brake light FORD FIESTA 2007 User Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 2007, Model line: FIESTA, Model: FORD FIESTA 2007Pages: 1226, PDF Size: 61.26 MB

Page 192 of 1226

206-00-20 Brake System - General Information 206=00-20

DIAGNOSIS AND TESTING

TEST CONDITIONS

DETAILSIRESULTSIACTIONS

F4: BLEED THE BRAKE SYSTEM

rn Check for air in the brake system. Bleed the

brake system. REFER to: (206-00 Brake System

- General lnformation)

Brake System Bleeding (General Procedures),

Brake System Pressure Bleeding (General Procedures)

.

Is the condition still present?

+ Yes

GO to F5.

+ No

Vehicle OK.

F5: CHECK FRONT WHEEL HUB RETAINING NUT

Check the front wheel hub retaining nut for

looseness.

Is the front wheel hub retaining nut loose?

+ Yes

INSTALL a new front wheel hub retaining nut.

REFER to: Specifications (204-01 Front

Suspension, Specifications).

Do not reuse the

frontwheel hub retaining nut.

TEST the system for normal operation.

+ No

CHECK the parking bake adjustment. REFER

to: (206-05 Parking Brake and Actuation)

Parking Brake Cable Adjustment

- Vehicles With:

Rear Drum Brakes (General Procedures),

Parking Brake Cable Adjustment

- Vehicles With:

Rear Disc Brakes (General Procedures).

PINPOINT TEST G

: BRAKE LOCK UP DURING LIGHT BRAKE PEDAL FORCE

TEST CONDITIONS

DETAILSIRESULTSIACTIONS

I GI : ROAD TEST-THE VEHICLE I

Road test the vehicle and apply the brake pedal

lightly.

Do the rear brakes lock up?

+ Yes

GO to G2. GO to Pinpoint Test G.

+ No

Vehicle OK.

2006.0 Fiesta 12/2006 G28494en

procarmanuals.com

Page 196 of 1226

206-00-24 Brake System - General Information 206-00-24

DIAGNOSIS AND TESTING

TEST CONDITIONS DETAILSIRESU LTSIACTIONS

12: ROAD TEST THE VEHICLE

rn Road test the vehicle and apply the brakes.

Are the brakes functioning correctly?

-+ Yes

Vehicle OK.

+ No

INSPECT individual wheel cylinders or

calipers for binding or sticking components.

INSTALL new components as necessary.

BLEED the brake system. REFER to: (206-00

Brake System

- General Information)

Brake System Bleeding (General Procedures),

Brake System Pressure Bleeding (General Procedures).

TEST the system for normal operation.

PINPOINT TEST J

: EXCESSIVE BRAKE PEDAL EFFORT

TEST CONDITIONS

DETAILSIRESULTSIACTIONS

J1: CHECK BRAKE APPLICATION

With the engine off, apply and release the brake

pedal five times to deplete all vacuum from the

brake booster. Apply the brake pedal, hold with

light pressure. Start the engine.

Does the brake pedal hold?

+ Yes

GO to J2.

+ No

GO to J6.

52: CHECK BRAKE BOOSTER FOR LEAKS

rn Run the engine at medium idle, release the

accelerator pedal and turn the engine off. Wait

90 seconds and apply the brakes. Two or more

brake applications should be power assisted.

Does the brake booster work?

+ Yes

Vehicle OK.

-+ No

GO to

J3.

2006.0 Fiesta 1212006 G28494en

procarmanuals.com

Page 201 of 1226

206-00-29 Brake System - General Information 206-00-29

DIAGNOSIS AND TESTING

and repair the external leak. If the fluid level drops

and no external leak can be found, check for a

brake master cylinder bore end seal leak.

Brake System Check

Brake Pedal Reserve Check

Where a low brake pedal or the feel of a

bottomed-out condition exists, check for brake

pedal reserve.

1. Operate the engine at idle with the transaxle in

NEUTRAL.

2. Apply the brake pedal lightly three or four times.

3. Allow 15 seconds for vacuum to replenish the

brake booster.

N0TE:This increased resistance may feel like

something has bottomed out.

4. Apply the brake pedal until it stops moving

downward or an increased resistance to the

pedal travel occurs.

5. Hold the brake pedal in the applied position and

raise the engine speed to approximately 2000

rpm.

N0TE:The additional movement of the brake pedal

is the result of the increased engine intake manifold

vacuum which exerts more force on the brake

booster during engine rundown. This means that

additional stroke is available in the brake master

cylinder and the brake system is not bottoming out.

6. Release the accelerator pedal and observe that

the brake pedal moves downward as the engine

returns to idle speed.

Brake Booster Functional Test

lnspect all hoses and connections. All unused

vacuum connectors should be capped. Hoses and

their connections should be correctly secured and

in good condition with no holes and no collapsed 2.

With the transaxle in NEUTRAL, stop the engine

and apply the parking brake. Apply the brake

pedal several times to exhaust all vacuum in

the system.

3. With the engine turned off and all vacuum in the

system exhausted, apply the brake pedal and hold it down. Start the engine. If the vacuum

system is operating, the brake pedal will tend

to move downward under constant foot

pressure. If no motion is felt, the vacuum

booster system is not functioning.

4. Remove the vacuum hose from the brake

booster.

Intake manifold vacuum should be

available at the brake booster end of the hose

with the engine at idle speed and the transaxle

in NEUTRAL. Make sure that all unused vacuum

outlets are correctly capped, hose connectors

are correctly secured and vacuum hoses are in

good condition. When it is established that

manifold vacuum is available to the brake

booster, connector the vacuum hose to the

brake booster and repeat Step

3. If no

downward movement of the brake pedal is felt,

install a new brake booster. REFER to: (206-07

Power Brake Actuation)

Brake Booster

- LHD (Removal and lnstallation),

Brake Booster

- RHD (Removal and lnstallation).

5. Operate the engine a minimum of 10 seconds

at fast idle. Stop the engine and let the vehicle

stand for

10 minutes. Then, apply the brake

pedal with approximately 89

N (20 lb) force. The

pedal feel (brake application) should be the

same as that noted with the engine operating.

If the brake pedal feels hard (no power assist),

install a new vacuum check valve and then

repeat the test. If the brake pedal still feels hard,

install a new brake booster. REFER to: (206-07

Power Brake Actuation)

Brake Booster

- LHD (Removal and Installation),

Brake Booster

- RHD e em oval and installation).

If the brake pedal movement feels spongy, bleed

the brake system. REFER to: (206-00 Brake

System

- General Information)

areas. Inspect the check valve on the brake booster Brake System Bleeding (General Procedures),

for damage. Brake

System Pressure Bleeding (General

Procedures).

Brake Booster Operation Check

Brake Master Cylinder

1. Check the hydraulic brake system for leaks or

low fluid. Usually,

the first and strongest indicator of anything

wrong with the braking system is a feeling through

the brake pedal. In diagnosing the condition of the

brake master cylinder, check pedal feel as

2006.0 Fiesta 1212006 G28494en I

i

procarmanuals.com

Page 202 of 1226

Brake System - General Information

DIAGNOSIS AND TESTING

evidence of a brake concern. Check for the brake

warning indicator illumination and the fluid level in

the master cylinder reservoir.

Normal Conditions

The following conditions are considered normal

and are not indications that the brake master

cylinder is in need of service.

- Modern brake systems are not designed to

produce as hard a pedal effort as in the past.

Complaints of light pedal efforts should be

compared to pedal efforts of another vehicle, of

the same model and year.

- During normal operation of the brake the fluid

level in the reservoir will rise during brake

application and fall during release. The net fluid

level

(i.e., after brake application and release)

will remain unchanged.

- A trace of brake fluid will exists on the brake

booster shell below the master cylinder

mounting flange. This results from the normal

lubricating action of the master cylinder bore

end seal.

- The fluid level will fall with brake shoe and lining

wear.

Abnormal Conditions

N0TE:Prior to performing any diagnosis, make

sure the brake system warning indicator is

functional.

Changes in brake pedal feel or travel are indicators

that something could be wrong with the braking system. The diagnostic procedure and techniques

use brake pedal feel, warning indicator illumination

and low brake fluid level as indicators in diagnosing

braking system concerns. The following conditions

are considered abnormal and indicate that the

brake master cylinder is in need of service.

- The brake pedal effort is excessive. This may

be caused by a bind or obstruction in the pedal

.

or linkage, clogged fluid control valve or ( ' insufficient booster vacuum.

- The rear brakes lock up during light pedal force.

This may be caused by incorrect tire pressures,

grease or fluid on the brake shoes and linings,

damaged brake shoes and linings, incorrectly

adjusted parking brake, or damaged or

contaminated brake pressure control valves.

- The brake pedal effort is erratic. This condition

could be caused by a brake booster malfunction,

extreme caliper piston knock back or incorrectly

installed brake shoes and linings.

- The brake warning indicator is ON. This may

be caused by low fluid level, ignition wire routing

too close to the fluid level indicator assembly,

or float assembly damage.

Bypass Condition Test

1. Check the fluid in brake master cylinder. Fill the

brake master cylinder reservoir if low or empty.

2. Observe the fluid level in the brake master

cylinder reservoir. If after several brake

applications, the fluid level remains the same,

measure the wheel turning torque required to

rotate the wheels with the brakes applied as

follows:

Place the transaxle in NEUTRAL and raise and

support the vehicle. REFER to: (1 00-02 Jacking

and Lifting)

Jacking (Description and Operation),

Lifting (Description and Operation).

Apply the brakes with a minimum of 445 N (100

Ib) and hold for approximately 15 seconds. With

the brakes still applied, exert a torque on the front

wheels of 10.1 Nm (75

1b.R). If either wheel rotates,

install a new brake master cylinder. REFER to:

(206-06 Hydraulic Brake Actuation)

- The brake pedal goes down fast. This could be Brake Master Cylinder - RHD (Removal and

caused by an external or internal leak. Installation),

- The brake

pedal eases down slowly. This could Brake Master Cylinder - LHD

(Removal and

be caused by an external or internal leak. Installation).

- The

brake pedal is low and or feels spongy. This

condition may be caused by no fluid in the brake

Non-Pressure Leaks master cylinder reservoir, reservoir cap vent

holes clogged or air in the hydraulic system.

Any empty brake master cylinder reservoir

condition may be caused by two types of

non-pressure external leaks.

2006.0 Fiesta 1212006

procarmanuals.com

Page 549 of 1226

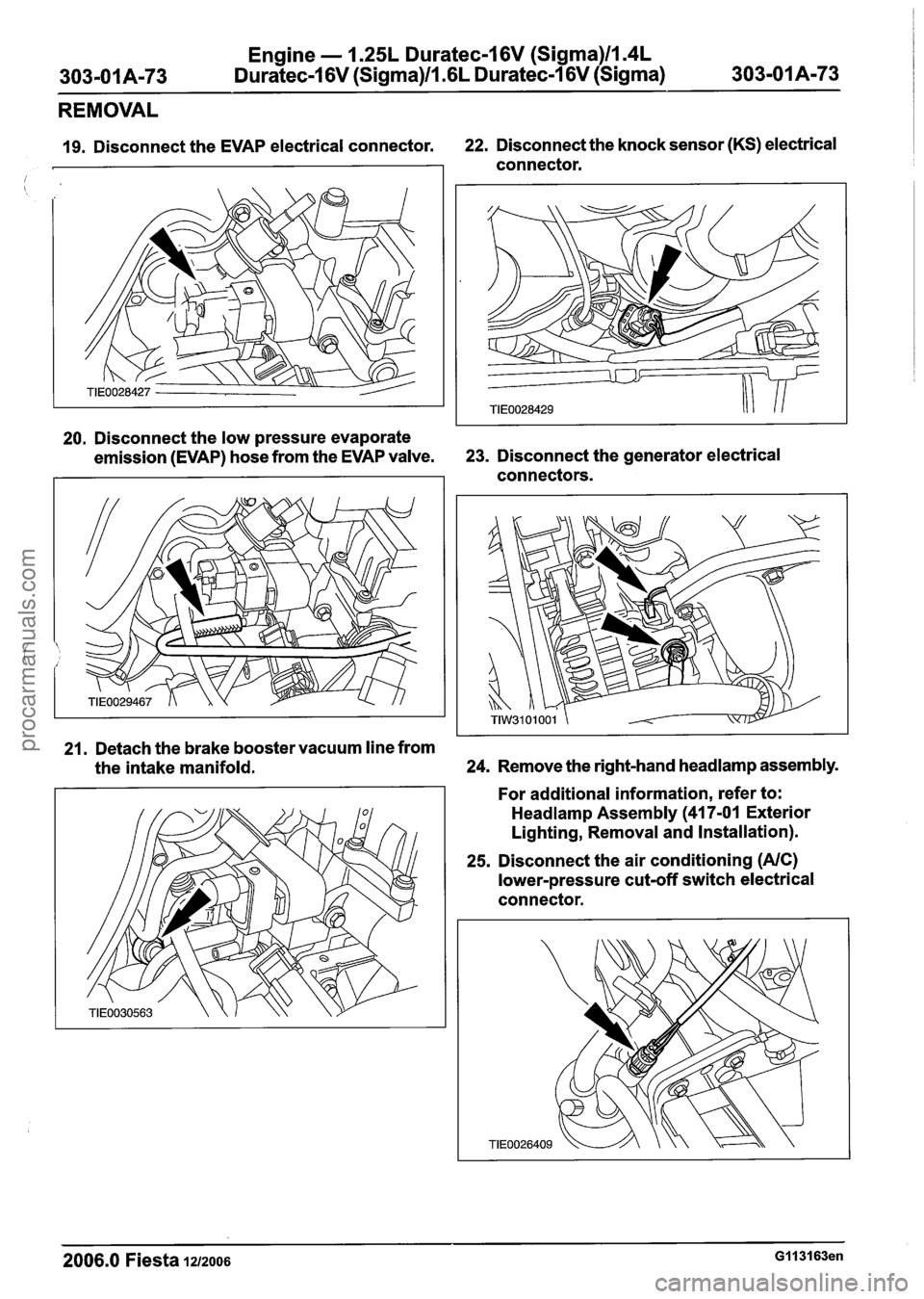

Engine - 1.25L Duratec-1 6V (Sigma)lIl4L

Duratec-1 6V (Sigma)ll .6L Duratec-1 6V (Sigma)

REMOVAL

19. Disconnect the EVAP electrical connector. 22.

Disconnect the knock sensor (KS) electrical

connector.

20. Disconnect the low pressure evaporate

emission (EVAP) hose from the EVAP valve. 23.

Disconnect the generator electrical

connectors.

21. Detach the brake booster vacuum line from

the intake manifold. 24.

Remove the right-hand

headlamp assembly.

For additional information, refer to:

Headlamp Assembly (41 7-01 Exterior

Lighting, Removal and Installation).

25. Disconnect the air conditioning

(AIC)

lower-pressure cut-off switch electrical

connector.

2006.0 Fiesta 1212006 GI 131 63en

procarmanuals.com

Page 741 of 1226

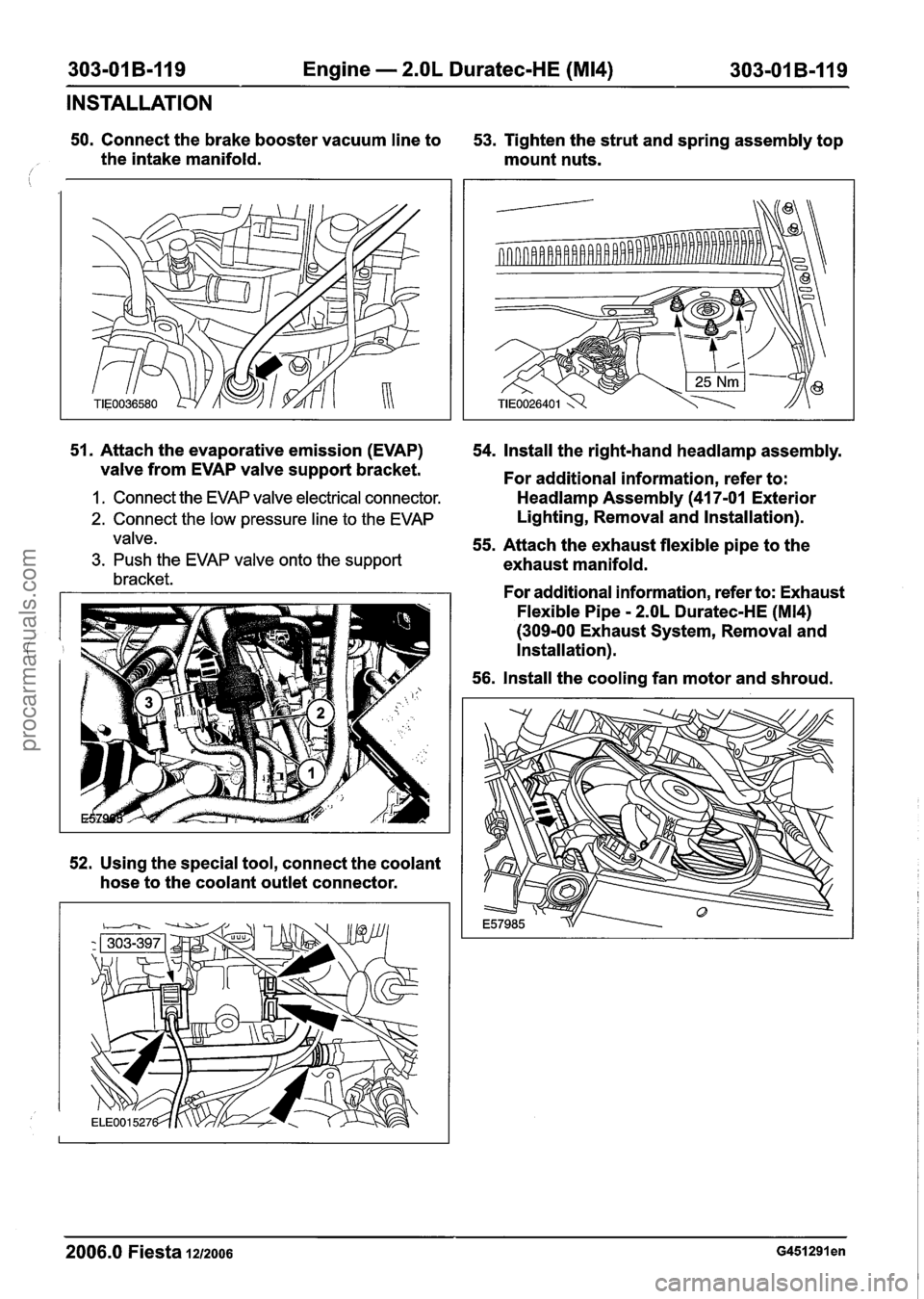

303-01 B-1/19 Engine - 2.OL Duratec-HE (M14) 303-01 B-119

INSTALLATION

50. Connect the brake booster vacuum line to

53. Tighten the strut and spring assembly top

the intake manifold. mount nuts.

/

51. Attach the evaporative emission (EVAP)

valve from EVAP valve support bracket.

I. Connect the EVAP valve electrical connector.

2. Connect the low pressure line to the EVAP

valve.

3. Push the EVAP valve onto the support

bracket.

52. Using the special tool, connect the coolant

hose to the coolant outlet connector. 54.

Install the right-hand

headlamp assembly.

For additional information, refer to:

Headlamp Assembly (41 7-01 Exterior

Lighting, Removal and Installation).

55. Attach the exhaust flexible pipe to the

exhaust manifold.

For additional information, refer to: Exhaust

Flexible Pipe

- 2.OL Duratec-HE (M14)

(309-00 Exhaust System, Removal and

Installation).

56. Install the cooling fan motor and shroud.

2006.0 Fiesta 1212006 ~451291 en

procarmanuals.com

Page 990 of 1226

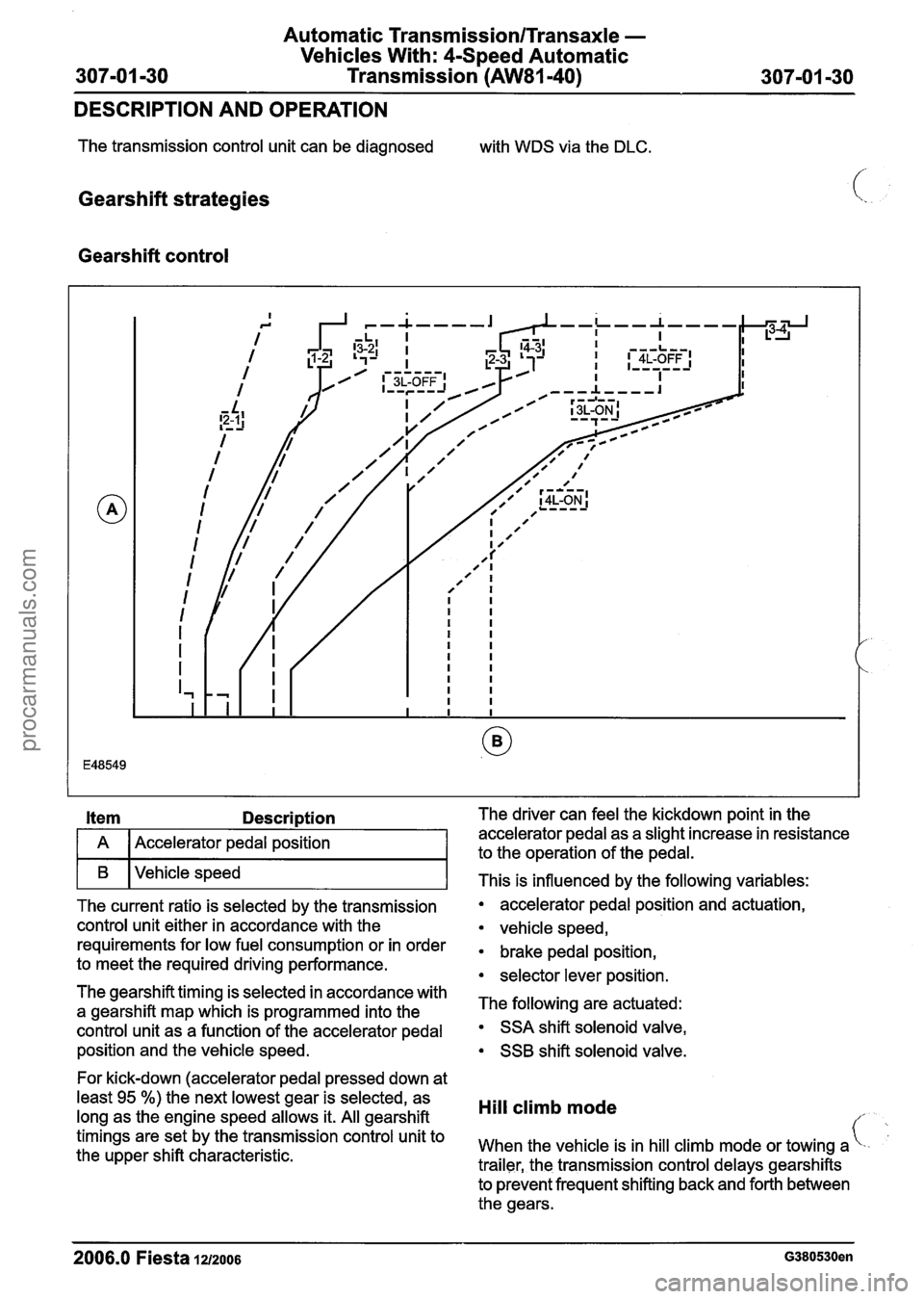

Automatic Transmission/Transaxle -

Vehicles With: 4-Speed Automatic

307-01 -30 Transmission (AW81-40) 307-01 -30

DESCRIPTION AND OPERATION

The transmission control unit can be diagnosed

with WDS via the DLC.

Gearshift strategies

Gearshift control

I A I Accelerator pedal position I

I B I vehicle speed 1

The current ratio is selected by the transmission

control unit either in accordance with the

requirements for low fuel consumption or in order

to meet the required driving performance.

The gearshift timing is selected in accordance with

a gearshift map which is programmed into the

control unit as a function of the accelerator pedal

position and the vehicle speed.

For kick-down (accelerator pedal pressed down at

least

95 %) the next lowest gear is selected, as

long as the engine speed allows it. All gearshift

timings are set by the transmission control unit to

the upper shift characteristic. The driver can feel the

kickdown point

in the

accelerator pedal as a slight increase in resistance

to the operation of the pedal.

This is influenced by the following variables:

accelerator pedal position and actuation,

vehicle speed,

brake pedal position,

selector lever position.

The following are actuated:

SSA shift solenoid valve,

SSB shift solenoid valve.

Hill climb mode

When the vehicle is in hill climb mode or towing a

trailer, the transmission control delays gearshifts

to prevent frequent shifting back and forth between

the gears.

2006.0 Fiesta 1u2oos

procarmanuals.com

Page 1219 of 1226

Acceleration Control - 1.3L Duratec-8V

(Rocam)ll.25L Duratec-1 6V (Sigma)ll.4L

31 0-02A-5 Duratec-1 6V (Sigma)/l .6L Duratec-1 6V (Sigma)

31 0-02A-5

DIAGNOSIS AND TESTING

PCM to the electronic throttle body including

the electrical connectors in area "B" (see

system overview).

- There is an obstruction inside the throttle

body bore. Remove the air cleaner outlet pipe

and check for obstructions.

- There is an obstruction inside the electronic

throttle body. Remove the air cleaner outlet

pipe and check that the plate moves freely

against the springs and returns to a slightly

open position. If it does not, install a new

electronic throttle body.

P2176 - Throttle plate adaptation error

- When the ignition is turned off, the throttle

body carries out an adaptation cycle and

spring check. This can be audible after a

short delay (up to 30 seconds) following the ignition key being turned to position

0 and

can be visually observed with the air cleaner

outlet pipe removed. The throttle plate is

moved through a series of positions to check

the TP sensor value and relearn the

electronic throttle body characteristics. If a

concern is detected during this test,

P2176

DTC will be set. If there are already any of

I the other DTCs, the adaptation test could

potentially fail. Therefore the other DTCs

should be resolved first

(e.g. low battery

voltage) and a retest can be carried out by

clearing the DTCs and keying on and off

again. Check the whole area "B" (see system

overview) for any concerns and if no concern

is found, install a new electronic throttle body.

P2100 - H bridge error

- A fault has been detected on the circuit

connecting the electronic throttle body motor

and the PCM. Check for any other

non-electronic accelerator control related

DTCs and rectify them first. Check area "B"

(see system overview) and if no failure is

found, install a new PCM.

PCM Related Codes

The PCM continuously monitors all the sensors. It

also checks that the monitor is functioning as

expected. If there is a fault with the monitor, the

following DTCs will be set.

P2107 - Processor monitoring on the main

controller fault.

P2108 -Analogue to digital converter

- Inferred intake mass air flow lower than

expected

- Engine speed monitor ratio error

- Pedal ratio monitor error

- TP sensor ratio monitor error

- Fault in torque generation

- Fault present in engine speed limitation

Multiple sensor faults can make the PCM assume

that there is a monitor fault. If other DTCs exist,

rectify these first. These DTCs indicate a failure in

area

"A or "B" and they are also related to the

manifold absolute pressure and temperature

(MAPT) sensor and the crankshaft position (CKP)

sensor. If no other failures are found, install a new

PCM.

Indirect Codes

There are two brake pedal switches located under

the brake pedal. Check that both of these are

connected and functioning correctly. A brake pedal

switch concern will only cause the "EAC FAIL"

message to be displayed, it will not lead to a limited

performance mode. Follow WDS instructions.

PO571 - Brake switch error

If the voltage to the accelerator pedal and the

electronic throttle body cannot be regulated

correctly, the components may not operate as

expected. Therefore it is important to detect if there

is a concern in the supply voltage

PO641 - Sensor voltage supply circuit I noisy

signal

PO642 - Sensor voltage supply circuit 1 short

to ground or open circuit

PO643 - Sensor voltage supply circuit 1 short

to battery

PO651 - Sensor voltage supply circuit 2 noisy

signal

PO652 - Sensor voltage supply circuit 2 short

to ground or open circuit

2006.0 Fiesta 1212006 G356253en

procarmanuals.com