tow FORD FIESTA 2007 Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2007, Model line: FIESTA, Model: FORD FIESTA 2007Pages: 1226, PDF Size: 61.26 MB

Page 18 of 1226

General Information

........................................................................\

............................. Lubricants and Greases

Transmission Fluids

........................................................................\

....................................

........................................................................\

.......................................................... Noise

Noise Insulation Materials

........................................................................\

..........................

0-Rings (Fluoroelastomer) ........................................................................\

.........................

........................................................................\

.......................................................... Paints

........................................................................\

.............................. Pressurized Equipment . . ........................................................................\

......................................................... Solder

........................................................................\

...................................................... Solvents

Sound Insulation

........................................................................\

.........................................

Suspended Loads ........................................................................\

.......................................

Transmission Brake Bands ........................................................................\

.........................

........................................................................\

................................................... Underseal

........................................................................\

............................................................ Viton

........................................................................\

....................................................... Welding

........................................................................\

.................... Warning Symbols on Vehicles

........................................................................\

................................................. White Spirit

Standard Workshop Practices

........................................................................\

....................

Vehicle in Workshop ........................................................................\

...................................

Alternative Fuel ........................................................................\

...........................................

Alternative Fuel - Do's ........................................................................\

..............................

Alternative Fuel - Do Nots ........................................................................\

........................

Towing the Vehicle ........................................................................\

......................................

Connecting a Slave Battery Using Jumper Cables ............................................................

Component Cleaning ........................................................................\

..................................

Calibration of Essential Measuring Equipment ...................................................................

Solvents. Sealants and Adhesives ........................................................................\

.............

........................................................................\

................................................. Introduction

RoadlRoller Testing ........................................................................\

....................................

Pre-Test Checks ........................................................................\

.........................................

Starting the Engine ........................................................................\

.....................................

Road or Roller Testing ........................................................................\

................................

Brake Testing ........................................................................\

..............................................

procarmanuals.com

Page 19 of 1226

100-00-3 General Information 100-00-3

DESCRIPTION AND OPERATION

About This Manual

-- . Introduction

This manual has been written in a format that is

designed to meet the needs of technicians

worldwide. The objective is to use common formats

and include similar content in each manual.

This manual provides general descriptions for accomplishing diagnosis and testing, service and

repair work with tested, effective techniques.

Following them will help assure reliability.

Special Tools

The special tool(s) table provided at the beginning

of each procedure shows all special tools required

to carry out a repair. Where possible, illustrations

are provided to assist in identifying the special tool

required.

Important Safety Instructions

Appropriate service methods and correct repair

--.! procedures are essential for the safe, reliable

operation of all motor vehicles as well as the

personal safety of the individual carrying out the

work.

This manual cannot possibly anticipate all such

variations and provide advice or cautions as to

each. Anyone who departs from the instructions

provided in this manual must first establish that he

compromises neither his personal safety nor the

vehicle integrity by his choice of methods, tools or

components.

Warnings, Cautions and Notes in This

Manual

A WARN1NG:Warnings are used to indicate

that failure to follow a procedure correctly

may result in personal injury.

A warning, caution or note is placed at the

beginning of a series of steps if it applies to multiple

steps. If the warning, caution or note only applies

to one step, it is placed at the beginning of the

specific step (after the step number).

How to Use This Manual

This manual covers diagnosis and testing, service

and repair procedures.

This manual is structured into groups and sections,

with specific system sections collected together

under their relevant group.

A group covers a specific portion of the vehicle.

The manual is divided into five groups, General

Information, Chassis, Powertrain, Electrical and

Body and Paint. The number of the group is the

first number of a section number.

Pages at the start of the manual list all sections

available. Each section has a contents list detailing

Specifications, Description and Operation,

Diagnosis and Testing, In Vehicle Repairs,

Disassembly and Assembly, Removal and

Installation.

If components need to be removed or

disassembled in sequence, the sequence will be

identified numerically in a graphic and the

corresponding text will be numbered accordingly.

All left and right-hand references to the vehicle are

taken from a position sitting in the driver seat

looking forward.

All left and right-hand references to the engine are

taken from a position at the flywheel looking

towards the front camshaft pulley.

Where appropriate, instructions will be given for

the use of the diagnostic tool.

Overview Procedures

Overview procedures contain an exploded view

A CAUTI0N:Cautions are used to indicate illustration(s). The numbered sequence within the

that failure to follow a procedure correctly illustration(s) indicate the order to be followed when

may result in damage to the vehicle or removingldisassem bling or when

equipment being used. installinglassembling a component. Additional

information,

symbol(s) or a torque figure, may also

, , N0TE:Notes are used to provide additional

be shown alonaside the com~onent.

essential information required to carry out a

complete and satisfactory repair. There are

ten symbols used to give additional

information when

removina/disassemblincr or when V AS YOU read through this manual, YOU will come /"itallinglassembling a c&ponent.

across WARNINGS, CAUTIONS and NOTES.

2006.0 Fiesta 1212006 GI 7371 en

procarmanuals.com

Page 36 of 1226

100-00-20 General Information 100-00-20

DESCRIPTION AND OPERATION

Towing the Vehicle

an instance, the discharged battery must

be recharged immediately after jump

A WARN1NG:When the vehicle is being starting

to avoid permanent damage. ( towed, the ignition switch must be in - Always make sure that the jumper cables are

position ll (steering lock released and adequate for the task. Heavy duty cables must

warning lamps illuminated). Only then will be used.

the turn signal lamps, horn and - Always make sure that the slave battery is of stop lamps be operational. Failure to follow the same voltage as the vehicle battery. The these instructions may result in personal batteries must be connected in parallel. injury. - Always make sure that switched electric circuits

N0TE:The removable towing eye (if equipped),

are switched off before connecting jumper

has a left-hand thread and must be fully tightened cables. This reduces the risk of arcing occurring

before towing can commence.

when the final connection is made.

When towing is necessary, the vehicle towing eyes

should be used. The rope must be securely

fastened to the towing eyes and must also be

attached to the other vehicle such that the rope will

not foul the bodywork.

When a vehicle with automatic transmission is

towed, the gear selector must be in position

N

(Neutral). Never tow a vehicle with automatic

transmission at a speed greater than 30 mph (50

kmlh) or for a distance greater than 30 miles (50

km). If it is necessary to tow the vehicle a greater

distance, the drive wheels must be lifted clear off

the ground.

I A WARN1NG:Make sure that the ends of the Alternatively the vehicle can be transported on a jumper cables do not touch each other or low loader or a trailer. ground against the vehicle body at any

time while the cables are attached to the

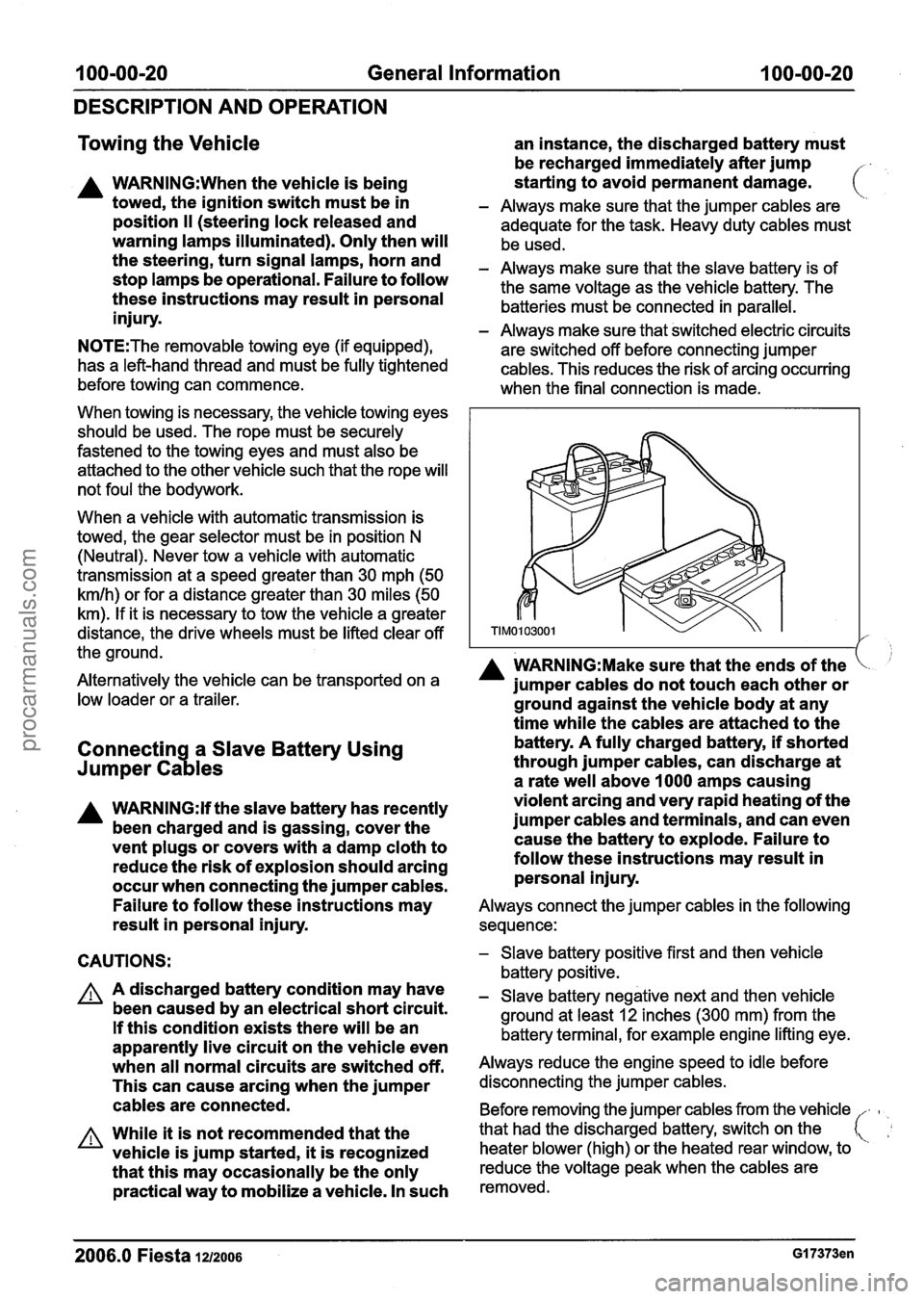

Connectin a Slave Battery Using

73

battery. A fully charged battery, if shorted

Jumper Ca les through jumper cables, can discharge at

a rate well above

I000 amps causing

A WARNING:H the slave battery has recently violent arcing

and very rapid heating of the

been charged and is gassing, cover the jumper cables and

terminals, and can even

vent plugs or covers with a damp cloth to cause

the battery to explode. Failure to

reduce the risk of explosion should arcing follow

these instructions may result in

occur when connecting the jumper cables. personal injury.

Failure to follow these instructions may

Always connect the jumper cables in the following

result in personal injury. sequence:

CAUTIONS:

A A discharged battery condition may have

been caused by an electrical short circuit.

If this condition exists there will be an

apparently live circuit on the vehicle even

when all normal circuits are switched off.

This can cause arcing when the jumper

cables are connected.

A While it is not recommended that the

vehicle is jump started,

it is recognized

that this may occasionally be the only

practical way to mobilize a vehicle. In such

- Slave battery positive first and then vehicle

battery positive.

- Slave battery negative next and then vehicle

ground at least

12 inches (300 mm) from the

battery terminal, for example engine lifting eye.

Always reduce the engine speed to idle before

disconnecting the jumper cables.

Before removing the jumper cables from the vehicle

-

heater blower (high) or the heated rear window, to

that

had the discharged battery, switch on the

reduce the voltage peak when the cables are

removed.

2006.0 Fiesta 1~12006 GI 7373en

procarmanuals.com

Page 120 of 1226

204-01 -22 Front Suspension 204101 122

REMOVAL AND INSTALLATION

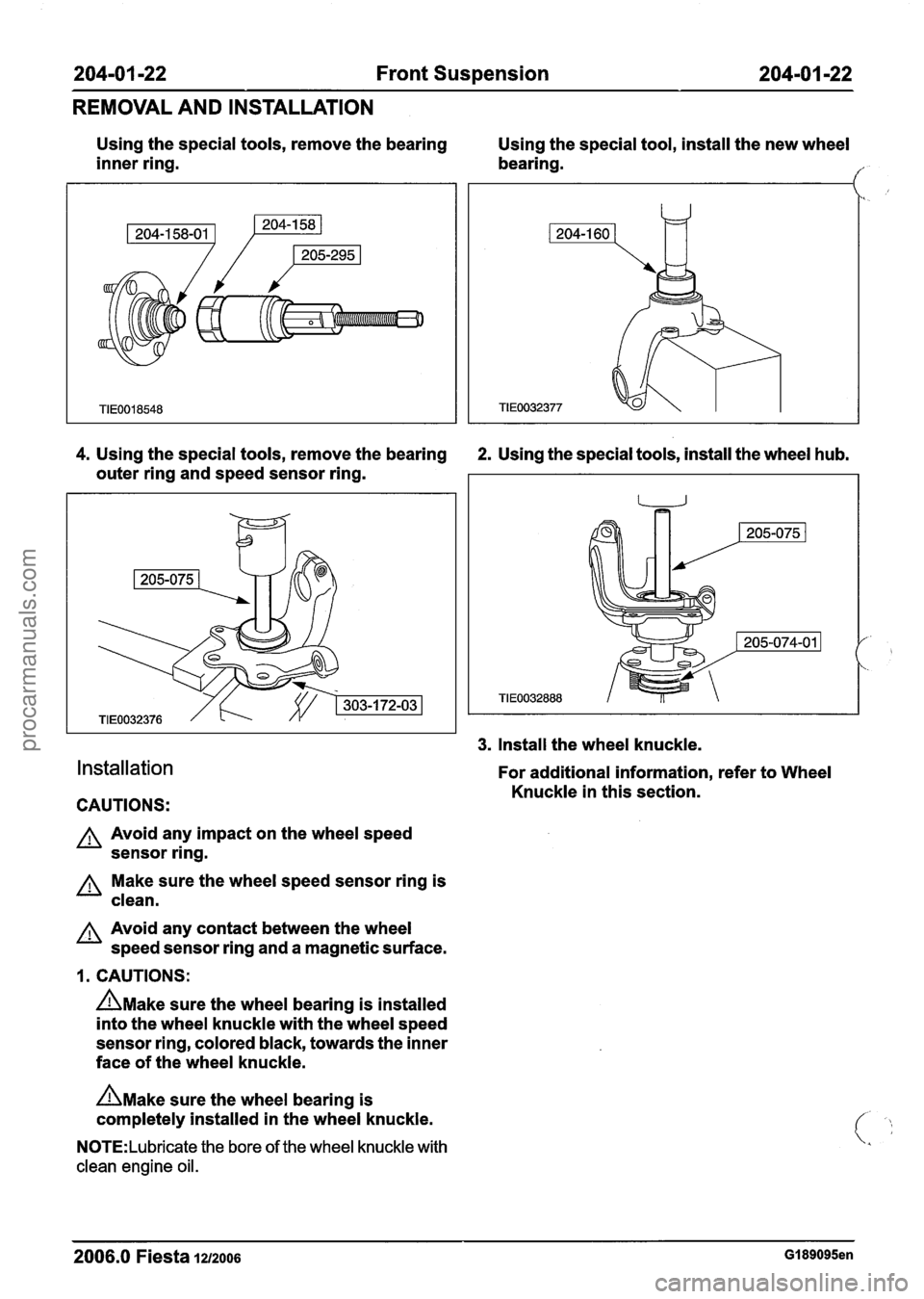

Using the special tools, remove the bearing

Using the special tool, install the new wheel

inner ring. bearing.

I"

4. Using the special tools, remove the bearing 2. Using the special tools, install the wheel hub.

outer ring and speed sensor ring.

Installation

CAUTIONS:

A Avoid any impact on the wheel speed

sensor ring.

Make sure the wheel speed sensor ring is

clean.

A Avoid any contact between the wheel

speed sensor ring and a magnetic surface.

1. CAUTIONS:

n~ake sure the wheel bearing is installed

into the wheel knuckle with the wheel speed

sensor ring, colored black, towards the inner

face of the wheel knuckle.

n~ake sure the wheel bearing is

completely installed in the wheel knuckle.

N0TE:Lubricate the bore of the wheel knuckle with

clean engine oil.

3. Install the wheel knuckle.

For additional information, refer to Wheel

Knuckle in this section.

--

2006.0 Fiesta 1212006 GI 89095en

procarmanuals.com

Page 157 of 1226

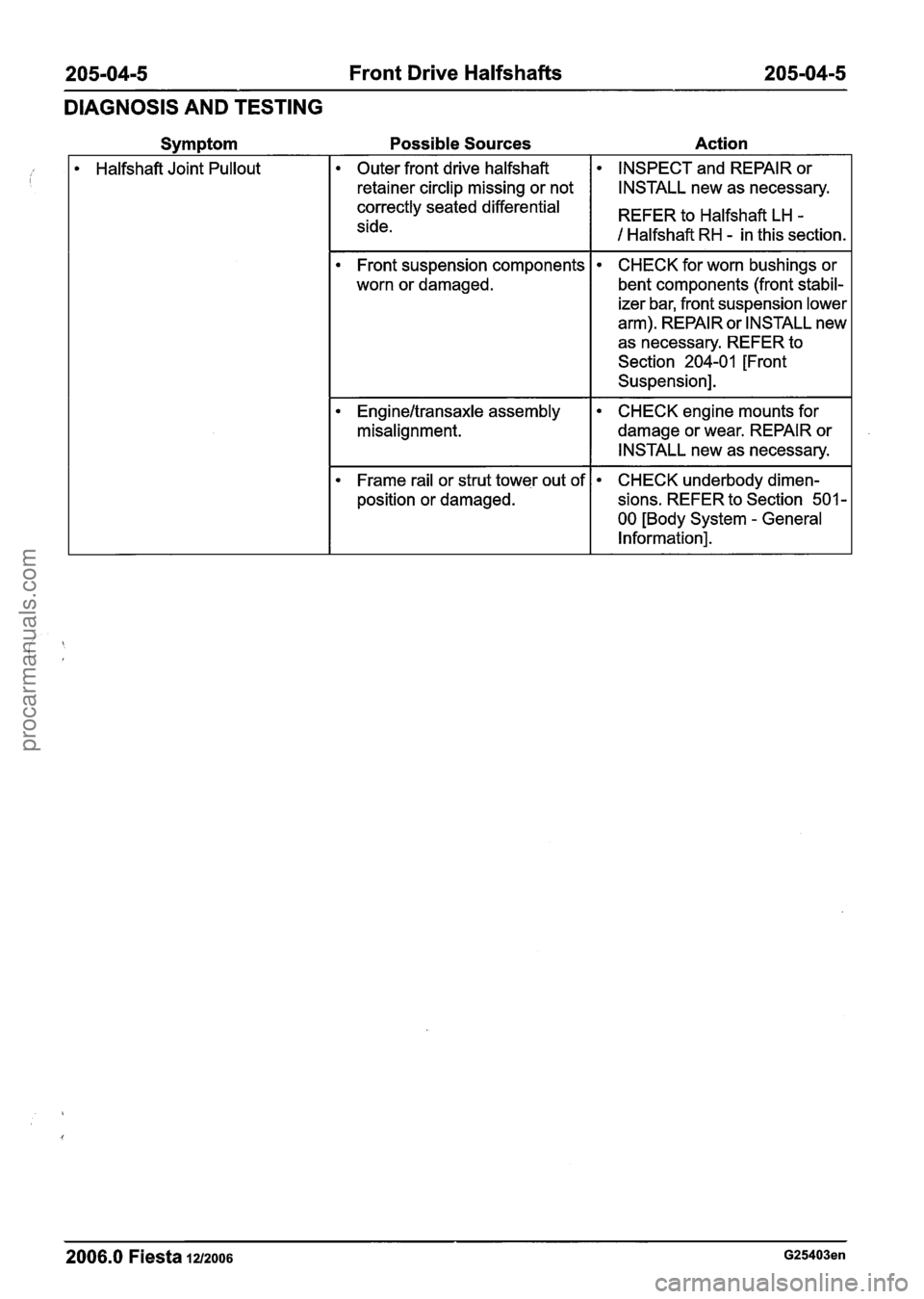

205-04-5 Front Drive Halfshafts 205-04-5

DIAGNOSIS AND TESTING

Possible Sources Action

Halfshaft Joint Pullout Outer front drive halfshaft INSPECT

and REPAIR or

retainer circlip missing or not

I I INSTALL new as necessary.

Front suspension components

worn or damaged.

correctly seated differential

side. CHECK

for worn bushings or

bent components (front stabil-

izer bar, front suspension lower

arm). REPAIR or INSTALL new

as necessary. REFER to

Section

204-01 [Front

Suspension]. REFER to Halfshaft

LH

-

1 Halfshaft RH - in this section.

Engineltransaxle assembly

misalignment. CHECK engine mounts for

damage or wear. REPAIR or

INSTALL new as necessary.

Frame rail or strut tower out of

position or damaged. CHECK underbody dimen-

sions. REFER to Section

501 -

00 [Body System - General

Information].

-- - --

2006.0 Fiesta 1212006 G25403en

procarmanuals.com

Page 168 of 1226

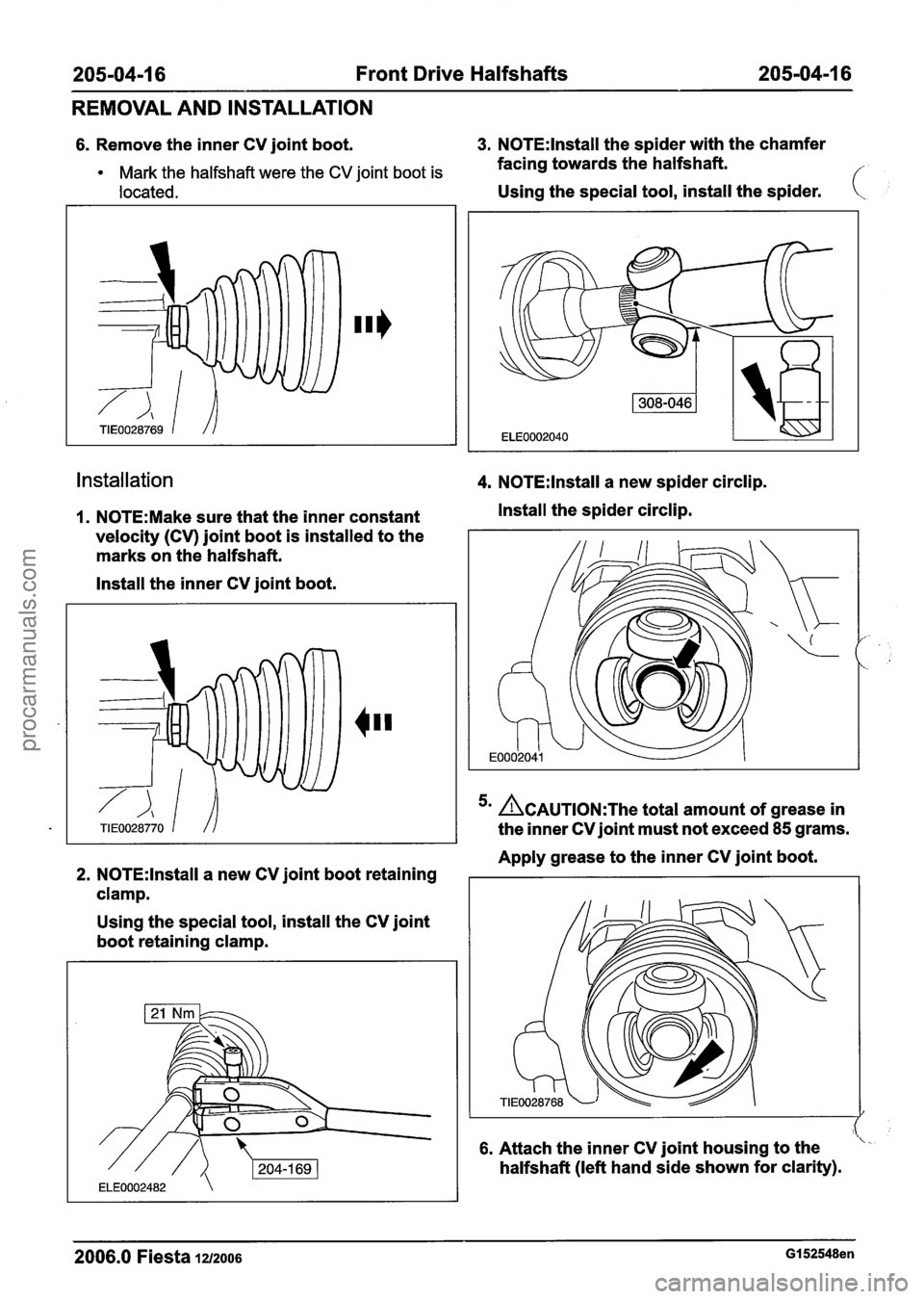

205-04-1 6 Front Drive Halfshafts 205-04-1 6

REMOVAL AND INSTALLATION

6. Remove the inner CV joint boot. 3. N0TE:lnstall the spider with the chamfer

Mark the halfshaft were the CV joint boot is facing towards the halfshaft.

located. Using the special tool, install the spider. (

installation 4. N0TE:lnstall a new spider circlip.

I. N0TE:Make sure that the inner constant Install the spider circlip.

velocity (CV) joint boot is installed to the

marks on the halfshaft.

Install the inner CV joint boot.

'' ACAUTION:T~~ total amount of grease in

the inner CV joint must not exceed

85 grams.

Apply grease to the inner CV joint boot.

2. N0TE:lnstall a new CV joint boot retaining I I

clamp.

Using the special tool, install the CV joint

boot retaining clamp.

6. Attach the inner CV joint housing to the

halfshaft (left hand side shown for clarity).

2006.0 Fiesta iu200s GI 52548en

procarmanuals.com

Page 209 of 1226

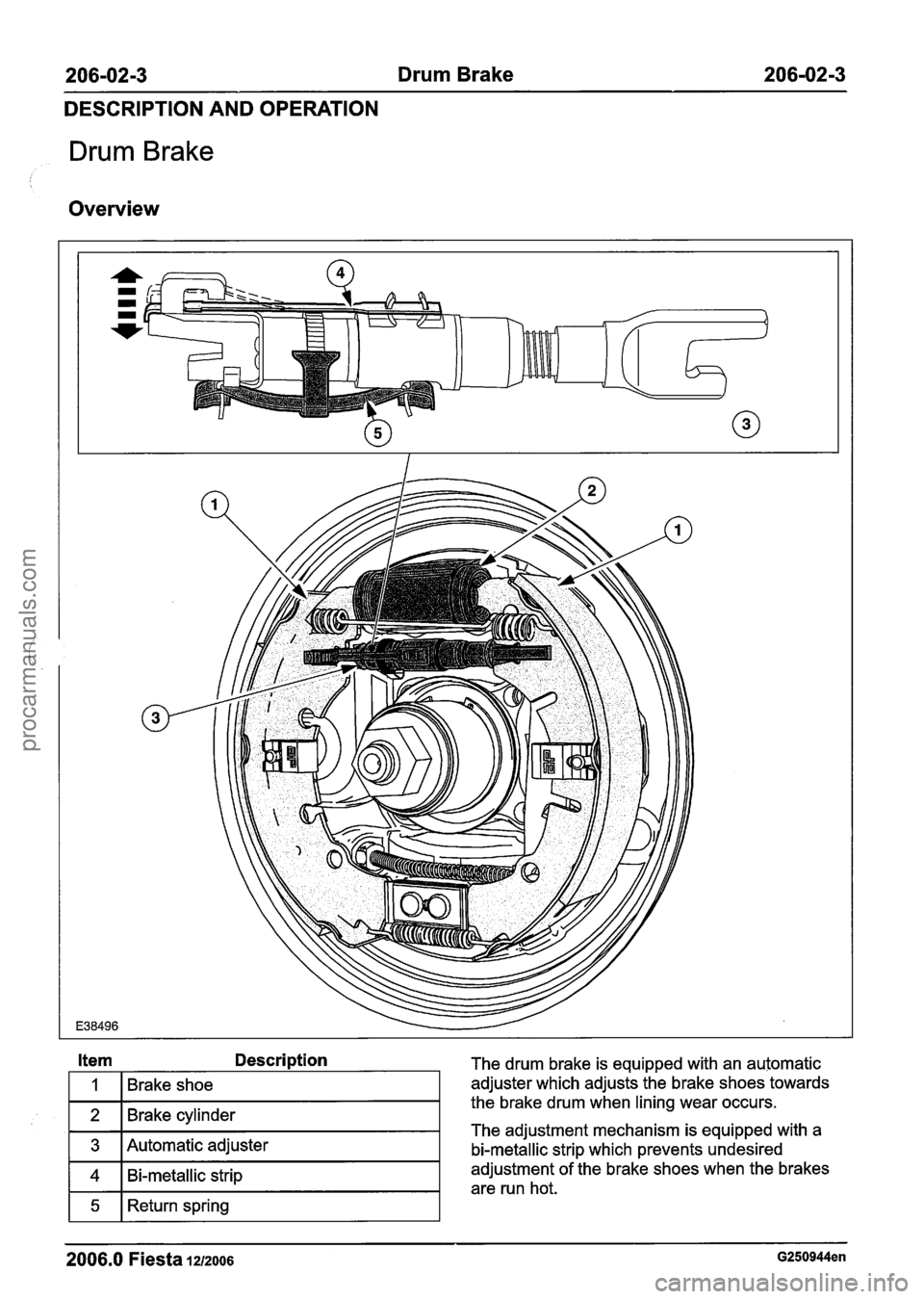

206-02-3 Drum Brake 206-02-3

DESCRIPTION AND OPERATION

Drum Brake

Overview

2006.0 Fiesta 1212006 G250944en

Item Description The drum brake is equipped with an automatic

adjuster which adjusts the brake shoes towards

the brake drum when lining wear occurs.

The adjustment mechanism is equipped with a

bi-metallic strip which prevents undesired

adjustment of the brake shoes when the brakes

are run hot.

1

2

3

4

5

Brake shoe

Brake cylinder

Automatic adjuster

Bi-metallic strip

Return spring

procarmanuals.com

Page 260 of 1226

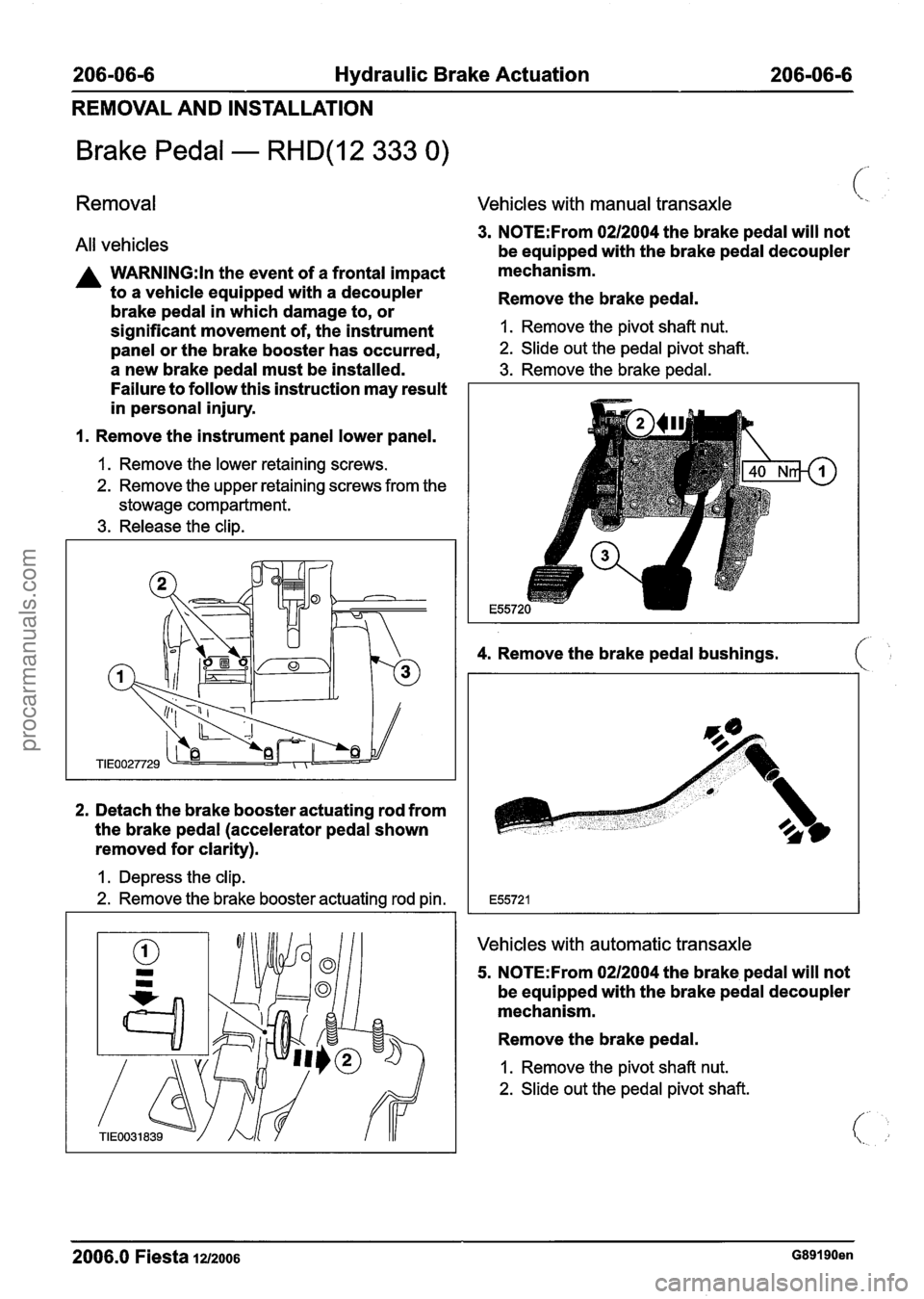

206-06-6 Hydraulic Brake Actuation 206-06-6

REMOVAL AND INSTALLATION

Brake Pedal - RHD(12 333 0)

Removal

All vehicles

A WARNING:ln the event of a frontal impact

to a vehicle equipped with a decoupler

brake pedal in which damage to, or

significant movement of, the instrument

panel or the brake booster has occurred,

a new brake pedal must be installed.

Failure to follow this instruction may result

in personal injury.

1. Remove the instrument panel lower panel.

1. Remove the lower retaining screws.

2. Remove the upper retaining screws from the

stowage compartment.

3. Release the clip.

2. Detach the brake booster actuating rod from

the brake pedal (accelerator pedal shown

removed for clarity).

I. Depress the clip.

2. Remove the brake booster actuating rod pin.

Vehicles with manual transaxle 1.

3. N0TE:From 0212004 the brake pedal will not

be equipped with the brake pedal decoupler

mechanism.

Remove the brake pedal.

1. Remove the pivot shaft nut.

2. Slide out the pedal pivot shaft.

3. Remove the brake pedal.

4. Remove the brake pedal bushings. ( ,:

Vehicles with automatic transaxle

5. N0TE:From 0212004 the brake. pedal will not

be equipped with the brake pedal decoupler

mechanism.

Remove the brake pedal.

1. Remove the pivot shaft nut.

2. Slide out the pedal pivot shaft.

2006.0 Fiesta 1212006 G89190en

procarmanuals.com

Page 272 of 1226

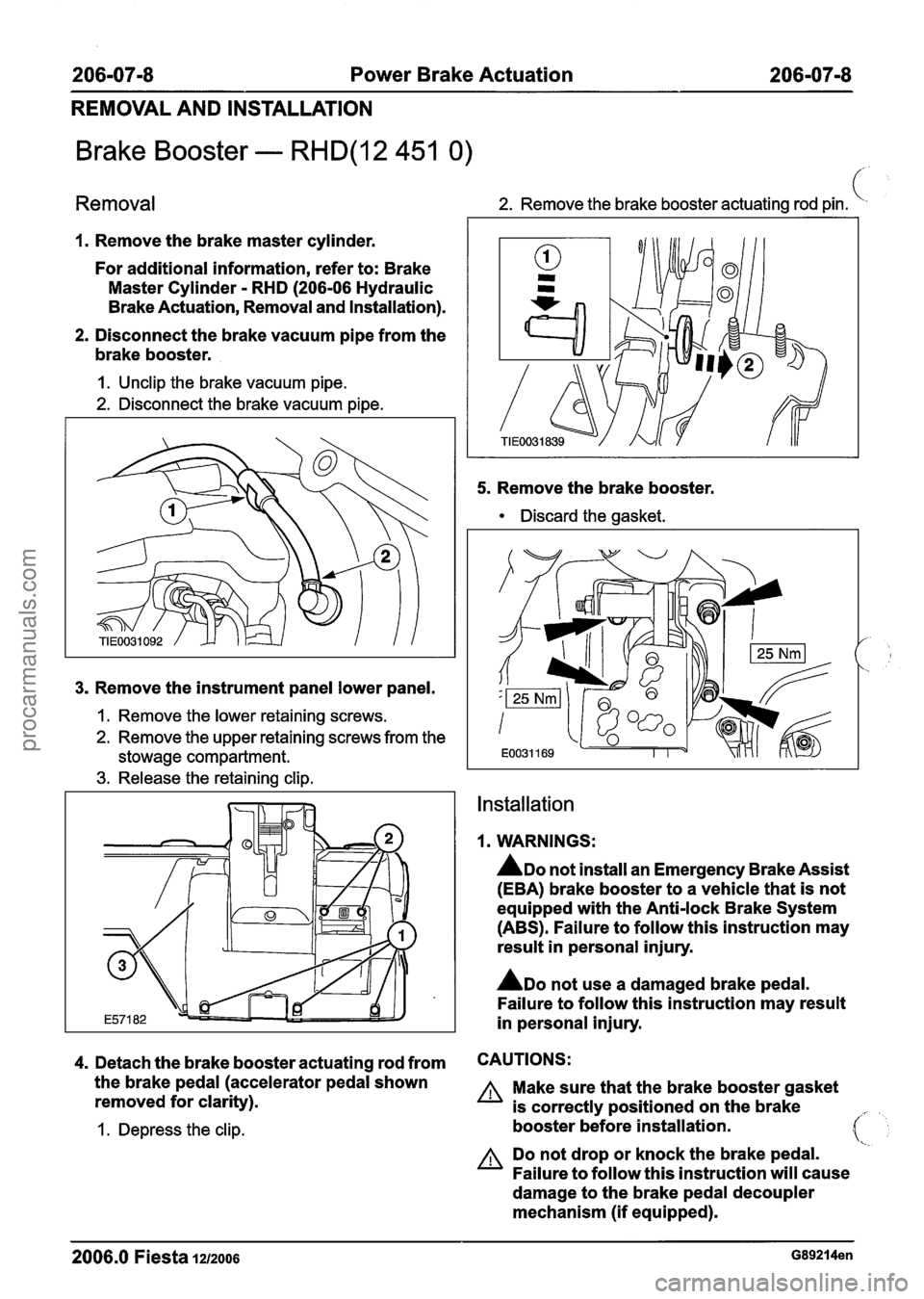

206-07-8 Power Brake Actuation 206-07-8

REMOVAL AND INSTALLATION

Brake Booster - RHD(12 451 0)

Removal 2. Remove the brake booster actuating rod pin. (

1. Remove the brake master cylinder.

For additional information, refer to: Brake

Master Cylinder

- RHD (206-06 Hydraulic

Brake Actuation, Removal and Installation).

2. Disconnect the brake vacuum pipe from the

brake booster.

I. Unclip the brake vacuum pipe.

2. Disconnect the brake vacuum pipe.

3. Remove the instrument panel lower panel.

1. Remove the lower retaining screws.

2. Remove the upper retaining screws from the

stowage compartment.

3. Release the retaining clip. 5.

Remove

the brake booster.

Discard the gasket.

Installation

1. WARNINGS:

ADO not install an Emergency Brake Assist

(EBA) brake booster to a vehicle that is not

equipped with the Anti-lock Brake System

(ABS). Failure to follow this instruction may

result in personal injury.

ADO not use a damaged brake pedal.

Failure to follow this instruction may result

in personal injury.

4. Detach the brake booster actuating rod from CAUTIONS:

the brake pedal (accelerator pedal shown A Make sure that the brake booster gasket

removed for clarity).

is correctly positioned on the brake

I. Depress the clip. booster before installation. 41

A Do not drop or knock the brake pedal.

Failure to follow this instruction will cause

damage to the brake pedal decoupler

mechanism (if equipped).

2006.0 Fiesta 12/2006 G89214en

procarmanuals.com

Page 413 of 1226

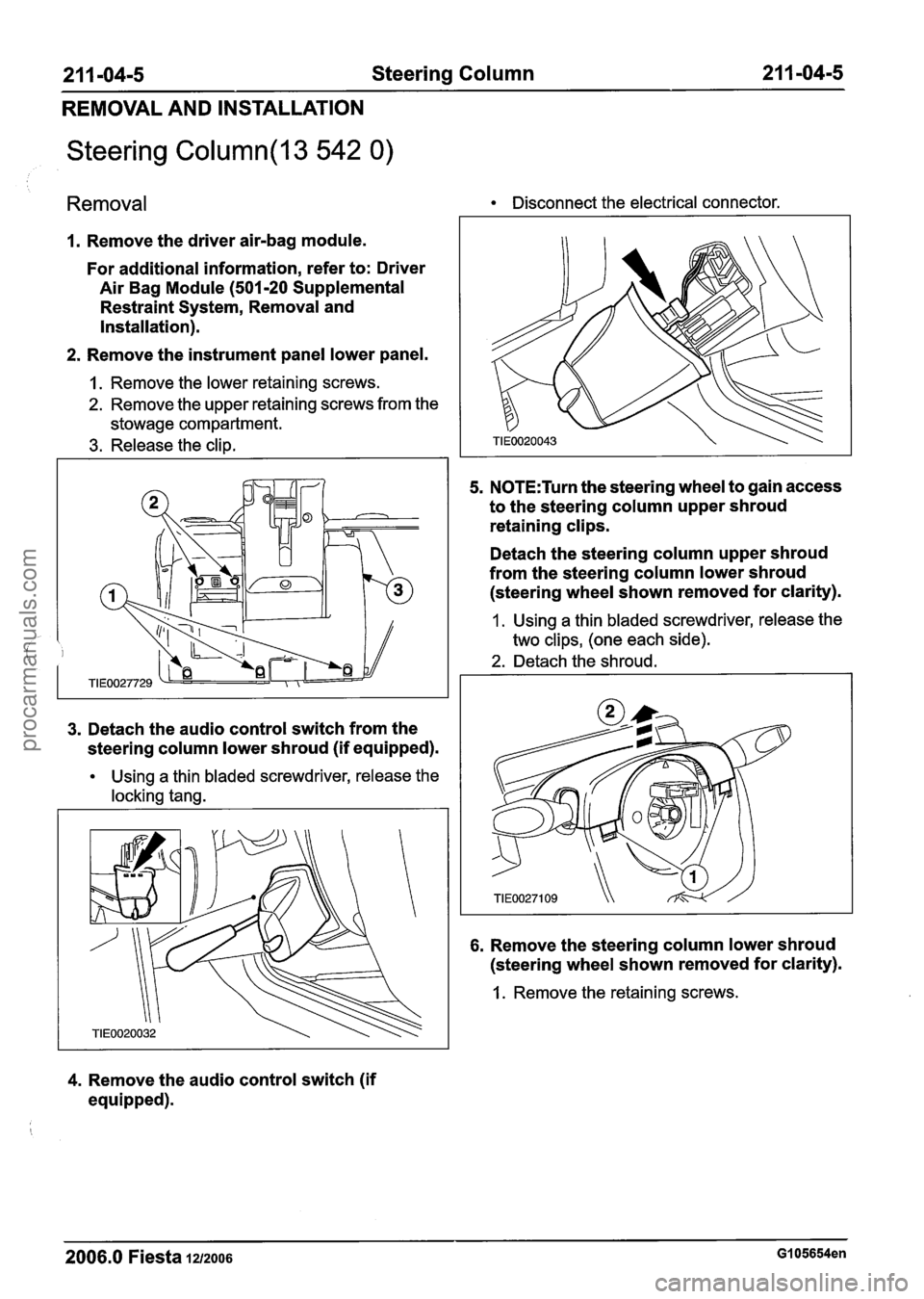

21 1 -04-5 Steering Column 2 I I -04-5

REMOVAL AND INSTALLATION

Steering Column(l3 542 0)

Removal Disconnect the electrical connector.

1. Remove the driver air-bag module.

For additional information, refer to: Driver

Air Bag Module (501-20 Supplemental

Restraint System, Removal and

Installation).

2. Remove the instrument panel lower panel.

1. Remove the lower retaining screws.

2. Remove the upper retaining screws from the

stowage compartment.

3. Release the clip.

3. Detach the audio control switch from the

steering column lower shroud (if equipped).

Using a thin bladed screwdriver, release the

locking tang.

4. Remove the audio control switch (if

equipped).

5. N0TE:Turn the steering wheel to gain access

to the steering column upper shroud

retaining clips.

Detach the steering column upper shroud

from the steering column lower shroud (steering wheel shown removed for clarity).

1 . Using a thin bladed screwdriver, release the

two clips, (one each side).

2. Detach the shroud.

6. Remove the steering column lower shroud

(steering wheel shown removed for clarity).

1. Remove the retaining screws.

2006.0 Fiesta 1212006 GI 05654en

procarmanuals.com