coolant FORD FIESTA 2007 Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2007, Model line: FIESTA, Model: FORD FIESTA 2007Pages: 1226, PDF Size: 61.26 MB

Page 995 of 1226

Automatic Transmission/Transaxle -

Vehicles With: 4Speed Automatic

307-01 -35 Transmission (AW81-40) 307-01 -35

DESCRIPTION AND OPERATION

Engine speed

1 The engine speed is detected by the crankshaft

position (CKP) sensor and passed on to the PCM.

The engine speed is transmitted from the PCM via

the CAN

databus to the transmission control unit.

The transmission control unit uses this signal for:

Torque reduction during gearshifts,

Pressure control during gearshifts.

Engine load

The PCM determines a load signal which is

transmitted via the CAN

databus to the

transmission control unit.

The transmission control unit uses this signal for:

Torque reduction during gearshifts,

Pressure control during gearshifts,

Shift timing adaptation during upshifts,

Shift timing adaptation during shifts from 3rd to

4th gear,

Hill climb mode,

( ' Hill descent mode. ' ,

Torque reduction request signal

Before performing a gearshift, the transmission

control unit sends a signal via the CAN

databus to

the PCM requesting a torque reduction.

The PCM then reduces the engine torque, ensuring

that the gearshift is as smooth and judder-free as

possible.

Brake signal

The PCM receives a signal from the stoplamp

switch when the brake pedal is depressed.

This signal is transmitted via the CAN

databus to

the transmission control unit.

The transmission control unit uses this signal for:

Gearshift control,

Engagement of the TCC

Accelerator pedal position

The PCM receives the current accelerator pedal

position signal from the Accelerator Pedal Position

(APP) sensor.

This signal is transmitted via the CAN

databus to

the transmission control unit.

The transmission control unit uses this signal for:

Controlling the main line pressure,

Gearshift control,

Engagement of the TCC,

Shift timing adaptation during upshifts,

Shift timing adaptation during shifts from 3rd to

4th gear,

Shift timing adaptation during shifts from 4th to

3rd gear,

Avoidance of gearshift judder during

engagement of a transmission range,

Torque reduction when pulling away.

Coolant temperature

The coolant temperature is detected by the Engine

Coolant Temperature (ECT) sensor and passed

on to the PCM.

This signal is transmitted via the CAN

databus to

the transmission control unit.

The transmission control unit uses this signal for:

Cold start mode,

Engagement of the TCC

Selector lever position

The transmission control unit transmits the selector

lever position to the instrument cluster.

The instrument cluster uses the signal to send a

request for a warning tone to the GEM when the

selector lever is not in position "P" and the driver's

door is opened.

-

2006.0 Fiesta 1212006 G380530en

procarmanuals.com

Page 1006 of 1226

Automatic Transmission/Transaxle -

Vehicles With: 4Speed Automatic

307-01 -46 Transmission

(AW81-40) 307101 -46

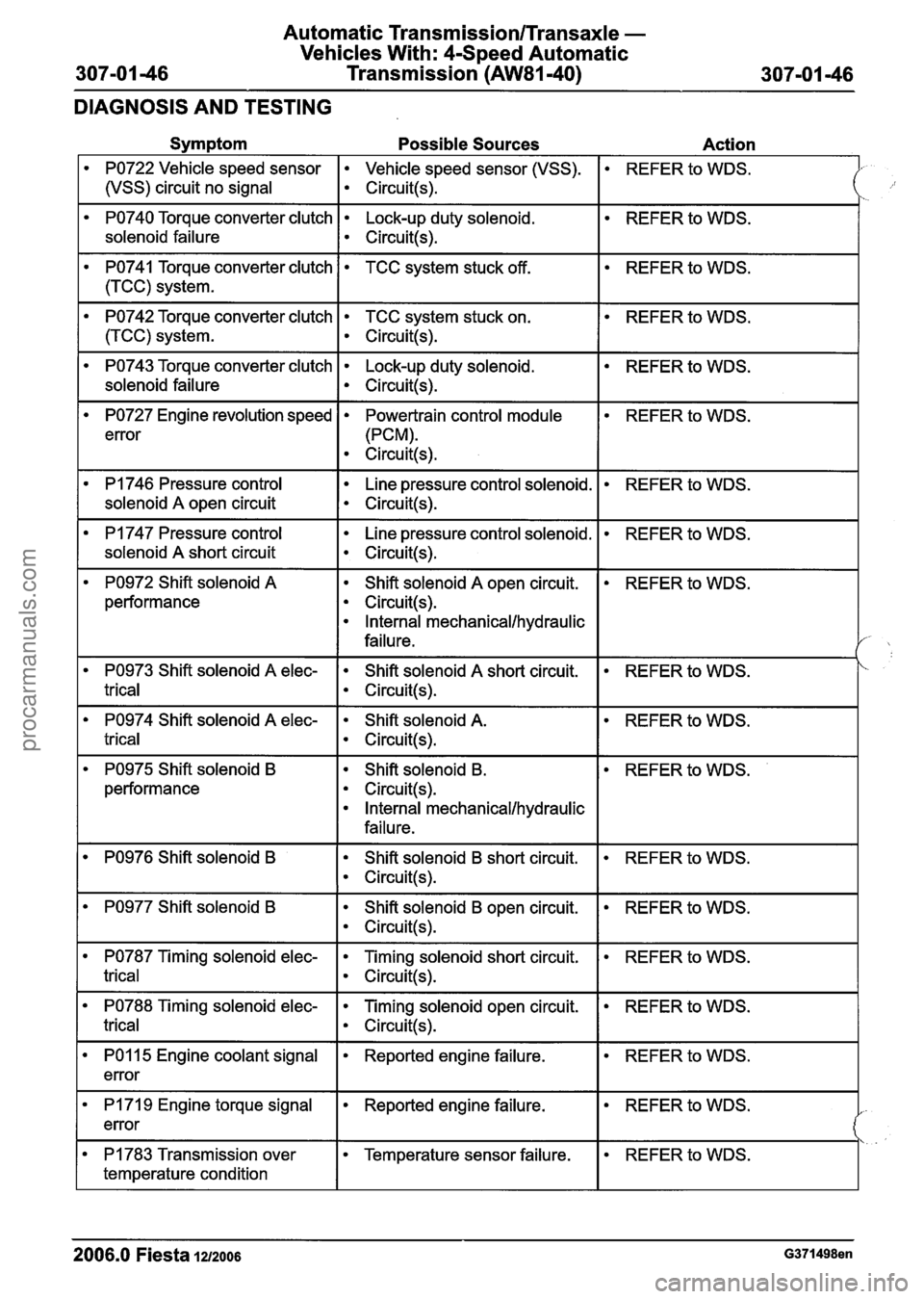

DIAGNOSIS AND TESTING

Symptom Possible Sources Action

PO722 Vehicle speed sensor Vehicle speed sensor (VSS).

1 (vSS) circuit no signal I circuit(+

REFER to WDS.

PO740 Torque converter clutch Lock-up duty solenoid.

solenoid failure

I ~ircuit(s).

REFER to WDS.

REFER to WDS.

PO741 Torque converter clutch

1 (TCC) system.

PO742 Torque converter clutch TCC system stuck on.

I circuit(s).

TCC system stuck off.

REFER to WDS.

PO743 Torque converter clutch Lock-up duty solenoid.

solenoid failure

I circuit(s).

REFER to WDS.

REFER to WDS.

PO727 Engine revolution speed

error

PI 746 Pressure control

I solenoid A open circuit

Powertrain control module

(PCM).

Circuit(s).

I

Line pressure control solenoid.

Circuit(s).

REFER to WDS.

PI 747 Pressure control

solenoid

A short circuit

Line pressure control solenoid.

Circuit(s).

REFER to WDS.

PO972 Shift solenoid A

performance Shift solenoid

A open

circuit.

Circuit(s).

Internal mechanical/hydraulic

failure.

REFER to WDS.

REFER to WDS.

PO974 Shift solenoid A elec- Shift solenoid A.

trical I circuit(!+

PO973 Shift solenoid A elec-

trical

REFER to WDS. Shift solenoid A short circuit.

Circuit(s).

PO975 Shift solenoid B

performance Shift solenoid

B.

Circuit(s).

Internal mechanical/hydraulic

failure.

REFER

to WDS.

PO976 Shift solenoid B Shift solenoid B short circuit.

Circuit(s).

REFER to WDS.

PO977 Shift solenoid B Shift solenoid B open circuit.

Circuit(s).

REFER to WDS.

PO787 Timing solenoid elec- Timing solenoid short circuit.

trical I circuit(s).

REFER to WDS.

REFER to WDS. PO788 Timing solenoid elec-

trical

-- - -

Timing solenoid open circuit.

Circuit(s).

REFER to WDS. PO1 15 Engine coolant signal

error Reported engine failure.

REFER to WDS. I PI 71 9 Engine torque signal

error Reported engine failure.

REFER to WDS. PI 783 Transmission over

temperature condition

2006.0 Fiesta 12/2006 G371498en

Temperature sensor failure.

procarmanuals.com

Page 1117 of 1226

308-03-27 Manual TransmissionlTransaxle 308-03-27

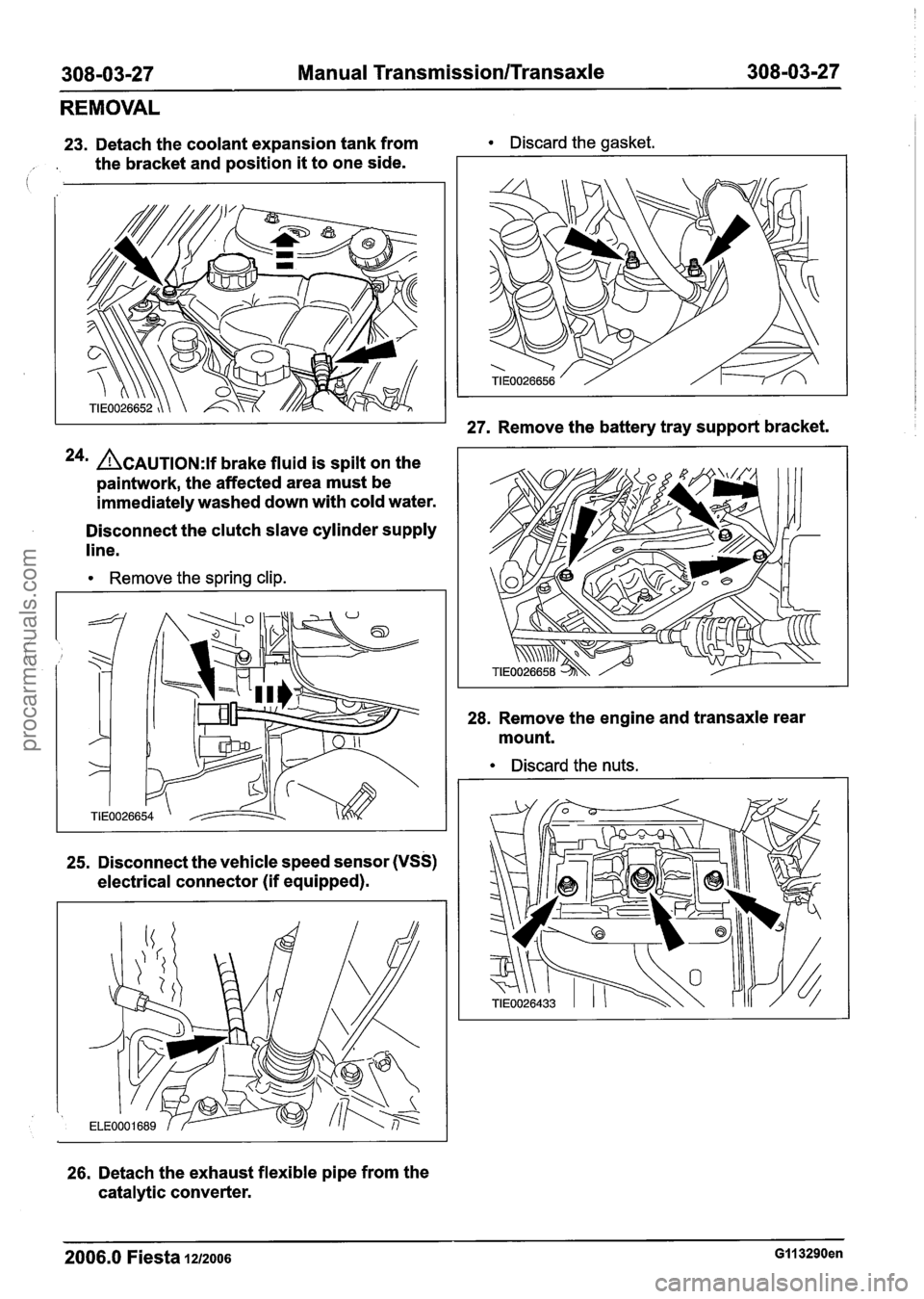

REMOVAL

23. Detach the coolant expansion tank from Discard the gasket.

, . the bracket and position it to one side.

24m ACAUTION:~~ brake fluid is spilt on the

paintwork, the affected area must be

immediately washed down with cold water.

Disconnect the clutch slave cylinder supply

line.

Remove the spring clip.

25. Disconnect the vehicle speed sensor (VSS)

electrical connector (if equipped).

26. Detach the exhaust flexible pipe from the

catalytic converter.

27. Remove the battery tray support bracket.

28. Remove the engine and transaxle rear

mount.

Discard the nuts.

2006.0 Fiesta 1212006 GI1 3290en

procarmanuals.com

Page 1154 of 1226

308-03-64 Manual Transmission/Transaxle 308-03-64

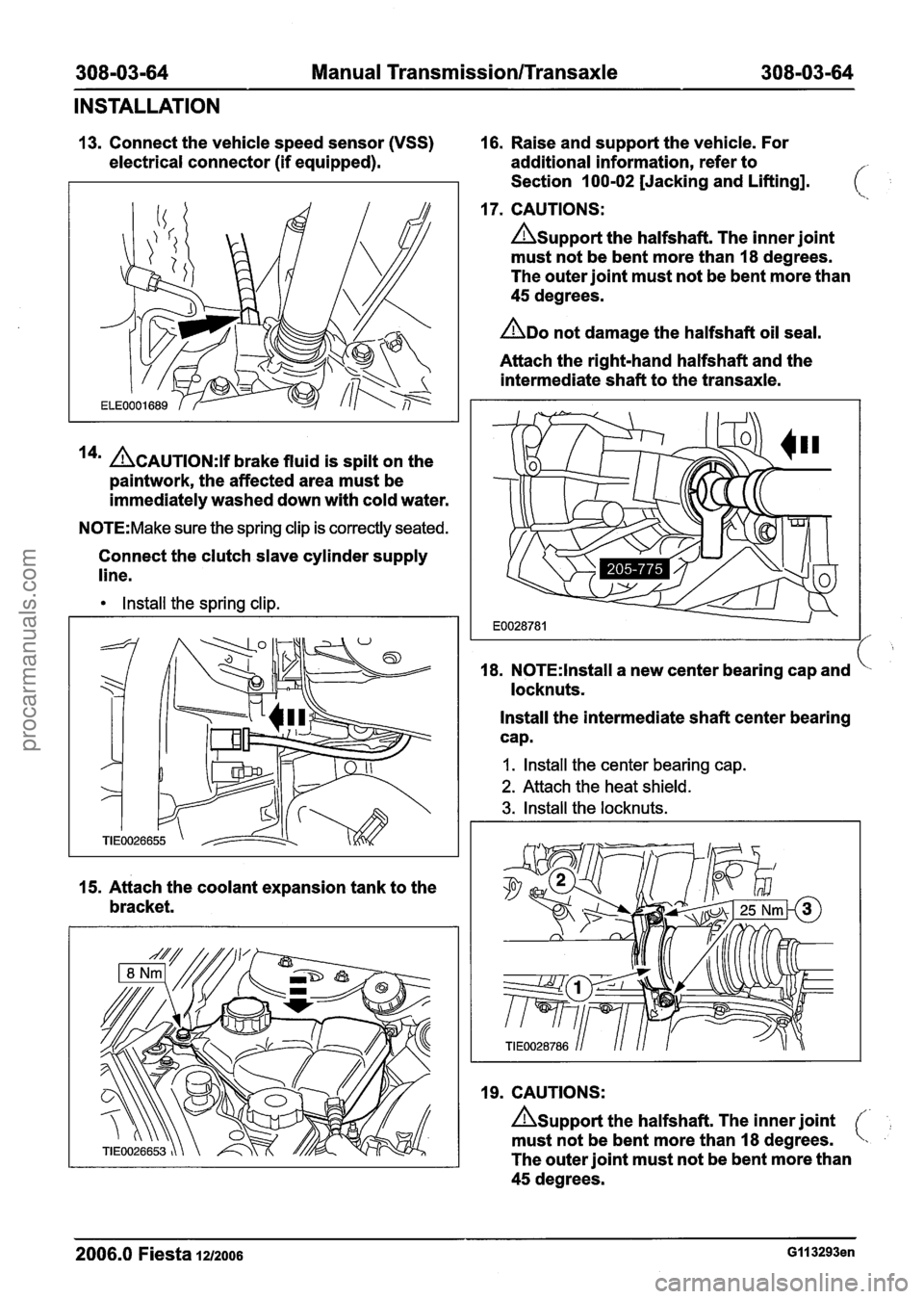

INSTALLATION

13. Connect the vehicle speed sensor (VSS) 16. Raise and support the vehicle. For

electrical connector (if equipped). additional information, refer to

Section 100-02 [Jacking and Lifting].

17. CAUTIONS:

Asupport the halfshaft. The inner joint

must not be bent more than 18 degrees.

The outer joint must not be bent more than

45 degrees.

ADO not damage the halfshaft oil seal.

Attach the right-hand halfshaft and the

intermediate shaft to the transaxle.

14' ACAUTION:~~ brake fluid is spilt on the

paintwork, the affected area must be

immediately washed down with cold water.

N0TE:Make sure the spring clip is correctly seated.

Connect the clutch slave cylinder supply

line.

Install the spring clip.

15. Attach the coolant expansion tank to the

bracket. 18.

N0TE:lnstall a

new center bearing cap and

locknuts.

Install the intermediate shaft center bearing

cap.

I. Install the center bearing cap.

2. Attach the heat shield.

3. Install the locknuts.

19. CAUTIONS:

Asupport the halfshaft. The inner joint

must not be bent more than 18 degrees.

The outer joint must not be bent more than

45 degrees.

2006.0 Fiesta 1212006 GI I 3293en

procarmanuals.com