drain bolt FORD FIESTA 1989 Service Repair Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1989, Model line: FIESTA, Model: FORD FIESTA 1989Pages: 296, PDF Size: 10.65 MB

Page 4 of 296

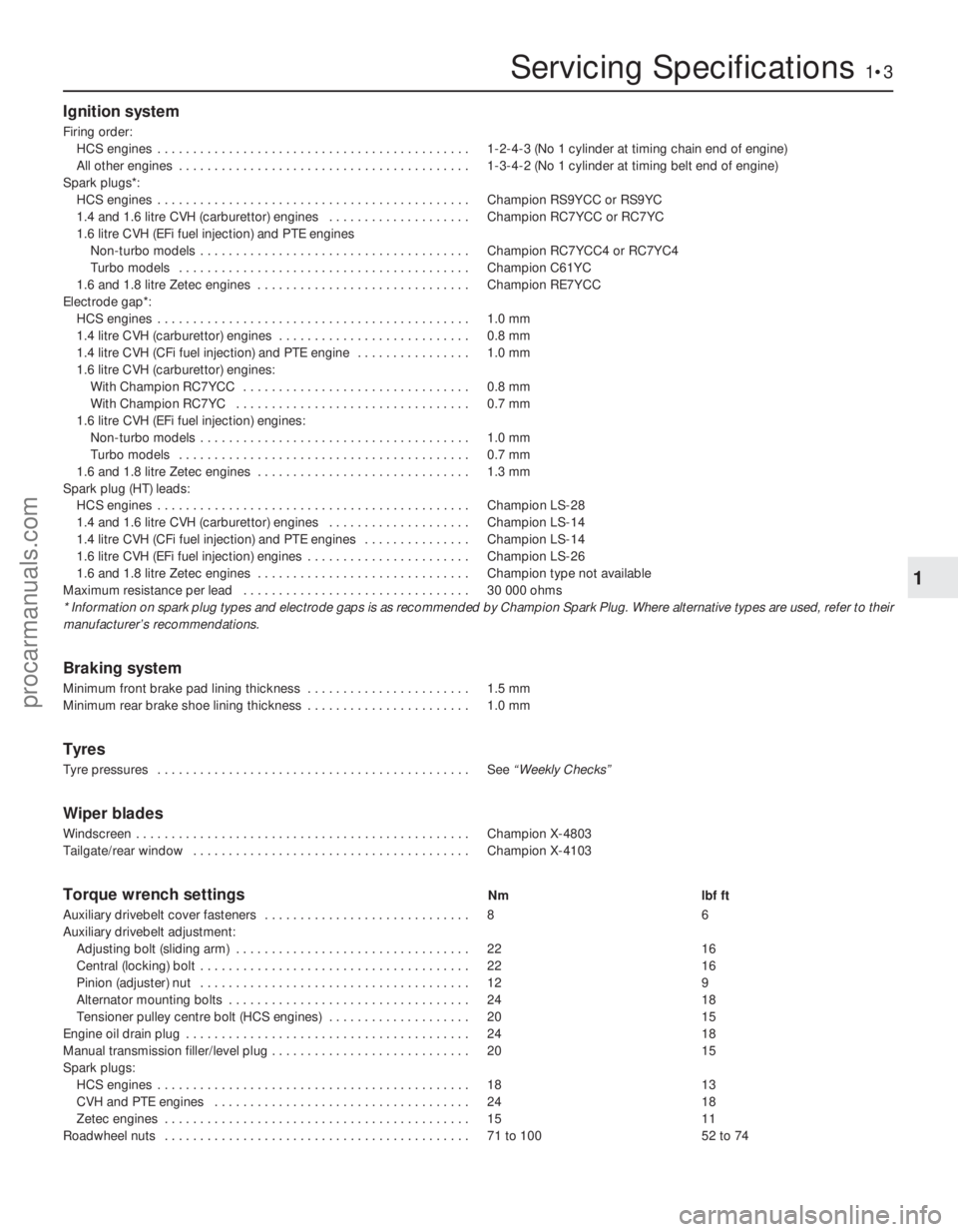

Ignition system

Firing order:HCS engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . 1-2-4-3 (No 1 cylinder at timing chain end of engine)

All other engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . 1-3-4-2 (No 1 cylinder at timing belt end of engine)

Spark plugs*:

HCS engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . Champion RS9YCC or RS9YC

1.4 and 1.6 litre CVH (carburettor) engines . . . . . . . . . . . . . . . . . . . . Champion RC7YCC or RC7YC

1.6 litre CVH (EFi fuel injection) and PTE engines Non-turbo models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . Champion RC7YCC4 or RC7YC4

Turbo models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . Champion C61YC

1.6 and 1.8 litre Zetec engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion RE7YCC

Electrode gap*:

HCS engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . 1.0 mm

1.4 litre CVH (carburettor) engines . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.8 mm

1.4 litre CVH (CFi fuel injection) and PTE engine . . . . . . . . . . . . . . . . 1.0 mm

1.6 litre CVH (carburettor) engines: With Champion RC7YCC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.8 mmWith Champion RC7YC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.7 mm

1.6 litre CVH (EFi fuel injection) engines: Non-turbo models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . 1.0 mm

Turbo models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . 0.7 mm

1.6 and 1.8 litre Zetec engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.3 mm

Spark plug (HT) leads: HCS engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . Champion LS-28

1.4 and 1.6 litre CVH (carburettor) engines . . . . . . . . . . . . . . . . . . . . Champion LS-14

1.4 litre CVH (CFi fuel injection) and PTE engines . . . . . . . . . . . . . . . Champion LS-14

1.6 litre CVH (EFi fuel injection) engines . . . . . . . . . . . . . . . . . . . . . . . Champion LS-26

1.6 and 1.8 litre Zetec engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion type not available

Maximum resistance per lead . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30 000 ohms * Information on spark plug types and electrode gaps is as recommended b\

y Champion Spark Plug. Where alternative types are used, refer to their

manufacturer’s recommendations.

Braking system

Minimum front brake pad lining thickness . . . . . . . . . . . . . . . . . . . . . . . 1.5 mm

Minimum rear brake shoe lining thickness . . . . . . . . . . . . . . . . . . . . . . . 1.0 mm

Tyres

Tyre pressures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . See “Weekly Checks”

Wiper blades

Windscreen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . . . Champion X-4803Tailgate/rear window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . Champion X-4103

Torque wrench settingsNm lbf ft

Auxiliary drivebelt cover fasteners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 6

Auxiliary drivebelt adjustment: Adjusting bolt (sliding arm) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2216

Central (locking) bolt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . 2216

Pinion (adjuster) nut . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . 129

Alternator mounting bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2418

Tensioner pulley centre bolt (HCS engines) . . . . . . . . . . . . . . . . . . . . 2015

Engine oil drain plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . 2418

Manual transmission filler/level plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2015

Spark plugs: HCS engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . 1813

CVH and PTE engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

2418

Zetec engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . 1511

Roadwheel nuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . 71 to 100 52 to 74

Servicing Specifications1•3

1

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 32 of 296

8Reassemble in the reverse order of

dismantling. Make sure that the “flat” on the

rear end of the rocker shaft is to the same side

as the rocker arm adjusting screws (closest to

the thermostat end of the cylinder head when

fitted) (see illustration) . This is essential for

the correct lubrication of the cylinder head

components.

9 Refit the rocker shaft assembly. As it is

fitted, ensure that the rocker adjuster screws

engage with their corresponding pushrods.

10 Refit the rocker shaft retaining bolts,

hand-tighten them and then tighten them to

the specified torque wrench setting. As they

are tightened, some of the rocker arms will

apply pressure to the ends of the valve stems,

and some of the rocker pedestals will not

initially be in contact with the cylinder head -

these should pull down as the bolts are

tightened to their specified torque. If for any

reason they do not, avoid the temptation to

overtighten in order to pull them into position;

loosen off the bolts, and check the cause of

the problem. It may be that the rocker adjuster

screws require loosening off in order to allow

the assembly to be tightened down as

required.

11 Adjust the valve clearances as described

in Section 5.

7 Cylinder head -

removal and refitting

3

Removal

Note: The following procedure describes

removal and refitting of the cylinder head

complete with inlet and exhaust manifolds. If

wished, the manifolds may be removed first,

as described in the relevant Part of Chapter 4,

and the cylinder head then removed on its

own.

1 On fuel injection engines, depressurise the

fuel system as described in Chapter 4, Part B.

2 Disconnect the battery negative (earth) lead

(refer to Chapter 5A, Section 1).

3 Refer to Chapter 4A or 4B as applicable

and remove the air cleaner.

4 Refer to Section 4 and remove the rocker

cover. 5

Refer to Chapter 1 and drain the cooling

system.

6 Disconnect the hoses from the thermostat

housing.

7 Disconnect the heater (coolant) hoses from

the inlet manifold and CFi unit, where

applicable.

8 Disconnect the accelerator and choke

cables as applicable (see Chapter 4A or 4B).

9 Disconnect the vacuum and breather hoses

from the carburettor/CFi unit, and inlet

manifold as applicable.

10 Disconnect the fuel feed and return lines

at the carburettor, or at the quick-release

couplings, then unclip the fuel hoses from the

inlet manifold; use rag to soak up any spilt

fuel.

11 Disconnect the HT leads from the spark

plugs and the support bracket. Unscrew and

remove the spark plugs.

12 Disconnect the electrical leads from the

temperature gauge sender, radiator cooling

fan, the engine coolant temperature sender,

and the anti-run-on (anti-dieselling) valve at

the carburettor.

13 Disconnect the remaining wiring multi-

plugs from the engine sensors at the inlet

manifold and from the oxygen sensor (where

fitted) in the exhaust manifold or downpipe.

14 On vehicles equipped with a pulse-air

system, remove the pulse-air piping and filter

assembly as described in Chapter 4E.

15 Chock the rear wheels then jack up the

front of the car and support it on axle stands

(see “Jacking and Vehicle Support” ).

16 Undo the retaining nuts and bolts, and

disconnect the exhaust downpipe from the

manifold. Remove the flange gasket. (Note

that both the gasket and the joint self-locking

nuts must be renewed.) To prevent the

exhaust system from being strained, tie the

downpipe up using strong wire or a length of

cord to support it. Lower the vehicle.

17 Undo the four retaining bolts and lift clear

the rocker gear assembly from the cylinder

head.

18 Lift out the pushrods. Keep them in order

of fitting by labelling them 1 to 8, starting from

the thermostat end of the cylinder head.

Alternatively, push them through a piece of

card in their fitted sequence.

19 Progressively unscrew and loosen off the

cylinder head retaining bolts in the reverse

sequence to that shown for tightening (see

illustration 7.27a). When they are all loosened off, remove the bolts, then lift the

cylinder head clear and remove the gasket. If

it is stuck, tap it upwards using a hammer and

block of wood. Do not try to turn it, as it is

located by dowels; make no attempt

whatsoever to prise it free using a screwdriver

inserted between the block and head faces.

The gasket must always be renewed; it should

be noted that the cylinder head retaining bolts

may be re-used, but only once. They should

be marked accordingly with a punch or paint

mark. If there is any doubt as to how many

times the bolts have been used, they must be

renewed.

20

To dismantle/overhaul the cylinder head,

refer to Part D of this Chapter. It is normal for

the cylinder head to be decarbonised and the

valves to be reground whenever the head is

removed.

Preparation for refitting

21 The mating faces of the cylinder head and

cylinder block must be perfectly clean before

refitting the head. Use a hard plastic or wood

scraper to remove all traces of gasket and

carbon; also clean the piston crowns. Take

particular care during the cleaning operations,

as aluminium alloy is easily damaged. Also,

make sure that the carbon is not allowed to

enter the oil and water passages - this is

particularly important for the lubrication

system, as carbon could block the oil supply

to the engine’s components. Using adhesive

tape and paper, seal the water, oil and bolt

holes in the cylinder block.

22 Check the mating surfaces of the cylinder

block and the cylinder head for nicks, deep

scratches and other damage. If slight, they

may be removed carefully with a file, but if

excessive, machining may be the only

alternative to renewal.

23 If warpage of the cylinder head gasket

surface is suspected, use a straight-edge to

check it for distortion. Refer to Part D of this

Chapter if necessary.

24 Clean the threads of the cylinder head

bolts or fit new ones (as applicable) and clean

out the bolt holes in the block. Screwing a bolt

into an oil-filled hole can (in extreme cases)

cause the block to fracture, due to the

hydraulic pressure.

Refitting

25 Check that the new cylinder head gasket

is the same type as the original, and that the

“TOP” (or “OBEN”) marking is facing

upwards. Locate the new cylinder head

HCS engine in-car repair procedures 2A•5

6.8 Flat on the rocker shaft (arrowed) to

same side as rocker arm adjusting screws

2A

1595Ford Fiesta Remake

Whenever you disconnect

any vacuum lines, coolant or

emissions hoses, wiring

connectors and fuel lines,

always label them clearly, so that they

can be correctly reassembled. Masking

tape and/or a touch-up paint applicator

work well for marking items. Take

instant photos, or sketch the locations

of components and brackets.

To prevent carbon entering

the gap between the pistons

and bores, smear a little

grease in the gap. After

cleaning each piston, use a small brush

to remove all traces of grease and

carbon from the gap, then wipe away

the remainder with a clean rag.

procarmanuals.com

http://vnx.su

Page 33 of 296

gasket onto the top face of the cylinder block

and over the dowels. Ensure that it is correctly

aligned with the coolant passages and

oilways (see illustration) .

26 Lower the cylinder head carefully into

position, then insert the retaining bolts and

hand-tighten them.

27 Tightening of the cylinder head bolts must

done in three stages, and in the correct

sequence (see illustration) . First tighten all of

the bolts in the sequence shown to the

Stage 1 torque setting (see illustration).

When all of the bolts are tightened to the

Stage 1 setting, further tighten each bolt (in

sequence) through the Stage 2 specified

angle of rotation. When the second stage

tightening is completed on all of the bolts,

further tighten them to the Stage 3 angle

setting (in sequence) to complete. Where

possible, use an angular torque setting gauge

attachment tool for accurate tightening of

stages two and three (see illustration).

28 Lubricate the pushrods with clean engine

oil, and then insert them into their original

locations in the engine.

29 Refit the rocker shaft assembly. As it is

fitted, ensure that the rocker adjuster screws

engage with their corresponding pushrods.

30 Refit the rocker shaft retaining bolts,

hand-tighten them and then tighten them

to the specified torque wrench setting. As

they are tightened, some of the rocker arms

will apply pressure to the ends of the valve

stems, and some of the rocker pedestals will

not initially be in contact with the cylinder head - these should pull down as the bolts are

tightened. If for any reason they do not, avoid

the temptation to overtighten in order to pull

them into position; loosen off the bolts, and

check the cause of the problem. It may be

that the rocker adjuster screws require

loosening off in order to allow the assembly to

be tightened down as required.

31

Adjust the valve clearances as described

in Section 5.

32 Refit the rocker cover as described in

Section 4.

33 The remainder of the refitting procedure is

a reversal of the removal process. Tighten all

fastenings to their specified torque setting

(where given). Refer to the appropriate Parts

of Chapter 4 for details on reconnecting the

fuel and exhaust system components. Ensure

that all coolant, fuel, vacuum and electrical

connections are securely made.

34 On completion, refill the cooling system

and top-up the engine oil (see Chapter 1 and

“Weekly Checks” ). When the engine is

restarted, check for any sign of fuel, oil and/or

coolant leakages from the various cylinder

head joints.

8 Crankshaft pulley -

removal and refitting

2

Removal

1 Disconnect the battery negative (earth) lead

(refer to Chapter 5A, Section 1).

2 Chock the rear wheels then jack up the

front of the car and support it on axle stands

(see “Jacking and Vehicle Support” ). Remove

the right-hand front roadwheel.

3 Remove the auxiliary drivebelt as described

in Chapter 1.

4 Loosen off the crankshaft pulley retaining

bolt. To prevent the crankshaft from turning,

unbolt and remove the clutch housing cover

plate. Lock the starter ring gear on the

flywheel using a large screwdriver or similar

tool inserted through the cover plate aperture.

Alternatively, remove the starter motor

(Chapter 5A) and lock the ring gear through

the starter motor aperture. 5

Fully unscrew the crankshaft pulley bolt,

and withdraw the pulley from the front end of

the crankshaft. If it does not pull off by hand,

lever it free using a pair of suitable levers

positioned diagonally opposite each other

behind the pulley.

6 If required, the crankshaft front oil seal can

be renewed at this stage, as described in

Section 14.

Refitting

7 Refitting is a reversal of the removal

procedure ensuring that the pulley retaining

bolt is tightened to the specified torque

setting.

8 Refit the auxiliary drivebelt as described in

Chapter 1, and lower the vehicle to complete.

9 Timing chain cover -

removal and refitting

2

Removal

1 Remove the sump as described in Sec-

tion 11.

2 Remove the crankshaft pulley as described

in the previous Section.

3 A combined timing cover and water pump

gasket is fitted during production; if this is still

in position, it will be necessary to drain the

cooling system and remove the water pump

as described in Chapter 3. If the water pump

and/or the timing cover have been removed at

any time, the single gasket used originally will

have been replaced by an individual gasket

for each component, in which case the water

pump can remain in position.

4 Unscrew the retaining bolts, and carefully

prise free the timing chain cover.

5 Clean the mating faces of the timing chain

cover, and the engine.

6 If necessary, renew the crankshaft front oil

seal in the timing cover prior to refitting the

cover (see Section 14).

Refitting

7 Lightly lubricate the front end of the

crankshaft and the radial lip of the timing

chain cover oil seal (already installed in the

2A•6 HCS engine in-car repair procedures

7.27c Cylinder head bolt tightening

(Stages 2 and 3) using an angle gauge

7.27b Tightening the cylinder head bolts (Stage 1)7.27a Cylinder head bolt tighteningsequence7.25 Cylinder head gasket top-facemarking (“OBEN”)

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 34 of 296

cover). Using a new gasket, fit the timing

chain cover, centring it with the aid of the

crankshaft pulley - lubricate the seal contact

surfaces beforehand. Refit and tighten the

retaining bolts but, where applicable, leave

out the timing cover bolt which also secures

the water pump at this stage.

8Where applicable, refit the water pump as

described in Chapter 3.

9 Refit the crankshaft pulley as described in

the previous Section.

10 Refit the sump as described in Section 11.

10Timing chain, sprockets and

tensioner - removal,

inspection and refitting

3

Removal

1 Remove the timing chain cover as

described in the previous Section.

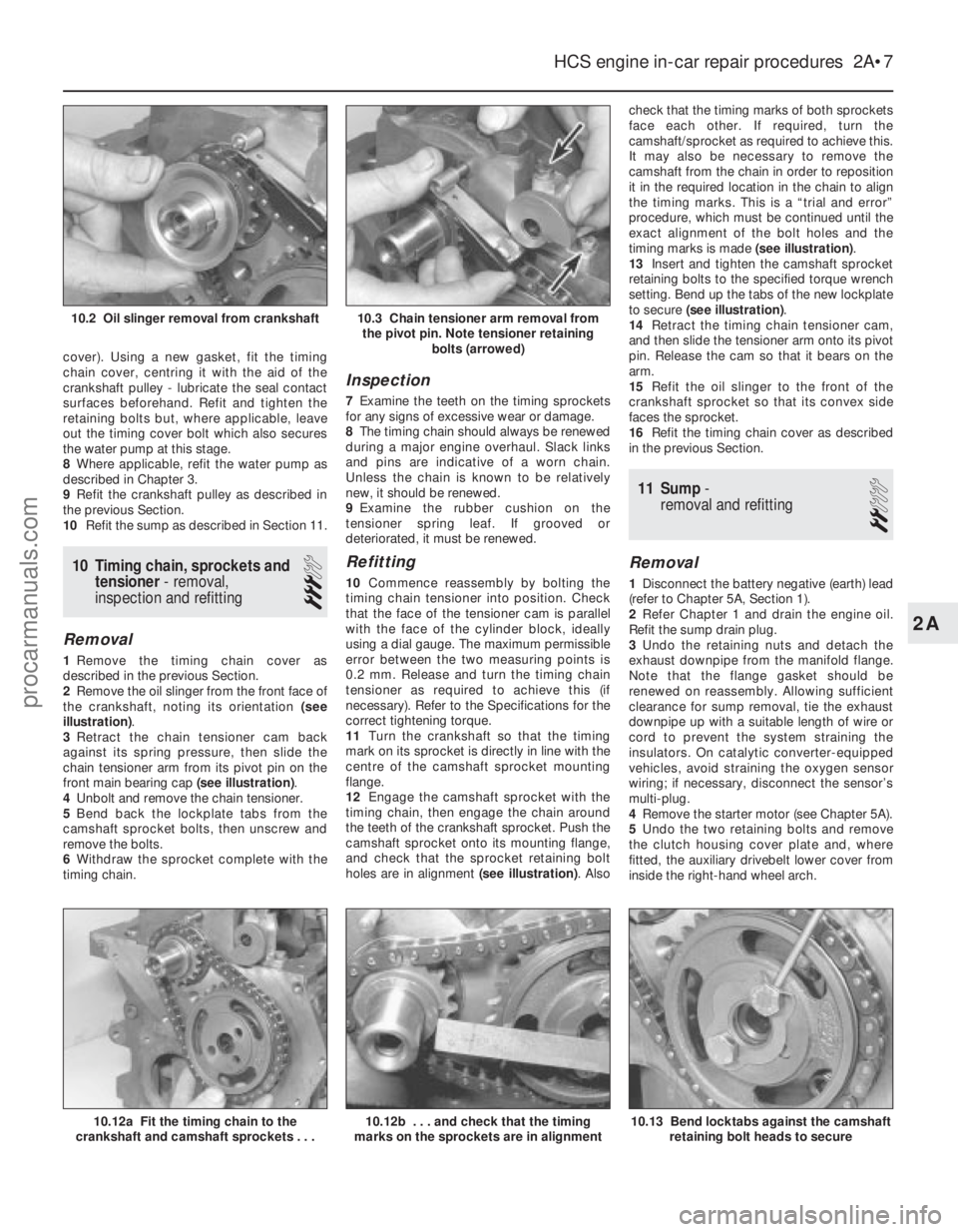

2 Remove the oil slinger from the front face of

the crankshaft, noting its orientation (see

illustration) .

3 Retract the chain tensioner cam back

against its spring pressure, then slide the

chain tensioner arm from its pivot pin on the

front main bearing cap (see illustration).

4 Unbolt and remove the chain tensioner.

5 Bend back the lockplate tabs from the

camshaft sprocket bolts, then unscrew and

remove the bolts.

6 Withdraw the sprocket complete with the

timing chain.

Inspection

7 Examine the teeth on the timing sprockets

for any signs of excessive wear or damage.

8 The timing chain should always be renewed

during a major engine overhaul. Slack links

and pins are indicative of a worn chain.

Unless the chain is known to be relatively

new, it should be renewed.

9 Examine the rubber cushion on the

tensioner spring leaf. If grooved or

deteriorated, it must be renewed.

Refitting

10 Commence reassembly by bolting the

timing chain tensioner into position. Check

that the face of the tensioner cam is parallel

with the face of the cylinder block, ideally

using a dial gauge. The maximum permissible

error between the two measuring points is

0.2 mm. Release and turn the timing chain

tensioner as required to achieve this (if

necessary). Refer to the Specifications for the

correct tightening torque.

11 Turn the crankshaft so that the timing

mark on its sprocket is directly in line with the

centre of the camshaft sprocket mounting

flange.

12 Engage the camshaft sprocket with the

timing chain, then engage the chain around

the teeth of the crankshaft sprocket. Push the

camshaft sprocket onto its mounting flange,

and check that the sprocket retaining bolt

holes are in alignment (see illustration). Alsocheck that the timing marks of both sprockets

face each other. If required, turn the

camshaft/sprocket as required to achieve this.

It may also be necessary to remove the

camshaft from the chain in order to reposition

it in the required location in the chain to align

the timing marks. This is a “trial and error”

procedure, which must be continued until the

exact alignment of the bolt holes and the

timing marks is made

(see illustration).

13 Insert and tighten the camshaft sprocket

retaining bolts to the specified torque wrench

setting. Bend up the tabs of the new lockplate

to secure (see illustration) .

14 Retract the timing chain tensioner cam,

and then slide the tensioner arm onto its pivot

pin. Release the cam so that it bears on the

arm.

15 Refit the oil slinger to the front of the

crankshaft sprocket so that its convex side

faces the sprocket.

16 Refit the timing chain cover as described

in the previous Section.

11 Sump -

removal and refitting

2

Removal

1 Disconnect the battery negative (earth) lead

(refer to Chapter 5A, Section 1).

2 Refer Chapter 1 and drain the engine oil.

Refit the sump drain plug.

3 Undo the retaining nuts and detach the

exhaust downpipe from the manifold flange.

Note that the flange gasket should be

renewed on reassembly. Allowing sufficient

clearance for sump removal, tie the exhaust

downpipe up with a suitable length of wire or

cord to prevent the system straining the

insulators. On catalytic converter-equipped

vehicles, avoid straining the oxygen sensor

wiring; if necessary, disconnect the sensor’s

multi-plug.

4 Remove the starter motor (see Chapter 5A).

5 Undo the two retaining bolts and remove

the clutch housing cover plate and, where

fitted, the auxiliary drivebelt lower cover from

inside the right-hand wheel arch.

HCS engine in-car repair procedures 2A•7

10.12a Fit the timing chain to the

crankshaft and camshaft sprockets . . .

10.3 Chain tensioner arm removal from the pivot pin. Note tensioner retaining bolts (arrowed)10.2 Oil slinger removal from crankshaft

10.13 Bend locktabs against the camshaftretaining bolt heads to secure10.12b . . . and check that the timing

marks on the sprockets are in alignment

2A

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 35 of 296

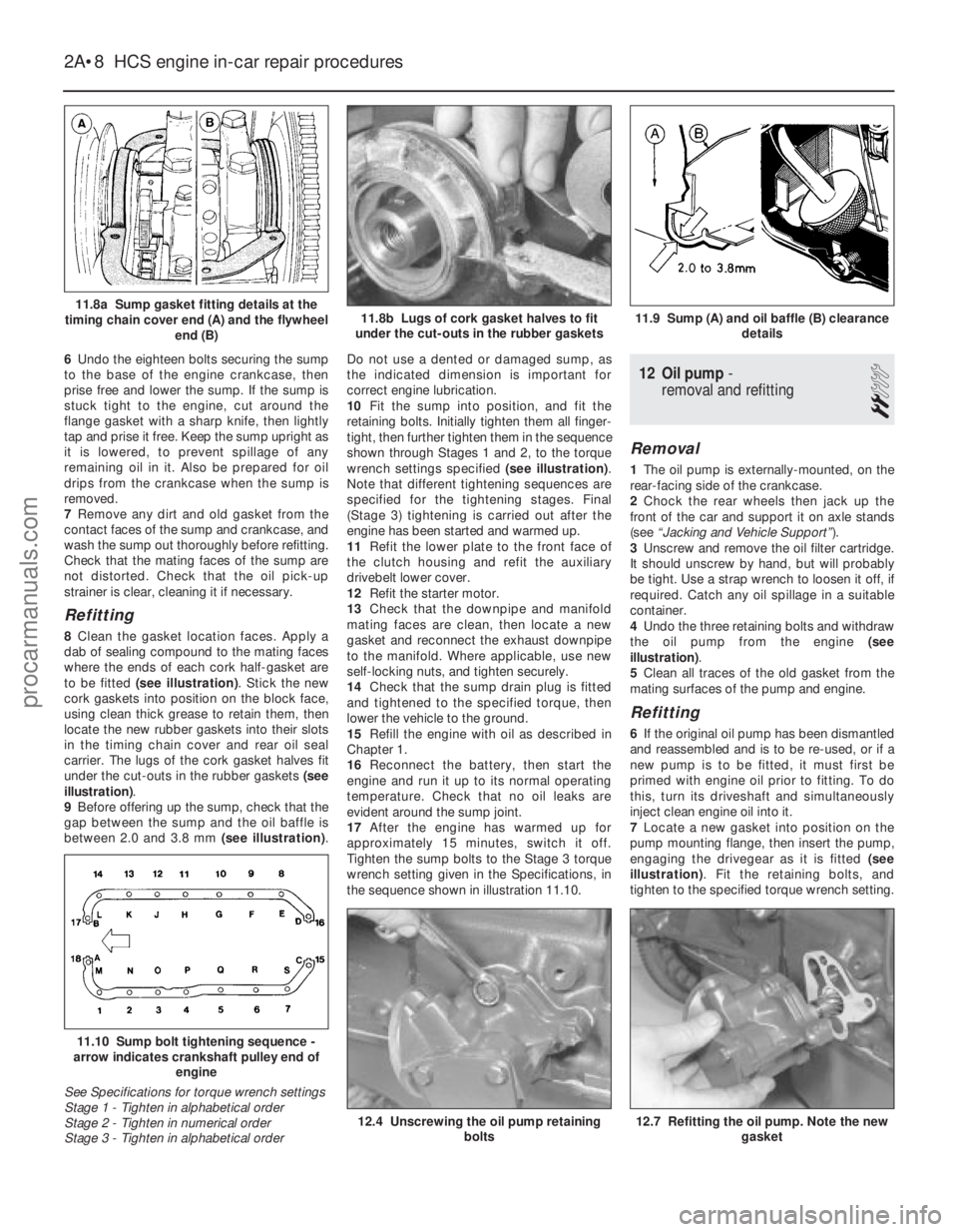

6Undo the eighteen bolts securing the sump

to the base of the engine crankcase, then

prise free and lower the sump. If the sump is

stuck tight to the engine, cut around the

flange gasket with a sharp knife, then lightly

tap and prise it free. Keep the sump upright as

it is lowered, to prevent spillage of any

remaining oil in it. Also be prepared for oil

drips from the crankcase when the sump is

removed.

7 Remove any dirt and old gasket from the

contact faces of the sump and crankcase, and

wash the sump out thoroughly before refitting.

Check that the mating faces of the sump are

not distorted. Check that the oil pick-up

strainer is clear, cleaning it if necessary.

Refitting

8 Clean the gasket location faces. Apply a

dab of sealing compound to the mating faces

where the ends of each cork half-gasket are

to be fitted (see illustration) . Stick the new

cork gaskets into position on the block face,

using clean thick grease to retain them, then

locate the new rubber gaskets into their slots

in the timing chain cover and rear oil seal

carrier. The lugs of the cork gasket halves fit

under the cut-outs in the rubber gaskets (see

illustration) .

9 Before offering up the sump, check that the

gap between the sump and the oil baffle is

between 2.0 and 3.8 mm (see illustration).Do not use a dented or damaged sump, as

the indicated dimension is important for

correct engine lubrication.

10

Fit the sump into position, and fit the

retaining bolts. Initially tighten them all finger-

tight, then further tighten them in the sequence

shown through Stages 1 and 2, to the torque

wrench settings specified (see illustration).

Note that different tightening sequences are

specified for the tightening stages. Final

(Stage 3) tightening is carried out after the

engine has been started and warmed up.

11 Refit the lower plate to the front face of

the clutch housing and refit the auxiliary

drivebelt lower cover.

12 Refit the starter motor.

13 Check that the downpipe and manifold

mating faces are clean, then locate a new

gasket and reconnect the exhaust downpipe

to the manifold. Where applicable, use new

self-locking nuts, and tighten securely.

14 Check that the sump drain plug is fitted

and tightened to the specified torque, then

lower the vehicle to the ground.

15 Refill the engine with oil as described in

Chapter 1.

16 Reconnect the battery, then start the

engine and run it up to its normal operating

temperature. Check that no oil leaks are

evident around the sump joint.

17 After the engine has warmed up for

approximately 15 minutes, switch it off.

Tighten the sump bolts to the Stage 3 torque

wrench setting given in the Specifications, in

the sequence shown in illustration 11.10.

12 Oil pump -

removal and refitting

2

Removal

1 The oil pump is externally-mounted, on the

rear-facing side of the crankcase.

2 Chock the rear wheels then jack up the

front of the car and support it on axle stands

(see “Jacking and Vehicle Support” ).

3 Unscrew and remove the oil filter cartridge.

It should unscrew by hand, but will probably

be tight. Use a strap wrench to loosen it off, if

required. Catch any oil spillage in a suitable

container.

4 Undo the three retaining bolts and withdraw

the oil pump from the engine (see

illustration) .

5 Clean all traces of the old gasket from the

mating surfaces of the pump and engine.

Refitting

6 If the original oil pump has been dismantled

and reassembled and is to be re-used, or if a

new pump is to be fitted, it must first be

primed with engine oil prior to fitting. To do

this, turn its driveshaft and simultaneously

inject clean engine oil into it.

7 Locate a new gasket into position on the

pump mounting flange, then insert the pump,

engaging the drivegear as it is fitted (see

illustration) . Fit the retaining bolts, and

tighten to the specified torque wrench setting.

2A•8 HCS engine in-car repair procedures

12.7 Refitting the oil pump. Note the new gasket12.4 Unscrewing the oil pump retaining bolts

11.10 Sump bolt tightening sequence -

arrow indicates crankshaft pulley end of

engine

See Specifications for torque wrench settings

Stage 1 - Tighten in alphabetical order

Stage 2 - Tighten in numerical order

Stage 3 - Tighten in alphabetical order

11.9 Sump (A) and oil baffle (B) clearance details11.8b Lugs of cork gasket halves to fit

under the cut-outs in the rubber gaskets11.8a Sump gasket fitting details at the

timing chain cover end (A) and the flywheel end (B)

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 43 of 296

complete turn, and all the markings should

now align.

7With the engine set at No 1 piston on TDC

compression, refit the crankshaft pulley cover,

lower the vehicle and refit the upper timing

belt cover.

4 Cylinder head rocker cover -

removal and refitting

2

Removal

1 Disconnect the battery negative (earth) lead

(refer to Chapter 5A, Section 1).

2 Remove the air cleaner assembly and air

inlet components as necessary for access as

described in the relevant Part of Chapter 4.

Disconnect the crankcase ventilation hose

from the rocker cover.

3 Remove the timing belt upper cover as

described in Section 7.

4 Referring to the relevant Part of Chapter 4

for details, disconnect the accelerator cable

from the throttle linkage and from the adjuster

bracket above the rocker cover. Position the

cable out of the way.

5 Where applicable, disconnect the choke

cable from the carburettor, referring to

Chapter 4A for details.

6 Unscrew and remove the rocker cover

retaining bolts and washers, then lift the cover

from the cylinder head. Note that a new

rocker cover gasket will be needed on

refitting.

Refitting

7 Before refitting the rocker cover, clean the

mating surfaces of both the cylinder head and

the cover.

8 Locate the new gasket in position, then fit

the cover retaining bolts and washers. Ensure

that the grooves in the plate washers are

facing upwards as they are fitted (see

illustrations) . Tighten the cover retaining

bolts to the specified torque wrench setting.

Refer to Chapter 4 for details on reconnecting

the accelerator cable, choke cable, air inlet

components and air cleaner (as applicable).

9 Refit the timing belt cover and reconnect

the battery earth lead.

5 Valve clearances -

general information

It is necessary for a clearance to exist

between the tip of each valve stem and the

valve operating mechanism, to allow for the

expansion of the various components as the

engine reaches normal operating

temperature. On most older engine designs, this meant

that the valve clearances (also known as

“tappet” clearances) had to be checked and

adjusted regularly. If the clearances were

allowed to be too slack, the engine would be

very noisy, its power output would suffer, and

its fuel consumption would increase. If the

clearances were allowed to be too tight, the

engine’s power output would be reduced, and

the valves and their seats could be severely

damaged. These engines employ hydraulic tappets

which use the lubricating system’s oil

pressure to automatically take up the

clearance between each camshaft lobe and

its respective valve stem. Therefore, there is

no need for regular checking and adjustment

of the valve clearances. However, it is

essential that only good-quality oil of the

recommended viscosity and specification is

used in the engine, and that this oil is always

changed at the recommended intervals. If this

advice is not followed, the oilways and

tappets may become clogged with particles of

dirt, or deposits of burnt (inferior) engine oil,

so that the system cannot work properly;

ultimately, one or more of the tappets may fail,

and expensive repairs may be required. On starting the engine from cold, there will

be a slight delay while full oil pressure builds

up in all parts of the engine, especially in the

tappets; the valve components, therefore,

may well “rattle” for about 10 seconds or so,

and then quieten. This is a normal state of

affairs, and is nothing to worry about,

provided that all tappets quieten quickly and

stay quiet. After the vehicle has been standing for

several days, the valve components may

“rattle” for longer than usual, as nearly all the oil will have drained away from the engine’s

top-end components and bearing surfaces.

While this is only to be expected, care must

be taken not to damage the engine under

these circumstances - avoid high-speed

running until all the tappets are refilled with oil

and operating normally. With the vehicle

stationary, hold the engine at no more than a

fast idle speed (maximum 2000 to 2500 rpm)

for 10 to 15 minutes, or until the noise ceases.

Do not run the engine at more than 3000 rpm

until the tappets are fully charged with oil and

the noise has ceased.

If the valve components are thought to be

noisy, or if a light rattle persists from the top

end after the engine has warmed up to normal

operating temperature, take the vehicle to a

Ford dealer for expert advice. Depending on

the mileage covered and the usage to which

each vehicle has been put, some vehicles may

be noisier than others; only a good mechanic

experienced in these engines can tell if the

noise level is typical for the vehicle’s mileage,

or if a genuine fault exists. If any tappet’s

operation is faulty, it must be renewed

(Section 11).

6 Crankshaft pulley -

removal and refitting

2

Removal

1 Disconnect the battery negative (earth) lead

(refer to Chapter 5A, Section 1).

2 Chock the rear wheels then jack up the

front of the car and support it on axle stands

(see “Jacking and Vehicle Support” ).

3 Unbolt and remove the cover from the

underside of the crankshaft pulley.

4 Remove the auxiliary drivebelt as described

in Chapter 1.

5 If timing belt renewal is also intended, set

the engine at TDC as described in Section 3

before removing the crankshaft pulley and

retaining bolt.

6 To prevent the crankshaft from turning as

the pulley bolt is loosened off, remove the

starter motor as described in Chapter 5A, and

then lock the starter ring gear using a suitable

lever (see illustration) .

2B•4 CVH and PTE engine in-car repair procedures

6.6 Using a suitable bar to lock the

flywheel ring gear4.8b Rocker cover retaining bolts and plate washers4.8a Fitting a new gasket to the rocker cover

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 48 of 296

23Refer to the procedure in Section 9 when

refitting the camshaft sprocket.

24 Refit and tension the timing belt as

described in Section 8.

25 Lubricate the hydraulic tappets with

hypoid oil before refitting them into their

original locations in the cylinder head.

26 Lubricate and refit the rocker arms and

guides in their original sequence, use new

nuts and tighten them to the specified torque

setting. It is essential, before each rocker arm

is installed and its nut tightened, that the

respective cam follower is positioned at its

lowest point (in contact with the cam base

circle). Turn the cam (using the crankshaft

pulley bolt) as necessary to achieve this.

27 Refit the rocker cover as described in

Section 4.

28 Refit the remaining components with

reference to the relevant Sections in this

Chapter or elsewhere in the manual.

29 On completion, reconnect the battery

negative lead.

12 Cylinder head -

removal and refitting

4

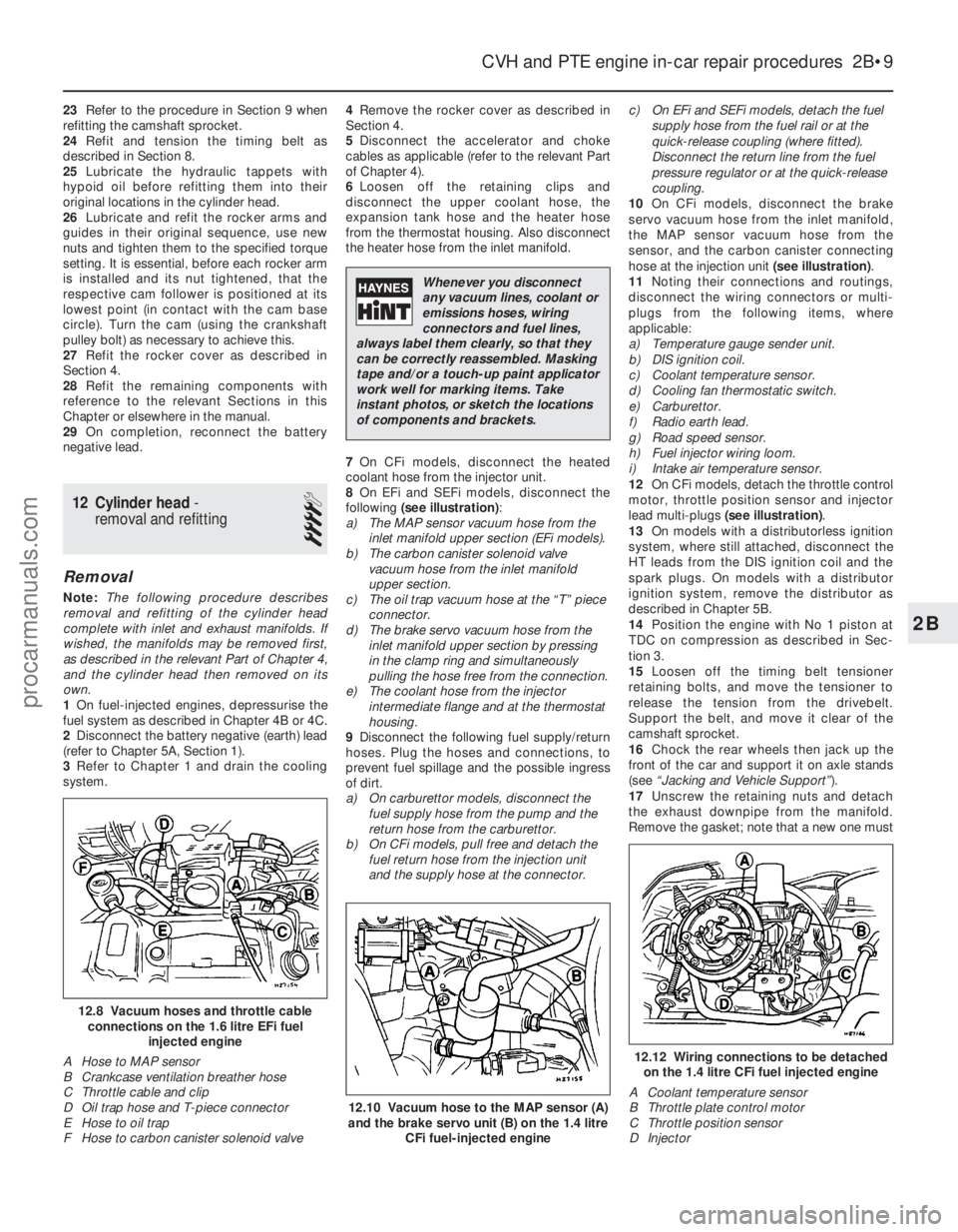

Removal

Note: The following procedure describes

removal and refitting of the cylinder head

complete with inlet and exhaust manifolds. If

wished, the manifolds may be removed first,

as described in the relevant Part of Chapter 4,

and the cylinder head then removed on its

own.

1 On fuel-injected engines, depressurise the

fuel system as described in Chapter 4B or 4C.

2 Disconnect the battery negative (earth) lead

(refer to Chapter 5A, Section 1).

3 Refer to Chapter 1 and drain the cooling

system. 4

Remove the rocker cover as described in

Section 4.

5 Disconnect the accelerator and choke

cables as applicable (refer to the relevant Part

of Chapter 4).

6 Loosen off the retaining clips and

disconnect the upper coolant hose, the

expansion tank hose and the heater hose

from the thermostat housing. Also disconnect

the heater hose from the inlet manifold.

7 On CFi models, disconnect the heated

coolant hose from the injector unit.

8 On EFi and SEFi models, disconnect the

following (see illustration) :

a) The MAP sensor vacuum hose from the inlet manifold upper section (EFi models).

b) The carbon canister solenoid valve

vacuum hose from the inlet manifold

upper section.

c) The oil trap vacuum hose at the “T” piece

connector.

d) The brake servo vacuum hose from the

inlet manifold upper section by pressing

in the clamp ring and simultaneously

pulling the hose free from the connection.

e) The coolant hose from the injector

intermediate flange and at the thermostat

housing.

9 Disconnect the following fuel supply/return

hoses. Plug the hoses and connections, to

prevent fuel spillage and the possible ingress

of dirt.

a) On carburettor models, disconnect the fuel supply hose from the pump and the

return hose from the carburettor.

b) On CFi models, pull free and detach the

fuel return hose from the injection unit

and the supply hose at the connector. c) On EFi and SEFi models, detach the fuel

supply hose from the fuel rail or at the

quick-release coupling (where fitted).

Disconnect the return line from the fuel

pressure regulator or at the quick-release

coupling.

10 On CFi models, disconnect the brake

servo vacuum hose from the inlet manifold,

the MAP sensor vacuum hose from the

sensor, and the carbon canister connecting

hose at the injection unit (see illustration).

11 Noting their connections and routings,

disconnect the wiring connectors or multi-

plugs from the following items, where

applicable:

a) Temperature gauge sender unit.

b) DIS ignition coil.

c) Coolant temperature sensor.

d) Cooling fan thermostatic switch.

e) Carburettor.

f) Radio earth lead.

g) Road speed sensor.

h) Fuel injector wiring loom.

i) Intake air temperature sensor.

12 On CFi models, detach the throttle control

motor, throttle position sensor and injector

lead multi-plugs (see illustration) .

13 On models with a distributorless ignition

system, where still attached, disconnect the

HT leads from the DIS ignition coil and the

spark plugs. On models with a distributor

ignition system, remove the distributor as

described in Chapter 5B.

14 Position the engine with No 1 piston at

TDC on compression as described in Sec-

tion 3.

15 Loosen off the timing belt tensioner

retaining bolts, and move the tensioner to

release the tension from the drivebelt.

Support the belt, and move it clear of the

camshaft sprocket.

16 Chock the rear wheels then jack up the

front of the car and support it on axle stands

(see “Jacking and Vehicle Support” ).

17 Unscrew the retaining nuts and detach

the exhaust downpipe from the manifold.

Remove the gasket; note that a new one must

CVH and PTE engine in-car repair procedures 2B•9

12.12 Wiring connections to be detached on the 1.4 litre CFi fuel injected engine

A Coolant temperature sensor

B Throttle plate control motor

C Throttle position sensor

D Injector

12.10 Vacuum hose to the MAP sensor (A)

and the brake servo unit (B) on the 1.4 litre

CFi fuel-injected engine

12.8 Vacuum hoses and throttle cableconnections on the 1.6 litre EFi fuel injected engine

A Hose to MAP sensor

B Crankcase ventilation breather hose

C Throttle cable and clip

D Oil trap hose and T-piece connector

E Hose to oil trap

F Hose to carbon canister solenoid valve

2B

1595Ford Fiesta Remake

Whenever you disconnect

any vacuum lines, coolant or

emissions hoses, wiring

connectors and fuel lines,

always label them clearly, so that they

can be correctly reassembled. Masking

tape and/or a touch-up paint applicator

work well for marking items. Take

instant photos, or sketch the locations

of components and brackets.

procarmanuals.com

http://vnx.su

Page 49 of 296

be fitted on reassembly. Tie the downpipe up

to support it.

18Before it is released and removed, the

cylinder head must first have cooled down to

room temperature (about 20ºC).

19 Unscrew the cylinder head retaining bolts

progressively in the reverse order to that

shown for tightening (see illustration 12.28).

The cylinder head bolts must be discarded

and new bolts obtained for refitting the

cylinder head.

20 Remove the cylinder head complete with

its manifolds. If necessary, grip the manifolds

and rock it free from the location dowels on

the top face of the cylinder block. Do not

attempt to tap it sideways or lever between

the head and the block top face.

21 Remove the cylinder head gasket. This must

always be renewed; it is essential that the

correct type is obtained. Save the old gasket, so

that the identification marks (teeth) can be used

when ordering the new one (see illustration).

Preparation for refitting

22The mating faces of the cylinder head and

cylinder block must be perfectly clean before

refitting the head. Use a hard plastic or wood

scraper to remove all traces of gasket and

carbon; also clean the piston crowns. Take

particular care during the cleaning operations,

as aluminium alloy is easily damaged. Also,

make sure that the carbon is not allowed to

enter the oil and water passages - this is

particularly important for the lubrication

system, as carbon could block the oil supply

to the engine’s components. Using adhesive

tape and paper, seal the water, oil and bolt

holes in the cylinder block.

23 Check the mating surfaces of the cylinder

block and the cylinder head for nicks, deep

scratches and other damage. If slight, they may be removed carefully with a file, but if

excessive, machining may be the only

alternative to renewal.

24

If warpage of the cylinder head gasket

surface is suspected, use a straight-edge to

check it for distortion. Refer to Part D of this

Chapter if necessary.

25 Ensure that new cylinder head bolts are

used when refitting and clean out the bolt

holes in the block. Screwing a bolt into an oil-

filled hole can (in extreme cases) cause the

block to fracture, due to the hydraulic

pressure.

Refitting

26 To prevent the possibility of the valves

and pistons coming into contact as the head

is fitted, turn the crankshaft over to position

No 1 piston approximately 20 mm below its

TDC position in the bore.

27 Locate the cylinder head gasket on the

top face of the cylinder block, locating it over

the dowels. Ensure that the gasket is fitted the

correct way up, as indicated by its “OBEN-

TOP” marking (see illustration) .

28 Lower the cylinder head into position,

ensuring that it fits over the locating dowels,

then insert the new retaining bolts. Hand-

tighten the bolts initially, then tighten them in

the order shown in the four stages to the

specified torque setting (see illustration).

Where possible, use an angular torque setting

gauge attachment tool for accurate tightening

of stages three and four. Alternatively, after

the first two stages, mark the bolt heads with

a dab of quick drying paint, so that the paint

spots all face the same direction. Now tighten

all the bolts in the sequence to the Stage 3

setting, by tightening them through the

specified angle. Finally, angle-tighten all the

bolts through the Stage 4 angle.

29 The camshaft sprocket should be

positioned so that its TDC index mark pointer

is in alignment with the TDC index spot mark

on the front end face of the cylinder head (see

illustration 3.6b).

30 Now turn the crankshaft pulley to bring its

TDC notch in alignment with the TDC (0)

indicator on the front face of the timing belt

cover, taking the shortest route (not vice-

versa) (see illustration 3.6a). 31

Refit the timing belt over the camshaft

sprocket, and then tension the belt as

described in Section 8.

32 The remainder of the refitting procedure is

a reversal of the removal process. Tighten all

fastenings to their specified torque setting

(where given). Refer to the appropriate Parts

of Chapter 4 for details on reconnecting the

fuel and exhaust system components, and to

Chapter 5B for details on reconnecting the

ignition system components. Ensure that all

coolant, fuel, vacuum and electrical

connections are securely made.

33 On completion, refill the cooling system

and top-up the engine oil (see Chapter 1 and

“Weekly Checks” ). When the engine is

restarted, check for any sign of fuel, oil and/or

coolant leakages from the various cylinder

head joints.

13 Sump -

removal and refitting

2

Removal

1 Disconnect the battery negative (earth) lead

(refer to Chapter 5A, Section 1).

2 Drain the engine oil as described in Chapter

1.

3 Chock the rear wheels then jack up the

front of the car and support it on axle stands

(see “Jacking and Vehicle Support” ). Remove

the auxiliary drivebelt lower cover from inside

the right-hand wheel arch.

4 Where fitted, pull free the oxygen sensor

lead multi-plug, and disconnect it. If the

engine has been recently run, take particular

care against burning when working in the area

of the catalytic converter.

5 Undo the retaining nuts, and detach the

exhaust downpipe from the manifold. The

flange gasket must be renewed when

reconnecting. Where applicable, also detach

the downpipe at the rear of the catalytic

converter, and release it from the front

mounting.

6 On XR2i models, remove the front

suspension crossmember as described in

Chapter 10. On all models, undo the nut and

2B•10 CVH and PTE engine in-car repair procedures

12.28 Cylinder head bolt tightening

sequence12.27 Fit the cylinder head gasket with the“OBEN/TOP” marking upwards . . .12.21 Cylinder head location dowels (A)and gasket identification teeth (B)

1595Ford Fiesta Remake

To prevent carbon entering

the gap between the pistons

and bores, smear a little

grease in the gap. After

cleaning each piston, use a small brush

to remove all traces of grease and

carbon from the gap, then wipe away

the remainder with a clean rag.

procarmanuals.com

http://vnx.su

Page 50 of 296

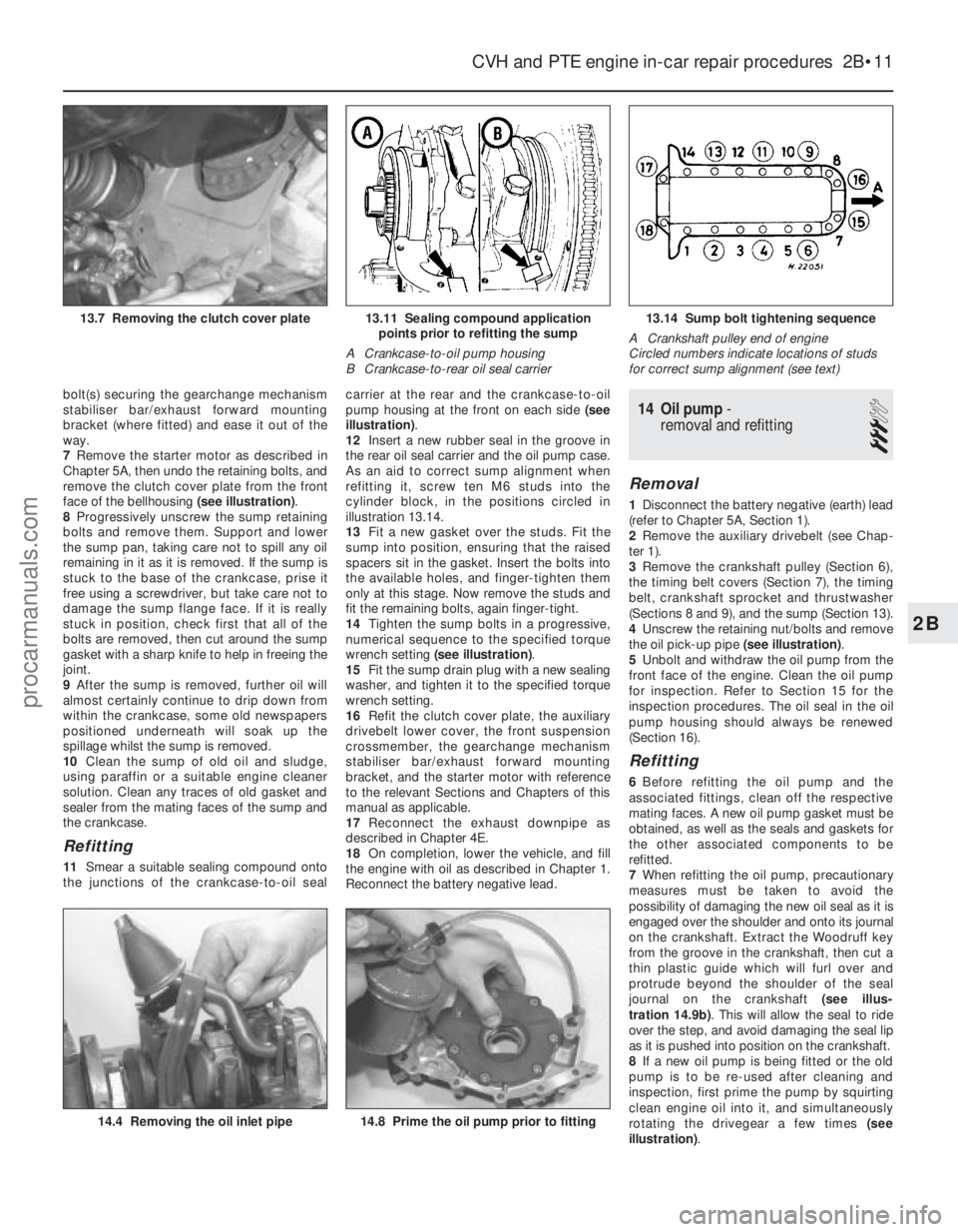

bolt(s) securing the gearchange mechanism

stabiliser bar/exhaust forward mounting

bracket (where fitted) and ease it out of the

way.

7Remove the starter motor as described in

Chapter 5A, then undo the retaining bolts, and

remove the clutch cover plate from the front

face of the bellhousing (see illustration).

8 Progressively unscrew the sump retaining

bolts and remove them. Support and lower

the sump pan, taking care not to spill any oil

remaining in it as it is removed. If the sump is

stuck to the base of the crankcase, prise it

free using a screwdriver, but take care not to

damage the sump flange face. If it is really

stuck in position, check first that all of the

bolts are removed, then cut around the sump

gasket with a sharp knife to help in freeing the

joint.

9 After the sump is removed, further oil will

almost certainly continue to drip down from

within the crankcase, some old newspapers

positioned underneath will soak up the

spillage whilst the sump is removed.

10 Clean the sump of old oil and sludge,

using paraffin or a suitable engine cleaner

solution. Clean any traces of old gasket and

sealer from the mating faces of the sump and

the crankcase.

Refitting

11 Smear a suitable sealing compound onto

the junctions of the crankcase-to-oil seal carrier at the rear and the crankcase-to-oil

pump housing at the front on each side

(see

illustration) .

12 Insert a new rubber seal in the groove in

the rear oil seal carrier and the oil pump case.

As an aid to correct sump alignment when

refitting it, screw ten M6 studs into the

cylinder block, in the positions circled in

illustration 13.14.

13 Fit a new gasket over the studs. Fit the

sump into position, ensuring that the raised

spacers sit in the gasket. Insert the bolts into

the available holes, and finger-tighten them

only at this stage. Now remove the studs and

fit the remaining bolts, again finger-tight.

14 Tighten the sump bolts in a progressive,

numerical sequence to the specified torque

wrench setting (see illustration) .

15 Fit the sump drain plug with a new sealing

washer, and tighten it to the specified torque

wrench setting.

16 Refit the clutch cover plate, the auxiliary

drivebelt lower cover, the front suspension

crossmember, the gearchange mechanism

stabiliser bar/exhaust forward mounting

bracket, and the starter motor with reference

to the relevant Sections and Chapters of this

manual as applicable.

17 Reconnect the exhaust downpipe as

described in Chapter 4E.

18 On completion, lower the vehicle, and fill

the engine with oil as described in Chapter 1.

Reconnect the battery negative lead.

14 Oil pump -

removal and refitting

3

Removal

1 Disconnect the battery negative (earth) lead

(refer to Chapter 5A, Section 1).

2 Remove the auxiliary drivebelt (see Chap-

ter 1).

3 Remove the crankshaft pulley (Section 6),

the timing belt covers (Section 7), the timing

belt, crankshaft sprocket and thrustwasher

(Sections 8 and 9), and the sump (Section 13).

4 Unscrew the retaining nut/bolts and remove

the oil pick-up pipe (see illustration).

5 Unbolt and withdraw the oil pump from the

front face of the engine. Clean the oil pump

for inspection. Refer to Section 15 for the

inspection procedures. The oil seal in the oil

pump housing should always be renewed

(Section 16).

Refitting

6 Before refitting the oil pump and the

associated fittings, clean off the respective

mating faces. A new oil pump gasket must be

obtained, as well as the seals and gaskets for

the other associated components to be

refitted.

7 When refitting the oil pump, precautionary

measures must be taken to avoid the

possibility of damaging the new oil seal as it is

engaged over the shoulder and onto its journal

on the crankshaft. Extract the Woodruff key

from the groove in the crankshaft, then cut a

thin plastic guide which will furl over and

protrude beyond the shoulder of the seal

journal on the crankshaft (see illus-

tration 14.9b) . This will allow the seal to ride

over the step, and avoid damaging the seal lip

as it is pushed into position on the crankshaft.

8 If a new oil pump is being fitted or the old

pump is to be re-used after cleaning and

inspection, first prime the pump by squirting

clean engine oil into it, and simultaneously

rotating the drivegear a few times (see

illustration) .

CVH and PTE engine in-car repair procedures 2B•11

13.14 Sump bolt tightening sequence

A Crankshaft pulley end of engine

Circled numbers indicate locations of studs

for correct sump alignment (see text)13.11 Sealing compound application points prior to refitting the sump

A Crankcase-to-oil pump housing

B Crankcase-to-rear oil seal carrier13.7 Removing the clutch cover plate

14.8 Prime the oil pump prior to fitting14.4 Removing the oil inlet pipe

2B

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 64 of 296

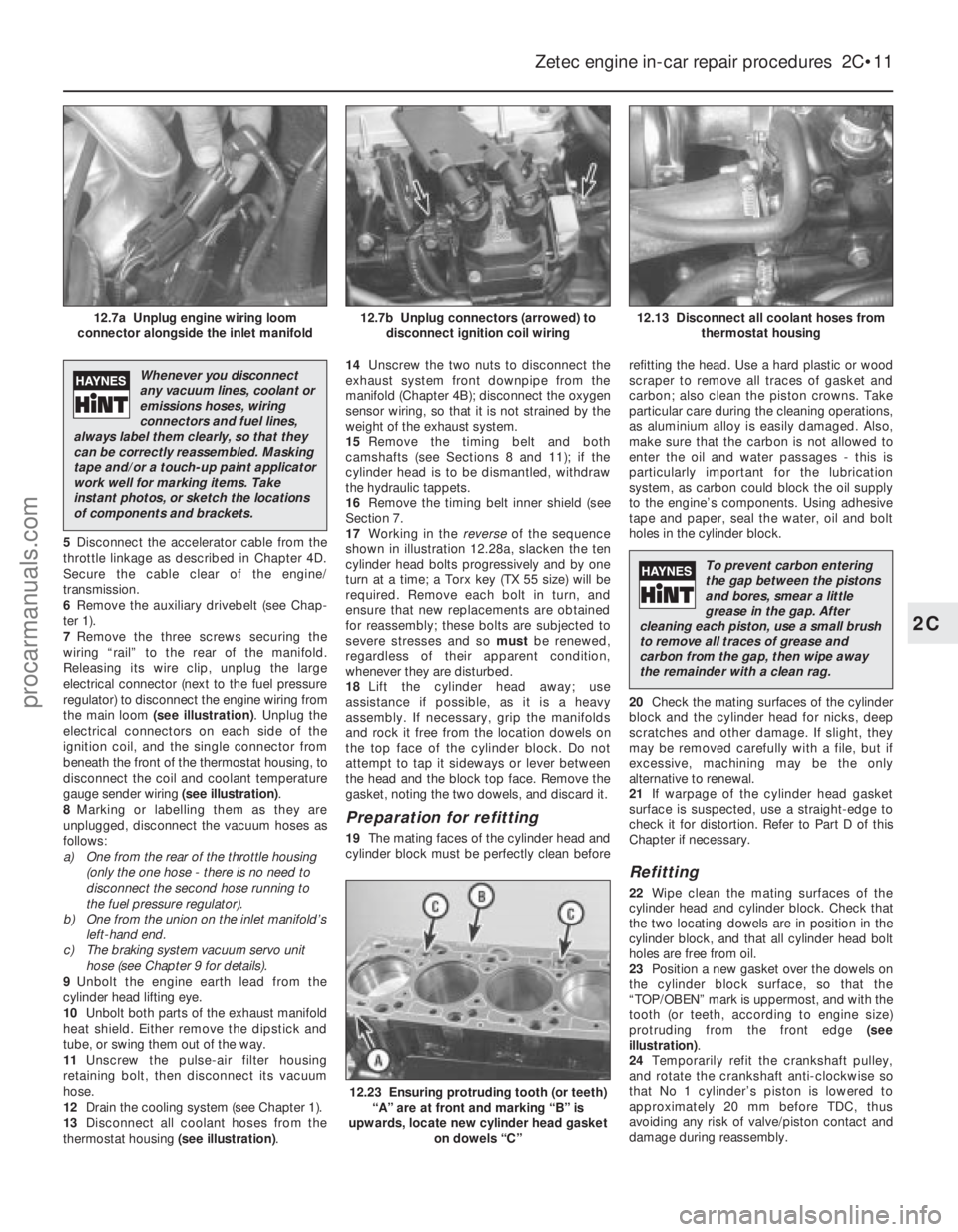

5Disconnect the accelerator cable from the

throttle linkage as described in Chapter 4D.

Secure the cable clear of the engine/

transmission.

6 Remove the auxiliary drivebelt (see Chap-

ter 1).

7 Remove the three screws securing the

wiring “rail” to the rear of the manifold.

Releasing its wire clip, unplug the large

electrical connector (next to the fuel pressure

regulator) to disconnect the engine wiring from

the main loom (see illustration) . Unplug the

electrical connectors on each side of the

ignition coil, and the single connector from

beneath the front of the thermostat housing, to

disconnect the coil and coolant temperature

gauge sender wiring (see illustration).

8 Marking or labelling them as they are

unplugged, disconnect the vacuum hoses as

follows:

a) One from the rear of the throttle housing

(only the one hose - there is no need to

disconnect the second hose running to

the fuel pressure regulator).

b) One from the union on the inlet manifold’s

left-hand end.

c) The braking system vacuum servo unit hose (see Chapter 9 for details).

9 Unbolt the engine earth lead from the

cylinder head lifting eye.

10 Unbolt both parts of the exhaust manifold

heat shield. Either remove the dipstick and

tube, or swing them out of the way.

11 Unscrew the pulse-air filter housing

retaining bolt, then disconnect its vacuum

hose.

12 Drain the cooling system (see Chapter 1).

13 Disconnect all coolant hoses from the

thermostat housing (see illustration).14

Unscrew the two nuts to disconnect the

exhaust system front downpipe from the

manifold (Chapter 4B); disconnect the oxygen

sensor wiring, so that it is not strained by the

weight of the exhaust system.

15 Remove the timing belt and both

camshafts (see Sections 8 and 11); if the

cylinder head is to be dismantled, withdraw

the hydraulic tappets.

16 Remove the timing belt inner shield (see

Section 7.

17 Working in the reverseof the sequence

shown in illustration 12.28a, slacken the ten

cylinder head bolts progressively and by one

turn at a time; a Torx key (TX 55 size) will be

required. Remove each bolt in turn, and

ensure that new replacements are obtained

for reassembly; these bolts are subjected to

severe stresses and so mustbe renewed,

regardless of their apparent condition,

whenever they are disturbed.

18 Lift the cylinder head away; use

assistance if possible, as it is a heavy

assembly. If necessary, grip the manifolds

and rock it free from the location dowels on

the top face of the cylinder block. Do not

attempt to tap it sideways or lever between

the head and the block top face. Remove the

gasket, noting the two dowels, and discard it.

Preparation for refitting

19 The mating faces of the cylinder head and

cylinder block must be perfectly clean before refitting the head. Use a hard plastic or wood

scraper to remove all traces of gasket and

carbon; also clean the piston crowns. Take

particular care during the cleaning operations,

as aluminium alloy is easily damaged. Also,

make sure that the carbon is not allowed to

enter the oil and water passages - this is

particularly important for the lubrication

system, as carbon could block the oil supply

to the engine’s components. Using adhesive

tape and paper, seal the water, oil and bolt

holes in the cylinder block.

20

Check the mating surfaces of the cylinder

block and the cylinder head for nicks, deep

scratches and other damage. If slight, they

may be removed carefully with a file, but if

excessive, machining may be the only

alternative to renewal.

21 If warpage of the cylinder head gasket

surface is suspected, use a straight-edge to

check it for distortion. Refer to Part D of this

Chapter if necessary.

Refitting

22 Wipe clean the mating surfaces of the

cylinder head and cylinder block. Check that

the two locating dowels are in position in the

cylinder block, and that all cylinder head bolt

holes are free from oil.

23 Position a new gasket over the dowels on

the cylinder block surface, so that the

“TOP/OBEN” mark is uppermost, and with the

tooth (or teeth, according to engine size)

protruding from the front edge (see

illustration) .

24 Temporarily refit the crankshaft pulley,

and rotate the crankshaft anti-clockwise so

that No 1 cylinder’s piston is lowered to

approximately 20 mm before TDC, thus

avoiding any risk of valve/piston contact and

damage during reassembly.

Zetec engine in-car repair procedures 2C•11

12.13 Disconnect all coolant hoses from thermostat housing12.7b Unplug connectors (arrowed) todisconnect ignition coil wiring12.7a Unplug engine wiring loom

connector alongside the inlet manifold

12.23 Ensuring protruding tooth (or teeth) “A” are at front and marking “B” is

upwards, locate new cylinder head gasket on dowels “C”

2C

1595Ford Fiesta Remake

Whenever you disconnect

any vacuum lines, coolant or

emissions hoses, wiring

connectors and fuel lines,

always label them clearly, so that they

can be correctly reassembled. Masking

tape and/or a touch-up paint applicator

work well for marking items. Take

instant photos, or sketch the locations

of components and brackets.

To prevent carbon entering

the gap between the pistons

and bores, smear a little

grease in the gap. After

cleaning each piston, use a small brush

to remove all traces of grease and

carbon from the gap, then wipe away

the remainder with a clean rag.

procarmanuals.com

http://vnx.su