oil filter FORD FESTIVA 1991 Service Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1991, Model line: FESTIVA, Model: FORD FESTIVA 1991Pages: 454, PDF Size: 9.53 MB

Page 102 of 454

levels to proper level.

Removal (1.6L & 1.6L Turbo)

1. Relieve fuel pressure and discharge air conditioning system (if equipped). See FUEL PRESSURE RELEASE under REMOVAL &

INSTALLATION. Disconnect and remove battery, battery tray and battery tray support bracket.

2. Release wiring harness retaining straps from battery support tray. Disconnect windshield washer supply hose between fluid reservoir and

hood. Mark hinge locations and remove hood.

3. Disconnect intake air tube and wiring to ignition coil and vane airflow meter. Remove air cleaner/vane airflow meter assembly. Remove

air cleaner assembly support brackets. Disconnect intercooler hoses from turbocharger (if equipped).

4. Drain engine coolant and remove radiator. Disconnect accelerator cable, and remove retaining bracket from cam cover. Position cable to

one side.

5. Disconnect and plug fuel lines at fuel filter and pressure regulator. Disconnect power brake booster manifold vacuum hose from

manifold. Disconnect heater hoses at heater core tubes. Label and remove vacuum hoses located at throttle body.

6. For manual transaxle turbocharged vehicles, disconnect clutch cable and remove support bracket and cable from transmission. On non-

turbo vehicles, disconnect clutch slave hydraulic line. For automatic transaxle, remove transaxle cooler lines.

7. Disconnect starter wiring at starter. Remove harness from locating strap on bracket. Disconnect alternator wiring. Disconnect wiring

from engine coolant sensors located on rear of engine block. Remove ground connection at bracket on thermostat cover. Disconnect O2

sensor wire, main wiring harness connector, TPS connector (turbocharged only), knock sensor connector, distributor wiring and

transaxle wiring. Disconnect ground wire and strap at front of engine, and reinstall lifting eye.

8. Remove engine oil dipstick and retaining clip. Remove power steering pump from mounting bracket. Remove power steering pump

mounting bracket. With hoses attached, position pump aside. Remove upper air conditioning compressor retaining bolts (if equipped).

9. Raise vehicle on hoist. Drain engine oil and cooling system. On vehicles with air conditioning, remove lower air conditioning

compressor mounting bolts, and position compressor out of way.

10. Remove front wheels and tires. Remove front ball joints-to-ste e r in g kn u c kl e s r e t a in in g b o l t s. R e mo ve sp l a sh gu a r d s. Dr a in t ransmission

oil and remove half shafts from differential. Remove front exhaust pipe bracket located on lower side of engine. Disconnect front

exhaust pipe from exhaust manifold, or turbocharger (if equipped).

11. Remove frame support bar-to-engine support bolt. Loosen right control arm bolt and, pivot support bar downward. Disengage rubber

exhaust hangers located directly behind catalytic converter. Allow exhaust system to hang down 6 inches, and support system with

mechanic's wire. Unbolt shift linkage and stabilizer bar at transaxle. Remove nuts from front and rear engine mounts, and lower vehicle.

12. Attach chains onto lift eyes at ends of cylinder head, and support engine with hoist. Remove RH engine mount through bolt. Raise

engine off mounts and slightly pivot engine/transaxle assembly. Disconnect oil pressure sensor and route starter/alternator wiring

harness from engine. Carefully lift engine/transaxle assembly, turn assembly while raising to clear brake master cylinder, shift linkage

universal joint, radiator support and air conditioning lines (if equipped).

13. Remove intake manifold support bracket. Remove gusset plate(s) (if equipped). Remove starter. Remove transaxle-to-engine retaining

bolts. Identify bolts to ensure correct installation. Separate transaxle from engine. On manual transaxle, remove pressure plate, clutch

disc and flywheel. On automatic transaxle, remove flexplate.

Installation (1.6L & 1.6L Turbo)

1. Install transaxle to engine in reverse order of removal. Attach hoist to engine/transaxle assembly and position assembly in vehicle.

Before engine contacts mounts, route starter, alternator and oil pressure sensor wiring, and connect oil pressure sensor. Lower engine

until front mount seats on crossmember. Install through bolt on RH engine mount. DO NOT tighten bolt.

2. Remove hoist. Raise vehicle and support with jackstands. Align rear engine mount to crossmember, and install retaining nuts to front

and rear engine mounts. Tighten nuts to specification. See TORQUE SPECIFICATIONS

table at end of article.

3. On manual transaxles, connect shift coupling and stabilizer. Tighten to specification. On automatic transaxles, connect shift linkage and

oil cooler lines. Tighten linkage retaining bolt, shift cable pivot and oil cooler hose clamps to specification. Connect front exhaust pipe

to manifold (or turbocharger). Install exhaust pipe to support bracket. Tighten bolts to specification. Tighten manifold (or turbocharger)

to specification. Attach rubber exhaust hangers. Position cross brace. Tighten retaining nut and bolt and right control arm front bolt.

4. Install drive axles. Install ball joint retaining bolts and tighten to specification. Mount A/C Compressor to engine (if equipped). Tighten

lower retaining bolts to specification. Install splash guards. Install tire and wheel assemblies. Tighten retaining nuts to specification.

5. Lower vehicle. Install upper A/C compressor retaining bolts (if equipped). Tighten bolts to specification. Tighten RH engine mo u n t

through bolt to specification. Connect alternator wiring.

6. Position power steering pump bracket on stud. Lower pump into engine compartment. Install power steering pump bracket retaining

bolts and nut. Tighten to specification. Install power steering pump and belt. Tighten adjustment nut and pivot bolt to specification.

7. Install engine oil dipstick and retaining clip. Install ground strap and ground wire to cylinder head. Install clutch cable (if equipped).

Connect clutch hydraulic line if equipped with manual transaxle or naturally aspirated. Connect transmission electrical connectors.

Connect fuel lines to fuel filter and pressure regulator. Install intake air tube to throttle body.

8. Install intercooler hoses on turbocharged models. Install air cleaner assembly brackets. Install air cleaner assembly with airflow meter

attached. Install intake air tube. Install coil and airflow meter connectors. Connect coolant crankcase and air bypass hoses. Install

vacuum hoses as noted in disassembly.

9. Connect accelerator cable. Install retaining bracket. Install power brake booster hose. Remove speedometer cable from transaxle. Fill

transaxle to specification. See CAPACITIES in SERVICE & ADJUSTMENT SPECIFICATIONS article. Install speedometer cable.

Connect speedometer cable connector. Fill engine oil to capacity.

10. Install radiator/fan assembly. Tighten bracket retaining bolts to specification. Connect coolant hoses and fan electrical connector. Fill

coolant to specification.

11. Install hood and connect washer hose. Install battery tray support, battery tray, battery and battery hold-down. Connect battery

terminal. Evacuate and charge air conditioning system (if equipped). Road test vehicle and inspect for leaks.

INTAKE MANIFOLD

Removal (1.3L)

CAUT ION: DO NOT allow com pressor to hang by hoses. T ie up com pressor with m echanic's wire.

Page 2 of 19 MITCHELL 1 ARTICLE - ENGINE OVERHAUL 1991-92 FORD MOTOR CO. ENGINES 1.3L & 1.6L 4-Cylinder

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 103 of 454

Disconnect negative battery cable. Drain cooling system. Remove air cleaner. Remove intake manifold bracket. Disconnect throttle cable.

Mark and disconnect vacuum hoses, fuel hoses and wiring. Remove intake manifold bolts. Remove intake manifold and gasket.

Installation (1.3L)

Clean all gasket mating surfaces. Ensure surface is free of burrs, scratches and cracks. Replace all gaskets. Position gasket and manifold to

cylinder head. Install bolts and tighten to specification. To complete installation, reverse removal procedure.

Removal (1.6L)

1. Disconnect negative battery terminal. Relieve fuel pressure. See FUEL PRESSURE RELEASE under REMOVAL &

INSTALLATION. Drain cooling system. Disconnect intercooler tube and/or air intake tube. Disconnect air by-pass hoses. Disconnect

main engine harness electrical connection and TPS connector. Disconnect vacuum hoses from throttle body.

2. Disconnect fuel lines from fuel filter and pressure regulator. Disconnect throttle cable. Disconnect hoses from By-pass Air Control valve

( B AC ) . R e mo ve B AC va l ve r e t a in in g n u t a n d b o l t . R e mo ve in t a ke manifold retaining nuts and bolts from support bracket and cylinder

head. Remove intake manifold and throttle body assembly.

Installation (1.6L)

1. Install new intake manifold gasket, ensuring coolant passage openings align with openings in cylinder head and manifold. Install intake

manifold. Tighten retaining nut and bolts and support bracket bolts to specification. See TORQUE SPECIFICATIONS

table at end of

article.

2. Install BAC valve and connect air hoses. Connect throttle cable. Connect fuel lines to fuel filters and pressure regulator. Connect main

engine harness connector and TPS connector. Connect vacuum lines to throttle body. Install intake air tube. Connect intercooler tube

and/or intake air tube. Connect air by-pass hoses. Fill cooling system. Connect negative battery terminal. Start engine and check for

fluid leaks and correct operation.

EXHAUST MANIFOLD

Removal (1.3L)

1. Raise vehicle. Remove catalytic converter inlet pipe at exhaust manifold. Remove pulse air tube nuts at inlet pipe. Remove inlet pipe

support bracket bolts. Lower vehicle. Remove air intake duct. Remove exhaust manifold heat shroud bolts and remove shroud.

2. Disconnect oxygen sensor connector. Remove exhaust manifold nuts and remove exhaust manifold. Remove gasket from inlet pipe and

cylinder head.

Installation

Position new gasket on cylinder head and inlet pipe. Install exhaust manifold and nuts. Tighten nuts to specification. See, at end of article,

TORQUE SPECIFICATIONS

table. To complete installation, reverse removal procedure. Tighten all bolts and nuts to specification.

Removal (1.6L Non-Turbo)

Remove intake air tube. Remove front exhaust pipe to exhaust manifold retaining nuts. Remove exhaust support bracket (if equipped). Remove

heat shield. Disconnect O2 sensor electrical connector. Remove exhaust manifold.

Installation (1.6L Non-Turbo)

Install exhaust manifold gaskets. Install heavier gasket first. Install exhaust manifold and tighten retaining nuts to specification. See TORQUE

SPECIFICATIONS table at end of article. Connect O2 sensor electrical connector. Install manifold heat shield. Install intake air tube.

Connect front exhaust pipe to intake manifold and tighten retaining nuts to specification. Install exhaust support bracket, if removed, and

tighten engine mount bolt to specification. Start engine and check for leaks.

Removal (1.6L Turbo)

1. Disconnect negative battery cable. Drain cooling system. Remove throttle body air intake tube. Disconnect intercooler hose from

turbocharger assembly and position both intercooler hoses out of the way. Remove O2 sensor connector from its retaining clip, and

disconnect O2 sensor. Remove lower heat shield and then upper heat shield. Remove turbocharger side heat shield.

2. Remove power steering pump (leave hoses attached) and lay aside. Disconnect lower radiator hose from water pump. Position power

steering pump to access mounting bracket retaining bolts and nut. Remove both bolts and one nut, and remove bracket from engine.

Remove 2 screws retaining air cleaner duct tube, loosen clamp at turbocharger and position duct tube out of the way. Disconnect

coolant return hose at turbocharger. Remove bolt and brass sealing washers from oil supply line at engine block.

3. Raise vehicle. Remove retaining nuts and washers from exhaust pipe flange. Remove 2 bolts retaining exhaust hangers to engine block.

Slide off two rubber exhaust hangers at catalytic converter. Pull exhaust pipe downward and to LH side of vehicle. Disconnect oil return

hose at turbocharger. Disconnect coolant return hose at turbocharger. Remove 2 retaining bolts from turbocharger support bracket.

Remove 2 bolts retaining coolant by-pass tube outlet to water pump. Lower vehicle.

4. Loosen retaining clamp bolt on coolant by-pass tube at rear of cylinder head. Remove 11 retaining nuts from exhaust manifold. Pull

coolant by-pass tube bracket from exhaust stud, and position tube out of way. Grasp manifold, pull off studs and move assembly slightly

to RH side of engine compartment to clear cooling fan, and remove assembly from vehicle.

5. Working on bench, remove 4 nuts retaining turbocharger to exhaust manifold, separate assembly and discard gasket.

Installation (1.6L Turbo)

NOTE:Feed O2 sensor wire and guide through upper heat shield.

NOTE:When reinstalling turbocharger, thoroughly rem ove all gaskets and sealant. Use new gaskets. Add .85

oz. (25 cc) of engine oil in the oil passage of the turbocharger.

Page 3 of 19 MITCHELL 1 ARTICLE - ENGINE OVERHAUL 1991-92 FORD MOTOR CO. ENGINES 1.3L & 1.6L 4-Cylinder

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 106 of 454

article. Install timing belt and covers. Install cam cover. On non-turbo engines, connect front exhaust pipe to exhaust manifold. Tighten

nuts to specification.

4. On turbocharged engines, install exhaust manifold and turbocharger assembly. Install ground wire and strap to cylinder head with

retaining bolts. Connect intercooler tubes (if equipped). Connect O2 sensor connector, and install ground wires to bracket on cylinder

head with retaining screw. Connect main engine harness connector. Connect fuel lines to fuel filter and pressure regulator. Install

throttle cable and retaining brackets.

5. Install coolant hoses and vacuum lines to intake manifold and throttle body. Install coolant hose to thermostat cover. Install intake air

tube to air cleaner. Install spark plug wires and retainers. Install intake air tube to throttle body, and connect by-pass hoses. Fill cooling

system. Connect negative battery terminal. Start engine, check for leaks and system operation.

TIMING BELT COVER

Removal & Installation (1.3L)

Remove accessory belts. Remove water pump pulley. Remove crankshaft damper. Remove bolts retaining upper and lower cover halves to

engine front. Remove both covers. To install, reverse removal procedure.

Removal & Installation (1.6L)

Raise vehicle on hoist. Remove RF tire and wheel assembly. Remove RF splash guard. Lower vehicle. Remove spark plugs and set camsh aft

timing to TDC No. 1 cylinder. Remove oil dipstick. Remove water pump pulley. Remove crankshaft pulley, damper and baffle plate. Remove

upper timing belt cover. Remove center and lower timing belt covers. To install, reverse removal procedure.

TIMING BELT

Removal (1.3L)

Remove accessory belts, water pump pulley, crankshaft damper and upper and lower timing belt covers. Mark timing belt direction of rotation

for installation reference. Remove timing belt tensioner pulley bolt. Remove tensioner pulley, spring and spring cover. Remove timing belt.

Installation (1.3L)

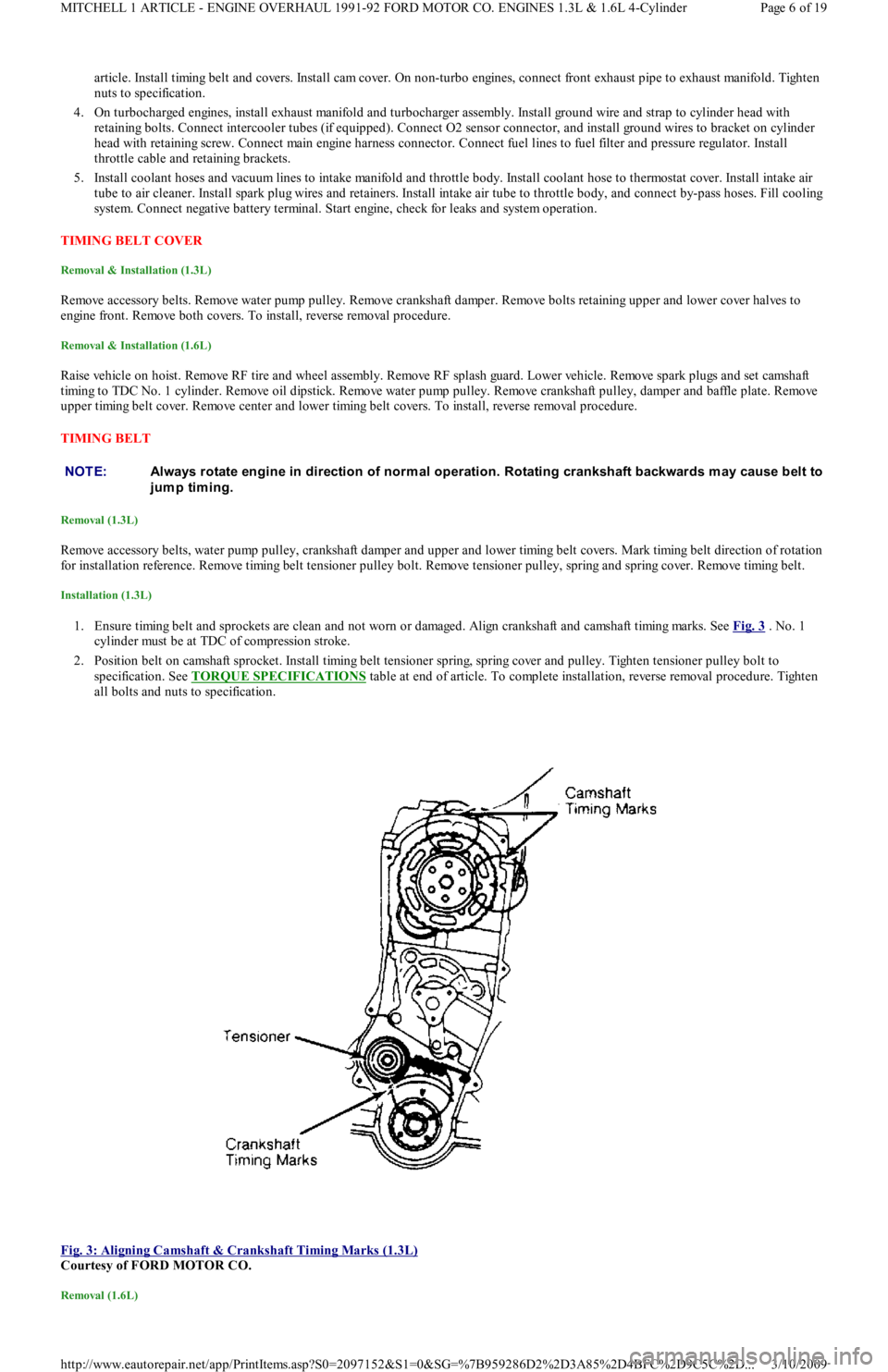

1. Ensure timing belt and sprockets are clean and not worn or damaged. Align crankshaft and camshaft timing marks. See Fig. 3 . No. 1

cylinder must be at TDC of compression stroke.

2. Position belt on camshaft sprocket. Install timing belt tensioner spring, spring cover and pulley. Tighten tensioner pulley bolt to

specification. See TORQUE SPECIFICATIONS

table at end of article. To complete installation, reverse removal procedure. Tighten

all bolts and nuts to specification.

Fig. 3: Aligning Camshaft & Crankshaft Timing Marks (1.3L)

Courtesy of FORD MOTOR CO.

Removal (1.6L)

NOTE:Always rotate engine in direction of norm al operation. Rotating crankshaft backwards m ay cause belt to

jump timing.

Page 6 of 19 MITCHELL 1 ARTICLE - ENGINE OVERHAUL 1991-92 FORD MOTOR CO. ENGINES 1.3L & 1.6L 4-Cylinder

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 114 of 454

2. Remove main bearing cap bolts. Remove cap and lower bearing insert. Use bearing remover or fabricated cotter key to remove upper

bearing insert. Insert bearing remover in journal lubrication hole. Rotate crankshaft in normal direction of operation only. Repeat

procedure for remaining main bearings.

3. Check bearings for abnormal wear. Check crankshaft for grooves, scratches and pitting. Using Plastigage method, check clearance of

main bearing-to-crankshaft. Always keep at least 2 bearings and caps tight during clearance check. See, at end of article,

CRANKSHAFT MAIN & CONNECTING ROD BEARINGS

table under ENGINE SPECIFICATIONS.

4. Lubricate and install new bearings in cap and block. Match bearing tangs with notch in cap and block. Position cap in its proper

location and position. Install cap bolts and tighten to specification. See TORQUE SPECIFICATIONS

table at end of article. Repeat

procedure for remaining main bearings.

CRANKSHAFT END PLAY

Check crankshaft end play with dial indicator. End play should be .0031-.0111" (.08-.282 mm). Service limit is .012" (.30 mm). If end play is

not within specification, replace thrust bearings as necessary.

CYLINDER BLOCK

1. Using straightedge and feeler gauge, check entire cylinder head surface of cylinder block. Ensure warpage does not exceed .006" (.15

mm). If warpage exceeds specification, cylinder block surface can be machined a maximum of .008" (.20 mm).

2. Replace cylinder block if it needs to be machined more than .008" (.20 mm). Check cylinder bore for wear, out-of-round, taper and

piston fit. See CYLINDER BORE SPECIFICATIONS

table. Oversize pistons are available in .010" and .020" (.25 mm and .50 mm).

CYLINDER BORE SPECIFICATIONS

LUBRICATION

ENGINE OILING SYSTEM

Oiling system is force-feed type and uses a full-flow oil filter. Oil is retrieved from oil pan by oil pump pick-up tube and distributed to oil

filter. Oil is then filtered and routed throughout engine.

Crankcase Capacity

1.3 L crankcase capacity is 3.2 qts. (3.0 L) without filter change and 3.6 qts. (3.4 L) with filter change. For 1.6 L vehicles, capacity is 3.2 qts

(3.2 L) without filter and 3.72 qts. (3.5 L) with filter.

Normal Oil Pressure (Hot)

Normal oil pressure is 50-64 psi (3.5-4.5 kg/cm2 ) at 3000 RPM.

Pressure Regulator Valve

Pressure regulator valve is located in oil pump body and is nonadjustable.

OIL PUMP

Removal

Remove oil pan, pick-up tube and screen, timing belt and crankshaft sprocket. Remove front engine cover bolts and remove front cover.

R e mo ve b o l t s r e t a in in g p u mp c o ve r t o b a c k sid e o f fr o n t c o ve r h o u sin g.

2) Remove pump cover and inner and outer gears. Pry out front seal from front cover. Remove cotter pin. Remove pressure regulator retainer,

spring and valve.

OIL PUMP SPECIFICATIONS or replacem ent.

ApplicationIn. (mm)

Cylinder Diameter

Standard Bore

1.3L2.7953-2.7960 (71.000-71.019)

1.6L3.0709-3.0716 (78.000-78.019)

Maximu m Bo re

1.3L2.8020 (71.17)

1.6L3.0905-3.0913 (78.500-78.519)

Maximu m Ou t -Of-Ro u n d & Tap er.0007 (.019)

Piston-To-Bore Clearance.006 (.15)

ApplicationIn. (mm)

Inner Gear-To-Outer Gear

1.3L.008 (.20)

1.6L.0008-.0063 (.02-.16)

Outer Gear-To-Housing

1.3L.009 (.22)

1.6L.0035-.0071 (.09-.18)

End Play

1.3L.006 (.14)

Page 14 of 19 MITCHELL 1 ARTICLE - ENGINE OVERHAUL 1991-92 FORD MOTOR CO. ENGINES 1.3L & 1.6L 4-Cylinder

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 149 of 454

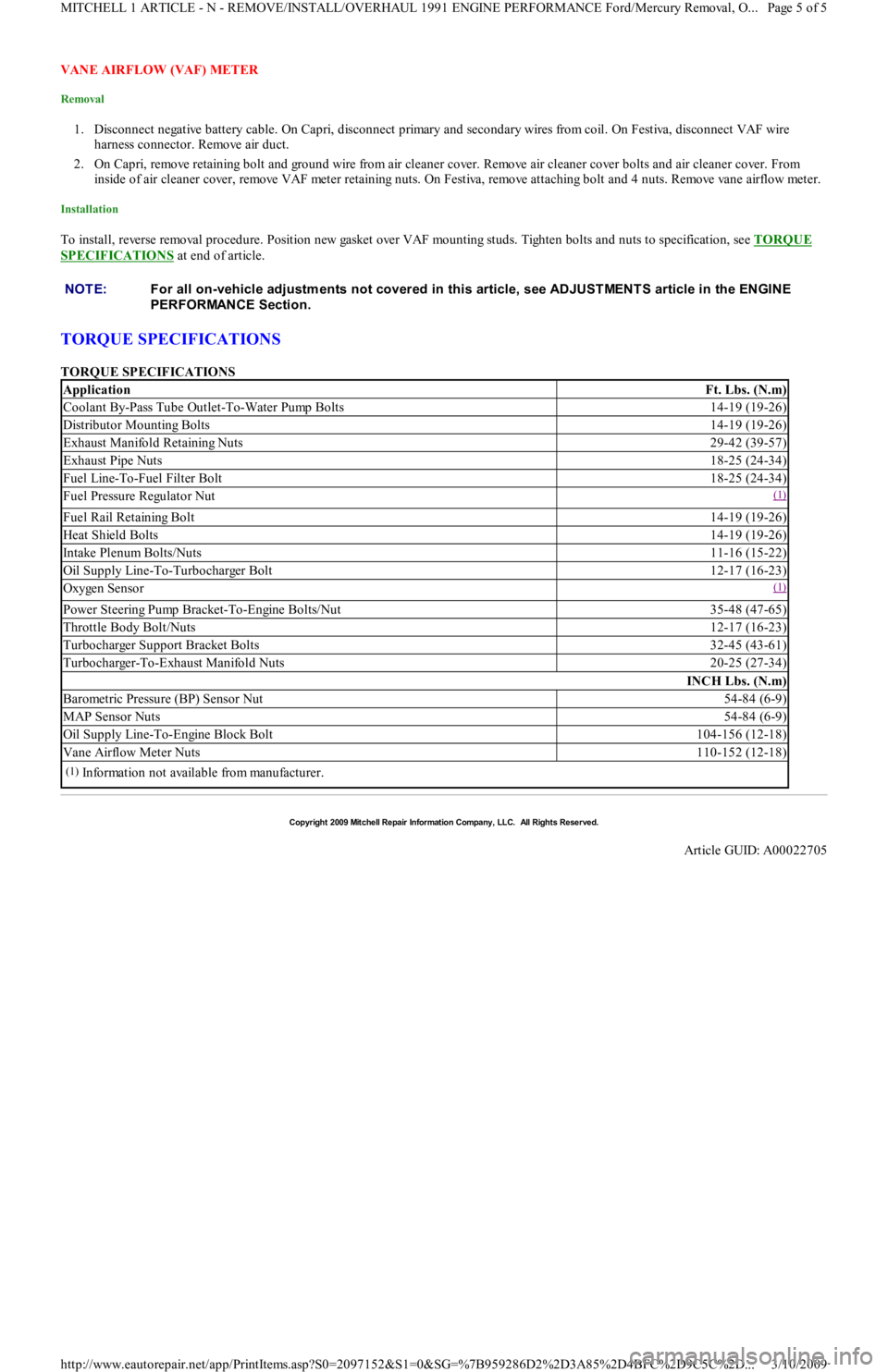

VANE AIRFLOW (VAF) METER

Removal

1. Disconnect negative battery cable. On Capri, disconnect primary and secondary wires from coil. On Festiva, disconnect VAF wire

harness connector. Remove air duct.

2. On Capri, remove retaining bolt and ground wire from air cleaner cover. Remove air cleaner cover bolts and air cleaner cover. From

inside of air cleaner cover, remove VAF meter retaining nuts. On Festiva, remove attaching bolt and 4 nuts. Remove vane airflow met er.

Installation

To install, reverse removal procedure. Position new gasket over VAF mounting studs. Tighten bolts and nuts to specification, see TORQUE

SPECIFICATIONS at end of article.

TORQUE SPECIFICATIONS

TORQUE SPECIFICATIONS NOTE:For all on-vehicle adjustm ents not covered in this article, see ADJUST MENT S article in the ENGINE

PERFORMANCE Section.

ApplicationFt. Lbs. (N.m)

Coolant By-Pass Tube Outlet-To-Water Pump Bolts14-19 (19-26)

Distributor Mounting Bolts14-19 (19-26)

Exhaust Manifold Retaining Nuts29-42 (39-57)

Exhaust Pipe Nuts18-25 (24-34)

Fuel Line-To-Fuel Filter Bolt18-25 (24-34)

Fuel Pressure Regulator Nut(1)

Fuel Rail Retaining Bolt14-19 (19-26)

Heat Shield Bolts14-19 (19-26)

Intake Plenum Bolts/Nuts11-16 (15-22)

Oil Supply Line-To-Turbocharger Bolt12-17 (16-23)

Oxygen Sensor(1)

Power Steering Pump Bracket-To-Engine Bolts/Nut35-48 (47-65)

Throttle Body Bolt/Nuts12-17 (16-23)

Turbocharger Support Bracket Bolts32-45 (43-61)

Turbocharger-To-Exhaust Manifold Nuts20-25 (27-34)

INCH Lbs. (N.m)

Barometric Pressure (BP) Sensor Nut54-84 (6-9)

MAP Sensor Nuts54-84 (6-9)

Oil Supply Line-To-Engine Block Bolt104-156 (12-18)

Vane Airflow Meter Nuts110-152 (12-18)

(1)Information not available from manufacturer.

Copyr ight 2009 Mitchell Repair Information Company, LLC. All Rights Reserved.

Article GUID: A00022705

Page 5 of 5 MITCHELL 1 ARTICLE - N - REMOVE/INSTALL/OVERHAUL 1991 ENGINE PERFORMANCE Ford/Mercury Removal, O

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 153 of 454

Back To Article

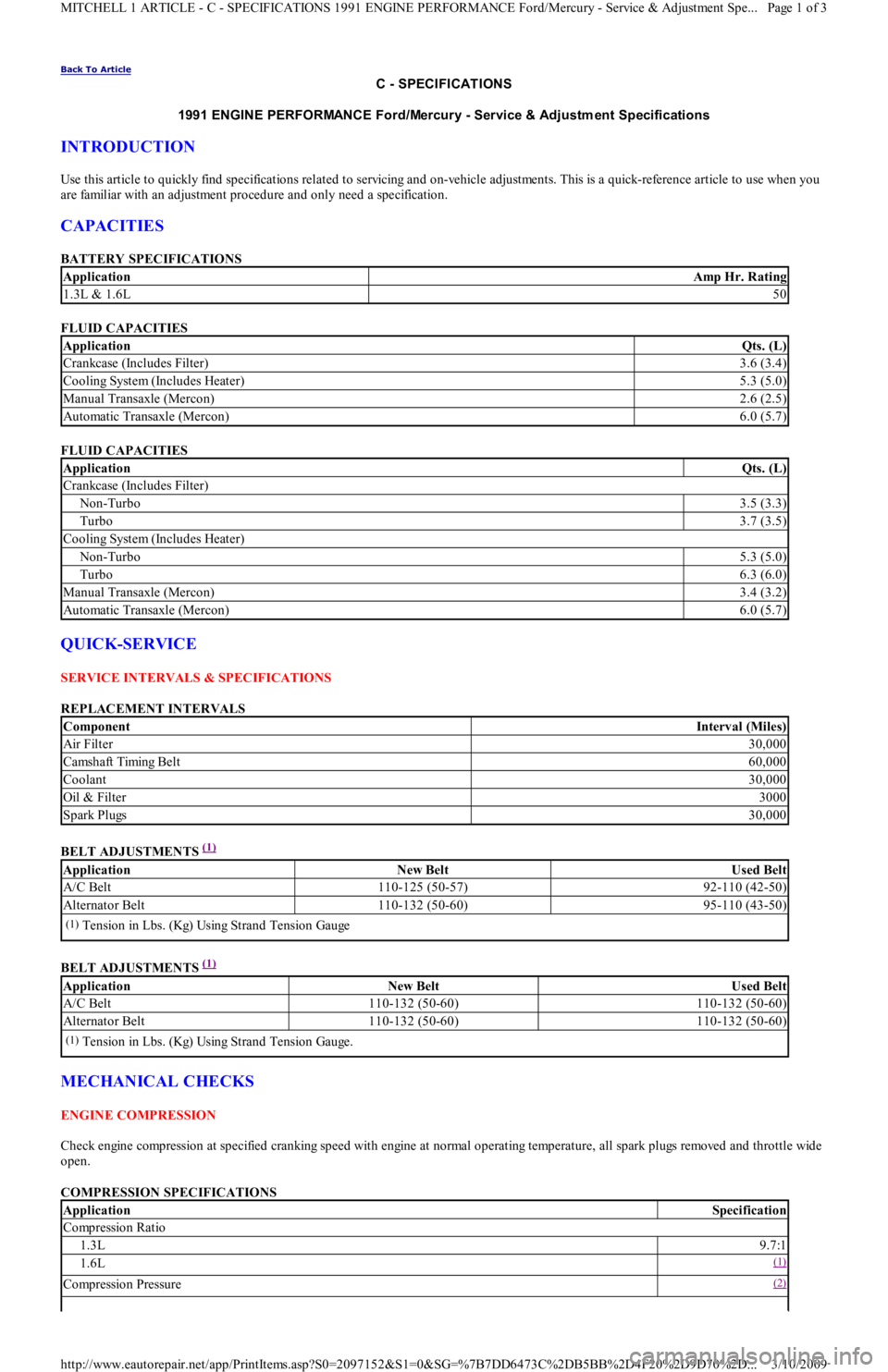

C - SPECIFICATIONS

1991 ENGINE PERFORMANCE Ford/Mercury - Service & Adjustm ent Specifications

INTRODUCTION

Use this article to quickly find specifications related to servicing and on-vehicle adjustments. This is a quick-reference article to use when you

are familiar with an adjustment procedure and only need a specification.

CAPACITIES

BATTERY SPECIFICATIONS

FLUID CAPACITIES

FLUID CAPACITIES

QUICK-SERVICE

SERVICE INTERVALS & SPECIFICATIONS

REPLACEMENT INTERVALS

BELT ADJUSTMENTS

(1)

BELT ADJUSTMENTS

(1)

MECHANICAL CHECKS

ENGINE COMPRESSION

Check engine compression at specified cranking speed with engine at normal operating temperature, all spark plugs removed and throttle wide

open.

COMPRESSION SPECIFICATIONS

ApplicationAmp Hr. Rating

1.3L & 1.6L50

ApplicationQts. (L)

Crankcase (Includes Filter)3.6 (3.4)

Cooling System (Includes Heater)5.3 (5.0)

Manual Transaxle (Mercon)2.6 (2.5)

Automatic Transaxle (Mercon)6.0 (5.7)

ApplicationQts. (L)

Crankcase (Includes Filter)

Non-Turbo3.5 (3.3)

Turbo3.7 (3.5)

Cooling System (Includes Heater)

Non-Turbo5.3 (5.0)

Turbo6.3 (6.0)

Manual Transaxle (Mercon)3.4 (3.2)

Automatic Transaxle (Mercon)6.0 (5.7)

ComponentInterval (Miles)

Air Filter30,000

Camsh aft Timin g Bel t60,000

Coolant30,000

Oil & Filter3000

Spark Plugs30,000

ApplicationNew BeltUsed Belt

A/C Belt110-125 (50-57)92-110 (42-50)

Alternator Belt110-132 (50-60)95-110 (43-50)

(1)Tension in Lbs. (Kg) Using Strand Tension Gauge

ApplicationNew BeltUsed Belt

A/C Belt110-132 (50-60)110-132 (50-60)

Alternator Belt110-132 (50-60)110-132 (50-60)

(1)Tension in Lbs. (Kg) Using Strand Tension Gauge.

ApplicationSpecification

Compression Ratio

1.3L9.7:1

1.6L(1)

Compression Pressure(2)

Page 1 of 3 MITCHELL 1 ARTICLE - C - SPECIFICATIONS 1991 ENGINE PERFORMANCE Ford/Mercury - Service & Adjustment Spe

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 156 of 454

Back To Article

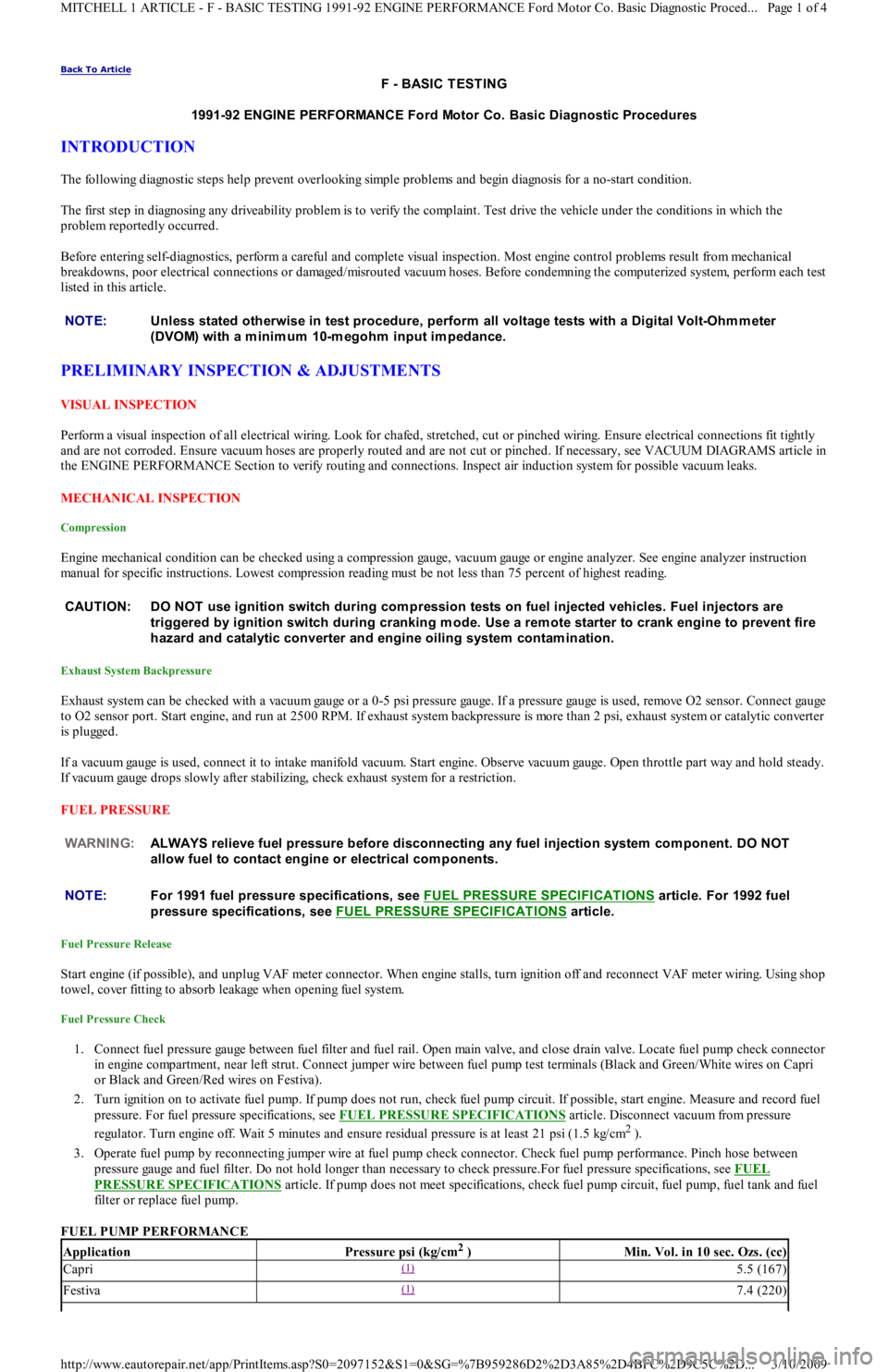

F - BASIC TESTING

1991-92 ENGINE PERFORMANCE Ford Motor Co. Basic Diagnostic Procedures

INTRODUCTION

The following diagnostic steps help prevent overlooking simple problems and begin diagnosis for a no-start condition.

The first step in diagnosing any driveability problem is to verify the complaint. Test drive the vehicle under the conditions in which the

problem reportedly occurred.

Before entering self-diagnostics, perform a careful and complete visual inspection. Most engine control problems result from mechanical

breakdowns, poor electrical connections or damaged/misrouted vacuum hoses. Before condemning the computerized system, perform each test

listed in this article.

PRELIMINARY INSPECTION & ADJUSTMENTS

VISUAL INSPECTION

Perform a visual inspection of all electrical wiring. Look for chafed, stretched, cut or pinched wiring. Ensure electrical connections fit tightly

and are not corroded. Ensure vacuum hoses are properly routed and are not cut or pinched. If necessary, see VACUUM DIAGRAMS article in

the ENGINE PERFORMANCE Section to verify routing and connections. Inspect air induction system for possible vacuum leaks.

MECHANICAL INSPECTION

Compression

Engine mechanical condition can be checked using a compression gauge, vacuum gauge or engine analyzer. See engine analyzer instruction

manual for specific instructions. Lowest compression reading must be not less than 75 percent of highest reading.

Exhaust System Backpressure

Exhaust system can be checked with a vacuum gauge or a 0-5 psi pressure gauge. If a pressure gauge is used, remove O2 sensor. Connect gauge

to O2 sensor port. Start engine, and run at 2500 RPM. If exhaust system backpressure is more than 2 psi, exhaust system or catalytic converter

is plugged.

If a vacuum gauge is used, connect it to intake manifold vacuum. Start engine. Observe vacuum gauge. Open throttle part way and hold steady.

If vacuum gauge drops slowly after stabilizing, check exhaust system for a restriction.

FUEL PRESSURE

Fuel Pressure Release

Start engine (if possible), and unplug VAF meter connector. When engine stalls, turn ignition off and reconnect VAF meter wiring. Usin g sh o p

towel, cover fitting to absorb leakage when opening fuel system.

Fuel Pressure Check

1. Connect fuel pressure gauge between fuel filter and fuel rail. Open main valve, and close drain valve. Locate fuel pump check connector

in engine compartment, near left strut. Connect jumper wire between fuel pump test terminals (Black and Green/White wires on Capri

or Black and Green/Red wires on Festiva).

2. Turn ignition on to activate fuel pump. If pump does not run, check fuel pump circuit. If possible, start engine. Measure and record fuel

pressure. For fuel pressure specifications, see FUEL PRESSURE SPECIFICATIONS

article. Disconnect vacuum from pressure

regulator. Turn engine off. Wait 5 minutes and ensure residual pressure is at least 21 psi (1.5 kg/cm

2 ).

3. Operate fuel pump by reconnecting jumper wire at fuel pump check connector. Check fuel pump performance. Pinch hose between

pressure gauge and fuel filter. Do not hold longer than necessary to check pressure.For fuel pressure specifications, see FUEL

PRESSURE SPECIFICATIONS article. If pump does not meet specifications, check fuel pump circuit, fuel pump, fuel tank and fuel

filter or replace fuel pump.

FUEL PUMP PERFORMANCE NOTE:Unless stated otherwise in test procedure, perform all voltage tests with a Digital Volt-Ohm m eter

(DVOM) with a m inim um 10-m egohm input im pedance.

CAUT ION: DO NOT use ignition switch during com pression tests on fuel injected vehicles. Fuel injectors are

triggered by ignition switch during cranking m ode. Use a rem ote starter to crank engine to prevent fire

hazard and catalytic converter and engine oiling system contam ination.

WARNING:ALWAYS relieve fuel pressure before disconnecting any fuel injection system com ponent. DO NOT

allow fuel to contact engine or electrical com ponents.

NOTE:For 1991 fuel pressure specifications, see FUEL PRESSURE SPECIFICAT IONS

article. For 1992 fuel

pressure specifications, see FUEL PRESSURE SPECIFICAT IONS

article.

ApplicationPressure psi (kg/cm2 )Min. Vol. in 10 sec. Ozs. (cc)

Capri(1) 5.5 (167)

Festiva(1) 7.4 (220)

Page 1 of 4 MITCHELL 1 ARTICLE - F - BASIC TESTING 1991-92 ENGINE PERFORMANCE Ford Motor Co. Basic Diagnostic Proced

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 195 of 454

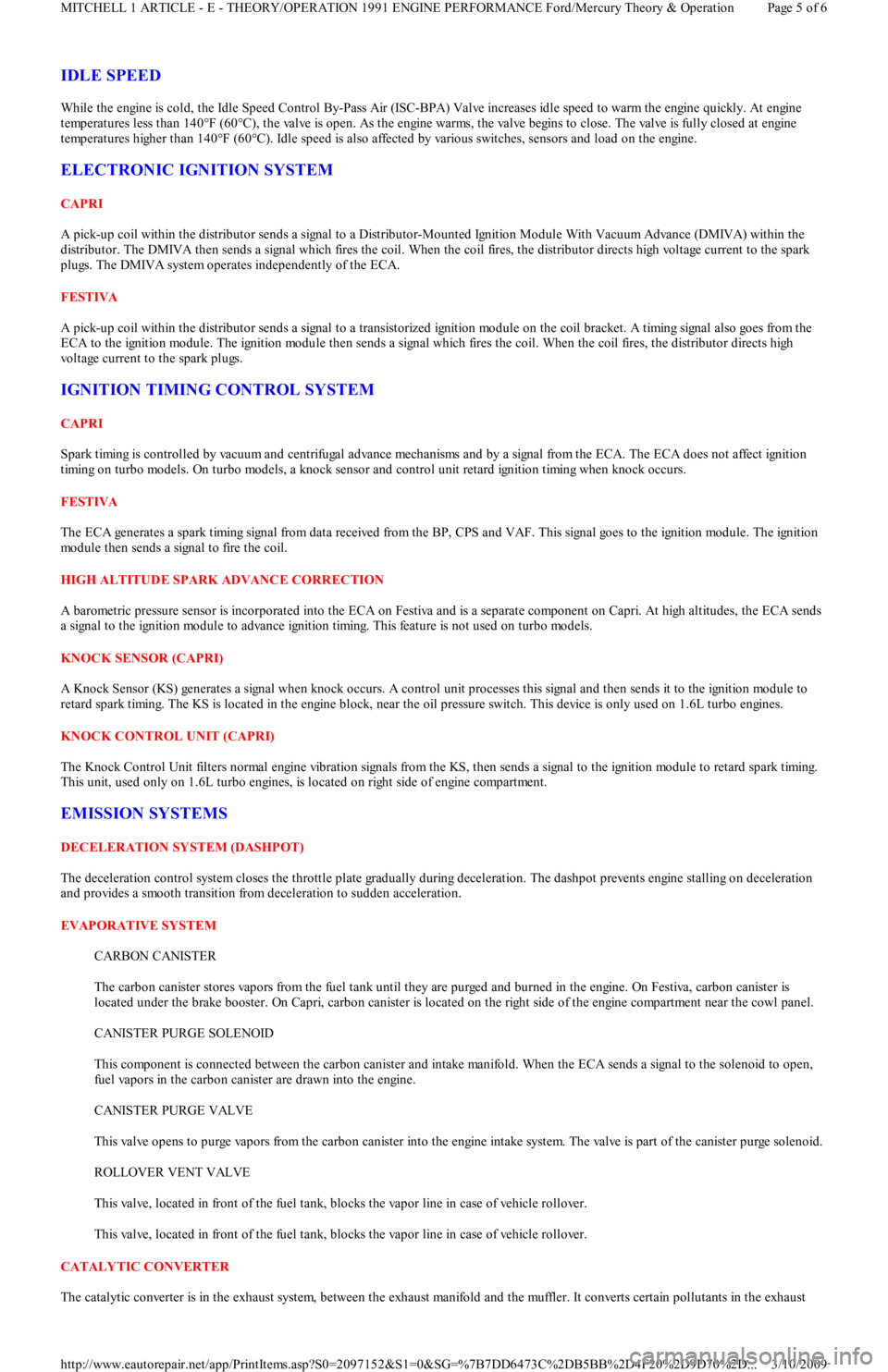

IDLE SPEED

While the engine is cold, the Idle Speed Control By-Pass Air (ISC-BPA) Valve increases idle speed to warm the engine quickly. At engine

temperatures less than 140°F (60°C), the valve is open. As the engine warms, the valve begins to close. The valve is fully closed at engine

temperatures higher than 140°F (60°C). Idle speed is also affected by various switches, sensors and load on the engine.

ELECTRONIC IGNITION SYSTEM

CAPRI

A pick-up coil within the distributor sends a signal to a Distributor-Mounted Ignition Module With Vacuum Advance (DMIVA) within the

distributor. The DMIVA then sends a signal which fires the coil. When the coil fires, the distributor directs high voltage current to the spark

plugs. The DMIVA system operates independently of the ECA.

FESTIVA

A pick-up coil within the distributor sends a signal to a transistorized ignition module on the coil bracket. A timing signal also goes from the

ECA to the ignition module. The ignition module then sends a signal which fires the coil. When the coil fires, the distributor directs high

voltage current to the spark plugs.

IGNITION TIMING CONTROL SYSTEM

CAPRI

Spark timing is controlled by vacuum and centrifugal advance mechanisms and by a signal from the ECA. The ECA does not affect ignition

timing on turbo models. On turbo models, a knock sensor and control unit retard ignition timing when knock occurs.

FESTIVA

The ECA generates a spark timing signal from data received from the BP, CPS and VAF. This signal goes to the ignition module. The ignition

module then sends a signal to fire the coil.

HIGH ALTITUDE SPARK ADVANCE CORRECTION

A barometric pressure sensor is incorporated into the ECA on Festiva and is a separate component on Capri. At high altitudes, the ECA sends

a signal to the ignition module to advance ignition timing. This feature is not used on turbo models.

KNOCK SENSOR (CAPRI)

A Knock Sensor (KS) generates a signal when knock occurs. A control unit processes this signal and then sends it to the ignition module to

retard spark timing. The KS is located in the engine block, near the oil pressure switch. This device is only used on 1.6L turbo engines.

KNOCK CONTROL UNIT (CAPRI)

The Knock Control Unit filters normal engine vibration signals from the KS, then sends a signal to the ignition module to retard spark timing.

This unit, used only on 1.6L turbo engines, is located on right side of engine compartment.

EMISSION SYSTEMS

DECELERATION SYSTEM (DASHPOT)

The deceleration control system closes the throttle plate gradually during deceleration. The dashpot prevents engine stalling on deceleration

and provides a smooth transition from deceleration to sudden acceleration.

EVAPORATIVE SYSTEM

CARBON CANISTER

The carbon canister stores vapors from the fuel tank until they are purged and burned in the engine. On Festiva, carbon canister is

located under the brake booster. On Capri, carbon canister is located on the right side of the engine compartment near the cowl panel.

CANISTER PURGE SOLENOID

This component is connected between the carbon canister and intake manifold. When the ECA sends a signal to the solenoid to open,

fuel vapors in the carbon canister are drawn into the engine.

CANISTER PURGE VALVE

This valve opens to purge vapors from the carbon canister into the engine intake system. The valve is part of the canister purge solenoid.

ROLLOVER VENT VALVE

This valve, located in front of the fuel tank, blocks the vapor line in case of vehicle rollover.

This valve, located in front of the fuel tank, blocks the vapor line in case of vehicle rollover.

CATALYTIC CONVERTER

The catalytic converter is in the exhaust system, between the exhaust manifold and the muffler. It converts certain pollutants in the exhaust

Page 5 of 6 MITCHELL 1 ARTICLE - E - THEORY/OPERATION 1991 ENGINE PERFORMANCE Ford/Mercury Theory & Operation

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 223 of 454

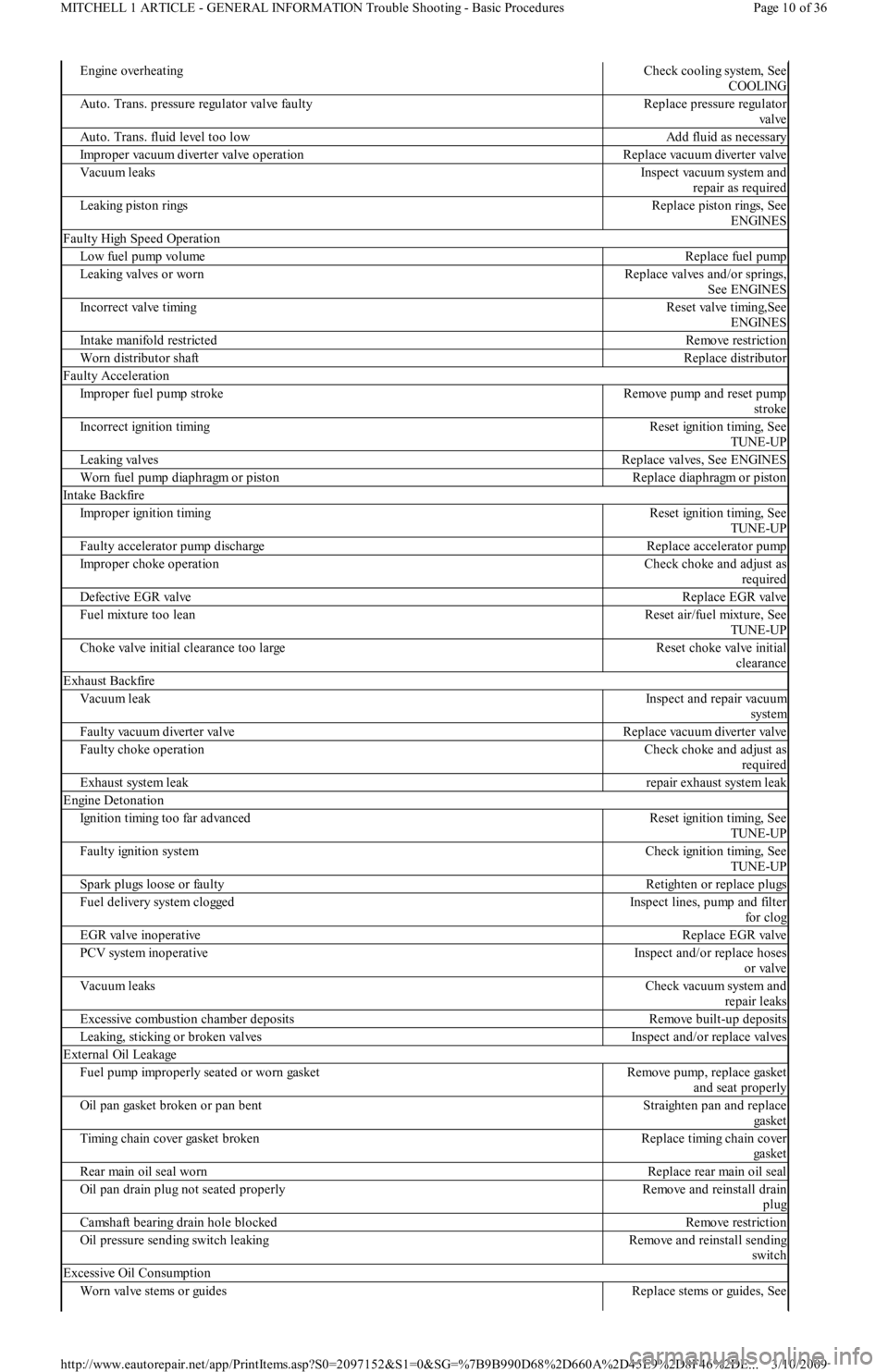

Engine overheatingCheck cooling system, See

COOLING

Auto. Trans. pressure regulator valve faultyReplace pressure regulator

va l ve

Auto. Trans. fluid level too lowAdd fluid as necessary

Improper vacuum diverter valve operationReplace vacuum diverter valve

Vacuum leaksInspect vacuum system and

repair as required

Leaking piston ringsReplace piston rings, See

ENGINES

Faulty High Speed Operation

Low fuel pump volumeReplace fuel pump

Le a kin g va l ve s o r wo r nReplace valves and/or springs,

See ENGINES

Incorrect valve timingReset valve timing,See

ENGINES

In t ake man ifo l d rest rict edRemove restriction

Worn distributor shaftReplace distributor

Faulty Acceleration

Improper fuel pump strokeRemove pump and reset pump

stroke

Incorrect ignition timingReset ignition timing, See

TUNE-UP

Le a kin g va l ve sReplace valves, See ENGINES

Worn fuel pump diaphragm or pistonReplace diaphragm or piston

In t ake Backfire

Improper ignition timingReset ignition timing, See

TUNE-UP

Faulty accelerator pump dischargeReplace accelerator pump

Improper choke operationCheck choke and adjust as

required

Defective EGR valveReplace EGR valve

Fuel mixture too leanReset air/fuel mixture, See

TUNE-UP

Choke valve initial clearance too largeReset choke valve initial

clearance

Exhaust Backfire

Vacuum leakInspect and repair vacuum

system

Faulty vacuum diverter valveReplace vacuum diverter valve

Faulty choke operationCheck choke and adjust as

required

Exhaust system leakrepair exhaust system leak

Engine Detonation

Ignition timing too far advancedReset ignition timing, See

TUNE-UP

Faulty ignition systemCheck ignition timing, See

TUNE-UP

Spark plugs loose or faultyRetighten or replace plugs

Fuel delivery system cloggedInspect lines, pump and filter

fo r cl o g

EGR valve inoperativeReplace EGR valve

PCV system inoperativeInspect and/or replace hoses

or valve

Vacuum leaksCheck vacuum system and

repair leaks

Excessive combustion chamber depositsRemove built-up deposits

Leaking, sticking or broken valvesInspect and/or replace valves

External Oil Leakage

Fuel pump improperly seated or worn gasketRemove pump, replace gasket

and seat properly

Oil pan gasket broken or pan bentStraighten pan and replace

ga ske t

Timing chain cover gasket brokenReplace timing chain cover

ga ske t

Rear main oil seal wornReplace rear main oil seal

Oil pan drain plug not seated properlyRemove and reinstall drain

plug

Camshaft bearing drain hole blockedRemove restriction

Oil pressure sending switch leakingRemove and reinstall sending

switch

Excessive Oil Consumption

Worn valve stems or guidesReplace stems or guides, See

Page 10 of 36 MITCHELL 1 ARTICLE - GENERAL INFORMATION Trouble Shooting - Basic Procedures

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 227 of 454

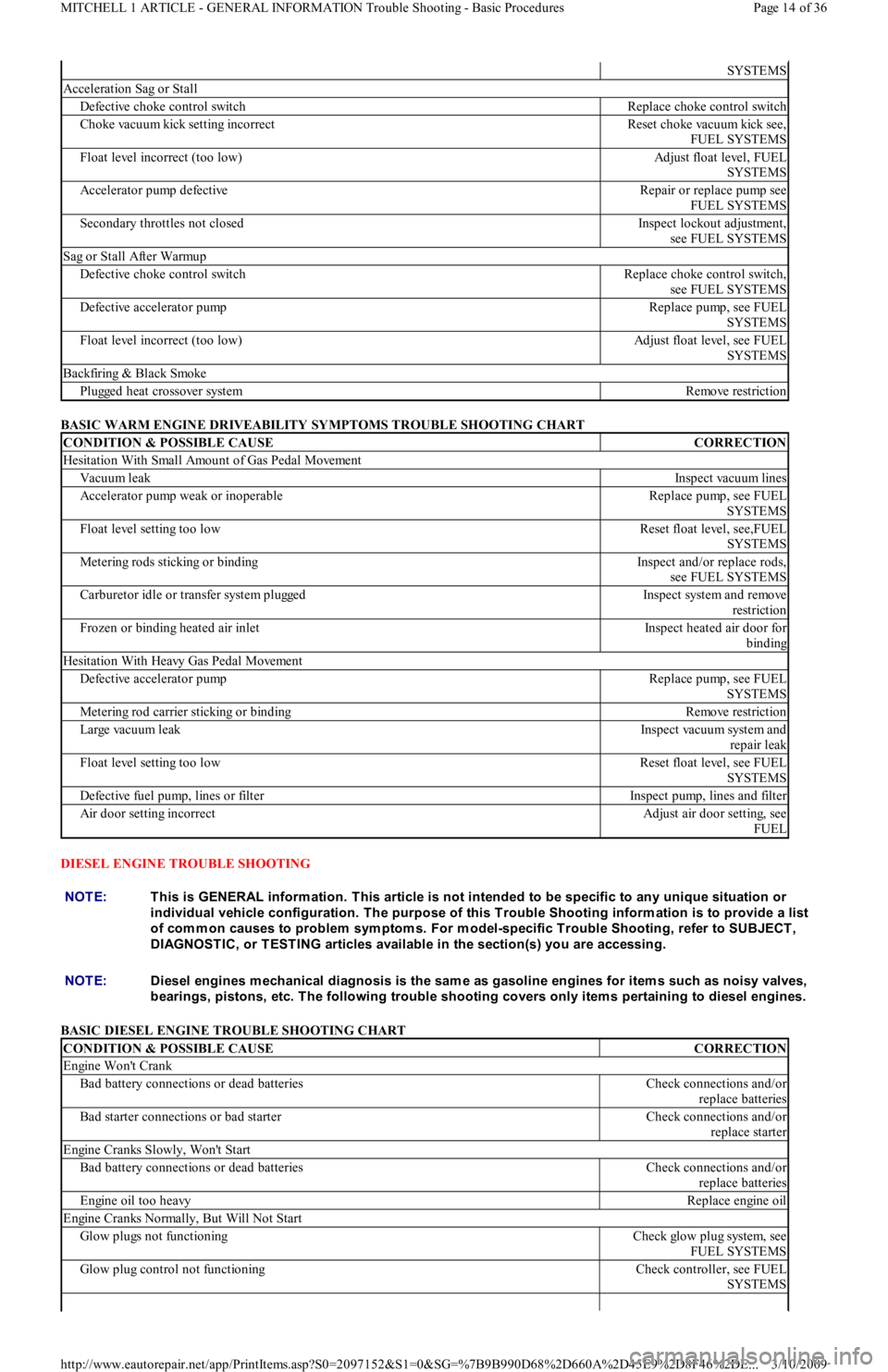

BASIC WARM ENGINE DRIVEABILITY SYMPTOMS TROUBLE SHOOTING CHART

DIESEL ENGINE TROUBLE SHOOTING

BASIC DIESEL ENGINE TROUBLE SHOOTING CHART

SYSTEMS

Acceleration Sag or Stall

Defective choke control switchReplace choke control switch

Choke vacuum kick setting incorrectReset choke vacuum kick see,

FUEL SYSTEMS

Float level incorrect (too low)Adjust float level, FUEL

SYSTEMS

Accelerator pump defectiveRepair or replace pump see

FUEL SYSTEMS

Secondary throttles not closedInspect lockout adjustment,

see FUEL SYSTEMS

Sag or Stall After Warmup

Defective choke control switchReplace choke control switch,

see FUEL SYSTEMS

Defective accelerator pumpReplace pump, see FUEL

SYSTEMS

Float level incorrect (too low)Adjust float level, see FUEL

SYSTEMS

Backfiring & Black Smoke

Plugged heat crossover systemRemove restriction

CONDITION & POSSIBLE CAUSECORRECTION

Hesitation With Small Amount of Gas Pedal Movement

Vacuum leakInspect vacuum lines

Accelerator pump weak or inoperableReplace pump, see FUEL

SYSTEMS

Float level setting too lowReset float level, see,FUEL

SYSTEMS

Metering rods sticking or bindingInspect and/or replace rods,

see FUEL SYSTEMS

Carburetor idle or transfer system pluggedInspect system and remove

restriction

Frozen or binding heated air inletInspect heated air door for

binding

Hesitation With Heavy Gas Pedal Movement

Defective accelerator pumpReplace pump, see FUEL

SYSTEMS

Metering rod carrier sticking or bindingRemove restriction

Large vacuum leakInspect vacuum system and

repair leak

Float level setting too lowReset float level, see FUEL

SYSTEMS

Defective fuel pump, lines or filterInspect pump, lines and filter

Air door setting incorrectAdjust air door setting, see

FUEL

NOTE:This is GENERAL inform ation. This article is not intended to be specific to any unique situation or

individual vehicle configuration. T he purpose of this T rouble Shooting inform ation is to provide a list

of com m on causes to problem sym ptom s. For m odel-specific T rouble Shooting, refer to SUBJECT ,

DIAGNOST IC, or T EST ING articles available in the section(s) you are accessing.

NOTE:Diesel engines m echanical diagnosis is the sam e as gasoline engines for item s such as noisy valves,

bearings, pistons, etc. T he following trouble shooting covers only item s pertaining to diesel engines.

CONDITION & POSSIBLE CAUSECORRECTION

Engine Won't Crank

Bad battery connections or dead batteriesCheck connections and/or

replace batteries

Bad starter connections or bad starterCheck connections and/or

replace starter

Engine Cranks Slowly, Won't Start

Bad battery connections or dead batteriesCheck connections and/or

replace batteries

Engine oil too heavyReplace engine oil

Engine Cranks Normally, But Will Not Start

Glow plugs not functioningCheck glow plug system, see

FUEL SYSTEMS

Glow plug control not functioningCheck controller, see FUEL

SYSTEMS

Page 14 of 36 MITCHELL 1 ARTICLE - GENERAL INFORMATION Trouble Shooting - Basic Procedures

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...