEORY/OPERATION 1991 ENGINE PERFORMANCE Ford/Mercury Theory & Operation

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 194 of 454

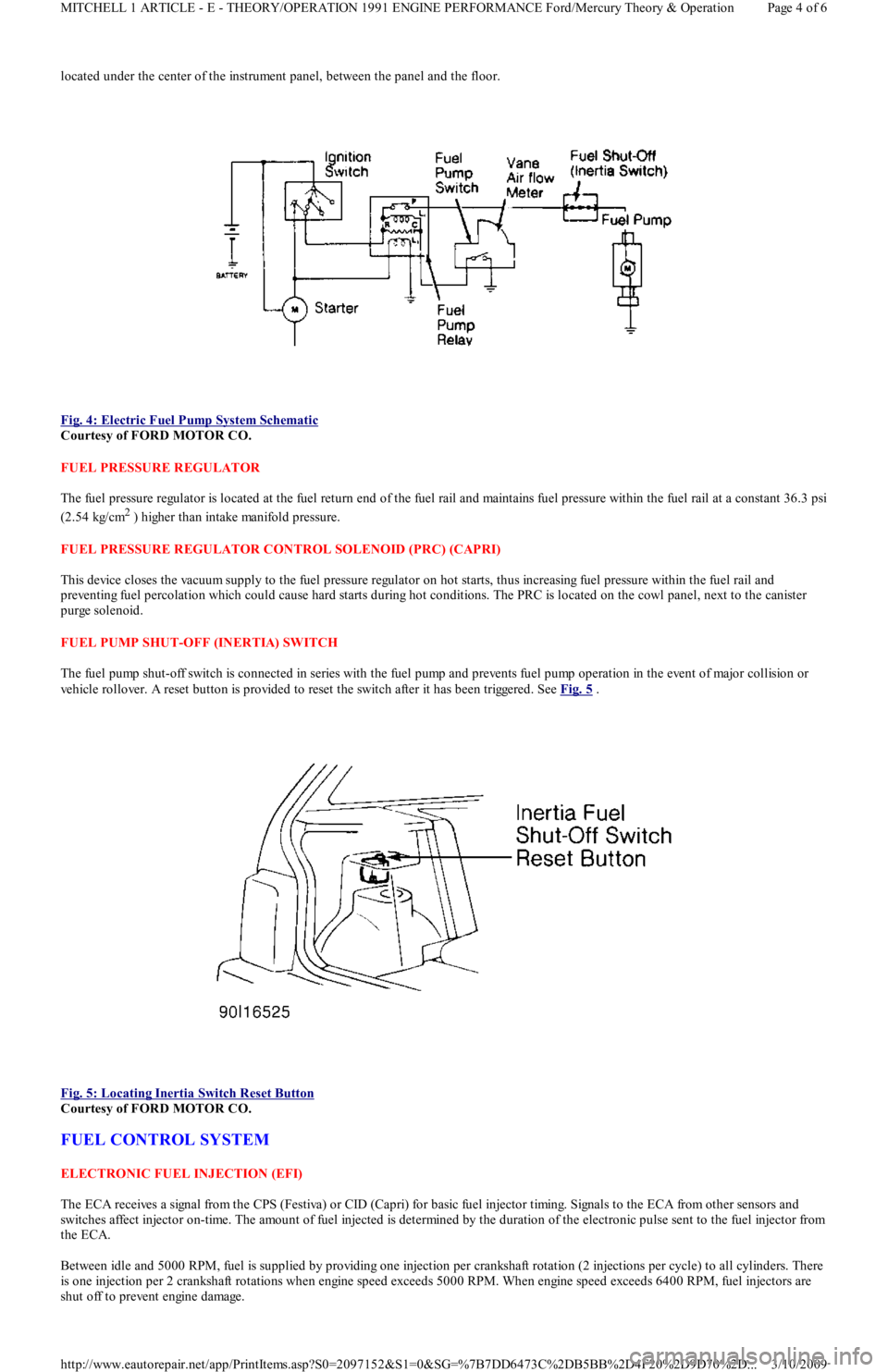

located under the center of the instrument panel, between the panel and the floor.

Fig. 4: Electric Fuel Pump System Schematic

Courtesy of FORD MOTOR CO.

FUEL PRESSURE REGULATOR

The fuel pressure regulator is located at the fuel return end of the fuel rail and maintains fuel pressure within the fuel rail at a constant 36.3 psi

(2.54 kg/cm

2 ) higher than intake manifold pressure.

FUEL PRESSURE REGULATOR CONTROL SOLENOID (PRC) (CAPRI)

This device closes the vacuum supply to the fuel pressure regulator on hot starts, thus increasing fuel pressure within the fuel rail and

preventing fuel percolation which could cause hard starts during hot conditions. The PRC is located on the cowl panel, next to the canister

purge solenoid.

FUEL PUMP SHUT-OFF (INERTIA) SWITCH

The fuel pump shut-off switch is connected in series with the fuel pump and prevents fuel pump operation in the event of major collision or

vehicle rollover. A reset button is provided to reset the switch after it has been triggered. See Fig. 5

.

Fig. 5: Locating Inertia Switch Reset Button

Courtesy of FORD MOTOR CO.

FUEL CONTROL SYSTEM

ELECTRONIC FUEL INJECTION (EFI)

The ECA receives a signal from the CPS (Festiva) or CID (Capri) for basic fuel injector timing. Signals to the ECA from other sensors and

switches affect injector on-time. The amount of fuel injected is determined by the duration of the electronic pulse sent to the fuel injector from

the ECA.

Between idle and 5000 RPM, fuel is supplied by providing one injection per crankshaft rotation (2 injections per cycle) to all cylinders. There

is one injection per 2 crankshaft rotations when engine speed exceeds 5000 RPM. When engine speed exceeds 6400 RPM, fuel injectors are

shut off to prevent engine damage.

Page 4 of 6 MITCHELL 1 ARTICLE - E - THEORY/OPERATION 1991 ENGINE PERFORMANCE Ford/Mercury Theory & Operation

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 206 of 454

High Performance

HSC

High Swirl Combustion

HSO

High Specific Output

HTR

Heater

Hz

Hertz (Cycles Per Second)

"I"

IAC

Idle Air Control

IACV

Idle Air Control Valve

IAT

Intake Air Temperature

IC

Integrated Circuit

ID

Identification

I.D.

Inside Diameter

Ign.

Ignition

IMRC

Intake Manifold Runner Control

In.

In ch es

INCH Lbs.

Inch Pounds

in. Hg

Inches of Mercury

Inj.

Injector

IP

Instrument Panel

ISC

Idle Speed Control

IVSV

Idle Vacuum Switching Valve

Page 8 of 15 MITCHELL 1 ARTICLE - GENERAL INFORMATION Commonly Used Abbreviations

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 247 of 454

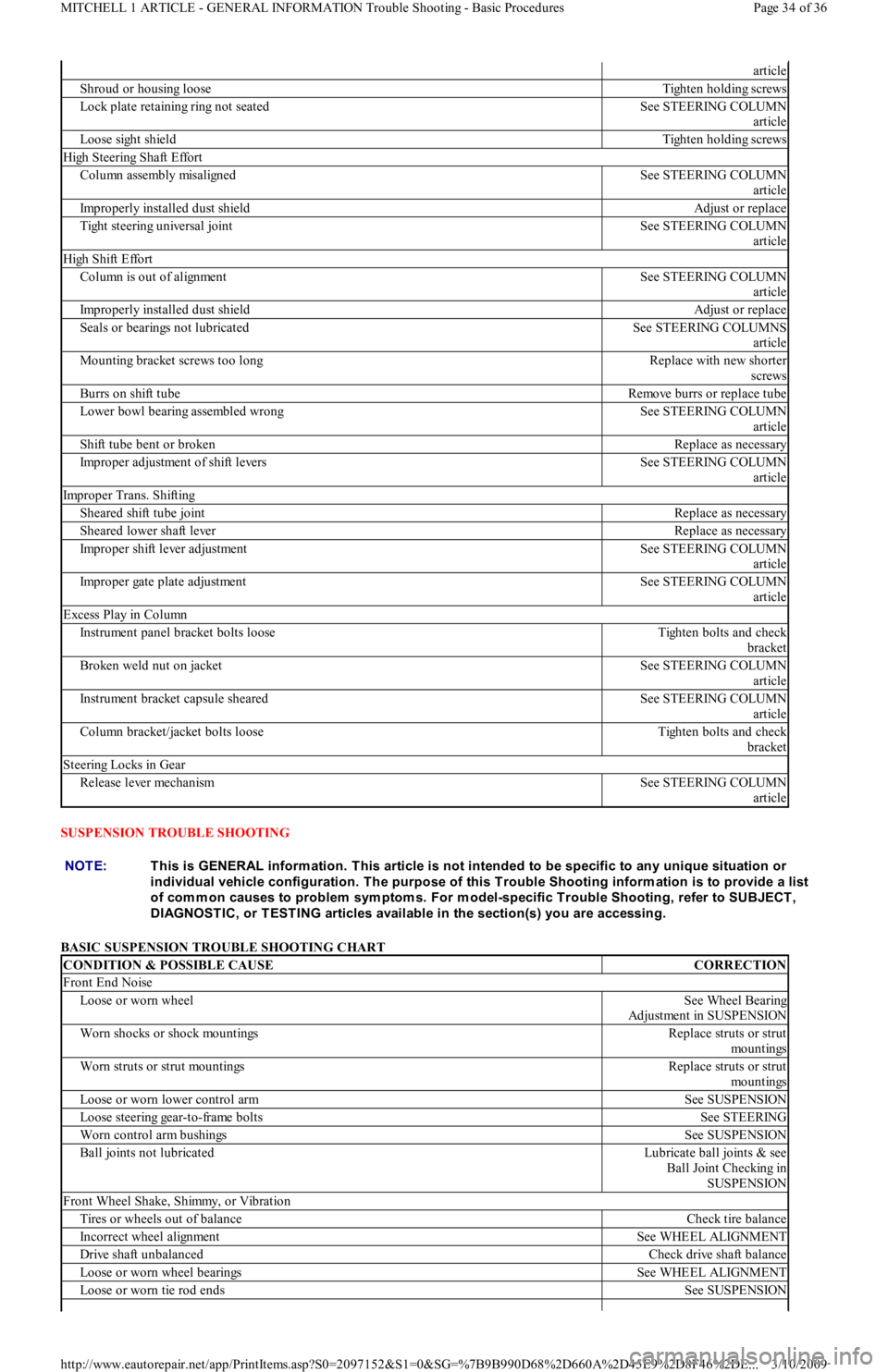

SUSPENSION TROUBLE SHOOTING

BASIC SUSPENSION TROUBLE SHOOTING CHART

article

Shroud or housing looseTighten holding screws

Lock plate retaining ring not seatedSee STEERING COLUMN

article

Loose sight shieldTighten holding screws

High Steering Shaft Effort

Co l u mn assemb l y misal ign edSee STEERING COLUMN

article

Improperly installed dust shieldAdjust or replace

Tight steering universal jointSee STEERING COLUMN

article

High Shift Effort

Column is out of alignmentSee STEERING COLUMN

article

Improperly installed dust shieldAdjust or replace

Seals or bearings not lubricatedSee STEERING COLUMNS

article

Mounting bracket screws too longReplace with new shorter

screws

Burrs on shift tubeRemove burrs or replace tube

Lower bowl bearing assembled wrongSee STEERING COLUMN

article

Shift tube bent or brokenReplace as necessary

Improper adjustment of shift leversSee STEERING COLUMN

article

Improper Trans. Shifting

Sheared shift tube jointReplace as necessary

Sheared lower shaft leverReplace as necessary

Improper shift lever adjustmentSee STEERING COLUMN

article

Improper gate plate adjustmentSee STEERING COLUMN

article

Excess Play in Column

Instrument panel bracket bolts looseTighten bolts and check

bracket

Broken weld nut on jacketSee STEERING COLUMN

article

Instrument bracket capsule shearedSee STEERING COLUMN

article

Column bracket/jacket bolts looseTighten bolts and check

bracket

Steering Locks in Gear

Release lever mechanismSee STEERING COLUMN

article

NOTE:This is GENERAL inform ation. This article is not intended to be specific to any unique situation or

individual vehicle configuration. T he purpose of this T rouble Shooting inform ation is to provide a list

of com m on causes to problem sym ptom s. For m odel-specific T rouble Shooting, refer to SUBJECT ,

DIAGNOST IC, or T EST ING articles available in the section(s) you are accessing.

CONDITION & POSSIBLE CAUSECORRECTION

Front End Noise

Loose or worn wheelSee Wheel Bearing

Adjustment in SUSPENSION

Worn shocks or shock mountingsReplace struts or strut

mo u n t in gs

Worn struts or strut mountingsReplace struts or strut

mo u n t in gs

Loose or worn lower control armSee SUSPENSION

Loose steering gear-to-frame boltsSee STEERING

Worn control arm bushingsSee SUSPENSION

Ball joints not lubricatedLubricate ball joints & see

Ball Joint Checking in

SUSPENSION

Front Wheel Shake, Shimmy, or Vibration

Tires or wheels out of balanceCheck tire balance

Incorrect wheel alignmentSee WHEEL ALIGNMENT

Drive shaft unbalancedCheck drive shaft balance

Loose or worn wheel bearingsSee WHEEL ALIGNMENT

Loose or worn tie rod endsSee SUSPENSION

Page 34 of 36 MITCHELL 1 ARTICLE - GENERAL INFORMATION Trouble Shooting - Basic Procedures

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 345 of 454

Back To Article

HEAT ER SYST EM

1990-92 HEAT ER SYST EMS Ford Motor Co.

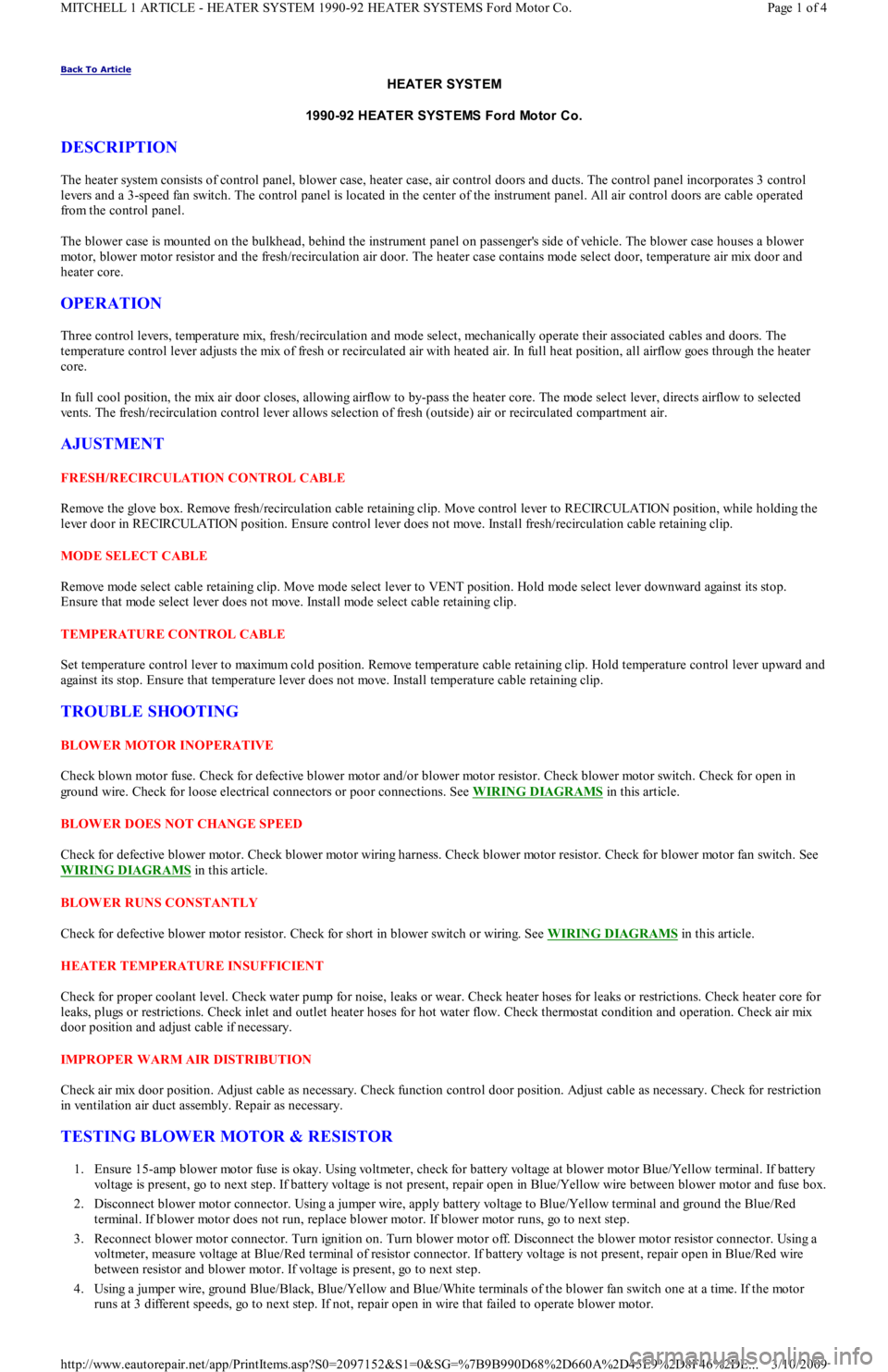

DESCRIPTION

The heater system consists of control panel, blower case, heater case, air control doors and ducts. The control panel incorporates 3 control

levers and a 3-speed fan switch. The control panel is located in the center of the instrument panel. All air control doors are cable operated

from the control panel.

The blower case is mounted on the bulkhead, behind the instrument panel on passenger's side of vehicle. The blower case houses a blower

motor, blower motor resistor and the fresh/recirculation air door. The heater case contains mode select door, temperature air mix door and

heater core.

OPERATION

Three control levers, temperature mix, fresh/recirculation and mode select, mechanically operate their associated cables and doors. The

temperature control lever adjusts the mix of fresh or recirculated air with heated air. In full heat position, all airflow goes through the heater

core.

In full cool position, the mix air door closes, allowing airflow to by-pass the heater core. The mode select lever, directs airflow to selected

vents. The fresh/recirculation control lever allows selection of fresh (outside) air or recirculated compartment air.

AJUSTMENT

FRESH/RECIRCULATION CONTROL CABLE

Remove the glove box. Remove fresh/recirculation cable retaining clip. Move control lever to RECIRCULATION position, while holding the

lever door in RECIRCULATION position. Ensure control lever does not move. Install fresh/recirculation cable retaining clip.

MODE SELECT CABLE

Remove mode select cable retaining clip. Move mode select lever to VENT position. Hold mode select lever downward against its stop.

Ensure that mode select lever does not move. Install mode select cable retaining clip.

TEMPERATURE CONTROL CABLE

Set temperature control lever to maximum cold position. Remove temperature cable retaining clip. Hold temperature control lever upward and

against its stop. Ensure that temperature lever does not move. Install temperature cable retaining clip.

TROUBLE SHOOTING

BLOWER MOTOR INOPERATIVE

Check blown motor fuse. Check for defective blower motor and/or blower motor resistor. Check blower motor switch. Check for open in

ground wire. Check for loose electrical connectors or poor connections. See WIRING DIAGRAMS

in this article.

BLOWER DOES NOT CHANGE SPEED

Check for defective blower motor. Check blower motor wiring harness. Check blower motor resistor. Check for blower motor fan switch. See

WIRING DIAGRAMS

in this article.

BLOWER RUNS CONSTANTLY

Check for defective blower motor resistor. Check for short in blower switch or wiring. See WIRING DIAGRAMS

in this article.

HEATER TEMPERATURE INSUFFICIENT

Check for proper coolant level. Check water pump for noise, leaks or wear. Check heater hoses for leaks or restrictions. Check heater core for

leaks, plugs or restrictions. Check inlet and outlet heater hoses for hot water flow. Check thermostat condition and operation. Check air mix

door position and adjust cable if necessary.

IMPROPER WARM AIR DISTRIBUTION

Check air mix door position. Adjust cable as necessary. Check function control door position. Adjust cable as necessary. Check for restriction

in ventilation air duct assembly. Repair as necessary.

TESTING BLOWER MOTOR & RESISTOR

1. Ensure 15-amp blower motor fuse is okay. Using voltmeter, check for battery voltage at blower motor Blue/Yellow terminal. If battery

voltage is present, go to next step. If battery voltage is not present, repair open in Blue/Yellow wire between blower motor and fuse box.

2. Disconnect blower motor connector. Using a jumper wire, apply battery voltage to Blue/Yellow terminal and ground the Blue/Red

terminal. If blower motor does not run, replace blower motor. If blower motor runs, go to next step.

3. Reconnect blower motor connector. Turn ignition on. Turn blower motor off. Disconnect the blower motor resistor connector. Using a

voltmeter, measure voltage at Blue/Red terminal of resistor connector. If battery voltage is not present, repair open in Blue/Red wire

between resistor and blower motor. If voltage is present, go to next step.

4. Using a jumper wire, ground Blue/Black, Blue/Yellow and Blue/White terminals of the blower fan switch one at a time. If the motor

runs at 3 different speeds, go to next step. If not, repair open in wire that failed to operate blower motor.

Page 1 of 4 MITCHELL 1 ARTICLE - HEATER SYSTEM 1990-92 HEATER SYSTEMS Ford Motor Co.

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 346 of 454

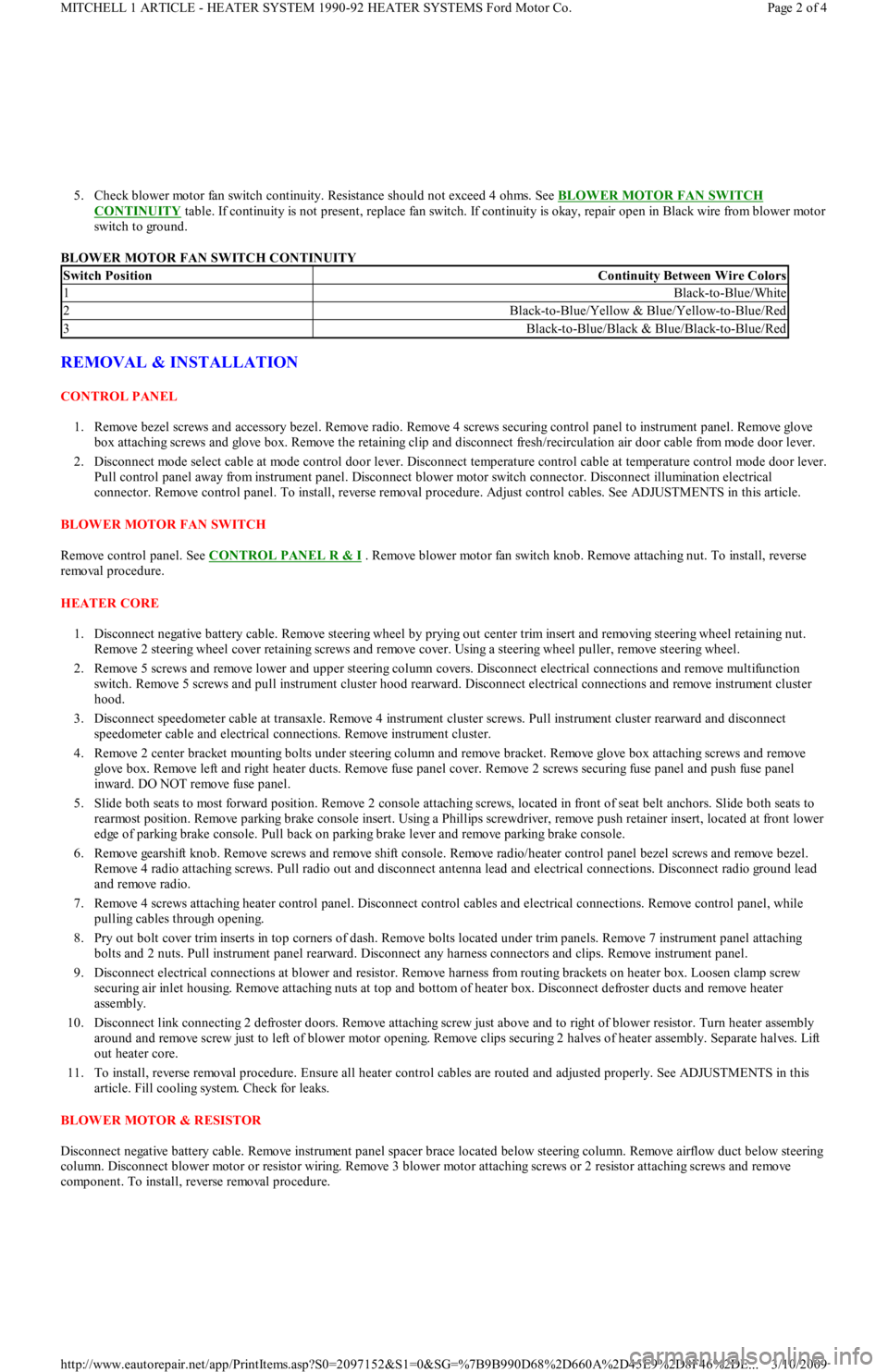

5. Check blower motor fan switch continuity. Resistance should not exceed 4 ohms. See BLOWER MOTOR FAN SWITCH

CONTINUITY table. If continuity is not present, replace fan switch. If continuity is okay, repair open in Black wire from blower motor

switch to ground.

BLOWER MOTOR FAN SWITCH CONTINUITY

REMOVAL & INSTALLATION

CONTROL PANEL

1. Remove bezel screws and accessory bezel. Remove radio. Remove 4 screws securing control panel to instrument panel. Remove glove

box attaching screws and glove box. Remove the retaining clip and disconnect fresh/recirculation air door cable from mode door lever.

2. Disconnect mode select cable at mode control door lever. Disconnect temperature control cable at temperature control mode door lever.

Pull control panel away from instrument panel. Disconnect blower motor switch connector. Disconnect illumination electrical

connector. Remove control panel. To install, reverse removal procedure. Adjust control cables. See ADJUSTMENTS in this article.

BLOWER MOTOR FAN SWITCH

Remove control panel. See CONTROL PANEL R & I

. Remove blower motor fan switch knob. Remove attaching nut. To install, reverse

removal procedure.

HEATER CORE

1. Disconnect negative battery cable. Remove steering wheel by prying out center trim insert and removing steering wheel retaining nut.

Remove 2 steering wheel cover retaining screws and remove cover. Using a steering wheel puller, remove steering wheel.

2. Remove 5 screws and remove lower and upper steering column covers. Disconnect electrical connections and remove multifunction

switch. Remove 5 screws and pull instrument cluster hood rearward. Disconnect electrical connections and remove instrument cluster

hood.

3. Disconnect speedometer cable at transaxle. Remove 4 instrument cluster screws. Pull instrument cluster rearward and disconnect

speedometer cable and electrical connections. Remove instrument cluster.

4. Remove 2 center bracket mounting bolts under steering column and remove bracket. Remove glove box attaching screws and remove

glove box. Remove left and right heater ducts. Remove fuse panel cover. Remove 2 screws securing fuse panel and push fuse panel

inward. DO NOT remove fuse panel.

5. Slide both seats to most forward position. Remove 2 console attaching screws, located in front of seat belt anchors. Slide both seats to

rearmost position. Remove parking brake console insert. Using a Phillips screwdriver, remove push retainer insert, located at front lower

edge of parking brake console. Pull back on parking brake lever and remove parking brake console.

6. Remove gearshift knob. Remove screws and remove shift console. Remove radio/heater control panel bezel screws and remove bezel.

Remove 4 radio attaching screws. Pull radio out and disconnect antenna lead and electrical connections. Disconnect radio ground lead

and remove radio.

7. Remove 4 screws attaching heater control panel. Disconnect control cables and electrical connections. Remove control panel, while

pulling cables through opening.

8. Pry out bolt cover trim inserts in top corners of dash. Remove bolts located under trim panels. Remove 7 instrument panel attaching

bolts and 2 nuts. Pull instrument panel rearward. Disconnect any harness connectors and clips. Remove instrument panel.

9. Disconnect electrical connections at blower and resistor. Remove harness from routing brackets on heater box. Loosen clamp screw

securing air inlet housing. Remove attaching nuts at top and bottom of heater box. Disconnect defroster ducts and remove heater

assembly.

10. Disconnect link connecting 2 defroster doors. Remove attaching screw just above and to right of blower resistor. Turn heater assembly

around and remove screw just to left of blower motor opening. Remove clips securing 2 halves of heater assembly. Separate halves. Lift

out heater core.

11. To install, reverse removal procedure. Ensure all heater control cables are routed and adjusted properly. See ADJUSTMENTS in this

article. Fill cooling system. Check for leaks.

BLOWER MOTOR & RESISTOR

Disconnect negative battery cable. Remove instrument panel spacer brace located below steering column. Remove airflow duct below steering

column. Disconnect blower motor or resistor wiring. Remove 3 blower motor attaching screws or 2 resistor attaching screws and remove

component. To install, reverse removal procedure.

Switch PositionContinuity Between Wire Colors

1Black-to-Blue/White

2Black-to-Blue/Yellow & Blue/Yellow-to-Blue/Red

3Black-to-Blue/Black & Blue/Black-to-Blue/Red

Page 2 of 4 MITCHELL 1 ARTICLE - HEATER SYSTEM 1990-92 HEATER SYSTEMS Ford Motor Co.

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 350 of 454

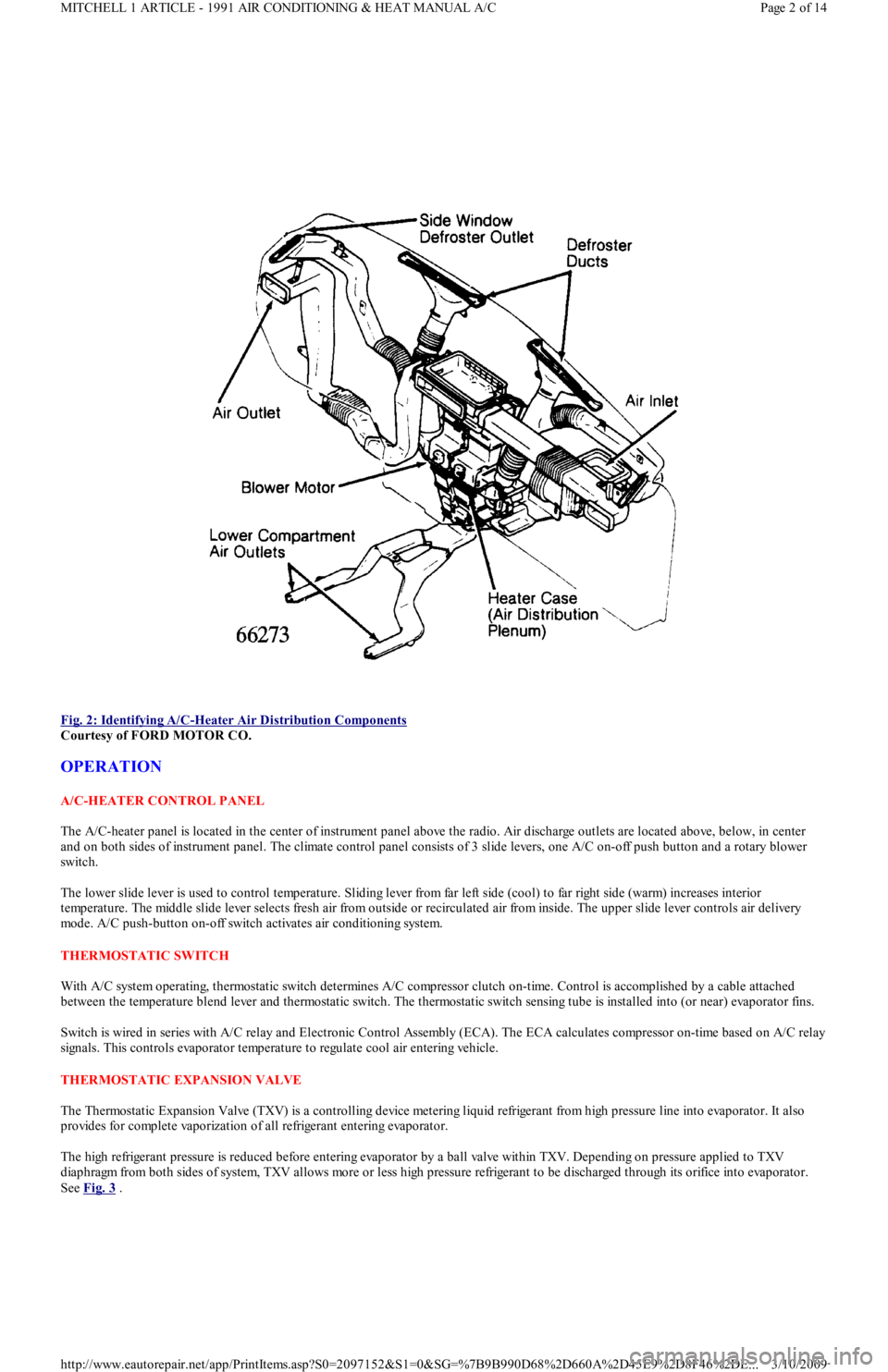

Fig. 2: Identifying A/C

-Heater Air Distribution Components

Courtesy of FORD MOTOR CO.

OPERATION

A/C-HEATER CONTROL PANEL

The A/C-heater panel is located in the center of instrument panel above the radio. Air discharge outlets are located above, below, in center

and on both sides of instrument panel. The climate control panel consists of 3 slide levers, one A/C on-off push button and a rotary blower

switch.

The lower slide lever is used to control temperature. Sliding lever from far left side (cool) to far right side (warm) increases interior

temperature. The middle slide lever selects fresh air from outside or recirculated air from inside. The upper slide lever controls air delivery

mode. A/C push-button on-off switch activates air conditioning system.

THERMOSTATIC SW ITCH

With A/C system operating, thermostatic switch determines A/C compressor clutch on-time. Control is accomplished by a cable attached

between the temperature blend lever and thermostatic switch. The thermostatic switch sensing tube is installed into (or near) evaporator fins.

Switch is wired in series with A/C relay and Electronic Control Assembly (ECA). The ECA calculates compressor on-time based on A/C relay

signals. This controls evaporator temperature to regulate cool air entering vehicle.

THERMOSTATIC EXPANSION VALVE

The Thermostatic Expansion Valve (TXV) is a controlling device metering liquid refrigerant from high pressure line into evaporator. It also

provides for complete vaporization of all refrigerant entering evaporator.

The high refrigerant pressure is reduced before entering evaporator by a ball valve within TXV. Depending on pressure applied to TXV

diaphragm from both sides of system, TXV allows more or less high pressure refrigerant to be discharged through its orifice into evaporator.

See Fig. 3

.

Page 2 of 14 MITCHELL 1 ARTICLE - 1991 AIR CONDITIONING & HEAT MANUAL A/C

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 353 of 454

Fig. 5: Adjusting Recirculated/Fresh Air Door Cable

Courtesy of FORD MOTOR CO.

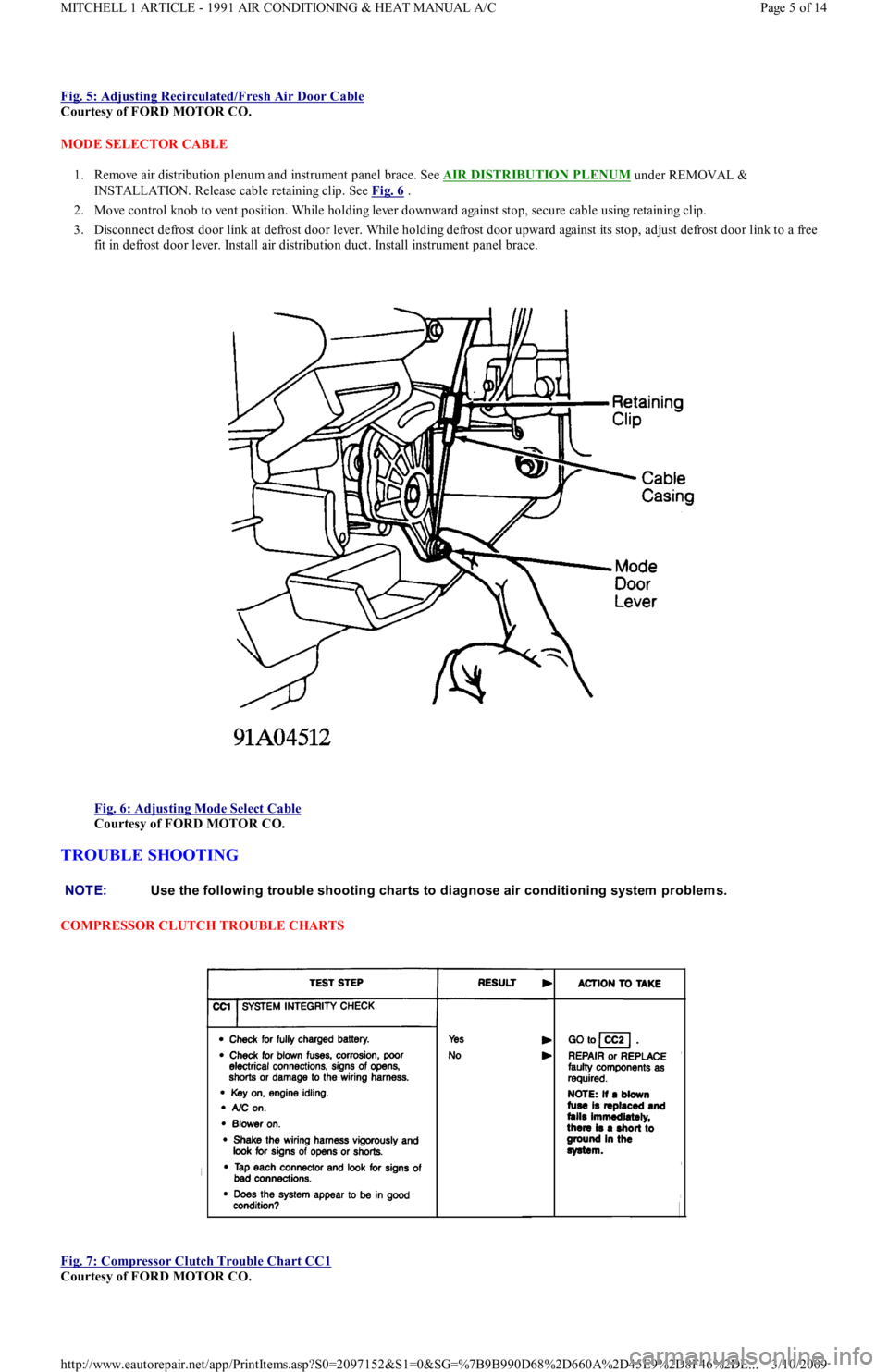

MODE SELECTOR CABLE

1. Remove air distribution plenum and instrument panel brace. See AIR DISTRIBUTION PLENUM

under REMOVAL &

INSTALLATION. Release cable retaining clip. See Fig. 6

.

2. Move control knob to vent position. While holding lever downward against stop, secure cable using retaining clip.

3. Disconnect defrost door link at defrost door lever. While holding defrost door upward against its stop, adjust defrost door link to a free

fit in defrost door lever. Install air distribution duct. Install instrument panel brace.

Fig. 6: Adjusting Mode Select Cable

Courtesy of FORD MOTOR CO.

TROUBLE SHOOTING

COMPRESSOR CLUTCH TROUBLE CHARTS

Fig. 7: Compressor Clutch Trouble Chart CC1

Courtesy of FORD MOTOR CO.

NOTE:Use the following trouble shooting charts to diagnose air conditioning system problem s.

Page 5 of 14 MITCHELL 1 ARTICLE - 1991 AIR CONDITIONING & HEAT MANUAL A/C

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...