weight FORD FIESTA 1989 Service Repair Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1989, Model line: FIESTA, Model: FORD FIESTA 1989Pages: 296, PDF Size: 10.65 MB

Page 37 of 296

(see illustration). Centralise the seal on the

shaft, then insert and tighten the housing

retaining bolts to the specified torque setting.

Refit the sump with reference to Section 11.

12 Check that the crankshaft rear flange

and the flywheel mating faces are clean, then

refit the flywheel as described in Section 16.

15 Engine/transmission mountings - inspection and

renewal

2

Inspection

1 The engine/transmission mountings seldom

require attention, but broken or deteriorated

mountings should be renewed immediately, or

the added strain placed on the driveline

components may cause damage or wear.

2 During the check, the engine/transmission

must be raised slightly, to remove its weight

from the mountings.

3 Chock the rear wheels then jack up the

front of the car and support it on axle stands

(see “Jacking and Vehicle Support” ). Position

a jack under the sump, with a large block of

wood between the jack head and the sump,

then carefully raise the engine/transmission

just enough to take the weight off the

mountings.

4 Check the mountings to see if the rubber is

cracked, hardened or separated from the metal components. Sometimes, the rubber

will split right down the centre.

5

Check for relative movement between each

mounting’s brackets and the

engine/transmission or body (use a large

screwdriver or lever to attempt to move the

mountings). If movement is noted, lower the

engine and check-tighten the mounting

fasteners.

Renewal

6 The engine mountings can be removed if

the weight of the engine/transmission is

supported by one of the following alternative

methods.

7 Either support the weight of the assembly

from underneath using a jack and a suitable

piece of wood between the jack saddle and

the sump or transmission (to prevent

damage), or from above by attaching a hoist

to the engine. A third method is to use a

suitable support bar with end pieces which

will engage in the water channel each side of

the bonnet lid aperture. Using an adjustable hook and chain connected to the engine, the

weight of the engine and transmission can

then be taken from the mountings.

Engine right-hand mounting

8

Unscrew and remove the mounting side

bolt from under the right-hand wheel arch

(see illustration) .

9 Unscrew and remove the mounting

retaining nut and washer from the suspension

strut cup retaining plate (see illustration).

10 Undo the three bolts securing the

mounting unit to the cylinder block. The

mounting unit and bracket can then be

lowered from the engine (see illustration).

11 Unbolt and remove the mounting from its

support bracket.

Transmission bearer and mountings

12 Unscrew and remove the two nuts

securing the mountings (front and rear) to the

transmission bearer (see illustration).

13 Support the transmission bearer, then

undo and remove the four retaining bolts from

the floorpan, two at the front and two at the

2A•10 HCS engine in-car repair procedures

15.12 Exploded view of the transmission bearer mountings

15.10 Undo the three bolts securing the

mounting assembly to the cylinder block

and withdraw the mounting

15.9 Unscrew and remove the mountingretaining nut and washer from the

suspension strut cup retaining plate15.8 Unscrew and remove the engine

mounting side bolt (arrowed) from under the wheel arch14.11b Fitting the rear oil seal housing

with a new gasket in position on the rear face of the cylinder block

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 57 of 296

clamp brackets and disconnect the pipe joint

union over the top of the cylinder head cover.

Place absorbent rags beneath the union as it

is disconnected to soak up escaping fluid and

plug the open unions to prevent dirt entry and

further fluid loss. Move the pipe(s) clear just

sufficiently to allow removal of the cylinder

head cover.

5Remove the timing belt upper cover (see

Section 7).

6 Disconnect the crankcase breather hose

from the cylinder head cover union (see

illustration) .

7 Unplug the HT leads from the spark plugs

and withdraw them, unclipping the leads from

the cover.

8 Working progressively, unscrew the

cylinder head cover retaining bolts, noting the

spacer sleeve and rubber seal at each, then

withdraw the cover (see illustration).

9 Discard the cover gasket; this mustbe

renewed whenever it is disturbed. Check that

the sealing faces are undamaged, and that the

rubber seal at each retaining bolt is

serviceable; renew any worn or damaged

seals.

Refitting

10 On refitting, clean the cover and cylinder

head gasket faces carefully, then fit a new

gasket to the cover, ensuring that it locates

correctly in the cover grooves (see illustration).

11 Refit the cover to the cylinder head, then

insert the rubber seal and spacer sleeve at

each bolt location (see illustration). Start allbolts finger-tight, ensuring that the gasket

remains seated in its groove.

12

Working in a diagonal sequence from the

centre outwards, and in two stages (see

Specifications), tighten the cover bolts to the

specified torque wrench setting.

13 Refit the HT leads, clipping them into

place so that they are correctly routed; each is

numbered, and can also be identified by the

numbering on its respective coil terminal.

14 Reconnect the crankcase breather hose,

and refit the timing belt upper cover.

Reconnect and adjust the accelerator cable,

then refit the air inlet components (see

Chapter 4B).

15 On models with power steering,

reconnect the high pressure fluid pipe then

bleed the system as described in Chapter 10.

5 Valve clearances -

general information

Refer to Section 5 in Part B of this Chapter.

6 Crankshaft pulley -

removal and refitting

1

Removal

1 Remove the auxiliary drivebelt - either

remove the drivebelt completely, or just secure it clear of the crankshaft pulley,

depending on the work to be carried out (see

Chapter 1).

2

If necessary, rotate the crankshaft until the

timing marks align (see Section 3).

3 The crankshaft must now be locked to

prevent its rotation while the pulley bolt is

unscrewed. To do this, remove the starter

motor (Chapter 5A) and lock the starter ring

gear teeth using a suitable screwdriver.

4 It should now just be possible to reach

between the crankshaft pulley and the body

side member to undo and remove the pulley

bolt and withdraw the pulley. However, if

additional working clearance is needed,

proceed as follows.

5 If not already done, chock the rear wheels

then jack up the front of the car and support it

on axle stands (see “Jacking and Vehicle

Support” ). Remove the front right-hand

roadwheel.

6 Support the weight of the

engine/transmission using a trolley jack, with

a wooden spacer to prevent damage to the

sump.

7 From above, unscrew the three bolts

securing the engine’s front right-hand (Y-

shaped) mounting bracket to the alternator

mounting bracket. Unfasten the engine’s rear

right-hand mounting from the body by

unscrewing first the single nut (and washer)

immediately to the rear of the timing belt

cover, then the bolt in the wheel arch

8 With the engine’s right-hand mountings

unfastened from the body, lower the

engine/transmission on the jack until a socket

spanner can be fitted to the crankshaft pulley

bolt.

9 With the starter ring gear teeth locked,

unscrew the crankshaft pulley bolt and

withdraw the pulley (see illustration).

Refitting

10Refitting is the reverse of the removal

procedure; ensure that the pulley’s keyway is

aligned with the crankshaft’s locating key, and

tighten the pulley bolt to the specified torque

wrench setting. If the engine mountings were

disturbed, use the jack to adjust the height of

the engine/transmission until the bolts (and

nut, with washer) can be refitted and screwed

2C•4 Zetec engine in-car repair procedures

6.9 Unscrew pulley bolt to release

crankshaft pulley4.11 Ensure rubber seal is fitted to eachcover bolt spacer, as shown

4.10 Ensure gasket is located correctly in cover groove4.8 Removing cylinder head cover

1595Ford Fiesta Remake

4.6 Disconnecting crankcase breather

hose from cylinder head cover unionprocarmanuals.com

http://vnx.su

Page 64 of 296

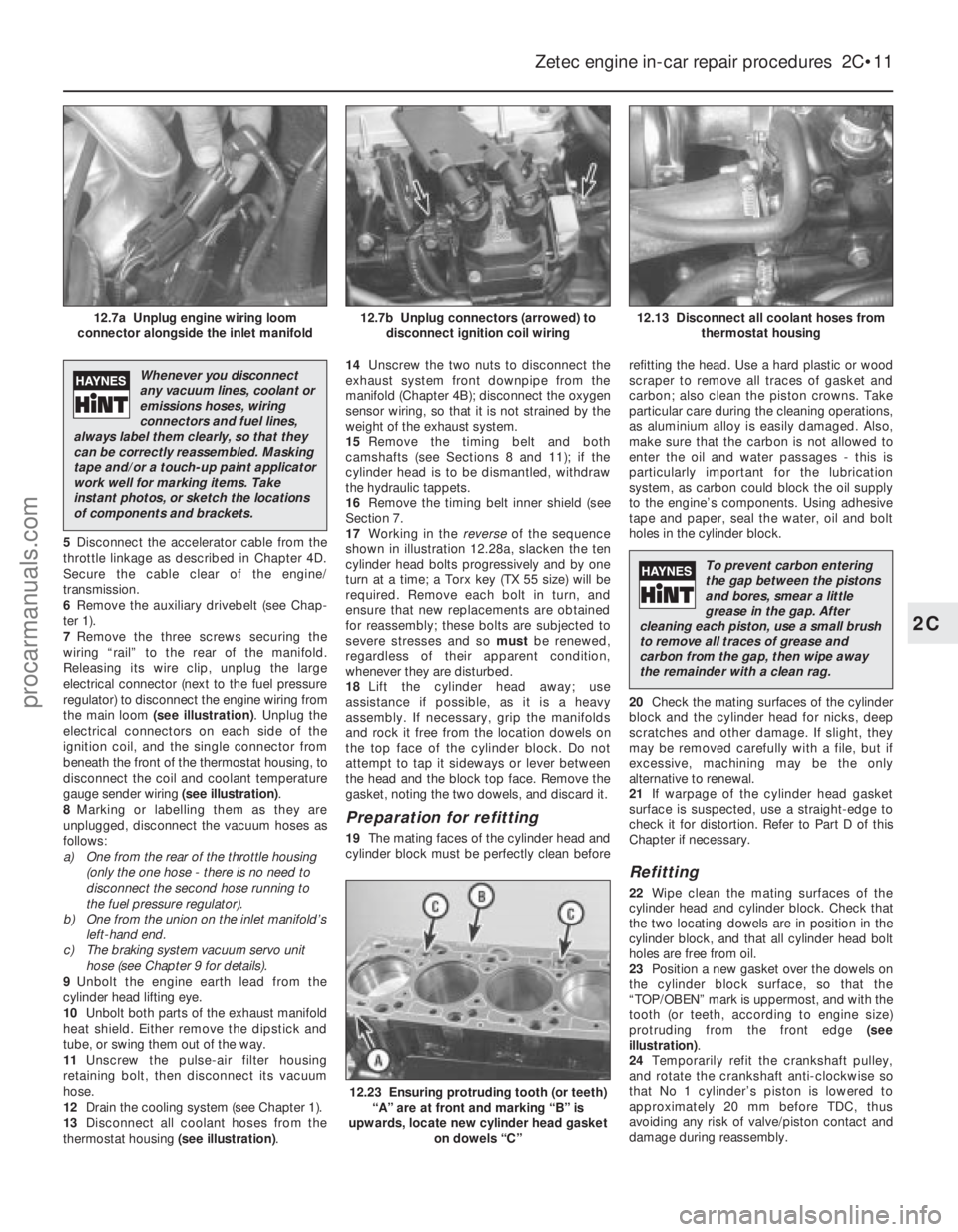

5Disconnect the accelerator cable from the

throttle linkage as described in Chapter 4D.

Secure the cable clear of the engine/

transmission.

6 Remove the auxiliary drivebelt (see Chap-

ter 1).

7 Remove the three screws securing the

wiring “rail” to the rear of the manifold.

Releasing its wire clip, unplug the large

electrical connector (next to the fuel pressure

regulator) to disconnect the engine wiring from

the main loom (see illustration) . Unplug the

electrical connectors on each side of the

ignition coil, and the single connector from

beneath the front of the thermostat housing, to

disconnect the coil and coolant temperature

gauge sender wiring (see illustration).

8 Marking or labelling them as they are

unplugged, disconnect the vacuum hoses as

follows:

a) One from the rear of the throttle housing

(only the one hose - there is no need to

disconnect the second hose running to

the fuel pressure regulator).

b) One from the union on the inlet manifold’s

left-hand end.

c) The braking system vacuum servo unit hose (see Chapter 9 for details).

9 Unbolt the engine earth lead from the

cylinder head lifting eye.

10 Unbolt both parts of the exhaust manifold

heat shield. Either remove the dipstick and

tube, or swing them out of the way.

11 Unscrew the pulse-air filter housing

retaining bolt, then disconnect its vacuum

hose.

12 Drain the cooling system (see Chapter 1).

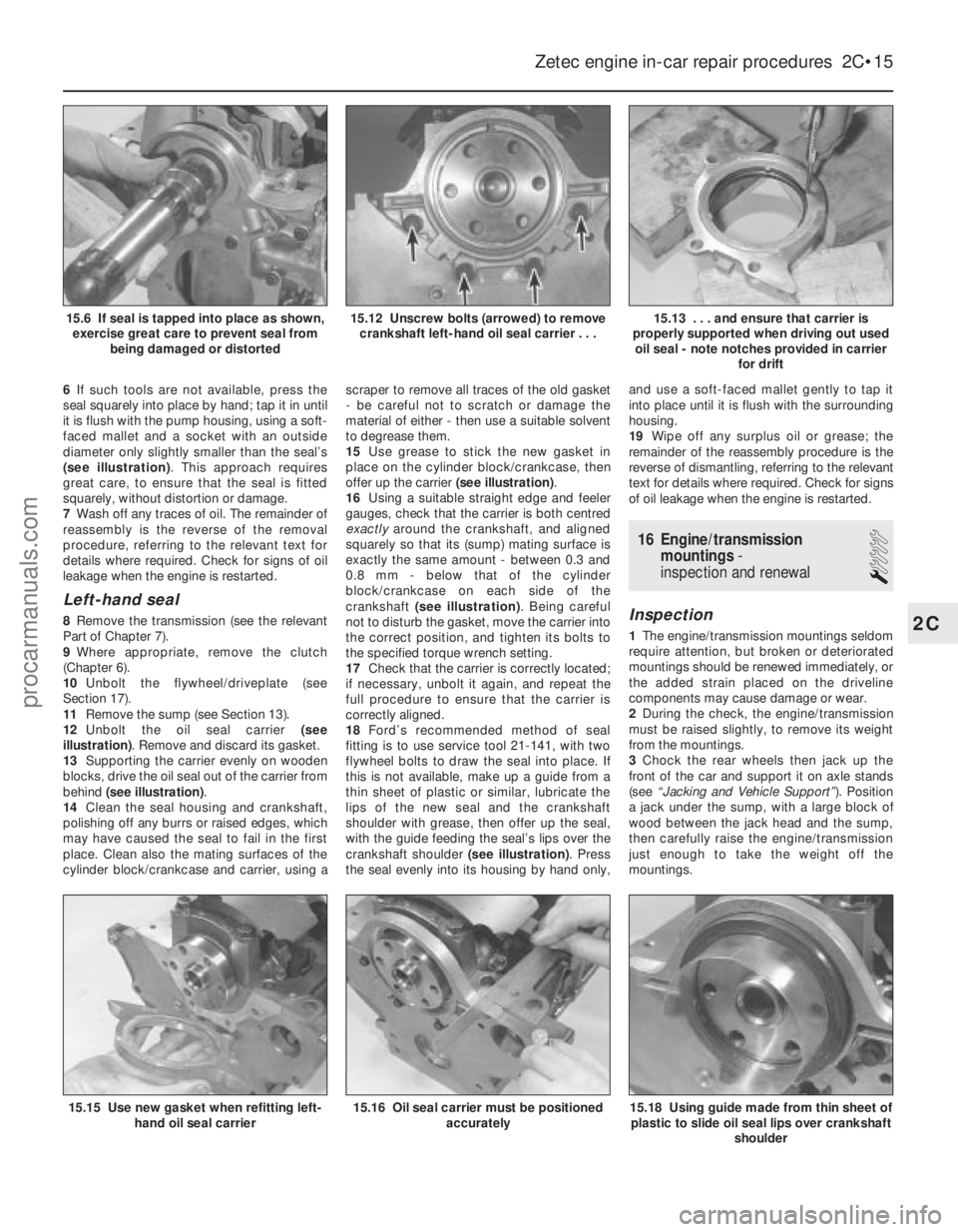

13 Disconnect all coolant hoses from the

thermostat housing (see illustration).14

Unscrew the two nuts to disconnect the

exhaust system front downpipe from the

manifold (Chapter 4B); disconnect the oxygen

sensor wiring, so that it is not strained by the

weight of the exhaust system.

15 Remove the timing belt and both

camshafts (see Sections 8 and 11); if the

cylinder head is to be dismantled, withdraw

the hydraulic tappets.

16 Remove the timing belt inner shield (see

Section 7.

17 Working in the reverseof the sequence

shown in illustration 12.28a, slacken the ten

cylinder head bolts progressively and by one

turn at a time; a Torx key (TX 55 size) will be

required. Remove each bolt in turn, and

ensure that new replacements are obtained

for reassembly; these bolts are subjected to

severe stresses and so mustbe renewed,

regardless of their apparent condition,

whenever they are disturbed.

18 Lift the cylinder head away; use

assistance if possible, as it is a heavy

assembly. If necessary, grip the manifolds

and rock it free from the location dowels on

the top face of the cylinder block. Do not

attempt to tap it sideways or lever between

the head and the block top face. Remove the

gasket, noting the two dowels, and discard it.

Preparation for refitting

19 The mating faces of the cylinder head and

cylinder block must be perfectly clean before refitting the head. Use a hard plastic or wood

scraper to remove all traces of gasket and

carbon; also clean the piston crowns. Take

particular care during the cleaning operations,

as aluminium alloy is easily damaged. Also,

make sure that the carbon is not allowed to

enter the oil and water passages - this is

particularly important for the lubrication

system, as carbon could block the oil supply

to the engine’s components. Using adhesive

tape and paper, seal the water, oil and bolt

holes in the cylinder block.

20

Check the mating surfaces of the cylinder

block and the cylinder head for nicks, deep

scratches and other damage. If slight, they

may be removed carefully with a file, but if

excessive, machining may be the only

alternative to renewal.

21 If warpage of the cylinder head gasket

surface is suspected, use a straight-edge to

check it for distortion. Refer to Part D of this

Chapter if necessary.

Refitting

22 Wipe clean the mating surfaces of the

cylinder head and cylinder block. Check that

the two locating dowels are in position in the

cylinder block, and that all cylinder head bolt

holes are free from oil.

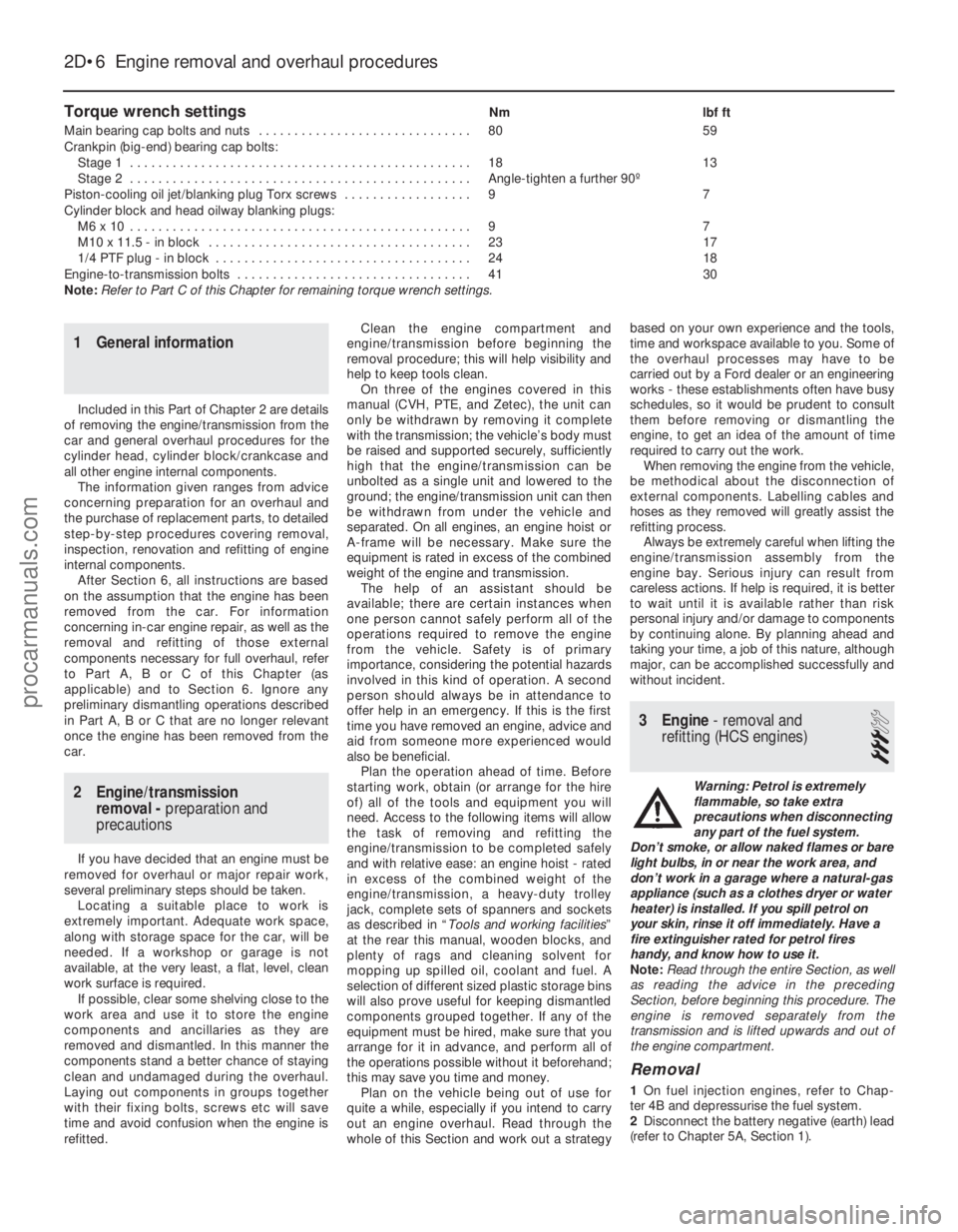

23 Position a new gasket over the dowels on

the cylinder block surface, so that the

“TOP/OBEN” mark is uppermost, and with the

tooth (or teeth, according to engine size)

protruding from the front edge (see

illustration) .

24 Temporarily refit the crankshaft pulley,

and rotate the crankshaft anti-clockwise so

that No 1 cylinder’s piston is lowered to

approximately 20 mm before TDC, thus

avoiding any risk of valve/piston contact and

damage during reassembly.

Zetec engine in-car repair procedures 2C•11

12.13 Disconnect all coolant hoses from thermostat housing12.7b Unplug connectors (arrowed) todisconnect ignition coil wiring12.7a Unplug engine wiring loom

connector alongside the inlet manifold

12.23 Ensuring protruding tooth (or teeth) “A” are at front and marking “B” is

upwards, locate new cylinder head gasket on dowels “C”

2C

1595Ford Fiesta Remake

Whenever you disconnect

any vacuum lines, coolant or

emissions hoses, wiring

connectors and fuel lines,

always label them clearly, so that they

can be correctly reassembled. Masking

tape and/or a touch-up paint applicator

work well for marking items. Take

instant photos, or sketch the locations

of components and brackets.

To prevent carbon entering

the gap between the pistons

and bores, smear a little

grease in the gap. After

cleaning each piston, use a small brush

to remove all traces of grease and

carbon from the gap, then wipe away

the remainder with a clean rag.

procarmanuals.com

http://vnx.su

Page 68 of 296

6If such tools are not available, press the

seal squarely into place by hand; tap it in until

it is flush with the pump housing, using a soft-

faced mallet and a socket with an outside

diameter only slightly smaller than the seal’s

(see illustration) . This approach requires

great care, to ensure that the seal is fitted

squarely, without distortion or damage.

7 Wash off any traces of oil. The remainder of

reassembly is the reverse of the removal

procedure, referring to the relevant text for

details where required. Check for signs of oil

leakage when the engine is restarted.

Left-hand seal

8 Remove the transmission (see the relevant

Part of Chapter 7).

9 Where appropriate, remove the clutch

(Chapter 6).

10 Unbolt the flywheel/driveplate (see

Section 17).

11 Remove the sump (see Section 13).

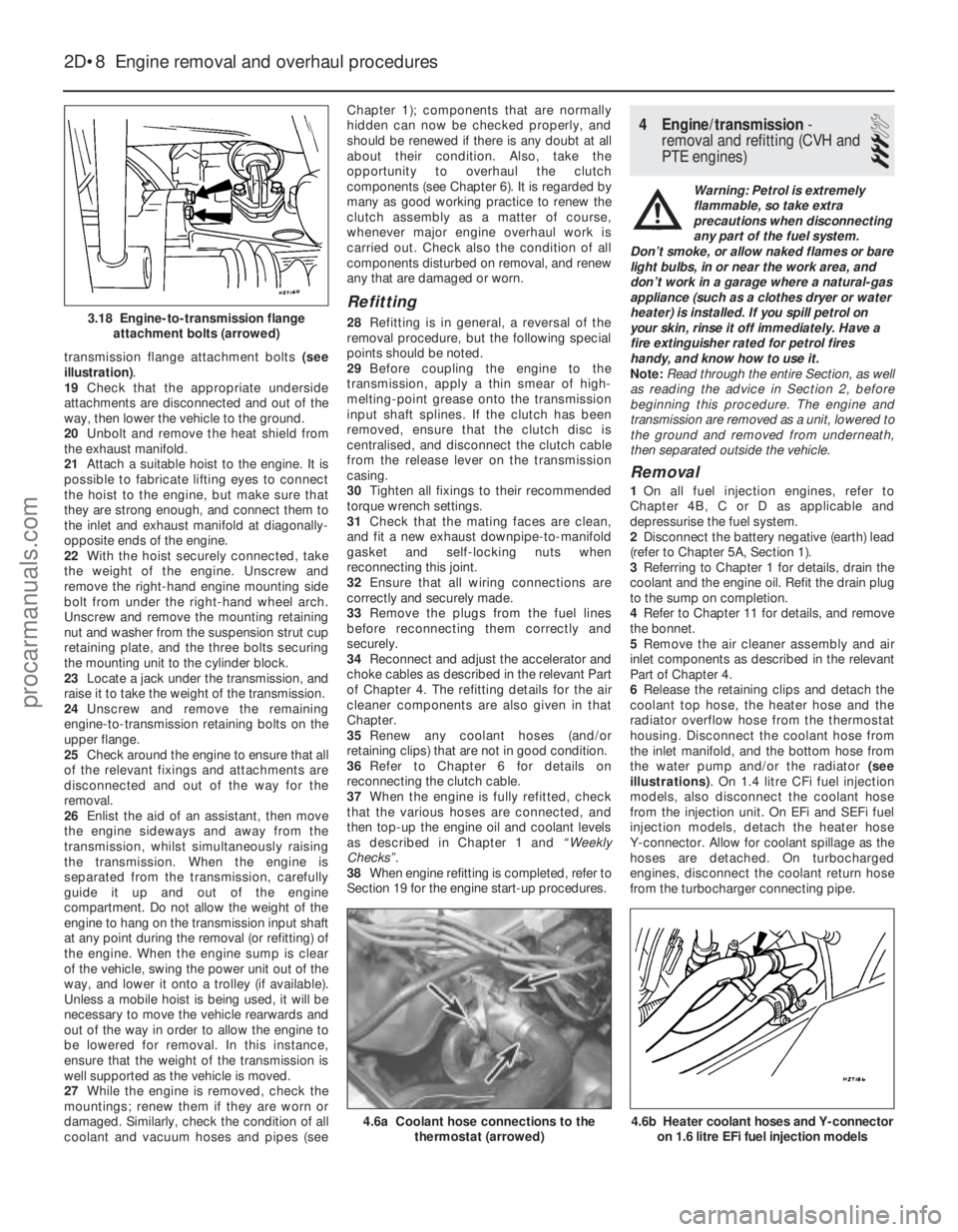

12 Unbolt the oil seal carrier (see

illustration) . Remove and discard its gasket.

13 Supporting the carrier evenly on wooden

blocks, drive the oil seal out of the carrier from

behind (see illustration) .

14 Clean the seal housing and crankshaft,

polishing off any burrs or raised edges, which

may have caused the seal to fail in the first

place. Clean also the mating surfaces of the

cylinder block/crankcase and carrier, using a scraper to remove all traces of the old gasket

- be careful not to scratch or damage the

material of either - then use a suitable solvent

to degrease them.

15

Use grease to stick the new gasket in

place on the cylinder block/crankcase, then

offer up the carrier (see illustration).

16 Using a suitable straight edge and feeler

gauges, check that the carrier is both centred

exactly around the crankshaft, and aligned

squarely so that its (sump) mating surface is

exactly the same amount - between 0.3 and

0.8 mm - below that of the cylinder

block/crankcase on each side of the

crankshaft (see illustration) . Being careful

not to disturb the gasket, move the carrier into

the correct position, and tighten its bolts to

the specified torque wrench setting.

17 Check that the carrier is correctly located;

if necessary, unbolt it again, and repeat the

full procedure to ensure that the carrier is

correctly aligned.

18 Ford’s recommended method of seal

fitting is to use service tool 21-141, with two

flywheel bolts to draw the seal into place. If

this is not available, make up a guide from a

thin sheet of plastic or similar, lubricate the

lips of the new seal and the crankshaft

shoulder with grease, then offer up the seal,

with the guide feeding the seal’s lips over the

crankshaft shoulder (see illustration) . Press

the seal evenly into its housing by hand only, and use a soft-faced mallet gently to tap it

into place until it is flush with the surrounding

housing.

19

Wipe off any surplus oil or grease; the

remainder of the reassembly procedure is the

reverse of dismantling, referring to the relevant

text for details where required. Check for signs

of oil leakage when the engine is restarted.

16 Engine/transmission mountings -

inspection and renewal

1

Inspection

1 The engine/transmission mountings seldom

require attention, but broken or deteriorated

mountings should be renewed immediately, or

the added strain placed on the driveline

components may cause damage or wear.

2 During the check, the engine/transmission

must be raised slightly, to remove its weight

from the mountings.

3 Chock the rear wheels then jack up the

front of the car and support it on axle stands

(see “Jacking and Vehicle Support” ). Position

a jack under the sump, with a large block of

wood between the jack head and the sump,

then carefully raise the engine/transmission

just enough to take the weight off the

mountings.

Zetec engine in-car repair procedures 2C•15

15.13 . . . and ensure that carrier is

properly supported when driving out used oil seal - note notches provided in carrier for drift15.12 Unscrew bolts (arrowed) to removecrankshaft left-hand oil seal carrier . . .15.6 If seal is tapped into place as shown,exercise great care to prevent seal from being damaged or distorted

15.18 Using guide made from thin sheet ofplastic to slide oil seal lips over crankshaft

shoulder15.16 Oil seal carrier must be positionedaccurately15.15 Use new gasket when refitting left-hand oil seal carrier

2C

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 69 of 296

4Check the mountings to see if the rubber is

cracked, hardened or separated from the

metal components. Sometimes, the rubber

will split right down the centre.

5 Check for relative movement between each

mounting’s brackets and the engine/

transmission or body (use a large screwdriver

or lever to attempt to move the mountings). If

movement is noted, lower the engine and

check-tighten the mounting fasteners.

Renewal

6 The engine mountings can be removed if

the weight of the engine/transmission is

supported by one of the following alternative

methods.

7 Either support the weight of the assembly

from underneath using a jack and a suitable

piece of wood between the jack saddle and

the sump or transmission (to prevent

damage), or from above by attaching a hoist

to the engine. A third method is to use a

suitable support bar with end pieces which

will engage in the water channel each side of

the bonnet lid aperture. Using an adjustable

hook and chain connected to the engine, the

weight of the engine and transmission can

then be taken from the mountings.

Engine front right-hand mounting

8 This mounting consists of a two-piece

bracket bolted to the inner wing panel,

connected by the bonded-rubber mounting

itself to a (Y-shaped) bracket, bolted (via the

alternator mounting bracket) to the cylinder

block (see illustration) .

9 Unscrew the three bolts securing the front

right-hand mounting bracket to the alternator

mounting bracket.

10 Unscrew the bolts securing the mounting

bracket to the inner wing panel and chassis

rail and withdraw the mounting assembly.

Engine rear right-hand mounting

11 This mounting consists of the bonded-

rubber mounting secured to the inner wing

panel by a (horizontal) bolt, accessible from

within the wheel arch, and a (vertical) stud, the

retaining nut of which is accessible from the

engine compartment. The mounting is bolted

to a bracket, which is in turn bolted to the

cylinder block.

12 Unbolt the mounting from the body by

unscrewing first the single nut (and washer)

immediately to the rear of the timing belt

cover, then the bolt in the wheel arch.

13 Unbolt the mounting from the cylinder

block bracket and withdraw the mounting

assembly.

Transmission bearer and mountings

14 On XR2i models, remove the front

suspension crossmember as described in

Chapter 10.

15 Unscrew and remove the two nuts

securing the mountings (front and rear) to the

transmission bearer

16 Support the transmission bearer, then

undo and remove the four retaining bolts from

the floorpan, two at the front and two at the

rear, and lower the transmission bearer from

the vehicle. Note plate fitment, as applicable,

for reassembly.

17 To remove the mountings from the

transmission, unscrew the upper bolt and

lower stud (front mounting) or the three nuts

(rear mounting) and withdraw the relevant

mounting and bracket assembly from the

transmission.

All mountings

18 Refitting of all mountings is a reversal of

removal. Make sure that the original sequence

of assembly of washers and plates is

maintained.

19 Do not fully tighten any mounting bolts

until they are all located. As the mounting

bolts and nuts are tightened, check that the

mounting rubbers do not twist.

17 Flywheel/driveplate -

removal, inspection and

refitting

3

Removal

1 Remove the transmission (see the relevant

Part of Chapter 7).

2 Where appropriate, remove the clutch

(Chapter 6).

3 Use a centre-punch or paint to make alignment marks on the flywheel/driveplate

and crankshaft, to ensure correct alignment

during refitting.

4

Prevent the flywheel/driveplate from turning

by locking the ring gear teeth, or by bolting a

strap between the flywheel/driveplate and the

cylinder block/crankcase. Slacken the bolts

evenly until all are free.

5 Remove each bolt in turn, and ensure that

new replacements are obtained for

reassembly; these bolts are subjected to

severe stresses, and so must be renewed,

regardless of their apparent condition,

whenever they are disturbed.

6 Noting the reinforcing plate (automatic

transmission models only), withdraw the

flywheel/driveplate; do not drop it - it is very

heavy.

Inspection

7 Clean the flywheel/driveplate to remove

grease and oil. Inspect the surface for cracks,

rivet grooves, burned areas and score marks.

Light scoring can be removed with emery

cloth. Check for cracked and broken ring gear

teeth. Lay the flywheel/driveplate on a flat

surface, and use a straight edge to check for

warpage.

8 Clean and inspect the mating surfaces of

the flywheel/driveplate and the crankshaft. If

the crankshaft left-hand seal is leaking, renew

it (see Section 15) before refitting the

flywheel/driveplate.

9 While the flywheel/driveplate is removed,

clean carefully its inboard (right-hand) face,

particularly the recesses which serve as the

reference points for the crankshaft speed/

position sensor. Clean the sensor’s tip, and

check that the sensor is securely fastened.

Refitting

10 On refitting, ensure that the engine/

transmission adapter plate is in place (where

necessary), then fit the flywheel/driveplate to

the crankshaft so that all bolt holes align - it

will fit only one way - check this using the

marks made on removal. Do not forget the

reinforcing plate (automatic transmission

models).

11 Lock the flywheel/driveplate by the

method used on dismantling. Working in a

diagonal sequence to tighten them evenly,

and increasing to the final amount in two or

three stages, tighten the new bolts to the

specified torque wrench setting.

12 The remainder of reassembly is the

reverse of the removal procedure, referring to

the relevant text for details where required.

2C•16 Zetec engine in-car repair procedures

16.8 Engine front right-hand mounting

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 75 of 296

Torque wrench settingsNmlbf ft

Main bearing cap bolts and nuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8059

Crankpin (big-end) bearing cap bolts: Stage 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . . . . 1813

Stage 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . . . . Angle-tighten a further 90º

Piston-cooling oil jet/blanking plug Torx screws . . . . . . . . . . . . . . . . . . 9 7

Cylinder block and head oilway blanking plugs:

M6 x 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . . . . 9 7

M10 x 11.5 - in block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. 2317

1/4 PTF plug - in block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

2418

Engine-to-transmission bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4130

Note: Refer to Part C of this Chapter for remaining torque wrench settings.

2D•6 Engine removal and overhaul procedures

1595Ford Fiesta Remake

1 General information

Included in this Part of Chapter 2 are details

of removing the engine/transmission from the

car and general overhaul procedures for the

cylinder head, cylinder block/crankcase and

all other engine internal components.

The information given ranges from advice

concerning preparation for an overhaul and

the purchase of replacement parts, to detailed

step-by-step procedures covering removal,

inspection, renovation and refitting of engine

internal components.

After Section 6, all instructions are based

on the assumption that the engine has been

removed from the car. For information

concerning in-car engine repair, as well as the

removal and refitting of those external

components necessary for full overhaul, refer

to Part A, B or C of this Chapter (as

applicable) and to Section 6. Ignore any

preliminary dismantling operations described

in Part A, B or C that are no longer relevant

once the engine has been removed from the

car.

2 Engine/transmission removal - preparation and

precautions

If you have decided that an engine must be

removed for overhaul or major repair work,

several preliminary steps should be taken.

Locating a suitable place to work is

extremely important. Adequate work space,

along with storage space for the car, will be

needed. If a workshop or garage is not

available, at the very least, a flat, level, clean

work surface is required. If possible, clear some shelving close to the

work area and use it to store the engine

components and ancillaries as they are

removed and dismantled. In this manner the

components stand a better chance of staying

clean and undamaged during the overhaul.

Laying out components in groups together

with their fixing bolts, screws etc will save

time and avoid confusion when the engine is

refitted. Clean the engine compartment and

engine/transmission before beginning the

removal procedure; this will help visibility and

help to keep tools clean. On three of the engines covered in this

manual (CVH, PTE, and Zetec), the unit can

only be withdrawn by removing it complete

with the transmission; the vehicle’s body must

be raised and supported securely, sufficiently

high that the engine/transmission can be

unbolted as a single unit and lowered to the

ground; the engine/transmission unit can then

be withdrawn from under the vehicle and

separated. On all engines, an engine hoist or

A- frame will be necessary. Make sure the

equipment is rated in excess of the combined

weight of the engine and transmission. The help of an assistant should be

available; there are certain instances when

one person cannot safely perform all of the

operations required to remove the engine

from the vehicle. Safety is of primary

importance, considering the potential hazards

involved in this kind of operation. A second

person should always be in attendance to

offer help in an emergency. If this is the first

time you have removed an engine, advice and

aid from someone more experienced would

also be beneficial. Plan the operation ahead of time. Before

starting work, obtain (or arrange for the hire

of) all of the tools and equipment you will

need. Access to the following items will allow

the task of removing and refitting the

engine/transmission to be completed safely

and with relative ease: an engine hoist - rated

in excess of the combined weight of the

engine/transmission, a heavy-duty trolley

jack, complete sets of spanners and sockets

as described in “ Tools and working facilities ”

at the rear this manual, wooden blocks, and

plenty of rags and cleaning solvent for

mopping up spilled oil, coolant and fuel. A

selection of different sized plastic storage bins

will also prove useful for keeping dismantled

components grouped together. If any of the

equipment must be hired, make sure that you

arrange for it in advance, and perform all of

the operations possible without it beforehand;

this may save you time and money. Plan on the vehicle being out of use for

quite a while, especially if you intend to carry

out an engine overhaul. Read through the

whole of this Section and work out a strategy based on your own experience and the tools,

time and workspace available to you. Some of

the overhaul processes may have to be

carried out by a Ford dealer or an engineering

works - these establishments often have busy

schedules, so it would be prudent to consult

them before removing or dismantling the

engine, to get an idea of the amount of time

required to carry out the work.

When removing the engine from the vehicle,

be methodical about the disconnection of

external components. Labelling cables and

hoses as they removed will greatly assist the

refitting process.

Always be extremely careful when lifting the

engine/transmission assembly from the

engine bay. Serious injury can result from

careless actions. If help is required, it is better

to wait until it is available rather than risk

personal injury and/or damage to components

by continuing alone. By planning ahead and

taking your time, a job of this nature, although

major, can be accomplished successfully and

without incident.

3 Engine - removal and

refitting (HCS engines)

3

Warning: Petrol is extremely

flammable, so take extra

precautions when disconnecting

any part of the fuel system.

Don’t smoke, or allow naked flames or bare

light bulbs, in or near the work area, and

don’t work in a garage where a natural-gas

appliance (such as a clothes dryer or water

heater) is installed. If you spill petrol on

your skin, rinse it off immediately. Have a

fire extinguisher rated for petrol fires

handy, and know how to use it.

Note: Read through the entire Section, as well

as reading the advice in the preceding

Section, before beginning this procedure. The

engine is removed separately from the

transmission and is lifted upwards and out of

the engine compartment.

Removal

1 On fuel injection engines, refer to Chap-

ter 4B and depressurise the fuel system.

2 Disconnect the battery negative (earth) lead

(refer to Chapter 5A, Section 1).

procarmanuals.com

http://vnx.su

Page 77 of 296

transmission flange attachment bolts (see

illustration) .

19 Check that the appropriate underside

attachments are disconnected and out of the

way, then lower the vehicle to the ground.

20 Unbolt and remove the heat shield from

the exhaust manifold.

21 Attach a suitable hoist to the engine. It is

possible to fabricate lifting eyes to connect

the hoist to the engine, but make sure that

they are strong enough, and connect them to

the inlet and exhaust manifold at diagonally-

opposite ends of the engine.

22 With the hoist securely connected, take

the weight of the engine. Unscrew and

remove the right-hand engine mounting side

bolt from under the right-hand wheel arch.

Unscrew and remove the mounting retaining

nut and washer from the suspension strut cup

retaining plate, and the three bolts securing

the mounting unit to the cylinder block.

23 Locate a jack under the transmission, and

raise it to take the weight of the transmission.

24 Unscrew and remove the remaining

engine-to-transmission retaining bolts on the

upper flange.

25 Check around the engine to ensure that all

of the relevant fixings and attachments are

disconnected and out of the way for the

removal.

26 Enlist the aid of an assistant, then move

the engine sideways and away from the

transmission, whilst simultaneously raising

the transmission. When the engine is

separated from the transmission, carefully

guide it up and out of the engine

compartment. Do not allow the weight of the

engine to hang on the transmission input shaft

at any point during the removal (or refitting) of

the engine. When the engine sump is clear

of the vehicle, swing the power unit out of the

way, and lower it onto a trolley (if available).

Unless a mobile hoist is being used, it will be

necessary to move the vehicle rearwards and

out of the way in order to allow the engine to

be lowered for removal. In this instance,

ensure that the weight of the transmission is

well supported as the vehicle is moved.

27 While the engine is removed, check the

mountings; renew them if they are worn or

damaged. Similarly, check the condition of all

coolant and vacuum hoses and pipes (see Chapter 1); components that are normally

hidden can now be checked properly, and

should be renewed if there is any doubt at all

about their condition. Also, take the

opportunity to overhaul the clutch

components (see Chapter 6). It is regarded by

many as good working practice to renew the

clutch assembly as a matter of course,

whenever major engine overhaul work is

carried out. Check also the condition of all

components disturbed on removal, and renew

any that are damaged or worn.

Refitting

28

Refitting is in general, a reversal of the

removal procedure, but the following special

points should be noted.

29 Before coupling the engine to the

transmission, apply a thin smear of high-

melting-point grease onto the transmission

input shaft splines. If the clutch has been

removed, ensure that the clutch disc is

centralised, and disconnect the clutch cable

from the release lever on the transmission

casing.

30 Tighten all fixings to their recommended

torque wrench settings.

31 Check that the mating faces are clean,

and fit a new exhaust downpipe-to-manifold

gasket and self-locking nuts when

reconnecting this joint.

32 Ensure that all wiring connections are

correctly and securely made.

33 Remove the plugs from the fuel lines

before reconnecting them correctly and

securely.

34 Reconnect and adjust the accelerator and

choke cables as described in the relevant Part

of Chapter 4. The refitting details for the air

cleaner components are also given in that

Chapter.

35 Renew any coolant hoses (and/or

retaining clips) that are not in good condition.

36 Refer to Chapter 6 for details on

reconnecting the clutch cable.

37 When the engine is fully refitted, check

that the various hoses are connected, and

then top-up the engine oil and coolant levels

as described in Chapter 1 and “Weekly

Checks”.

38 When engine refitting is completed, refer to

Section 19 for the engine start-up procedures.

4 Engine/transmission -

removal and refitting (CVH and

PTE engines)

3

Warning: Petrol is extremely

flammable, so take extra

precautions when disconnecting

any part of the fuel system.

Don’t smoke, or allow naked flames or bare

light bulbs, in or near the work area, and

don’t work in a garage where a natural-gas

appliance (such as a clothes dryer or water

heater) is installed. If you spill petrol on

your skin, rinse it off immediately. Have a

fire extinguisher rated for petrol fires

handy, and know how to use it.

Note: Read through the entire Section, as well

as reading the advice in Section 2, before

beginning this procedure. The engine and

transmission are removed as a unit, lowered to

the ground and removed from underneath,

then separated outside the vehicle.

Removal

1 On all fuel injection engines, refer to

Chapter 4B, C or D as applicable and

depressurise the fuel system.

2 Disconnect the battery negative (earth) lead

(refer to Chapter 5A, Section 1).

3 Referring to Chapter 1 for details, drain the

coolant and the engine oil. Refit the drain plug

to the sump on completion.

4 Refer to Chapter 11 for details, and remove

the bonnet.

5 Remove the air cleaner assembly and air

inlet components as described in the relevant

Part of Chapter 4.

6 Release the retaining clips and detach the

coolant top hose, the heater hose and the

radiator overflow hose from the thermostat

housing. Disconnect the coolant hose from

the inlet manifold, and the bottom hose from

the water pump and/or the radiator (see

illustrations) . On 1.4 litre CFi fuel injection

models, also disconnect the coolant hose

from the injection unit. On EFi and SEFi fuel

injection models, detach the heater hose

Y-connector. Allow for coolant spillage as the

hoses are detached. On turbocharged

engines, disconnect the coolant return hose

from the turbocharger connecting pipe.

2D•8 Engine removal and overhaul procedures

4.6b Heater coolant hoses and Y-connector on 1.6 litre EFi fuel injection models4.6a Coolant hose connections to the thermostat (arrowed)

3.18 Engine-to-transmission flangeattachment bolts (arrowed)

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 79 of 296

25Unscrew the retaining bolt, and detach

the shift rod stabiliser from the transmission.

As it is detached, note the washer located

between the stabiliser and the transmission.

Tie the stabiliser and the shift rod up out of

the way.

Automatic transmission models

26 Unclip and detach the wiring connector

from the starter inhibitor switch (on the

transmission housing).

27 Referring to the relevant Part of Chapter 4

for details, unhook the accelerator (cam plate)

cable from the carburettor or fuel injection unit

(as applicable) at the transmission end of

the cable. Undo the retaining bolt and

detach the cable sheath bracket from the

transmission. Detach the cam plate cable

from the link.

28 Undo the two nuts from the selector cable

bracket which connects it to the lever on the

selector shaft. Disconnect the yoke from the

lever on the selector shaft and the cable from

the lever.

29 Unscrew the union nuts, and disconnect

the oil cooler feed and return pipes from the

transmission. Allow for a certain amount of

spillage, and plug the connections to prevent

the ingress of dirt.

All models

30 Unscrew the retaining nut and withdraw

the Torx-type clamp bolt securing the lower

suspension arm to the spindle carrier on each

side.

31 Refer to Chapter 10 for details, and

detach the right-hand and left-hand track rod

end balljoints from the spindle carriers.

32 On vehicles fitted with the anti-lock

braking system, refer to Chapter 9 and release

the right-hand modulator from its mounting

bracket without disconnecting the rigid brake

pipes or return hose. Tie the modulator

securely to the bulkhead. Additionally, undo

the three bolts securing the modulator

bracket.

33 Insert a suitable lever between the right-

hand driveshaft inner joint and the

transmission housing, and prise free the

driveshaft from the transmission; be prepared

for oil spillage from the transmission case

through the vacated driveshaft aperture. As it

is being prised free, simultaneously pull the

roadwheel outwards on that side, to enable

the driveshaft inboard end to separate

from the transmission. Once it is free,

suspend and support the driveshaft from the

steering gear, to prevent unnecessary strain

being placed on the driveshaft joints.

34 Insert a suitable plastic plug (or if

available, an old driveshaft joint), into the

transmission driveshaft aperture, to

immobilise the gears of the differential unit.

35 Proceed as described above in

paragraphs 33 and 34, and disconnect the

left-hand driveshaft from the transmission.

36 Connect a suitable lift hoist and sling to

the engine, connecting to the lifting eyes. When securely connected, take the weight of

the engine/transmission unit so that the

tension is relieved from the mountings.

37

Undo the retaining bolts and nuts and

detach the right-hand engine mounting from

the vehicle body.

38 Undo the four bolts securing the

transmission bearer to the underside of the

vehicle body. The transmission bearer is

removed with the engine/transmission

assembly.

39 Unscrew the three retaining bolts, and

remove the auxiliary drivebelt cover from

under the crankshaft pulley.

40 The engine/transmission unit should now

be ready for removal from the vehicle. Check

that all of the associated connections and

fittings are disconnected from the engine and

transmission, and positioned out of the way.

41 Enlist the aid of an assistant to help

steady and guide the power unit down

through the engine compartment as it is

removed. If available, position a suitable

engine trolley or crawler board under the

engine/transmission so that when lowered,

the power unit can be withdrawn from the

front end of the vehicle, and then moved to

the area where it is to be cleaned and

dismantled. On automatic transmission

models, particular care must be taken not to

damage the transmission fluid pan (sump)

during the removal and subsequent refitting

processes.

42 Carefully lower the engine and

transmission unit, ensuring that no fittings

become snagged. Detach the hoist and

remove the power unit from under the vehicle.

43 Referring to the relevant Part of Chapter 7,

separate the transmission from the engine.

44 While the engine/transmission is removed,

check the mountings; renew them if they are

worn or damaged. Similarly, check the

condition of all coolant and vacuum hoses

and pipes (see Chapter 1). Components that

are normally hidden can now be checked

properly, and should be renewed if there is

any doubt at all about their condition. Where

the vehicle is fitted with manual transmission,

take the opportunity to inspect the clutch

components (see Chapter 6). It is regarded by

many as good working practice to renew the

clutch assembly as a matter of course,

whenever major engine overhaul work is

carried out. Check also the condition of all

components (such as the transmission oil

seals) disturbed on removal, and renew any

that are damaged or worn.

Refitting

45 Refitting is a reversal of removal, however

note the following additional points:

a) Refer to the applicable Chapters and Sections as for removal.

b) Fit new spring clips to the grooves in the

inboard end of the right- and left-hand

driveshaft joints. Lubricate the splines

with transmission oil prior to fitting. c) Renew the exhaust flange gasket when

reconnecting the exhaust. Ensure that all

wires are routed clear of the exhaust

system and, on catalytic converter

models, ensure that the heat shields are

securely and correctly fitted.

d) Ensure that all earth lead connections are

clean and securely made.

e) Tighten all nuts and bolts to the specified torque.

f) Fit a new oil filter, and refill the engine and transmission with oil, with reference to

Chapter 1.

g) Refill the cooling system with reference to Chapter 1.

h) Refit the alternator and starter motor with reference to Chapter 5A.

i) Where applicable, refit the power steering pump with reference to Chapter 10.

46 When engine and transmission refitting is

complete, refer to the procedures described

in Section 19 before restarting the engine.

5 Engine/transmission -

removal and refitting

(Zetec engines)

3

Warning: Petrol is extremely

flammable, so take extra

precautions when disconnecting

any part of the fuel system.

Don’t smoke, or allow naked flames or

bare light bulbs, in or near the work area,

and don’t work in a garage where a

natural-gas appliance (such as a clothes

dryer or water heater) is installed. If you

spill petrol on your skin, rinse it off

immediately. Have a fire extinguisher rated

for petrol fires handy, and know how to

use it.

Note: Read through the entire Section, as well

as reading the advice in Section 2, before

beginning this procedure. The engine and

transmission are removed as a unit, lowered to

the ground and removed from underneath,

then separated outside the vehicle.

Removal

1 Park the vehicle on firm, level ground, apply

the handbrake firmly, and slacken the nuts

securing both front roadwheels.

2 Depressurise the fuel system as described

in Chapter 4D.

3 Disconnect the battery negative (earth) lead

(refer to Chapter 5A, Section 1).

4 Place protective covers on the wings, then

remove the bonnet (see Chapter 11).

5 Drain the cooling system and the engine oil

(see Chapter 1).

6 Remove the air inlet components and the

complete air cleaner assembly as described in

Chapter 4D.

7 Equalise the pressure in the fuel tank by

removing the filler cap, then release the fuel

feed and return quick-release couplings, and

pull the hoses off the fuel pipes. Plug or cap

all open fittings.

2D•10 Engine removal and overhaul procedures

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 81 of 296

25On automatic transmission models, clean

around the unions, then disconnect the fluid

pipes from the transmission. Plug the

openings in the transmission and the pipe

unions after removal.

26 Refer to Chapter 10 and remove the front

suspension crossmember.

27 Unscrew the nuts to disconnect the

exhaust system front downpipe from the

manifold. Undo the nuts securing the catalytic

converter to the rear part of the exhaust

system, and remove the converter and

downpipe assembly.

28 On vehicles fitted with the anti-lock braking

system, refer to Chapter 9 and release the

right-hand modulator from its mounting

bracket without disconnecting the rigid brake

pipes or return hose. Tie the modulator

securely to the bulkhead. Additionally, undo

the three bolts securing the modulator bracket.

29 Disconnect both anti-roll bar links from

their respective suspension struts, and both

track rod end ball joints from their spindle

carriers (see Chapter 10).

30 Unscrew the retaining nut and withdraw

the Torx-type clamp bolt securing the lower

suspension arm to the spindle carrier on each

side.

31 Insert a suitable lever between the right-

hand driveshaft inner joint and the

transmission housing, and prise free the

driveshaft from the transmission; be prepared

for oil spillage from the transmission case

through the vacated driveshaft aperture. As it

is being prised free, simultaneously pull the

roadwheel outwards on that side to enable the

driveshaft inboard end to separate from the

transmission. Once it is free, suspend and

support the driveshaft from the steering gear,

to prevent unnecessary strain being placed on

the driveshaft joints.

32 Insert a suitable plastic plug (or if

available, an old driveshaft joint), into the

transmission driveshaft aperture, to

immobilise the gears of the differential unit.

33 Proceed as described above in

paragraphs 31 and 32, and disconnect the

left-hand driveshaft from the transmission.

34 Remove the oil filter, referring to Chapter 1

if necessary.

35 Connect a suitable lift hoist and sling to

the engine, connecting to the lift eyes. When

securely connected, take the weight of the

engine/transmission unit so that the tension is

relieved from the mountings.

36 Unbolt the engine rear right-hand

mounting from the body (one bolt in the wheel

arch, one nut in the engine compartment),

then unbolt the engine front right-hand

mounting from the alternator mounting

bracket. Unbolt the transmission bearer from

the underbody.

37 The engine/transmission unit should now

be hanging on the hoist only, with all

components which connect it to the rest of

the vehicle disconnected or removed, and

secured well clear of the unit. Make a final

check that this is the case. 38

Lower the engine/transmission to the

ground, and withdraw it from under the

vehicle.

39 Referring to the relevant Part of Chapter 7,

separate the transmission from the engine.

40 While the engine/transmission is removed,

check the mountings; renew them if they are

worn or damaged. Similarly, check the

condition of all coolant and vacuum hoses

and pipes (see Chapter 1); components that

are normally hidden can now be checked

properly, and should be renewed if there is

any doubt at all about their condition. Where

the vehicle is fitted with manual transmission,

take the opportunity to overhaul the clutch

components (see Chapter 6). It is regarded by

many as good working practice to renew the

clutch assembly as a matter of course,

whenever major engine overhaul work is

carried out. Check also the condition of all

components (such as the transmission oil

seals) disturbed on removal, and renew any

that are damaged or worn.

Refitting

41 Refitting is a reversal of removal, however

note the following additional points:

a) Refer to the applicable Chapters and Sections as for removal.

b) Fit new spring clips to the grooves in the

inboard end of the right- and left-hand

driveshaft joints. Lubricate the splines

with transmission oil prior to fitting.

c) Renew the exhaust flange gaskets when reconnecting the exhaust. Ensure that all

wires are routed clear of the exhaust

system, and that the heat shields are

securely and correctly fitted.

d) Ensure that all earth lead connections are

clean and securely made.

e) Tighten all nuts and bolts to the specified

torque.

f) Fit a new oil filter, and refill the engine and transmission with oil, with reference to

Chapter 1.

g) Refill the cooling system with reference to

Chapter 1.

h) Bleed the power steering system with reference to Chapter 10.

42 When engine and transmission refitting is

complete, refer to the procedures described

in Section 19 before restarting the engine.

6 Engine overhaul - preliminary information

It is much easier to dismantle and work on

the engine if it is mounted on a portable

engine stand. These stands can often be hired

from a tool hire shop. Before the engine is

mounted on a stand, the flywheel/driveplate

should be removed so that the stand bolts

can be tightened into the end of the cylinder

block/crankcase. If a stand is not available, it is possible to

dismantle the engine with it suitably supported on a sturdy, workbench or on the

floor. Be careful not to tip or drop the engine

when working without a stand.

If you intend to obtain a reconditioned

engine, all ancillaries must be removed first, to

be transferred to the replacement engine (just

as they will if you are doing a complete engine

overhaul yourself). These components include

the following:

a) Alternator/power steering pump and

mounting brackets.

b) DIS/E-DIS ignition coil unit (and mounting

bracket), distributor, HT leads and spark

plugs.

c) The thermostat and housing cover.

d) Carburettor/fuel injection system

components.

e) Inlet and exhaust manifolds.

f) Oil filter.

g) Fuel pump.

h) Engine mountings.

i) Flywheel/driveplate.

j) Water pump.

Note: When removing the external

components from the engine, pay close

attention to details that may be helpful or

important during refitting. Note the fitted

positions of gaskets, seals, washers, bolts and

other small items. If you are obtaining a “short” engine

(cylinder block/crankcase, crankshaft, pistons

and connecting rods all assembled), then the

cylinder head, timing chain/belt (together with

tensioner, tensioner and idler pulleys and

covers) sump and oil pump will have to be

removed also. If a complete overhaul is planned, the

engine can be dismantled in the order given

below, referring to Part A, B or C of this

Chapter unless otherwise stated.

a) Inlet and exhaust manifolds.

b) Timing chain/belt, tensioner and

sprockets.

c) Cylinder head.

d) Flywheel/driveplate.

e) Sump.

f) Oil pump.

g) Pistons (with connecting rods).

h) Crankshaft.

i) Camshaft and tappets (HCS engines).

7 Cylinder head - dismantling

4

Note:New and reconditioned cylinder heads

are available from the manufacturers, and from

engine overhaul specialists. Due to the fact

that some specialist tools are required for the

dismantling and inspection procedures, and

new components may not be readily available,

it may be more practical and economical for

the home mechanic to purchase a

reconditioned head, rather than to dismantle,

inspect and recondition the original head.

1 Remove the cylinder head as described in

Part A, B or C of this Chapter (as applicable).

2D•12 Engine removal and overhaul procedures

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 111 of 296

container which can be sealed (see

illustration) . Where quick-release couplings

are used on the fuel hoses, release the

protruding locking lugs on each union, by

squeezing them together and carefully pulling

the coupling apart. Note that the fuel supply

hose couplings are identified by a white

colour band and the return hose couplings by

a yellow colour band.

6 Disconnect the filler neck sensing pipe

connection from the rear of the tank (see

illustration) .

7 Support beneath the tank to hold it in

position and remove its four securing bolts

(see illustration) .

8 Partially lower the fuel tank and disconnect

the ventilation tube from the tank top surface

and also disconnect the sender unit multi-

plug. The filler pipe should release from its

fuel tank seal location as the tank is

withdrawn.

Inspection

9 Whilst removed, the fuel tank can be

inspected for damage or deterioration.

Removal of the sender unit (see Section 9) will

allow a partial inspection of the interior. If the

tank is contaminated with sediment or water,

swill it out with clean petrol. Do not under any

circumstances undertake any repairs on a

leaking or damaged fuel tank; this work must

be carried out by a professional who has

experience in this critical and potentially-

dangerous work.

10 Whilst the fuel tank is removed from the

vehicle, it should not be placed in an area

where sparks or open flames could ignite the

fumes coming out of the tank. Be especially

careful inside garages where a natural-gas

type appliance is located, because the pilot

light could cause an explosion.

11 Check the condition of the filler pipe seal

in the fuel tank, and renew it if necessary.

Refitting

All models

12 Refitting is a reversal of the removal

procedure. Apply a light smear of grease to the

filler pipe seal, to ease fitting. Ensure that all

connections are securely fitted. Where quick-

release fuel couplings are fitted, press them together until the locking lugs snap into their

groove. If evidence of contamination was

found, do not return any previously-drained

fuel to the tank unless it is carefully filtered first.

9

Fuel gauge sender unit -

removal and refitting

3

Note: Ford specify the use of their service tool

23-014 (a large box spanner with projecting

teeth to engage the fuel gauge sender unit

retaining ring’s slots) for this task. While

alternatives are possible, in view of the difficulty

experienced in removing and refitting the

sender unit, owners are strongly advised to

obtain the correct tool before starting work. The

help of an assistant will be required. Refer to the

warning note in Section 1 before proceeding.

Removal

1 Remove the fuel tank as described in

Section 8.

2 Engage the special tool into the sender unit

then carefully turn the sender unit and release

it from the top of the tank.

Refitting

3 Refit the sender unit in the reverse order of

removal. Be sure to fit a new seal, and

lubricate it with a smear of grease to prevent it

from distorting when fitting the sender unit.

10 Fuel tank ventilation tube -

removal and refitting

3

Note: Refer to the warning note in Section 1

before proceeding.

Removal

1 The fuel tank ventilation tube runs from the

top surface of the fuel tank to the combined roll-

over/anti-trickle-fill valve assembly mounted in

the left-hand rear wheelarch (see illustration).

Its purpose is to eliminate any possibility of

vacuum or pressure build-up in the fuel tank.

2 Disconnect the battery negative (earth) lead

(refer to Chapter 5A, Section 1).

3 Chock the front wheels then jack up the

rear of the car and support it on axle stands

(see “Jacking and vehicle support” ). Remove

the left-hand rear roadwheel.

4 Support the fuel tank from underneath on a

suitable jack, using a large thick sheet of

board to spread the weight, then undo and

remove the four fuel tank securing bolts.

5 Lower the fuel tank slightly in such a manner

so as to allow access to disconnect the

ventilation tube from the tank top surface.

Ensure that the fuel tank does not foul or strain

any adjacent components as it is lowered;

take appropriate action, as necessary.

6 Disconnect the ventilation tube from the

combined roll-over/anti-trickle-fill valve, release

the tube from its retaining clips and remove.

Refitting

7 Refitting is a reversal of the removal

procedure, ensuring that the fuel tank filler

pipe is located correctly with the tank.

11 Fuel tank filler pipe -

removal and refitting

3

Note: Refer to the warning note in Section 1

before proceeding.

Removal

1 Remove the fuel tank as described in

Section 8.

4A•6 Fuel system – carburettor engines

10.1 Combined roll-over anti-trickle-fill valve assembly

A Tube ventilating to atmosphere

B Ventilation tube from fuel tank

8.7 Fuel tank securing bolts (arrowed)8.6 Filler neck sensing pipe connection at the rear of the fuel tank

1595Ford Fiesta Remake

8.5 Fuel feed and return pipe connections

(arrowed)procarmanuals.com

http://vnx.su