FORD FIESTA 1989 Service Repair Manual

Manufacturer: FORD, Model Year: 1989, Model line: FIESTA, Model: FORD FIESTA 1989Pages: 296, PDF Size: 10.65 MB

Page 201 of 296

8 Front suspension lower arm- removal and refitting

3

Removal

1Chock the rear wheels then jack up the

front of the car and support it on axle stands

(see “Jacking and Vehicle Support” ). Remove

the appropriate front roadwheel.

2 Remove the one-piece undertray (where

fitted), by turning its bayonet-type fasteners.

3 If lower arm mounting brackets are to be

removed on XR2i models, remove the front

suspension crossmember as described in the

previous Section.

4 Unscrew and remove the lower arm

balljoint-to-spindle carrier pinch-bolt. Prise

the joint open using a large flat-bladed tool,

and detach the balljoint from the spindle

carrier. Take care not to damage the balljoint

seal during the separation procedures.

5 Where an anti-roll bar is fitted, undo the two

bolts and remove the clamp bracket.

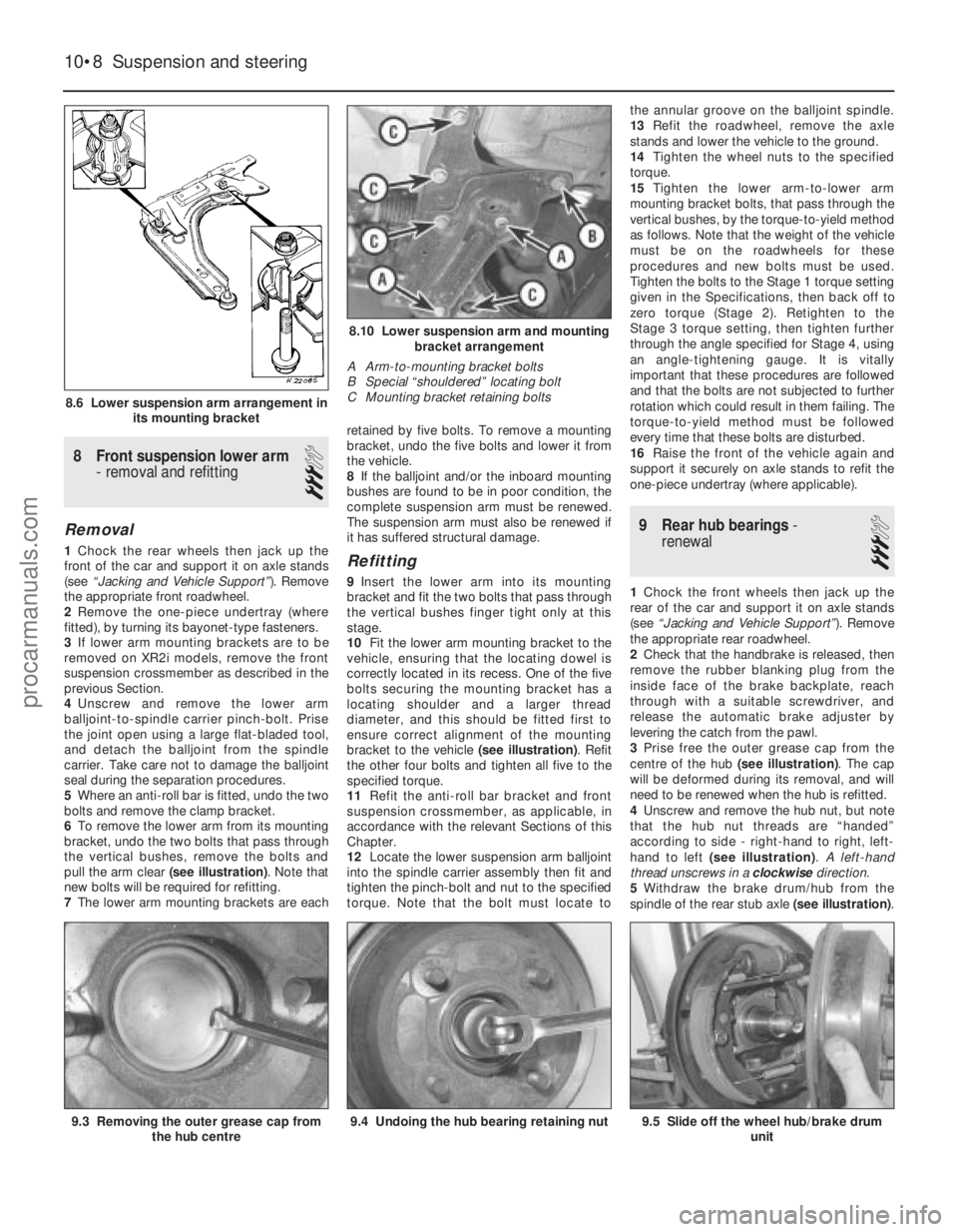

6 To remove the lower arm from its mounting

bracket, undo the two bolts that pass through

the vertical bushes, remove the bolts and

pull the arm clear (see illustration). Note that

new bolts will be required for refitting.

7 The lower arm mounting brackets are each retained by five bolts. To remove a mounting

bracket, undo the five bolts and lower it from

the vehicle.

8

If the balljoint and/or the inboard mounting

bushes are found to be in poor condition, the

complete suspension arm must be renewed.

The suspension arm must also be renewed if

it has suffered structural damage.Refitting

9 Insert the lower arm into its mounting

bracket and fit the two bolts that pass through

the vertical bushes finger tight only at this

stage.

10 Fit the lower arm mounting bracket to the

vehicle, ensuring that the locating dowel is

correctly located in its recess. One of the five

bolts securing the mounting bracket has a

locating shoulder and a larger thread

diameter, and this should be fitted first to

ensure correct alignment of the mounting

bracket to the vehicle (see illustration). Refit

the other four bolts and tighten all five to the

specified torque.

11 Refit the anti-roll bar bracket and front

suspension crossmember, as applicable, in

accordance with the relevant Sections of this

Chapter.

12 Locate the lower suspension arm balljoint

into the spindle carrier assembly then fit and

tighten the pinch-bolt and nut to the specified

torque. Note that the bolt must locate to the annular groove on the balljoint spindle.

13

Refit the roadwheel, remove the axle

stands and lower the vehicle to the ground.

14 Tighten the wheel nuts to the specified

torque.

15 Tighten the lower arm-to-lower arm

mounting bracket bolts, that pass through the

vertical bushes, by the torque-to-yield method

as follows. Note that the weight of the vehicle

must be on the roadwheels for these

procedures and new bolts must be used.

Tighten the bolts to the Stage 1 torque setting

given in the Specifications, then back off to

zero torque (Stage 2). Retighten to the

Stage 3 torque setting, then tighten further

through the angle specified for Stage 4, using

an angle-tightening gauge. It is vitally

important that these procedures are followed

and that the bolts are not subjected to further

rotation which could result in them failing. The

torque-to-yield method must be followed

every time that these bolts are disturbed.

16 Raise the front of the vehicle again and

support it securely on axle stands to refit the

one-piece undertray (where applicable).

9 Rear hub bearings -

renewal

3

1 Chock the front wheels then jack up the

rear of the car and support it on axle stands

(see “Jacking and Vehicle Support” ). Remove

the appropriate rear roadwheel.

2 Check that the handbrake is released, then

remove the rubber blanking plug from the

inside face of the brake backplate, reach

through with a suitable screwdriver, and

release the automatic brake adjuster by

levering the catch from the pawl.

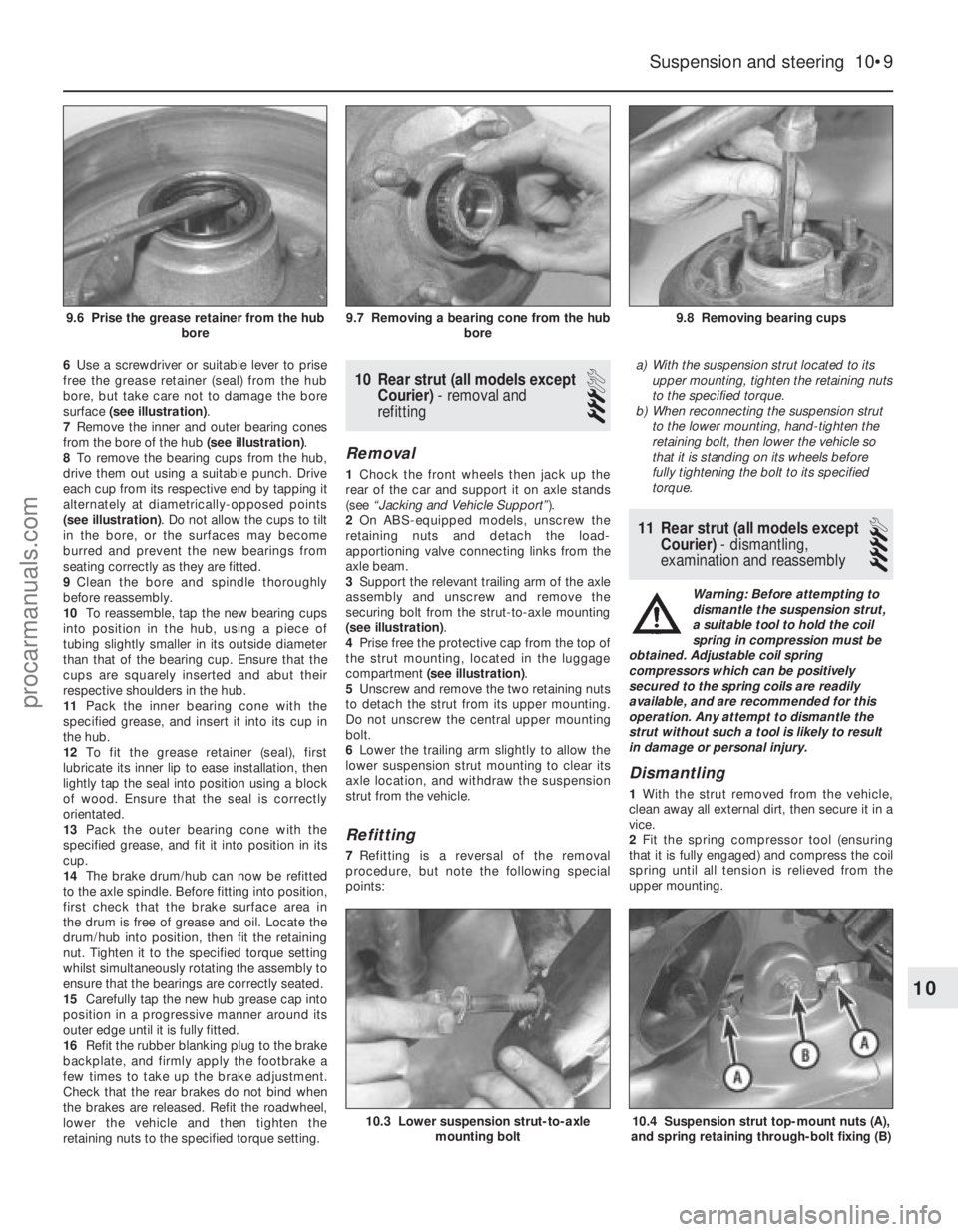

3 Prise free the outer grease cap from the

centre of the hub (see illustration). The cap

will be deformed during its removal, and will

need to be renewed when the hub is refitted.

4 Unscrew and remove the hub nut, but note

that the hub nut threads are “handed”

according to side - right-hand to right, left-

hand to left (see illustration) . A left-hand

thread unscrews in a clockwisedirection.

5 Withdraw the brake drum/hub from the

spindle of the rear stub axle (see illustration).

10•8 Suspension and steering

9.5 Slide off the wheel hub/brake drum

unit9.4 Undoing the hub bearing retaining nut9.3 Removing the outer grease cap fromthe hub centre

8.10 Lower suspension arm and mountingbracket arrangement

A Arm-to-mounting bracket bolts

B Special “shouldered” locating bolt

C Mounting bracket retaining bolts

8.6 Lower suspension arm arrangement in its mounting bracket

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 202 of 296

6Use a screwdriver or suitable lever to prise

free the grease retainer (seal) from the hub

bore, but take care not to damage the bore

surface (see illustration) .

7 Remove the inner and outer bearing cones

from the bore of the hub (see illustration).

8 To remove the bearing cups from the hub,

drive them out using a suitable punch. Drive

each cup from its respective end by tapping it

alternately at diametrically-opposed points

(see illustration) . Do not allow the cups to tilt

in the bore, or the surfaces may become

burred and prevent the new bearings from

seating correctly as they are fitted.

9 Clean the bore and spindle thoroughly

before reassembly.

10 To reassemble, tap the new bearing cups

into position in the hub, using a piece of

tubing slightly smaller in its outside diameter

than that of the bearing cup. Ensure that the

cups are squarely inserted and abut their

respective shoulders in the hub.

11 Pack the inner bearing cone with the

specified grease, and insert it into its cup in

the hub.

12 To fit the grease retainer (seal), first

lubricate its inner lip to ease installation, then

lightly tap the seal into position using a block

of wood. Ensure that the seal is correctly

orientated.

13 Pack the outer bearing cone with the

specified grease, and fit it into position in its

cup.

14 The brake drum/hub can now be refitted

to the axle spindle. Before fitting into position,

first check that the brake surface area in

the drum is free of grease and oil. Locate the

drum/hub into position, then fit the retaining

nut. Tighten it to the specified torque setting

whilst simultaneously rotating the assembly to

ensure that the bearings are correctly seated.

15 Carefully tap the new hub grease cap into

position in a progressive manner around its

outer edge until it is fully fitted.

16 Refit the rubber blanking plug to the brake

backplate, and firmly apply the footbrake a

few times to take up the brake adjustment.

Check that the rear brakes do not bind when

the brakes are released. Refit the roadwheel,

lower the vehicle and then tighten the

retaining nuts to the specified torque setting.10 Rear strut (all models except Courier) - removal and

refitting

3

Removal

1 Chock the front wheels then jack up the

rear of the car and support it on axle stands

(see “Jacking and Vehicle Support” ).

2 On ABS-equipped models, unscrew the

retaining nuts and detach the load-

apportioning valve connecting links from the

axle beam.

3 Support the relevant trailing arm of the axle

assembly and unscrew and remove the

securing bolt from the strut-to-axle mounting

(see illustration) .

4 Prise free the protective cap from the top of

the strut mounting, located in the luggage

compartment (see illustration) .

5 Unscrew and remove the two retaining nuts

to detach the strut from its upper mounting.

Do not unscrew the central upper mounting

bolt.

6 Lower the trailing arm slightly to allow the

lower suspension strut mounting to clear its

axle location, and withdraw the suspension

strut from the vehicle.

Refitting

7 Refitting is a reversal of the removal

procedure, but note the following special

points: a)

With the suspension strut located to its

upper mounting, tighten the retaining nuts

to the specified torque.

b) When reconnecting the suspension strut

to the lower mounting, hand-tighten the

retaining bolt, then lower the vehicle so

that it is standing on its wheels before

fully tightening the bolt to its specified

torque.

11 Rear strut (all models except

Courier) - dismantling,

examination and reassembly

4

Warning: Before attempting to

dismantle the suspension strut,

a suitable tool to hold the coil

spring in compression must be

obtained. Adjustable coil spring

compressors which can be positively

secured to the spring coils are readily

available, and are recommended for this

operation. Any attempt to dismantle the

strut without such a tool is likely to result

in damage or personal injury.

Dismantling

1 With the strut removed from the vehicle,

clean away all external dirt, then secure it in a

vice.

2 Fit the spring compressor tool (ensuring

that it is fully engaged) and compress the coil

spring until all tension is relieved from the

upper mounting.

Suspension and steering 10•9

9.8 Removing bearing cups9.7 Removing a bearing cone from the hub bore9.6 Prise the grease retainer from the hubbore

10.4 Suspension strut top-mount nuts (A),

and spring retaining through-bolt fixing (B)10.3 Lower suspension strut-to-axle mounting bolt

10

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 203 of 296

3Unscrew and remove the upper mounting

through-bolt and nut.

4 Withdraw the upper mounting cup and the

spring seat.

5 The suspension strut and coil spring can now

be separated. If the coil spring or strut is to be

renewed, the original coil spring must be

released from the compressor. If it is to be re-

used, the coil spring can be left in compression.

Examination

6 With the strut assembly now completely

dismantled, examine the mounting

components for wear, damage or deformation.

Renew any of the components as necessary.

7 Examine the strut for signs of fluid leakage.

Check the strut piston for signs of pitting

along its entire length, and check the strut

body for signs of damage or deterioration of

the mountings. Test the operation of the strut,

holding it in an upright position, by moving the

piston through a full stroke, and then through

short strokes of 50 to 100 mm. In both cases,

the resistance felt should be smooth and

continuous. If the resistance is jerky, or

uneven, or if there is any visible sign of wear

or damage to the strut, renewal is necessary.

Reassembly

8 Reassembly is a reversal of the dismantling

procedure but note the following points: a) When the spring is located over the

suspension strut, the spring seat, cup and

through-bolt fitted, tighten the retaining

bolt to the specified torque.

b) When reassembled, check that the upper

and lower spring tails are correctly

engaged with their spring seats before

removing the spring compressor.

12 Rear axle (all models except

Courier) -

removal and refitting

3

Removal

1 Chock the front wheels then jack up the

rear of the car and support it on axle stands

(see “Jacking and Vehicle Support” ). Remove

the rear roadwheels.

2 Refer to Chapter 9 for details, and disconnect

the handbrake cable equaliser from the primary

cable. Remove the handbrake rear cable from

its adjuster and its fixed body locations.

3 Disconnect the rear brake flexible hydraulic

brake hoses from their rigid line connections.

Clamp the hoses before disconnecting them,

to minimise the fluid loss and air entry into the

hydraulic system (see Chapter 9 for details).

4 On ABS-equipped models, undo the

retaining nuts and detach the ABS load-

apportioning valve operating links from the

axle beam. Do not remove the load-

apportioning valve (see Chapter 9).

5 Locate suitable jacks or axle stands under

the axle beam to support its weight (not to lift

it), then unscrew the four mounting bracket

bolts each side. 6

Unscrew and remove the strut-to-axle

mounting bolt each side.

7 Check that all associated fittings are clear,

then lower the axle and remove it from under

the vehicle.

8 If the twist beam axle has been damaged, it

must be renewed. Refer to Chapter 9 for

details on removing the rear brakes from the

axle. To remove the front mounting/pivot

brackets from the axle, unscrew the pivot bolt.

Refitting

9 Refitting is a reversal of the removal

procedure, but note the following: a) Reconnect the axle at the front floor mountings first, and tighten the retaining

bolts to the specified torque.

b) Reconnect the axle to the suspension struts, but do not fully retighten the securing

bolts until after the vehicle is lowered to the

ground and is standing on its wheels.

c) Ensure that all brake fluid line connections are clean before reconnecting them. Refer

to the appropriate Sections in Chapter 9

for specific details on reconnecting the

brake lines, bleeding the brake hydraulic

system, and for reconnecting the

handbrake cable and its adjustment.

d) When the vehicle is lowered and is standing

on its wheels, tighten the suspension

fastenings to their specified torque settings.

13 Rear axle pivot bushes (all

models except Courier) -

renewal

3

Note: Two different types of pivot bushes

have been fitted during the course of Fiesta

production. It is understood that once stocks

of the early type are exhausted, only the latter

type will be supplied by Ford parts dealers. If

renewing pivot bushes on a pre-April 1990

model, and only the later type bushes are

available, fit the new bushes as described

from paragraph 15 onward.

Pre-April 1990 models

1 Chock the front wheels then jack up the

rear of the car and support it on axle stands

(see “Jacking and Vehicle Support” ).2

Position a suitable support (preferably

adjustable) under the axle twist beam so that

it is capable of carrying the weight of the axle

(not the weight of the vehicle).

3 On ABS-equipped models, undo the

retaining nuts and detach the ABS load-

apportioning valve operating links from the

axle beam. Do not remove the load-

apportioning valve (see Chapter 9).

4 Unscrew the nuts, withdraw the pivot bolts,

then lower the rear axle so that the bushes are

clear of their mounting brackets (see

illustration) . Take care not to allow the brake

pipes to become distorted and stretched - if

necessary, disconnect the hydraulic lines (see

Chapter 9 for details).

5 Undo the four body mounting bracket bolts

and remove the brackets.

6 Using a soft-faced hammer and a suitable

punch or drift, drive the bushes from their

locations, taking care not to raise any burrs on

the trailing arm eyes.

7 To fit the new bushes, obtain a steel tube of

a diameter slightly less than that of the bush

location in the axle, various flat washers and a

long bolt and nut.

8 Place the new bush in position in its axle

location with the bush collar nearest to the

outer edge of the vehicle. The bush must be

installed with its voids positioned as shown

(see illustration) . Using the steel tube,

washers, long bolt and nut, draw the bush

inwards towards the centre of the vehicle (see

illustration) . Care should be taken to avoid

damage to the bush and to obtain correct

10•10 Suspension and steering

13.8b Fitting pivot bush with its collar

(arrowed) towards the outer edge of the vehicle13.8a Correct pivot bush positioning intrailing arm

A Left-hand side B Right-hand side

13.4 Pivot bush bolt (A) and body mounting bracket bolts (B)

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 204 of 296

positioning of the voids. Install the bush on

the other side in the same way.

9With the new bushes in position, refit the

body mounting brackets loosely to the trailing

arms - do not fully tighten the pivot bolts at

this stage. Final tightening is carried out with

the vehicle standing on its roadwheels.

10 Raise the axle assembly so that the

conical locating pegs on the body mounting

brackets engage in their body locations. Refit

the body mounting bracket bolts and tighten

to the specified torque.

11 On ABS equipped models, reconnect the

load-apportioning valve operating links to the

rear axle beam

12 If the flexible brake hoses were

disconnected during this operation, reconnect

them and bleed the brake hydraulic system

(see Chapter 9).

13 Lower the vehicle to the ground.

14 Fully tighten the bush pivot bolt nuts to

the specified torque.

April 1990 models onward

15 As mentioned in the note at the start of

this Section, all later models are fitted with

revised bushes which use 12 mm (thread size)

pivot bolts. If the later type bushes are to be

fitted to a pre-April 1990 model, two

corresponding bolts and nuts must be

obtained at the same time, and either the

body mounting brackets must be replaced by

the corresponding modified items, or the

holes in the original brackets must be opened

out (to 12.5 mm) to suit the new bolts.

16 Carry out the operations described in

paragraphs 1 to 4 above.

17 Using a steel tube of suitable diameter,

various flat washers and a long bolt and nut,

draw the bush out of its location in the axle

trailing arm.

18 Clean the bush eye in the trailing arm;

lubricate it, and the new bush, with a soapy

solution (washing-up liquid, for example) prior

to installation.

19 Locate the new bush in position, together

with the steel tube, washers, bolt and nut as

used for removal. Ensure that the bush flange

is positioned on the outside, then draw the

bush fully into position so that its lip is

engaged (see illustration) .

20 Raise the axle to reposition the bush pin bores in line with the bolt holes in the

mounting brackets, then insert the pivot bolts.

Screw the retaining nuts into position on the

pivot bolts, but do not fully tighten them at

this stage.

21

Carry out the operations described in

paragraphs 11 to 14 above.

14 Rear suspension anti-roll bar (all models except Courier) -

removal and refitting

2

Removal

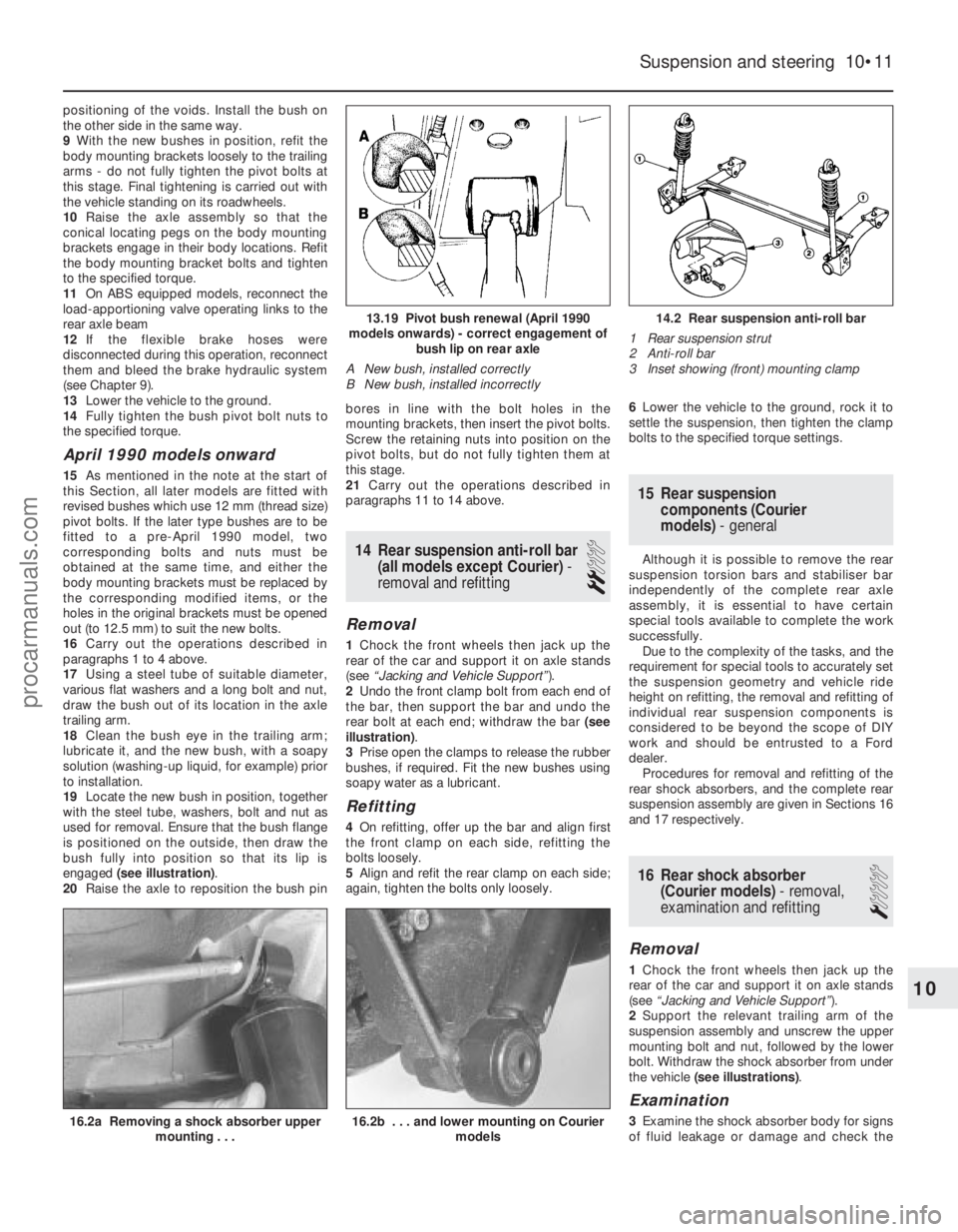

1 Chock the front wheels then jack up the

rear of the car and support it on axle stands

(see “Jacking and Vehicle Support” ).

2 Undo the front clamp bolt from each end of

the bar, then support the bar and undo the

rear bolt at each end; withdraw the bar (see

illustration) .

3 Prise open the clamps to release the rubber

bushes, if required. Fit the new bushes using

soapy water as a lubricant.

Refitting

4 On refitting, offer up the bar and align first

the front clamp on each side, refitting the

bolts loosely.

5 Align and refit the rear clamp on each side;

again, tighten the bolts only loosely. 6

Lower the vehicle to the ground, rock it to

settle the suspension, then tighten the clamp

bolts to the specified torque settings.

15 Rear suspension components (Courier

models) - general

Although it is possible to remove the rear

suspension torsion bars and stabiliser bar

independently of the complete rear axle

assembly, it is essential to have certain

special tools available to complete the work

successfully.

Due to the complexity of the tasks, and the

requirement for special tools to accurately set

the suspension geometry and vehicle ride

height on refitting, the removal and refitting of

individual rear suspension components is

considered to be beyond the scope of DIY

work and should be entrusted to a Ford

dealer. Procedures for removal and refitting of the

rear shock absorbers, and the complete rear

suspension assembly are given in Sections 16

and 17 respectively.

16 Rear shock absorber (Courier models) - removal,

examination and refitting

1

Removal

1 Chock the front wheels then jack up the

rear of the car and support it on axle stands

(see “Jacking and Vehicle Support” ).

2 Support the relevant trailing arm of the

suspension assembly and unscrew the upper

mounting bolt and nut, followed by the lower

bolt. Withdraw the shock absorber from under

the vehicle (see illustrations) .

Examination

3Examine the shock absorber body for signs

of fluid leakage or damage and check the

Suspension and steering 10•11

14.2 Rear suspension anti-roll bar

1 Rear suspension strut

2 Anti-roll bar

3 Inset showing (front) mounting clamp13.19 Pivot bush renewal (April 1990

models onwards) - correct engagement of bush lip on rear axle

A New bush, installed correctly

B New bush, installed incorrectly

16.2b . . . and lower mounting on Courier models16.2a Removing a shock absorber uppermounting . . .

10

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 205 of 296

mountings for signs of wear. Test the

operation of the unit, holding it in an upright

position, by moving the piston through a full

stroke, and then through short strokes of 50

to 100 mm. In both cases, the resistance felt

should be smooth and continuous. If the

resistance is jerky, or uneven, or if there is any

visible sign of wear or damage, the shock

absorber should be renewed. Note that if

either unit is to be renewed, it is good practice

to renew both together as a matched pair.

Refitting

4Locate the unit in position and refit the

mounting bolts and nut. Do not fully tighten

the mountings at this stage.

5 Lower the vehicle to the ground and rock it

to settle the suspension. Raise the vehicle

again, as necessary, until the shock absorber

is at an angle of 50° ± 5° to the horizontal.

With the shock absorber in this position,

tighten the upper and lower mountings to the

specified torque.

17 Rear suspension assembly (Courier models) -

removal and refitting

3

Removal

1 Chock the front wheels then jack up the

rear of the car and support it on axle stands

(see “Jacking and Vehicle Support” ). Remove

the rear roadwheels.

2 Refer to Chapter 9 for details, and

disconnect the handbrake cable equaliser

from the primary cable. Remove the

handbrake rear cable from its adjuster and its

fixed body locations. Release the exhaust

system mountings as necessary to allow the

handbrake cable to be withdrawn over the

rear of the exhaust.

3 Disconnect the rear brake flexible hydraulic

brake hoses from their rigid line connections

(see illustration) . Clamp the hoses before

disconnecting them, to minimise the fluid loss

and air entry into the hydraulic system (see

Chapter 9 for details).

4 Detach the light-laden valve linkage from

the bracket on the suspension assembly. 5

Locate suitable jacks under the suspension

assembly to support its weight (not to lift it).

6 Unscrew the shock absorber lower

mounting bolts on each side.

7 Unscrew the two mounting bracket bolts

each side (see illustration) , check that all

associated fittings are clear, then lower the

suspension assembly and remove it from

under the vehicle.

Refitting

8 Refitting is a reversal of the removal

procedure, but note the following: a) Refit the front mounting brackets first,

and tighten the retaining bolts to the

specified torque.

b) Reconnect the shock absorber lower

mountings, but do not fully retighten the

securing bolts until after the vehicle is

lowered to the ground and is standing on

its wheels.

c) Ensure that all brake fluid line connections are clean before reconnecting them. Refer

to the appropriate Sections in Chapter 9

for specific details on reconnecting the

brake lines, bleeding the brake hydraulic

system, adjusting the light laden valve,

and reconnecting and adjusting the

handbrake cable.

d) Once the vehicle is standing on its

wheels, raise it again, as necessary, until

the shock absorbers are at an angle of

50° ± 5° to the horizontal. With the shock

absorbers in this position, tighten the

lower mountings to the specified torque.

18 Rear suspension ride height (Courier models) - adjustment

4

Checking of the ride height requires the use

of Ford special tools to accurately compress

the suspension to a pre-determined value.

Further special tools are then required to

reposition the torsion bars to the new setting.

This operation should be entrusted to a

Ford dealer, as it is not possible to carry out

the procedure accurately without the use

of the appropriate tools.

19 Steering wheel -

removal and refitting

2

Removal

Models without air bag

1 Drive the vehicle in a straight line onto a

level surface, so that the roadwheels are

pointing straight ahead.

2 Carefully prise the motif from the centre of

the steering wheel (see illustration).

3 Mark the relative positions of the steering

wheel and steering column shaft.

4 Unscrew the retaining bolt from the centre

of the steering wheel, then insert the ignition

key and turn it to position “I”. Grip the wheel

each side, then pull and withdraw it from the

column shaft.

Models with air bag

Warning: Handle the air bag with

extreme care as a precaution

against personal injury, and

always hold it with the cover

facing away from your body. If in doubt

concerning any proposed work involving

the air bag or its control circuitry, consult a

Ford dealer or other qualified specialist.

5 Disconnect the battery negative (earth) lead

(refer to Chapter 5A, Section 1).

Warning: Before proceeding,

wait a minimum of 15 minutes,

as a precaution against

accidental firing of the air bag.

This period ensures that any stored energy

in the back-up capacitor is dissipated.

6 Undo the screws, and remove the steering

column lower shroud.

7 Undo the two external screws and the two

internal screws and remove the steering

column upper shroud.

10•12 Suspension and steering

19.2 Removing the motif from the steering wheel17.7 Courier rear suspension pivot

brackets locate on dowels in underbody17.3 Brake hose and rigid pipe connection on Courier rear suspension assembly

1595Ford Fiesta Remake

If the wheel is tight, tap it up

near the centre, using the

palm of your hand, or twist it

from side to side, whilst

pulling upwards to release it from the

shaft splines.

procarmanuals.com

http://vnx.su

Page 206 of 296

8Turn the steering wheel as necessary so

that one of the air bag module retaining bolts

becomes accessible from the rear of the

steering wheel. Undo the bolt, then turn

the steering wheel again until the second bolt

is accessible. Undo this bolt also.

9 Withdraw the air bag module from the

steering wheel far enough to access the

wiring multi-plug. Some force may be needed

to free the module from the additional steering

wheel spoke retainers.

10 Disconnect the multi-plug from the rear of

the module, and remove the module from the

vehicle. Warning: Position the air bag

module in a safe place, with the

mechanism facing downwards

as a precaution against

accidental operation.

11 Release the wiring harness from the side

of the steering column and disconnect the air

bag module wiring multi-plug (yellow lead).

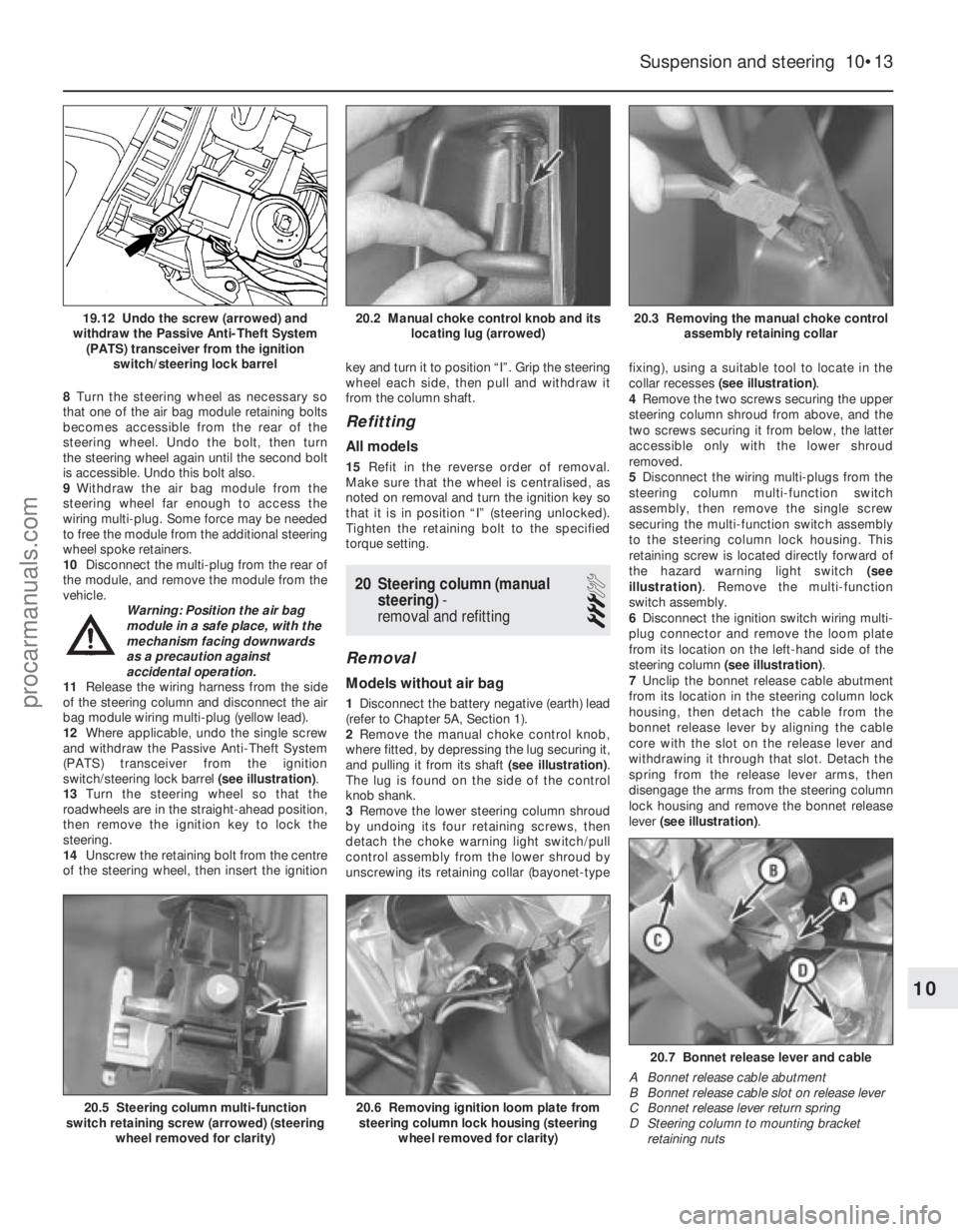

12 Where applicable, undo the single screw

and withdraw the Passive Anti-Theft System

(PATS) transceiver from the ignition

switch/steering lock barrel (see illustration).

13 Turn the steering wheel so that the

roadwheels are in the straight-ahead position,

then remove the ignition key to lock the

steering.

14 Unscrew the retaining bolt from the centre

of the steering wheel, then insert the ignition key and turn it to position “I”. Grip the steering

wheel each side, then pull and withdraw it

from the column shaft.

Refitting

All models

15

Refit in the reverse order of removal.

Make sure that the wheel is centralised, as

noted on removal and turn the ignition key so

that it is in position “I” (steering unlocked).

Tighten the retaining bolt to the specified

torque setting.

20 Steering column (manual steering) -

removal and refitting

3

Removal

Models without air bag

1 Disconnect the battery negative (earth) lead

(refer to Chapter 5A, Section 1).

2 Remove the manual choke control knob,

where fitted, by depressing the lug securing it,

and pulling it from its shaft (see illustration).

The lug is found on the side of the control

knob shank.

3 Remove the lower steering column shroud

by undoing its four retaining screws, then

detach the choke warning light switch/pull

control assembly from the lower shroud by

unscrewing its retaining collar (bayonet-type fixing), using a suitable tool to locate in the

collar recesses

(see illustration) .

4 Remove the two screws securing the upper

steering column shroud from above, and the

two screws securing it from below, the latter

accessible only with the lower shroud

removed.

5 Disconnect the wiring multi-plugs from the

steering column multi-function switch

assembly, then remove the single screw

securing the multi-function switch assembly

to the steering column lock housing. This

retaining screw is located directly forward of

the hazard warning light switch (see

illustration) . Remove the multi-function

switch assembly.

6 Disconnect the ignition switch wiring multi-

plug connector and remove the loom plate

from its location on the left-hand side of the

steering column (see illustration) .

7 Unclip the bonnet release cable abutment

from its location in the steering column lock

housing, then detach the cable from the

bonnet release lever by aligning the cable

core with the slot on the release lever and

withdrawing it through that slot. Detach the

spring from the release lever arms, then

disengage the arms from the steering column

lock housing and remove the bonnet release

lever (see illustration) .

Suspension and steering 10•13

20.3 Removing the manual choke control

assembly retaining collar20.2 Manual choke control knob and its locating lug (arrowed)19.12 Undo the screw (arrowed) and

withdraw the Passive Anti-Theft System (PATS) transceiver from the ignition switch/steering lock barrel

20.7 Bonnet release lever and cable

A Bonnet release cable abutment

B Bonnet release cable slot on release lever

C Bonnet release lever return spring

D Steering column to mounting bracket retaining nuts

20.6 Removing ignition loom plate fromsteering column lock housing (steering

wheel removed for clarity)20.5 Steering column multi-function

switch retaining screw (arrowed) (steering

wheel removed for clarity)

10

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 207 of 296

8Remove the nuts securing the steering

column mounting bracket.

9 Remove the pinch-bolt securing the lower

steering shaft universal joint to the steering

rack pinion splined shaft, located at the rear of

the engine compartment (see illustration),

and separate the two as far as possible.

10 Pull the steering column assembly from its

bulkhead location and withdraw it from the

vehicle, ensuring that the lower steering shaft

universal joint and the steering rack pinion

splined shaft separate fully. The effort

required to remove the column assembly may

be quite high, due to the close tolerance of

the lower column tube support bush in its

location.

Models with air bag

Warning: Handle the air bag

with extreme care as a

precaution against personal

injury, and always hold it with

the cover facing away from your body. If in

doubt concerning any proposed work

involving the air bag or its control circuitry,

consult a Ford dealer or other qualified

specialist.

11 Disconnect the battery negative (earth)

lead (refer to Chapter 5A, Section 1).

Warning: Before proceeding,

wait a minimum of 15 minutes,

as a precaution against

accidental firing of the air bag.

This period ensures that any stored energy

in the back-up capacitor is dissipated.

12 Undo the screws, and remove the

steering column lower shroud.

13 Undo the two external screws and the two

internal screws and remove the steering

column upper shroud.

14 Turn the steering wheel as necessary so

that one of the air bag module retaining bolts

becomes accessible from the rear of the

steering wheel. Undo the bolt, then turn

the steering wheel again until the second bolt

is accessible. Undo this bolt also.

15 Withdraw the air bag module from the

steering wheel far enough to access the

wiring multi-plug. Some force may be needed

to free the module from the additional steering

wheel spoke retainers. 16

Disconnect the multi-plug from the rear of

the module, and remove the module from the

vehicle. Warning: Position the air bag

module in a safe place, with the

mechanism facing downwards

as a precaution against

accidental operation.

17 Turn the steering wheel so that the

roadwheels are in the straight-ahead position,

then remove the ignition key to lock the

steering.

18 Release the wiring harness from the side

of the steering column and disconnect the air

bag module wiring multi-plug (yellow lead).

19 Disconnect the wiring multi-plugs from

the steering column multi-function switch

assembly.

20 Disconnect the ignition switch wiring

multi-plug connector and remove the loom

plate from its location on the left-hand side of

the steering column.

21 Where applicable, undo the single screw

and withdraw the Passive Anti-Theft System

(PATS) transceiver from the ignition

switch/steering lock barrel (see illus-

tration 19.12) .

22 Unclip the bonnet release cable abutment

from its location in the steering column lock

housing, then detach the cable from the

bonnet release lever by aligning the cable

core with the slot on the release lever and

withdrawing it through that slot. Detach the

spring from the release lever arms, then

disengage the arms from the steering column

lock housing and remove the bonnet release

lever.

23 Remove the nuts securing the steering

column mounting bracket.

24 Remove the pinch-bolt securing the lower

steering shaft universal joint to the steering

rack pinion splined shaft, located at the rear of

the engine compartment, and separate the

two as far as possible.

25 Pull the steering column assembly from its bulkhead location and withdraw it from the

vehicle, ensuring that the lower steering shaft

universal joint and the steering rack pinion

splined shaft separate fully. The effort

required to remove the column assembly may

be quite high, due to the close tolerance of

the lower column tube support bush in its

location.

Refitting

All models

26

Ensure that the roadwheels are in the

straight-ahead position. With the help of an

assistant, insert the steering column assembly

into the vehicle so that the lower steering

shaft universal joint and the pinion splined

shaft on the steering rack locate correctly,

with the steering wheel centralized. Loosely

refit the pinch-bolt to secure. Ensure that the

steering shaft bulkhead seal seats correctly in

its location.

27 With the column assembly located loosely

in position, refit the nuts securing it to its

mounting bracket, taking care to ensure that

the lower column tube support bush seats

correctly as the nuts are tightened to the

specified torque.

28 Refit the steering column ancillary

components, reversing the removal procedure

given in paragraphs 2 to 7 (for models without

air bag) or 12 to 22 (for models with air bag).

29 Tighten the pinch-bolt securing the lower

steering shaft universal joint to the pinion

splined shaft to the specified torque. Ensure

that the pinch-bolt sits in the annular groove

on the pinion splined shaft (see illustration).

30 Reconnect the battery negative lead.

21 Steering column (power

steering) -

removal and refitting

3

Removal

Warning: Handle the air bag

with extreme care as a

precaution against personal

injury, and always hold it with

the cover facing away from your body. If in

doubt concerning any proposed work

involving the air bag or its control circuitry,

consult a Ford dealer or other qualified

specialist.

1 Disconnect the battery negative (earth) lead

(refer to Chapter 5A, Section 1). Warning: Before proceeding,

wait a minimum of 15 minutes,

as a precaution against

accidental firing of the air bag.

This period ensures that any stored energy

in the back-up capacitor is dissipated.

2 Undo the screws, and remove the steering

column lower shroud.

3 Undo the two external screws and the two

internal screws and remove the steering

column upper shroud.

4 Turn the steering wheel as necessary so

10•14 Suspension and steering

20.29 Steering rack-to-column

engagement

A Steering rack pinion splined shaft

B Annular groove to ensure correct location of pinch-bolt

C Pinch-bolt

D Lower steering shaft universal joint

20.9 Pinch-bolt securing lower steering

shaft universal joint to pinion splined shaft (arrowed)

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 208 of 296

that one of the air bag module retaining bolts

becomes accessible from the rear of the

steering wheel. Undo the bolt, then turn

the steering wheel again until the second bolt

is accessible. Undo this bolt also.

5Withdraw the air bag module from the

steering wheel far enough to access the

wiring multi-plug. Some force may be needed

to free the module from the additional steering

wheel spoke retainers.

6 Disconnect the multi-plug from the rear of

the module, and remove the module from the

vehicle. Warning: Position the air bag

module in a safe place, with the

mechanism facing downwards

as a precaution against

accidental operation.

7 Turn the steering wheel so that the

roadwheels are in the straight-ahead position,

then remove the ignition key to lock the

steering.

8 Release the wiring harness from the side of

the steering column and disconnect the air

bag module wiring multi-plug (yellow lead).

9 Disconnect the wiring multi-plugs from the

steering column multi-function switch

assembly.

10 Disconnect the ignition switch wiring

multi-plug connector and remove the loom

plate from its location on the left-hand side of

the steering column.

11 Undo the single screw and withdraw the

Passive Anti-Theft System (PATS) transceiver

from the ignition switch/steering lock barrel

(see illustration 19.12) .

12 Unclip the bonnet release cable abutment

from its location in the steering column lock

housing, then detach the cable from the

bonnet release lever by aligning the cable

core with the slot on the release lever and

withdrawing it through that slot. Detach the

spring from the release lever arms, then

disengage the arms from the steering column

lock housing and remove the bonnet release

lever.

13 Remove the C-clip at the base of the

steering column shaft, below the universal

joint.

14 Remove the nuts securing the steering

column mounting bracket.

15 Pull the steering column assembly from its

bulkhead location and withdraw it from the

vehicle, ensuring that the steering column

shaft and flexible coupling separate fully.

Refitting

16 Ensure that the roadwheels are in the

straight-ahead position and the steering

column is locked. With the help of an

assistant, insert the steering column assembly

into the vehicle so that the steering column

shaft engages with the flexible coupling.

17 Refit the steering column shaft C-clip.

18 With the column assembly located loosely

in position, refit and tighten the nuts securing

it to its mounting bracket.

19 Refit the steering column ancillary components, reversing the removal procedure

given in paragraphs 2 to 12.

20

Reconnect the battery negative lead.

22 Steering gear rubber gaiters

- renewal

3

1Remove the track rod end balljoint as

described in Section 28.

2 Remove the one-piece undertray where

fitted, by turning its bayonet-type fasteners,

and on XR2i models, remove the front

suspension crossmember as described in

Section 7.

3 Count the number of exposed threads

visible, from the end of the track rod to the

track rod end balljoint locknut, and record this

figure. Now unscrew the locknut from the

track rod.

4 Release the clip(s), and slide the gaiter off

the rack-and-pinion housing and track rod.

5 Scrape off all grease from the old gaiter,

and apply to the track rod inner joint. Wipe

clean the seating areas on the rack-and-

pinion housing and track rod.

6 Slide the new gaiter onto the housing and

track rod, and secure with the retaining clips.

Ensure that the narrow neck locates correctly

in the track rod groove.

7 Screw the track rod end balljoint locknut

back onto the track rod until the same number

of threads, as counted on removal, are visible.

8 Refit the track rod end balljoint as

described in Section 28.

9 Refit the front suspension crossmember

and one-piece undertray, as applicable.

23 Steering gear (manual steering) -

removal and refitting

3

Removal

1 Disconnect the battery negative (earth) lead

(refer to Chapter 5A, Section 1).

2 Chock the rear wheels then jack up the

front of the car and support it on axle stands

(see “Jacking and Vehicle Support” ). Remove

the front roadwheels.

3 Remove the one-piece undertray where

fitted, by turning its bayonet-type fasteners,

and on XR2i models, remove the front

suspension crossmember as described in

Section 7.

4 Remove the pinch-bolt securing the pinion

splined shaft to the lower steering shaft

universal joints, located at the rear of the

engine compartment.

5 Separate the track rod end balljoints from

the steering arms, as described in Section 28.

6 Remove the lower brake servo support

bracket bolt.

7 Remove the other bolt securing the steering

rack assembly to the bulkhead, then withdraw

it from the right-hand side of the vehicle, taking care to disengage the pinion splined

shaft from the lower steering shaft universal

joint as the assembly is moved.

Refitting

8

Centralize the rack and steering wheel, then

engage the pinion splined shaft to the lower

steering shaft universal joint.

9 Refit the steering rack assembly mounting

bolts to the bulkhead and tighten to the

specified torque, ensuring that the servo

support bracket is correctly held.

10 Refit the pinion splined shaft-to-lower

steering shaft universal joint pinch-bolt and

nut and tighten to the specified torque,

ensuring that the pinch-bolt locates to the

annular groove as the pinion splined shaft.

11 Refit the track rod end balljoints to the

steering arms, as detailed in Section 28. As

long as the track rod end-to-track rod relative

positions have not been disturbed, it will not

be necessary to reset the front wheel

alignment.

12 Refit the front suspension crossmember

and one-piece undertray, as applicable.

13 Refit the roadwheels, then lower the

vehicle to the ground. Tighten the roadwheel

nuts to the specified torque with the vehicle

on its wheels.

24 Steering gear (power steering) -

removal and refitting

4

Removal

1 Disconnect the battery negative (earth) lead

(refer to Chapter 5A, Section 1).

2 Chock the rear wheels then jack up the

front of the car and support it on axle stands

(see “Jacking and Vehicle Support” ). Remove

the front roadwheels.

3 Remove the one-piece undertray where

fitted, by turning its bayonet-type fasteners,

and on XR2i models, remove the front

suspension crossmember as described in

Section 7.

4 Remove the pinch-bolt securing the pinion

splined shaft to the lower steering shaft

flexible coupling, located at the rear of the

engine compartment.

5 Undo the retaining screws, and detach the

clips securing the power steering hydraulic

pressure pipes to the steering gear.

6 Position a suitable container under the

hydraulic pipe connections to the steering

gear. Unscrew the pipe unions, then detach

the pipes from the valve body. Withdraw the

pipes from the steering gear, and drain the

hydraulic fluid into the container.

7 Plug the exposed ends of the hydraulic line

connections, to prevent the ingress of dirt and

further fluid loss. Note that new O-ring seals

will be needed for the pressure and return

hose connections when reconnecting.

8 Slacken the upper bolts securing the

steering gear support brackets. On left-hand

Suspension and steering 10•15

10

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 209 of 296

drive models, remove the brace from the stud

on the left-hand side of the steering gear.

9Undo the two bolts securing the support

brackets to the steering gear and move the

brackets and swing the brackets clear.

10 Unhook the steering gear from the

apertures in the bulkhead and remove the

assembly from the right-hand wheel arch.

Ensure that the pressure check valve does not

fall out of the pressure port in the valve body

as the steering gear is removed.

Refitting

11 Centralize the steering gear and steering

wheel, then engage the pinion splined shaft to

the lower steering shaft flexible coupling.

12 Hook the steering gear into the apertures

in the bulkhead then align the support

brackets and refit the two bolts. Tighten the

support bracket upper bolts and support

bracket-to-steering gear bolts to the specified

torque.

13 On left-hand drive models, refit the brace

to the stud on the left-hand side of the

steering gear.

14 Fit new O-ring seals to the pressure and

return hoses, then reconnect the hydraulic

lines to the steering gear. Secure the pipes

with the retaining clips.

15 Refit the pinion splined shaft-to-lower

steering shaft flexible coupling pinch-bolt and

nut and tighten to the specified torque.

16 Refit the track rod end balljoints to the

steering arms, as detailed in Section 28. As

long as the track rod end-to-track rod relative

positions have not been disturbed, it will not

be necessary to reset the front wheel

alignment.

17 Refit the front suspension crossmember

and one-piece undertray, as applicable.

18 Refit the roadwheels, then lower the

vehicle to the ground. Tighten the roadwheel

nuts with the vehicle on its wheels to the

specified torque.

19 On completion, bleed the power steering

hydraulic system as described in Section 27.

Check for any signs of fluid leakage from the

system hoses and connections.

25 Power steering pump -

removal and refitting

4

Removal

HCS engine models

1 Disconnect the battery negative (earth) lead

(refer to Chapter 5A, Section 1).

2 Chock the rear wheels then jack up the

front of the car and support it on axle stands

(see “Jacking and Vehicle Support” ). Remove

the front roadwheel.

3 Remove the auxiliary drivebelt as described

in Chapter 1.

4 Insert a 9 mm Allen key into the centre of

the pump drive spindle to prevent it from turning, then unscrew and remove the three

pump pulley retaining bolts. Withdraw the

pulley from the pump.

5

Position a suitable container beneath the

power steering pump, then unscrew and detach

the fluid high pressure pipe and fluid return

hose from the pump. As they are detached from

the pump, allow the fluid to drain from the pipe

and hose (and the pump) into the container.

Plug the exposed ends of the pipe, hose and

the pump connections, to prevent the ingress of

dirt and excessive fluid loss.

6 Unscrew the four retaining bolts (three from

the front and one from the rear) and withdraw

the pump from the vehicle.

PTE engine models

7 Disconnect the battery negative (earth) lead

(refer to Chapter 5A, Section 1).

8 Refer to the relevant Part of Chapter 4 and

remove the air cleaner assembly and air inlet

components as necessary for access to the

pump.

9 Chock the rear wheels then jack up the

front of the car and support it on axle stands

(see “Jacking and Vehicle Support” ). Remove

the front roadwheel.

10 Refer to Chapter 1 and drain the cooling

system.

11 Refer to Chapter 1 and remove the

auxiliary drivebelt.

12 Insert a 9 mm Allen key into the centre of

the pump drive spindle to prevent it from

turning, then unscrew and remove the three

pump pulley retaining bolts. Refit the

roadwheel, lower the vehicle and withdraw the

pump pulley from above.

13 Disconnect the cooling system hoses as

necessary to gain access to the power

steering pump.

14 Disconnect the pressure switch multi-plug

from the pressure switch located in the fluid

high pressure pipe.

15 Position a suitable container beneath the

power steering pump, then disconnect the

high pressure pipe at the union located part

way along the pipe. Allow the fluid to drain

from the pipe into the container.

16 Disconnect the high pressure pipe clamp

bracket and the fluid return hose from the

pump. Allow the fluid to drain into the

container then plug the exposed ends of the

pipe, hose and the pump connections, to

prevent the ingress of dirt and excessive fluid

loss.

17 Unscrew the pump mounting bolt located

at the rear of the pump and remove the pipe

clamp bracket.

18 Unscrew the three pump mounting bolts

located at the front of the pump and remove

the pump, complete with high pressure pipe,

from the vehicle.

19 If required, the high pressure pipe can be

removed from the pump after unscrewing the

union nut.

Zetec engine models

Note: For this operation, the engine will need

to be supported from above to allow removal of the right-hand engine mounting, and also to

allow the vehicle to be raised for work

underneath, and lowered for work from above.

A proprietary engine support bar (or home-

made alternative) fitted in the front wing drain

channel each side is ideal for this purpose, but

care must be taken not to damage the wings

or their paintwork.

20

Disconnect the battery negative (earth)

lead (refer to Chapter 5A, Section 1).

21 Suitably support the right-hand side of the

engine (see the note at the beginning of this

sub-Section) so that all the load is removed

from the engine mounting.

22 Remove the right-hand engine mounting

as described in Chapter 2C.

23 Refer to Chapter 1 and drain the cooling

system.

24 Chock the rear wheels then jack up the

front of the car and support it on axle stands

(see “Jacking and Vehicle Support” ). Remove

the front roadwheel.

25 Undo the retaining screws, and remove

the drivebelt lower guard from the underbody.

26 Refer to Chapter 11 and remove the wheel

arch liner.

27 Refer to Chapter 1 and remove the

auxiliary drivebelt.

28 Insert a 9 mm Allen key into the centre of

the pump drive spindle to prevent it from

turning, then unscrew and remove the three

pump pulley retaining bolts. Refit the

roadwheel, lower the vehicle and withdraw the

pump pulley from above.

29 Refer to Chapter 12 and remove the right-

hand headlight unit.

30 Refit the roadwheel and lower the vehicle

to the ground.

31 Position a suitable container beneath the

power steering fluid reservoir, then disconnect

the fluid return hose from the reservoir. Allow

the fluid to drain from the hose and reservoir

into the container.

32 Plug the exposed ends of the hose and

the reservoir, to prevent the ingress of dirt and

excessive fluid loss.

33 Remove the high pressure pipe clamp

brackets from the engine then disconnect the

high pressure pipe at the union located over

the camshaft cover. Place absorbent rags

under the union as it is disconnected to

collect any escaping fluid. Plug the

disconnected pipe ends to prevent the

ingress of dirt and excessive fluid loss.

34 Disconnect the cooling system hoses as

necessary to gain access to the power

steering pump.

35 Unscrew the two pump mounting bolts

located at the rear of the pump.

36 Unscrew the two pump mounting bolts

located at the front of the pump and remove

the pump, complete with high pressure pipe

and fluid return hose, upwards and out of the

engine compartment.

37 If required, the high pressure pipe and

fluid return hose can be removed from the

pump after unscrewing the union nut or

slackening the hose clip as applicable.

10•16 Suspension and steering

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 210 of 296

Refitting

All models

38Refitting is a reversal of removal, bearing

in mind the following points:

a) Tighten all nuts and bolts to the specified torque. Remove the plugs from the

disconnected pipes, hoses and unions

and ensure that the pipes are located

correctly so that they do not foul any

surrounding components.

b) Refit the auxiliary drivebelt as described in

Chapter 1.

c) Where drained, refill the cooling system as described in Chapter 1.

d) Refit or reconnect any additional

components removed for access as

described in the relevant Sections and

Chapters of this manual.

e) On completion, bleed the power steering

hydraulic system as described in Section

27. Check for any signs of fluid leakage

from the system hoses and connections.

26 Power steering fluid cooler -

removal and refitting

2

Removal

1 Disconnect the battery negative (earth) lead

(refer to Chapter 5A, Section 1).

2 Position a suitable container beneath the

power steering fluid cooler hose connections,

then disconnect the hoses at the quick-fit

couplings on the fluid cooler. Allow the fluid to

drain from the hose and reservoir into the

container.

3 Plug the exposed ends of the hose and the

reservoir, to prevent the ingress of dirt and

excessive fluid loss.

4 Refer to Chapter 11 and remove the bonnet

lock assembly and the front bumper.

5 Undo the bolts securing the cooler side

support bracket and the bonnet lock stay, and

remove the fluid cooler and bonnet lock stay

as an assembly.

6 Undo the two bolts and remove the stay

from the fluid cooler.

Refitting

7 Refitting is a reversal of removal. On

completion, bleed the power steering

hydraulic system as described in Section 27.

27 Power steering hydraulic system - bleeding

2

1Following any operation in which the power

steering fluid lines have been disconnected,

the power steering system must be bled to

remove any trapped air.

2 With the front wheel in the straight-ahead

position, check the power steering fluid level

in the reservoir and, if low, top-up with fresh fluid to the “MAX” or “MAX COLD” level mark.

Pour the fluid slowly to prevent air bubbles

forming, and use only the specified fluid (refer

to

“Lubricants, fluids and tyre pressures” ).

3 Start the engine and allow it to idle. Check

the hoses and connections for leaks.

4 Stop the engine and recheck the fluid level.

Add more, if necessary, up to the “MAX” or

“MAX COLD” level mark.

5 Start the engine again, allow it to idle, then

bleed the system by slowly moving the

steering from lock-to-lock several times. This

should purge the system of all internal air.

However, if air remains in the system

(indicated by the steering operation being very

noisy), leave the vehicle overnight and repeat

the procedure again the next day.

6 If air still remains in the system, it may be

necessary to resort to the Ford method of

bleeding, which uses a vacuum pump and a

modified reservoir filler cap to which the pump

can be connected. Turn the steering to the

right until it is near the stop, then fit the

vacuum pump to the fluid reservoir, and apply

0.51 bars of vacuum. Maintain the vacuum for

a minimum of 5 minutes, then repeat

the procedure with the steering turned to the

left.

7 Keep the fluid level topped-up throughout

the bleeding procedure; note that the fluid

temperature increases, the level will rise.

8 On completion, switch the engine off, and

return the wheels to the straight-ahead

position.

28 Track rod end balljoint -

removal and refitting

2

Removal

1 Chock the rear wheels then jack up the

front of the car and support it on axle stands

(see “Jacking and Vehicle Support” ). Remove

the appropriate front roadwheel.

2 Using a suitable spanner, slacken the track

rod end balljoint locknut on the track rod by a

quarter of a turn only (see illustration). Holdthe balljoint stationary with another spanner

engaged with the flats at its inner end to

prevent it from turning.

3

Extract the split pin, then loosen off the

retaining nut. If the balljoint is to be renewed,

the nut can be fully removed. If the existing

balljoint is to be reconnected, the nut should

be slackened off a couple of turns only at first,

and left in position to protect the joint threads

as the joint is separated from the spindle

carrier. To release the tapered shank of the

joint from the spindle carrier, use a balljoint

separator tool as shown (see illustration). If

the joint is to be re-used, take care not to

damage the rubber dust cover when using a

separator tool.

4 Unscrew the balljoint from the track rod,

counting the number of turns necessary to

remove it.

Refitting

5 Screw the balljoint into the track rod the

number of turns noted during removal until the

balljoint just contacts the locknut. Now tighten

the locknut while holding the balljoint.

6 Engage the shank of the balljoint with the

spindle carrier arm, and refit the retaining nut.

Tighten the nut to the specified torque and

secure with a new split pin.

7 Refit the roadwheel, and lower the vehicle

to the ground.

8 Finally, have the front wheel toe setting

checked (see Section 29).

29 Wheel alignment and steering angles - general

information

4

General

1 A car’s steering and suspension geometry

is defined in four basic settings - all angles

are expressed in degrees (toe settings are

also expressed as a measurement); the

relevant settings are camber, castor, steering

axis inclination, and toe-setting. With the

exception of front wheel toe-setting, none of

these settings are adjustable.

Suspension and steering 10•17

28.3 Balljoint separator tool in position.

Note that the nut should be left loosely in position to protect the thread for re-use28.2 Track rod end balljoint showing the locknut (A) retaining flats (B) and the

balljoint-to-spindle carrier arm retaining

nut and split pin (C)

10

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su