mileage FORD FESTIVA 1991 Service Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1991, Model line: FESTIVA, Model: FORD FESTIVA 1991Pages: 454, PDF Size: 9.53 MB

Page 238 of 454

VACUUM PUMP - DIESEL TROUBLE SHOOTING

VACUUM PUMP (DIESEL) TROUBLE SHOOTING CHART

MANUAL TRANSMISSION

MANUAL TRANSMISSION TROUBLE SHOOTING

MANUAL TRANSMISSION/TRANSAXLE TROUBLE SHOOTING

Clogged air bleedsRemove restriction

EGR valve malfunctionReplace EGR valve

Restricted air cleaner filterReplace air filter

Cracked or broken vacuum hosesReplace vacuum hoses

Cracked or broken ignition wiresReplace ignition wires

Vacuum advance malfunctionCheck unit and replace as

necessary

Defective or fouled spark plugsReplace spark plugs

Ping or Spark Knock

Incorrect ignition timingReset ignition timing see

ENGINE PERFORMANCE

Distributor centrifugal or vacuum advance malfunctionCheck operation and replace

as necessary

Carburetor setting too leanReadjust mixture setting, see

ENGINE PERFORMANCE

Vacuum leakEliminate vacuum leak

EGR valve malfunctionReplace EGR valve

Poor Gasoline Mileage

Cracked or broken vacuumReplace vacuum hoses hoses

Vacuum leaksRepair vacuum leaks

Defective ignition wiresReplace wires

Incorrect choke settingReadjust setting, see ENGINE

PERFORMANCE

Defective vacuum advanceReplace vacuum advance

Defective spark plugsReplace spark plugs

Binding carburetor power pistonEliminate binding

Dirt in carburetor jetsClean and/or replace jets

Incorrect float adjustmentReadjust float setting, see

FUEL

Defective power valveReplace power valve, see

ENGINE PERFORMANCE

Incorrect idle speedReadjust idle speed

Engine Stalls

Improper float levelReadjust float level

Leaking needle valve and seatReplace needle valve and seat

Vacuum leaksEliminate vacuum leaks

NOTE:This is GENERAL inform ation. This article is not intended to be specific to any unique situation or

individual vehicle configuration. T he purpose of this T rouble Shooting inform ation is to provide a list

of com m on causes to problem sym ptom s. For m odel-specific T rouble Shooting, refer to SUBJECT ,

DIAGNOST IC, or T EST ING articles available in the section(s) you are accessing.

NOTE:Diesel engines m echanical diagnosis is the sam e as gasoline engines for item s such as noisy valves,

bearings, pistons, etc. T he following trouble shooting covers only item s pertaining to diesel engines.

CONDITION & POSSIBLE CAUSECORRECTION

Excessive Noise

Loose pump-to-drive assembly screwsTighten screws

Loose tube on pump assemblyTighten tube

Valves not functioning properlyReplace valves

Oil Leakage

Loose end plugTighten end plug

Bad seal crimpRemove and re-crimp

seal

NOTE:This is GENERAL inform ation. This article is not intended to be specific to any unique situation or

individual vehicle configuration. T he purpose of this T rouble Shooting inform ation is to provide a list

of com m on causes to problem sym ptom s. For m odel-specific T rouble Shooting, refer to SUBJECT ,

DIAGNOST IC, or T EST ING articles available in the section(s) you are accessing.

ConditionPossible Cause

Noisy In Forward GearsLow gear oil level, Loose bell housing bolts, Worn bearings or

gears

Clunk On Deceleration (FWD Only)Loose engine mounts, Worn inboard CV joints, Worn differential

pinion shaft, Side gear hub counterbore in case worn oversize

Page 25 of 36 MITCHELL 1 ARTICLE - GENERAL INFORMATION Trouble Shooting - Basic Procedures

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 252 of 454

Back To Article

GENERAL INFORMATION

Com puter Relearn Procedures

COMPUTER RELEARN PROCEDURES

Vehicles equipped with engine or transmission computers may require a relearn procedure after vehicle battery is disconnected. Many vehicle

computers memorize and store vehicle operation patterns for optimum driveability and performance. When vehicle battery is disconnected,

this memory is lost. The computer will use default data until new data from each key start is stored. As computer memorizes vehicle operation

for each new key start, driveability is restored. Vehicle computers may memorize vehicles operation patterns for 40 of more key starts.

Customers often complain of driveability problems during relearn stage because vehicle acts differently then before being serviced. Depending

on type and make of vehicle and how it is equipped, the following complaints (driveability problems) may exist:

Harsh Or Poor Shift Quality

Rough Or Unstable Idle

Hesitation Or Stumble

Rich Or Lean Running

Poor Fuel Mileage

These symptoms and complaints should disappear after a number of drive cycles have been memorized. To reduce the possibility of

complaints, after any service which requires battery power to be disconnected, vehicle should be road tested.

GENERIC COMPUTER RELEARN PROCEDURES

Some manufacturers identify a specific relearn procedure which will help establish suitable driveability during relearn stage. These procedures

are especially important if vehicle is equipped with and electronically controlled automatic transmission or transaxle. Always complete

procedure before returning vehicle to customer. The following general procedures are to be used if driveability problems are encountered after

power loss or battery has been disconnected. These procedures may provide an aid in eliminating these problems.

Automatic Transmission

Set parking brake, start engine in "P" or "N" position. Warm-up vehicle to normal operating temperature or until cooling fan cycles.

Allow vehicle to idle for one minute in "N" position. Select "D" and allow engine to idle for one minute.

Accelerate at normal throttle position (20-50%) until vehicle shifts into top gear.

Cruise at light to medium throttle.

Decelerate to a stop, allowing vehicle to downshift, and use brakes normally.

Process may be repeated as necessary.

Manual Transmission

Place transmission in Neutral position.

Ensure emergency brake has been set and all accessories are turned off.

Start engine and bring to normal operating temperature.

Allow vehicle to idle in Neutral for one minute.

Initial relearn is complete, and process will be completed during normal driving.

Copyr ight 2009 Mitchell Repair Information Company, LLC. All Rights Reserved.

Article GUID: A00012612

Page 1 of 1 MITCHELL 1 ARTICLE - GENERAL INFORMATION Computer Relearn Procedures

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 272 of 454

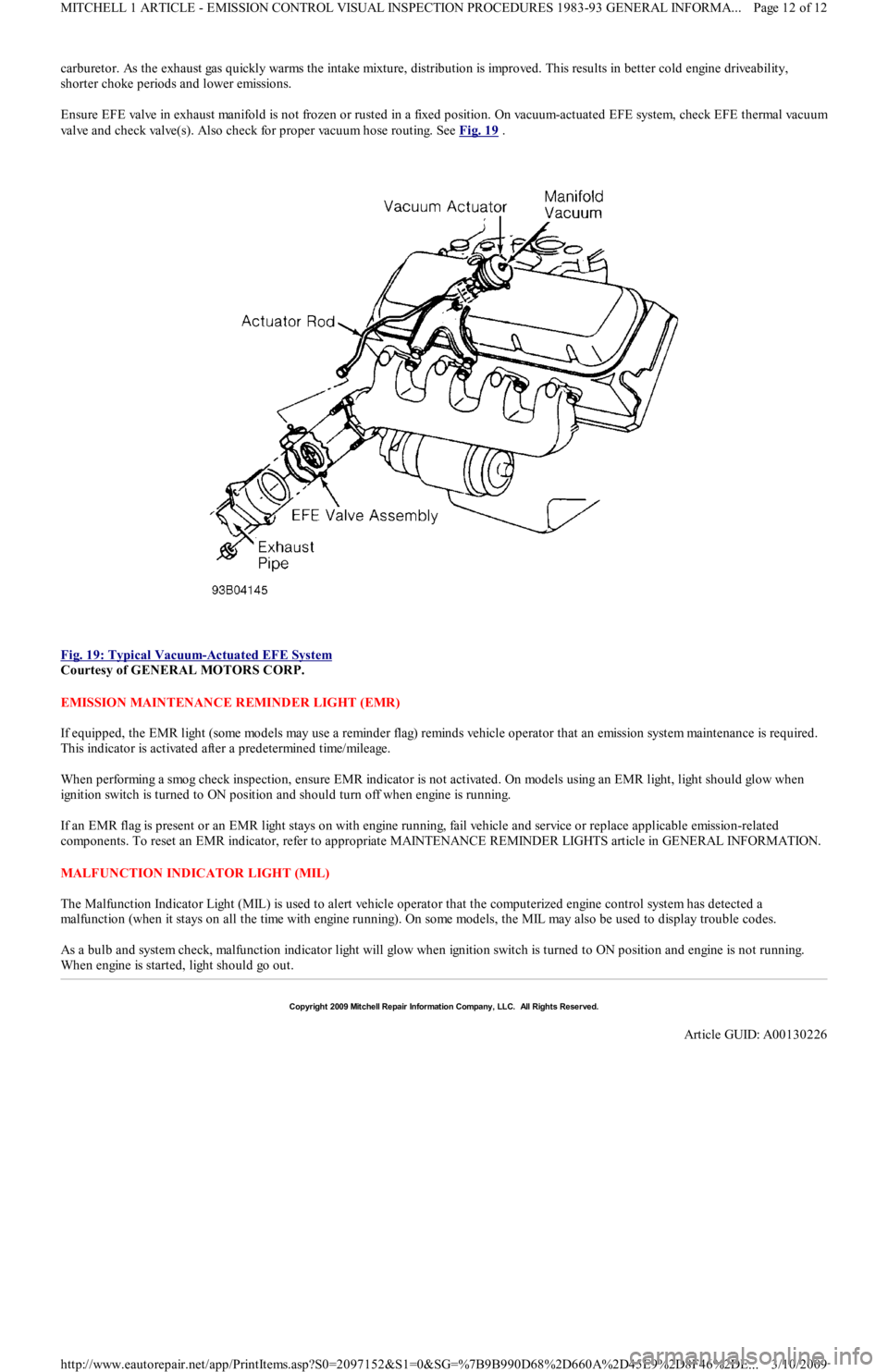

carburetor. As the exhaust gas quickly warms the intake mixture, distribution is improved. This results in better cold engine driveability,

shorter choke periods and lower emissions.

Ensure EFE valve in exhaust manifold is not frozen or rusted in a fixed position. On vacuum-actuated EFE system, check EFE thermal vacuu

m

valve and check valve(s). Also check for proper vacuum hose routing. See Fig. 19

.

Fig. 19: Typical Vacuum

-Actuated EFE System

Courtesy of GENERAL MOTORS CORP.

EMISSION MAINTENANCE REMINDER LIGHT (EMR)

If equipped, the EMR light (some models may use a reminder flag) reminds vehicle operator that an emission system maintenance is required.

This indicator is activated after a predetermined time/mileage.

When performing a smog check inspection, ensure EMR indicator is not activated. On models using an EMR light, light should glow when

ignition switch is turned to ON position and should turn off when engine is running.

If an EMR flag is present or an EMR light stays on with engine running, fail vehicle and service or replace applicable emission-related

components. To reset an EMR indicator, refer to appropriate MAINTENANCE REMINDER LIGHTS article in GENERAL INFORMATION.

MALFUNCTION INDICATOR LIGHT (MIL)

The Malfunction Indicator Light (MIL) is used to alert vehicle operator that the computerized engine control system has detected a

malfunction (when it stays on all the time with engine running). On some models, the MIL may also be used to display trouble codes.

As a bulb and system check, malfunction indicator light will glow when ignition switch is turned to ON position and engine is not running.

When engine is started, light should go out.

Copyr ight 2009 Mitchell Repair Information Company, LLC. All Rights Reserved.

Article GUID: A00130226

Page 12 of 12 MITCHELL 1 ARTICLE - EMISSION CONTROL VISUAL INSPECTION PROCEDURES 1983-93 GENERAL INFORMA...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 365 of 454

Back To Article

MAINTENANCE INFORMATION

1988-93 MAINT ENANCE Ford Motor Co. Maintenance Inform ation

MODEL IDENTIFICATION

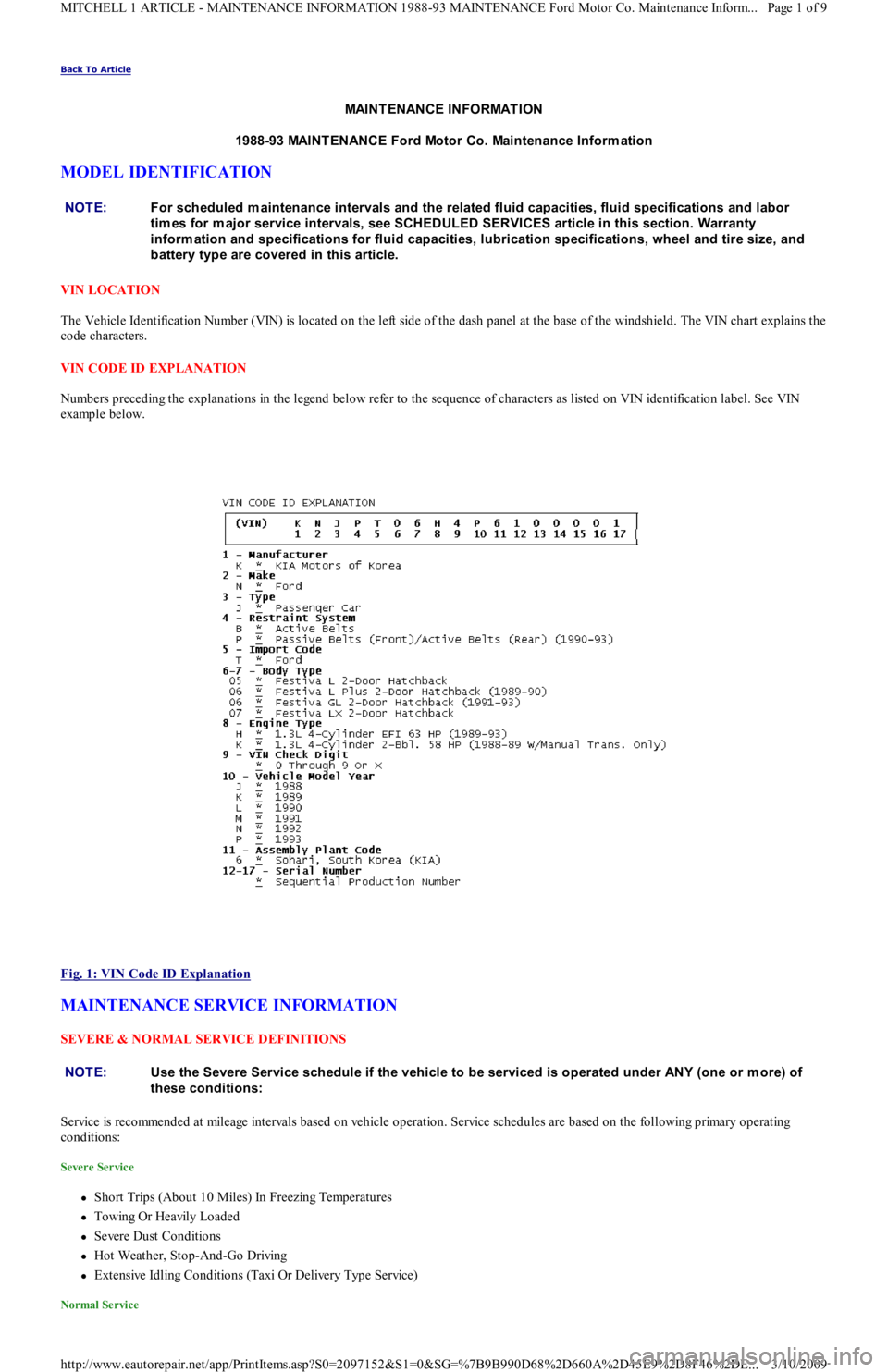

VIN LOCATION

The Vehicle Identification Number (VIN) is located on the left side of the dash panel at the base of the windshield. The VIN chart explains the

code characters.

VIN CODE ID EXPLANATION

Numbers preceding the explanations in the legend below refer to the sequence of characters as listed on VIN identification label. See VIN

example below.

Fig. 1: VIN Code ID Explanation

MAINTENANCE SERVICE INFORMATION

SEVERE & NORMAL SERVICE DEFINITIONS

Service is recommended at mileage intervals based on vehicle operation. Service schedules are based on the following primary operating

conditions:

Severe Service

Short Trips (About 10 Miles) In Freezing Temperatures

Towing Or Heavily Loaded

Severe Dust Conditions

Hot Weather, Stop-And-Go Driving

Extensive Idling Conditions (Taxi Or Delivery Type Service)

Normal Service

NOTE:For scheduled m aintenance intervals and the related fluid capacities, fluid specifications and labor

tim es for m ajor service intervals, see SCHEDULED SERVICES article in this section. Warranty

inform ation and specifications for fluid capacities, lubrication specifications, wheel and tire size, and

battery type are covered in this article.

NOTE:Use the Severe Service schedule if the vehicle to be serviced is operated under ANY (one or m ore) of

these conditions:

Page 1 of 9 MITCHELL 1 ARTICLE - MAINTENANCE INFORMATION 1988-93 MAINTENANCE Ford Motor Co. Maintenance Inform...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 366 of 454

Driven More Than 10 Miles Daily

No Operating Conditions From Severe Service Schedule

CAMSHAFT TIMING BELT

The condition of camshaft drive belts should always be checked on vehicles which have more than 50,000 miles. Although some

manufacturers do not recommend belt replacement at a specified mileage, others require it at 60,000-100,000 miles. A camshaft drive belt

failure may cause extensive damage to internal engine components on most engines, although some designs do not allow piston-to-va l ve

contact. These designs are often called "Free Wheeling".

Many manufacturers changed their maintenance and warranty schedules in the mid-1980's to reflect timing belt inspection and/or replacement

at 50,000-60,000 miles. Most service interval schedules in this manual reflect these changes.

Belts or components should be inspected and replaced if any of the following conditions exist:

Cracks Or Tears In Belt Surface

Missing, Damaged, Cracked Or Rounded Teeth

Oil Contamination

Damaged Or Faulty Tensioners

Incorrect Tension Adjustment

Replace camshaft timing belt every 60,000 miles.

COOLING SYSTEM

Replace engine coolant every 36 months or 30,000 miles. Check condition of hoses and clamps every 12 months or 15,000 miles, whichever

comes first. Replace hoses and clamps if necessary.

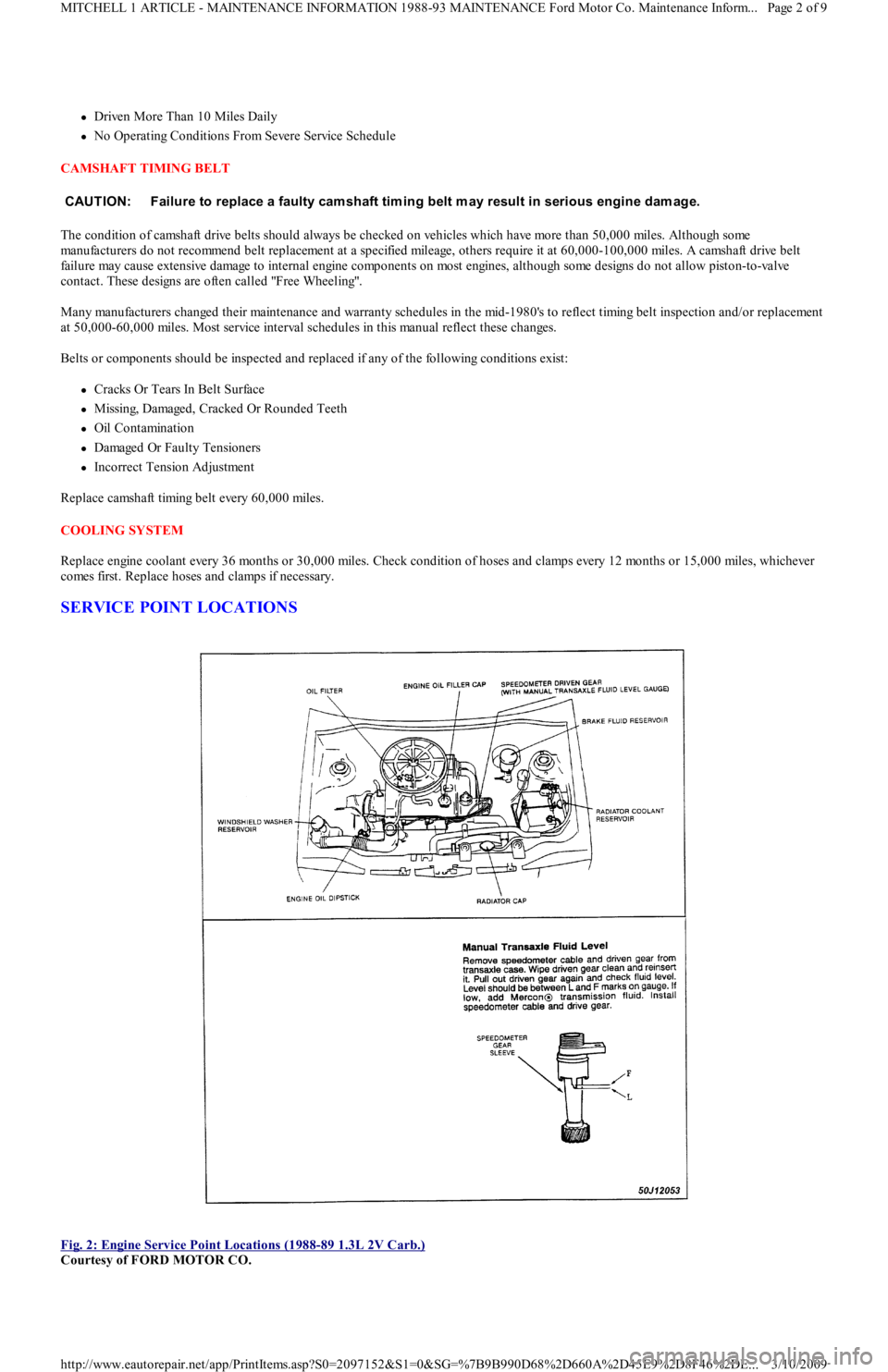

SERVICE POINT LOCATIONS

Fig. 2: Engine Service Point Locations (1988

-89 1.3L 2V Carb.)

Courtesy of FORD MOTOR CO. CAUT ION: Failure to replace a faulty cam shaft tim ing belt m ay result in serious engine dam age.

Page 2 of 9 MITCHELL 1 ARTICLE - MAINTENANCE INFORMATION 1988-93 MAINTENANCE Ford Motor Co. Maintenance Inform...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...