manual transmission FORD FIESTA 2007 Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2007, Model line: FIESTA, Model: FORD FIESTA 2007Pages: 1226, PDF Size: 61.26 MB

Page 4 of 1226

Intake Air Distribution and

- Filtering

303-1 2

Evaporative Emissions 303-1 3

Electronic Engine Controls 303-14

Automatic Transmission/Transaxle

Automatic TransmissionlTransaxle -

Vehicles With: 4-Speed Automatic

Transmission

(AW81-40) 307-01

TransmissionlTransaxle Cooling -

Vehicles With: 4-Speed Automatic

Transmission

(AW81-40) 307-02

Automatic

TransmissionlTransaxle

External Controls - Vehicles With:

4-Speed Automatic Transmission

(AW8 1 -40) 307-05

Manual Transmissionrrransaxle, Clutch and

Transfer Case

Manual TransmissionlTransaxle and

Clutch

- General Information 308-00

Clutch 308-0 1

Clutch Controls 308-02

Manual

Transmission/Transaxle 308-03

Manual TransmissionlTransaxle

External Controls 308-06

Exhaust System

Exhaust System 309-00

Fuel System

Fuel System - General

Information 31 0-00

Fuel Tank and Lines

31 0-01

Acceleration Control - I .3L Duratec-8V

(Rocam)ll.25L Duratec-I 6V

Instrumentation and Warning Systems

lnstrument Cluster and Panel

(

Illumination 41 3-00

Instrument Cluster

413-01

Horn 41 3-06

lnformation and Message

Center 41 3-08

Warning Devices

4 1 3-09

Parking Aid 41 3-1 3

Battery and Charging System

Charging System - General

Information 4 14-00

Battery, Mounting and Cables 414-01

Generator and Regulator 41 4-02

lnformation and Entertainment Systems

lnformation and Entertainment System

- General Information 41 5-00

Audio Unit 41 5-01

Antenna 41 5-02

Lighting

Exterior Lighting 41 7-01

Interior Lighting 4 1 7-02

Electrical Distribution

Module Communications ( 'j

Network 41 8-00

Module Configuration 41 8-01

Electronic Feature Group

Anti-Theft - Active 419-01A

Anti-Theft

- Passive 41 9-01 B

Cellular Phone 41 9-08

Multifunction Electronic

Modules 41 9-1 0

Climate Control System

Climate Control System - General

Information

Air Distribution and Filtering

Heating and Ventilation

Air Conditioning

Control Components

(Sigma)ll.4L Duratec-I 6V

lnterior Trim and

Ornamentation

Exterior Trim and

Ornamentation

Rear View Mirrors

Seating

Glass, Frames and

Mechanisms

(Sigma)/l .6L Duratec-1 6V

Instrument Panel and Console 501 -1 2

0512005 2006.0 Fiesta

GROUP 5 Body and Paint

(Sigma) 3 1 0-02A

Acceleration Control

- 2.OL Duratec-HE Body and Paint

(M14) 31 0-028 Body System - General

Information 501 -00

GROUP 4 Electrical Front End Body Panels 50 1 -02

Body Closures 50 1 -03

procarmanuals.com

Page 11 of 1226

GROUP

Powertrain

SECTION TITLE PAGE

Engine

Engine System . General Information ........................................................................\

.... 303-00

Enginel.25L Duratec-I 6V (Sigma)ll.4L Duratec-1 6V (Sigma)ll . 6L Duratec-I 6V

........................................................................\

.............................................. (Sigma) -303-0 I A

........................................................................\

............... Engine2.0L Duratec-HE (M14) .30 3-01 B

Engine

Cooling1.3L Duratec-8V (Rocam)ll.25L Duratec-I 6V (Sigma)ll.4L

Duratec-1 6V (Sigma)ll . 6L Duratec-1 6V (Sigma) ...................................................... .30 3-03A

Engine

Cooling2.0L Duratec-HE (M14) ........................................................................\

.. 303-038

Fuel Charging and Controlsl.25L Duratec-1 6V (Sigma)ll.4L Duratec-1 6V

........................................................................\

... (Sigma)ll . 6L Duratec-1 6V (Sigma) .30 3-0414

Fuel Charging

and Controls2.0L Duratec-HE (M14) ....................................................... 303-04B

........................................................................\

.................................... Accessory Drive .30 3-05

Starting System

........................................................................\

...................................... 303-06

Engine Ignition

........................................................................\

....................................... 303-07A

Engine Ignition2.01 Duratec-HE (M14) ........................................................................\

... 303-07B

Engine Emission

Controll.3L Duratec-8V (Rocam)ll.25L Duratec-1 6V (Sigma)ll.4L

Duratec-1 6V (Sigma)ll . 6L Duratec-1 6V (Sigma) ...................................................... .30 3-08A

Engine Emission

Control2.0L Duratec-HE (M14) ........................................................... 303-088

........................................................................\

........ Intake Air Distribution and Filtering 303-1 2

........................................................................\

.......................... Evaporative

Emissions .30 3-13

........................................................................\

.................... Electronic Engine Controls .304 3-1

Automatic Transmission/Transaxle

Automatic Transmission/TransaxleVehicles With: 4-Speed Automatic Transmission

........................................................................\

......................................... (AW8 1 .40) .301 7.0

Transmission/Transaxle CoolingVehicles With: 4-Speed Automatic Transmission

........................................................................\

.......................................... (AW81-40) 307-02

Automatic

TransmissionlTransaxle External ControlsVehicles With: 4-Speed

........................................................................\

.. Automatic Transmission (AW81-40) .30 7.05

Manual Transmission/Transaxle. Clutch and Transfer Case

Manual Transmission/Transaxle and Clutch . General Information ............................... 308-00

........................................................................\

.................................................... Clutch .301 8.0

........................................................................\

..................................... Clutch Controls .30 8.02

Manual

TransmissionlTransaxle ........................................................................\

............ 308-03

Manual

TransmissionlTransaxle External Controls ........................................................ 308-06

0512005 2006.0 Fiesta

procarmanuals.com

Page 18 of 1226

General Information

........................................................................\

............................. Lubricants and Greases

Transmission Fluids

........................................................................\

....................................

........................................................................\

.......................................................... Noise

Noise Insulation Materials

........................................................................\

..........................

0-Rings (Fluoroelastomer) ........................................................................\

.........................

........................................................................\

.......................................................... Paints

........................................................................\

.............................. Pressurized Equipment . . ........................................................................\

......................................................... Solder

........................................................................\

...................................................... Solvents

Sound Insulation

........................................................................\

.........................................

Suspended Loads ........................................................................\

.......................................

Transmission Brake Bands ........................................................................\

.........................

........................................................................\

................................................... Underseal

........................................................................\

............................................................ Viton

........................................................................\

....................................................... Welding

........................................................................\

.................... Warning Symbols on Vehicles

........................................................................\

................................................. White Spirit

Standard Workshop Practices

........................................................................\

....................

Vehicle in Workshop ........................................................................\

...................................

Alternative Fuel ........................................................................\

...........................................

Alternative Fuel - Do's ........................................................................\

..............................

Alternative Fuel - Do Nots ........................................................................\

........................

Towing the Vehicle ........................................................................\

......................................

Connecting a Slave Battery Using Jumper Cables ............................................................

Component Cleaning ........................................................................\

..................................

Calibration of Essential Measuring Equipment ...................................................................

Solvents. Sealants and Adhesives ........................................................................\

.............

........................................................................\

................................................. Introduction

RoadlRoller Testing ........................................................................\

....................................

Pre-Test Checks ........................................................................\

.........................................

Starting the Engine ........................................................................\

.....................................

Road or Roller Testing ........................................................................\

................................

Brake Testing ........................................................................\

..............................................

procarmanuals.com

Page 24 of 1226

100=00=8 General Information 100=00=8

DESCRIPTION AND OPERATION

drowsiness. In extreme cases, loss of

consciousness may result. Long term exposure to

vapor concentrations may result in adverse health

effects.

Prolonged contact with the skin may have a

defatting effect which may lead to skin irritation

and in some cases, dermatitis.

Splashes entering the eye will cause discomfort

and possible damage.

Any spraying should preferably be carried out in

exhaust ventilated booths, removing vapors and

spray droplets from the breathing zone.

Wear appropriate gloves, eye and respiratory

protection. Asbestos dust

waste should be dampened, placed

in a sealed container and marked for safe disposal.

If any cutting or drilling is attempted on materials

(

containing asbestos the item should be dampened "

and only hand tools or low speed power tools used.

Battery Acids

See also Acids and Alkalis.

Gases released during charging are explosive.

Never use naked flames or allow sparks near

charging or recently charged batteries.

Make sure there is adequate ventilation.

Brake and Clutch Linings and Pads

Antifreeze

See Asbestos.

See also Fire, Solvents.

For example isopropanol, ethylene glycol,

methanol.

Highly flammable, flammable, combustible.

Used in vehicle coolant systems, brake air pressure

systems, screenwash solutions.

Vapors may be given off from coolant antifreeze

(glycol) when heated. Avoid breathing these

vapors.

Antifreeze may be absorbed through the skin in

toxic or harmful quantities. Antifreeze, if swallowed,

can be fatal and MEDICAL ATTENTION SHOULD

BE SOUGHT IMMEDIATELY.

These products must not be used in any cooling

or industrial water system that is connected or

linked to general, food preparation or drinking water

supplies.

Asbestos

See also Warning Symbols on Vehicles at the end

of this subsection.

Breathing asbestos dust may cause lung damage

or, in some cases, cancer.

Used in brake and clutch linings, transmission

brake bands and gaskets.

The use of drum cleaning units, vacuum cleaning

or damp wiping is preferred.

Brake Fluids (Polyal kylene Glycols)

See also Fire.

Splashes to the skin and eyes are slightly irritating.

Avoid skin and

eye'contact as far as possible.

Inhalation vapor hazards do not arise at ambient

temperatures because of the very low vapor

pressure.

Brazing

See Welding.

Chemical Materials

See also Legal Aspects.

Chemical materials such as solvents, sealers,

adhesives, paints, resin foams, battery acids,

antifreeze, brake fluids, fuels, oils and grease

should always be used with caution and stored and

handled with care. They may be toxic, harmful,

corrosive, irritant or highly flammable and give rise

to hazardous fumes and dusts.

The effects of excessive exposure to chemicals may be immediate or delayed; briefly experienced

or permanent; cumulative; superficial; life

threatening; or may reduce life expectancy.

2006.0 Fiesta 1212006 GI 7372en

procarmanuals.com

Page 29 of 1226

100-00-1 3 General Information 100-00-1 3

DESCRIPTION AND OPERATION

Do not use damaged or defective tools or

equipment, particularly high-speed equipment such

i as grinding wheels. A damaged grinding wheel can

disintegrate without warning and cause serious

injury.

Wear suitable eye protection when using grinding,

chiseling or sand blasting equipment.

Wear a suitable breathing mask when using

abrasive blasting equipment, working with

asbestos-based materials or using spraying

equipment.

Make sure there is adequate ventilation to control

dusts, mists and fumes.

High Pressure Air, Lubrication and Oil

Test Equipment

See also Lubricants and Greases.

Always keep high-pressure equipment in good

condition, and regularly maintained, particularly at

joints and unions.

Never direct a high-pressure nozzle, for example

diesel injector, at the skin as the fluid may

, penetrate to the underlying tissue, and cause

serious injury.

Halon

See CFCs.

Legal Aspects

There are many laws and regulations relating to

health and safety in the use and disposal of

materials and equipment in a workshop.

For a safe working environment and to avoid

environmental pollution, workshops should be

familiar, in detail, with the many health and safety

laws and regulations within their country, published

by both national and local authorities.

Lubricants and Greases

Avoid all prolonged and repeated contact with

mineral oils. All lubricants and greases may be

irritating to the eyes and skin.

'

Transmission Fluids

Safety instructions

Certain Transmission and Power Steering fluids

supplied to Ford may contain additives which have

the potential to cause skin disease (dermatitis) to

exposed persons. The dermatitis may be irritant

or allergic in nature. Risks are higher where

prolonged or repeated skin contact with a fluid may

occur. These fluids are used for vehicle initial

fill

and service purposes. This sub-section is to:

Inform Service personnel who may come into

contact with these vehicle fluids (hazard

communication).

Summarise appropriate workplace control

measures and personal protective equipment

requirements.

Draw attention to the existence of Material

Safety Datasheets (MSDS's) for the fluids

(available from Ford Customer Service Division).

These MSDS's contain detailed information on

hazards and appropriate controls.

Control measures

Workplace risk assessments made under national

chemical control regulations should identify

operations involving the fluids as potentially

hazardous and specify workplace control and

worker awareness measures. In such

circumstances, the relevant Material Safety

Datasheet (see the details specified below) which

specifies hazards and control measures in detail

should be made available for guidance.

Avoid unprotected skin contact with the fluids, and

in particular, avoid prolonged or repeated skin

contact. Work practices should be organised so as

to minimise the potential for skin contact. This may

include the use of drip trays, absorbents, correct

fluid handling equipment (funnels etc), and

workplace housekeeping measures such as the

cleaning of contaminated surfaces.

Personnel engaged in operations where skin

contact could occur (such as fluid draining or filling)

should wear impervious gloves made from

nitrile

rubber, certified to a chemical protection standard,

e.g. Europe Standard EN374. This glove type is

widely available from reputable suppliers of gloves

for chemical protection [including the manufacturers

Ansell-Admont

(Solvex Range), North Safety

products (North

Nitrile Latex Gloves range), and

2006.0 Fiesta 1212006 GI 7372en

procarmanuals.com

Page 30 of 1226

![FORD FIESTA 2007 Workshop Manual

100-00-1 4 General Information 100-00-1 4

DESCRIPTION AND OPERATION

Marigold Industrial (Blue Nitrile range)]. If gloves

become torn or contaminated on the inside they

should be replaced. Eye FORD FIESTA 2007 Workshop Manual

100-00-1 4 General Information 100-00-1 4

DESCRIPTION AND OPERATION

Marigold Industrial (Blue Nitrile range)]. If gloves

become torn or contaminated on the inside they

should be replaced. Eye](/img/11/56936/w960_56936-29.png)

100-00-1 4 General Information 100-00-1 4

DESCRIPTION AND OPERATION

Marigold Industrial (Blue Nitrile range)]. If gloves

become torn or contaminated on the inside they

should be replaced. Eye protection with safety

glasses is appropriate. Use of an impervious apron

and arm protectors may be necessary if more

extensive exposure is possible. Use of skin barrier

creams suitable for work with mineral oil products

may offer some supplementary protection, but such

barrier creams should not be used in place of

protective clothing.

If accidental skin contact occurs with the fluids,

wash the area thoroughly with soap or skin

cleanser and water.

Accidental eye contact should be dealt with as per

normal first aid practices, by flushing the eyes with

an eye wash or clean cool water for

10 minutes,

after which medical attention should be obtained.

Remove and launder clothing which becomes

contaminated with the fluids. Do not place rags

contaminated with fluid in clothing pockets.

Wash thoroughly

after completing operations where

skin exposure may have occurred.

It is important that personnel do not smoke, eat or

drink whilst handling the fluids or affected

transmissions. These measures are designed to

limit the risk from accidental ingestion.

Label any decanted fluid

properlyluse an equivalent

label to that on original product containers.

Clean up any spills promptly using an inert

absorbent and wash down contaminated surfaces

with detergent and water.

Dispose of any waste fluids safely as hazardous

waste. Do

not employ used engine oils as lubricants or

for any application where appreciable skin contact

is likely to occur.

Environmental Precautions

Burning used engine oil in small space heaters or

boilers can be recommended only for units of

.

approved design. If in doubt check with the

appropriate local authority and manufacturer of

approved appliances.

Dispose of used oil and used oil filters through

authorized waste disposal contractors or licensed

waste disposal sites, or to the waste oil reclamation

trade. If in doubt, contact the relevant local

authority for advice on disposal facilities.

It is illegal to pour used oil on to the ground, down

sewers or drains, or into watercourses.

Noise

Some operations may produce high noise levels,

which could, in time, damage hearing. In these

cases, suitable ear protection must be worn.

Noise Insulation Materials

See Foams, Fibre Insulation.

0-Rings (Fluoroelastomer)

See Viton.

Paints

Safety Data Sheets

See also Solvents, Chemical Materials.

Safety Data Sheets, which detail specific material handling instructions and precautions are available

from the respective national sales company, and

via internet

www.msds.ford .corn.

Used Engine Oil

Prolonged and repeated contact with mineral oil

will result in the removal of natural fats from the

skin, leading to dryness, irritation and dermatitis.

In addition, used engine oil contains potentially

harmful contaminants, which may cause skin

cancer. Adequate means of skin protection and

washing facilities must be provided. Highly flammable, flammable

- observe No

Smoking policy

One Pack

Can contain harmful or toxic pigments, driers and

other components as well as solvents. Spraying

should be carried out only with adequate

ventilation.

2006.0 Fiesta 1212006 GI 7372en

procarmanuals.com

Page 32 of 1226

100-00-1 6 General Information 100-00-1 6 '

DESCRIPTION AND OPERATION

Transmission Brake Bands

See Asbestos.

Underseal Welding

See

also Fire, Electric Shock, Gas Cylinders. (

Welding processes include Resistance Welding

(Spot Welding), Arc Welding and Gas Welding.

See Corrosion Protection.

Resistance Welding

Viton

In common with many other manufacturers

vehicles, some components have O-rings, seals

or gaskets, which contain a material known as

'Viton'.

Viton is a fluoroelastomer, that is a synthetic rubber

type material, which contains Fluorine. It is

commonly used for O-rings, gaskets and seals of

all types. Although Viton is the most well known

fluoroelastomer, there are others, including

Fluorel

and Tecmoflon.

When used under design conditions

fluoroelastomers are perfectly safe. If, however,

they are exposed to temperatures in excess of

400°C, the material will not burn, but will

decompose, and one of the products formed is

hydrofluoric acid.

This acid is extremely corrosive and may be

absorbed directly, through contact, into the general

body system.

O-rings, seals or gaskets which have been exposed

to very high temperatures will appear charred or

as a black sticky substance.

DO NOT; under any circumstances touch them or

the attached components.

Enquiries should be made to determine whether

Viton or any other fluoroelastomer has been used

in the affected O-ring, seal or gasket. If they are of

natural rubber or

nitrile there is no hazard. If in

doubt, be cautious, as the material may be Viton

or any fluoroelastomer.

If Viton or any other fluoroelastomers have been

used, the affected area should be decontaminated

before the commencement of work.

Disposable heavy duty plastic gloves should be

worn at all times, and the affected area washed

down using wire wool and a limewater (calcium

hydroxide) solution to neutralize the acid before

disposing of the decomposed Viton residue and

final cleaning of the area. After use, the plastic

gloves should be discarded carefully and safely. This process may cause particles of molten metal

to

be emitted at a high velocity, and the eyes and

skin must be protected.

Arc Welding

This process emits a high level of ultra-violet radiation, which may cause arc-eye, and skin burns

to the operator and to other persons nearby.

Gas-shielded welding processes are particularly

hazardous in this respect. Personal protection must

be worn, and screens used to shield other

~eo~le. . .

CONTACT LENS WEARERS ARE ADVISED TO

REVERT TO ORDINARY SPECTACLES WHEN

ARC WELDING as the arc spectrum is believed to

emit microwaves which dry out the fluid between

the lens and the eye. This may result in blindness

when the lens is removed from the eve.

Metal spatter will also occur, and appropriate eye

and skin protection is necessary.

The heat of the welding arc will produce fumes and

gases from the metals being welded, the rods and

from any applied coatings or contamination on the

surfaces being worked on. These gases and fumes

may be toxic and inhalation of these should be

avoided. The use of extraction ventilation to remove

the fumes from the working area may be necessary

particularly in cases where the general ventilation

is poor, or where considerable welding work is

anticipated. In extreme cases or confined spaces

where adequate ventilation cannot be provided,

air-fed respirators may be necessary.

Gas Welding (and Cutting)

Oxy-acetylene torches may be used for welding

and cutting, and special care must be taken to

prevent leakage of these gases, with consequent

risk of fire and explosion.

("

The process will produce metal spatter and eye "

and skin protection is necessary.

2006.0 Fiesta 1212006 GI 7372en

procarmanuals.com

Page 36 of 1226

100-00-20 General Information 100-00-20

DESCRIPTION AND OPERATION

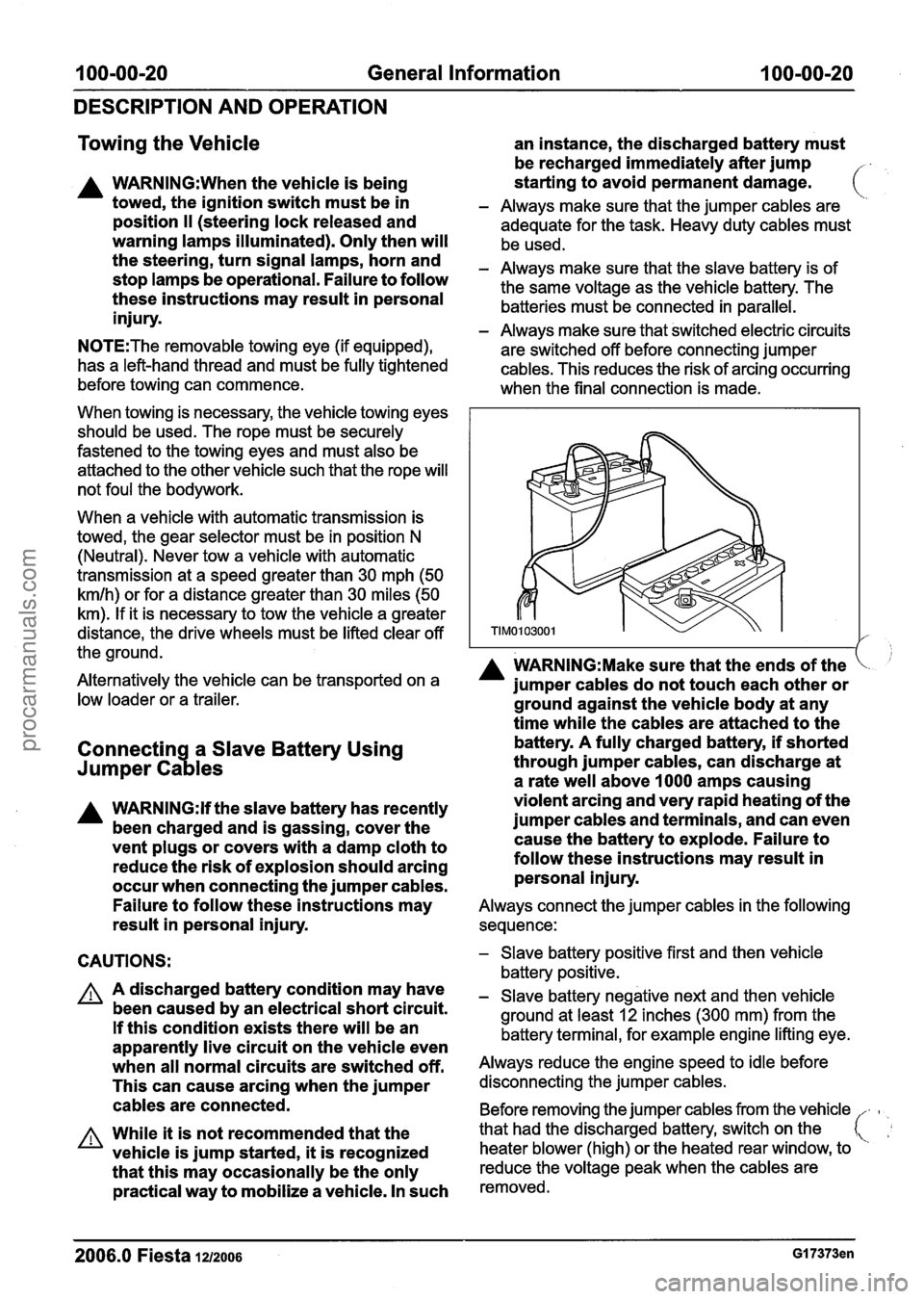

Towing the Vehicle

an instance, the discharged battery must

be recharged immediately after jump

A WARN1NG:When the vehicle is being starting

to avoid permanent damage. ( towed, the ignition switch must be in - Always make sure that the jumper cables are

position ll (steering lock released and adequate for the task. Heavy duty cables must

warning lamps illuminated). Only then will be used.

the turn signal lamps, horn and - Always make sure that the slave battery is of stop lamps be operational. Failure to follow the same voltage as the vehicle battery. The these instructions may result in personal batteries must be connected in parallel. injury. - Always make sure that switched electric circuits

N0TE:The removable towing eye (if equipped),

are switched off before connecting jumper

has a left-hand thread and must be fully tightened cables. This reduces the risk of arcing occurring

before towing can commence.

when the final connection is made.

When towing is necessary, the vehicle towing eyes

should be used. The rope must be securely

fastened to the towing eyes and must also be

attached to the other vehicle such that the rope will

not foul the bodywork.

When a vehicle with automatic transmission is

towed, the gear selector must be in position

N

(Neutral). Never tow a vehicle with automatic

transmission at a speed greater than 30 mph (50

kmlh) or for a distance greater than 30 miles (50

km). If it is necessary to tow the vehicle a greater

distance, the drive wheels must be lifted clear off

the ground.

I A WARN1NG:Make sure that the ends of the Alternatively the vehicle can be transported on a jumper cables do not touch each other or low loader or a trailer. ground against the vehicle body at any

time while the cables are attached to the

Connectin a Slave Battery Using

73

battery. A fully charged battery, if shorted

Jumper Ca les through jumper cables, can discharge at

a rate well above

I000 amps causing

A WARNING:H the slave battery has recently violent arcing

and very rapid heating of the

been charged and is gassing, cover the jumper cables and

terminals, and can even

vent plugs or covers with a damp cloth to cause

the battery to explode. Failure to

reduce the risk of explosion should arcing follow

these instructions may result in

occur when connecting the jumper cables. personal injury.

Failure to follow these instructions may

Always connect the jumper cables in the following

result in personal injury. sequence:

CAUTIONS:

A A discharged battery condition may have

been caused by an electrical short circuit.

If this condition exists there will be an

apparently live circuit on the vehicle even

when all normal circuits are switched off.

This can cause arcing when the jumper

cables are connected.

A While it is not recommended that the

vehicle is jump started,

it is recognized

that this may occasionally be the only

practical way to mobilize a vehicle. In such

- Slave battery positive first and then vehicle

battery positive.

- Slave battery negative next and then vehicle

ground at least

12 inches (300 mm) from the

battery terminal, for example engine lifting eye.

Always reduce the engine speed to idle before

disconnecting the jumper cables.

Before removing the jumper cables from the vehicle

-

heater blower (high) or the heated rear window, to

that

had the discharged battery, switch on the

reduce the voltage peak when the cables are

removed.

2006.0 Fiesta 1~12006 GI 7373en

procarmanuals.com

Page 39 of 1226

100-00-23 General Information 100-00-23

DESCRIPTION AND OPERATION

RoadIRoller Testing

I Road or roller testing may be carried out for various

reasons and a procedure detailing pre-test checks,

engine starting and stopping, pre-driving checks,

on-test checks and final checks to be completed

on completion of the test is given below.

Unless complete vehicle performance is being

checked, the full road test procedure need not be

carried out. Instead, those items particularly

relevant to the

system(s) being checked can be

extracted.

Pre-Test Checks

A WARNING:lf the brake system hydraulic

fluid level is low, pedal travel is excessive

or a hydraulic leak is found, do not attempt

to road test the vehicle until the reason for

the low fluid level, excessive pedal travel

or hydraulic leak is found and rectified.

It is suggested that pre-test checks and functional

tests of those systems and circuits which affect the

safe and legal operations of the vehicle, such as

( , brakes, lights and steering, should always be

carried out before the road or roller test.

With the ignition switched off, check:

- the engine oil level.

- the engine coolant level.

- the tires, for correct pressure, compatible types

and tread patterns, and wear within limits.

- that there is sufficient fuel in the tank to

complete the test.

- all around the engine, transmission and under

the vehicle for oil, coolant, hydraulic and fuel

leaks. Make a note of any apparent leaks and

wipe off the surrounding areas to make it easier

to identify the extent of the leak on completion

of the test.

Starting the Engine

N0TE:On initial drive away from cold and within

the first 1.5 km (1 mile), do not depress the

accelerator pedal beyond half travel until the

vehicle has attained a minimum speed of

25 kmlh

(15 mileslh). Never operate at high engine speed

or with the accelerator pedal at full travel whilst the

engine is cold.

With the ignition switched off, check:

- that the parking brake is applied.

- that the gear lever is in the neutral position.

- that all instrument gauges (except fuel gauge)

read zero.

With the ignition switched on, check:

- that the ignition controlled warning lamps are

illuminated.

- that the engine temperature gauge registers a reading compatible with the engine temperature.

- that the fuel gauge registers a reading

appropriate to the fuel level in the tank.

- the operation of the parking brake warning lamp

and fluid level warning indicator.

Road or Roller Testing

A CAUTI0N:lf road testing, check the brake

operation while still traveling at low speed

before continuing with the test. If the

brakes pull to one side, or appear to be

otherwise faulty, do not continue with the

road test until the fault has been found and

rectified.

During the road or roller test, check:

- that the clutch pedal operation is not stiff or

heavy.

- that the initial gear engagement is smooth and

there is no evidence of clutch drag.

- that the parking brake control operates smoothly

and releases quickly and completely.

- that the clutch takes up the drive smoothly,

without slip or judder.

- that gear changing is smooth with no abnormal

noises or vibrations from the transmission.

- the engine power output is satisfactory, full

power is achieved, acceleration is smooth and

pedal operation is not stiff or heavy, and engine

speed returns to idle correctly.

- there is no excessive or abnormally colored

smoke from the engine under normal driving,

heavy load or overrun conditions.

- that steering operation, including power steering

(if equipped), is smooth, accurate, not

excessively heavy or with excessive free play

or vibration.

- that the steering does not pull to one side and

self centers smoothly after cornering.

2006.0 Fiesta 1212006 GI 7375en

procarmanuals.com

Page 40 of 1226

100-00-24 General Information 100-00-24

DESCRIPTION AND OPERATION

- that the speedometer, coolant temperature - oil, coolant, hydraulic, air and fuel leaks.

gauge and tachometer (if equipped) register the - abnormal temperature of any moving

correct readings and operate correctly.

components or assemblies, for example wheel

(

- that the switches and controls operate smoothly hubs, transmission and axle, which might

and positively, warning and indicator lamps

indicate over tightness or lack of lubrication.

operate correctly and the direction indicator

control self cancels when the steering is

returned to the straight ahead position.

- that the heating and ventilation systems operate

correctly and effectively.

- the brake operation and efficiency.

Brake Testing

A WARNING:When brake testing, avoid

breathing the fumes from hot brakes, this

may contain asbestos dust which is

hazardous to health. Failure to follow this

instruction may result in personal injury.

For additional information, refer to: Health

and Safety Precautions

(1 00-00 General

Information, Description and Operation).

CAUTIONS:

A Avoid brake testing on busy roads where

it may cause inconvenience or danger to

other road users.

A Brake testing which includes heavy brake

applications should not be carried out with

new brake

padsldiscs or liningsldrums

until the components have bedded-in. New

brake friction components will not reach

full efficiency until the bedding-in process

is complete.

Test the brakes at several speeds within the normal

operating range using both light and heavy pedal

pressure. Note any tendency to snatch, pull or

drag, and any undue delay in application or

release.

Allow the vehicle to coast and note any tendency

to pull to one side, or evidence that the brakes are

binding.

After stopping the vehicle (not immediately after a

period of heavy braking), carefully check the brake

temperature.

A brake disc or brake drum that feels

hot or is appreciably hotter than the others,

indicates that the brake is binding.

After completion of the test, check for:

2006.0 Fiesta 1212006 GI 7375en

procarmanuals.com