sensor FORD FESTIVA 1991 Manual PDF

[x] Cancel search | Manufacturer: FORD, Model Year: 1991, Model line: FESTIVA, Model: FORD FESTIVA 1991Pages: 454, PDF Size: 9.53 MB

Page 276 of 454

SERVICE & ADJUSTMENT SPECIFICATIONS

If you want a specification quickly, this is the place to look. Instead of hunting through a long article, we've separated out the important

specifications and arranged them into easy-to-use tables in a centralized location. You can find valuable information like spark plug wire

resistance, valve clearance, timing, firing orders, etc.

ADJUSTMENT

ON-VEHICLE ADJUSTMENTS

The ON-VEHICLE ADJUSTMENTS article contains the type of information that was previously thought of as TUNE-UP information.

Procedures for checking and adjusting valves, base ignition timing and idle speed are found in this section. Use this section in conjunction with

SERVICE & ADJUSTMENT SPECIFICATIONS for performing routine maintenance. Also, if you have a driveability problem, ensure all on-

vehicle adjustments are within specification before attempting further diagnosis.

THEORY & OPERATION

This article covers basic THEORY & OPERATION of engine performance-related systems and components. Before diagnosing vehicles or new

systems with which you are not completely familiar, read this article.

TESTING & DIAGNOSTICS

BASIC DIAGNOSTIC PROCEDURES/BASIC TESTING

The procedures listed in this article can help you avoid skipping a simple step early, like checking base timing, which could be costly in both

time and money later. This is also a potential starting point for diagnosis of a "no-start" condition. If all systems check out okay here, proceed

to SELF-DIAGNOSTICS/TESTS W/CODES or TROUBLE SHOOTING - NO CODES/TESTS W/O CODES article.

SELF-DIAGNOSTICS/TESTS W/CODES

Use this information to retrieve and interpret Diagnostic Trouble Codes (DTCs) accessed from the vehicle's self-diagnostic system. Once

information is retrieved, manufacturer diagnostic procedures are given to help pinpoint and repair computer system/component faults. Also

included are steps for clearing trouble codes once these faults are repaired. If there is a driveability symptom with no trouble codes set,

proceed to TROUBLE SHOOTING - NO CODES/TESTS W/O CODES article.

TROUBLE SHOOTING - NO CODES/TESTS W/O CODES

This is where to go when you have a problem that does not set a trouble code. It can help determine cause of problem using driveability

symptoms and intermittent testing procedures. Procedures in this information should lead you to a specific component or system test.

SYSTEM & COMPONENT TESTING

Here you will find various tests for engine performance systems and their components, such as air induction (turbochargers and superchargers),

fuel control, ignition control and emission systems.

PIN VOLTAGE CHARTS

These are supplied (when available from manufacturer) to quicken the diagnostic process. By checking pin voltages at the Powertrain Control

Module (PCM), you can determine if the PCM is receiving and/or transmitting proper voltage signals. Pin charts may also be referred to as PID

charts by some manufacturers.

SENSOR RANGE CHARTS

SENSOR OPERATING RANGE CHARTS

These are supplied (when available from manufacturer) to determine if a sensor is out of calibration. An out-of-calibration sensor may not set a

trouble code, but it may cause driveability problems.

VACUUM DIAGRAMS

NOTE:T his article is generic in nature and all inform ation does not apply to all vehicles. For vehicle specific

inform ation, see the appropriate articles in the ENGINE PERFORMANCE category.

NOTE:T his article is generic in nature and all inform ation does not apply to all vehicles. For vehicle specific

inform ation, see the appropriate articles in the ENGINE PERFORMANCE category.

NOTE:T his article is generic in nature and all inform ation does not apply to all vehicles. For vehicle specific

inform ation, see the appropriate articles in the ENGINE PERFORMANCE category.

NOTE:T his article is generic in nature and all inform ation does not apply to all vehicles. For vehicle specific

inform ation, see the appropriate articles in the ENGINE PERFORMANCE category.

NOTE:T his article is generic in nature and all inform ation does not apply to all vehicles. For vehicle specific

inform ation, see the appropriate articles in the ENGINE PERFORMANCE category.

NOTE:T his article is generic in nature and all inform ation does not apply to all vehicles. For vehicle specific

inform ation, see the appropriate articles in the ENGINE PERFORMANCE category.

Page 2 of 3 MITCHELL 1 ARTICLE - GENERAL INFORMATION How To Use The Engine Performance Section - 1989 & Newer Models

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 285 of 454

Let's go back to figuring out dwell/duty readings by using injector on-time specification. This is not generally practical, but we will cover it for

completeness. You NEED to know three things:

Injector mS on-time specification.

Engine RPM when specification is valid.

How many times the injectors fire per crankshaft revolution.

The first two are self-explanatory. The last one may require some research into whether it is a bank-fire type that injects every 360° of

crankshaft rotation, a bank-fire that injects every 720°, or an SFI that injects every 720°. Many manufacturers do not release this data so you

may have to figure it out yourself with a frequency meter.

Here are the four complete steps to convert millisecond on-time:

1. Determine the injector pulse width and RPM it was obtained at. Let's say the specification is for one millisecond of on-time at a hot idle

of 600 RPM.

2. Determine injector firing method for the complete 4 stroke cycle. Let's say this is a 360° bank-fired, meaning an injector fires each and

every crankshaft revolution.

3. Determine how many times the injector will fire at the specified engine speed (600 RPM) in a fixed time period. We will use 100

milliseconds because it is easy to use. Six hundred crankshaft Revolutions Per Minute (RPM) divided by 60 seconds equals 10

revolutions per second. Multiplying 10 times .100 yields one; the crankshaft turns one time in 100 milliseconds. With exactly one

crankshaft rotation in 100 milliseconds, we know that the injector fires exactly one time.

4. Determine the ratio of injector on-time vs. off-time in the fixed time period, then figure duty cycle and/or dwell. The injector fires one

time for a total of one millisecond in any given 100 millisecond period. One hundred minus one equals 99. We have a 99% duty cycle.

If we wanted to know the dwell (on 6 cylinder scale), multiple 99% times .6; this equals 59.4° dwell.

Weaknesses of Dwell/Duty Meter

The weaknesses are significant. First, there is no one-to-one correspondence to actual mS on-time. No manufacturer releases dwell/duty data,

and it is time-consuming to convert the mS on-time readings. Besides, there can be a large degree of error because the conversion forces you to

assume that the injector(s) are always firing at the same rate for the same period of time. This can be a dangerous assumption.

Second, all level of detail is lost in the averaging process. This is the primary weakness. You cannot see the details you need to make a

confident diagnosis.

Here is one example. Imagine a vehicle that has a faulty injector driver that occasionally skips an injector pulse. Every skipped pulse means

that that cylinder does not fire, thus unburned O2 gets pushed into the exhaust and passes the O2 sensor. The O2 sensor indicates lean, so the

computer fattens up the mixture to compensate for the supposed "lean" condition.

A connected dwell/duty meter would see the fattened pulse width but would also see the skipped pulses. It would tally both and likely come

back with a reading that indicated the "pulse width" was within specification because the rich mixture and missing pulses offset each other.

This situation is not a far-fetched scenario. Some early GM 3800 engines were suffering from exactly this. The point is that a lack of detail

could cause misdiagnosis.

As yo u migh t h a ve gu e sse d , a lab scope would not miss this.

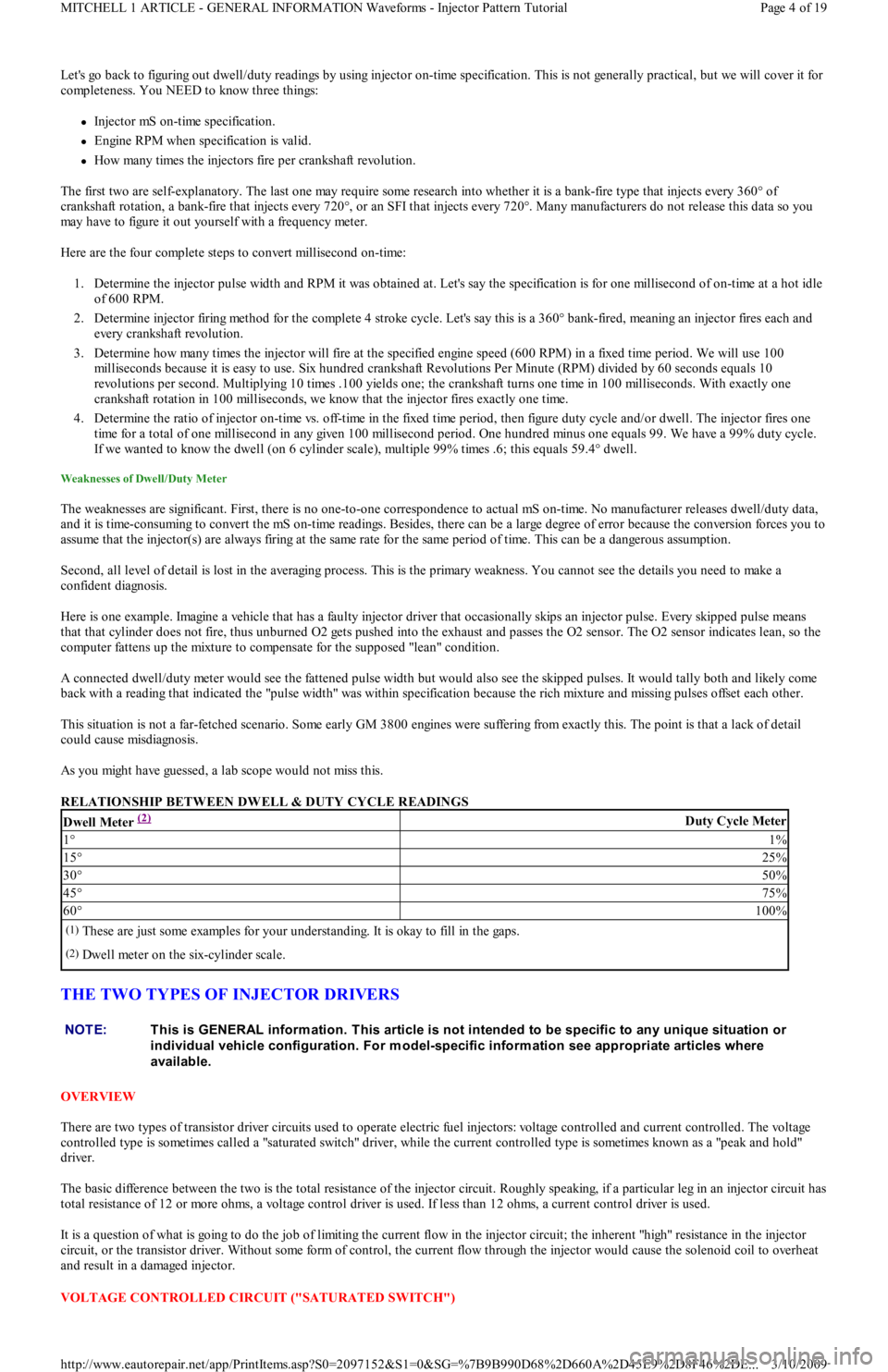

RELATIONSHIP BETWEEN DWELL & DUTY CYCLE READINGS

THE TWO TYPES OF INJECTOR DRIVERS

OVERVIEW

There are two types of transistor driver circuits used to operate electric fuel injectors: voltage controlled and current controlled. The voltage

controlled type is sometimes called a "saturated switch" driver, while the current controlled type is sometimes known as a "peak and hold"

driver.

The basic difference between the two is the total resistance of the injector circuit. Roughly speaking, if a particular leg in an injector circuit has

total resistance of 12 or more ohms, a voltage control driver is used. If less than 12 ohms, a current control driver is used.

It is a question of what is going to do the job of limiting the current flow in the injector circuit; the inherent "high" resistance in the injector

circuit, or the transistor driver. Without some form of control, the current flow through the injector would cause the solenoid coil to overheat

and result in a damaged injector.

VOLTAGE CONTROLLED CIRCUIT ("SATURATED SWITCH")

Dwell Meter (2)Duty Cycle Meter

1°1%

15°25%

30°50%

45°75%

60°100%

(1)These are just some examples for your understanding. It is okay to fill in the gaps.

(2)Dwell meter on the six-cylinder scale.

NOTE:This is GENERAL inform ation. This article is not intended to be specific to any unique situation or

individual vehicle configuration. For m odel-specific inform ation see appropriate articles where

available.

Page 4 of 19 MITCHELL 1 ARTICLE - GENERAL INFORMATION Waveforms - Injector Pattern Tutorial

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...