tire size FORD FESTIVA 1991 Service Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1991, Model line: FESTIVA, Model: FORD FESTIVA 1991Pages: 454, PDF Size: 9.53 MB

Page 3 of 454

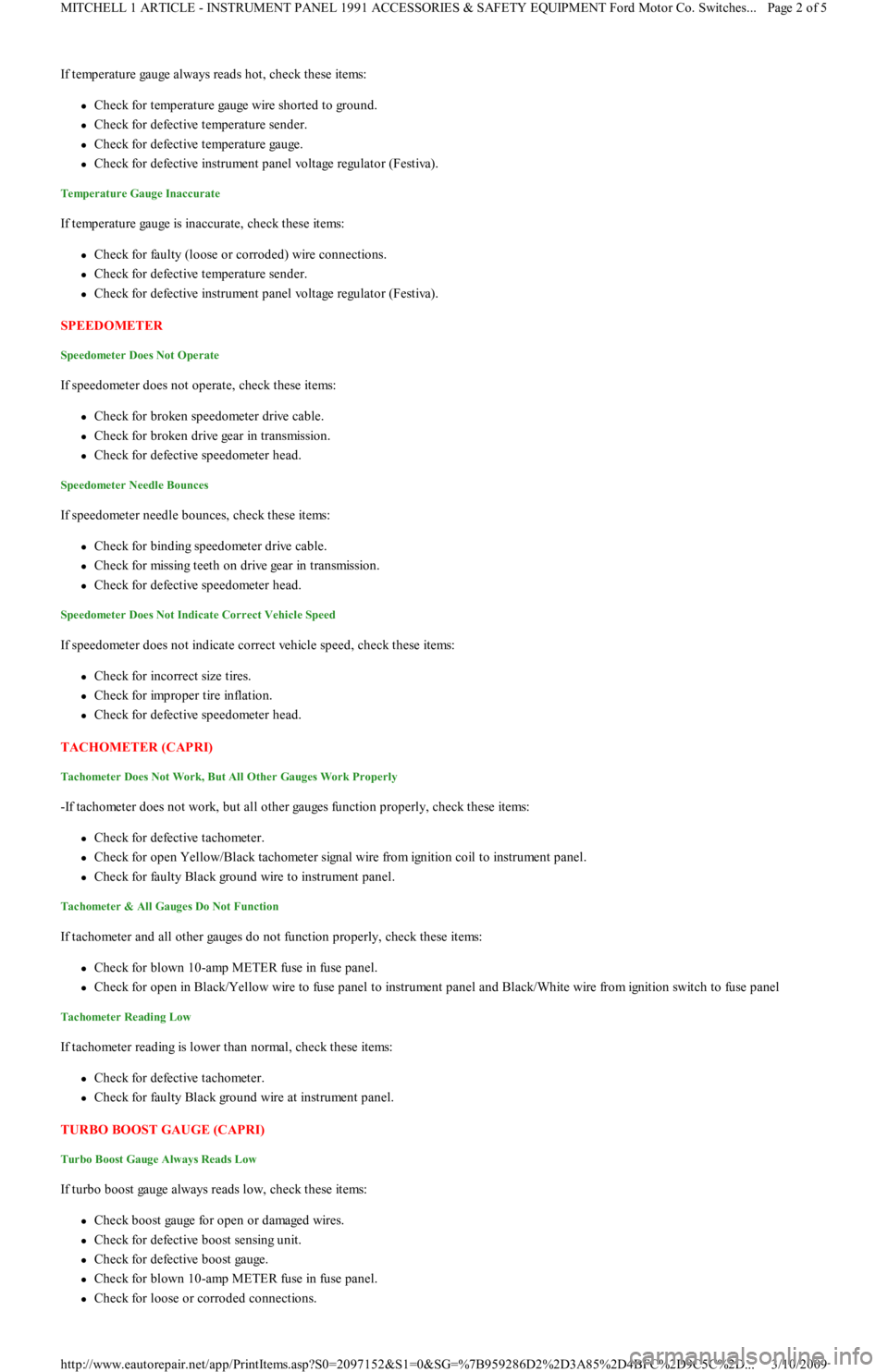

If temperature gauge always reads hot, check these items:

Check for temperature gauge wire shorted to ground.

Check for defective temperature sender.

Check for defective temperature gauge.

Check for defective instrument panel voltage regulator (Festiva).

Temperature Gauge Inaccurate

If temperature gauge is inaccurate, check these items:

Check for faulty (loose or corroded) wire connections.

Check for defective temperature sender.

Check for defective instrument panel voltage regulator (Festiva).

SPEEDOMETER

Speedometer Does Not Operate

If speedometer does not operate, check these items:

Check for broken speedometer drive cable.

Check for broken drive gear in transmission.

Check for defective speedometer head.

Speedometer Needle Bounces

If speedometer needle bounces, check these items:

Check for binding speedometer drive cable.

Check for missing teeth on drive gear in transmission.

Check for defective speedometer head.

Speedometer Does Not Indicate Correct Vehicle Speed

If speedometer does not indicate correct vehicle speed, check these items:

Check for incorrect size tires.

Check for improper tire inflation.

Check for defective speedometer head.

TACHOMETER (CAPRI)

Tachometer Does Not Work, But All Other Gauges Work Properly

-If tachometer does not work, but all other gauges function properly, check these items:

Check for defective tachometer.

Check for open Yellow/Black tachometer signal wire from ignition coil to instrument panel.

Check for faulty Black ground wire to instrument panel.

Tachometer & All Gauges Do Not Function

If tachometer and all other gauges do not function properly, check these items:

Check for blown 10-amp METER fuse in fuse panel.

Check for open in Black/Yellow wire to fuse panel to instrument panel and Black/White wire from ignition switch to fuse panel

Tachometer Reading Low

If tachometer reading is lower than normal, check these items:

Check for defective tachometer.

Check for faulty Black ground wire at instrument panel.

TURBO BOOST GAUGE (CAPRI)

Turbo Boost Gauge Always Reads Low

If turbo boost gauge always reads low, check these items:

Check boost gauge for open or damaged wires.

Check for defective boost sensing unit.

Check for defective boost gauge.

Check for blown 10-amp METER fuse in fuse panel.

Check for loose or corroded connections.

Page 2 of 5 MITCHELL 1 ARTICLE - INSTRUMENT PANEL 1991 ACCESSORIES & SAFETY EQUIPMENT Ford Motor Co. Switches

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 114 of 454

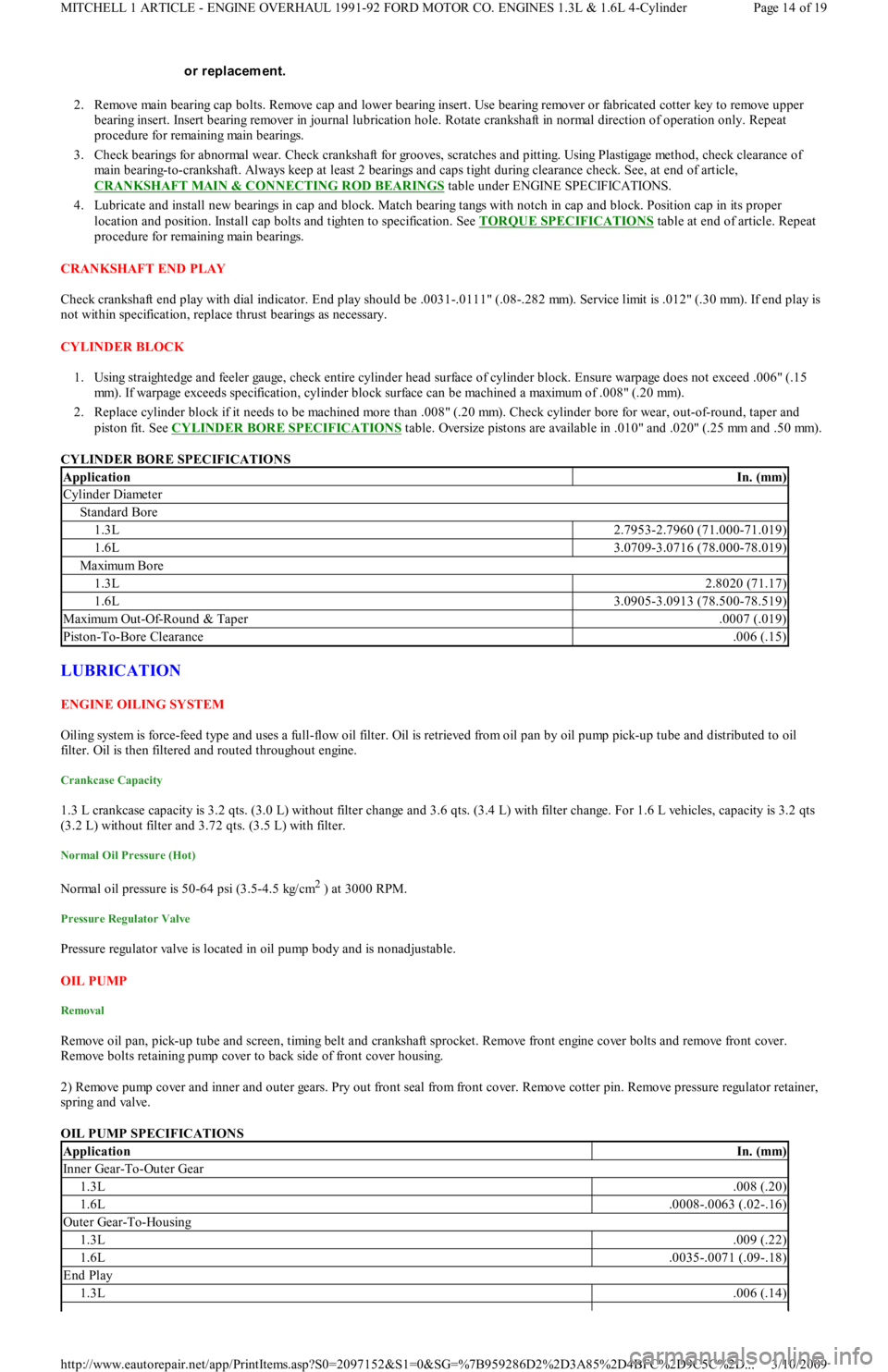

2. Remove main bearing cap bolts. Remove cap and lower bearing insert. Use bearing remover or fabricated cotter key to remove upper

bearing insert. Insert bearing remover in journal lubrication hole. Rotate crankshaft in normal direction of operation only. Repeat

procedure for remaining main bearings.

3. Check bearings for abnormal wear. Check crankshaft for grooves, scratches and pitting. Using Plastigage method, check clearance of

main bearing-to-crankshaft. Always keep at least 2 bearings and caps tight during clearance check. See, at end of article,

CRANKSHAFT MAIN & CONNECTING ROD BEARINGS

table under ENGINE SPECIFICATIONS.

4. Lubricate and install new bearings in cap and block. Match bearing tangs with notch in cap and block. Position cap in its proper

location and position. Install cap bolts and tighten to specification. See TORQUE SPECIFICATIONS

table at end of article. Repeat

procedure for remaining main bearings.

CRANKSHAFT END PLAY

Check crankshaft end play with dial indicator. End play should be .0031-.0111" (.08-.282 mm). Service limit is .012" (.30 mm). If end play is

not within specification, replace thrust bearings as necessary.

CYLINDER BLOCK

1. Using straightedge and feeler gauge, check entire cylinder head surface of cylinder block. Ensure warpage does not exceed .006" (.15

mm). If warpage exceeds specification, cylinder block surface can be machined a maximum of .008" (.20 mm).

2. Replace cylinder block if it needs to be machined more than .008" (.20 mm). Check cylinder bore for wear, out-of-round, taper and

piston fit. See CYLINDER BORE SPECIFICATIONS

table. Oversize pistons are available in .010" and .020" (.25 mm and .50 mm).

CYLINDER BORE SPECIFICATIONS

LUBRICATION

ENGINE OILING SYSTEM

Oiling system is force-feed type and uses a full-flow oil filter. Oil is retrieved from oil pan by oil pump pick-up tube and distributed to oil

filter. Oil is then filtered and routed throughout engine.

Crankcase Capacity

1.3 L crankcase capacity is 3.2 qts. (3.0 L) without filter change and 3.6 qts. (3.4 L) with filter change. For 1.6 L vehicles, capacity is 3.2 qts

(3.2 L) without filter and 3.72 qts. (3.5 L) with filter.

Normal Oil Pressure (Hot)

Normal oil pressure is 50-64 psi (3.5-4.5 kg/cm2 ) at 3000 RPM.

Pressure Regulator Valve

Pressure regulator valve is located in oil pump body and is nonadjustable.

OIL PUMP

Removal

Remove oil pan, pick-up tube and screen, timing belt and crankshaft sprocket. Remove front engine cover bolts and remove front cover.

R e mo ve b o l t s r e t a in in g p u mp c o ve r t o b a c k sid e o f fr o n t c o ve r h o u sin g.

2) Remove pump cover and inner and outer gears. Pry out front seal from front cover. Remove cotter pin. Remove pressure regulator retainer,

spring and valve.

OIL PUMP SPECIFICATIONS or replacem ent.

ApplicationIn. (mm)

Cylinder Diameter

Standard Bore

1.3L2.7953-2.7960 (71.000-71.019)

1.6L3.0709-3.0716 (78.000-78.019)

Maximu m Bo re

1.3L2.8020 (71.17)

1.6L3.0905-3.0913 (78.500-78.519)

Maximu m Ou t -Of-Ro u n d & Tap er.0007 (.019)

Piston-To-Bore Clearance.006 (.15)

ApplicationIn. (mm)

Inner Gear-To-Outer Gear

1.3L.008 (.20)

1.6L.0008-.0063 (.02-.16)

Outer Gear-To-Housing

1.3L.009 (.22)

1.6L.0035-.0071 (.09-.18)

End Play

1.3L.006 (.14)

Page 14 of 19 MITCHELL 1 ARTICLE - ENGINE OVERHAUL 1991-92 FORD MOTOR CO. ENGINES 1.3L & 1.6L 4-Cylinder

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 220 of 454

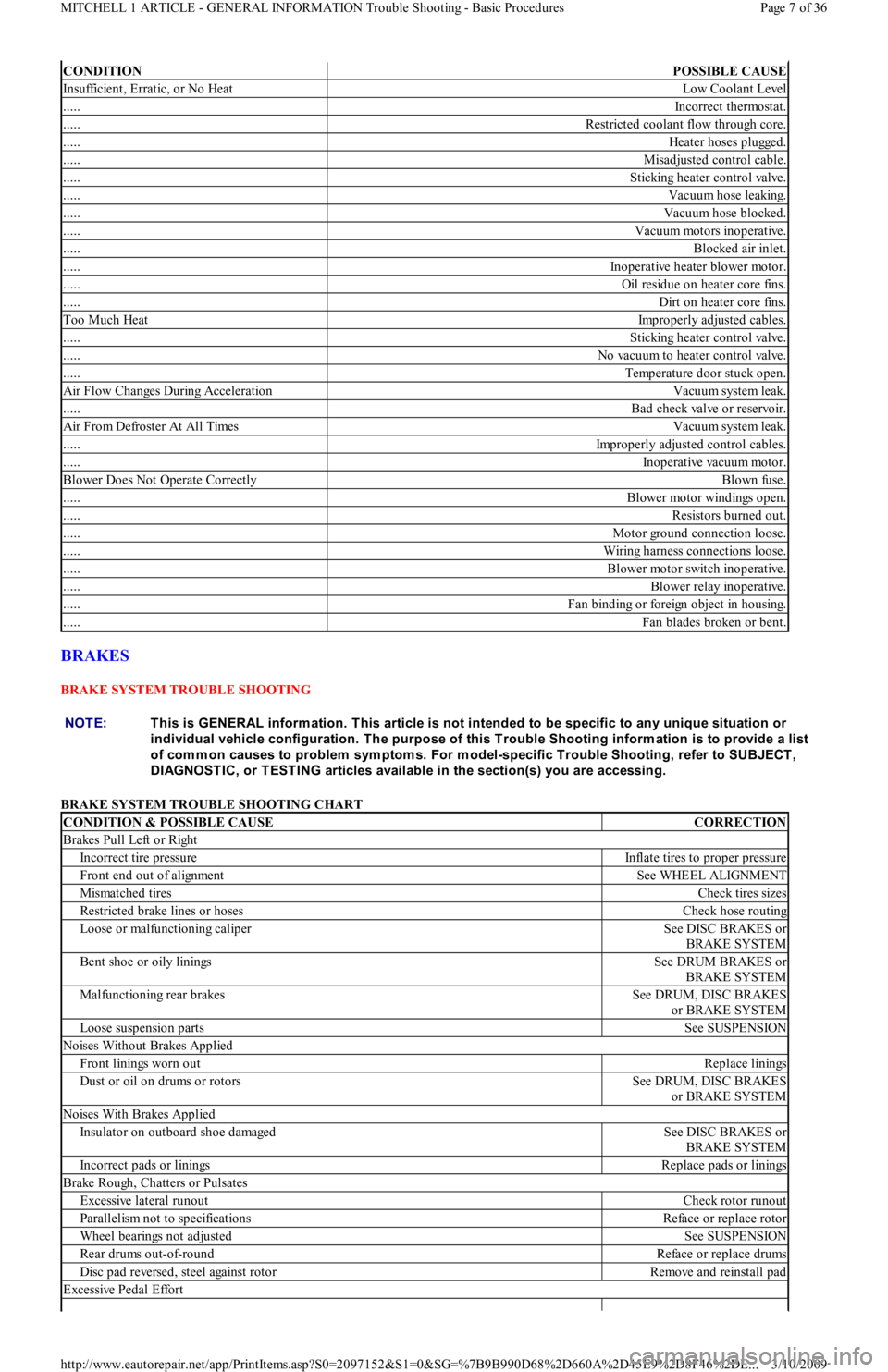

BRAKES

BRAKE SYSTEM TROUBLE SHOOTING

BRAKE SYSTEM TROUBLE SHOOTING CHART

CONDITIONPOSSIBLE CAUSE

Insufficient, Erratic, or No HeatLow Coolant Level

.....Incorrect thermostat.

.....Restricted coolant flow through core.

.....Heater hoses plugged.

.....Misadjusted control cable.

.....Sticking heater control valve.

.....Vacuum hose leaking.

.....Vacuum hose blocked.

.....Vacuum motors inoperative.

.....Blocked air inlet.

.....Inoperative heater blower motor.

.....Oil residue on heater core fins.

.....Dirt on heater core fins.

Too Much HeatImproperly adjusted cables.

.....Sticking heater control valve.

.....No vacuum to heater control valve.

.....Temperature door stuck open.

Air Flow Changes During AccelerationVacuum system leak.

.....Bad check valve or reservoir.

Air From Defroster At All TimesVacuum system leak.

.....Improperly adjusted control cables.

.....Inoperative vacuum motor.

Blower Does Not Operate CorrectlyBlown fuse.

.....Blower motor windings open.

.....Resistors burned out.

.....Motor ground connection loose.

.....Wiring harness connections loose.

.....Blower motor switch inoperative.

.....Blower relay inoperative.

.....Fan binding or foreign object in housing.

.....Fan blades broken or bent.

NOTE:This is GENERAL inform ation. This article is not intended to be specific to any unique situation or

individual vehicle configuration. T he purpose of this T rouble Shooting inform ation is to provide a list

of com m on causes to problem sym ptom s. For m odel-specific T rouble Shooting, refer to SUBJECT ,

DIAGNOST IC, or T EST ING articles available in the section(s) you are accessing.

CONDITION & POSSIBLE CAUSECORRECTION

Brakes Pull Left or Right

Incorrect tire pressureInflate tires to proper pressure

Front end out of alignmentSee WHEEL ALIGNMENT

Mismatched tiresCheck tires sizes

Restricted brake lines or hosesCheck hose routing

Loose or malfunctioning caliperSee DISC BRAKES or

BRAKE SYSTEM

Bent shoe or oily liningsSee DRUM BRAKES or

BRAKE SYSTEM

Malfunctioning rear brakesSee DRUM, DISC BRAKES

or BRAKE SYSTEM

Loose suspension partsSee SUSPENSION

Noises Without Brakes Applied

Front linings worn outReplace linings

Dust or oil on drums or rotorsSee DRUM, DISC BRAKES

or BRAKE SYSTEM

Noises With Brakes Applied

Insulator on outboard shoe damagedSee DISC BRAKES or

BRAKE SYSTEM

Incorrect pads or liningsReplace pads or linings

Brake Rough, Chatters or Pulsates

Excessive lateral runoutCheck rotor runout

Parallelism not to specificationsReface or replace rotor

Wheel bearings not adjustedSee SUSPENSION

Rear drums out-of-roundReface or replace drums

Disc pad reversed, steel against rotorRemove and reinstall pad

Excessive Pedal Effort

Page 7 of 36 MITCHELL 1 ARTICLE - GENERAL INFORMATION Trouble Shooting - Basic Procedures

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 243 of 454

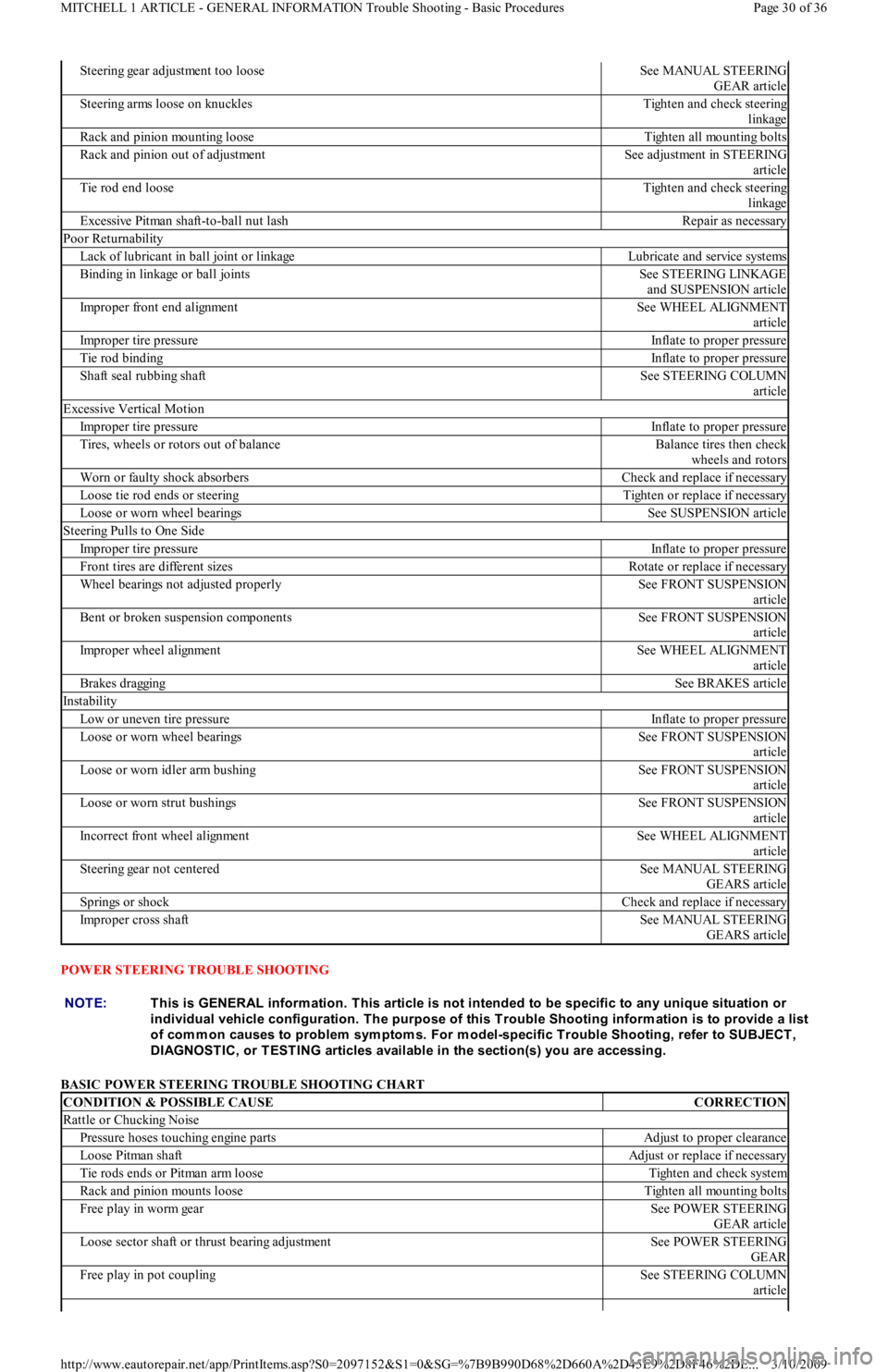

POWER STEERING TROUBLE SHOOTING

BASIC POWER STEERING TROUBLE SHOOTING CHART

Steering gear adjustment too looseSee MANUAL STEERING

GEAR article

Steering arms loose on knucklesTighten and check steering

linkage

Rack and pinion mounting looseTighten all mounting bolts

Rack and pinion out of adjustmentSee adjustment in STEERING

article

Tie rod end looseTighten and check steering

linkage

Excessive Pitman shaft-to-ball nut lashRepair as necessary

Poor Returnability

Lack of lubricant in ball joint or linkageLubricate and service systems

Binding in linkage or ball jointsSee STEERING LINKAGE

and SUSPENSION article

Improper front end alignmentSee WHEEL ALIGNMENT

article

Improper tire pressureInflate to proper pressure

Tie rod bindingInflate to proper pressure

Shaft seal rubbing shaftSee STEERING COLUMN

article

Excessive Vertical Motion

Improper tire pressureInflate to proper pressure

Tires, wheels or rotors out of balanceBalance tires then check

wheels and rotors

Worn or faulty shock absorbersCheck and replace if necessary

Loose tie rod ends or steeringTighten or replace if necessary

Loose or worn wheel bearingsSee SUSPENSION article

Steering Pulls to One Side

Improper tire pressureInflate to proper pressure

Front tires are different sizesRotate or replace if necessary

Wheel bearings not adjusted properlySee FRONT SUSPENSION

article

Bent or broken suspension componentsSee FRONT SUSPENSION

article

Improper wheel alignmentSee WHEEL ALIGNMENT

article

Brakes draggingSee BRAKES article

Instability

Low or uneven tire pressureInflate to proper pressure

Loose or worn wheel bearingsSee FRONT SUSPENSION

article

Loose or worn idler arm bushingSee FRONT SUSPENSION

article

Loose or worn strut bushingsSee FRONT SUSPENSION

article

Incorrect front wheel alignmentSee WHEEL ALIGNMENT

article

Steering gear not centeredSee MANUAL STEERING

GEARS article

Springs or shockCheck and replace if necessary

Improper cross shaftSee MANUAL STEERING

GEARS article

NOTE:This is GENERAL inform ation. This article is not intended to be specific to any unique situation or

individual vehicle configuration. T he purpose of this T rouble Shooting inform ation is to provide a list

of com m on causes to problem sym ptom s. For m odel-specific T rouble Shooting, refer to SUBJECT ,

DIAGNOST IC, or T EST ING articles available in the section(s) you are accessing.

CONDITION & POSSIBLE CAUSECORRECTION

Rattle or Chucking Noise

Pressure hoses touching engine partsAdjust to proper clearance

Loose Pitman shaftAdjust or replace if necessary

Tie rods ends or Pitman arm looseTighten and check system

Rack and pinion mounts looseTighten all mounting bolts

Free play in worm gearSee POWER STEERING

GEAR article

Loose sector shaft or thrust bearing adjustmentSee POWER STEERING

GEAR

Free play in pot couplingSee STEERING COLUMN

article

Page 30 of 36 MITCHELL 1 ARTICLE - GENERAL INFORMATION Trouble Shooting - Basic Procedures

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 305 of 454

Back To Article

GENERAL INFORMATION

Manual Transmission Trouble Shooting

* PLEASE READ THIS FIRST *

INTRODUCTION

There are many times when the transmission is incorrectly blamed for shifting problems or noises that are actually caused by other reasons.

Shift difficulties are frequently caused by conditions outside of the transmission or transaxle. Typical conditions include: shift linkage, shift

cables, alignment of engine to transmission, worn engine mounts or clutch problems. Drive train noises may come from many sources such as

tires, road surfaces, wheel bearings, differentials, engine or exhaust system. Repairing or overhauling transmission will not cure these

problems.

No manufacturer makes a perfectly quiet transmission. Gear rollover noise is present in most constant mesh transmissions and will tend to

disappear when the clutch is disengaged or transmission is placed in gear. If clutch is properly adjusted, clutch release bearing noise will

disappear when release bearing is moved enough to slide release bearing away from pressure plate.

Trouble shooting can be helped by driving vehicle on a smooth level road to help eliminate tire and body noise. Note whether noise occurs on

acceleration, coasting, deceleration or steady driving conditions. Some problems may only occur when transmission is either hot or cold. Gear

lubricant that is too thick can cause hard shifting on cold mornings before engine is warm and vehicle has been driven.

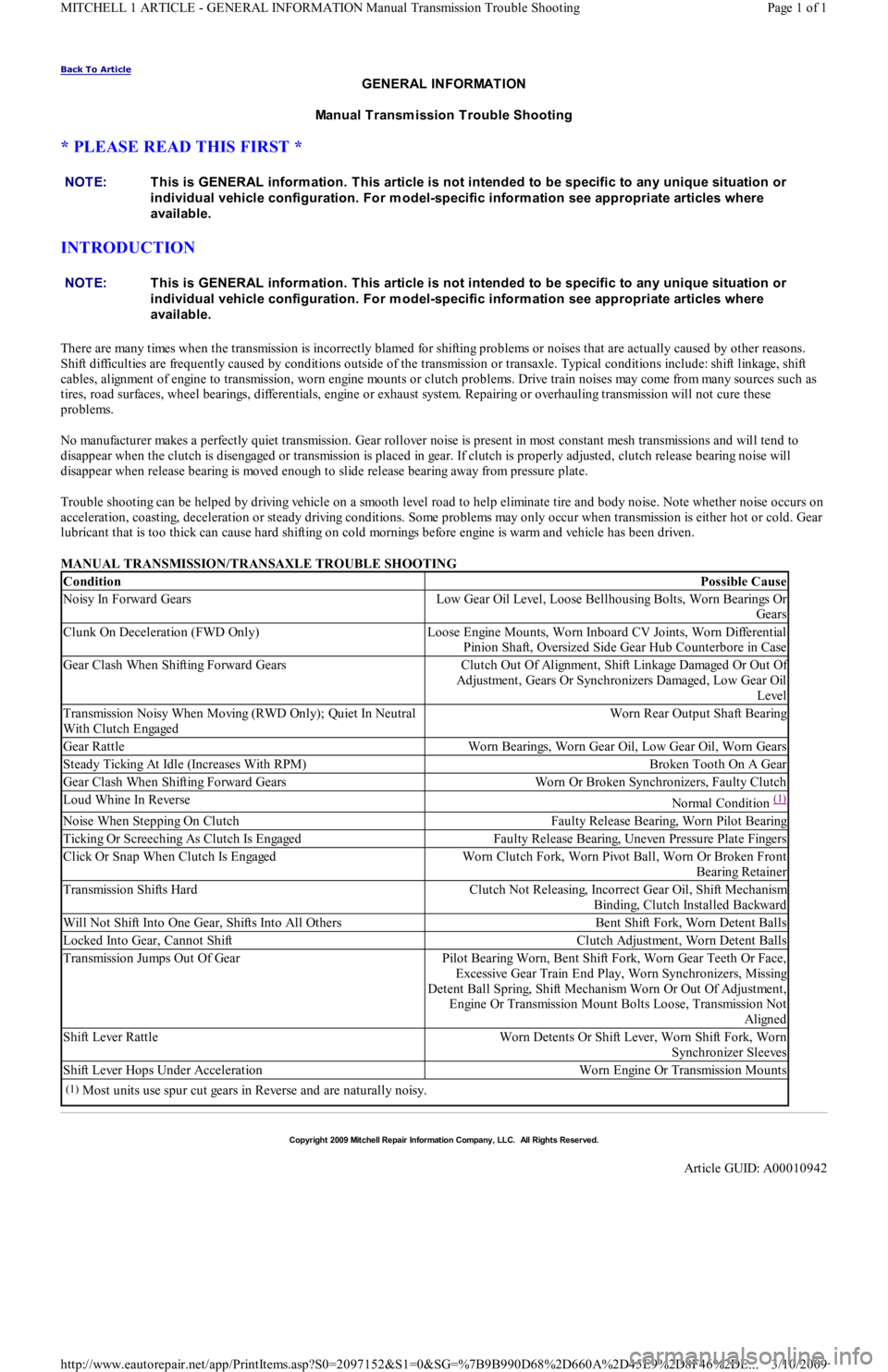

MANUAL TRANSMISSION/TRANSAXLE TROUBLE SHOOTING NOTE:This is GENERAL inform ation. This article is not intended to be specific to any unique situation or

individual vehicle configuration. For m odel-specific inform ation see appropriate articles where

available.

NOTE:This is GENERAL inform ation. This article is not intended to be specific to any unique situation or

individual vehicle configuration. For m odel-specific inform ation see appropriate articles where

available.

ConditionPossible Cause

Noisy In Forward GearsLow Gear Oil Level, Loose Bellhousing Bolts, Worn Bearings Or

Gears

Clunk On Deceleration (FWD Only)Loose Engine Mounts, Worn Inboard CV Joints, Worn Differential

Pinion Shaft, Oversized Side Gear Hub Counterbore in Case

Gear Clash When Shifting Forward GearsClutch Out Of Alignment, Shift Linkage Damaged Or Out Of

Adjustment, Gears Or Synchronizers Damaged, Low Gear Oil

Level

Transmission Noisy When Moving (RWD Only); Quiet In Neutral

With Clutch EngagedWorn Rear Output Shaft Bearing

Gear RattleWorn Bearings, Worn Gear Oil, Low Gear Oil, Worn Gears

Steady Ticking At Idle (Increases With RPM)Broken Tooth On A Gear

Gear Clash When Shifting Forward GearsWorn Or Broken Synchronizers, Faulty Clutch

Loud Whine In ReverseNormal Condition (1)

Noise When Stepping On ClutchFaulty Release Bearing, Worn Pilot Bearing

Ticking Or Screeching As Clutch Is EngagedFaulty Release Bearing, Uneven Pressure Plate Fingers

Click Or Snap When Clutch Is EngagedWorn Clutch Fork, Worn Pivot Ball, Worn Or Broken Front

Bearing Retainer

Transmission Shifts HardClutch Not Releasing, Incorrect Gear Oil, Shift Mechanism

Binding, Clutch Installed Backward

Will Not Shift Into One Gear, Shifts Into All OthersBent Shift Fork, Worn Detent Balls

Locked Into Gear, Cannot ShiftClutch Adjustment, Worn Detent Balls

Transmission Jumps Out Of GearPilot Bearing Worn, Bent Shift Fork, Worn Gear Teeth Or Face,

Excessive Gear Train End Play, Worn Synchronizers, Missing

Detent Ball Spring, Shift Mechanism Worn Or Out Of Adjustment,

Engine Or Transmission Mount Bolts Loose, Transmission Not

Aligned

Shift Lever RattleWorn Detents Or Shift Lever, Worn Shift Fork, Worn

Synchronizer Sleeves

Shift Lever Hops Under AccelerationWorn Engine Or Transmission Mounts

(1)Most units use spur cut gears in Reverse and are naturally noisy.

Copyr ight 2009 Mitchell Repair Information Company, LLC. All Rights Reserved.

Article GUID: A00010942

Page 1 of 1 MITCHELL 1 ARTICLE - GENERAL INFORMATION Manual Transmission Trouble Shooting

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 338 of 454

compressor label before adding refrigerant oil to A/C compressor/system. See Fig. 2 . The following R-134a refrigerant oils are currently

available.

Lexus

PAG Refrigerant Oil (ND-OIL 8) with 10P/10PA swashplate (piston) compressor. Synthetic Refrigerant Oil (ND-OIL 9) with through-va n e

(rotary vane) compressor.

Mercedes-Benz

PAG Refrigerant Oil (001 989 08 03).

Nissan

PAG Refrigerant Oil (KLH00-PAGR0) with rotary vane compressor. PAG Refrigerant Oil (KLH00-PAGS0) with piston (swashplate)

compressor.

Saab

PAG Refrigerant Oil (40 74 787).

SERVICE EQUIPMENT

Because R-134a is not interchangeable with R-12, separate sets of hoses, manifold gauge set and recovery/recycling equipment are required to

service vehicles. This is necessary to avoid cross-contaminating and damaging system.

All equipment used to service systems using R-134a must meet SAE standard J1991. The service hoses on the manifold gauge set must have

manual (turn wheel) or automatic back-flow valves at the service port connector ends. This will prevent refrigerant from being released into

the atmosphere.

For identification purposes, R-134a service hoses must have a Black stripe along its length and be clearly labeled SAE J2196/R-134a. The low

pressure test hose is Blue with a Black stripe. The high pressure test hose is Red with a Black stripe, and the center test hose is Yellow with a

Black stripe.

R-134a manifold gauge sets can be identified by one or all of the following.

Labeled FOR USE WITH R-134a on set

Labeled HFC-134 or R-134a on gauge face

Light Blue color on gauge face

In addition, pressure/temperature scales on R-134a gauge sets are different from R-12 manifold gauge sets.

SYSTEM SERVICE VALVES

SCHRADER-TYPE VALVES

Schrader valve is similar in construction and operation to a tire valve. When a test gauge hose with built-in valve core depressor is attached,

Schrader stem is pushed inward to the open position and allows system pressure to reach gauge.

If test hose does not have a built-in core depressor, an adapter must be used. Never attach hose or adapter to Schrader valve unless it is first

connected to manifold gauge set.

Refrigerant R-12 Schrader-type valve cores have TV5 thread size. Refrigerant R-134a Schrader-type valve cores use M6 (Metric) threads. R-

134a valve cores can be easily identified by use of "O" rings and external spring. See Fig. 1

.

SERVICE VALVE LOCATIONS

SERVICE VALVE LOCATIONS NOTE:Synthetic/PAG oils absorb m oisture very rapidly, 2.3-5.6% by weight, as com pared to a m ineral oil

absorption rate of .005% by weight.

NOTE:Refrigerant R-12 service hoses will ONLY be labeled SAE J2196.

NOTE:Although sim ilar in construction and operation to a tire valve, NEVER replace a Schrader-type valve

with a tire valve.

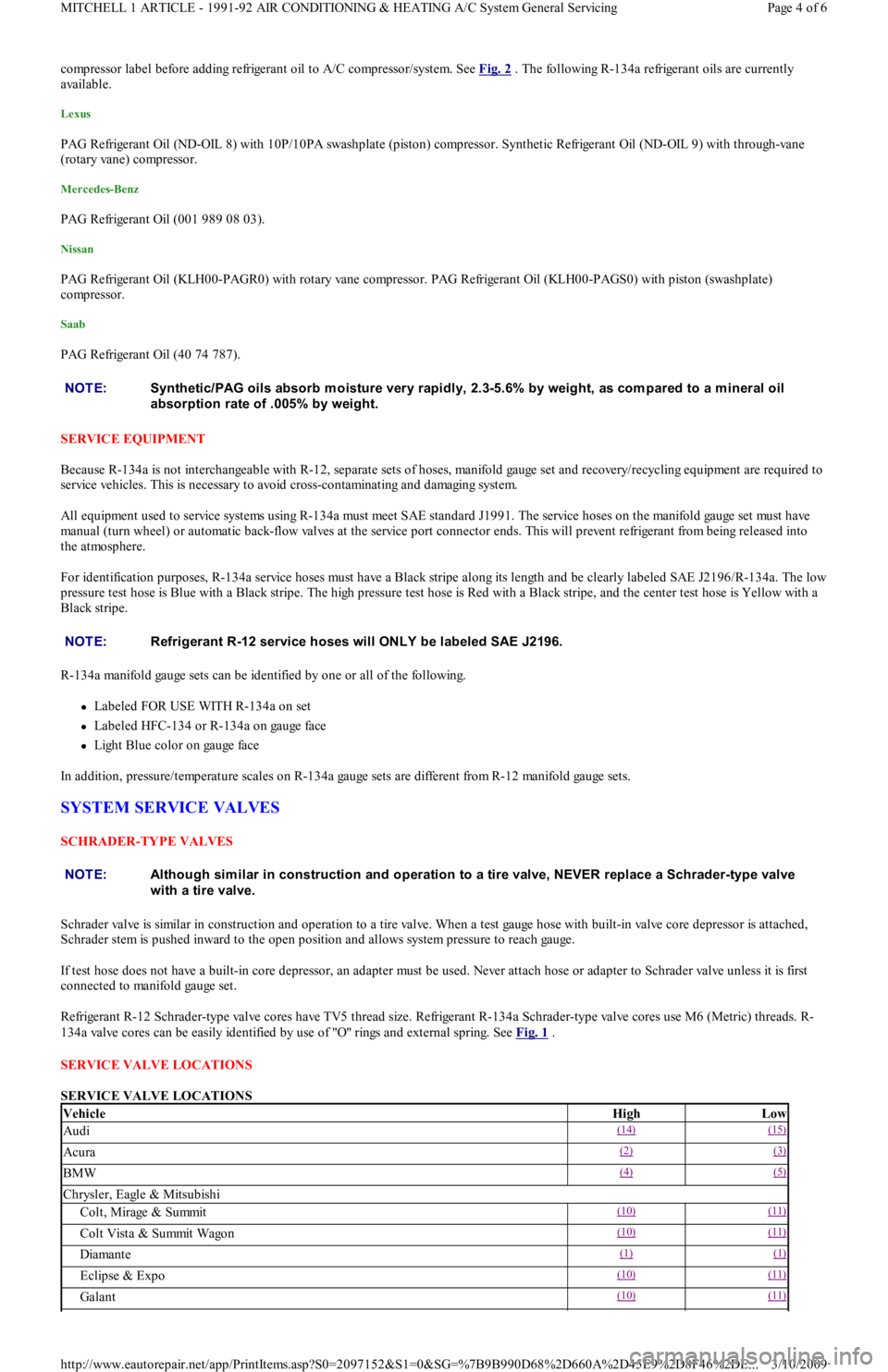

VehicleHighLow

Audi(14) (15)

Acura(2) (3)

BMW(4) (5)

Chrysler, Eagle & Mitsubishi

Colt, Mirage & Summit(10) (11)

Colt Vista & Summit Wagon(10) (11)

Diamante(1) (1)

Eclipse & Expo(10) (11)

Galant(10) (11)

Page 4 of 6 MITCHELL 1 ARTICLE - 1991-92 AIR CONDITIONING & HEATING A/C System General Servicing

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 365 of 454

Back To Article

MAINTENANCE INFORMATION

1988-93 MAINT ENANCE Ford Motor Co. Maintenance Inform ation

MODEL IDENTIFICATION

VIN LOCATION

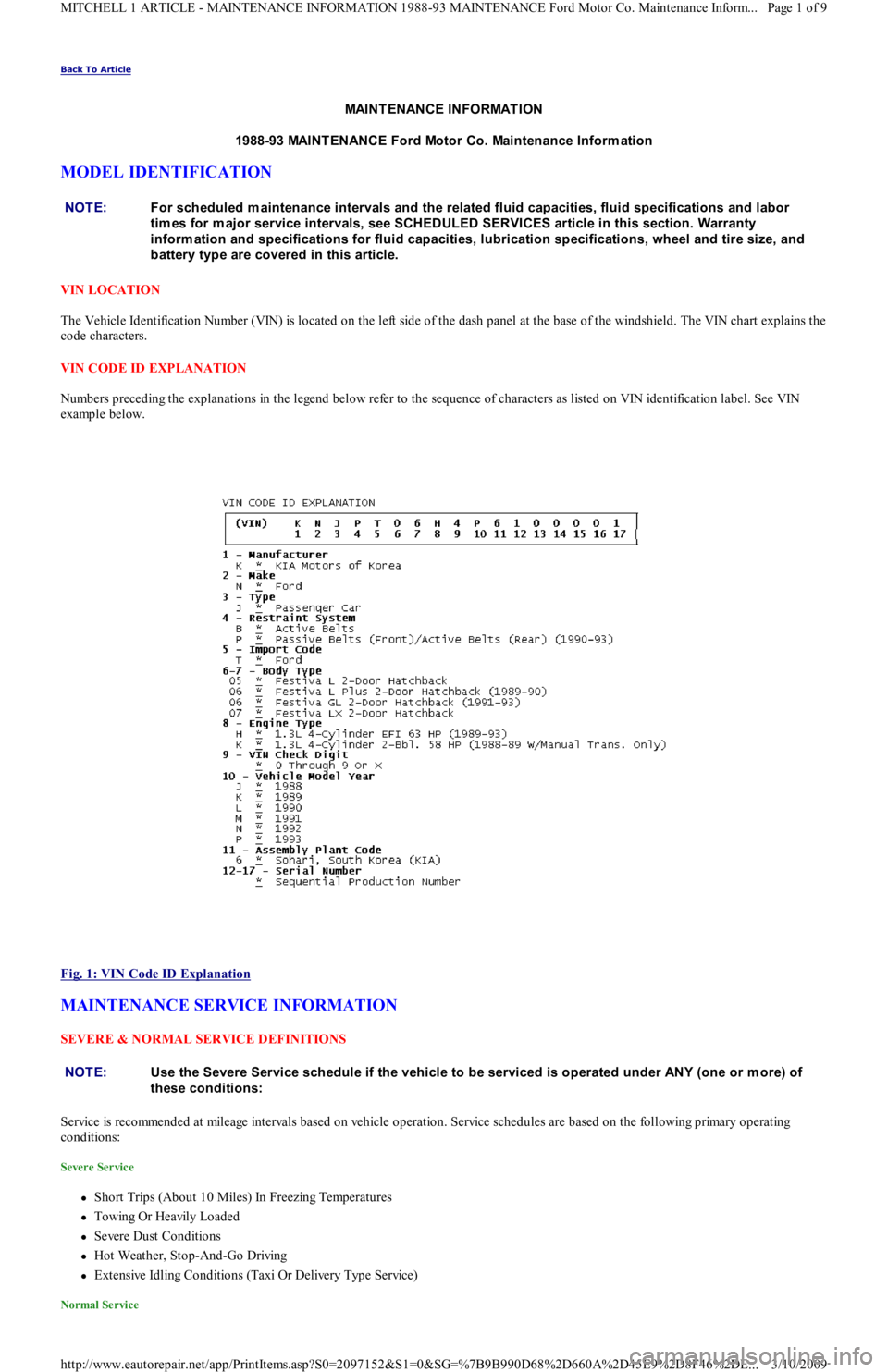

The Vehicle Identification Number (VIN) is located on the left side of the dash panel at the base of the windshield. The VIN chart explains the

code characters.

VIN CODE ID EXPLANATION

Numbers preceding the explanations in the legend below refer to the sequence of characters as listed on VIN identification label. See VIN

example below.

Fig. 1: VIN Code ID Explanation

MAINTENANCE SERVICE INFORMATION

SEVERE & NORMAL SERVICE DEFINITIONS

Service is recommended at mileage intervals based on vehicle operation. Service schedules are based on the following primary operating

conditions:

Severe Service

Short Trips (About 10 Miles) In Freezing Temperatures

Towing Or Heavily Loaded

Severe Dust Conditions

Hot Weather, Stop-And-Go Driving

Extensive Idling Conditions (Taxi Or Delivery Type Service)

Normal Service

NOTE:For scheduled m aintenance intervals and the related fluid capacities, fluid specifications and labor

tim es for m ajor service intervals, see SCHEDULED SERVICES article in this section. Warranty

inform ation and specifications for fluid capacities, lubrication specifications, wheel and tire size, and

battery type are covered in this article.

NOTE:Use the Severe Service schedule if the vehicle to be serviced is operated under ANY (one or m ore) of

these conditions:

Page 1 of 9 MITCHELL 1 ARTICLE - MAINTENANCE INFORMATION 1988-93 MAINTENANCE Ford Motor Co. Maintenance Inform...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 404 of 454

Back To Article

1983-95 WHEEL ALIGNMENT

Pre-Alignm ent Inspection Procedures

PRE-ALIGNMENT CHECKS

Before making wheel alignment adjustment, perform the following checks:

1. Tires should be equal in size and runout must not be excessive. Tires and wheels should be in balance, and inflated to manufacturer's

specifications.

2. Wheel bearings must be properly adjusted. Steering linkage and suspension must not have excessive looseness. Check for wear in tie rod

ends and ball joints.

3. Steering gear box must not have excessive play. Check and adjust to manufacturer's specifications.

4. Vehicle must be at curb height with full fuel load and spare tire in vehicle. No extra load should be on vehicle.

5. Vehicle must be level with floor and with suspension settled. Jounce front and rear of vehicle several times and allow it to settle to

normal curb height.

6. If steering wheel is not centered with front wheels in straight-ahead position, correct by shortening one tie rod adjusting sleeve and

lengthening opposite sleeve equal amounts.

7. Ensure wheel lug nuts are tightened to torque specifications.

Copyr ight 2009 Mitchell Repair Information Company, LLC. All Rights Reserved.

Article GUID: A00060347

Page 1 of 1 MITCHELL 1 ARTICLE - 1983-95 WHEEL ALIGNMENT Pre-Alignment Inspection Procedures

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 416 of 454

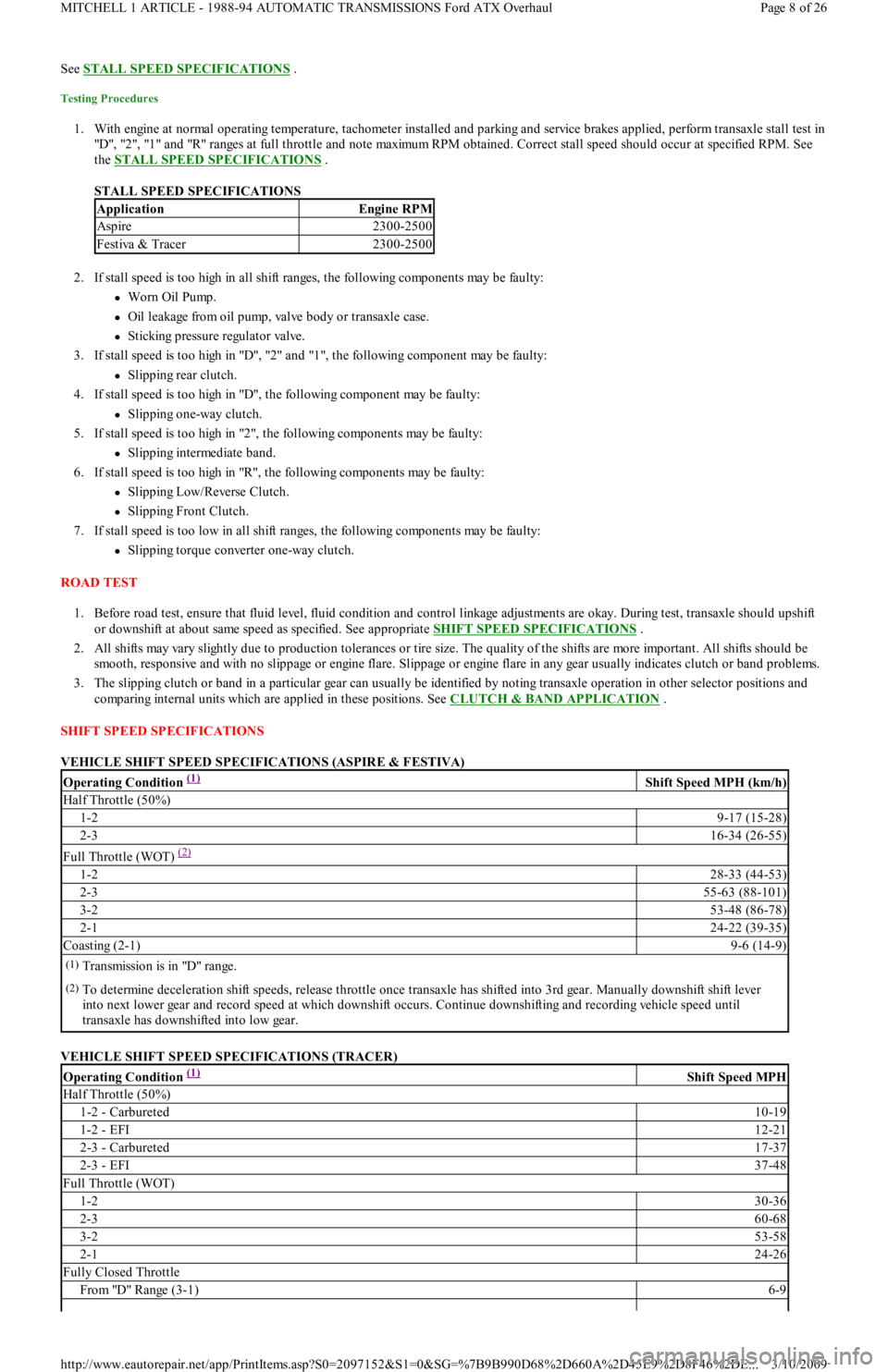

See STALL SPEED SPECIFICATIONS .

Testing Procedures

1. With engine at normal operating temperature, tachometer installed and parking and service brakes applied, perform transaxle stall test in

"D", "2", "1" and "R" ranges at full throttle and note maximum RPM obtained. Correct stall speed should occur at specified RPM. See

the STALL SPEED SPECIFICATIONS

.

STALL SPEED SPECIFICATIONS

2. If stall speed is too high in all shift ranges, the following components may be faulty:

Worn Oil Pump.

Oil leakage from oil pump, valve body or transaxle case.

Sticking pressure regulator valve.

3. If stall speed is too high in "D", "2" and "1", the following component may be faulty:

Slipping rear clutch.

4. If stall speed is too high in "D", the following component may be faulty:

Slipping one-way clutch.

5. If stall speed is too high in "2", the following components may be faulty:

Slipping intermediate band.

6. If stall speed is too high in "R", the following components may be faulty:

Slipping Low/Reverse Clutch.

Slipping Front Clutch.

7. If stall speed is too low in all shift ranges, the following components may be faulty:

Slipping torque converter one-way clutch.

ROAD TEST

1. Before road test, ensure that fluid level, fluid condition and control linkage adjustments are okay. During test, transaxle should upshift

or downshift at about same speed as specified. See appropriate SHIFT SPEED SPECIFICATIONS

.

2. All shifts may vary slightly due to production tolerances or tire size. The quality of the shifts are more important. All shifts should be

smooth, responsive and with no slippage or engine flare. Slippage or engine flare in any gear usually indicates clutch or band problems.

3. The slipping clutch or band in a particular gear can usually be identified by noting transaxle operation in other selector positions and

comparing internal units which are applied in these positions. See CLUTCH & BAND APPLICATION

.

SHIFT SPEED SPECIFICATIONS

VEHICLE SHIFT SPEED SPECIFICATIONS (ASPIRE & FESTIVA)

VEHICLE SHIFT SPEED SPECIFICATIONS (TRACER)

ApplicationEngine RPM

Aspire2300-2500

Festiva & Tracer2300-2500

Operating Condition (1) Shift Speed MPH (km/h)

Half Throttle (50%)

1-29-17 (15-28)

2-316-34 (26-55)

Full Throttle (WOT) (2)

1-228-33 (44-53)

2-355-63 (88-101)

3-253-48 (86-78)

2-124-22 (39-35)

Coasting (2-1)9-6 (14-9)

(1)Transmission is in "D" range.

(2)To determine deceleration shift speeds, release throttle once transaxle has shifted into 3rd gear. Manually downshift shift lever

into next lower gear and record speed at which downshift occurs. Continue downshifting and recording vehicle speed until

transaxle has downshifted into low gear.

Operating Condition (1) Shift Speed MPH

Half Throttle (50%)

1-2 - Carbureted10-19

1-2 - EFI12-21

2-3 - Carbureted17-37

2-3 - EFI37-48

Full Throttle (WOT)

1-230-36

2-360-68

3-253-58

2-124-26

Fully Closed Throttle

Fro m "D" Ran ge (3 -1 )6-9

Page 8 of 26 MITCHELL 1 ARTICLE - 1988-94 AUTOMATIC TRANSMISSIONS Ford ATX Overhaul

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...