automatic transmission fluid FORD FESTIVA 1991 Service Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1991, Model line: FESTIVA, Model: FORD FESTIVA 1991Pages: 454, PDF Size: 9.53 MB

Page 28 of 454

Back To Article

BRAKE SYST EM

1991-92 BRAKES Disc & Drum

DESCRIPTION & OPERATION

On Capri, vehicle braking is provided by front and rear disc brakes. Front and rear brakes are a full-floating, single piston design. The rear

caliper houses a self-adjusting parking brake.

On Festiva, vehicle braking is provided by front disc brakes and rear drum brakes. Rear brakes are a standard non-servo, self-en e r giz in g d e sign .

Front brakes are a full-floating, single piston design with caliper attached to steering knuckle.

BLEEDING BRAKE SYSTEM

BLEEDING PROCEDURES

Manual Bleeding

1. Exhaust vacuum from power brake unit by depressing brake pedal several times. Fill master cylinder with clean brake fluid. Install clear

vinyl bleeder hose onto first bleeder valve to be serviced. See BRAKE LINE BLEEDING SEQUENCE table. Place other end of hose in

clean transparent container.

2. Partially fill container with clean brake fluid. Open the bleeder valve 3/4 turn. Slowly depress brake pedal through its full travel. Close

bleeder valve and release pedal. Pump pedal several times to push air toward wheel cylinders. Repeat procedure until flow of brake

fluid is clear and shows no signs of air bubbles. Proceed to next bleeder valve in sequence and repeat procedure.

BRAKE LINE BLEEDING SEQUENCE

Pressure Bleeding

1. Exhaust vacuum from power brake unit by depressing brake pedal several times. Fill master cylinder with clean brake fluid. With

pressure bleeder at least 1/2 full, connect pressure bleeder to master cylinder using appropriate adaptor.

2. Install clear vinyl bleeder hose onto first bleeder valve to be serviced. See BRAKE LINE BLEEDING SEQUENCE table. Place other

end of hose in clean transparent container. Partially fill container with clean brake fluid. Open bleeder valve 1-2 turns. Allow fluid to

run until flow of fluid is clear and shows no signs of air bubbles. Proceed to next bleeder valve in sequence and repeat procedure.

Remove pressure bleeder and fill master cylinder with clean brake fluid.

ADJUSTMENTS

BRAKE PEDAL HEIGHT (FESTIVA)

1. Block wheels to prevent vehicle from rolling. Start engine and place transmission in Neutral. Fully release parking brake. Move carpet

and insulation away from firewall and brake pedal. Measure distance horizontally between upper center of brake pedal pad and firewall.

Distance should be 8.03-8.23" (204-209 mm).

2. If pedal height is incorrect, inspect pedal assembly for missing, worn or damaged bushings or for loose attaching bolts. Ensure firewall is

not distorted and pedal is not bent. If pedal height is still not within specifications, check brake pedal, booster or master cylinder for

correct and/or correctly installed parts

BRAKE PEDAL FREE PLAY (FESTIVA)

Pump brake pedal several to bleed vacuum from power brake booster. Gently depress brake pedal by hand and measure and measure play

before resistance is felt. Free play should be .16-.28" (4-7 mm). If free play is not within specifications, adjust brake pedal push rod.

BRAKE PEDAL FLOOR CLEARANCE

Capri

1. Move carpet and insulation away from floor board and brake pedal. With engine running and using Brake Pedal Effort Gauge (021-

00001), apply 132 lbs. (59.9 kg) of force to brake pedal. Measure distance from upper surface of brake pedal pad to floor board. If

distance is less than 3.27" (83 mm), inspect pedal assembly for missing, worn or damaged bushings or for loose attaching bolts.

2. Verify that floor board is not distorted and pedal is not bent. If pedal height is still not within specifications, check brake pedal, booster

or master cylinder for correct and/or correctly installed parts. Check for air in hydraulic system.

Festiva

Move carpet and insulation away from floor board and brake pedal. Using Brake Pedal Effort Gauge (021-00001) or equivalent, apply 132

lbs. (59.9 kg) of force to brake pedal. Measure distance from upper surface of brake pedal pad to floor board. If distance is less than 2.68" (68

mm), check for air in hydraulic system, faulty automatic adjusters or excessive shoe clearance.

POWER BRAKE UNIT PUSH ROD

Capri

ApplicationSequence

CapriRR, LF, LR & RF

FestivaRR, LR, RF & LF

NOTE:Check fluid level in m aster cylinder frequently during the bleeding sequence.

Page 1 of 12 MITCHELL 1 ARTICLE - BRAKE SYSTEM 1991-92 BRAKES Disc & Drum

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 102 of 454

levels to proper level.

Removal (1.6L & 1.6L Turbo)

1. Relieve fuel pressure and discharge air conditioning system (if equipped). See FUEL PRESSURE RELEASE under REMOVAL &

INSTALLATION. Disconnect and remove battery, battery tray and battery tray support bracket.

2. Release wiring harness retaining straps from battery support tray. Disconnect windshield washer supply hose between fluid reservoir and

hood. Mark hinge locations and remove hood.

3. Disconnect intake air tube and wiring to ignition coil and vane airflow meter. Remove air cleaner/vane airflow meter assembly. Remove

air cleaner assembly support brackets. Disconnect intercooler hoses from turbocharger (if equipped).

4. Drain engine coolant and remove radiator. Disconnect accelerator cable, and remove retaining bracket from cam cover. Position cable to

one side.

5. Disconnect and plug fuel lines at fuel filter and pressure regulator. Disconnect power brake booster manifold vacuum hose from

manifold. Disconnect heater hoses at heater core tubes. Label and remove vacuum hoses located at throttle body.

6. For manual transaxle turbocharged vehicles, disconnect clutch cable and remove support bracket and cable from transmission. On non-

turbo vehicles, disconnect clutch slave hydraulic line. For automatic transaxle, remove transaxle cooler lines.

7. Disconnect starter wiring at starter. Remove harness from locating strap on bracket. Disconnect alternator wiring. Disconnect wiring

from engine coolant sensors located on rear of engine block. Remove ground connection at bracket on thermostat cover. Disconnect O2

sensor wire, main wiring harness connector, TPS connector (turbocharged only), knock sensor connector, distributor wiring and

transaxle wiring. Disconnect ground wire and strap at front of engine, and reinstall lifting eye.

8. Remove engine oil dipstick and retaining clip. Remove power steering pump from mounting bracket. Remove power steering pump

mounting bracket. With hoses attached, position pump aside. Remove upper air conditioning compressor retaining bolts (if equipped).

9. Raise vehicle on hoist. Drain engine oil and cooling system. On vehicles with air conditioning, remove lower air conditioning

compressor mounting bolts, and position compressor out of way.

10. Remove front wheels and tires. Remove front ball joints-to-ste e r in g kn u c kl e s r e t a in in g b o l t s. R e mo ve sp l a sh gu a r d s. Dr a in t ransmission

oil and remove half shafts from differential. Remove front exhaust pipe bracket located on lower side of engine. Disconnect front

exhaust pipe from exhaust manifold, or turbocharger (if equipped).

11. Remove frame support bar-to-engine support bolt. Loosen right control arm bolt and, pivot support bar downward. Disengage rubber

exhaust hangers located directly behind catalytic converter. Allow exhaust system to hang down 6 inches, and support system with

mechanic's wire. Unbolt shift linkage and stabilizer bar at transaxle. Remove nuts from front and rear engine mounts, and lower vehicle.

12. Attach chains onto lift eyes at ends of cylinder head, and support engine with hoist. Remove RH engine mount through bolt. Raise

engine off mounts and slightly pivot engine/transaxle assembly. Disconnect oil pressure sensor and route starter/alternator wiring

harness from engine. Carefully lift engine/transaxle assembly, turn assembly while raising to clear brake master cylinder, shift linkage

universal joint, radiator support and air conditioning lines (if equipped).

13. Remove intake manifold support bracket. Remove gusset plate(s) (if equipped). Remove starter. Remove transaxle-to-engine retaining

bolts. Identify bolts to ensure correct installation. Separate transaxle from engine. On manual transaxle, remove pressure plate, clutch

disc and flywheel. On automatic transaxle, remove flexplate.

Installation (1.6L & 1.6L Turbo)

1. Install transaxle to engine in reverse order of removal. Attach hoist to engine/transaxle assembly and position assembly in vehicle.

Before engine contacts mounts, route starter, alternator and oil pressure sensor wiring, and connect oil pressure sensor. Lower engine

until front mount seats on crossmember. Install through bolt on RH engine mount. DO NOT tighten bolt.

2. Remove hoist. Raise vehicle and support with jackstands. Align rear engine mount to crossmember, and install retaining nuts to front

and rear engine mounts. Tighten nuts to specification. See TORQUE SPECIFICATIONS

table at end of article.

3. On manual transaxles, connect shift coupling and stabilizer. Tighten to specification. On automatic transaxles, connect shift linkage and

oil cooler lines. Tighten linkage retaining bolt, shift cable pivot and oil cooler hose clamps to specification. Connect front exhaust pipe

to manifold (or turbocharger). Install exhaust pipe to support bracket. Tighten bolts to specification. Tighten manifold (or turbocharger)

to specification. Attach rubber exhaust hangers. Position cross brace. Tighten retaining nut and bolt and right control arm front bolt.

4. Install drive axles. Install ball joint retaining bolts and tighten to specification. Mount A/C Compressor to engine (if equipped). Tighten

lower retaining bolts to specification. Install splash guards. Install tire and wheel assemblies. Tighten retaining nuts to specification.

5. Lower vehicle. Install upper A/C compressor retaining bolts (if equipped). Tighten bolts to specification. Tighten RH engine mo u n t

through bolt to specification. Connect alternator wiring.

6. Position power steering pump bracket on stud. Lower pump into engine compartment. Install power steering pump bracket retaining

bolts and nut. Tighten to specification. Install power steering pump and belt. Tighten adjustment nut and pivot bolt to specification.

7. Install engine oil dipstick and retaining clip. Install ground strap and ground wire to cylinder head. Install clutch cable (if equipped).

Connect clutch hydraulic line if equipped with manual transaxle or naturally aspirated. Connect transmission electrical connectors.

Connect fuel lines to fuel filter and pressure regulator. Install intake air tube to throttle body.

8. Install intercooler hoses on turbocharged models. Install air cleaner assembly brackets. Install air cleaner assembly with airflow meter

attached. Install intake air tube. Install coil and airflow meter connectors. Connect coolant crankcase and air bypass hoses. Install

vacuum hoses as noted in disassembly.

9. Connect accelerator cable. Install retaining bracket. Install power brake booster hose. Remove speedometer cable from transaxle. Fill

transaxle to specification. See CAPACITIES in SERVICE & ADJUSTMENT SPECIFICATIONS article. Install speedometer cable.

Connect speedometer cable connector. Fill engine oil to capacity.

10. Install radiator/fan assembly. Tighten bracket retaining bolts to specification. Connect coolant hoses and fan electrical connector. Fill

coolant to specification.

11. Install hood and connect washer hose. Install battery tray support, battery tray, battery and battery hold-down. Connect battery

terminal. Evacuate and charge air conditioning system (if equipped). Road test vehicle and inspect for leaks.

INTAKE MANIFOLD

Removal (1.3L)

CAUT ION: DO NOT allow com pressor to hang by hoses. T ie up com pressor with m echanic's wire.

Page 2 of 19 MITCHELL 1 ARTICLE - ENGINE OVERHAUL 1991-92 FORD MOTOR CO. ENGINES 1.3L & 1.6L 4-Cylinder

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 200 of 454

ASCS

Air Suction Control Solenoid

ASD

Auto Shutdown

ASDM

Air Bag System Diagnostic Module

ASV

Air Suction Valve

A/T

Automatic Transmission/Transaxle

ATC

Automatic Temperature Control

ATDC

After Top Dead Center

ATF

Automatic Transmission Fluid

ATS

Air Temperature Sensor

Aux.

Auxiliary

Avg.

Average

AXOD

Automatic Transaxle Overdrive (Ford Models Only)

"B"

BAC

By-Pass Air Control

BAP

Barometric Absolute Pressure Sensor

BARO

Barometric

Batt.

Battery

Bbl.

Barrel (Example: 4-Bbl.)

BCM

Body Control Module

BHP

Brake Horsepower

BMAP

Page 2 of 15 MITCHELL 1 ARTICLE - GENERAL INFORMATION Commonly Used Abbreviations

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 409 of 454

Back To Article

1988-94 AUT OMAT IC T RANSMISSIONS

Ford ATX Overhaul

APPLICATION

APPLICATION

DESCRIPTION

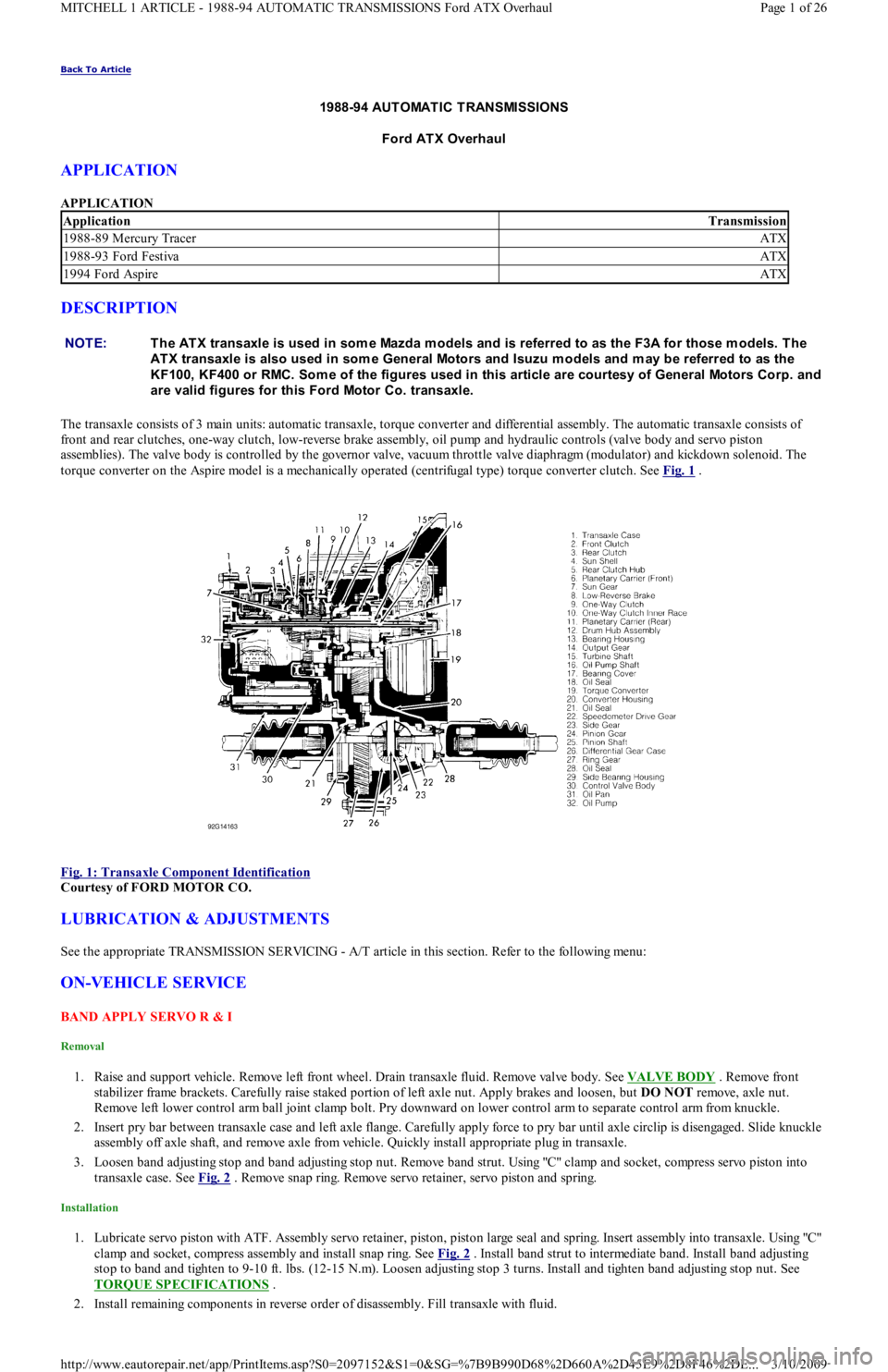

The transaxle consists of 3 main units: automatic transaxle, torque converter and differential assembly. The automatic transaxle consists of

front and rear clutches, one-way clutch, low-reverse brake assembly, oil pump and hydraulic controls (valve body and servo piston

assemblies). The valve body is controlled by the governor valve, vacuum throttle valve diaphragm (modulator) and kickdown solenoid. The

torque converter on the Aspire model is a mechanically operated (centrifugal type) torque converter clutch. See Fig. 1

.

Fig. 1: Transaxle Component Identification

Courtesy of FORD MOTOR CO.

LUBRICATION & ADJUSTMENTS

See the appropriate TRANSMISSION SERVICING - A/T article in this section. Refer to the following menu:

ON-VEHICLE SERVICE

BAND APPLY SERVO R & I

Removal

1. Raise and support vehicle. Remove left front wheel. Drain transaxle fluid. Remove valve body. See VALVE BODY . Remove front

stabilizer frame brackets. Carefully raise staked portion of left axle nut. Apply brakes and loosen, but DO NOT remove, axle nut.

Remove left lower control arm ball joint clamp bolt. Pry downward on lower control arm to separate control arm from knuckle.

2. Insert pry bar between transaxle case and left axle flange. Carefully apply force to pry bar until axle circlip is disengaged. Slide knuckle

assembly off axle shaft, and remove axle from vehicle. Quickly install appropriate plug in transaxle.

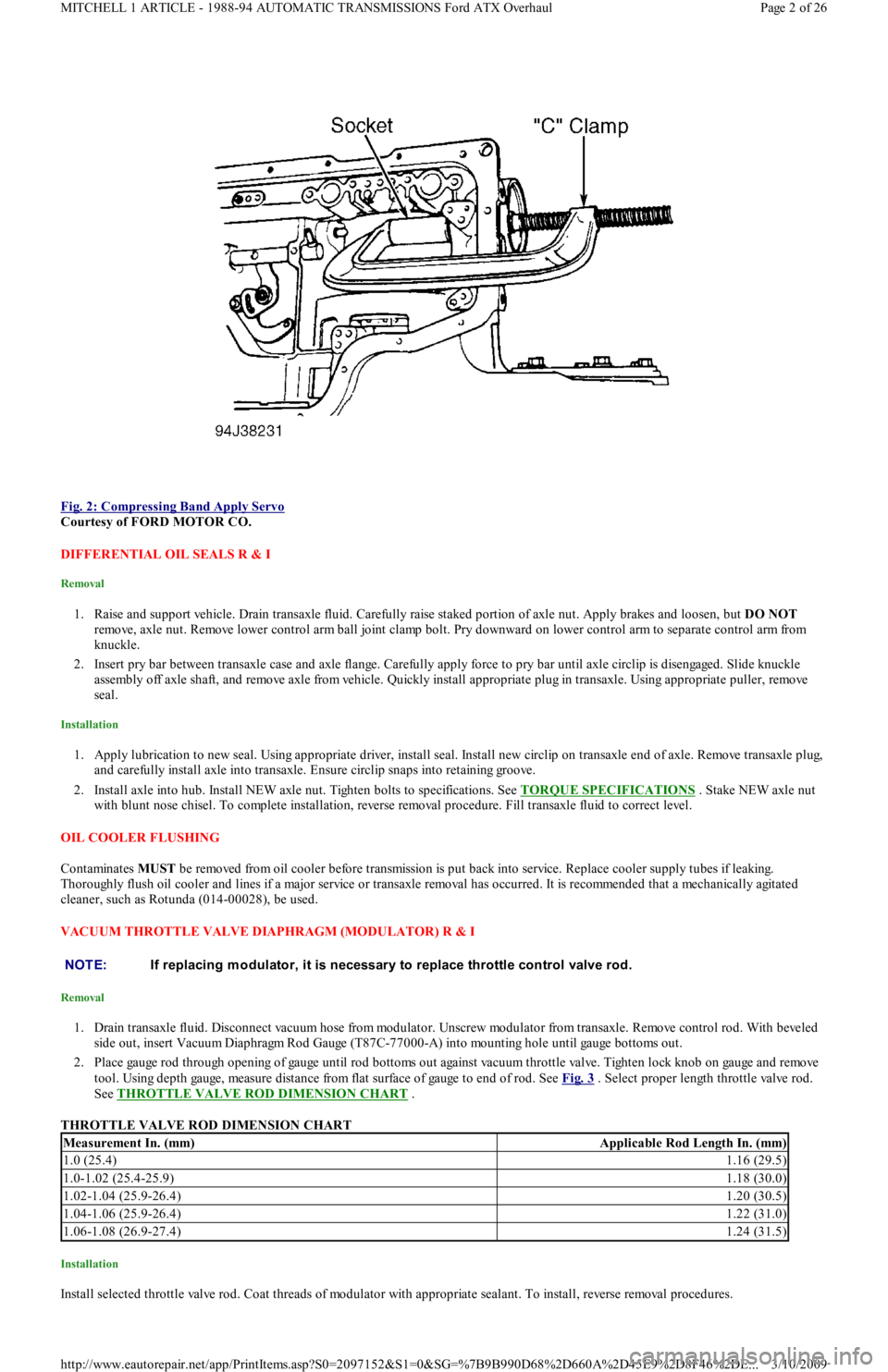

3. Loosen band adjusting stop and band adjusting stop nut. Remove band strut. Using "C" clamp and socket, compress servo piston into

transaxle case. See Fig. 2

. Remove snap ring. Remove servo retainer, servo piston and spring.

Installation

1. Lubricate servo piston with ATF. Assembly servo retainer, piston, piston large seal and spring. Insert assembly into transaxle. Usin g "C"

clamp and socket, compress assembly and install snap ring. See Fig. 2

. Install band strut to intermediate band. Install band adjusting

stop to band and tighten to 9-10 ft. lbs. (12-15 N.m). Loosen adjusting stop 3 turns. Install and tighten band adjusting stop nut. See

TORQUE SPECIFICATIONS

.

2. Install remaining components in reverse order of disassembly. Fill transaxle with fluid.

ApplicationTransmission

1988-89 Mercury TracerATX

1988-93 Ford FestivaATX

1994 Ford AspireATX

NOTE:T he AT X transaxle is used in som e Mazda m odels and is referred to as the F3A for those m odels. T he

AT X transaxle is also used in som e General Motors and Isuzu m odels and m ay be referred to as the

KF100, KF400 or RMC. Som e of the figures used in this article are courtesy of General Motors Corp. and

are valid figures for this Ford Motor Co. transaxle.

Page 1 of 26 MITCHELL 1 ARTICLE - 1988-94 AUTOMATIC TRANSMISSIONS Ford ATX Overhaul

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 410 of 454

Fig. 2: Compressing Band Apply Servo

Courtesy of FORD MOTOR CO.

DIFFERENTIAL OIL SEALS R & I

Removal

1. Raise and support vehicle. Drain transaxle fluid. Carefully raise staked portion of axle nut. Apply brakes and loosen, but DO NOT

remove, axle nut. Remove lower control arm ball joint clamp bolt. Pry downward on lower control arm to separate control arm from

knuckle.

2. Insert pry bar between transaxle case and axle flange. Carefully apply force to pry bar until axle circlip is disengaged. Slide knuckle

assembly off axle shaft, and remove axle from vehicle. Quickly install appropriate plug in transaxle. Using appropriate puller, remove

seal.

Installation

1. Apply lubrication to new seal. Using appropriate driver, install seal. Install new circlip on transaxle end of axle. Remove transaxle plug,

and carefully install axle into transaxle. Ensure circlip snaps into retaining groove.

2. Install axle into hub. Install NEW axle nut. Tighten bolts to specifications. See TORQUE SPECIFICATIONS

. Stake NEW axle nut

with blunt nose chisel. To complete installation, reverse removal procedure. Fill transaxle fluid to correct level.

OIL COOLER FLUSHING

Contaminates MUST be removed from oil cooler before transmission is put back into service. Replace cooler supply tubes if leaking.

Thoroughly flush oil cooler and lines if a major service or transaxle removal has occurred. It is recommended that a mechanically agitated

cleaner, such as Rotunda (014-00028), be used.

VACUUM THROTTLE VALVE DIAPHRAGM (MODULATOR) R & I

Removal

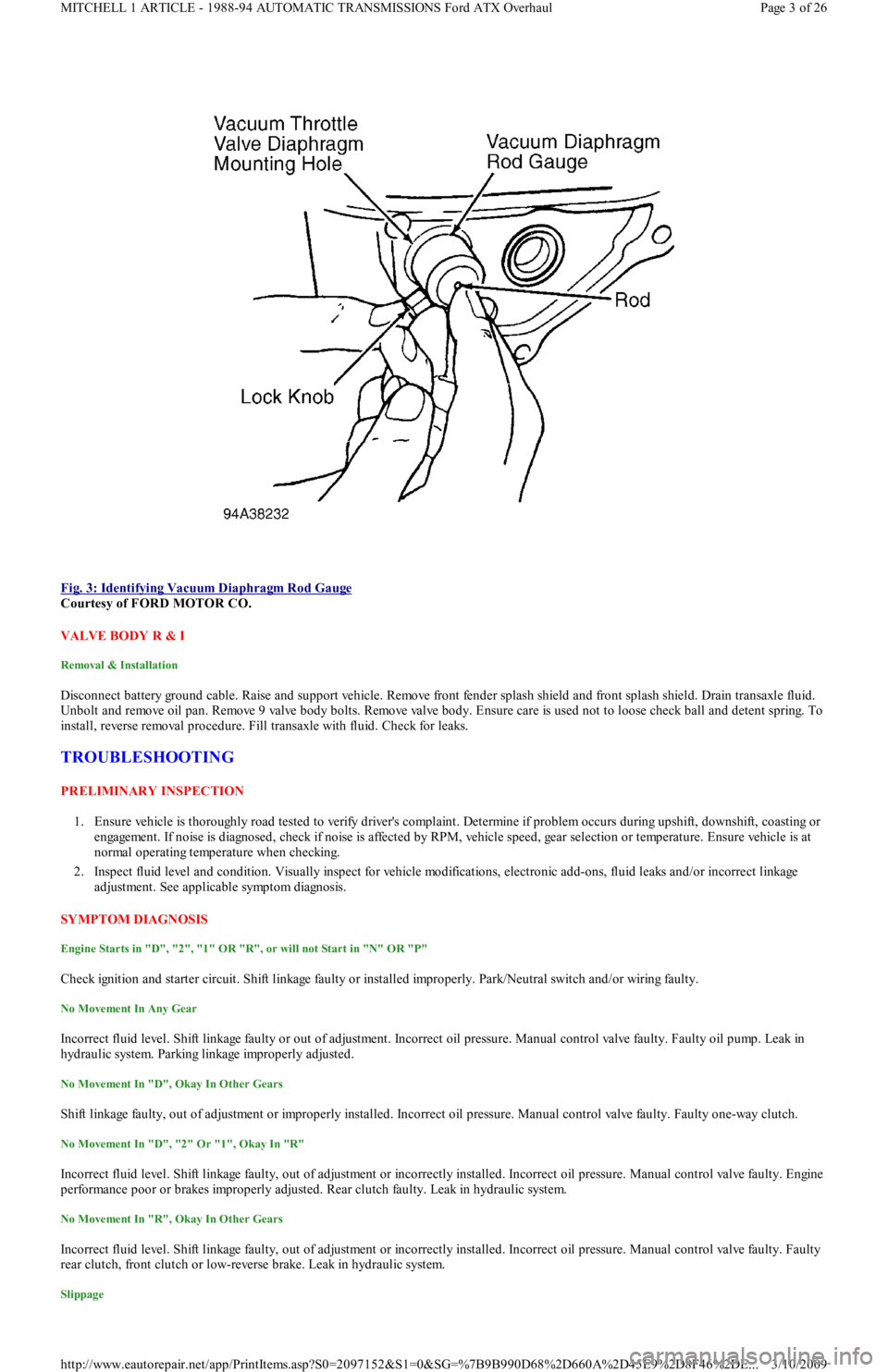

1. Drain transaxle fluid. Disconnect vacuum hose from modulator. Unscrew modulator from transaxle. Remove control rod. With beveled

side out, insert Vacuum Diaphragm Rod Gauge (T87C-77000-A) into mounting hole until gauge bottoms out.

2. Place gauge rod through opening of gauge until rod bottoms out against vacuum throttle valve. Tighten lock knob on gauge and remove

tool. Using depth gauge, measure distance from flat surface of gauge to end of rod. See Fig. 3

. Select proper length throttle valve rod.

See THROTTLE VALVE ROD DIMENSION CHART

.

THROTTLE VALVE ROD DIMENSION CHART

Installation

Install selected throttle valve rod. Coat threads of modulator with appropriate sealant. To install, reverse removal procedures.

NOTE:If replacing m odulator, it is necessary to replace throttle control valve rod.

Measurement In. (mm)Applicable Rod Length In. (mm)

1.0 (25.4)1.16 (29.5)

1.0-1.02 (25.4-25.9)1.18 (30.0)

1.02-1.04 (25.9-26.4)1.20 (30.5)

1.04-1.06 (25.9-26.4)1.22 (31.0)

1.06-1.08 (26.9-27.4)1.24 (31.5)

Page 2 of 26 MITCHELL 1 ARTICLE - 1988-94 AUTOMATIC TRANSMISSIONS Ford ATX Overhaul

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 411 of 454

Fig. 3: Identifying Vacuum Diaphragm Rod Gauge

Courtesy of FORD MOTOR CO.

VALVE BODY R & I

Removal & Installation

Disconnect battery ground cable. Raise and support vehicle. Remove front fender splash shield and front splash shield. Drain transaxle fluid.

Unbolt and remove oil pan. Remove 9 valve body bolts. Remove valve body. Ensure care is used not to loose check ball and detent spring. To

install, reverse removal procedure. Fill transaxle with fluid. Check for leaks.

TROUBLESHOOTING

PRELIMINARY INSPECTION

1. Ensure vehicle is thoroughly road tested to verify driver's complaint. Determine if problem occurs during upshift, downshift, coasting or

engagement. If noise is diagnosed, check if noise is affected by RPM, vehicle speed, gear selection or temperature. Ensure vehicle is at

normal operating temperature when checking.

2. Inspect fluid level and condition. Visually inspect for vehicle modifications, electronic add-ons, fluid leaks and/or incorrect linkage

adjustment. See applicable symptom diagnosis.

SYMPTOM DIAGNOSIS

Engine Starts in "D", "2", "1" OR "R", or will not Start in "N" OR "P"

Check ignition and starter circuit. Shift linkage faulty or installed improperly. Park/Neutral switch and/or wiring faulty.

No Movement In Any Gear

Incorrect fluid level. Shift linkage faulty or out of adjustment. Incorrect oil pressure. Manual control valve faulty. Faulty oil pump. Leak in

hydraulic system. Parking linkage improperly adjusted.

No Movement In "D", Okay In Other Gears

Shift linkage faulty, out of adjustment or improperly installed. Incorrect oil pressure. Manual control valve faulty. Faulty one-way clutch.

No Movement In "D", "2" Or "1", Okay In "R"

Incorrect fluid level. Shift linkage faulty, out of adjustment or incorrectly installed. Incorrect oil pressure. Manual control valve faulty. Engine

performance poor or brakes improperly adjusted. Rear clutch faulty. Leak in hydraulic system.

No Movement In "R", Okay In Other Gears

Incorrect fluid level. Shift linkage faulty, out of adjustment or incorrectly installed. Incorrect oil pressure. Manual control valve faulty. Faulty

rear clutch, front clutch or low-reverse brake. Leak in hydraulic system.

Slippage

Page 3 of 26 MITCHELL 1 ARTICLE - 1988-94 AUTOMATIC TRANSMISSIONS Ford ATX Overhaul

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 412 of 454

ATF level incorrect or contaminated. Manual valve out of adjustment. Vacuum modulator faulty or leak in vacuum circuit. Fluid pressures

incorrect. Oil pump faulty. Leak in hydraulic circuit.

Vehicle Creeps In "N" Position

Shift linkage faulty, out of adjustment or incorrectly installed. Manual control valve faulty. Contaminated fluid. Faulty rear clutch.

Vehicle Creeps Excessively

Engine idle speed too high.

Vehicle Will Not Creep

Fluid level incorrect or fluid contaminated. Shift linkage faulty, out of adjustment or incorrectly installed. Engine idle too low. Manual

control valve faulty. Faulty oil pump. Leak in hydraulic system. Faulty front or rear clutch.

Low Maximum Speed & Poor Acceleration

Incorrect ATF level or contaminated fluid. Selector linkage out of adjustment. Engine stall speed incorrect. Poor engine performance. Brake

band faulty or out of adjustment. Faulty low-reverse brake, front clutch, rear clutch or hydraulic circuit.

Harsh "N" To "D" Engagement

Engine idle too high. Leak in vacuum circuit. Incorrect oil pressure. Manual control valve faulty. Faulty rear clutch. Low fluid level.

Harsh 1-2 Shift

Leak in vacuum circuit. Engine stall speed incorrect. Contaminated fluid. Manual control valve faulty. Band servo faulty. Brake band damaged

or out of adjustment.

Harsh 2-3 Shift

Leak in vacuum circuit. Incorrect oil pressure. Manual control valve faulty. Band servo or front clutch faulty. Brake band faulty.

Shift Shock Felt On Kickdown Downshift

Shift linkage damaged, out of adjustment or incorrectly installed. Leak in vacuum circuit. Kickdown solenoid, switch or wiring fau l t y.

Incorrect oil pressure. Manual control valve or governor valve faulty. Leak in hydraulic system.

2-1 Shift Shock With Lever In "1" Position

Leak in vacuum circuit. Engine stall speed incorrect. Manual control valve faulty. Contaminated fluid. Low-reverse brake faulty. Line pressure

high.

Shift Shock On Deceleration

Range selector out of adjustment. Vacuum diaphragm or piping faulty. Kickdown solenoid out of adjustment or faulty. Excessive line pressure.

M a n u a l va l ve fa u l t y. Go ve r n o r va l ve fa u l t y.

Vehicle Brakes In "R" Position

Band servo faulty. Contaminated fluid. Faulty rear clutch. Brake band damaged or out of adjustment. Parking linkage damaged or improperly

adjusted.

Vehicle Brakes On 1-2 Shift

Manual control valve faulty. Contaminated fluid. Front clutch or low-reverse brake faulty. One-way clutch faulty.

Vehicle Brakes On 2-3 Shift

Manual control valve faulty. Band servo faulty. Contaminated fluid. Brake band out of adjustment or damaged.

No Engine Braking In "1" Position

Shift linkage damaged, out of adjustment or installed incorrectly. Incorrect oil pressure. Manual control valve faulty. Contaminated fluid.

Low-reverse brake faulty. Leak in hydraulic system.

No Shift Shock; Slippage On 1-2 Shift

Incorrect fluid level. Shift linkage damaged, out of adjustment or incorrectly installed. Leak in vacuum circuit. Oil pressure incorrect. Manual

control valve faulty. Band servo faulty. Contaminated fluid. Brake band faulty. Leakage in hydraulic system.

No Shift Shock; Slippage When Manually Shifted From "1" To "2" Position

Incorrect fluid level. Shift linkage damaged, out of adjustment or installed incorrectly. Leak in vacuum circuit. Engine idle speed incorrect.

Engine stall speed incorrect. Manual control valve faulty. Contaminated fluid. Brake band out of adjustment or damaged. Oil pump faulty.

No Shift Shock; Slippage On 2-3 Shift

ATF contaminated or level incorrect. Shift linkage faulty. Vacuum modulator faulty or leak in vacuum circuit. Line pressure not correct. Band

servo faulty. Front clutch faulty. Leak in hydraulic system.

Slippage On 3-2 Kickdown

Page 4 of 26 MITCHELL 1 ARTICLE - 1988-94 AUTOMATIC TRANSMISSIONS Ford ATX Overhaul

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 413 of 454

Leak in vacuum circuit. Oil pressure incorrect. Manual valve faulty. Band servo faulty. Contaminated fluid. Front clutch faulty. Brake band

out of adjustment or damaged. Leak in hydraulic system.

Transaxle Slips In 1st Gear

Incorrect fluid level. Shift linkage faulty, out of adjustment or incorrectly installed. Incorrect oil pressure. Manual control valve faulty.

Contaminated fluid. Incorrect idle speed. Faulty kickdown solenoid, switch or wiring.

No 1-2 Shift

Shift linkage defective, out of adjustment or incorrectly installed. Leak in vacuum circuit. Faulty kickdown solenoid, switch or wiring.

Contaminated fluid. Manual control valve faulty. Governor valve faulty. Band servo faulty. Brake band out of adjustment. Leak in hydraulic

system. Rear clutch faulty.

No 2-3 Shift

Shift linkage defective, out of adjustment or incorrectly installed. Leak in vacuum circuit. Faulty kickdown solenoid, switch or wiring.

Contaminated fluid. Manual control valve, governor valve or band servo faulty. Leak in hydraulic system. Front clutch faulty.

No Lock-Up

Faulty torque converter, wiring or solenoid.

1-3 Shift; Skips 2nd

Contaminated fluid. Brake band out of adjustment or damaged. Leak in hydraulic system.

No 3-2 Downshift

Leak in vacuum circuit. Manual control valve, governor valve or band servo faulty. Contaminated fluid. Faulty front clutch. Brake band out of

adjustment of damaged. Leak in hydraulic system.

No 2-1 or 3-1 Downshift

Leak in vacuum circuit. Manual control valve, governor valve or band servo faulty. Contaminated fluid. Brake band out of adjustmen t o r

damaged. One-way clutch faulty.

Slippage When Accelerating In 3rd Gear Above Kickdown Speed

Shift linkage damaged, out of adjustment or installed incorrectly. Leak in vacuum circuit. Oil pressure incorrect. Manual control valve or

governor valve faulty. Contaminated fluid. Front clutch faulty. Leak in hydraulic system.

No Kickdown At Normal Speeds In 3rd Gear

Leak in vacuum circuit. Kickdown solenoid, switch or wiring faulty. Manual control valve or governor valve faulty. Contaminated fluid. Brake

band out of adjustment or damaged. Leak in hydraulic system.

1-2 & 2-3 Shift Points Too High

ATF contaminated or level incorrect. Vacuum modulator faulty or leak in vacuum circuit. Line pressures incorrect. Manual valve out of

adjustment. Governor valve faulty. Hydraulic circuit leaking.

3-2 & 2-1 Shift Points Too High

Shift linkage damaged, out of adjustment or incorrectly installed. Kickdown solenoid, switch or wiring faulty. Leak in vacuum circuit.

Incorrect oil pressure. Manual control valve or governor valve faulty. Leak in hydraulic system.

1-2 Or 2-3 Shifts With Shift Lever In "1" Position

Shift linkage damaged, out of adjustment or installed incorrectly. Manual control valve faulty. Leak in hydraulic system.

2-1 or 2-3 Shifts With Shift Lever In "2" Position

Shift linkage damaged, out of adjustment or installed incorrectly. Incorrect oil pressure. Manual control valve faulty.

Vehicle Moves In "P" Or Parking Gear Remains Engaged When

Shifted Out Of "P" Position

Shift linkage damaged, out of adjustment or incorrectly installed. Parking linkage out of adjustment or damaged.

Transaxle Noisy In "P" Or "N" Position

Incorrect fluid level. Incorrect oil pressure. Faulty rear clutch, oil pump, one-way clutch or planetary gear.

Transaxle Noisy In "D", "1", "2" or "R"

Oil pressure incorrect. Rear clutch, oil pump, one-way clutch or planetary gears faulty.

Transmission Overheats

ATF level incorrect. Engine stall speed and/or line pressure incorrect. Faulty band servo, front clutch, rear clutch, brake band, low-reverse

brake, oil pump, torque converter or planetary gear. Leak in hydraulic circuit.

Page 5 of 26 MITCHELL 1 ARTICLE - 1988-94 AUTOMATIC TRANSMISSIONS Ford ATX Overhaul

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 416 of 454

See STALL SPEED SPECIFICATIONS .

Testing Procedures

1. With engine at normal operating temperature, tachometer installed and parking and service brakes applied, perform transaxle stall test in

"D", "2", "1" and "R" ranges at full throttle and note maximum RPM obtained. Correct stall speed should occur at specified RPM. See

the STALL SPEED SPECIFICATIONS

.

STALL SPEED SPECIFICATIONS

2. If stall speed is too high in all shift ranges, the following components may be faulty:

Worn Oil Pump.

Oil leakage from oil pump, valve body or transaxle case.

Sticking pressure regulator valve.

3. If stall speed is too high in "D", "2" and "1", the following component may be faulty:

Slipping rear clutch.

4. If stall speed is too high in "D", the following component may be faulty:

Slipping one-way clutch.

5. If stall speed is too high in "2", the following components may be faulty:

Slipping intermediate band.

6. If stall speed is too high in "R", the following components may be faulty:

Slipping Low/Reverse Clutch.

Slipping Front Clutch.

7. If stall speed is too low in all shift ranges, the following components may be faulty:

Slipping torque converter one-way clutch.

ROAD TEST

1. Before road test, ensure that fluid level, fluid condition and control linkage adjustments are okay. During test, transaxle should upshift

or downshift at about same speed as specified. See appropriate SHIFT SPEED SPECIFICATIONS

.

2. All shifts may vary slightly due to production tolerances or tire size. The quality of the shifts are more important. All shifts should be

smooth, responsive and with no slippage or engine flare. Slippage or engine flare in any gear usually indicates clutch or band problems.

3. The slipping clutch or band in a particular gear can usually be identified by noting transaxle operation in other selector positions and

comparing internal units which are applied in these positions. See CLUTCH & BAND APPLICATION

.

SHIFT SPEED SPECIFICATIONS

VEHICLE SHIFT SPEED SPECIFICATIONS (ASPIRE & FESTIVA)

VEHICLE SHIFT SPEED SPECIFICATIONS (TRACER)

ApplicationEngine RPM

Aspire2300-2500

Festiva & Tracer2300-2500

Operating Condition (1) Shift Speed MPH (km/h)

Half Throttle (50%)

1-29-17 (15-28)

2-316-34 (26-55)

Full Throttle (WOT) (2)

1-228-33 (44-53)

2-355-63 (88-101)

3-253-48 (86-78)

2-124-22 (39-35)

Coasting (2-1)9-6 (14-9)

(1)Transmission is in "D" range.

(2)To determine deceleration shift speeds, release throttle once transaxle has shifted into 3rd gear. Manually downshift shift lever

into next lower gear and record speed at which downshift occurs. Continue downshifting and recording vehicle speed until

transaxle has downshifted into low gear.

Operating Condition (1) Shift Speed MPH

Half Throttle (50%)

1-2 - Carbureted10-19

1-2 - EFI12-21

2-3 - Carbureted17-37

2-3 - EFI37-48

Full Throttle (WOT)

1-230-36

2-360-68

3-253-58

2-124-26

Fully Closed Throttle

Fro m "D" Ran ge (3 -1 )6-9

Page 8 of 26 MITCHELL 1 ARTICLE - 1988-94 AUTOMATIC TRANSMISSIONS Ford ATX Overhaul

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 417 of 454

CLUTCH & BAND APPLICATION

CLUTCH & BAND APPLICATION CHART

HYDRAULIC PRESSURE TESTS

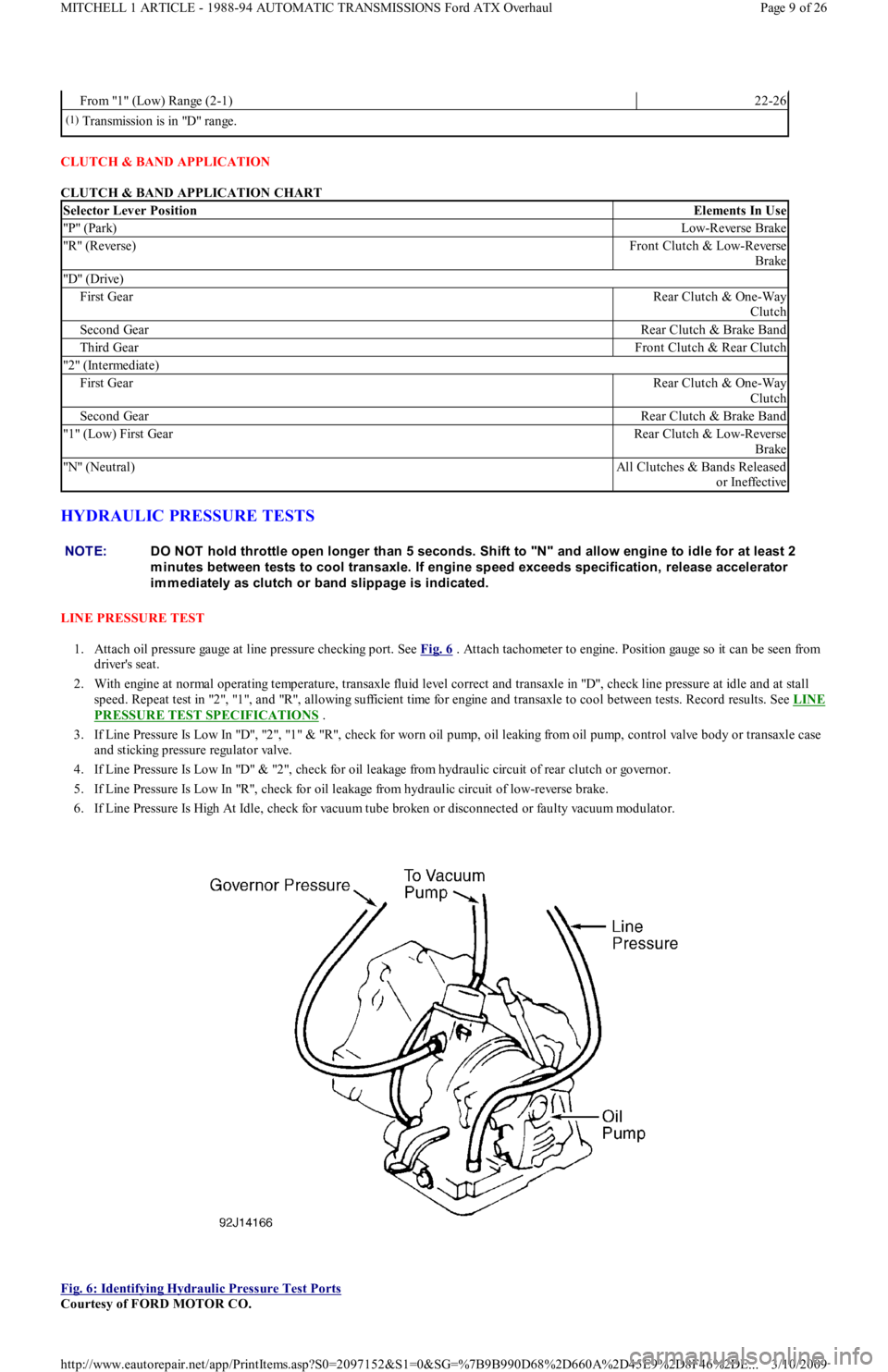

LINE PRESSURE TEST

1. Attach oil pressure gauge at line pressure checking port. See Fig. 6

. Attach tachometer to engine. Position gauge so it can be seen from

driver's seat.

2. With engine at normal operating temperature, transaxle fluid level correct and transaxle in "D", check line pressure at idle and at stall

sp eed . Rep eat t est in "2 ", "1 ", an d "R", al l o win g su fficien t t ime for engine and transaxle to cool between tests. Record results. See LINE

PRESSURE TEST SPECIFICATIONS .

3 . If Lin e Pressu re Is Lo w In "D", "2 ", "1 " & "R", ch eck fo r worn oil pump, oil leaking from oil pump, control valve body or transaxle case

and sticking pressure regulator valve.

4. If Line Pressure Is Low In "D" & "2", check for oil leakage from hydraulic circuit of rear clutch or governor.

5. If Line Pressure Is Low In "R", check for oil leakage from hydraulic circuit of low-reverse brake.

6. If Line Pressure Is High At Idle, check for vacuum tube broken or disconnected or faulty vacuum modulator.

Fig. 6: Identifying Hydraulic Pressure Test Ports

Courtesy of FORD MOTOR CO.

From "1" (Low) Range (2-1)22-26

(1)Transmission is in "D" range.

Selector Lever PositionElements In Use

"P" (Park)Low-Reverse Brake

"R" (Reverse)Front Clutch & Low-Reverse

Brake

"D" (Drive)

First GearRear Clutch & One-Way

Clutch

Second GearRear Clutch & Brake Band

Third GearFront Clutch & Rear Clutch

"2" (Intermediate)

First GearRear Clutch & One-Way

Clutch

Second GearRear Clutch & Brake Band

"1" (Low) First GearRear Clutch & Low-Reverse

Brake

"N" (Neutral)All Clutches & Bands Released

o r In effect ive

NOTE:DO NOT hold throttle open longer than 5 seconds. Shift to "N" and allow engine to idle for at least 2

m inutes between tests to cool transaxle. If engine speed exceeds specification, release accelerator

im m ediately as clutch or band slippage is indicated.

Page 9 of 26 MITCHELL 1 ARTICLE - 1988-94 AUTOMATIC TRANSMISSIONS Ford ATX Overhaul

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...