drain bolt FORD FIESTA 1989 Service Owner's Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1989, Model line: FIESTA, Model: FORD FIESTA 1989Pages: 296, PDF Size: 10.65 MB

Page 111 of 296

container which can be sealed (see

illustration) . Where quick-release couplings

are used on the fuel hoses, release the

protruding locking lugs on each union, by

squeezing them together and carefully pulling

the coupling apart. Note that the fuel supply

hose couplings are identified by a white

colour band and the return hose couplings by

a yellow colour band.

6 Disconnect the filler neck sensing pipe

connection from the rear of the tank (see

illustration) .

7 Support beneath the tank to hold it in

position and remove its four securing bolts

(see illustration) .

8 Partially lower the fuel tank and disconnect

the ventilation tube from the tank top surface

and also disconnect the sender unit multi-

plug. The filler pipe should release from its

fuel tank seal location as the tank is

withdrawn.

Inspection

9 Whilst removed, the fuel tank can be

inspected for damage or deterioration.

Removal of the sender unit (see Section 9) will

allow a partial inspection of the interior. If the

tank is contaminated with sediment or water,

swill it out with clean petrol. Do not under any

circumstances undertake any repairs on a

leaking or damaged fuel tank; this work must

be carried out by a professional who has

experience in this critical and potentially-

dangerous work.

10 Whilst the fuel tank is removed from the

vehicle, it should not be placed in an area

where sparks or open flames could ignite the

fumes coming out of the tank. Be especially

careful inside garages where a natural-gas

type appliance is located, because the pilot

light could cause an explosion.

11 Check the condition of the filler pipe seal

in the fuel tank, and renew it if necessary.

Refitting

All models

12 Refitting is a reversal of the removal

procedure. Apply a light smear of grease to the

filler pipe seal, to ease fitting. Ensure that all

connections are securely fitted. Where quick-

release fuel couplings are fitted, press them together until the locking lugs snap into their

groove. If evidence of contamination was

found, do not return any previously-drained

fuel to the tank unless it is carefully filtered first.

9

Fuel gauge sender unit -

removal and refitting

3

Note: Ford specify the use of their service tool

23-014 (a large box spanner with projecting

teeth to engage the fuel gauge sender unit

retaining ring’s slots) for this task. While

alternatives are possible, in view of the difficulty

experienced in removing and refitting the

sender unit, owners are strongly advised to

obtain the correct tool before starting work. The

help of an assistant will be required. Refer to the

warning note in Section 1 before proceeding.

Removal

1 Remove the fuel tank as described in

Section 8.

2 Engage the special tool into the sender unit

then carefully turn the sender unit and release

it from the top of the tank.

Refitting

3 Refit the sender unit in the reverse order of

removal. Be sure to fit a new seal, and

lubricate it with a smear of grease to prevent it

from distorting when fitting the sender unit.

10 Fuel tank ventilation tube -

removal and refitting

3

Note: Refer to the warning note in Section 1

before proceeding.

Removal

1 The fuel tank ventilation tube runs from the

top surface of the fuel tank to the combined roll-

over/anti-trickle-fill valve assembly mounted in

the left-hand rear wheelarch (see illustration).

Its purpose is to eliminate any possibility of

vacuum or pressure build-up in the fuel tank.

2 Disconnect the battery negative (earth) lead

(refer to Chapter 5A, Section 1).

3 Chock the front wheels then jack up the

rear of the car and support it on axle stands

(see “Jacking and vehicle support” ). Remove

the left-hand rear roadwheel.

4 Support the fuel tank from underneath on a

suitable jack, using a large thick sheet of

board to spread the weight, then undo and

remove the four fuel tank securing bolts.

5 Lower the fuel tank slightly in such a manner

so as to allow access to disconnect the

ventilation tube from the tank top surface.

Ensure that the fuel tank does not foul or strain

any adjacent components as it is lowered;

take appropriate action, as necessary.

6 Disconnect the ventilation tube from the

combined roll-over/anti-trickle-fill valve, release

the tube from its retaining clips and remove.

Refitting

7 Refitting is a reversal of the removal

procedure, ensuring that the fuel tank filler

pipe is located correctly with the tank.

11 Fuel tank filler pipe -

removal and refitting

3

Note: Refer to the warning note in Section 1

before proceeding.

Removal

1 Remove the fuel tank as described in

Section 8.

4A•6 Fuel system – carburettor engines

10.1 Combined roll-over anti-trickle-fill valve assembly

A Tube ventilating to atmosphere

B Ventilation tube from fuel tank

8.7 Fuel tank securing bolts (arrowed)8.6 Filler neck sensing pipe connection at the rear of the fuel tank

1595Ford Fiesta Remake

8.5 Fuel feed and return pipe connections

(arrowed)procarmanuals.com

http://vnx.su

Page 123 of 296

As it is detached, plug the end of the hose to

prevent excessive fuel spillage and the ingress

of dirt. Where a crimped type hose clip is fitted,

cut it free, taking care not to damage the hose;

a new screw type clip will need to be obtained

to replace the crimped clip during reassembly.

7Disconnect the relevant vacuum pipes from

the carburettor. As they are detached, label

them to ensure correct reassembly.

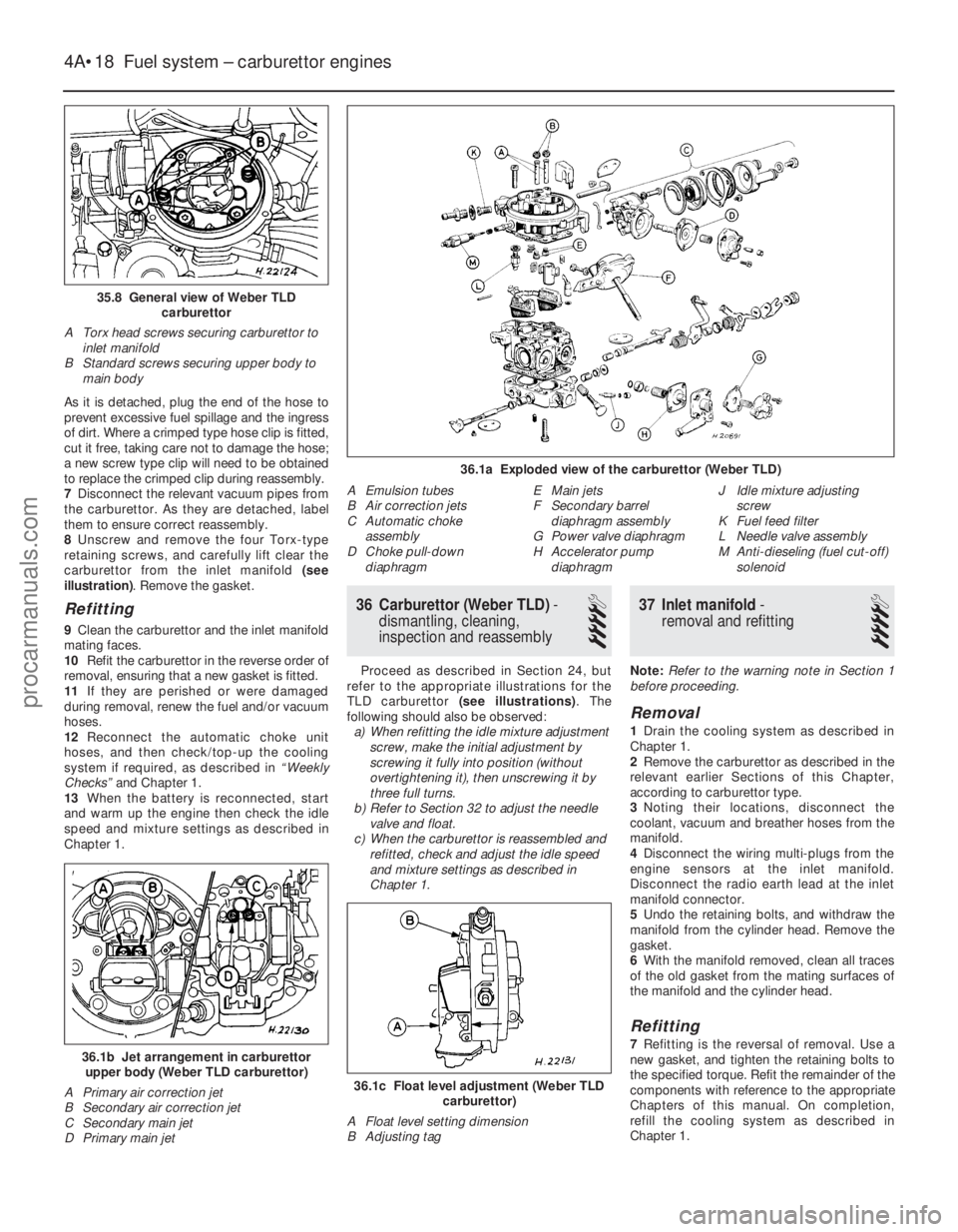

8 Unscrew and remove the four Torx-type

retaining screws, and carefully lift clear the

carburettor from the inlet manifold (see

illustration) . Remove the gasket.

Refitting

9Clean the carburettor and the inlet manifold

mating faces.

10 Refit the carburettor in the reverse order of

removal, ensuring that a new gasket is fitted.

11 If they are perished or were damaged

during removal, renew the fuel and/or vacuum

hoses.

12 Reconnect the automatic choke unit

hoses, and then check/top-up the cooling

system if required, as described in “Weekly

Checks” and Chapter 1.

13 When the battery is reconnected, start

and warm up the engine then check the idle

speed and mixture settings as described in

Chapter 1.

36 Carburettor (Weber TLD) -

dismantling, cleaning,

inspection and reassembly

4

Proceed as described in Section 24, but

refer to the appropriate illustrations for the

TLD carburettor (see illustrations) . The

following should also be observed: a) When refitting the idle mixture adjustment

screw, make the initial adjustment by

screwing it fully into position (without

overtightening it), then unscrewing it by

three full turns.

b) Refer to Section 32 to adjust the needle

valve and float.

c) When the carburettor is reassembled and refitted, check and adjust the idle speed

and mixture settings as described in

Chapter 1.

37 Inlet manifold -

removal and refitting

4

Note: Refer to the warning note in Section 1

before proceeding.

Removal

1 Drain the cooling system as described in

Chapter 1.

2 Remove the carburettor as described in the

relevant earlier Sections of this Chapter,

according to carburettor type.

3 Noting their locations, disconnect the

coolant, vacuum and breather hoses from the

manifold.

4 Disconnect the wiring multi-plugs from the

engine sensors at the inlet manifold.

Disconnect the radio earth lead at the inlet

manifold connector.

5 Undo the retaining bolts, and withdraw the

manifold from the cylinder head. Remove the

gasket.

6 With the manifold removed, clean all traces

of the old gasket from the mating surfaces of

the manifold and the cylinder head.

Refitting

7 Refitting is the reversal of removal. Use a

new gasket, and tighten the retaining bolts to

the specified torque. Refit the remainder of the

components with reference to the appropriate

Chapters of this manual. On completion,

refill the cooling system as described in

Chapter 1.

36.1c Float level adjustment (Weber TLD carburettor)

A Float level setting dimension

B Adjusting tag

36.1b Jet arrangement in carburettor upper body (Weber TLD carburettor)

A Primary air correction jet

B Secondary air correction jet

C Secondary main jet

D Primary main jet

4A•18 Fuel system – carburettor engines

36.1a Exploded view of the carburettor (Weber TLD)

A Emulsion tubes

B Air correction jets

C Automatic choke assembly

D Choke pull-down

diaphragm E Main jets

F Secondary barrel

diaphragm assembly

G Power valve diaphragm

H Accelerator pump

diaphragm J Idle mixture adjusting

screw

K Fuel feed filter

L Needle valve assembly

M Anti-dieseling (fuel cut-off) solenoid

35.8 General view of Weber TLD carburettor

A Torx head screws securing carburettor to inlet manifold

B Standard screws securing upper body to main body

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 129 of 296

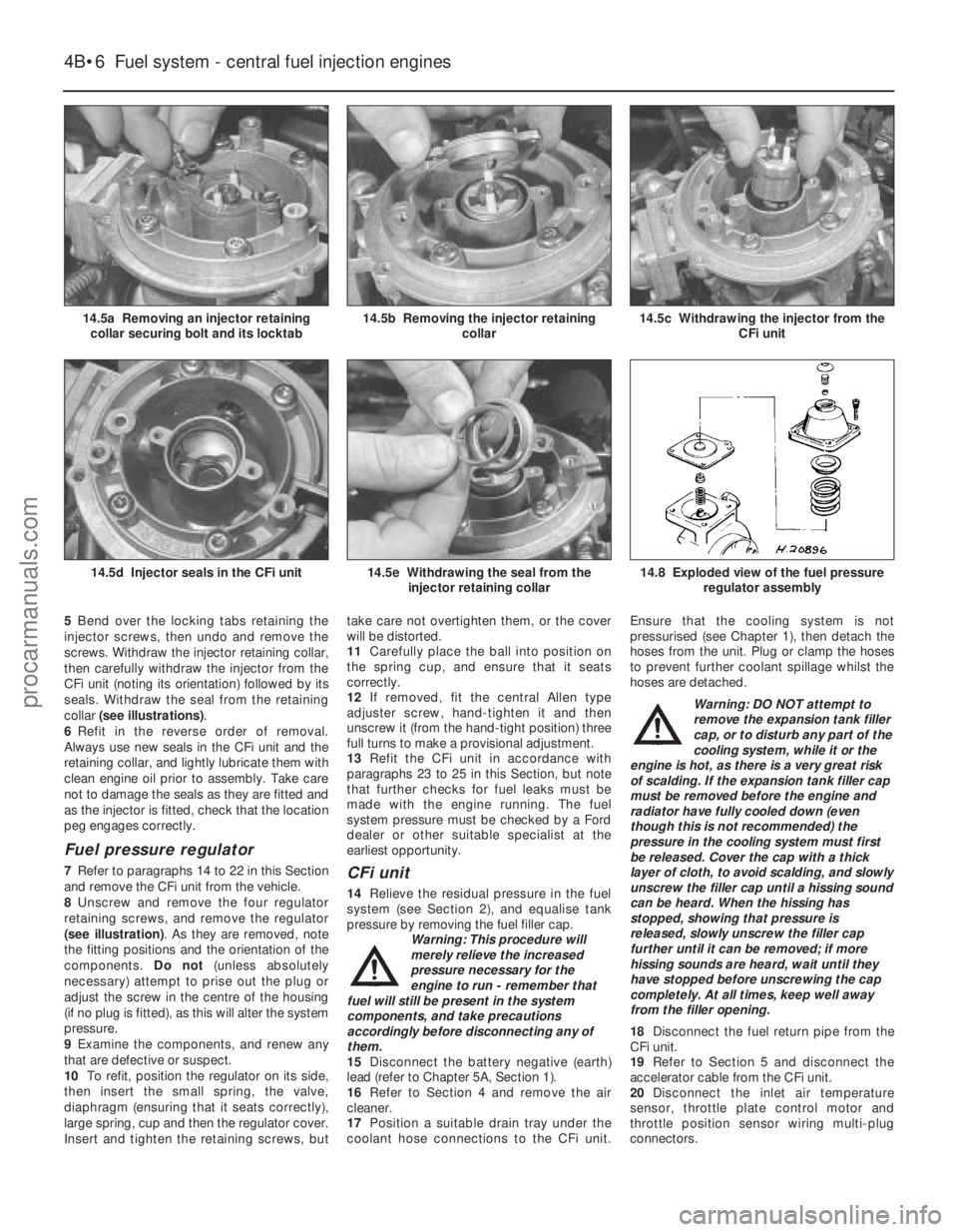

5Bend over the locking tabs retaining the

injector screws, then undo and remove the

screws. Withdraw the injector retaining collar,

then carefully withdraw the injector from the

CFi unit (noting its orientation) followed by its

seals. Withdraw the seal from the retaining

collar (see illustrations) .

6 Refit in the reverse order of removal.

Always use new seals in the CFi unit and the

retaining collar, and lightly lubricate them with

clean engine oil prior to assembly. Take care

not to damage the seals as they are fitted and

as the injector is fitted, check that the location

peg engages correctly.

Fuel pressure regulator

7 Refer to paragraphs 14 to 22 in this Section

and remove the CFi unit from the vehicle.

8 Unscrew and remove the four regulator

retaining screws, and remove the regulator

(see illustration) . As they are removed, note

the fitting positions and the orientation of the

components. Do not(unless absolutely

necessary) attempt to prise out the plug or

adjust the screw in the centre of the housing

(if no plug is fitted), as this will alter the system

pressure.

9 Examine the components, and renew any

that are defective or suspect.

10 To refit, position the regulator on its side,

then insert the small spring, the valve,

diaphragm (ensuring that it seats correctly),

large spring, cup and then the regulator cover.

Insert and tighten the retaining screws, but take care not overtighten them, or the cover

will be distorted.

11

Carefully place the ball into position on

the spring cup, and ensure that it seats

correctly.

12 If removed, fit the central Allen type

adjuster screw, hand-tighten it and then

unscrew it (from the hand-tight position) three

full turns to make a provisional adjustment.

13 Refit the CFi unit in accordance with

paragraphs 23 to 25 in this Section, but note

that further checks for fuel leaks must be

made with the engine running. The fuel

system pressure must be checked by a Ford

dealer or other suitable specialist at the

earliest opportunity.CFi unit

14 Relieve the residual pressure in the fuel

system (see Section 2), and equalise tank

pressure by removing the fuel filler cap. Warning: This procedure will

merely relieve the increased

pressure necessary for the

engine to run - remember that

fuel will still be present in the system

components, and take precautions

accordingly before disconnecting any of

them.

15 Disconnect the battery negative (earth)

lead (refer to Chapter 5A, Section 1).

16 Refer to Section 4 and remove the air

cleaner.

17 Position a suitable drain tray under the

coolant hose connections to the CFi unit. Ensure that the cooling system is not

pressurised (see Chapter 1), then detach the

hoses from the unit. Plug or clamp the hoses

to prevent further coolant spillage whilst the

hoses are detached.

Warning: DO NOT attempt to

remove the expansion tank filler

cap, or to disturb any part of the

cooling system, while it or the

engine is hot, as there is a very great risk

of scalding. If the expansion tank filler cap

must be removed before the engine and

radiator have fully cooled down (even

though this is not recommended) the

pressure in the cooling system must first

be released. Cover the cap with a thick

layer of cloth, to avoid scalding, and slowly

unscrew the filler cap until a hissing sound

can be heard. When the hissing has

stopped, showing that pressure is

released, slowly unscrew the filler cap

further until it can be removed; if more

hissing sounds are heard, wait until they

have stopped before unscrewing the cap

completely. At all times, keep well away

from the filler opening.

18 Disconnect the fuel return pipe from the

CFi unit.

19 Refer to Section 5 and disconnect the

accelerator cable from the CFi unit.

20 Disconnect the inlet air temperature

sensor, throttle plate control motor and

throttle position sensor wiring multi-plug

connectors.

4B•6 Fuel system - central fuel injection engines

14.8 Exploded view of the fuel pressure

regulator assembly14.5e Withdrawing the seal from theinjector retaining collar14.5d Injector seals in the CFi unit

14.5c Withdrawing the injector from the CFi unit14.5b Removing the injector retainingcollar14.5a Removing an injector retainingcollar securing bolt and its locktab

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 132 of 296

worn. Apply a smear of anti-seize compound

to the sensor’s threads, to prevent them from

welding themselves to the downpipe in

service. Refit the sensor, tightening it to its

specified torque wrench setting; a slotted

socket will be required to do this. Reconnect

the wiring, and heat shield then refit the

connector plug.

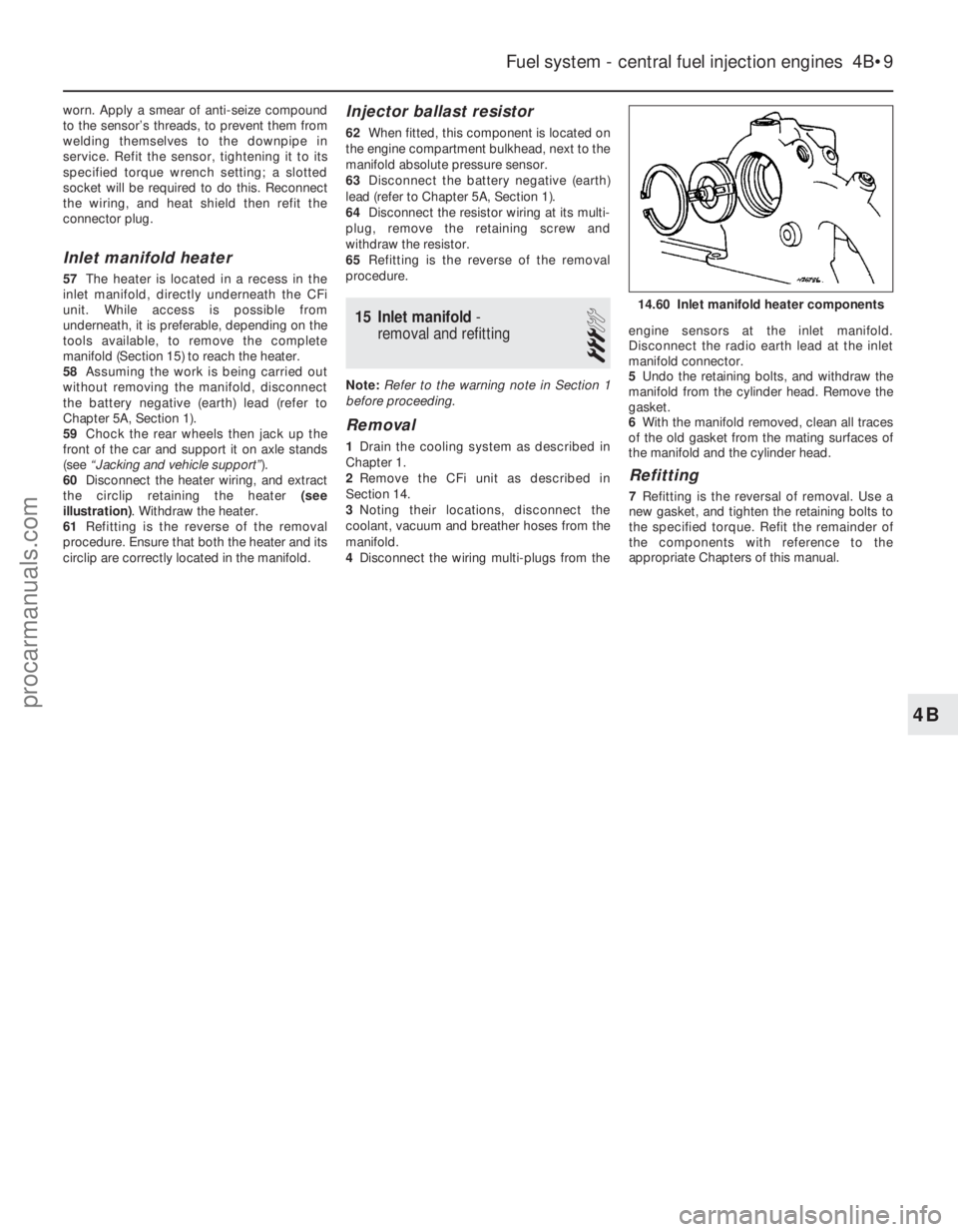

Inlet manifold heater

57The heater is located in a recess in the

inlet manifold, directly underneath the CFi

unit. While access is possible from

underneath, it is preferable, depending on the

tools available, to remove the complete

manifold (Section 15) to reach the heater.

58 Assuming the work is being carried out

without removing the manifold, disconnect

the battery negative (earth) lead (refer to

Chapter 5A, Section 1).

59 Chock the rear wheels then jack up the

front of the car and support it on axle stands

(see “Jacking and vehicle support” ).

60 Disconnect the heater wiring, and extract

the circlip retaining the heater (see

illustration) . Withdraw the heater.

61 Refitting is the reverse of the removal

procedure. Ensure that both the heater and its

circlip are correctly located in the manifold.

Injector ballast resistor

62 When fitted, this component is located on

the engine compartment bulkhead, next to the

manifold absolute pressure sensor.

63 Disconnect the battery negative (earth)

lead (refer to Chapter 5A, Section 1).

64 Disconnect the resistor wiring at its multi-

plug, remove the retaining screw and

withdraw the resistor.

65 Refitting is the reverse of the removal

procedure.

15 Inlet manifold -

removal and refitting

3

Note: Refer to the warning note in Section 1

before proceeding.

Removal

1 Drain the cooling system as described in

Chapter 1.

2 Remove the CFi unit as described in

Section 14.

3 Noting their locations, disconnect the

coolant, vacuum and breather hoses from the

manifold.

4 Disconnect the wiring multi-plugs from the engine sensors at the inlet manifold.

Disconnect the radio earth lead at the inlet

manifold connector.

5

Undo the retaining bolts, and withdraw the

manifold from the cylinder head. Remove the

gasket.

6 With the manifold removed, clean all traces

of the old gasket from the mating surfaces of

the manifold and the cylinder head.

Refitting

7 Refitting is the reversal of removal. Use a

new gasket, and tighten the retaining bolts to

the specified torque. Refit the remainder of

the components with reference to the

appropriate Chapters of this manual.

Fuel system - central fuel injection engines 4B•9

14.60 Inlet manifold heater components

4B

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 141 of 296

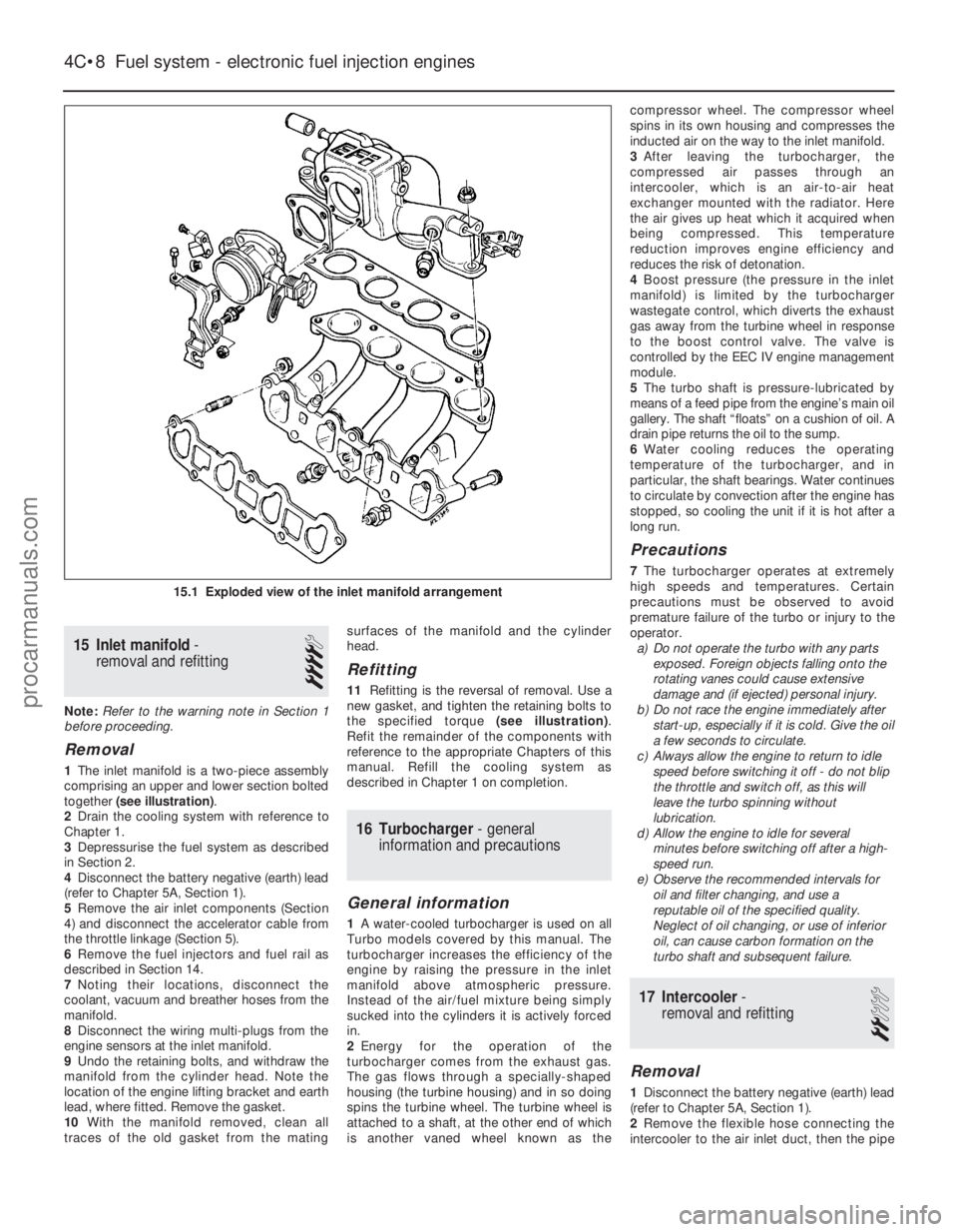

15 Inlet manifold-

removal and refitting

4

Note: Refer to the warning note in Section 1

before proceeding.

Removal

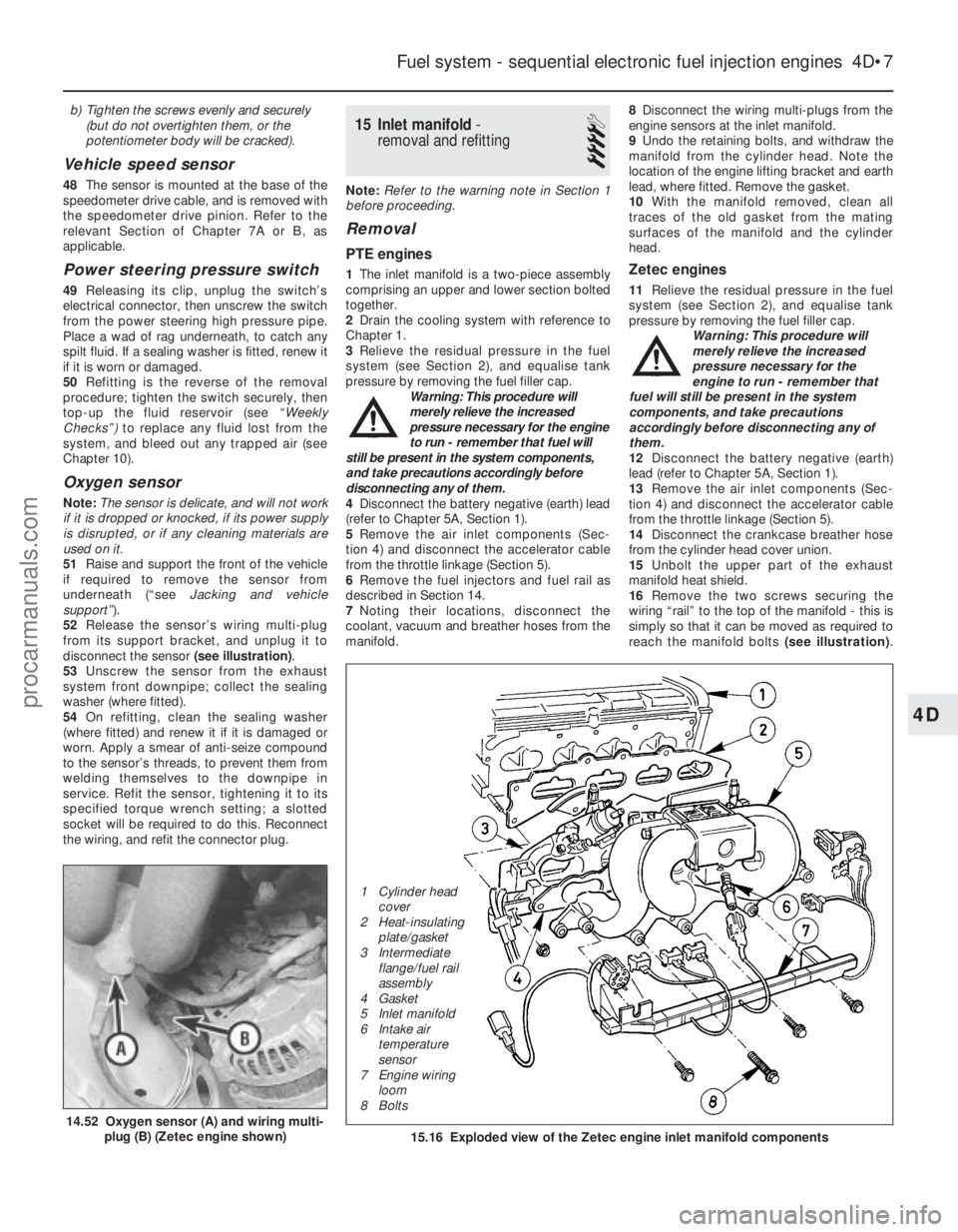

1 The inlet manifold is a two-piece assembly

comprising an upper and lower section bolted

together (see illustration) .

2 Drain the cooling system with reference to

Chapter 1.

3 Depressurise the fuel system as described

in Section 2.

4 Disconnect the battery negative (earth) lead

(refer to Chapter 5A, Section 1).

5 Remove the air inlet components (Section

4) and disconnect the accelerator cable from

the throttle linkage (Section 5).

6 Remove the fuel injectors and fuel rail as

described in Section 14.

7 Noting their locations, disconnect the

coolant, vacuum and breather hoses from the

manifold.

8 Disconnect the wiring multi-plugs from the

engine sensors at the inlet manifold.

9 Undo the retaining bolts, and withdraw the

manifold from the cylinder head. Note the

location of the engine lifting bracket and earth

lead, where fitted. Remove the gasket.

10 With the manifold removed, clean all

traces of the old gasket from the mating surfaces of the manifold and the cylinder

head.

Refitting

11

Refitting is the reversal of removal. Use a

new gasket, and tighten the retaining bolts to

the specified torque (see illustration).

Refit the remainder of the components with

reference to the appropriate Chapters of this

manual. Refill the cooling system as

described in Chapter 1 on completion.

16 Turbocharger - general

information and precautions

General information

1 A water-cooled turbocharger is used on all

Turbo models covered by this manual. The

turbocharger increases the efficiency of the

engine by raising the pressure in the inlet

manifold above atmospheric pressure.

Instead of the air/fuel mixture being simply

sucked into the cylinders it is actively forced

in.

2 Energy for the operation of the

turbocharger comes from the exhaust gas.

The gas flows through a specially-shaped

housing (the turbine housing) and in so doing

spins the turbine wheel. The turbine wheel is

attached to a shaft, at the other end of which

is another vaned wheel known as the compressor wheel. The compressor wheel

spins in its own housing and compresses the

inducted air on the way to the inlet manifold.

3

After leaving the turbocharger, the

compressed air passes through an

intercooler, which is an air-to-air heat

exchanger mounted with the radiator. Here

the air gives up heat which it acquired when

being compressed. This temperature

reduction improves engine efficiency and

reduces the risk of detonation.

4 Boost pressure (the pressure in the inlet

manifold) is limited by the turbocharger

wastegate control, which diverts the exhaust

gas away from the turbine wheel in response

to the boost control valve. The valve is

controlled by the EEC IV engine management

module.

5 The turbo shaft is pressure-lubricated by

means of a feed pipe from the engine’s main oil

gallery. The shaft “floats” on a cushion of oil. A

drain pipe returns the oil to the sump.

6 Water cooling reduces the operating

temperature of the turbocharger, and in

particular, the shaft bearings. Water continues

to circulate by convection after the engine has

stopped, so cooling the unit if it is hot after a

long run.

Precautions

7 The turbocharger operates at extremely

high speeds and temperatures. Certain

precautions must be observed to avoid

premature failure of the turbo or injury to the

operator. a) Do not operate the turbo with any parts

exposed. Foreign objects falling onto the

rotating vanes could cause extensive

damage and (if ejected) personal injury.

b) Do not race the engine immediately after

start-up, especially if it is cold. Give the oil

a few seconds to circulate.

c) Always allow the engine to return to idle

speed before switching it off - do not blip

the throttle and switch off, as this will

leave the turbo spinning without

lubrication.

d) Allow the engine to idle for several

minutes before switching off after a high-

speed run.

e) Observe the recommended intervals for oil and filter changing, and use a

reputable oil of the specified quality.

Neglect of oil changing, or use of inferior

oil, can cause carbon formation on the

turbo shaft and subsequent failure.

17 Intercooler -

removal and refitting

2

Removal

1 Disconnect the battery negative (earth) lead

(refer to Chapter 5A, Section 1).

2 Remove the flexible hose connecting the

intercooler to the air inlet duct, then the pipe

4C•8 Fuel system - electronic fuel injection engines

15.1 Exploded view of the inlet manifold arrangement

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 142 of 296

and flexible hose connecting the turbocharger

to the intercooler (see illustration 4.12) . Use

adhesive tape to seal the turbocharger ports

against the entry of dirt.

3 Unbolt the horn nearest the intercooler.

4 Unbolt the radiator/intercooler assembly

from the bonnet closure panel and the body

crossmember.

5 Move the assembly as far as possible

towards the engine, and unbolt the intercooler

from the radiator; withdraw the intercooler.

Refitting

6 Refitting is the reverse of the removal

procedure, tightening all nuts and bolts to the

specified torque settings, and not forgetting

to unseal the turbocharger openings before

reconnecting the intercooler pipe and hose.

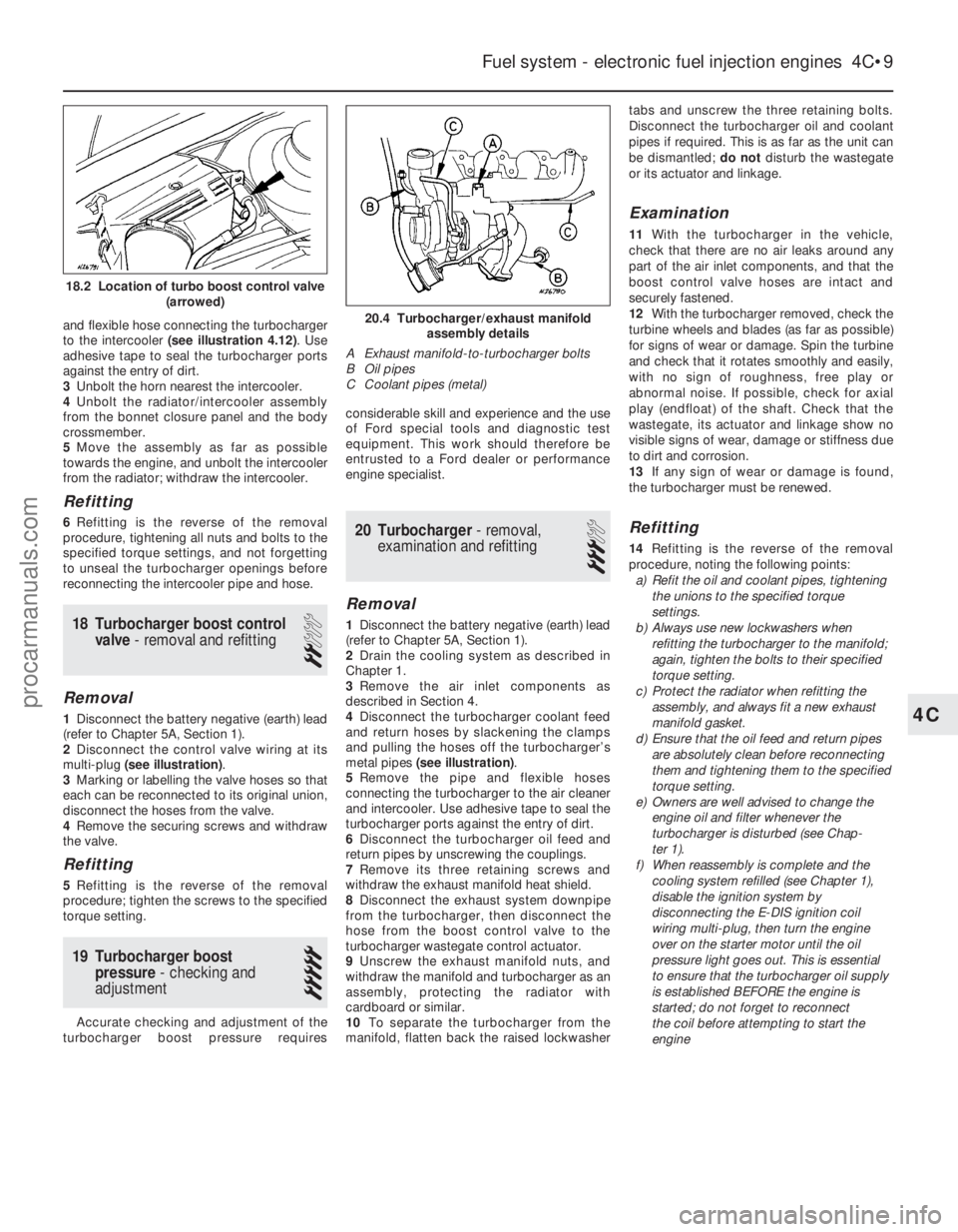

18 Turbocharger boost control valve - removal and refitting

2

Removal

1Disconnect the battery negative (earth) lead

(refer to Chapter 5A, Section 1).

2 Disconnect the control valve wiring at its

multi-plug (see illustration) .

3 Marking or labelling the valve hoses so that

each can be reconnected to its original union,

disconnect the hoses from the valve.

4 Remove the securing screws and withdraw

the valve.

Refitting

5 Refitting is the reverse of the removal

procedure; tighten the screws to the specified

torque setting.

19 Turbocharger boost pressure - checking and

adjustment

5

Accurate checking and adjustment of the

turbocharger boost pressure requires considerable skill and experience and the use

of Ford special tools and diagnostic test

equipment. This work should therefore be

entrusted to a Ford dealer or performance

engine specialist.

20 Turbocharger

- removal,

examination and refitting

3

Removal

1 Disconnect the battery negative (earth) lead

(refer to Chapter 5A, Section 1).

2 Drain the cooling system as described in

Chapter 1.

3 Remove the air inlet components as

described in Section 4.

4 Disconnect the turbocharger coolant feed

and return hoses by slackening the clamps

and pulling the hoses off the turbocharger’s

metal pipes (see illustration) .

5 Remove the pipe and flexible hoses

connecting the turbocharger to the air cleaner

and intercooler. Use adhesive tape to seal the

turbocharger ports against the entry of dirt.

6 Disconnect the turbocharger oil feed and

return pipes by unscrewing the couplings.

7 Remove its three retaining screws and

withdraw the exhaust manifold heat shield.

8 Disconnect the exhaust system downpipe

from the turbocharger, then disconnect the

hose from the boost control valve to the

turbocharger wastegate control actuator.

9 Unscrew the exhaust manifold nuts, and

withdraw the manifold and turbocharger as an

assembly, protecting the radiator with

cardboard or similar.

10 To separate the turbocharger from the

manifold, flatten back the raised lockwasher tabs and unscrew the three retaining bolts.

Disconnect the turbocharger oil and coolant

pipes if required. This is as far as the unit can

be dismantled;

do notdisturb the wastegate

or its actuator and linkage.

Examination

11 With the turbocharger in the vehicle,

check that there are no air leaks around any

part of the air inlet components, and that the

boost control valve hoses are intact and

securely fastened.

12 With the turbocharger removed, check the

turbine wheels and blades (as far as possible)

for signs of wear or damage. Spin the turbine

and check that it rotates smoothly and easily,

with no sign of roughness, free play or

abnormal noise. If possible, check for axial

play (endfloat) of the shaft. Check that the

wastegate, its actuator and linkage show no

visible signs of wear, damage or stiffness due

to dirt and corrosion.

13 If any sign of wear or damage is found,

the turbocharger must be renewed.

Refitting

14 Refitting is the reverse of the removal

procedure, noting the following points: a) Refit the oil and coolant pipes, tightening

the unions to the specified torque

settings.

b) Always use new lockwashers when

refitting the turbocharger to the manifold;

again, tighten the bolts to their specified

torque setting.

c) Protect the radiator when refitting the

assembly, and always fit a new exhaust

manifold gasket.

d) Ensure that the oil feed and return pipes

are absolutely clean before reconnecting

them and tightening them to the specified

torque setting.

e) Owners are well advised to change the engine oil and filter whenever the

turbocharger is disturbed (see Chap-

ter 1).

f) When reassembly is complete and the

cooling system refilled (see Chapter 1),

disable the ignition system by

disconnecting the E-DIS ignition coil

wiring multi-plug, then turn the engine

over on the starter motor until the oil

pressure light goes out. This is essential

to ensure that the turbocharger oil supply

is established BEFORE the engine is

started; do not forget to reconnect

the coil before attempting to start the

engine

Fuel system - electronic fuel injection engines 4C•9

20.4 Turbocharger/exhaust manifold assembly details

A Exhaust manifold-to-turbocharger bolts

B Oil pipes

C Coolant pipes (metal)

4C

1595Ford Fiesta Remake

18.2 Location of turbo boost control valve (arrowed)

procarmanuals.com

http://vnx.su

Page 148 of 296

and gasket. Discard the gasket - this must be

renewed whenever it is disturbed.

7Refit in the reverse order of removal. Check

that the mating faces are clean, and fit a new

gasket. Adjust the accelerator cable as

described in Section 5 on completion.

Fuel rail and injectors

Note: The following procedure is applicable

mainly to Zetec engines; specific information

for the PTE engine was not available at the

time of writing. However, apart from minor

differences in component attachments, both

engine types are very similar in this area.

8 Relieve the residual pressure in the fuel

system (see Section 2), and equalise tank

pressure by removing the fuel filler cap. Warning: This procedure will

merely relieve the increased

pressure necessary for the

engine to run - remember that

fuel will still be present in the system

components, and take precautions

accordingly before disconnecting any of

them.

9 Disconnect the battery negative (earth) lead

- see Chapter 5A, Section 1.

10 Remove the air inlet components as

described in Section 4.

11 Disconnect the accelerator cable from the

throttle linkage (see Section 5).

12 Disconnect the throttle position sensor

multi-plug.

13 Remove the throttle housing mounting

screws, then detach the throttle housing and gasket from the inlet manifold. Discard the

gasket - this must be renewed whenever it is

disturbed.

14

Detach the crankcase breather hose from

the cylinder head cover, and the fuel pressure

regulator vacuum hose from the inlet

manifold.

15 Releasing the wire clips, unplug the four

fuel injector multi-plugs and the inlet air

temperature sensor multi-plug.

16 Refer to Section 3 and disconnect the fuel

feed and return lines at the quick-release

couplings, then unclip the fuel hoses from the

inlet manifold; use rag to soak up any spilt

fuel. Note: Do not disturb the threaded

couplings at the fuel rail unions unless

absolutely necessary; these are sealed at the

factory. The quick-release couplings will

suffice for all normal service operations.

17 Unscrew the three bolts securing the fuel

rail (see illustration) . Withdraw the rail,

carefully prising it out of the inlet manifold,

and draining any remaining fuel into a suitable

clean container. Note the seals between the

rail noses and the manifold; these must be

renewed whenever the rail is removed (see

illustration) .

18 Clamping the rail carefully in a vice fitted

with soft jaws, unscrew the two bolts securing

each injector, and withdraw the injectors (see

illustration) . Place each in a clean, clearly-

labelled storage container.

19 If the injector(s) are being renewed,

discard the old injector, the nose seal and the

O- rings. If only the injector O-rings are being renewed, and it is intended that the same

injectors will be re-used, remove the old nose

seal and O-rings, and discard them.

20

Refitting is the reverse of the removal

procedure, noting the following points:

a) Lubricate each nose seal and O-ring with clean engine oil on installation.

b) Locate each injector carefully in the fuel

rail recess, ensuring that the locating tab

on the injector head fits into the slot

provided in the rail. Tighten the bolts

securely.

c) Fit a new seal to each fuel rail nose, and

ensure that the seals are not displaced as

the rail is refitted (see illustration).

Ensure that the fuel rail is settled fully in

the manifold before tightening the bolts.

d) Ensure that the hoses and wiring are

routed correctly, and secured on

reconnection by any clips or ties

provided.

e) Adjust the accelerator cable as described

in Section 5.

f) On completion, switch the ignition on and off five times, to activate the fuel pump

and pressurise the system, without

cranking the engine. Check for signs of

fuel leaks around all disturbed unions and

joints before attempting to start the

engine.

Fuel pressure regulator

21 Relieve the residual pressure in the fuel

system (see Section 2), and equalise tank

pressure by removing the fuel filler cap.

Warning: This procedure will

merely relieve the increased

pressure necessary for the

engine to run - remember that

fuel will still be present in the system

components, and take precautions

accordingly before disconnecting any of

them.

22 Disconnect the battery negative (earth)

lead - see Chapter 5A, Section 1.

23 Disconnect the vacuum hose from the

regulator.

24 Unscrew the two regulator retaining bolts

(see illustration) then use a wad of clean rag

to soak up any spilt fuel, and withdraw the

regulator.

Fuel system - sequential electronic fuel injection engines 4D•5

14.18 Removing an injector from the fuel rail. Note the O-ring seals (arrowed)14.17b Note nose seals (arrowed) between rail and intermediate flange14.17a Unscrewing fuel rail mounting bolts (arrowed)

14.24 Fuel pressure regulator vacuumhose (A) and retaining bolts (B)14.20 Fit new nose seals (arrowed) before refitting the fuel rail

4D

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 150 of 296

b)Tighten the screws evenly and securely

(but do not overtighten them, or the

potentiometer body will be cracked).

Vehicle speed sensor

48 The sensor is mounted at the base of the

speedometer drive cable, and is removed with

the speedometer drive pinion. Refer to the

relevant Section of Chapter 7A or B, as

applicable.

Power steering pressure switch

49 Releasing its clip, unplug the switch’s

electrical connector, then unscrew the switch

from the power steering high pressure pipe.

Place a wad of rag underneath, to catch any

spilt fluid. If a sealing washer is fitted, renew it

if it is worn or damaged.

50 Refitting is the reverse of the removal

procedure; tighten the switch securely, then

top-up the fluid reservoir (see “Weekly

Checks”) to replace any fluid lost from the

system, and bleed out any trapped air (see

Chapter 10).

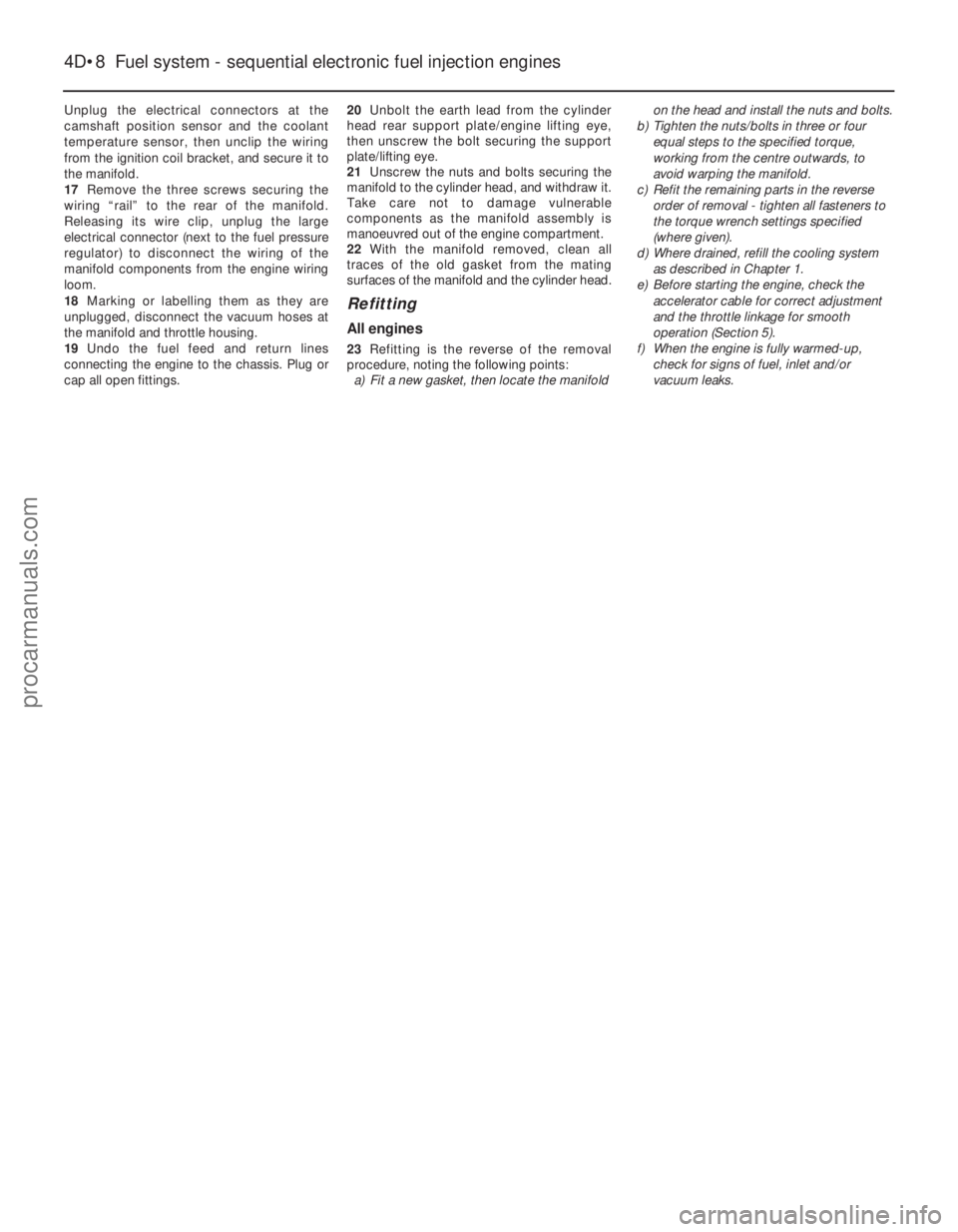

Oxygen sensor

Note: The sensor is delicate, and will not work

if it is dropped or knocked, if its power supply

is disrupted, or if any cleaning materials are

used on it.

51 Raise and support the front of the vehicle

if required to remove the sensor from

underneath (“see Jacking and vehicle

support” ).

52 Release the sensor’s wiring multi-plug

from its support bracket, and unplug it to

disconnect the sensor (see illustration).

53 Unscrew the sensor from the exhaust

system front downpipe; collect the sealing

washer (where fitted).

54 On refitting, clean the sealing washer

(where fitted) and renew it if it is damaged or

worn. Apply a smear of anti-seize compound

to the sensor’s threads, to prevent them from

welding themselves to the downpipe in

service. Refit the sensor, tightening it to its

specified torque wrench setting; a slotted

socket will be required to do this. Reconnect

the wiring, and refit the connector plug.

15 Inlet manifold -

removal and refitting

4

Note: Refer to the warning note in Section 1

before proceeding.

Removal

PTE engines

1 The inlet manifold is a two-piece assembly

comprising an upper and lower section bolted

together.

2 Drain the cooling system with reference to

Chapter 1.

3 Relieve the residual pressure in the fuel

system (see Section 2), and equalise tank

pressure by removing the fuel filler cap. Warning: This procedure will

merely relieve the increased

pressure necessary for the engine

to run - remember that fuel will

still be present in the system components,

and take precautions accordingly before

disconnecting any of them.

4 Disconnect the battery negative (earth) lead

(refer to Chapter 5A, Section 1).

5 Remove the air inlet components (Sec-

tion 4) and disconnect the accelerator cable

from the throttle linkage (Section 5).

6 Remove the fuel injectors and fuel rail as

described in Section 14.

7 Noting their locations, disconnect the

coolant, vacuum and breather hoses from the

manifold. 8

Disconnect the wiring multi-plugs from the

engine sensors at the inlet manifold.

9 Undo the retaining bolts, and withdraw the

manifold from the cylinder head. Note the

location of the engine lifting bracket and earth

lead, where fitted. Remove the gasket.

10 With the manifold removed, clean all

traces of the old gasket from the mating

surfaces of the manifold and the cylinder

head.Zetec engines

11 Relieve the residual pressure in the fuel

system (see Section 2), and equalise tank

pressure by removing the fuel filler cap. Warning: This procedure will

merely relieve the increased

pressure necessary for the

engine to run - remember that

fuel will still be present in the system

components, and take precautions

accordingly before disconnecting any of

them.

12 Disconnect the battery negative (earth)

lead (refer to Chapter 5A, Section 1).

13 Remove the air inlet components (Sec-

tion 4) and disconnect the accelerator cable

from the throttle linkage (Section 5).

14 Disconnect the crankcase breather hose

from the cylinder head cover union.

15 Unbolt the upper part of the exhaust

manifold heat shield.

16 Remove the two screws securing the

wiring “rail” to the top of the manifold - this is

simply so that it can be moved as required to

reach the manifold bolts (see illustration).

Fuel system - sequential electronic fuel injection engines 4D•7

14.52 Oxygen sensor (A) and wiring multi-

plug (B) (Zetec engine shown)15.16 Exploded view of the Zetec engine inlet manifold components

4D

1595Ford Fiesta Remake

1 Cylinder head

cover

2 Heat-insulating plate/gasket

3 Intermediate flange/fuel rail

assembly

4 Gasket

5 Inlet manifold

6 Intake air temperature

sensor

7 Engine wiring

loom

8 Boltsprocarmanuals.com

http://vnx.su

Page 151 of 296

Unplug the electrical connectors at the

camshaft position sensor and the coolant

temperature sensor, then unclip the wiring

from the ignition coil bracket, and secure it to

the manifold.

17Remove the three screws securing the

wiring “rail” to the rear of the manifold.

Releasing its wire clip, unplug the large

electrical connector (next to the fuel pressure

regulator) to disconnect the wiring of the

manifold components from the engine wiring

loom.

18 Marking or labelling them as they are

unplugged, disconnect the vacuum hoses at

the manifold and throttle housing.

19 Undo the fuel feed and return lines

connecting the engine to the chassis. Plug or

cap all open fittings. 20

Unbolt the earth lead from the cylinder

head rear support plate/engine lifting eye,

then unscrew the bolt securing the support

plate/lifting eye.

21 Unscrew the nuts and bolts securing the

manifold to the cylinder head, and withdraw it.

Take care not to damage vulnerable

components as the manifold assembly is

manoeuvred out of the engine compartment.

22 With the manifold removed, clean all

traces of the old gasket from the mating

surfaces of the manifold and the cylinder head.

Refitting

All engines

23 Refitting is the reverse of the removal

procedure, noting the following points: a) Fit a new gasket, then locate the manifold on the head and install the nuts and bolts.

b) Tighten the nuts/bolts in three or four

equal steps to the specified torque,

working from the centre outwards, to

avoid warping the manifold.

c) Refit the remaining parts in the reverse order of removal - tighten all fasteners to

the torque wrench settings specified

(where given).

d) Where drained, refill the cooling system

as described in Chapter 1.

e) Before starting the engine, check the accelerator cable for correct adjustment

and the throttle linkage for smooth

operation (Section 5).

f) When the engine is fully warmed-up,

check for signs of fuel, inlet and/or

vacuum leaks.

4D•8 Fuel system - sequential electronic fuel injection engines

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 155 of 296

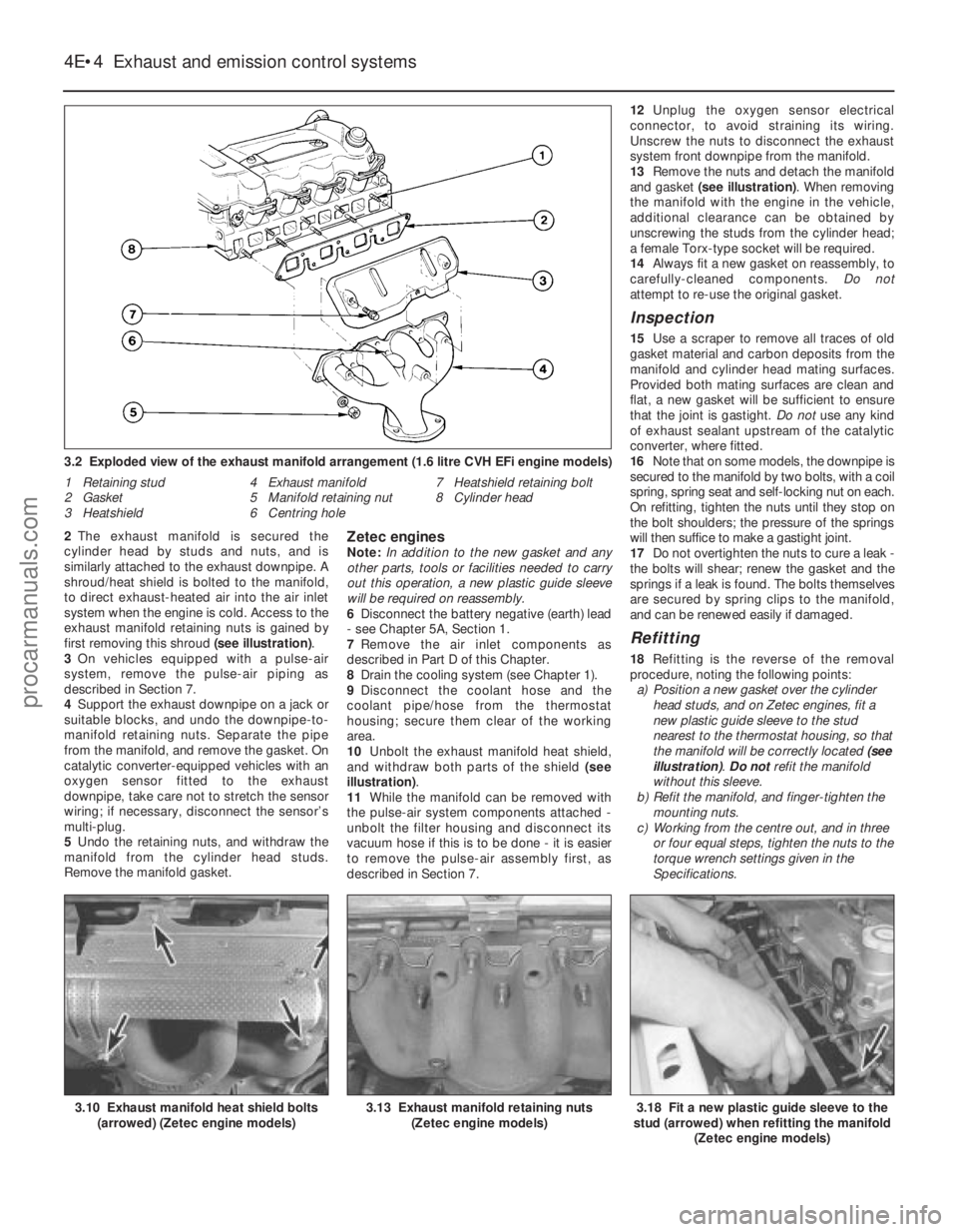

2The exhaust manifold is secured the

cylinder head by studs and nuts, and is

similarly attached to the exhaust downpipe. A

shroud/heat shield is bolted to the manifold,

to direct exhaust-heated air into the air inlet

system when the engine is cold. Access to the

exhaust manifold retaining nuts is gained by

first removing this shroud (see illustration).

3 On vehicles equipped with a pulse-air

system, remove the pulse-air piping as

described in Section 7.

4 Support the exhaust downpipe on a jack or

suitable blocks, and undo the downpipe-to-

manifold retaining nuts. Separate the pipe

from the manifold, and remove the gasket. On

catalytic converter-equipped vehicles with an

oxygen sensor fitted to the exhaust

downpipe, take care not to stretch the sensor

wiring; if necessary, disconnect the sensor’s

multi-plug.

5 Undo the retaining nuts, and withdraw the

manifold from the cylinder head studs.

Remove the manifold gasket.Zetec enginesNote: In addition to the new gasket and any

other parts, tools or facilities needed to carry

out this operation, a new plastic guide sleeve

will be required on reassembly.

6 Disconnect the battery negative (earth) lead

- see Chapter 5A, Section 1.

7 Remove the air inlet components as

described in Part D of this Chapter.

8 Drain the cooling system (see Chapter 1).

9 Disconnect the coolant hose and the

coolant pipe/hose from the thermostat

housing; secure them clear of the working

area.

10 Unbolt the exhaust manifold heat shield,

and withdraw both parts of the shield (see

illustration) .

11 While the manifold can be removed with

the pulse-air system components attached -

unbolt the filter housing and disconnect its

vacuum hose if this is to be done - it is easier

to remove the pulse-air assembly first, as

described in Section 7. 12

Unplug the oxygen sensor electrical

connector, to avoid straining its wiring.

Unscrew the nuts to disconnect the exhaust

system front downpipe from the manifold.

13 Remove the nuts and detach the manifold

and gasket (see illustration) . When removing

the manifold with the engine in the vehicle,

additional clearance can be obtained by

unscrewing the studs from the cylinder head;

a female Torx-type socket will be required.

14 Always fit a new gasket on reassembly, to

carefully-cleaned components. Do not

attempt to re-use the original gasket.

Inspection

15 Use a scraper to remove all traces of old

gasket material and carbon deposits from the

manifold and cylinder head mating surfaces.

Provided both mating surfaces are clean and

flat, a new gasket will be sufficient to ensure

that the joint is gastight. Do not use any kind

of exhaust sealant upstream of the catalytic

converter, where fitted.

16 Note that on some models, the downpipe is

secured to the manifold by two bolts, with a coil

spring, spring seat and self-locking nut on each.

On refitting, tighten the nuts until they stop on

the bolt shoulders; the pressure of the springs

will then suffice to make a gastight joint.

17 Do not overtighten the nuts to cure a leak -

the bolts will shear; renew the gasket and the

springs if a leak is found. The bolts themselves

are secured by spring clips to the manifold,

and can be renewed easily if damaged.

Refitting

18 Refitting is the reverse of the removal

procedure, noting the following points: a) Position a new gasket over the cylinder head studs, and on Zetec engines, fit a

new plastic guide sleeve to the stud

nearest to the thermostat housing, so that

the manifold will be correctly located (see

illustration) . Do notrefit the manifold

without this sleeve.

b) Refit the manifold, and finger-tighten the

mounting nuts.

c) Working from the centre out, and in three or four equal steps, tighten the nuts to the

torque wrench settings given in the

Specifications.

4E•4 Exhaust and emission control systems

3.18 Fit a new plastic guide sleeve to the

stud (arrowed) when refitting the manifold

(Zetec engine models)3.13 Exhaust manifold retaining nuts(Zetec engine models)3.10 Exhaust manifold heat shield bolts(arrowed) (Zetec engine models)

3.2 Exploded view of the exhaust manifold arrangement (1.6 litre CVH E\

Fi engine models)

1 Retaining stud

2 Gasket

3 Heatshield 4 Exhaust manifold

5 Manifold retaining nut

6 Centring hole 7 Heatshield retaining bolt

8 Cylinder head

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su