differential FORD FIESTA 1989 Service Repair Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1989, Model line: FIESTA, Model: FORD FIESTA 1989Pages: 296, PDF Size: 10.65 MB

Page 79 of 296

25Unscrew the retaining bolt, and detach

the shift rod stabiliser from the transmission.

As it is detached, note the washer located

between the stabiliser and the transmission.

Tie the stabiliser and the shift rod up out of

the way.

Automatic transmission models

26 Unclip and detach the wiring connector

from the starter inhibitor switch (on the

transmission housing).

27 Referring to the relevant Part of Chapter 4

for details, unhook the accelerator (cam plate)

cable from the carburettor or fuel injection unit

(as applicable) at the transmission end of

the cable. Undo the retaining bolt and

detach the cable sheath bracket from the

transmission. Detach the cam plate cable

from the link.

28 Undo the two nuts from the selector cable

bracket which connects it to the lever on the

selector shaft. Disconnect the yoke from the

lever on the selector shaft and the cable from

the lever.

29 Unscrew the union nuts, and disconnect

the oil cooler feed and return pipes from the

transmission. Allow for a certain amount of

spillage, and plug the connections to prevent

the ingress of dirt.

All models

30 Unscrew the retaining nut and withdraw

the Torx-type clamp bolt securing the lower

suspension arm to the spindle carrier on each

side.

31 Refer to Chapter 10 for details, and

detach the right-hand and left-hand track rod

end balljoints from the spindle carriers.

32 On vehicles fitted with the anti-lock

braking system, refer to Chapter 9 and release

the right-hand modulator from its mounting

bracket without disconnecting the rigid brake

pipes or return hose. Tie the modulator

securely to the bulkhead. Additionally, undo

the three bolts securing the modulator

bracket.

33 Insert a suitable lever between the right-

hand driveshaft inner joint and the

transmission housing, and prise free the

driveshaft from the transmission; be prepared

for oil spillage from the transmission case

through the vacated driveshaft aperture. As it

is being prised free, simultaneously pull the

roadwheel outwards on that side, to enable

the driveshaft inboard end to separate

from the transmission. Once it is free,

suspend and support the driveshaft from the

steering gear, to prevent unnecessary strain

being placed on the driveshaft joints.

34 Insert a suitable plastic plug (or if

available, an old driveshaft joint), into the

transmission driveshaft aperture, to

immobilise the gears of the differential unit.

35 Proceed as described above in

paragraphs 33 and 34, and disconnect the

left-hand driveshaft from the transmission.

36 Connect a suitable lift hoist and sling to

the engine, connecting to the lifting eyes. When securely connected, take the weight of

the engine/transmission unit so that the

tension is relieved from the mountings.

37

Undo the retaining bolts and nuts and

detach the right-hand engine mounting from

the vehicle body.

38 Undo the four bolts securing the

transmission bearer to the underside of the

vehicle body. The transmission bearer is

removed with the engine/transmission

assembly.

39 Unscrew the three retaining bolts, and

remove the auxiliary drivebelt cover from

under the crankshaft pulley.

40 The engine/transmission unit should now

be ready for removal from the vehicle. Check

that all of the associated connections and

fittings are disconnected from the engine and

transmission, and positioned out of the way.

41 Enlist the aid of an assistant to help

steady and guide the power unit down

through the engine compartment as it is

removed. If available, position a suitable

engine trolley or crawler board under the

engine/transmission so that when lowered,

the power unit can be withdrawn from the

front end of the vehicle, and then moved to

the area where it is to be cleaned and

dismantled. On automatic transmission

models, particular care must be taken not to

damage the transmission fluid pan (sump)

during the removal and subsequent refitting

processes.

42 Carefully lower the engine and

transmission unit, ensuring that no fittings

become snagged. Detach the hoist and

remove the power unit from under the vehicle.

43 Referring to the relevant Part of Chapter 7,

separate the transmission from the engine.

44 While the engine/transmission is removed,

check the mountings; renew them if they are

worn or damaged. Similarly, check the

condition of all coolant and vacuum hoses

and pipes (see Chapter 1). Components that

are normally hidden can now be checked

properly, and should be renewed if there is

any doubt at all about their condition. Where

the vehicle is fitted with manual transmission,

take the opportunity to inspect the clutch

components (see Chapter 6). It is regarded by

many as good working practice to renew the

clutch assembly as a matter of course,

whenever major engine overhaul work is

carried out. Check also the condition of all

components (such as the transmission oil

seals) disturbed on removal, and renew any

that are damaged or worn.

Refitting

45 Refitting is a reversal of removal, however

note the following additional points:

a) Refer to the applicable Chapters and Sections as for removal.

b) Fit new spring clips to the grooves in the

inboard end of the right- and left-hand

driveshaft joints. Lubricate the splines

with transmission oil prior to fitting. c) Renew the exhaust flange gasket when

reconnecting the exhaust. Ensure that all

wires are routed clear of the exhaust

system and, on catalytic converter

models, ensure that the heat shields are

securely and correctly fitted.

d) Ensure that all earth lead connections are

clean and securely made.

e) Tighten all nuts and bolts to the specified torque.

f) Fit a new oil filter, and refill the engine and transmission with oil, with reference to

Chapter 1.

g) Refill the cooling system with reference to Chapter 1.

h) Refit the alternator and starter motor with reference to Chapter 5A.

i) Where applicable, refit the power steering pump with reference to Chapter 10.

46 When engine and transmission refitting is

complete, refer to the procedures described

in Section 19 before restarting the engine.

5 Engine/transmission -

removal and refitting

(Zetec engines)

3

Warning: Petrol is extremely

flammable, so take extra

precautions when disconnecting

any part of the fuel system.

Don’t smoke, or allow naked flames or

bare light bulbs, in or near the work area,

and don’t work in a garage where a

natural-gas appliance (such as a clothes

dryer or water heater) is installed. If you

spill petrol on your skin, rinse it off

immediately. Have a fire extinguisher rated

for petrol fires handy, and know how to

use it.

Note: Read through the entire Section, as well

as reading the advice in Section 2, before

beginning this procedure. The engine and

transmission are removed as a unit, lowered to

the ground and removed from underneath,

then separated outside the vehicle.

Removal

1 Park the vehicle on firm, level ground, apply

the handbrake firmly, and slacken the nuts

securing both front roadwheels.

2 Depressurise the fuel system as described

in Chapter 4D.

3 Disconnect the battery negative (earth) lead

(refer to Chapter 5A, Section 1).

4 Place protective covers on the wings, then

remove the bonnet (see Chapter 11).

5 Drain the cooling system and the engine oil

(see Chapter 1).

6 Remove the air inlet components and the

complete air cleaner assembly as described in

Chapter 4D.

7 Equalise the pressure in the fuel tank by

removing the filler cap, then release the fuel

feed and return quick-release couplings, and

pull the hoses off the fuel pipes. Plug or cap

all open fittings.

2D•10 Engine removal and overhaul procedures

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 81 of 296

25On automatic transmission models, clean

around the unions, then disconnect the fluid

pipes from the transmission. Plug the

openings in the transmission and the pipe

unions after removal.

26 Refer to Chapter 10 and remove the front

suspension crossmember.

27 Unscrew the nuts to disconnect the

exhaust system front downpipe from the

manifold. Undo the nuts securing the catalytic

converter to the rear part of the exhaust

system, and remove the converter and

downpipe assembly.

28 On vehicles fitted with the anti-lock braking

system, refer to Chapter 9 and release the

right-hand modulator from its mounting

bracket without disconnecting the rigid brake

pipes or return hose. Tie the modulator

securely to the bulkhead. Additionally, undo

the three bolts securing the modulator bracket.

29 Disconnect both anti-roll bar links from

their respective suspension struts, and both

track rod end ball joints from their spindle

carriers (see Chapter 10).

30 Unscrew the retaining nut and withdraw

the Torx-type clamp bolt securing the lower

suspension arm to the spindle carrier on each

side.

31 Insert a suitable lever between the right-

hand driveshaft inner joint and the

transmission housing, and prise free the

driveshaft from the transmission; be prepared

for oil spillage from the transmission case

through the vacated driveshaft aperture. As it

is being prised free, simultaneously pull the

roadwheel outwards on that side to enable the

driveshaft inboard end to separate from the

transmission. Once it is free, suspend and

support the driveshaft from the steering gear,

to prevent unnecessary strain being placed on

the driveshaft joints.

32 Insert a suitable plastic plug (or if

available, an old driveshaft joint), into the

transmission driveshaft aperture, to

immobilise the gears of the differential unit.

33 Proceed as described above in

paragraphs 31 and 32, and disconnect the

left-hand driveshaft from the transmission.

34 Remove the oil filter, referring to Chapter 1

if necessary.

35 Connect a suitable lift hoist and sling to

the engine, connecting to the lift eyes. When

securely connected, take the weight of the

engine/transmission unit so that the tension is

relieved from the mountings.

36 Unbolt the engine rear right-hand

mounting from the body (one bolt in the wheel

arch, one nut in the engine compartment),

then unbolt the engine front right-hand

mounting from the alternator mounting

bracket. Unbolt the transmission bearer from

the underbody.

37 The engine/transmission unit should now

be hanging on the hoist only, with all

components which connect it to the rest of

the vehicle disconnected or removed, and

secured well clear of the unit. Make a final

check that this is the case. 38

Lower the engine/transmission to the

ground, and withdraw it from under the

vehicle.

39 Referring to the relevant Part of Chapter 7,

separate the transmission from the engine.

40 While the engine/transmission is removed,

check the mountings; renew them if they are

worn or damaged. Similarly, check the

condition of all coolant and vacuum hoses

and pipes (see Chapter 1); components that

are normally hidden can now be checked

properly, and should be renewed if there is

any doubt at all about their condition. Where

the vehicle is fitted with manual transmission,

take the opportunity to overhaul the clutch

components (see Chapter 6). It is regarded by

many as good working practice to renew the

clutch assembly as a matter of course,

whenever major engine overhaul work is

carried out. Check also the condition of all

components (such as the transmission oil

seals) disturbed on removal, and renew any

that are damaged or worn.

Refitting

41 Refitting is a reversal of removal, however

note the following additional points:

a) Refer to the applicable Chapters and Sections as for removal.

b) Fit new spring clips to the grooves in the

inboard end of the right- and left-hand

driveshaft joints. Lubricate the splines

with transmission oil prior to fitting.

c) Renew the exhaust flange gaskets when reconnecting the exhaust. Ensure that all

wires are routed clear of the exhaust

system, and that the heat shields are

securely and correctly fitted.

d) Ensure that all earth lead connections are

clean and securely made.

e) Tighten all nuts and bolts to the specified

torque.

f) Fit a new oil filter, and refill the engine and transmission with oil, with reference to

Chapter 1.

g) Refill the cooling system with reference to

Chapter 1.

h) Bleed the power steering system with reference to Chapter 10.

42 When engine and transmission refitting is

complete, refer to the procedures described

in Section 19 before restarting the engine.

6 Engine overhaul - preliminary information

It is much easier to dismantle and work on

the engine if it is mounted on a portable

engine stand. These stands can often be hired

from a tool hire shop. Before the engine is

mounted on a stand, the flywheel/driveplate

should be removed so that the stand bolts

can be tightened into the end of the cylinder

block/crankcase. If a stand is not available, it is possible to

dismantle the engine with it suitably supported on a sturdy, workbench or on the

floor. Be careful not to tip or drop the engine

when working without a stand.

If you intend to obtain a reconditioned

engine, all ancillaries must be removed first, to

be transferred to the replacement engine (just

as they will if you are doing a complete engine

overhaul yourself). These components include

the following:

a) Alternator/power steering pump and

mounting brackets.

b) DIS/E-DIS ignition coil unit (and mounting

bracket), distributor, HT leads and spark

plugs.

c) The thermostat and housing cover.

d) Carburettor/fuel injection system

components.

e) Inlet and exhaust manifolds.

f) Oil filter.

g) Fuel pump.

h) Engine mountings.

i) Flywheel/driveplate.

j) Water pump.

Note: When removing the external

components from the engine, pay close

attention to details that may be helpful or

important during refitting. Note the fitted

positions of gaskets, seals, washers, bolts and

other small items. If you are obtaining a “short” engine

(cylinder block/crankcase, crankshaft, pistons

and connecting rods all assembled), then the

cylinder head, timing chain/belt (together with

tensioner, tensioner and idler pulleys and

covers) sump and oil pump will have to be

removed also. If a complete overhaul is planned, the

engine can be dismantled in the order given

below, referring to Part A, B or C of this

Chapter unless otherwise stated.

a) Inlet and exhaust manifolds.

b) Timing chain/belt, tensioner and

sprockets.

c) Cylinder head.

d) Flywheel/driveplate.

e) Sump.

f) Oil pump.

g) Pistons (with connecting rods).

h) Crankshaft.

i) Camshaft and tappets (HCS engines).

7 Cylinder head - dismantling

4

Note:New and reconditioned cylinder heads

are available from the manufacturers, and from

engine overhaul specialists. Due to the fact

that some specialist tools are required for the

dismantling and inspection procedures, and

new components may not be readily available,

it may be more practical and economical for

the home mechanic to purchase a

reconditioned head, rather than to dismantle,

inspect and recondition the original head.

1 Remove the cylinder head as described in

Part A, B or C of this Chapter (as applicable).

2D•12 Engine removal and overhaul procedures

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 191 of 296

39With the drivebelt tensioned correctly,

tighten the pivot and adjuster bolts to the

specified torque. Re-check the tension of the

drivebelt after tightening the bolts.

40 Reconnect the rigid brake pipes to the

modulator, tightening the unions to seal the

system.

41 Refit the modulator drivebelt cover and

secure with its two retaining bolts. Take care

not to damage the driveshaft CV joint gaiter as

the cover is eased into position.

42 Refit the belt-break switch to the

modulator drivebelt cover, taking care not to

damage the belt contact arm as it passes

through the cover.

43 Reconnect the modulator return hose by

pushing the hose firmly into its brake fluid

reservoir location, then lever out the collar to

retain it.

44 Refit the front suspension crossmember

and the one-piece undertray, as applicable.

45 Refit the roadwheels, then remove the

axle stands and lower the vehicle to the

ground. Tighten the wheel nuts to the

specified torque.

46 Top-up the brake fluid reservoir using

fresh fluid of the specified type (see “ Weekly

checks ”), then bleed the brake hydraulic

system in accordance with Section 14. Refit

the reservoir filler cap and the warning

indicator wiring multi-plug on completion.

47 Reconnect the battery negative lead.

Modulator drivebelt

48Disconnect the battery negative (earth)

lead (refer to Chapter 5A, Section 1).

49 Chock the rear wheels then jack up the

front of the car and support it on axle stands

(see “Jacking and Vehicle Support” ). Remove

the relevant front roadwheel.

50 Remove the one-piece undertray where

fitted, by turning its bayonet-type fasteners,

and on XR2i models, remove the front

suspension crossmember (see Chapter 10).

51 Remove the belt-break switch from the

relevant drivebelt cover, then remove the

drivebelt cover, as described in the previous

sub-Section.

52 Slacken the modulator pivot and adjuster

bolts to release drivebelt tension, then slip the

drivebelt from the modulator.

53 Remove the track rod end balljoint from

the steering arm on the spindle carrier (see

Chapter 10).

54 Disconnect the anti-roll bar connecting

link (where applicable) and release the brake

hose from their locations on the suspension

strut.

55 Remove the pinch bolt and nut securing

the lower suspension arm balljoint to the

spindle carrier, and separate the balljoint from

the spindle carrier assembly.

56 To release the driveshaft inner CV joint

from the differential, have an assistant pull the

spindle carrier away from the centre of the

vehicle whilst you insert a lever between the

inner CV joint and the transmission casing,

then firmly strike the lever with the flat of the hand, but be careful not to damage adjacent

components. Make provision for escaping

transmission oil, if possible plugging the

opening to prevent excessive loss. Do not

allow the CV joints to bend more than 20°

from the horizontal or internal damage may

occur. If both driveshafts are to be removed,

immobilise the differential by inserting an old

joint or suitable shaft, before the other

driveshaft is removed.

57

Slide the drivebelt off the driveshaft.

58 Remove the snap-ring from the groove in

the splines of the inner CV joint. This snap-

ring must be renewed every time the

driveshaft is withdrawn from the differential.

59 With the drivebelt removed, closely

examine the condition of the belt over its

entire length. Renew the belt if any cracks are

noticed in the fabric at the roots of the teeth, if

there is any abrasion of the fabric facing

material, or if there are any tears starting from

the edge of the belt.

60 If, since the drivebelts were last renewed,

a vehicle has covered more than 30 000 miles

(48 000 km) or a period of more than two

years has elapsed, the drivebelts should be

renewed as a matter of course.

61 Prior to refitting the drivebelt, thoroughly

clean its CV joint pulley location.

62 Fit the drivebelt over the driveshaft then,

with a new snap-ring fitted to the inner CV

joint splines, lubricate the splines with

transmission oil. Remove the temporary plug

and insert the inner CV joint to its

transmission casing location. Press against

the spindle carrier so that the snap-ring

engages fully to hold the CV joint splines in

the differential.

63 Refitting is now a reversal of the removal

procedure, tensioning the drivebelt as

described in the previous sub-Section. Ensure

that the pinch-bolt securing the lower

suspension arm balljoint to the spindle carrier

locates in the annular groove on the balljoint

spindle. Secure the track rod and balljoint,

using a new split pin. Tighten the suspension

components to their specified torque (see

Chapter 10).

64 Check the level of the transmission oil,

and top-up as required (see Chapter 1).

Modulator belt-break switch

65 Modulator belt-break switches are fitted

to each of the two drivebelt covers, and clip

into position. To remove, gently squeeze the

protruding lever on the switch towards the

main switch body and lift out, ensuring that

the belt contact arm does not catch on the

drivebelt cover.

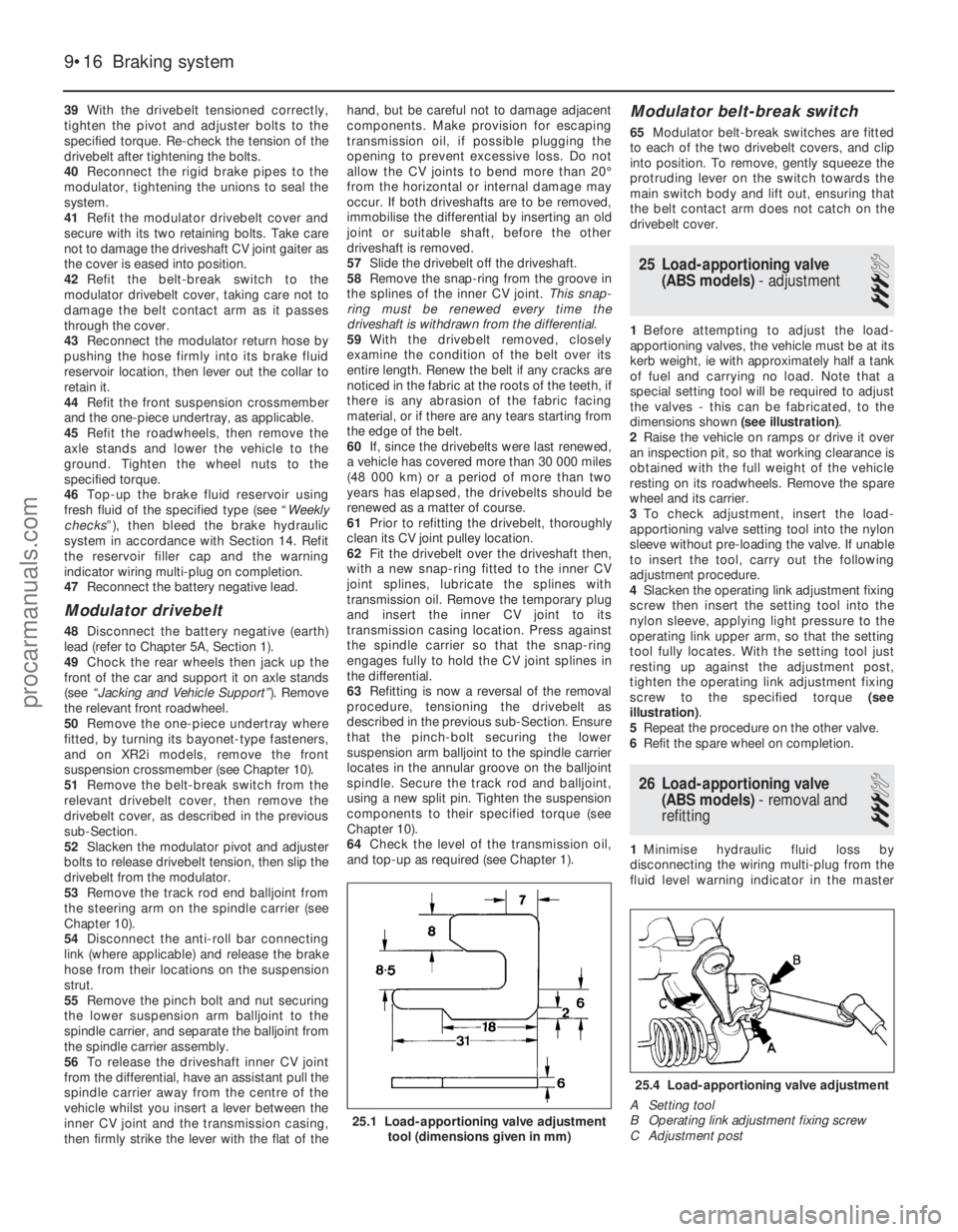

25 Load-apportioning valve (ABS models) - adjustment

3

1Before attempting to adjust the load-

apportioning valves, the vehicle must be at its

kerb weight, ie with approximately half a tank

of fuel and carrying no load. Note that a

special setting tool will be required to adjust

the valves - this can be fabricated, to the

dimensions shown (see illustration).

2 Raise the vehicle on ramps or drive it over

an inspection pit, so that working clearance is

obtained with the full weight of the vehicle

resting on its roadwheels. Remove the spare

wheel and its carrier.

3 To check adjustment, insert the load-

apportioning valve setting tool into the nylon

sleeve without pre-loading the valve. If unable

to insert the tool, carry out the following

adjustment procedure.

4 Slacken the operating link adjustment fixing

screw then insert the setting tool into the

nylon sleeve, applying light pressure to the

operating link upper arm, so that the setting

tool fully locates. With the setting tool just

resting up against the adjustment post,

tighten the operating link adjustment fixing

screw to the specified torque (see

illustration) .

5 Repeat the procedure on the other valve.

6 Refit the spare wheel on completion.

26 Load-apportioning valve

(ABS models) - removal and

refitting

3

1 Minimise hydraulic fluid loss by

disconnecting the wiring multi-plug from the

fluid level warning indicator in the master

9•16 Braking system

25.4 Load-apportioning valve adjustment

A Setting tool

B Operating link adjustment fixing screw

C Adjustment post

25.1 Load-apportioning valve adjustment tool (dimensions given in mm)

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 283 of 296

1595 Ford Fiesta Remake

Fault findingREF•17

REF

Fuel and exhaust systems

Excessive fuel consumption

m

mUnsympathetic driving style, or adverse conditions.

m

m Air filter element dirty or clogged (Chapter 1).

m

m Engine management system fault (Chapters 1, 4A, 4B, 4C, 4D, 4E

or 5B).

m m Tyres under-inflated ( “Weekly Checks”).

Fuel leakage and/or fuel odour

m

mDamaged or corroded fuel tank, pipes or connections (Chapter 1).

m

m Charcoal canister and/or connecting pipes leaking (Chapters 1

and 4E).

Excessive noise or fumes from exhaust system

m mLeaking exhaust system or manifold joints (Chapters 1 or 4E).

m

m Leaking, corroded or damaged silencers or pipe (Chapters 1 or 4E).

m

m Broken mountings, causing body or suspension contact (Chap-

ters 1 or 4E).

Clutch

Pedal travels to floor - no pressure or very little

resistance

m mBroken clutch cable (Chapter 6).

m

m Faulty clutch automatic adjuster (Chapter 6).

m

m Broken clutch release bearing or fork (Chapter 6).

m

m Broken diaphragm spring in clutch pressure plate (Chapter 6).

Clutch fails to disengage (unable to select gears)

m

mFaulty clutch automatic adjuster (Chapter 6).

m

m Clutch disc sticking on transmission input shaft splines (Chapter 6).

m

m Clutch disc sticking to flywheel or pressure plate (Chapter 6).

m

m Faulty pressure plate assembly (Chapter 6).

m

m Clutch release mechanism worn or incorrectly assembled (Chapter 6).

Clutch slips (engine speed increases, with no

increase in vehicle speed)

m mFaulty clutch automatic adjuster (Chapter 6).

m

m Clutch disc linings excessively worn (Chapter 6).

m

m Clutch disc linings contaminated with oil or grease (Chapter 6).

m

m Faulty pressure plate or weak diaphragm spring (Chapter 6).

Judder as clutch is engaged

m

mClutch disc linings contaminated with oil or grease (Chapter 6).

m

m Clutch disc linings excessively worn (Chapter 6).

m

m Clutch cable sticking or frayed (Chapter 6).

m

m Faulty or distorted pressure plate or diaphragm spring (Chapter 6).

m

m Worn or loose engine/transmission mountings (Chapters 2A, 2B

or 2C).

m m Clutch disc hub or transmission input shaft splines worn (Chap-

ter 6).

Noise when depressing or releasing clutch pedal

m mWorn clutch release bearing (Chapter 6).

m

m Worn or dry clutch pedal bushes (Chapter 6).

m

m Faulty pressure plate assembly (Chapter 6).

m

m Pressure plate diaphragm spring broken (Chapter 6).

m

m Broken clutch disc cushioning springs (Chapter 6).

Manual transmission

Noisy in neutral with engine running

m

mInput shaft bearings worn (noise apparent with clutch pedal

released, but not when depressed) (Chapter 7A).*

m m Clutch release bearing worn (noise apparent with clutch pedal

depressed, possibly less when released) (Chapter 6).

Noisy in one particular gear

m mWorn, damaged or chipped gear teeth (Chapter 7A).*

Difficulty engaging gears

m

mClutch fault (Chapter 6).

m

m Worn or damaged gear linkage (Chapter 7A).

m

m Incorrectly-adjusted gear linkage (Chapter 7A).

m

m Worn synchroniser assemblies (Chapter 7A).*

Vibration

m

mLack of oil (Chapter 1).

m

m Worn bearings (Chapter 7A).*

Jumps out of gear

m

mWorn or damaged gear linkage (Chapter 7A).

m

m Incorrectly-adjusted gear linkage (Chapter 7A).

m

m Worn synchroniser assemblies (Chapter 7A).*

m

m Worn selector forks (Chapter 7A).*

Lubricant leaks

m

mLeaking differential side gear oil seal (Chapter 7A).

m

m Leaking housing joint (Chapter 7A).*

m

m Leaking input shaft oil seal (Chapter 7A).*

m

m Leaking selector shaft oil seal (Chapter 7A).

m

m Leaking speedometer drive pinion O-ring (Chapter 7A).

* Although the corrective action necessary to remedy the symptoms

described is beyond the scope of the home mechanic, the above

information should be helpful in isolating the cause of the condition,

so that the owner can communicate clearly with a professional

mechanic.

procarmanuals.com

http://vnx.su

Page 284 of 296

1595 Ford Fiesta Remake

REF•18Fault finding

Braking system

Note:Before assuming that a brake problem exists, make sure that the

tyres are in good condition and correctly inflated, that the front wheel\

alignment is correct, and that the vehicle is not loaded with weight in \

an

unequal manner. Apart from checking the condition of all pipe and

hose connections, any faults occurring on the Anti-lock Braking System

(ABS) should be referred to a Ford dealer for diagnosis.

Vehicle pulls to one side under braking

m m Worn, defective, damaged or contaminated front or rear brake

pads/shoes on one side (Chapter 1).

m m Seized or partially-seized front or rear brake caliper/wheel cylinder

piston (Chapter 9).

m m A mixture of brake pad/shoe lining materials fitted between sides

Chapter 1).

m m Brake caliper mounting bolts loose (Chapter 9).

m

m Rear brake backplate mounting bolts loose (Chapter 9).

m

m Worn or damaged steering or suspension components (Chap-

ter 10).

Noise (grinding or high-pitched squeal) when

brakes applied

m mBrake pad or shoe friction lining material worn down to metal

backing Chapter 1).

m m Excessive corrosion of brake disc or drum (may be apparent after

the vehicle has been standing for some time) (Chapter 1).

Excessive brake pedal travel

m mInoperative rear brake self-adjust mechanism (Chapter 9).

m

m Faulty master cylinder (Chapter 9).

m

m Air in hydraulic system (Chapter 9).

Rear wheels locking under normal braking

m

mRear brake shoe linings contaminated (Chapter 1).

m

m Faulty brake pressure regulator (Chapter 9).

Brake pedal feels spongy when depressed

m

mAir in hydraulic system (Chapter 9).

m

m Deteriorated flexible rubber brake hoses (Chapter 9).

m

m Master cylinder mounting nuts loose (Chapter 9).

m

m Faulty master cylinder (Chapter 9).

Excessive brake pedal effort required to stop

vehicle

m mFaulty vacuum servo unit (Chapter 9).

m

m Disconnected, damaged or insecure brake servo vacuum hose

(Chapter 9).

m m Primary or secondary hydraulic circuit failure (Chapter 9).

m

m Seized brake caliper or wheel cylinder piston(s) (Chapter 9).

m

m Brake pads or brake shoes incorrectly fitted (Chapter 9).

m

m Incorrect grade of brake pads or brake shoes fitted (Chapter 1).

m

m Brake pads or brake shoe linings contaminated (Chapter 1).

Judder felt through brake pedal or steering wheel

when braking

m mExcessive run-out or distortion of front discs or rear drums

Chapter 9).

m m Brake pad or brake shoe linings worn (Chapter 1).

m

m Brake caliper or rear brake backplate mounting bolts loose

(Chapter 9).

m m Wear in suspension or steering components or mountings

(Chapter 10).

Brakes binding

m mSeized brake caliper or wheel cylinder piston(s) (Chapter 9).

m

m Faulty handbrake mechanism (Chapter 9).

m

m Faulty master cylinder (Chapter 9).

Automatic transmission

Note: Due to the complexity of the automatic transmission, it is difficult

for the home mechanic to properly diagnose and service this unit. For

problems other than the following, the vehicle should be taken to a

dealer service department or automatic transmission specialist.

Fluid leakage

m m Automatic transmission fluid is usually deep red in colour. Fluid

leaks should not be confused with engine oil, which can easily be

blown onto the transmission by airflow.

m m To determine the source of a leak, first remove all built-up dirt and

grime from the transmission housing and surrounding areas, using

a degreasing agent, or by steam-cleaning. Drive the vehicle at low

speed, so airflow will not blow the leak far from its source. Raise

and support the vehicle, and determine where the leak is coming

from. The following are common areas of leakage:

a) Transmission fluid sump (Chapters 1 and 7B).

b) Dipstick tube (Chapters 1 and 7B).

c) Transmission-to-fluid cooler pipes/unions (Chapter 7B).

d) Speedometer drive pinion O-ring.

e) Differential output fluid seals (Chapter 7B).

Transmission fluid brown, or has burned smell

m m Transmission fluid level low, or fluid in need of renewal (Chapter 1).\

Engine will not start in any gear, or starts in gears

other than Park or Neutral

m mStarter inhibitor switch faulty (Chapter 7B).

m

m Incorrect selector cable adjustment (Chapter 7B).

General gear selection problems

m

mChapter 7B deals with checking and adjusting the selector cable

on automatic transmissions. The following are common problems

which may be caused by a poorly-adjusted cable:

a) Engine starting in gears other than Park or Neutral.

b) Indicator on gear selector lever pointing to a gear other than the

one actually being used.

c) Vehicle moves when in Park or Neutral.

d) Poor gear shift quality or erratic gear changes.

Refer to Chapter 7B for the selector cable adjustment procedure.

Transmission will not downshift (kickdown) with

accelerator pedal fully depressed

m m Low transmission fluid level (Chapter 1).

m

m Incorrect selector cable adjustment (Chapter 7B).

m

m Engine management system fault (Chapters 1, 4A, 4B, 4C, 4D, 4E

or 5B).

Transmission slips, is noisy, or has no drive in

forward or reverse gears

m mThere are many probable causes for the above problems, but the

home mechanic should be concerned with only one possibility -

fluid level. Before taking the vehicle to a dealer or transmission

specialist, check the fluid level and condition of the fluid as

described in Chapter 1. Correct the fluid level as necessary, or

change the fluid if needed. If the problem persists, professional

help will be necessary.

procarmanuals.com

http://vnx.su

Page 288 of 296

1595 Ford Fiesta Remake

REF•22Glossary of technical terms

A

ABS (Anti-lock brake system)A system,

usually electronically controlled, that senses

incipient wheel lockup during braking and

r elieves hydraulic pressure at wheels that are

about to skid.

Air bag An inflatable bag hidden in the

steering wheel (driver’s side) or the dash or

glovebox (passenger side). In a head-on

collision, the bags inflate, preventing the

driver and front passenger from being thrown

forwar d into the steering wheel or windscreen.

Air cleaner A metal or plastic housing,

containing a filter element, which removes

dust and dirt from the air being drawn into the

engine.

Air filter element The actual filter in an air

cleaner system, usually manufactured fr om

pleated paper and requiring renewal at regular

intervals.

Allen key A hexagonal wrench which fits into

a recessed hexagonal hole.

Alligator clip A long-nosed spring-loaded

metal clip with meshing teeth. Used to make

temporary electrical connections.

Alternator A component in the electrical

system which converts mechanical energy

fr om a drivebelt into electrical energy to

char ge the battery and to operate the starting

system, ignition system and electrical

accessories.

Amper e (amp) A unit of measurement for the

flow of electric current. One amp is the

amount of current produced by one volt

acting through a resistance of one ohm.

Anaer obic sealer A substance used to

pr event bolts and screws from loosening.

Anaer obic means that it does not require

oxygen for activation. The Loctite brand is

widely used.

Antifreeze A substance (usually ethylene

glycol) mixed with water, and added to a

vehicle’ s cooling system, to prevent freezing

of the coolant in winter. Antifreeze also

contains chemicals to inhibit corrosion and

the formation of rust and other deposits that would tend to clog the radiator and coolant

passages and reduce cooling efficiency.

Anti-seize compound A coating that

r educes the risk of seizing on fasteners that

ar e subjected to high temperatures, such as

exhaust manifold bolts and nuts.

Asbestos A natural fibrous mineral with great

heat resistance, commonly used in the

composition of brake friction materials.

Asbestos is a health hazard and the dust

cr eated by brake systems should never be

inhaled or ingested.

Axle A shaft on which a wheel revolves, or

which revolves with a wheel. Also, a solid

beam that connects the two wheels at one

end of the vehicle. An axle which also

transmits power to the wheels is known as a

live axle.

Axleshaft A single rotating shaft, on either

side of the differential, which delivers power

fr om the final drive assembly to the drive

wheels. Also called a driveshaft or a halfshaft.

BBall bearing An anti-friction bearing

consisting of a hardened inner and outer race

with hardened steel balls between two races. Bearing

The curved surface on a shaft or in a

bor e, or the part assembled into either, that

permits relative motion between them with

minimum wear and friction.

Big-end bearing The bearing in the end of

the connecting rod that’s attached to the crankshaft.

Bleed nipple A valve on a brake wheel

cylinder , caliper or other hydraulic component

that is opened to purge the hydraulic system

of air. Also called a bleed screw.

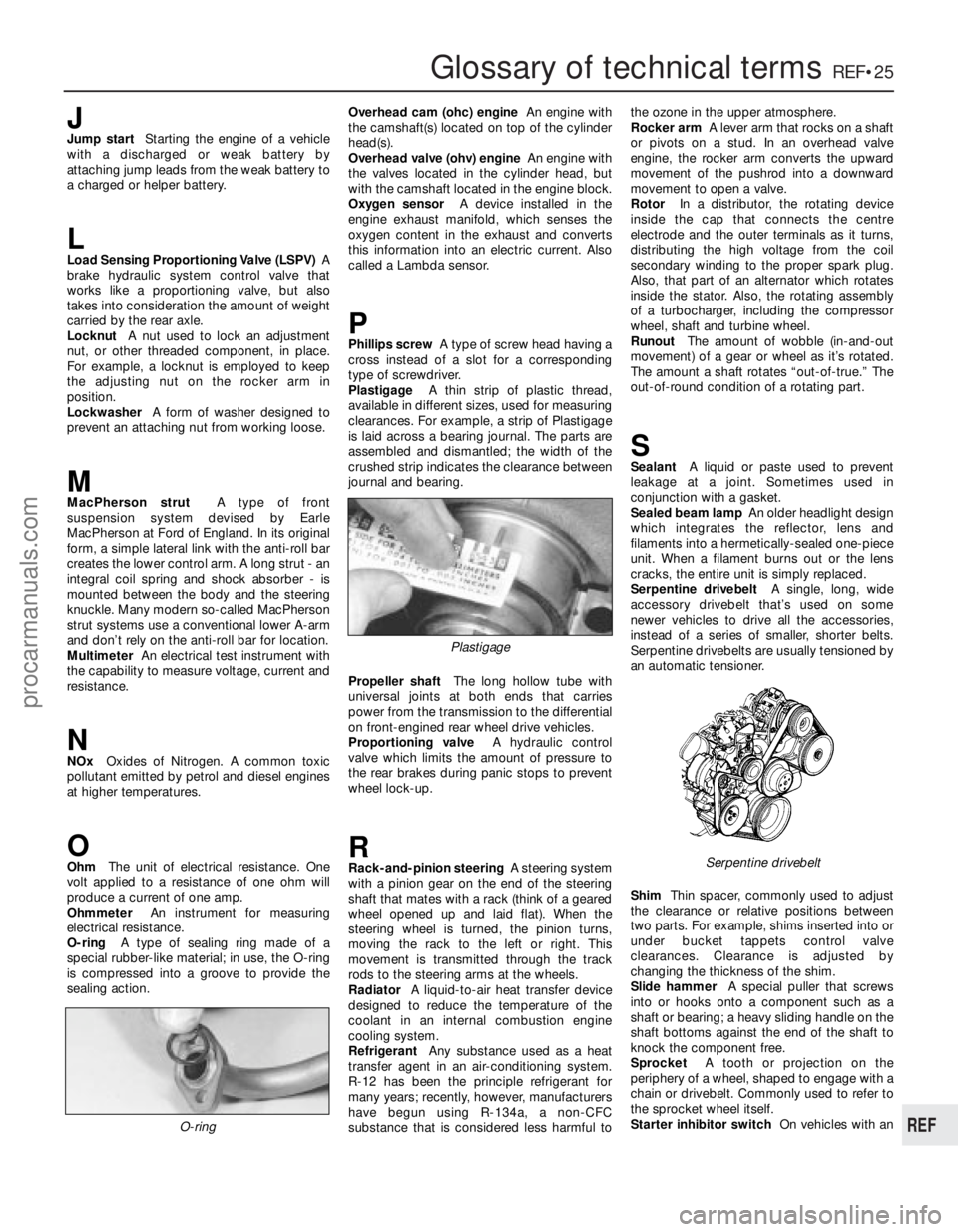

Brake bleeding Procedure for removing air

fr om lines of a hydraulic brake system.

Brake disc The component of a disc brake

that rotates with the wheels.

Brake drum The component of a drum brake

that rotates with the wheels.

Brake linings The friction material which

contacts the brake disc or drum to retard the

vehicle’ s speed. The linings are bonded or

riveted to the brake pads or shoes.

Brake pads The replaceable friction pads

that pinch the brake disc when the brakes are

applied. Brake pads consist of a friction

material bonded or riveted to a rigid backing

plate.

Brake shoe The crescent-shaped carrier to

which the brake linings are mounted and

which forces the lining against the rotating drum during braking.

Braking systems For more information on

braking systems, consult the Haynes

Automotive Brake Manual .

Br eaker bar A long socket wrench handle

pr oviding greater leverage.

Bulkhead The insulated partition between

the engine and the passenger compartment.

CCaliper The non-rotating part of a disc-brake

assembly that straddles the disc and carries

the brake pads. The caliper also contains the

hydraulic components that cause the pads to

pinch the disc when the brakes are applied. A

caliper is also a measuring tool that can be set

to measure inside or outside dimensions of an

object.

Brake bleeding

Bearing

Axle assembly

Anti-seize compound

Alter nator (exploded view)

Air filter

procarmanuals.com

http://vnx.su

Page 291 of 296

1595 Ford Fiesta Remake

Glossary of technical termsREF•25

REF

JJump startStarting the engine of a vehicle

with a discharged or weak battery by

attaching jump leads from the weak battery to

a charged or helper battery.

LLoad Sensing Proportioning Valve (LSPV) A

brake hydraulic system control valve that

works like a proportioning valve, but also

takes into consideration the amount of weight

carried by the rear axle.

Locknut A nut used to lock an adjustment

nut, or other threaded component, in place.

For example, a locknut is employed to keep

the adjusting nut on the rocker arm in

position.

Lockwasher A form of washer designed to

pr event an attaching nut from working loose.

MMacPherson strut A type of front

suspension system devised by Earle

MacPherson at Ford of England. In its original

form, a simple lateral link with the anti-roll bar

cr eates the lower control arm. A long strut - an

integral coil spring and shock absorber - is

mounted between the body and the steering

knuckle. Many modern so-called MacPherson

strut systems use a conventional lower A-arm

and don’t rely on the anti-roll bar for location. Multimeter An electrical test instrument with

the capability to measure voltage, current and

resistance.

NNOx Oxides of Nitrogen. A common toxic

pollutant emitted by petrol and diesel engines

at higher temperatures.

OOhm The unit of electrical resistance. One

volt applied to a resistance of one ohm will

pr oduce a current of one amp.

Ohmmeter An instrument for measuring

electrical resistance.

O-ring A type of sealing ring made of a

special rubber-like material; in use, the O-ring

is compressed into a groove to provide the

sealing action. Overhead cam (ohc) engine

An engine with

the camshaft(s) located on top of the cylinder

head(s).

Overhead valve (ohv) engine An engine with

the valves located in the cylinder head, but

with the camshaft located in the engine block.

Oxygen sensor A device installed in the

engine exhaust manifold, which senses the

oxygen content in the exhaust and converts

this information into an electric current. Also

called a Lambda sensor.

PPhillips screw A type of screw head having a

cr oss instead of a slot for a corresponding

type of screwdriver.

Plastigage A thin strip of plastic thread,

available in different sizes, used for measuring clearances. For example, a strip of Plastigage

is laid across a bearing journal. The parts areassembled and dismantled; the width of the

crushed strip indicates the clearance between

jour nal and bearing.

Pr opeller shaft The long hollow tube with

universal joints at both ends that carries

power from the transmission to the differential on front-engined rear wheel drive vehicles.

Pr oportioning valve A hydraulic control

valve which limits the amount of pressure to

the rear brakes during panic stops to prevent

wheel lock-up.

RRack-and-pinion steering A steering system

with a pinion gear on the end of the steering

shaft that mates with a rack (think of a geared

wheel opened up and laid flat). When the

steering wheel is turned, the pinion turns,

moving the rack to the left or right. This

movement is transmitted through the track

r ods to the steering arms at the wheels.

Radiator A liquid-to-air heat transfer device

designed to reduce the temperature of the

coolant in an internal combustion engine

cooling system.

Refrigerant Any substance used as a heat

transfer agent in an air-conditioning system.

R-12 has been the principle refrigerant for

many years; recently, however, manufacturers

have begun using R-134a, a non-CFC

substance that is considered less harmful to the ozone in the upper atmosphere.

Rocker arm

A lever arm that rocks on a shaft

or pivots on a stud. In an overhead valve

engine, the rocker arm converts the upward

movement of the pushrod into a downward

movement to open a valve.

Rotor In a distributor, the rotating device

inside the cap that connects the centre

electr ode and the outer terminals as it turns,

distributing the high voltage from the coil

secondary winding to the proper spark plug.

Also, that part of an alternator which rotates

inside the stator. Also, the rotating assembly

of a turbocharger, including the compressor

wheel, shaft and turbine wheel.

Runout The amount of wobble (in-and-out

movement) of a gear or wheel as it’ s rotated.

The amount a shaft rotates “out-of-true.” The

out-of-r ound condition of a rotating part.

SSealant A liquid or paste used to prevent

leakage at a joint. Sometimes used in

conjunction with a gasket.

Sealed beam lamp An older headlight design

which integrates the reflector, lens and

filaments into a hermetically-sealed one-piece

unit. When a filament burns out or the lens

cracks, the entire unit is simply replaced.

Serpentine drivebelt A single, long, wide

accessory drivebelt that’s used on some

newer vehicles to drive all the accessories,

instead of a series of smaller, shorter belts.

Serpentine drivebelts are usually tensioned by

an automatic tensioner.

Shim Thin spacer, commonly used to adjust

the clearance or relative positions between

two parts. For example, shims inserted into or

under bucket tappets control valve

clearances. Clearance is adjusted by

changing the thickness of the shim.

Slide hammer A special puller that screws

into or hooks onto a component such as a

shaft or bearing; a heavy sliding handle on the

shaft bottoms against the end of the shaft to

knock the component free.

Sprocket A tooth or projection on the

periphery of a wheel, shaped to engage with a

chain or drivebelt. Commonly used to refer to

the sprocket wheel itself.

Starter inhibitor switch On vehicles with an

O-ring

Serpentine drivebelt

Plastigage

procarmanuals.com

http://vnx.su

Page 293 of 296

1595 Ford Fiesta Remake

IndexREF•27

REF

Note: References throughout this index relate to Chapter•page number

A

Accelerator cable -4A•4, 4B•4, 4C•4, 4D•3

Accelerator pedal - 4A•4, 4B•4, 4C•4, 4D•3

Accelerator pump - 4A•8

Acknowledgements - 0•4

Aerial - 12•16

Air bags - 0•5, 12•17

Air cleaner - 1•22, 1•23, 4A•3, 4B•4, 4C•3,

4D•3, 4E•5

Air temperature control system - 1•23,

4B•8, 4C•7, 4D•6

Alarm system - 12•17, REF• 5

Alternator - 5A•4

Anti-lock braking system (ABS) - 9•11,

9•14, 9•16

Anti-roll bar - 10•7, 10•11

Anti-theft alarm system - 12•17, REF•5

Antifreeze - 0•12, 0•17, 1•21, 1•22, 3•2

Asbestos - 0•5

ATF - 0•17, 1•18, 1•24

Automatic choke - 4A•16, 4A•17

Automatic transmission -2A•10, 2B•13,

2C•15, 2D•6, 2D•8, 2D•10, 7B•1 et seq,

12 •6, 12 •8

Automatic transmission fault finding - REF• 18

Automatic transmission fluid - 0•17, 1•18,

1•24

Auxiliary lights - 12•7, 12•10

Axle - 10•10

B

Backfire - REF•16

Backrest - 11•17

Ballast resistor - 4B•9

Balljoint - 10•17

Battery - 0•5, 0•14, 5A•2, 5A•3

Battery fault - REF•20

Big-end bearings - 2D•21, 2D•24

Bleeding braking system - 9•10, 9•11

Bleeding power steering - 10•17

Body electrical systems -1•18, 12 •1et seq,

REF• 11

Body electrical system fault finding - 5A•2,

12 •3, REF •20

Bodywork and fittings -1•18, 11 •1et seq,

REF• 13

Bonnet - 1•18, 11•4,11•5

Boot - 1•16

Boots - 8•3, 8•4, 10 •15

Brake fluid - 0•13, 0•17, 1•26, 12 •6

Braking system -1•17, 9•1 et seq, 12•6,

REF• 10, REF•11, REF• 12

Braking system fault finding - REF•18 Bulbs -

0•16, 12 •7,12•8

Bumpers - 11•7, 11•8

Burning - 0•5

Buying spare parts - REF•5

C

Cables -4A•4, 4B•4, 4C•4, 4D•3, 6•1, 7B•2,

9•12, 9•13, 12 •12

Calipers - 9•3

Camshaft - 2B•6, 2B•7, 2C•7, 2C•8, 2D•16

Camshaft position sensor - 4D•6

Carburettor - 4A•7, 4A•8, 4A•9, 4A•11,

4A•13, 4A•14, 4A•15, 4A•17, 4A•18

Carpets - 11•2

Cassette player - 12•15, REF •5

Catalytic converter - 4E•2, 4E•5

Centre console - 11•20, 12 •5

Charcoal canister - 4E•6

Charging system - 5A•3

Choke - 4A•4, 4A•16, 4A•17

Cigarette lighter - 12•9, 12 •12

Clock - 12•8, 12•12

Clutch -1•18, 6•1 et seq

Clutch fault finding - REF•17

Coil - 5B•4

Compression test - 2A•3, 2B•3, 2C•3

Connecting rods - 2D•17, 2D•24, 2D•25

Console - 11•20, 12•5

Contents - 0•2

Conversion factors - REF•6

Coolant - 0•12, 0•17, 1•21, 1•22, 3•2

Coolant pump - 3•7

Coolant temperature sensor - 4B•8, 4C•7,

4D•6

Cooling ,heating and ventilation systems -

3•1 et seq

Cooling system fault finding - REF•16

Courtesy light - 12•6, 12•9

Crankcase - 2D•19

Crankcase ventilation system - 1•24

Crankshaft - 2A•6, 2A•9, 2B•4, 2B•6,

2B•12, 2C•4, 2C•7, 2C•14, 2D•18,

2D•22, 2D•24

Crankshaft position sensor - 4B•8, 4C•7,

4D•6, 5B•5

Crossmember - 10•7

Crushing - 0•5

Cushion - 11•17

CV joint - 1•16, 8•3, 8•4

CVH and PTE engine in-car repair

procedures -2B•1 et seq

Cylinder block - 2D•19

Cylinder head - 2A•4, 2A•5, 2B•4, 2B•9,

2C•3, 2C•10, 2D•12, 2D•14, 2D•15

D

Dents in bodywork - 11•2

Depressurising fuel system - 4B•3, 4C•3,

4D•2

Differential - 7A•3, 7B•3

Dimensions - REF•1

Direction indicators - 12•7, 12•9, 12•10

Discs - 9•4

Distributor - 1•20, 5B•5, 5B•6, 5B•7

Doors - 1•18, 11• 6,11•9, 11 •10,,11 •11,

11 •13, 11•14, 11•15, REF •11

Drip rail moulding - 11•5

Drivebelt - 1•11

Driveplate - 2B•14, 2C•16

Driveshafts -1•16, 8•1 et seq,REF•12

Driveshafts fault finding - REF•19

Drivetrain - 1•18

Drums - 9•4

E

Earth fault - 12•4

EEC IV engine management module - 4C•6

Electric shock - 0•5

Electric windows - 11•14, 12 •7, 12•15,

REF•20

Emblems - 11•5

Emission control system - 1•24, 4E•1

Engine fault finding - REF•15, REF•16,

REF •18

Engine oil - 0•12, 0•17, 1•9

Engine removal and overhaul procedures -

2D•1 et seq

Environmental considerations - REF•4

Evaporative emission control systems - 1•24, 4E•2, 4E•5

Exhaust and emission control systems -

4E•1 et seq

Exhaust emission checks - REF•13

Exhaust manifold - 4E•3

Exhaust system - 1•16, 4E•1, 4E•2, REF •5,

REF •12

Exhaust system fault - REF•17

Expansion tank - 3•6

F

Facia - 11•20, 12 •5

Fan - 3•4

Fast-idle speed adjustment - 4A•13, 4A•15,

4A•9, 4A•7

Fault finding - REF•14et seq

Fault finding - automatic transmission -

REF •18

Fault finding - braking system - REF•18

procarmanuals.com

http://vnx.su