driver seat adjustment FORD FIESTA 1989 Service Repair Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1989, Model line: FIESTA, Model: FORD FIESTA 1989Pages: 296, PDF Size: 10.65 MB

Page 127 of 296

4 Air cleaner assembly and airinlet components -

removal and refitting

1

Note: Air cleaner element renewal and air

cleaner temperature control system checks

(where applicable) are described in Chapter 1.

Air cleaner assembly

1 Disconnect the battery negative (earth) lead

(refer to Chapter 5A, Section 1).

2 Undo the retaining bolts and partially lift the

air cleaner from the CFi unit, so that the hose

and wiring connections to the underside of

the air cleaner body are accessible.

3 Note their connections and routings, then

detach the wiring and hoses from the

underside of the air cleaner.

4 Lift the air cleaner clear from the CFi unit.

5 Refit in the reverse order of removal.

6 Renew any hoses that are perished or

cracked, and ensure that all fittings are

securely and correctly reconnected.

Air inlet components

7 The air cleaner inlet spout and related

components are removed with the air cleaner

assembly as described above.

5 Accelerator cable - removal,

refitting and adjustment

1

Removal

1 Disconnect the battery negative (earth) lead

(refer to Chapter 5A, Section 1).

2 Fold back the carpet and insulation in the

driver’s footwell to gain access to the

accelerator pedal.

3 Detach the accelerator cable from the

pedal.

4 Remove the air cleaner assembly as

described in Section 4.

5 Working at the throttle housing end of the

cable, pivot the throttle quadrant by hand to

release the tension from the cable, then

detach the inner cable nipple from the throttle

lever.

6 Detach the outer cable from the

adjuster/support bracket, then remove the

cable.

Refitting and adjustment

7 Refit in the reverse order of removal. When

the cable is reconnected at each end, have an

assistant depress the accelerator, and check

that the throttle fully opens and shuts without

binding. Ensure that there is a small amount of

slack in the inner cable when the throttle is

fully released. If adjustment is required,

release the outer cable retaining clip from the

cable at the adjustment/support bracket, slide

the cable through the adjuster grommet to the

point required, then refit the retaining clip to

secure it in the set position.

6 Accelerator pedal -

removal and refitting

1

Refer to Part A, Section 5.

7 Fuel pump/fuel pressure -

checking

3

Note: Refer to the warning note in Section 1

before proceeding.

Fuel pump operation check

1 Switch on the ignition, and listen for the fuel

pump (the sound of an electric motor running,

audible from beneath the rear seats). Assuming

there is sufficient fuel in the tank, the pump

should start and run for approximately one or

two seconds, then stop, each time the ignition

is switched on. Note:If the pump runs

continuously all the time the ignition is switched

on, the electronic control system is running in

the backup (or “limp-home”) mode referred to

by Ford as “Limited Operation Strategy” (LOS).

This almost certainly indicates a fault in the

EEC IV module itself, and the vehicle should

therefore be taken to a Ford dealer for a full test

of the complete system, using the correct

diagnostic equipment; do not waste time or risk

damaging the components by trying to test the

system without such facilities.

2 Listen for fuel return noises from the fuel

pressure regulator. It should be possible to

feel the fuel pulsing in the regulator and in the

feed hose from the fuel filter.

3 If the pump does not run at all, check the

fuse, relay and wiring (see Chapter 12). Check

also that the fuel cut-off switch has not been

activated and if so, reset it.

Fuel pressure check

4 A fuel pressure gauge will be required for this

check and should be connected in the fuel line

between the fuel filter and the CFi unit, in

accordance with the gauge maker’s instructions.

5 Start the engine and allow it to idle. Note

the gauge reading as soon as the pressure

stabilises, and compare it with the figures

given for regulated fuel pressure in the

Specifications . If the pressure is high, check

for a restricted fuel return line. If the pressure

is low, renew the fuel pressure regulator. 6

Switch off the engine, and check that after

one minute, the hold pressure has not fallen

below that specified. If it has, check the seals

on the fuel injector (see Section 14) and renew

them if they appear in any way suspect. If the

seals are okay, then the fuel pressure

regulator or CFi unit are suspect.

7 Carefully disconnect the fuel pressure

gauge, depressurising the system first as

described in Section 2.

8 Run the engine, and check that there are no

fuel leaks.

8 Fuel tank - removal,

inspection and refitting

3

Proceed as described in Part A, Section 8, but

before disconnecting the battery, relieve the

residual pressure in the fuel system (see Sec-

tion 2), and equalise tank pressure by removing

the fuel filler cap. Note also that it will be

necessary to release any additional ventilation

tubes from their retaining clips, and to reposition

or remove the underbody heat shields on certain

models for access to the tank retaining bolts.

9 Fuel pump/fuel gauge

sender unit - removal and

refitting

3

Note: Refer to the warning note in Section 1

before proceeding. Ford specify the use of their

service tool 23-026 (a large box spanner with

projecting teeth to engage the fuel pump/sender

unit retaining ring’s slots) for this task. While

alternatives are possible, in view of the difficulty

experienced in removing and refitting the

pump/sender unit, it is strongly advised that the

correct tool is obtained before starting work.

Removal

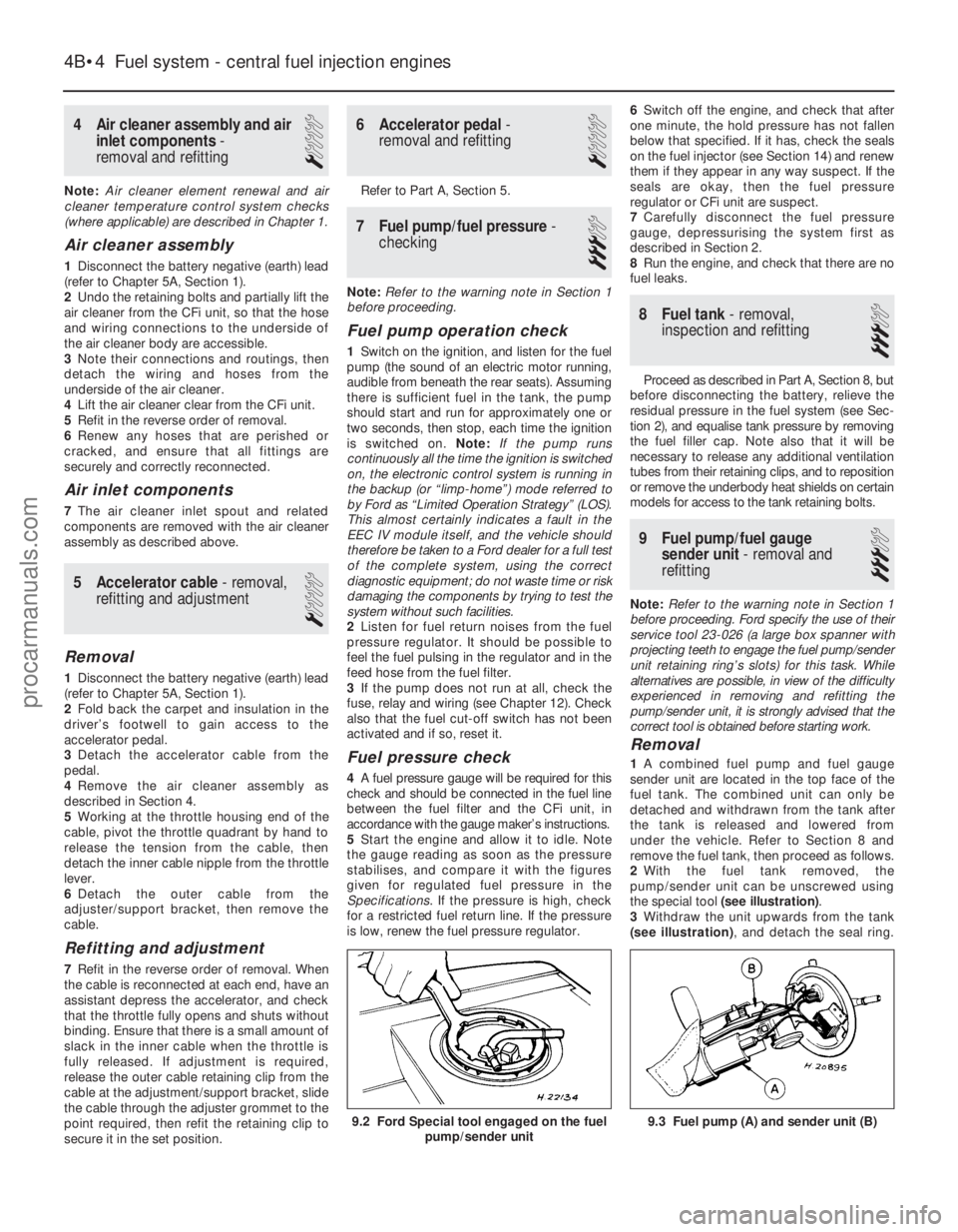

1 A combined fuel pump and fuel gauge

sender unit are located in the top face of the

fuel tank. The combined unit can only be

detached and withdrawn from the tank after

the tank is released and lowered from

under the vehicle. Refer to Section 8 and

remove the fuel tank, then proceed as follows.

2 With the fuel tank removed, the

pump/sender unit can be unscrewed using

the special tool (see illustration) .

3 Withdraw the unit upwards from the tank

(see illustration) , and detach the seal ring.

9.3 Fuel pump (A) and sender unit (B)

4B•4 Fuel system - central fuel injection engines

9.2 Ford Special tool engaged on the fuel

pump/sender unit

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 137 of 296

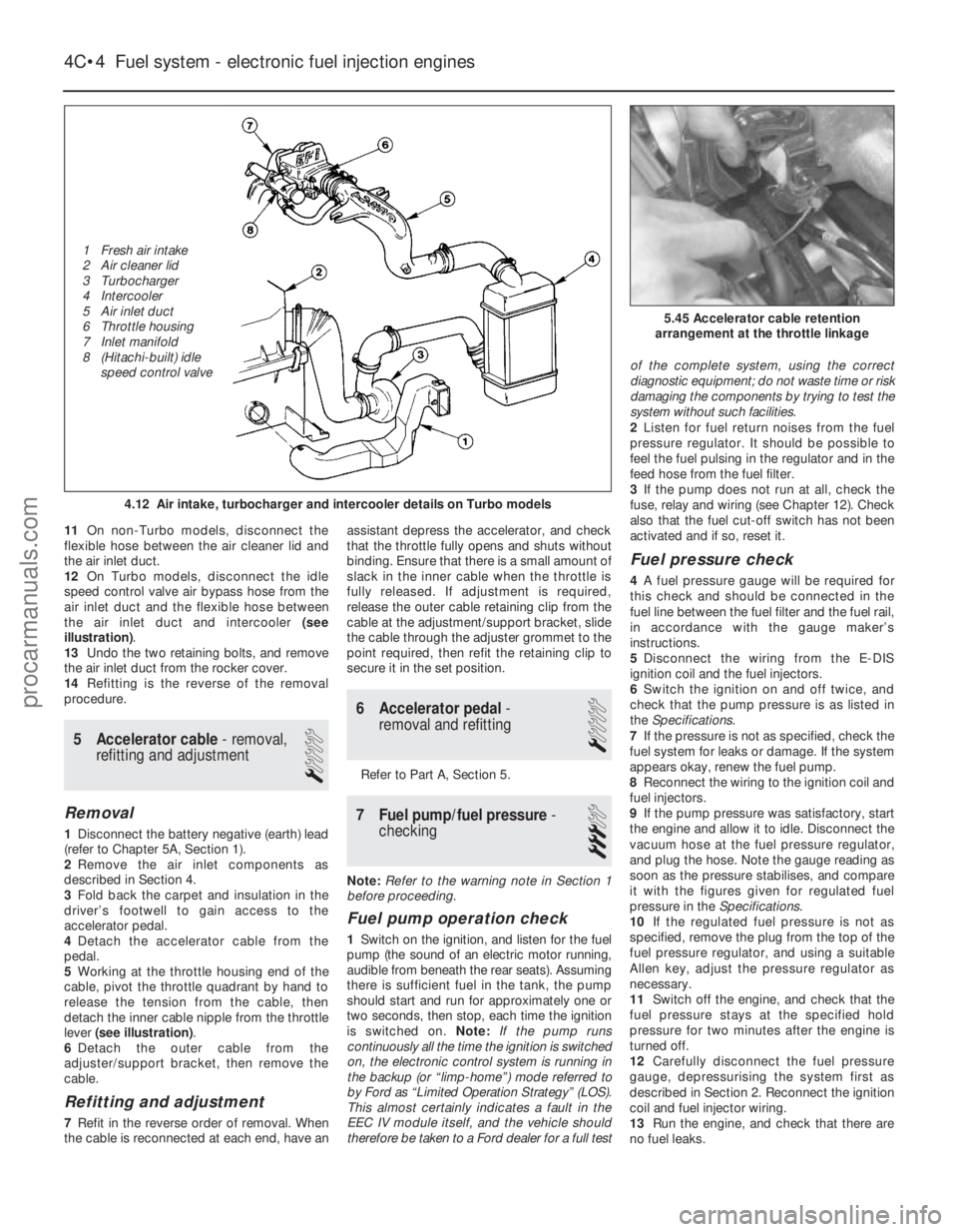

11On non-Turbo models, disconnect the

flexible hose between the air cleaner lid and

the air inlet duct.

12 On Turbo models, disconnect the idle

speed control valve air bypass hose from the

air inlet duct and the flexible hose between

the air inlet duct and intercooler (see

illustration) .

13 Undo the two retaining bolts, and remove

the air inlet duct from the rocker cover.

14 Refitting is the reverse of the removal

procedure.

5 Accelerator cable - removal,

refitting and adjustment

1

Removal

1 Disconnect the battery negative (earth) lead

(refer to Chapter 5A, Section 1).

2 Remove the air inlet components as

described in Section 4.

3 Fold back the carpet and insulation in the

driver’s footwell to gain access to the

accelerator pedal.

4 Detach the accelerator cable from the

pedal.

5 Working at the throttle housing end of the

cable, pivot the throttle quadrant by hand to

release the tension from the cable, then

detach the inner cable nipple from the throttle

lever (see illustration) .

6 Detach the outer cable from the

adjuster/support bracket, then remove the

cable.

Refitting and adjustment

7 Refit in the reverse order of removal. When

the cable is reconnected at each end, have an assistant depress the accelerator, and check

that the throttle fully opens and shuts without

binding. Ensure that there is a small amount of

slack in the inner cable when the throttle is

fully released. If adjustment is required,

release the outer cable retaining clip from the

cable at the adjustment/support bracket, slide

the cable through the adjuster grommet to the

point required, then refit the retaining clip to

secure it in the set position.

6 Accelerator pedal

-

removal and refitting

1

Refer to Part A, Section 5.

7 Fuel pump/fuel pressure -

checking

3

Note: Refer to the warning note in Section 1

before proceeding.

Fuel pump operation check

1 Switch on the ignition, and listen for the fuel

pump (the sound of an electric motor running,

audible from beneath the rear seats). Assuming

there is sufficient fuel in the tank, the pump

should start and run for approximately one or

two seconds, then stop, each time the ignition

is switched on. Note:If the pump runs

continuously all the time the ignition is switched

on, the electronic control system is running in

the backup (or “limp-home”) mode referred to

by Ford as “Limited Operation Strategy” (LOS).

This almost certainly indicates a fault in the

EEC IV module itself, and the vehicle should

therefore be taken to a Ford dealer for a full test of the complete system, using the correct

diagnostic equipment; do not waste time or risk

damaging the components by trying to test the

system without such facilities.

2

Listen for fuel return noises from the fuel

pressure regulator. It should be possible to

feel the fuel pulsing in the regulator and in the

feed hose from the fuel filter.

3 If the pump does not run at all, check the

fuse, relay and wiring (see Chapter 12). Check

also that the fuel cut-off switch has not been

activated and if so, reset it.

Fuel pressure check

4 A fuel pressure gauge will be required for

this check and should be connected in the

fuel line between the fuel filter and the fuel rail,

in accordance with the gauge maker’s

instructions.

5 Disconnect the wiring from the E-DIS

ignition coil and the fuel injectors.

6 Switch the ignition on and off twice, and

check that the pump pressure is as listed in

the Specifications .

7 If the pressure is not as specified, check the

fuel system for leaks or damage. If the system

appears okay, renew the fuel pump.

8 Reconnect the wiring to the ignition coil and

fuel injectors.

9 If the pump pressure was satisfactory, start

the engine and allow it to idle. Disconnect the

vacuum hose at the fuel pressure regulator,

and plug the hose. Note the gauge reading as

soon as the pressure stabilises, and compare

it with the figures given for regulated fuel

pressure in the Specifications.

10 If the regulated fuel pressure is not as

specified, remove the plug from the top of the

fuel pressure regulator, and using a suitable

Allen key, adjust the pressure regulator as

necessary.

11 Switch off the engine, and check that the

fuel pressure stays at the specified hold

pressure for two minutes after the engine is

turned off.

12 Carefully disconnect the fuel pressure

gauge, depressurising the system first as

described in Section 2. Reconnect the ignition

coil and fuel injector wiring.

13 Run the engine, and check that there are

no fuel leaks.

4C•4 Fuel system - electronic fuel injection engines

5.45 Accelerator cable retention

arrangement at the throttle linkage

4.12 Air intake, turbocharger and intercooler details on Turbo models

1595Ford Fiesta Remake

1 Fresh air intake

2 Air cleaner lid

3 Turbocharger

4 Intercooler

5 Air inlet duct

6 Throttle housing

7 Inlet manifold

8 (Hitachi-built) idle

speed control valveprocarmanuals.com

http://vnx.su

Page 146 of 296

4 Air cleaner assembly and airinlet components - removal

and refitting

1

Air cleaner assembly

1 Disconnect the battery negative (earth) lead

(refer to Chapter 5A, Section 1).

2 Disconnect the mass air flow sensor wiring

multi-plug, then release the clips and

withdraw the sensor, complete with inlet

hose, from the air cleaner cover (see

illustrations) . Carefully position the mass air

flow sensor and hose assembly to one side.

3 Detach the fresh air inlet duct from the air

cleaner housing.

4 Unscrew the air cleaner housing retaining

nut, then pull the housing upwards to release

the locating pegs from their rubber grommets.

As the housing is withdrawn, detach the

crankcase breather hose (see illustration).

Remove the assembly from the car.

5 Refitting is the reverse of the removal

procedure. Ensure that the housing pegs seat

fully in their grommets, and that the mass air

flow sensor is correctly located.

Air inlet components

6 On PTE engines, disconnect the HT leads

from the spark plugs, labelling them if

necessary to avoid confusion on refitting.

7 Slacken the hose clip, and detach the flexible air inlet hose from the mass air flow

sensor.

8

On PTE engines, disconnect the ventilation

hose from the inlet duct over the top of the

engine.

9 On PTE engines undo the two inlet duct

retaining bolts; On Zetec engines , undo the

two bolts and lift off the air inlet duct retaining

strap (see illustration) . Withdraw the inlet

duct from the throttle housing and remove the

duct and flexible hose from the engine.

10 Refitting is the reverse of the removal

procedure.

5 Accelerator cable - removal,

refitting and adjustment

1

Removal

1 Disconnect the battery negative (earth) lead

(refer to Chapter 5A, Section 1).

2 Fold back the carpet and insulation in the

driver’s footwell to gain access to the

accelerator pedal.

3 Detach the accelerator cable from the

pedal.

4 From within the engine compartment,

detach the outer cable from the

adjuster/support bracket by removing the

metal retaining clip (see illustration).5

Pivot the throttle quadrant by hand, detach

the inner cable nipple from the throttle lever

and remove the cable.

Refitting

6 Refit in the reverse order of removal. When

the cable is reconnected at each end, adjust

the cable as follows.

Adjustment

7 Remove the outer cable metal retaining clip

at the adjuster/support bracket and lubricate

the cable adjuster grommet with soapy water.

8 Remove any slack by pulling the cable

outer as far as possible out of the adjuster.

Have an assistant depress the accelerator

pedal fully - the cable outer will move back

into the adjuster - and hold it there while the

clip is refitted.

9 Check that the throttle quadrant moves

smoothly and easily from the fully-closed to

the fully-open position and back again as the

assistant depresses and releases the

accelerator pedal. Re-adjust the cable if

required.

6 Accelerator pedal -

removal and refitting

1

Refer to Part A, Section 5.

Fuel system - sequential electronic fuel injection engines 4D•3

4.2c . . . and withdraw the sensor4.2b . . . release the retaining clips . . .4.2a Disconnect the mass air flow sensor

wiring multi-plug . . .

5.4 Detach the accelerator outer cableretaining clip (arrowed)4.9 Unscrew the nuts (arrowed) to releasethe air intake duct on Zetec engines4.4 Unscrew front retaining nut and lift theair cleaner housing, disconnecting the

breather hose (arrowed)

4D

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 187 of 296

location. Slacken the other two nuts or

remove them, as necessary.

6Remove the four nuts securing the servo

unit to its mounting bracket assembly, then

pull the servo forward to remove the inner

servo support bracket (see illustration).

7 Remove the spring clip and clevis pin

securing the servo pushrod to the cross link,

then lift out the servo unit (see illustration).

8 Note that the servo unit cannot be

dismantled for repair or overhaul and, if faulty,

must be renewed.

Refitting

9 Refitting is a reversal of removal. Refer to

Section 9 for details of refitting the master

cylinder.

16 Vacuum servo unit vacuum

hose and non-return valve -

removal, testing and refitting

1

Removal

1 Depress the brake pedal three or four times

to exhaust any remaining vacuum from the

servo unit.

2 Carefully pull free and detach the servo

vacuum hose from the servo unit. If the hose

is reluctant to move, prise it free with the aid

of a screwdriver, inserting its blade under the

flange of the elbow.

3 Detach the vacuum hose from its inlet

manifold connection. Depending on the fixing,

undo the union nut and withdraw the hose, or

press the hose and its retaining collar

inwards, then holding the collar in, withdraw

the hose.

4 If the hose or the fixings are damaged or in

poor condition, they must be renewed.

Non-return valve testing

5 Examine the non-return valve for damage

and signs of deterioration, and renew it if

necessary. The valve may be tested by

blowing through its connecting hoses in

both directions. It should only be possible

to blow from the servo end to the manifold

end.

Refitting

6 Refitting is a reversal of removal. If fitting a

new non-return valve, ensure that it is fitted

the correct way round.

17 Handbrake lever -

removal and refitting

1

Removal

1 Disconnect the battery negative (earth) lead

(refer to Chapter 5A, Section 1), then chock

the wheels to secure the vehicle.

2 Undo the bolts securing the front seats to

the floorpan, and remove both seats from the

vehicle (see Chapter 11). Move the seats on

their slide mechanisms to expose the

mounting bolts, as necessary.

3 Remove the screws securing the rear seat

cushion, then raise the cushion to obtain

access to the carpet retaining screws.

Remove the carpet retaining screws.

4 Undo the bolt securing the seat belt clips to

the centre of the floorpan, then remove the

clip assembly.

5 Remove the seat belt lower anchor bracket

bolt from its location at the base of the B-pillar

behind the driver’s seat.

6 Remove the screws securing the sill scuff

plate to the driver’s side of the vehicle, then

carefully pull the sill scuff plate away from its

location so that the carpet is released. 7

Fold the carpet forwards, at the same time

carefully easing it out from under the sill scuff

plate. Lift the carpet over the handbrake lever.

8 Lift out the noise insulation for access to

the lever mounting bolts and the primary

cable fixing.

9 Fully release the handbrake lever, then

remove the handbrake primary cable clevis

pin securing clip (see illustration).

Remove the clevis pin and withdraw the

primary cable from the handbrake lever

assembly.

10 Remove the cover (see illustration), then

disconnect the handbrake warning light

switch wiring connection, and undo the two

screws securing the switch to the handbrake

lever assembly.

11 Undo the handbrake lever mounting bolts,

then withdraw the handbrake lever assembly

from the vehicle.

Refitting

12 Refitting is the reverse procedure to

removal, ensuring that the handbrake warning

light wiring is routed away from the lever

ratchet. The loom should be secured to the

floorpan with tape.

13 Check the handbrake adjustment as

described in Chapter 1 to complete.

18 Handbrake primary cable -

removal and refitting

1

Removal

1 Release the primary cable from the

handbrake lever, as described in the previous

Section.

2 Chock the front wheels then jack up the

rear of the car and support it on axle stands

(see “Jacking and Vehicle Support” ).

3 Where applicable, detach the exhaust

system and remove the heat shields from the

underside floorpan to allow access to the

primary cable connections underneath the

vehicle (see Chapter 4E).

4 Release the spring clip securing the pin,

and extract the equaliser/cable pin. Detach

9•12 Braking system

17.10 Removing the cover from the

handbrake warning light switch17.9 Removing the handbrake primary cable clevis pin securing clip

15.7 Spring clip (A) and clevis pin (B)

securing servo pushrod to the cross link15.6 Nuts securing servo unit to its

mounting bracket assembly (arrowed)

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 202 of 296

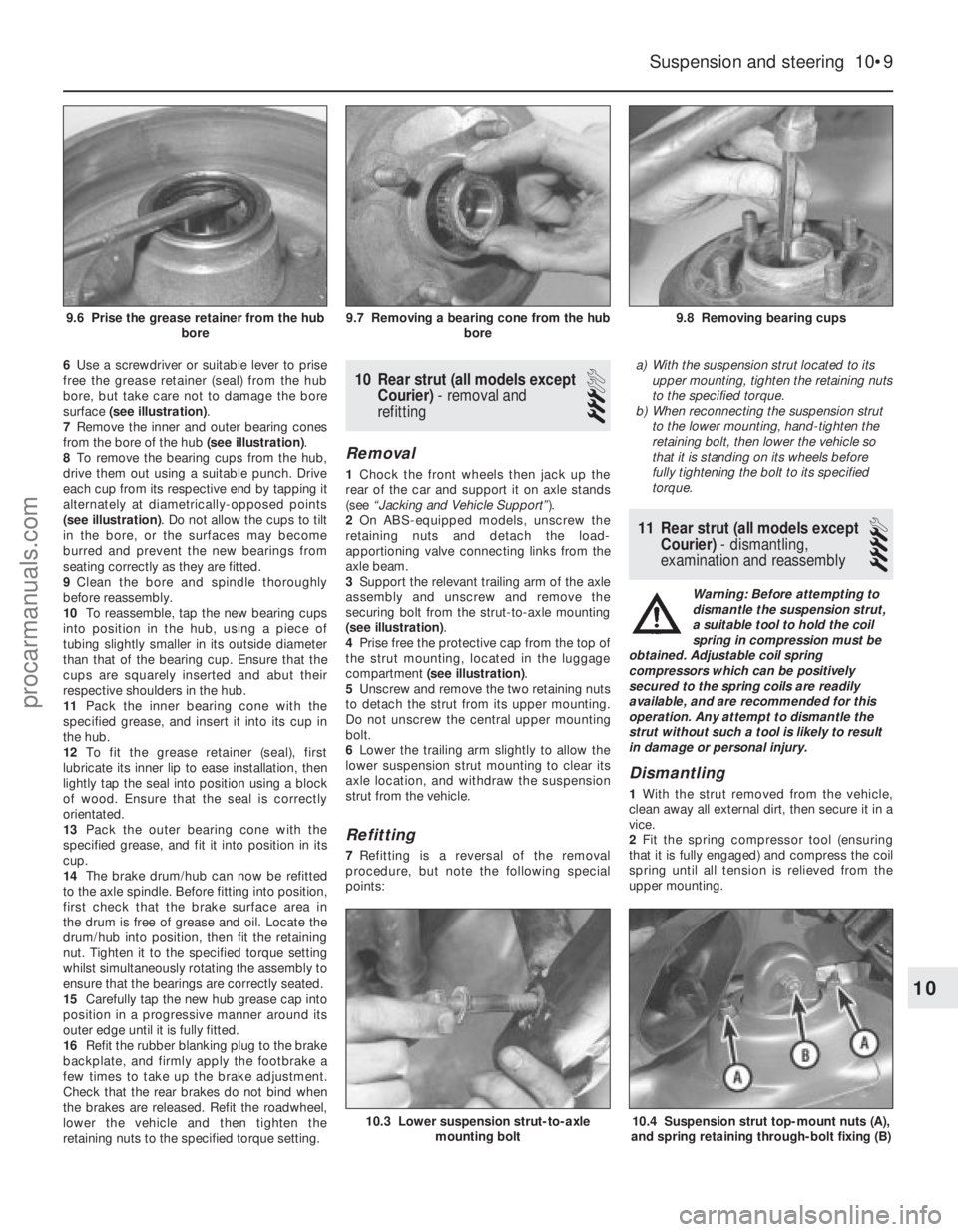

6Use a screwdriver or suitable lever to prise

free the grease retainer (seal) from the hub

bore, but take care not to damage the bore

surface (see illustration) .

7 Remove the inner and outer bearing cones

from the bore of the hub (see illustration).

8 To remove the bearing cups from the hub,

drive them out using a suitable punch. Drive

each cup from its respective end by tapping it

alternately at diametrically-opposed points

(see illustration) . Do not allow the cups to tilt

in the bore, or the surfaces may become

burred and prevent the new bearings from

seating correctly as they are fitted.

9 Clean the bore and spindle thoroughly

before reassembly.

10 To reassemble, tap the new bearing cups

into position in the hub, using a piece of

tubing slightly smaller in its outside diameter

than that of the bearing cup. Ensure that the

cups are squarely inserted and abut their

respective shoulders in the hub.

11 Pack the inner bearing cone with the

specified grease, and insert it into its cup in

the hub.

12 To fit the grease retainer (seal), first

lubricate its inner lip to ease installation, then

lightly tap the seal into position using a block

of wood. Ensure that the seal is correctly

orientated.

13 Pack the outer bearing cone with the

specified grease, and fit it into position in its

cup.

14 The brake drum/hub can now be refitted

to the axle spindle. Before fitting into position,

first check that the brake surface area in

the drum is free of grease and oil. Locate the

drum/hub into position, then fit the retaining

nut. Tighten it to the specified torque setting

whilst simultaneously rotating the assembly to

ensure that the bearings are correctly seated.

15 Carefully tap the new hub grease cap into

position in a progressive manner around its

outer edge until it is fully fitted.

16 Refit the rubber blanking plug to the brake

backplate, and firmly apply the footbrake a

few times to take up the brake adjustment.

Check that the rear brakes do not bind when

the brakes are released. Refit the roadwheel,

lower the vehicle and then tighten the

retaining nuts to the specified torque setting.10 Rear strut (all models except Courier) - removal and

refitting

3

Removal

1 Chock the front wheels then jack up the

rear of the car and support it on axle stands

(see “Jacking and Vehicle Support” ).

2 On ABS-equipped models, unscrew the

retaining nuts and detach the load-

apportioning valve connecting links from the

axle beam.

3 Support the relevant trailing arm of the axle

assembly and unscrew and remove the

securing bolt from the strut-to-axle mounting

(see illustration) .

4 Prise free the protective cap from the top of

the strut mounting, located in the luggage

compartment (see illustration) .

5 Unscrew and remove the two retaining nuts

to detach the strut from its upper mounting.

Do not unscrew the central upper mounting

bolt.

6 Lower the trailing arm slightly to allow the

lower suspension strut mounting to clear its

axle location, and withdraw the suspension

strut from the vehicle.

Refitting

7 Refitting is a reversal of the removal

procedure, but note the following special

points: a)

With the suspension strut located to its

upper mounting, tighten the retaining nuts

to the specified torque.

b) When reconnecting the suspension strut

to the lower mounting, hand-tighten the

retaining bolt, then lower the vehicle so

that it is standing on its wheels before

fully tightening the bolt to its specified

torque.

11 Rear strut (all models except

Courier) - dismantling,

examination and reassembly

4

Warning: Before attempting to

dismantle the suspension strut,

a suitable tool to hold the coil

spring in compression must be

obtained. Adjustable coil spring

compressors which can be positively

secured to the spring coils are readily

available, and are recommended for this

operation. Any attempt to dismantle the

strut without such a tool is likely to result

in damage or personal injury.

Dismantling

1 With the strut removed from the vehicle,

clean away all external dirt, then secure it in a

vice.

2 Fit the spring compressor tool (ensuring

that it is fully engaged) and compress the coil

spring until all tension is relieved from the

upper mounting.

Suspension and steering 10•9

9.8 Removing bearing cups9.7 Removing a bearing cone from the hub bore9.6 Prise the grease retainer from the hubbore

10.4 Suspension strut top-mount nuts (A),

and spring retaining through-bolt fixing (B)10.3 Lower suspension strut-to-axle mounting bolt

10

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 243 of 296

8Refitting is a reversal of the removal

procedure.

Front direction indicator side

repeater

9 Remove the appropriate front wheel arch

liner as described in Chapter 11.

10 Remove the appropriate sill scuff plate as

described in Chapter 11, and release the clip

securing the insulation to the panel forward of

the lower A-pillar.

11 Disconnect the supply lead connector and

the earth lead, then release their grommet

from its panel location.

12 From outside the vehicle, twist the light

assembly to release it, then withdraw it and its

leads.

13 Refitting is a reversal of the removal

procedure, ensuring that the grommet is

seated correctly in its panel location.

Rear light cluster

14 Disconnect the multi-plug from the

bulbholder, then press the retaining lugs on

the bulbholder together and remove it (see

illustration) . 15

Unscrew the four nuts securing the light

unit, then remove the unit and its seal.

16 Refitting is a reversal of the removal

procedure. Tighten the light unit securing nuts

to their specified torque.

Number plate light

17 Insert a thin flat-bladed screwdriver

between the light assembly and the bumper,

and carefully prise the light out. Use a rag, or

a piece of card, between the screwdriver and

the bumper, to prevent damage to the

bumper.

18 Detach the connections on the underside

of the light assembly.

19 Refitting is a reversal of the removal

procedure.

Auxiliary lights

S models

20 Disconnect the battery negative (earth)

lead (refer to Chapter 5A, Section 1).

21 Disconnect the light wiring multi-plug then

unscrew its retaining nut, withdraw the bolt

and remove the light unit (see illustration).22

Refitting is a reversal of the removal

procedure, tightening the retaining nut to the

specified torque. On completion, check the

auxiliary light beam alignment as described in

Section 8.

XR2i models

23 Disconnect the battery negative (earth)

lead (refer to Chapter 5A, Section 1).

24 Undo the four Torx retaining screws

securing the relevant dual light assembly to its

bumper location. Note that the retaining and

adjusting screws are captive within the light

assembly - they cannot be removed from

the assembly (see illustration) .

25 Withdraw the light assembly from its

location, then remove the caps protecting the

bulbs and disconnect the wiring.

26 If required, the lights may be removed

individually from their housing at this stage.

Each light is secured to its housing unit by a

combination of two types of clips - foglight

retention differs from driving light retention.

27 The adjusting/retaining clips are removed

by undoing the adjustment screws on the

front of the housing unit, then turning the clips

using pliers or similar tool, before

withdrawing. To remove a retaining-only clip,

lift the lug on the side of the clip using a

screwdriver, then turn the clip using pliers or

similar tool, before withdrawing.

28 Refitting is a reversal of the removal

procedure. On completion, check the auxiliary

light beam alignment as described in Section 8.

8 Headlight and auxiliary light

beam alignment - checking

and adjustment

2

1 Accurate adjustment of the headlight and

auxiliary light beams is only possible using

optical beam-setting equipment, and this

12•10 Body electrical systems

7.24 Auxiliary light assembly (XR2i models) - left-hand unit shown

A Light assembly retaining screws

B Fog light vertical adjustment screw

C Driving light vertical adjustment screw D Driving light horizontal

adjustment screw

E Bulb protective caps

F Fog light bulb connector

G Bulb earth leads

H Driving light bulb connector

7.21 Auxiliary light fixture (S models)

A Bracket retaining nuts C Auxiliary light multi-plug

B Auxiliary light retaining nut

7.14 Press the retaining lugs on the rear

light cluster bulbholder together (broken arrows) to release the bulbholder7.7b . . . then pull the light unit out to

enable the multi-plug (arrowed) to be disconnected

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 244 of 296

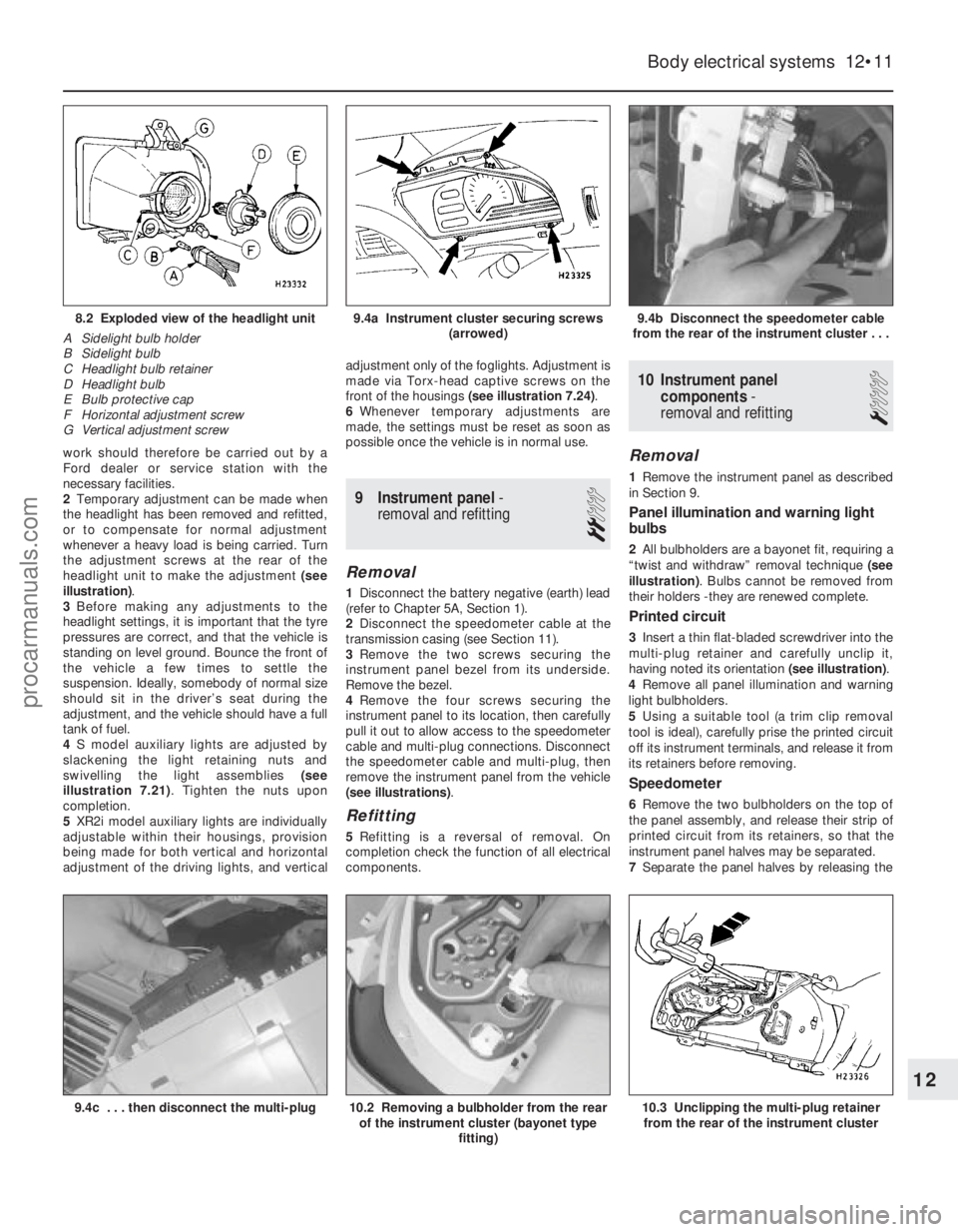

work should therefore be carried out by a

Ford dealer or service station with the

necessary facilities.

2Temporary adjustment can be made when

the headlight has been removed and refitted,

or to compensate for normal adjustment

whenever a heavy load is being carried. Turn

the adjustment screws at the rear of the

headlight unit to make the adjustment (see

illustration) .

3 Before making any adjustments to the

headlight settings, it is important that the tyre

pressures are correct, and that the vehicle is

standing on level ground. Bounce the front of

the vehicle a few times to settle the

suspension. Ideally, somebody of normal size

should sit in the driver’s seat during the

adjustment, and the vehicle should have a full

tank of fuel.

4 S model auxiliary lights are adjusted by

slackening the light retaining nuts and

swivelling the light assemblies (see

illustration 7.21) . Tighten the nuts upon

completion.

5 XR2i model auxiliary lights are individually

adjustable within their housings, provision

being made for both vertical and horizontal

adjustment of the driving lights, and vertical adjustment only of the foglights. Adjustment is

made via Torx-head captive screws on the

front of the housings

(see illustration 7.24) .

6 Whenever temporary adjustments are

made, the settings must be reset as soon as

possible once the vehicle is in normal use.

9 Instrument panel -

removal and refitting

2

Removal

1 Disconnect the battery negative (earth) lead

(refer to Chapter 5A, Section 1).

2 Disconnect the speedometer cable at the

transmission casing (see Section 11).

3 Remove the two screws securing the

instrument panel bezel from its underside.

Remove the bezel.

4 Remove the four screws securing the

instrument panel to its location, then carefully

pull it out to allow access to the speedometer

cable and multi-plug connections. Disconnect

the speedometer cable and multi-plug, then

remove the instrument panel from the vehicle

(see illustrations) .

Refitting

5Refitting is a reversal of removal. On

completion check the function of all electrical

components.

10 Instrument panel

components -

removal and refitting

1

Removal

1 Remove the instrument panel as described

in Section 9.

Panel illumination and warning light

bulbs

2 All bulbholders are a bayonet fit, requiring a

“twist and withdraw” removal technique (see

illustration) . Bulbs cannot be removed from

their holders -they are renewed complete.

Printed circuit

3 Insert a thin flat-bladed screwdriver into the

multi-plug retainer and carefully unclip it,

having noted its orientation (see illustration).

4 Remove all panel illumination and warning

light bulbholders.

5 Using a suitable tool (a trim clip removal

tool is ideal), carefully prise the printed circuit

off its instrument terminals, and release it from

its retainers before removing.

Speedometer

6 Remove the two bulbholders on the top of

the panel assembly, and release their strip of

printed circuit from its retainers, so that the

instrument panel halves may be separated.

7 Separate the panel halves by releasing the

Body electrical systems 12•11

9.4b Disconnect the speedometer cable

from the rear of the instrument cluster . . .9.4a Instrument cluster securing screws (arrowed)8.2 Exploded view of the headlight unit

A Sidelight bulb holder

B Sidelight bulb

C Headlight bulb retainer

D Headlight bulb

E Bulb protective cap

F Horizontal adjustment screw

G Vertical adjustment screw

10.3 Unclipping the multi-plug retainer from the rear of the instrument cluster10.2 Removing a bulbholder from the rear of the instrument cluster (bayonet type

fitting)9.4c . . . then disconnect the multi-plug

12

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 276 of 296

1595 Ford Fiesta Remake

REF•10MOT test checks

This is a guide to getting your vehicle through the MOT test.

Obviously it will not be possible to examine the vehicle to the same

standar d as the professional MOT tester. However, working through

the following checks will enable you to identify any problem areas

befor e submitting the vehicle for the test.

Wher e a testable component is in borderline condition, the tester

has discretion in deciding whether to pass or fail it. The basis of such

discr etion is whether the tester would be happy for a close relative or

friend to use the vehicle with the component in that condition. If the

vehicle presented is clean and evidently well cared for, the tester may

be more inclined to pass a borderline component than if the vehicle is

scruffy and apparently neglected.

It has only been possible to summarise the test requirements her e,

based on the regulations in force at the time of printing. Test standards ar e becoming increasingly stringent, although there are some

exemptions for older vehicles. For full details obtain a copy of the Hay\

nes

publication Pass the MOT! (available from stockists of Haynes manuals).

An assistant will be needed to help carry out some of these checks.

The checks have been sub-divided into four categories, as follows:

HandbrakeM Test the operation of the handbrake.

Excessive travel (too many clicks) indicates

incorr ect brake or cable adjustment.

M Check that the handbrake cannot be

r eleased by tapping the lever sideways. Check

the security of the lever mountings.

Footbrake

M Depr ess the brake pedal and check that it

does not creep down to the floor, indicating a master cylinder fault. Release the pedal, wait

a few seconds, then depress it again. If the

pedal travels nearly to the floor before firm

r esistance is felt, brake adjustment or repair is

necessary . If the pedal feels spongy, there is

air in the hydraulic system which must be

r emoved by bleeding. M

Check that the brake pedal is secure and in

good condition. Check also for signs of fluid

leaks on the pedal, floor or carpets, which

would indicate failed seals in the brake master

cylinder.

M Check the servo unit (when applicable) by

operating the brake pedal several times, then

keeping the pedal depressed and starting the

engine. As the engine starts, the pedal will

move down slightly. If not, the vacuum hose or

the servo itself may be faulty.

Steering wheel and column

M Examine the steering wheel for fractures or

looseness of the hub, spokes or rim.

M Move the steering wheel from side to side

and then up and down. Check that the

steering wheel is not loose on the column,

indicating wear or a loose retaining nut.

Continue moving the steering wheel as before,

but also turn it slightly from left to right.

M Check that the steering wheel is not loose

on the column, and that there is no abnormal movement of the steering wheel, indicating

wear in the column support bearings or

couplings.

W

indscreen and mirrors

M The windscreen must be free of cracks or

other significant damage within the driver’s

field of view. (Small stone chips are

acceptable.) Rear view mirrors must be

secur e, intact, and capable of being adjusted.

1Checks carried out

FROM THE DRIVER’S SEAT

1Checks carried out

FROM THE DRIVER’S

SEAT2Checks carried out

WITH THE VEHICLE

ON THE GROUND3Checks carried out

WITH THE VEHICLE

RAISED AND THE

WHEELS FREE TO

TURN4Checks carried out on

YOUR VEHICLE’S

EXHAUST EMISSION

SYSTEM

procarmanuals.com

http://vnx.su