jacking points FORD FIESTA 1989 Service Repair Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1989, Model line: FIESTA, Model: FORD FIESTA 1989Pages: 296, PDF Size: 10.65 MB

Page 22 of 296

23 Coolant renewal

1

Note: If the antifreeze used is Ford’s own, the

coolant need not be renewed for the life of the

vehicle. If the vehicle’s history is unknown, if

antifreeze of lesser quality is known to be in

the system, or simply if you prefer to follow

conventional servicing intervals, the coolant

should be changed periodically (typically,

every 3 years) as described here. Refer also to

“Antifreeze - notes on renewal” in this

Section.

Warning: Do not allow

antifreeze to come in contact

with your skin or painted

surfaces of the vehicle. Flush

contaminated areas immediately with

plenty of water. Don’t store new coolant,

or leave old coolant lying around, where

it’s accessible to children or pets - they’re

attracted by its sweet smell. Ingestion of

even a small amount of coolant can be

fatal! Wipe up garage-floor and drip-pan

spills immediately. Keep antifreeze

containers covered, and repair cooling

system leaks as soon as they’re noticed.

Warning: Never remove the expansion

tank filler cap when the engine is running,

or has just been switched off, as the

cooling system will be hot, and the

consequent escaping steam and scalding

coolant could cause serious injury.

Coolant draining

Warning: Wait until the engine is

cold before starting this

procedure.

1 To drain the system, first remove the

expansion tank filler cap (see “Weekly

Checks” ).

2 If additional working clearance is required,

raise the front of the vehicle and support it securely on axle stands (see

“Jacking and

Vehicle Support” ).

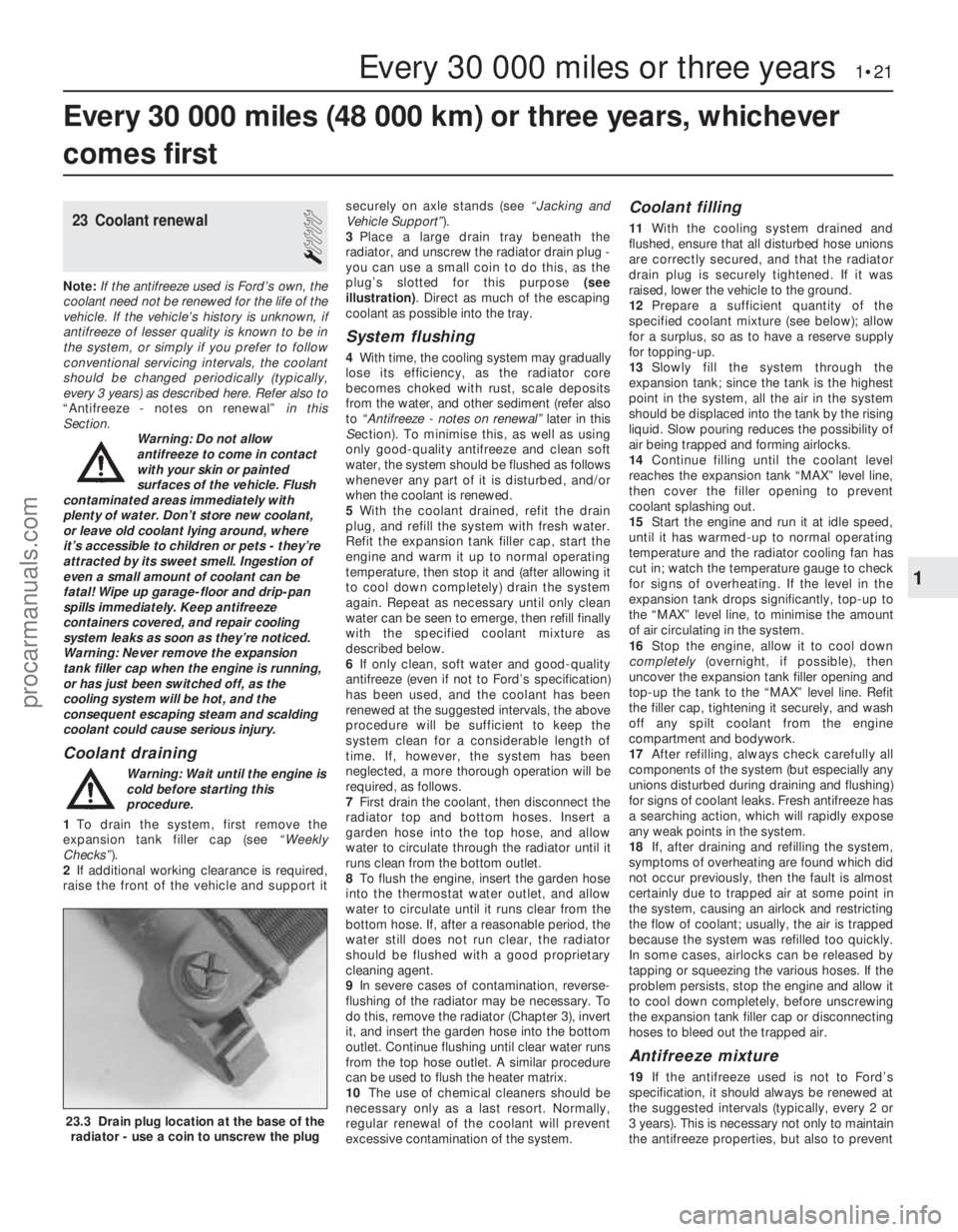

3 Place a large drain tray beneath the

radiator, and unscrew the radiator drain plug -

you can use a small coin to do this, as the

plug’s slotted for this purpose (see

illustration) . Direct as much of the escaping

coolant as possible into the tray.

System flushing

4 With time, the cooling system may gradually

lose its efficiency, as the radiator core

becomes choked with rust, scale deposits

from the water, and other sediment (refer also

to “Antifreeze - notes on renewal” later in this

S ection). To minimise this, as well as using

only good-quality antifreeze and clean soft

water, the system should be flushed as follows

whenever any part of it is disturbed, and/or

when the coolant is renewed.

5 With the coolant drained, refit the drain

plug, and refill the system with fresh water.

Refit the expansion tank filler cap, start the

engine and warm it up to normal operating

temperature, then stop it and (after allowing it

to cool down completely) drain the system

again. Repeat as necessary until only clean

water can be seen to emerge, then refill finally

with the specified coolant mixture as

described below.

6 If only clean, soft water and good-quality

antifreeze (even if not to Ford’s specification)

has been used, and the coolant has been

renewed at the suggested intervals, the above

procedure will be sufficient to keep the

system clean for a considerable length of

time. If, however, the system has been

neglected, a more thorough operation will be

required, as follows.

7 First drain the coolant, then disconnect the

radiator top and bottom hoses. Insert a

garden hose into the top hose, and allow

water to circulate through the radiator until it

runs clean from the bottom outlet.

8 To flush the engine, insert the garden hose

into the thermostat water outlet, and allow

water to circulate until it runs clear from the

bottom hose. If, after a reasonable period, the

water still does not run clear, the radiator

should be flushed with a good proprietary

cleaning agent.

9 In severe cases of contamination, reverse-

flushing of the radiator may be necessary. To

do this, remove the radiator (Chapter 3), invert

it, and insert the garden hose into the bottom

outlet. Continue flushing until clear water runs

from the top hose outlet. A similar procedure

can be used to flush the heater matrix.

10 The use of chemical cleaners should be

necessary only as a last resort. Normally,

regular renewal of the coolant will prevent

excessive contamination of the system.

Coolant filling

11 With the cooling system drained and

flushed, ensure that all disturbed hose unions

are correctly secured, and that the radiator

drain plug is securely tightened. If it was

raised, lower the vehicle to the ground.

12 Prepare a sufficient quantity of the

specified coolant mixture (see below); allow

for a surplus, so as to have a reserve supply

for topping-up.

13 Slowly fill the system through the

expansion tank; since the tank is the highest

point in the system, all the air in the system

should be displaced into the tank by the rising

liquid. Slow pouring reduces the possibility of

air being trapped and forming airlocks.

14 Continue filling until the coolant level

reaches the expansion tank “MAX” level line,

then cover the filler opening to prevent

coolant splashing out.

15 Start the engine and run it at idle speed,

until it has warmed-up to normal operating

temperature and the radiator cooling fan has

cut in; watch the temperature gauge to check

for signs of overheating. If the level in the

expansion tank drops significantly, top-up to

the “MAX” level line, to minimise the amount

of air circulating in the system.

16 Stop the engine, allow it to cool down

completely (overnight, if possible), then

uncover the expansion tank filler opening and

top-up the tank to the “MAX” level line. Refit

the filler cap, tightening it securely, and wash

off any spilt coolant from the engine

compartment and bodywork.

17 After refilling, always check carefully all

components of the system (but especially any

unions disturbed during draining and flushing)

for signs of coolant leaks. Fresh antifreeze has

a searching action, which will rapidly expose

any weak points in the system.

18 If, after draining and refilling the system,

symptoms of overheating are found which did

not occur previously, then the fault is almost

certainly due to trapped air at some point in

the system, causing an airlock and restricting

the flow of coolant; usually, the air is trapped

because the system was refilled too quickly.

In some cases, airlocks can be released by

tapping or squeezing the various hoses. If the

problem persists, stop the engine and allow it

to cool down completely, before unscrewing

the expansion tank filler cap or disconnecting

hoses to bleed out the trapped air.

Antifreeze mixture

19 If the antifreeze used is not to Ford’s

specification, it should always be renewed at

the suggested intervals (typically, every 2 or

3 years). This is necessary not only to maintain

the antifreeze properties, but also to prevent

Every 30 000 miles (48 000 km) or three years, whichever

comes first

Every 30 000 miles or three years 1•21

23.3 Drain plug location at the base of the radiator - use a coin to unscrew the plug

1

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 26 of 296

the specified type of fluid. It is essential that

no dirt is introduced into the transmission

during this operation.

7Depending on the extent to which the fluid

was allowed to drain, it is possible that the

amount of fluid required when filling the

transmission may be more than the specified

amount (see “Lubricants, fluids and tyre

pressures” ). However, due to fluid remaining in

the system, it is more likely that less than the

specified amount will be required. Add about

half the specified amount, then run the engine

up to its normal operating temperature and

check the level on the dipstick. When the level

approaches the maximum mark, proceed as

detailed in Section 20 to check the level and

complete the final topping-up as described.

27 Handbrake adjustment

3

1 Chock the front wheels then jack up the

rear of the car and support it on axle stands

(see “Jacking and Vehicle Support” ). Fully

release the handbrake.

2 Check that the handbrake cables are

correctly routed and secured by the retaining

clips at the appropriate points under the vehicle.

3 The handbrake is checked for adjustment

by measuring the amount of movement

possible in the handbrake adjuster plungers.

These are located on the inside face of each

rear brake backplate (see illustration) . Thetotal movement of the two plungers combined

should be between 0.5 and 2.0 mm. If the

movement measured is outside of this

tolerance, the handbrake is in need of

adjustment. Adjustment is made altering the

position of the in-line cable adjuster sleeve.

4

When adjustment to the handbrake is

necessary, a new adjustment sleeve locking

pin will be required, and this must therefore

be obtained before making the adjustment.

5 To adjust the handbrake, first ensure that it

is fully released, then firmly apply the

footbrake a few times to ensure that the rear

brake adjustment is taken up by the automatic

adjusters. Extract the locking pin from

the adjuster sleeve (see illustration), then

turn the sleeve to set the combined move-

ment of the plungers within the tolerance range specified (0.5 to 2.0 mm). Turn the

locking nut by hand as tight as is possible

(two clicks) against the adjustment sleeve.

Now grip the locknut with a suitable wrench,

and turn it a further two clicks (maximum).

6

Secure the adjustment by inserting the new

lock pin.

7 Check that the operation of the handbrake

is satisfactory, then lower the vehicle to the

ground, apply the handbrake and remove the

chocks from the front wheels.

28 Front wheel alignment check

4

Refer to Chapter 10, Section 29.

Every 30 000 miles or three years1•25

27.5 Handbrake cable adjuster locking

pin (A), locknut (B) and adjuster sleeve (C)27.3 Handbrake adjustment plunger

located on the inside face of each rear brake backplate

1

1595Ford Fiesta Remake

Every 40 000 miles

29 Timing belt renewal

4

Refer to Chapter 2, Part B or C as

applicable.

Every 60 000 miles

30 Fuel filter renewal

1

Warning: Petrol is extremely

flammable, so extra precautions

must be taken when working on

any part of the fuel system. Do

not smoke, or allow open flames or bare

light bulbs, near the work area. Also, do

not work in a garage if a natural gas-type appliance with a pilot light is present.

While performing any work on the fuel system, wear safety glasses, and have a

suitable (Class B) fire extinguisher on

hand. If you spill any fuel on your skin,

rinse it off immediately with soap and

water.

1

On fuel injection engines, an in-line fuel

filter is provided in the fuel pump outlet line.

The filter is located in the engine compartment

either below and behind the battery, or on the

left-hand side of the engine compartment

bulkhead. The renewal procedure is the same

for both locations. The filter performs a vital

role in keeping dirt and other foreign matter

out of the fuel system, and so must be renewed at regular intervals, or whenever you

have reason to suspect that it may be

clogged. It is always unpleasant working

under a vehicle - pressure-washing or hosing

clean the underbody in the filter’s vicinity will

make working conditions more tolerable, and

will reduce the risk of getting dirt into the fuel

system.

2

Depressurise the fuel system as described

in the relevant Part of Chapter 4.

3 Disconnect the battery negative (earth) lead

(refer to Chapter 5A, Section 1), then position

a suitable container beneath the fuel filter to

catch escaping fuel. Have a rag handy to soak

procarmanuals.com

http://vnx.su

Page 140 of 296

Crankshaft position sensor

40Refer to Chapter 5B.

Coolant temperature sensor

41Refer to Chapter 3.

Inlet air temperature sensor

42Remove the air inlet components as

described in Section 4.

43 Releasing its clip, unplug the sensor’s

electrical connector, then unscrew the sensor

from the inlet manifold (see illustration).

44 Refitting is the reverse of the removal

procedure.

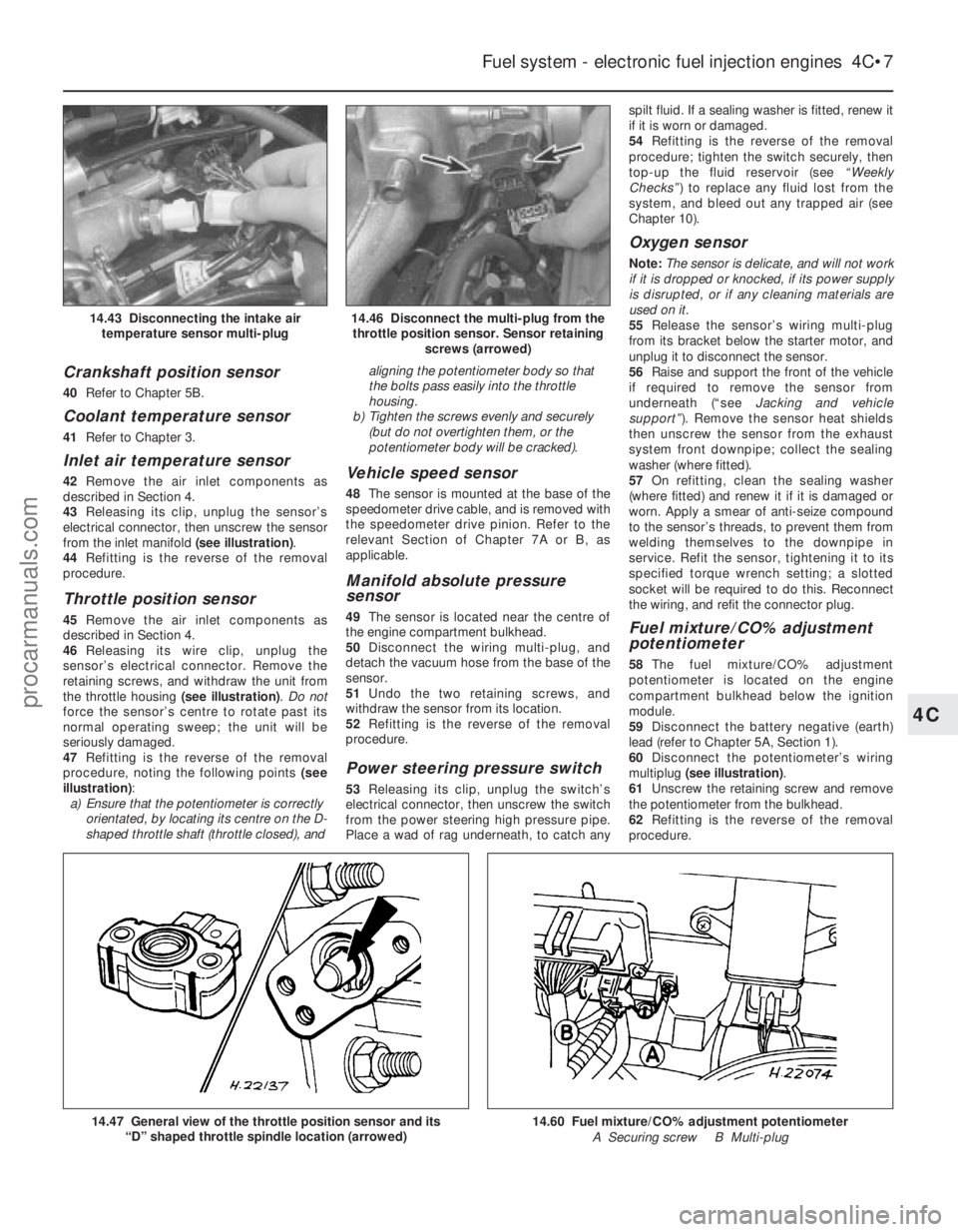

Throttle position sensor

45 Remove the air inlet components as

described in Section 4.

46 Releasing its wire clip, unplug the

sensor’s electrical connector. Remove the

retaining screws, and withdraw the unit from

the throttle housing (see illustration). Do not

force the sensor’s centre to rotate past its

normal operating sweep; the unit will be

seriously damaged.

47 Refitting is the reverse of the removal

procedure, noting the following points (see

illustration) :

a) Ensure that the potentiometer is correctly

orientated, by locating its centre on the D-

shaped throttle shaft (throttle closed), and aligning the potentiometer body so that

the bolts pass easily into the throttle

housing.

b) Tighten the screws evenly and securely

(but do not overtighten them, or the

potentiometer body will be cracked).

Vehicle speed sensor

48 The sensor is mounted at the base of the

speedometer drive cable, and is removed with

the speedometer drive pinion. Refer to the

relevant Section of Chapter 7A or B, as

applicable.

Manifold absolute pressure

sensor

49 The sensor is located near the centre of

the engine compartment bulkhead.

50 Disconnect the wiring multi-plug, and

detach the vacuum hose from the base of the

sensor.

51 Undo the two retaining screws, and

withdraw the sensor from its location.

52 Refitting is the reverse of the removal

procedure.

Power steering pressure switch

53 Releasing its clip, unplug the switch’s

electrical connector, then unscrew the switch

from the power steering high pressure pipe.

Place a wad of rag underneath, to catch any spilt fluid. If a sealing washer is fitted, renew it

if it is worn or damaged.

54

Refitting is the reverse of the removal

procedure; tighten the switch securely, then

top-up the fluid reservoir (see “Weekly

Checks” ) to replace any fluid lost from the

system, and bleed out any trapped air (see

Chapter 10).

Oxygen sensor

Note: The sensor is delicate, and will not work

if it is dropped or knocked, if its power supply

is disrupted, or if any cleaning materials are

used on it.

55 Release the sensor’s wiring multi-plug

from its bracket below the starter motor, and

unplug it to disconnect the sensor.

56 Raise and support the front of the vehicle

if required to remove the sensor from

underneath (“see Jacking and vehicle

support” ). Remove the sensor heat shields

then unscrew the sensor from the exhaust

system front downpipe; collect the sealing

washer (where fitted).

57 On refitting, clean the sealing washer

(where fitted) and renew it if it is damaged or

worn. Apply a smear of anti-seize compound

to the sensor’s threads, to prevent them from

welding themselves to the downpipe in

service. Refit the sensor, tightening it to its

specified torque wrench setting; a slotted

socket will be required to do this. Reconnect

the wiring, and refit the connector plug.

Fuel mixture/CO% adjustment

potentiometer

58 The fuel mixture/CO% adjustment

potentiometer is located on the engine

compartment bulkhead below the ignition

module.

59 Disconnect the battery negative (earth)

lead (refer to Chapter 5A, Section 1).

60 Disconnect the potentiometer’s wiring

multiplug (see illustration) .

61 Unscrew the retaining screw and remove

the potentiometer from the bulkhead.

62 Refitting is the reverse of the removal

procedure.

Fuel system - electronic fuel injection engines 4C•7

14.46 Disconnect the multi-plug from the throttle position sensor. Sensor retaining screws (arrowed)14.43 Disconnecting the intake airtemperature sensor multi-plug

14.60 Fuel mixture/CO% adjustment potentiometer

A Securing screw B Multi-plug14.47 General view of the throttle position sensor and its “D” shaped throttle spindle location (arrowed)

4C

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 177 of 296

1 General information

The braking system is of the diagonally

split, dual-circuit hydraulic type, with servo

assistance to the front disc brakes and rear

drum brakes. The dual-circuit hydraulic

system is a safety feature - in the event of a

malfunction somewhere in one of the

hydraulic circuits, the other circuit continues

to operate, providing at least some braking

effort. Under normal circumstances, both

brake circuits operate in unison, to provide

efficient braking.

The master cylinder (and the vacuum servo

unit to which it is bolted) is located on the left-

hand side of the bulkhead in the engine

compartment. On all right-hand drive variants,

they are jointly operated via a transverse

cross-link from the brake pedal.

Brake pressure control valves are fitted in-

line to each rear brake circuit, their function

being to regulate the braking force available at

each rear wheel, reducing the possibility of

the rear wheels locking up under heavy

braking. Courier models also have a “light-

laden” valve incorporated into the rear braking

circuits for the same reason. The front brake discs are of the ventilated

type on XR2i and ABS-equipped models, with

solid discs fitted on all other models. The front

brake calipers are of single sliding piston type

mounted on the front spindle carriers each

side. Each rear brake shoe assembly is operated

by a twin-piston wheel cylinder. The leading

brake shoe in each brake unit has a thicker

lining than the trailing shoe, so that they wear

proportionally. To take up the brake

adjustment as the linings wear, each rear

brake assembly incorporates an automatic

adjuster mechanism. The cable-operated handbrake acts on

both rear brakes, to provide an independent

means of brake operation. An anti-lock braking system (ABS) is

available on some models, and has many of

the components in common with the conventional braking system. Further details

on ABS can be found later in this Chapter.

Note:

When servicing any part of the system,

work carefully and methodically; also observe

scrupulous cleanliness when overhauling any

part of the hydraulic system. Always renew

components (in axle sets, where applicable) if

in doubt about their condition, and use only

genuine Ford replacement parts, or at least

those of known good quality. Note the

warnings given in “Safety first” and at relevant

points in this Chapter concerning the dangers

of asbestos dust and hydraulic fluid.

2 Front brake pads - renewal

2

Warning: Disc brake pads MUST

be renewed on both front

wheels at the same time -

NEVER renew the pads on only

one wheel, as uneven braking may result.

The front brake calipers will be of Bendix

or Teves manufacture, and if they or their

component parts require renewal, ensure

that the correct type is fitted. Dust created

by wear of the pads may contain asbestos,

which is a health hazard. Never blow it out

with compressed air, and do not inhale any

of it. DO NOT use petroleum-based

solvents to clean brake parts - use brake

cleaner or methylated spirit only. DO NOT allow any brake fluid, oil or grease to

contact the brake pads or disc. Also refer

to the warning in Section 13 concerning

the dangers of hydraulic fluid.

1

Chock the rear wheels then jack up the

front of the car and support it on axle stands

(see “Jacking and Vehicle Support” ). Remove

the front roadwheels.

2 Hold the caliper support spring with a pair

of pliers, and prise it out of its location in the

caliper housing using a screwdriver (see

illustration) .

3 Prise free the blanking plugs from the

caliper upper and lower mounting bolts.

Unscrew the bolts, then withdraw the caliper

from the anchor bracket (see illustrations).

Suitably support the caliper to avoid straining

the brake hose.

Torque wrench settingsNm lbf ft

Master cylinder to servo . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. 20 to 25 15 to 18

Servo to mounting bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35 to 45 26 to 33

Pedal-to-servo cross-link brackets to bulkhead . . . . . . . . . . . . . . . . . . 20 to 25 15 to 18

Rear drum/hub to axle flange bolts* . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56 to 76 41 to 56

Caliper-to-spindle carrier (anchor bracket) bolts . . . . . . . . . . . . . . . . . . 50 to 66 37 to 49

Caliper piston housing retaining bolts . . . . . . . . . . . . . . . . . . . . . . . . . . 20 to 25 15 to 18

Load-apportioning valves to bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 to 25 15 to 18

Load-apportioning valve bracket to vehicle . . . . . . . . . . . . . . . . . . . . . . 21 to 28 15 to 21

Load-apportioning valve adjustment screw . . . . . . . . . . . . . . . . . . . . . . 12 to 16 9 to 12

Load-apportioning valve-to-axle beam link rod nut . . . . . . . . . . . . . . . . 21 to 28 15 to 21

Modulator pivot and adjusting clamp bolts . . . . . . . . . . . . . . . . . . . . . . 22 to 28 16 to 21

Modulator drivebelt cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

8 to 12 6 to 9

Roadwheel nuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . 70 to 110 52 to 74

*Applies to all models except Courier. No figures are quoted by the manu\

facturers for Courier models.

9•2 Braking system

2.3b . . . unscrew the bolts then withdraw the caliper from the anchor bracket2.3a Remove the rubber blanking plugs foraccess to the caliper mounting bolts . . .

2.2 Prise out the caliper support spring with a screwdriver

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 199 of 296

16Using a suitable punch, tap the outer

bearing outer race at diametrically-opposed

points and remove the bearing assembly from

the spindle carrier. Do not allow the bearing to

tilt during its withdrawal from the housing, or it

will jam and possibly damage the surface of

the bore. Any burrs left in a bearing bore will

prevent the new bearing from seating

correctly.

17 Turn the spindle carrier over and remove

the inner bearing assembly in the same way.

18 Thoroughly clean the bearing bore and

hub, then secure the spindle carrier in the vice

in an upright position.

19 Draw the new outer bearing assembly into

the spindle carrier using a length of metal tube

of diameter slightly less than the outer race.

Do not apply any pressure to the inner race.

Alternatively, a long threaded rod or bolt, a nut

and large flat washers may be used to draw

the bearing into position (see illustration 3.7).

Once the bearing has been installed, take care

not to dislodge the inner race and seal.

20 Using the same method as for the outer

bearing, draw in the new inner bearing

assembly from the other side of the spindle

carrier. Again, take care not to dislodge the

inner race and seal once the bearing is in

position.

21 Using the same tooling arrangement as

before, and with the metal tube or washers

contacting the inner bearing inner race, draw

the hub fully into the bearings. Alternatively, if

a press is available, support the hub face

down on the press bed and using a metal tube

in contact with the inner bearing inner race,

press the spindle carrier onto the hub.

22 Check that the hub spins freely in the

bearings, then refit the spindle carrier as

described in Section 2.4 Front suspension strut -

removal and refitting

3

Removal

1 Chock the rear wheels then jack up the

front of the car and support it on axle stands

(see “Jacking and Vehicle Support” ). Remove

the appropriate front roadwheel.

2 Open and support the bonnet. Prise free

the protective cap from the suspension strut

top-mount retaining nut, then slacken the nut,

but do not remove it at this stage (see

illustrations) . Hold the strut piston rod with

an Allen key to prevent the rod from turning as

the nut is slackened.

3 Detach the front brake hose from the

support bracket on the strut.

4 Where applicable, unbolt and detach the

anti-roll bar connecting link from the strut

bracket.

5 Undo the two bolts securing the front brake

caliper anchor bracket to the spindle carrier.

Slide the caliper assembly, complete with

brake pads off the disc and spindle carrier

and suspend the caliper within the wheelarch

with a length of strong wire, to prevent the

flexible brake hose from straining.

6 Unscrew and remove the strut-to-spindle

carrier pinch-bolt.

7 Prise open the spindle carrier-to-strut joint

using a stout screwdriver, and separate the

carrier from the strut. Tap the carrier

downwards using a soft-faced hammer to

release it from the strut if necessary. Once the

two components are separated, support the

lower suspension arm to avoid straining the

CV joints. 8

Support the weight of the strut underneath,

and unscrew the previously slackened top-

mount retaining nut and lift off the upper cup

seat mounting. Lower the strut and remove it

from under the wheel arch.

Refitting

9 Locate the strut through the wheel arch and

refit the upper cup seat mounting and top-

mount retaining nut. Do not tighten the nut at

this stage.

10 Apply leverage to the spindle carrier slot

so that the spindle carrier can be refitted to

the base of the suspension strut. Refit the

suspension strut to spindle carrier pinch-bolt

and tighten to the specified torque.

11 Tighten the suspension strut top-mount

retaining nut to the specified torque, using an

Allen key to prevent the piston rod from

rotating. The final torque will have to be

applied without the use of the Allen key unless

a suitable open-ended torque wrench adapter

is available. Refit the cap over the nut.

12 Refit the brake caliper assembly to the

spindle carrier, and tighten the caliper anchor

bracket bolts to the specified torque (see

Chapter 9).

13 Refit the bolt to secure the brake hose

bracket to the suspension strut, and fully

tighten.

14 Remove the support from under the lower

suspension arm.

15 Reconnect the anti-roll bar connecting

link to the strut bracket, where applicable,

tightening the nut to the specified torque.

16 Refit the roadwheel, remove the axle

stands and lower the vehicle to the ground.

17 Tighten the roadwheel nuts according to

the specified torque.

5 Front suspension strut -

dismantling, examination and

reassembly

4

Warning: Before attempting to

dismantle the suspension strut,

a suitable tool to hold the coil

spring in compression must be

obtained. Adjustable coil spring

compressors which can be positively

secured to the spring coils are readily

available, and are recommended for this

operation. Any attempt to dismantle the

strut without such a tool is likely to result

in damage or personal injury.

Dismantling

1 With the strut removed from the vehicle,

clean away all external dirt, then mount it

upright in a vice.

2 Fit the spring compressor tool (ensuring

that it is fully engaged) and compress the coil

spring until all tension is relieved from the

upper mounting (see illustration) .

3 Remove the spring retaining nut, then

withdraw the lower cup seat mounting, thrust

10•6 Suspension and steering

5.2 Typical pair of coil spring compressors in use

4.2b Slackening the front suspension strut

top-mount retaining nut whilst preventing the piston rod from turning4.2a Removing cap from front suspensionstrut top-mount retaining nut

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 202 of 296

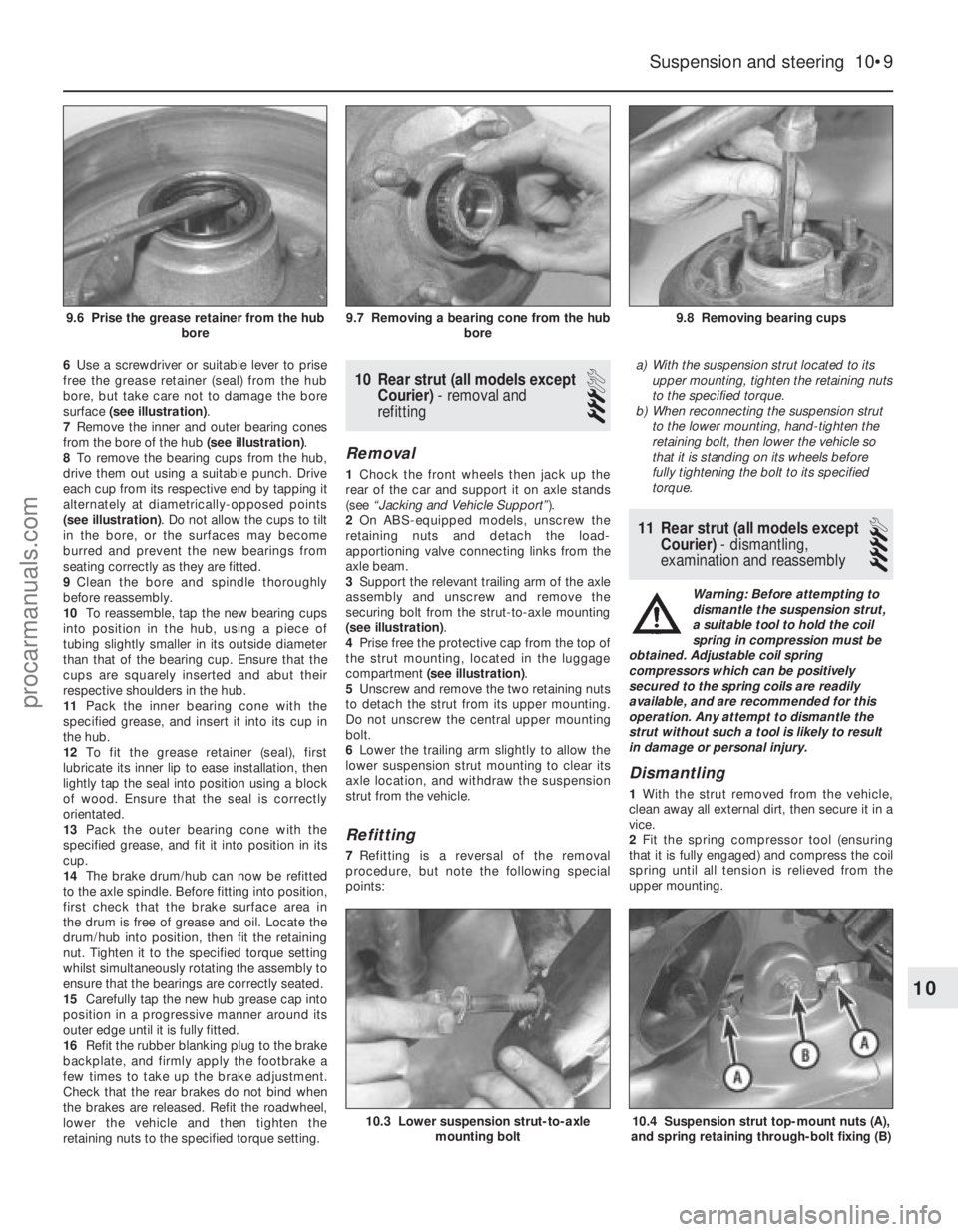

6Use a screwdriver or suitable lever to prise

free the grease retainer (seal) from the hub

bore, but take care not to damage the bore

surface (see illustration) .

7 Remove the inner and outer bearing cones

from the bore of the hub (see illustration).

8 To remove the bearing cups from the hub,

drive them out using a suitable punch. Drive

each cup from its respective end by tapping it

alternately at diametrically-opposed points

(see illustration) . Do not allow the cups to tilt

in the bore, or the surfaces may become

burred and prevent the new bearings from

seating correctly as they are fitted.

9 Clean the bore and spindle thoroughly

before reassembly.

10 To reassemble, tap the new bearing cups

into position in the hub, using a piece of

tubing slightly smaller in its outside diameter

than that of the bearing cup. Ensure that the

cups are squarely inserted and abut their

respective shoulders in the hub.

11 Pack the inner bearing cone with the

specified grease, and insert it into its cup in

the hub.

12 To fit the grease retainer (seal), first

lubricate its inner lip to ease installation, then

lightly tap the seal into position using a block

of wood. Ensure that the seal is correctly

orientated.

13 Pack the outer bearing cone with the

specified grease, and fit it into position in its

cup.

14 The brake drum/hub can now be refitted

to the axle spindle. Before fitting into position,

first check that the brake surface area in

the drum is free of grease and oil. Locate the

drum/hub into position, then fit the retaining

nut. Tighten it to the specified torque setting

whilst simultaneously rotating the assembly to

ensure that the bearings are correctly seated.

15 Carefully tap the new hub grease cap into

position in a progressive manner around its

outer edge until it is fully fitted.

16 Refit the rubber blanking plug to the brake

backplate, and firmly apply the footbrake a

few times to take up the brake adjustment.

Check that the rear brakes do not bind when

the brakes are released. Refit the roadwheel,

lower the vehicle and then tighten the

retaining nuts to the specified torque setting.10 Rear strut (all models except Courier) - removal and

refitting

3

Removal

1 Chock the front wheels then jack up the

rear of the car and support it on axle stands

(see “Jacking and Vehicle Support” ).

2 On ABS-equipped models, unscrew the

retaining nuts and detach the load-

apportioning valve connecting links from the

axle beam.

3 Support the relevant trailing arm of the axle

assembly and unscrew and remove the

securing bolt from the strut-to-axle mounting

(see illustration) .

4 Prise free the protective cap from the top of

the strut mounting, located in the luggage

compartment (see illustration) .

5 Unscrew and remove the two retaining nuts

to detach the strut from its upper mounting.

Do not unscrew the central upper mounting

bolt.

6 Lower the trailing arm slightly to allow the

lower suspension strut mounting to clear its

axle location, and withdraw the suspension

strut from the vehicle.

Refitting

7 Refitting is a reversal of the removal

procedure, but note the following special

points: a)

With the suspension strut located to its

upper mounting, tighten the retaining nuts

to the specified torque.

b) When reconnecting the suspension strut

to the lower mounting, hand-tighten the

retaining bolt, then lower the vehicle so

that it is standing on its wheels before

fully tightening the bolt to its specified

torque.

11 Rear strut (all models except

Courier) - dismantling,

examination and reassembly

4

Warning: Before attempting to

dismantle the suspension strut,

a suitable tool to hold the coil

spring in compression must be

obtained. Adjustable coil spring

compressors which can be positively

secured to the spring coils are readily

available, and are recommended for this

operation. Any attempt to dismantle the

strut without such a tool is likely to result

in damage or personal injury.

Dismantling

1 With the strut removed from the vehicle,

clean away all external dirt, then secure it in a

vice.

2 Fit the spring compressor tool (ensuring

that it is fully engaged) and compress the coil

spring until all tension is relieved from the

upper mounting.

Suspension and steering 10•9

9.8 Removing bearing cups9.7 Removing a bearing cone from the hub bore9.6 Prise the grease retainer from the hubbore

10.4 Suspension strut top-mount nuts (A),

and spring retaining through-bolt fixing (B)10.3 Lower suspension strut-to-axle mounting bolt

10

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 203 of 296

3Unscrew and remove the upper mounting

through-bolt and nut.

4 Withdraw the upper mounting cup and the

spring seat.

5 The suspension strut and coil spring can now

be separated. If the coil spring or strut is to be

renewed, the original coil spring must be

released from the compressor. If it is to be re-

used, the coil spring can be left in compression.

Examination

6 With the strut assembly now completely

dismantled, examine the mounting

components for wear, damage or deformation.

Renew any of the components as necessary.

7 Examine the strut for signs of fluid leakage.

Check the strut piston for signs of pitting

along its entire length, and check the strut

body for signs of damage or deterioration of

the mountings. Test the operation of the strut,

holding it in an upright position, by moving the

piston through a full stroke, and then through

short strokes of 50 to 100 mm. In both cases,

the resistance felt should be smooth and

continuous. If the resistance is jerky, or

uneven, or if there is any visible sign of wear

or damage to the strut, renewal is necessary.

Reassembly

8 Reassembly is a reversal of the dismantling

procedure but note the following points: a) When the spring is located over the

suspension strut, the spring seat, cup and

through-bolt fitted, tighten the retaining

bolt to the specified torque.

b) When reassembled, check that the upper

and lower spring tails are correctly

engaged with their spring seats before

removing the spring compressor.

12 Rear axle (all models except

Courier) -

removal and refitting

3

Removal

1 Chock the front wheels then jack up the

rear of the car and support it on axle stands

(see “Jacking and Vehicle Support” ). Remove

the rear roadwheels.

2 Refer to Chapter 9 for details, and disconnect

the handbrake cable equaliser from the primary

cable. Remove the handbrake rear cable from

its adjuster and its fixed body locations.

3 Disconnect the rear brake flexible hydraulic

brake hoses from their rigid line connections.

Clamp the hoses before disconnecting them,

to minimise the fluid loss and air entry into the

hydraulic system (see Chapter 9 for details).

4 On ABS-equipped models, undo the

retaining nuts and detach the ABS load-

apportioning valve operating links from the

axle beam. Do not remove the load-

apportioning valve (see Chapter 9).

5 Locate suitable jacks or axle stands under

the axle beam to support its weight (not to lift

it), then unscrew the four mounting bracket

bolts each side. 6

Unscrew and remove the strut-to-axle

mounting bolt each side.

7 Check that all associated fittings are clear,

then lower the axle and remove it from under

the vehicle.

8 If the twist beam axle has been damaged, it

must be renewed. Refer to Chapter 9 for

details on removing the rear brakes from the

axle. To remove the front mounting/pivot

brackets from the axle, unscrew the pivot bolt.

Refitting

9 Refitting is a reversal of the removal

procedure, but note the following: a) Reconnect the axle at the front floor mountings first, and tighten the retaining

bolts to the specified torque.

b) Reconnect the axle to the suspension struts, but do not fully retighten the securing

bolts until after the vehicle is lowered to the

ground and is standing on its wheels.

c) Ensure that all brake fluid line connections are clean before reconnecting them. Refer

to the appropriate Sections in Chapter 9

for specific details on reconnecting the

brake lines, bleeding the brake hydraulic

system, and for reconnecting the

handbrake cable and its adjustment.

d) When the vehicle is lowered and is standing

on its wheels, tighten the suspension

fastenings to their specified torque settings.

13 Rear axle pivot bushes (all

models except Courier) -

renewal

3

Note: Two different types of pivot bushes

have been fitted during the course of Fiesta

production. It is understood that once stocks

of the early type are exhausted, only the latter

type will be supplied by Ford parts dealers. If

renewing pivot bushes on a pre-April 1990

model, and only the later type bushes are

available, fit the new bushes as described

from paragraph 15 onward.

Pre-April 1990 models

1 Chock the front wheels then jack up the

rear of the car and support it on axle stands

(see “Jacking and Vehicle Support” ).2

Position a suitable support (preferably

adjustable) under the axle twist beam so that

it is capable of carrying the weight of the axle

(not the weight of the vehicle).

3 On ABS-equipped models, undo the

retaining nuts and detach the ABS load-

apportioning valve operating links from the

axle beam. Do not remove the load-

apportioning valve (see Chapter 9).

4 Unscrew the nuts, withdraw the pivot bolts,

then lower the rear axle so that the bushes are

clear of their mounting brackets (see

illustration) . Take care not to allow the brake

pipes to become distorted and stretched - if

necessary, disconnect the hydraulic lines (see

Chapter 9 for details).

5 Undo the four body mounting bracket bolts

and remove the brackets.

6 Using a soft-faced hammer and a suitable

punch or drift, drive the bushes from their

locations, taking care not to raise any burrs on

the trailing arm eyes.

7 To fit the new bushes, obtain a steel tube of

a diameter slightly less than that of the bush

location in the axle, various flat washers and a

long bolt and nut.

8 Place the new bush in position in its axle

location with the bush collar nearest to the

outer edge of the vehicle. The bush must be

installed with its voids positioned as shown

(see illustration) . Using the steel tube,

washers, long bolt and nut, draw the bush

inwards towards the centre of the vehicle (see

illustration) . Care should be taken to avoid

damage to the bush and to obtain correct

10•10 Suspension and steering

13.8b Fitting pivot bush with its collar

(arrowed) towards the outer edge of the vehicle13.8a Correct pivot bush positioning intrailing arm

A Left-hand side B Right-hand side

13.4 Pivot bush bolt (A) and body mounting bracket bolts (B)

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 210 of 296

Refitting

All models

38Refitting is a reversal of removal, bearing

in mind the following points:

a) Tighten all nuts and bolts to the specified torque. Remove the plugs from the

disconnected pipes, hoses and unions

and ensure that the pipes are located

correctly so that they do not foul any

surrounding components.

b) Refit the auxiliary drivebelt as described in

Chapter 1.

c) Where drained, refill the cooling system as described in Chapter 1.

d) Refit or reconnect any additional

components removed for access as

described in the relevant Sections and

Chapters of this manual.

e) On completion, bleed the power steering

hydraulic system as described in Section

27. Check for any signs of fluid leakage

from the system hoses and connections.

26 Power steering fluid cooler -

removal and refitting

2

Removal

1 Disconnect the battery negative (earth) lead

(refer to Chapter 5A, Section 1).

2 Position a suitable container beneath the

power steering fluid cooler hose connections,

then disconnect the hoses at the quick-fit

couplings on the fluid cooler. Allow the fluid to

drain from the hose and reservoir into the

container.

3 Plug the exposed ends of the hose and the

reservoir, to prevent the ingress of dirt and

excessive fluid loss.

4 Refer to Chapter 11 and remove the bonnet

lock assembly and the front bumper.

5 Undo the bolts securing the cooler side

support bracket and the bonnet lock stay, and

remove the fluid cooler and bonnet lock stay

as an assembly.

6 Undo the two bolts and remove the stay

from the fluid cooler.

Refitting

7 Refitting is a reversal of removal. On

completion, bleed the power steering

hydraulic system as described in Section 27.

27 Power steering hydraulic system - bleeding

2

1Following any operation in which the power

steering fluid lines have been disconnected,

the power steering system must be bled to

remove any trapped air.

2 With the front wheel in the straight-ahead

position, check the power steering fluid level

in the reservoir and, if low, top-up with fresh fluid to the “MAX” or “MAX COLD” level mark.

Pour the fluid slowly to prevent air bubbles

forming, and use only the specified fluid (refer

to

“Lubricants, fluids and tyre pressures” ).

3 Start the engine and allow it to idle. Check

the hoses and connections for leaks.

4 Stop the engine and recheck the fluid level.

Add more, if necessary, up to the “MAX” or

“MAX COLD” level mark.

5 Start the engine again, allow it to idle, then

bleed the system by slowly moving the

steering from lock-to-lock several times. This

should purge the system of all internal air.

However, if air remains in the system

(indicated by the steering operation being very

noisy), leave the vehicle overnight and repeat

the procedure again the next day.

6 If air still remains in the system, it may be

necessary to resort to the Ford method of

bleeding, which uses a vacuum pump and a

modified reservoir filler cap to which the pump

can be connected. Turn the steering to the

right until it is near the stop, then fit the

vacuum pump to the fluid reservoir, and apply

0.51 bars of vacuum. Maintain the vacuum for

a minimum of 5 minutes, then repeat

the procedure with the steering turned to the

left.

7 Keep the fluid level topped-up throughout

the bleeding procedure; note that the fluid

temperature increases, the level will rise.

8 On completion, switch the engine off, and

return the wheels to the straight-ahead

position.

28 Track rod end balljoint -

removal and refitting

2

Removal

1 Chock the rear wheels then jack up the

front of the car and support it on axle stands

(see “Jacking and Vehicle Support” ). Remove

the appropriate front roadwheel.

2 Using a suitable spanner, slacken the track

rod end balljoint locknut on the track rod by a

quarter of a turn only (see illustration). Holdthe balljoint stationary with another spanner

engaged with the flats at its inner end to

prevent it from turning.

3

Extract the split pin, then loosen off the

retaining nut. If the balljoint is to be renewed,

the nut can be fully removed. If the existing

balljoint is to be reconnected, the nut should

be slackened off a couple of turns only at first,

and left in position to protect the joint threads

as the joint is separated from the spindle

carrier. To release the tapered shank of the

joint from the spindle carrier, use a balljoint

separator tool as shown (see illustration). If

the joint is to be re-used, take care not to

damage the rubber dust cover when using a

separator tool.

4 Unscrew the balljoint from the track rod,

counting the number of turns necessary to

remove it.

Refitting

5 Screw the balljoint into the track rod the

number of turns noted during removal until the

balljoint just contacts the locknut. Now tighten

the locknut while holding the balljoint.

6 Engage the shank of the balljoint with the

spindle carrier arm, and refit the retaining nut.

Tighten the nut to the specified torque and

secure with a new split pin.

7 Refit the roadwheel, and lower the vehicle

to the ground.

8 Finally, have the front wheel toe setting

checked (see Section 29).

29 Wheel alignment and steering angles - general

information

4

General

1 A car’s steering and suspension geometry

is defined in four basic settings - all angles

are expressed in degrees (toe settings are

also expressed as a measurement); the

relevant settings are camber, castor, steering

axis inclination, and toe-setting. With the

exception of front wheel toe-setting, none of

these settings are adjustable.

Suspension and steering 10•17

28.3 Balljoint separator tool in position.

Note that the nut should be left loosely in position to protect the thread for re-use28.2 Track rod end balljoint showing the locknut (A) retaining flats (B) and the

balljoint-to-spindle carrier arm retaining

nut and split pin (C)

10

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 271 of 296

1595 Ford Fiesta Remake

The jack supplied with the vehicle tool kit

should only be used for changing the

roadwheels - see “Wheel changing” at the

front of this manual. When jacking up the

vehicle to carry out repair or maintenance

tasks, a pillar or trolley type jack of suitable

lifting capacity must be used, supplemented

with axle stands positioned only beneath the

appropriate points under the vehicle (see

illustration) . Note that the vehicle must never

be jacked up at the rear under the axle beam. The maximum kerb weight of the vehicle must

not be exceeded when jacking and supporting

the vehicle. Do not under any circumstances

jack up the rear of the vehicle under the rear axle.

Never work under, around or near a raised

vehicle unless it is adequately supported in at

least two places with axle stands.

The radio/cassette unit fitted as standard or

optional equipment may be equipped with a

built-in security code, to deter thieves. If the

power source to the unit is cut, the anti-theft

system will activate. Even if the power source

is immediately reconnected, the radio/

cassette unit will not function until the correct security code has been entered. Therefore,

if you do not know the correct security

code for the radio/cassette unit do not

disconnect either of the battery terminals, or

remove the radio/cassette unit from the

vehicle. To enter the correct security code, follow the instructions provided with the

radio/cassette player or vehicle handbook.

If an incorrect code is entered, the unit will

become locked, and cannot be operated.

If this happens, or if the security code is lost

or forgotten, seek the advice of your Ford

dealer.

Jacking and vehicle supportREF•5

REF

Radio/cassette unit anti-theft system - precaution

Underside view of the vehicle showing the jacking point locations

A Jacking points for trolley jack (always use a suitable block

of wood to protect the

vehicle body)

B Axle stand positions

C Jacking points for owner jack and wheel-free hoist

Buying spare parts

Spare parts are available from many

sources, including maker’s appointed

garages, accessory shops, and motor factors.

To be sure of obtaining the correct parts, it

will sometimes be necessary to quote the

vehicle identification number. If possible, it

can also be useful to take the old parts along

for positive identification. Items such as

starter motors and alternators may be

available under a service exchange scheme -

any parts returned should always be clean.

Our advice regarding spare part sources is

as follows.

Officially-appointed garages

This is the best source of parts which are

peculiar to your car, and which are not

otherwise generally available (eg badges,

interior trim, certain body panels, etc). It is

also the only place at which you should buy

parts if the vehicle is still under warranty.

Accessory shops

These are very good places to buy materials and components needed for the

maintenance of your car (oil, air and fuel

filters, spark plugs, light bulbs, drivebelts, oils

and greases, brake pads, touch-up paint, etc).

Components of this nature sold by a

reputable shop are of the same standard as

those used by the car manufacturer.

Besides components, these shops also sell

tools and general accessories, usually have

convenient opening hours, charge lower

prices, and can often be found not far from

home. Some accessory shops have parts

counters where the components needed for

almost any repair job can be purchased or

ordered.

Motor factors

Good factors will stock all the more

important components which wear out

comparatively quickly, and can sometimes

supply individual components needed for the

overhaul of a larger assembly (eg brake seals

and hydraulic parts, bearing shells, pistons,

valves, alternator brushes). They may also

handle work such as cylinder block reboring,

crankshaft regrinding and balancing, etc.

Tyre and exhaust specialists

These outlets may be independent, or

members of a local or national chain. They

frequently offer competitive prices when

compared with a main dealer or local garage,

but it will pay to obtain several quotes before

making a decision. When researching prices,

also ask what “extras” may be added - for

instance, fitting a new valve and balancing the

wheel are both commonly charged on top of

the price of a new tyre.

Other sources

Beware of parts or materials obtained from

market stalls, car boot sales or similar outlets.

Such items are not invariably sub-standard,

but there is little chance of compensation if

they do prove unsatisfactory. In the case of

safety-critical components such as brake

pads, there is the risk not only of financial loss

but also of an accident causing injury or

death. Second-hand components or assemblies

obtained from a car breaker can be a good

buy in some circumstances, but this sort of

purchase is best made by the experienced

DIY mechanic.

Buying spare parts

procarmanuals.com

http://vnx.su