park assist FORD FIESTA 2007 Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2007, Model line: FIESTA, Model: FORD FIESTA 2007Pages: 1226, PDF Size: 61.26 MB

Page 3 of 1226

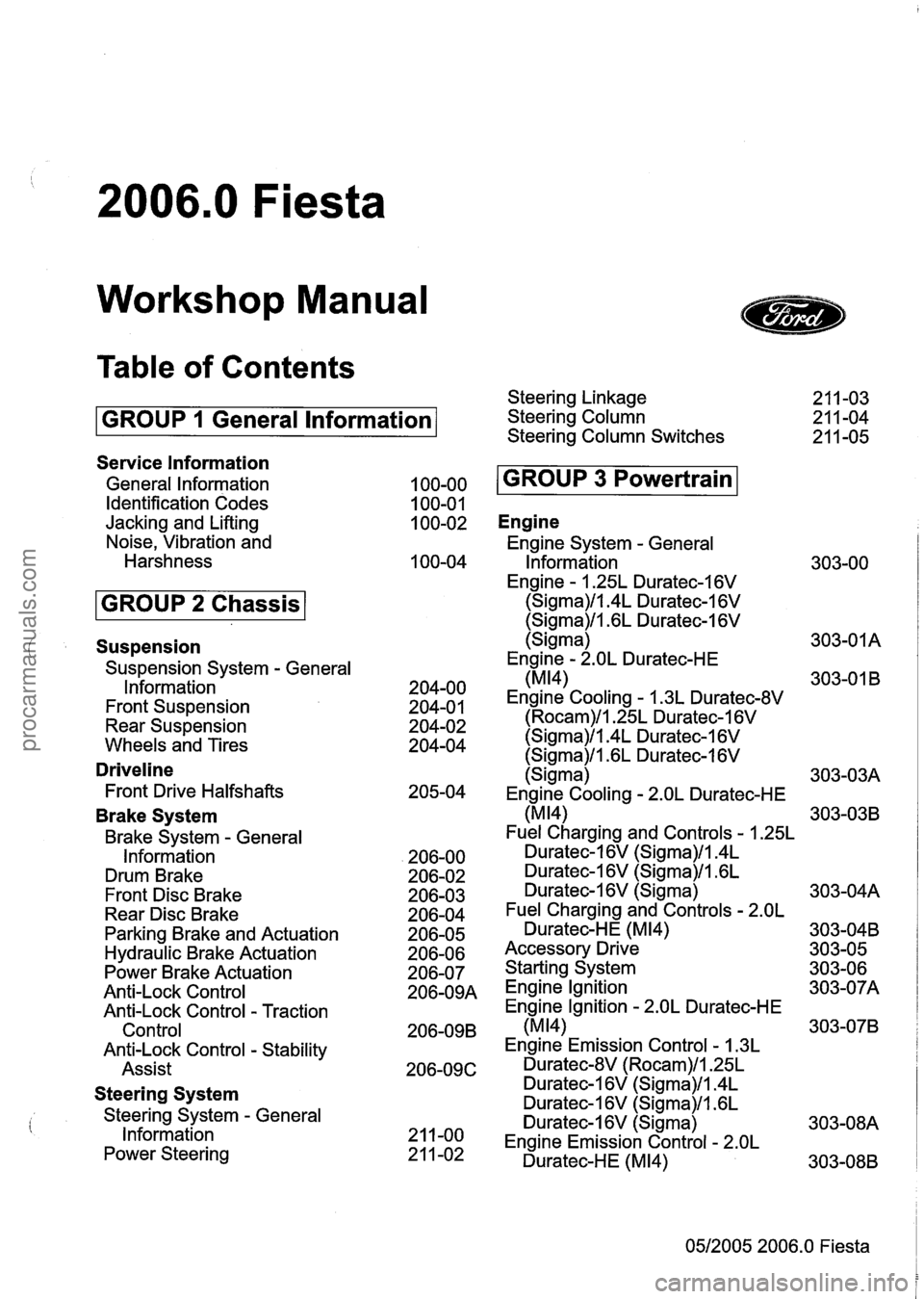

2006.0 Fiesta

Workshop Manual

Table of Contents

GROUP 1 General lnformation

Service lnformation

General lnformation

Identification Codes

Jacking and Lifting

Noise, Vibration and

Harshness

Suspension

Suspension System - General

lnformation

Front Suspension

Rear Suspension

Wheels and Tires

Driveline

Front Drive Halfshafts

Brake System

Brake System - General

Information

Drum Brake

Front Disc Brake

Rear Disc Brake

Parking Brake and Actuation

Hydraulic Brake Actuation

Power Brake Actuation

Anti-Lock Control

Anti-Lock Control

- Traction

Control

Anti-Lock Control

- Stability

Assist

Steering System

Steering System - General

lnformation

Power Steering Steering Linkage

Steering Column

Steering Column Switches

Engine

Engine System - General

lnformation

Engine

- 1.25L Duratec-1 6V

(Sigma)/l.4L Duratec-1 6V

(Sigma)/l.GL Duratec-I 6V

(Sigma)

Engine

- 2.OL Duratec-HE

(MI41

Engine Cooling - 1.3L Duratec-8V

(Rocam)/l.25L Duratec-1 6V

(Sigma)/l.4L Duratec-1 6V

(Sigma)/l .6L Duratec-1 6V

(Sigma)

Engine Cooling

- 2.OL Duratec-HE

(MI41

Fuel Charging and Controls - 1.25L

Duratec-1 6V (Sigma)/l.4L

Duratec-16V (Sigma)/l.GL

Duratec-1 6V (Sigma)

Fuel Charging and Controls

- 2.OL

Duratec-HE (M14)

Accessory Drive

Starting System

Engine lgnition

Engine Ignition

- 2.OL Duratec-HE

(M14)

Engine Emission Control - 1.3L

Duratec-8V (Rocam)/l.25L

Duratec-1 6V (Sigma)/l.4L

Duratec-1 6V (Sigma)/l .6L

Duratec-1

6V (Sigma)

Engine Emission Control

- 2.OL

Duratec-HE (M14)

05/2005 2006.0 Fiesta

procarmanuals.com

Page 9 of 1226

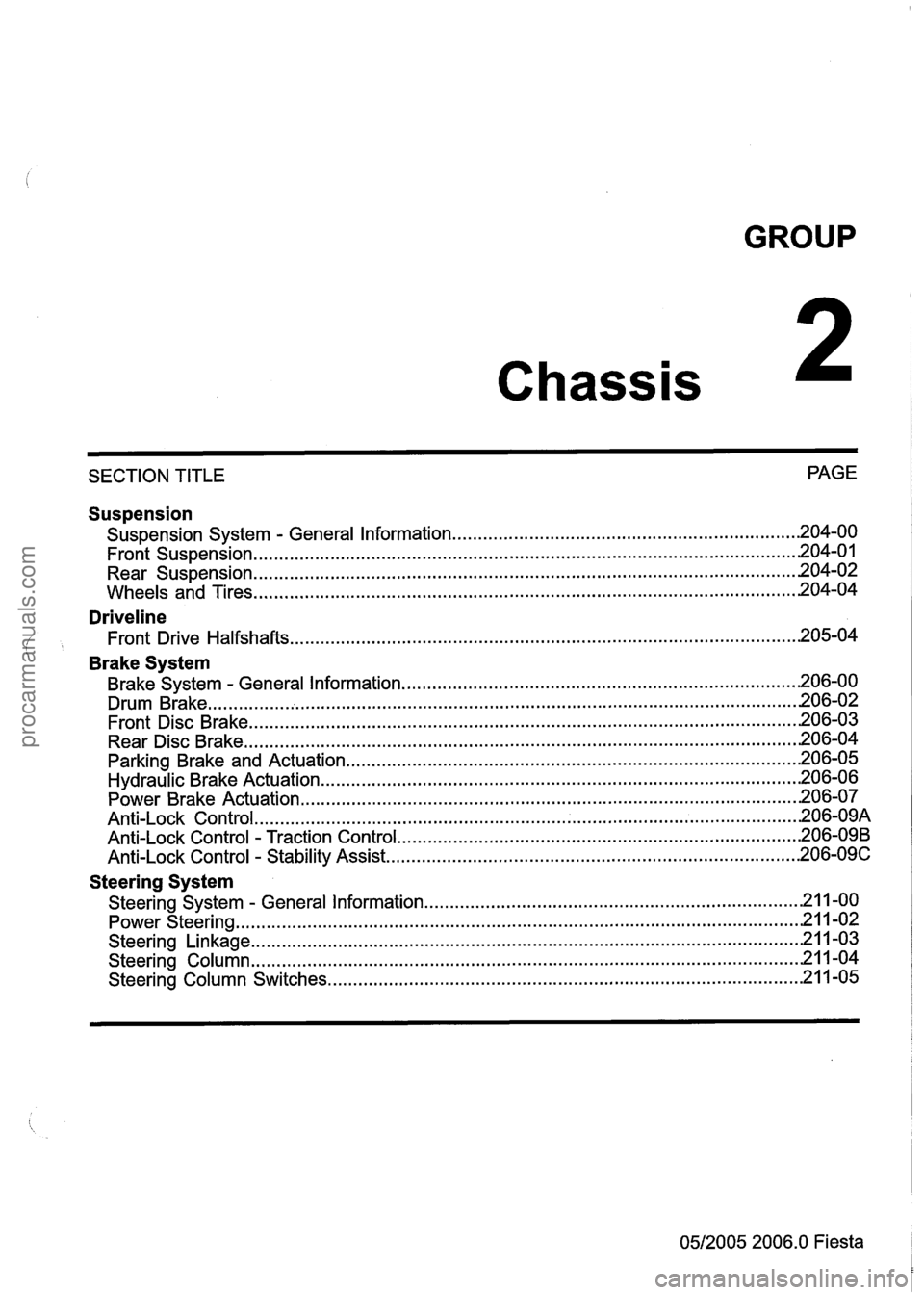

GROUP

Chassis

SECTION TITLE PAGE

Suspension

Suspension

System . General Information .................................................................... 204-00

........................................................................\

................................. Front Suspension .201 4.0

........................................................................\

................................. Rear Suspension .20 4.02

........................................................................\

.................................. Wheels and Tires 204-04

Driveline

Front Drive Halfshafts ........................................................................\

............................ 205-04

' Brake System

Brake System . General Information ........................................................................\

...... 206-00

........................................................................\

.......................................... Drum Brake .20 6.02

Front Disc Brake

........................................................................\

................................... 206-03

Rear Disc Brake

........................................................................\

.................................... 206-04

Parking Brake and Actuation

........................................................................\

................. 206-05

Hydraulic Brake Actuation ........................................................................\

...................... 206-06

Power Brake Actuation

........................................................................\

.......................... 206-07

........................................................................\

.................................. An ti-Lock Control .20 6.09A

Anti-Lock Control . Traction Control ........................................................................\

....... 206-09B

Anti-Lock Control . Stability Assist ........................................................................\

......... 206-09C

Steering System

........................................................................\

. Steering System . General Information .21 1.00

........................................................................\

..................................... Power Steering -21 1-02

........................................................................\

.................................. Steering Linkage -21 1-03

Steering Column

........................................................................\

................................... 21 1-04

Steering Column Switches

........................................................................\

..................... 21 1-05

0512005 2006.0 Fiesta

procarmanuals.com

Page 64 of 1226

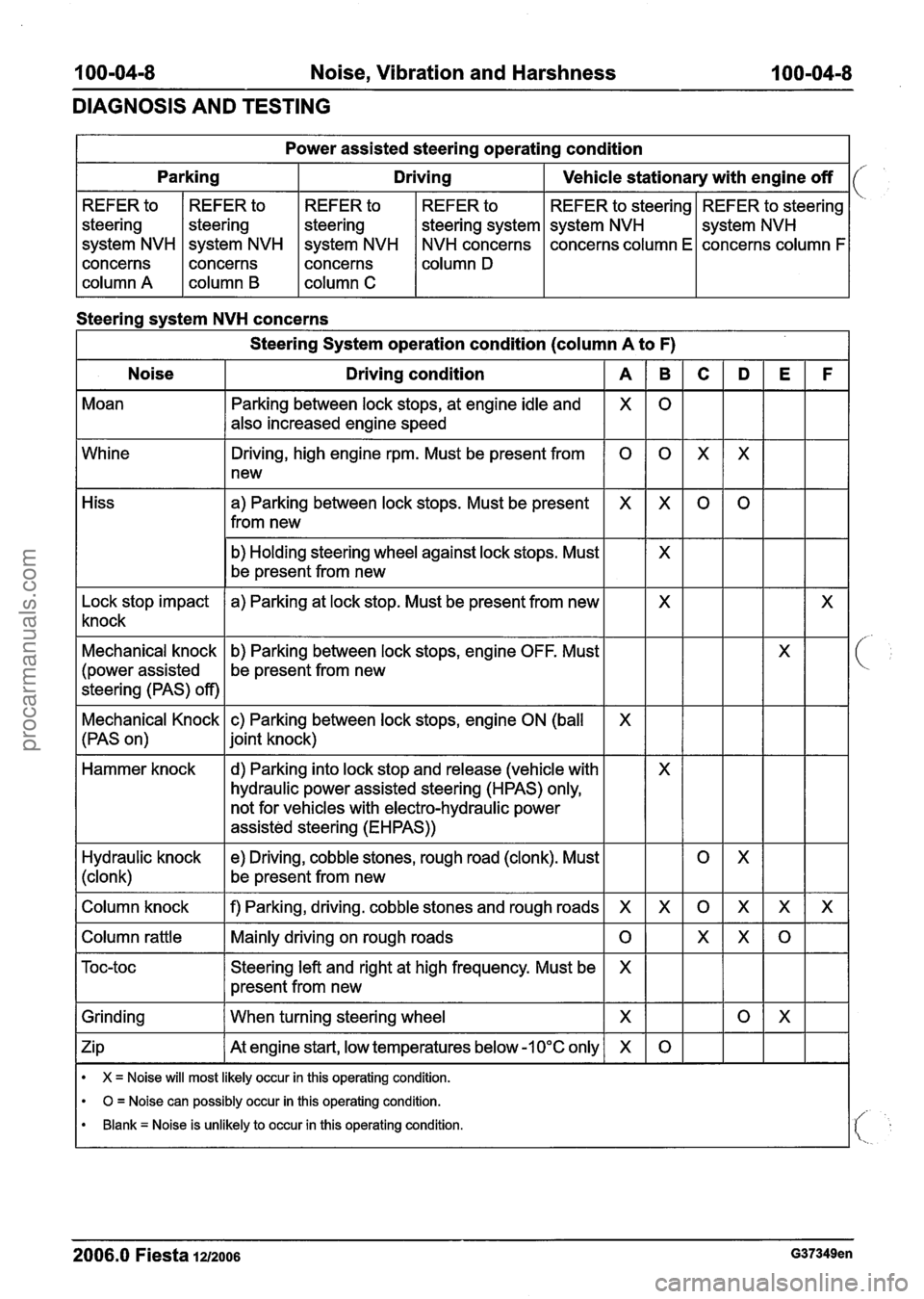

I 00-04-8 Noise, Vibration and Harshness 100-04-8

DIAGNOSIS AND TESTING

Steering system NVH concerns Power

assisted steering operating condition

I Steering System operation condition (column A to F) 1

Noise I Driving condition I A

Parking

Moan REFER

to

steering

system NVH

concerns

column A REFER

to

steering

system NVH

concerns

column

B

Driving

Whine REFER

to

steering

system NVH

concerns

column C

Vehicle stationary with engine off

Parking between lock stops, at engine idle and

also increased engine speed REFER

to

steering system

NVH concerns

column

D

REFER to steering

system NVH

concerns column E

X

Hiss REFER

to steering

system NVH

concerns column F

Driving, high engine rpm. Must be present from

1 new

0

b) Holding steering wheel against lock stops. Must

be present from new

a) Parking between lock

stops. Must be present

from new

X

Lock stop impact

knock a) Parking

at lock stop. Must be present from new

Mechanical knock

(power assisted

steering (PAS) off) b)

Parking between lock stops, engine OFF. Must

be present from new

Mechanical Knock c) Parking between lock stops, engine

ON (ball

(PAS on)

1 joint knock)

X

Hammer knock

Column knock

I f) Parking, driving. cobble stones and rough roads I X

- -

d) Parking into lock stop and release (vehicle

hydraulic power assisted steering (HPAS) only,

not for vehicles with electro-hydraulic power

assisted steering (EHPAS))

Hydraulic knock

(clonk)

Column rattle I Mainly driving on rough roads 1 0

e) Driving, cobble stones, rough road (clonk). Must

be present from new

Grinding

I When turning steering wheel I

Steering left and right at high frequency. Must be

present from new

Zip

I At engine start, -1 0°C only I X

X

X = Noise will most likely occur in this operating condition.

0 = Noise can possibly occur in this operating condition.

Blank = Noise is unlikely to occur in this operating condition.

2006.0 Fiesta 1212006 G37349en

procarmanuals.com

Page 68 of 1226

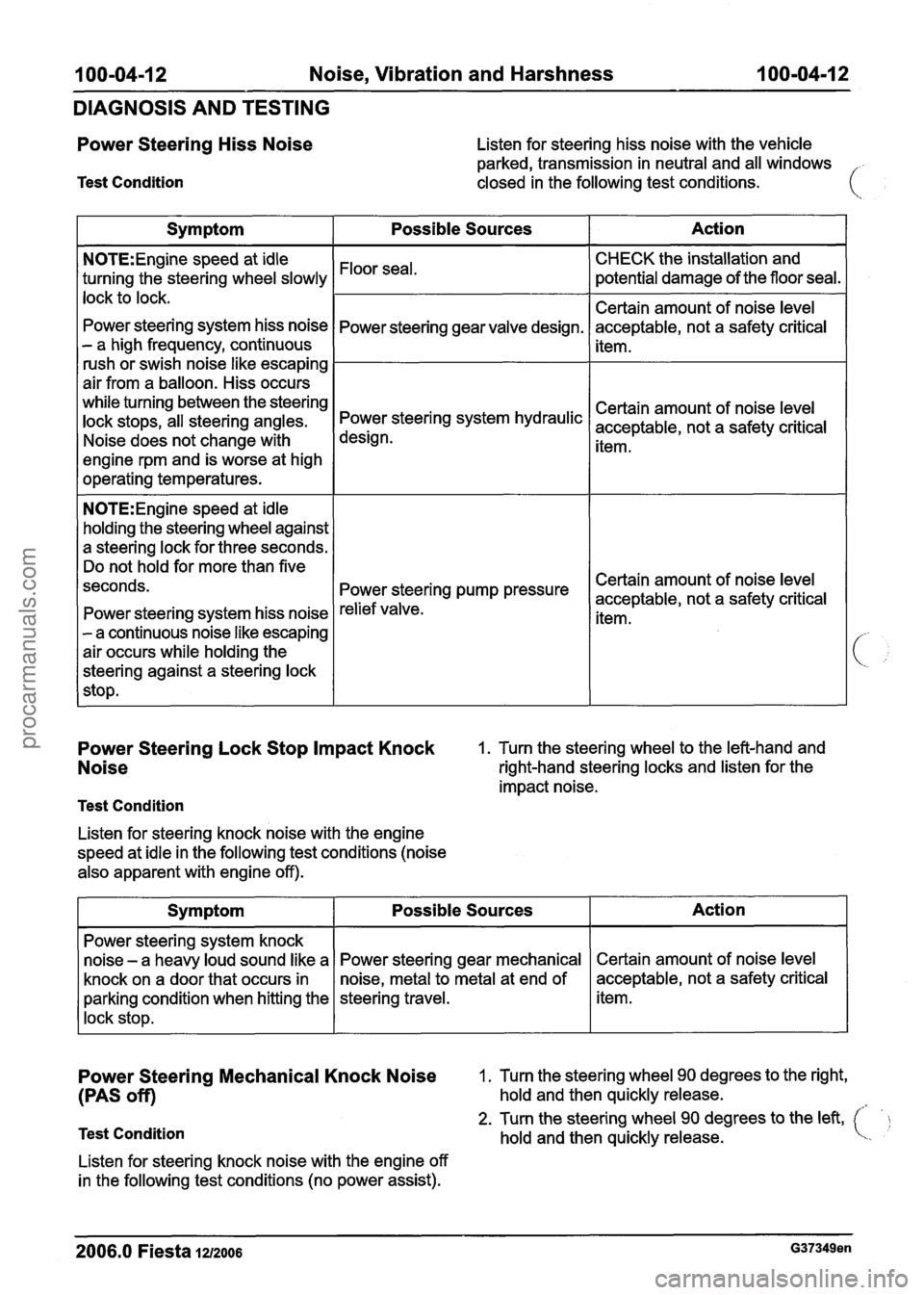

I 00-04-1 2 Noise, Vibration and Harshness I 00=04m12

DIAGNOSIS AND TESTING

Power Steering Hiss Noise

Test Condition

Listen for steering hiss noise with the vehicle

parked, transmission in neutral and all windows

-

closed in the following test conditions.

Power Steering Lock Stop Impact Knock 1. Turn the steering wheel to the left-hand and

Noise right-hand steering locks and listen for the

impact noise.

Test Condition

Listen for steering knock noise with the engine

speed at idle in the following test conditions (noise

also apparent with engine off).

Action

CHECK the installation and

potential damage of the floor seal.

Certain amount of noise level

acceptable, not a safety critical

item.

Certain amount of noise level

acceptable, not a safety critical

item.

Certain amount of noise level

acceptable, not a safety critical

item.

Symptom

N0TE:Engine speed at idle

turning the steering wheel slowly

lock to lock.

Power steering system hiss noise

- a high frequency, continuous

rush or swish noise like escaping

air from a balloon. Hiss occurs

while turning between the steering

lock stops, all steering angles.

Noise does not change with

engine rpm and is worse at high

operating temperatures.

N0TE:Engine speed at idle

holding the steering wheel against

a steering lock for three seconds.

Do not hold for more than five

seconds.

Power steering system hiss noise

- a continuous noise like escaping

air occurs while holding the

steering against a steering lock

stop.

Possible Sources

Floor seal.

Power steering gear valve design.

Power steering system hydraulic

design.

Power pump pressure

relief valve.

Power Steering Mechanical Knock Noise 1. Turn the steering wheel 90 degrees to the right,

(PAS off) hold and then quickly release.

2. Turn the steering wheel 90 degrees to the left, Test Condition hold and then quickly release.

Listen for steering knock noise with the engine off

in the following test conditions (no power assist).

2006.0 Fiesta 1212006 G37349en

Action

Certain amount of noise level

acceptable, not a safety critical

item.

Symptom

Power steering system knock

noise

- a heavy loud sound like a

knock on a door that occurs in

parking condition when hitting the

lock stop.

Possible Sources

Power steering gear mechanical

noise, metal to metal at end of

steering travel.

procarmanuals.com

Page 70 of 1226

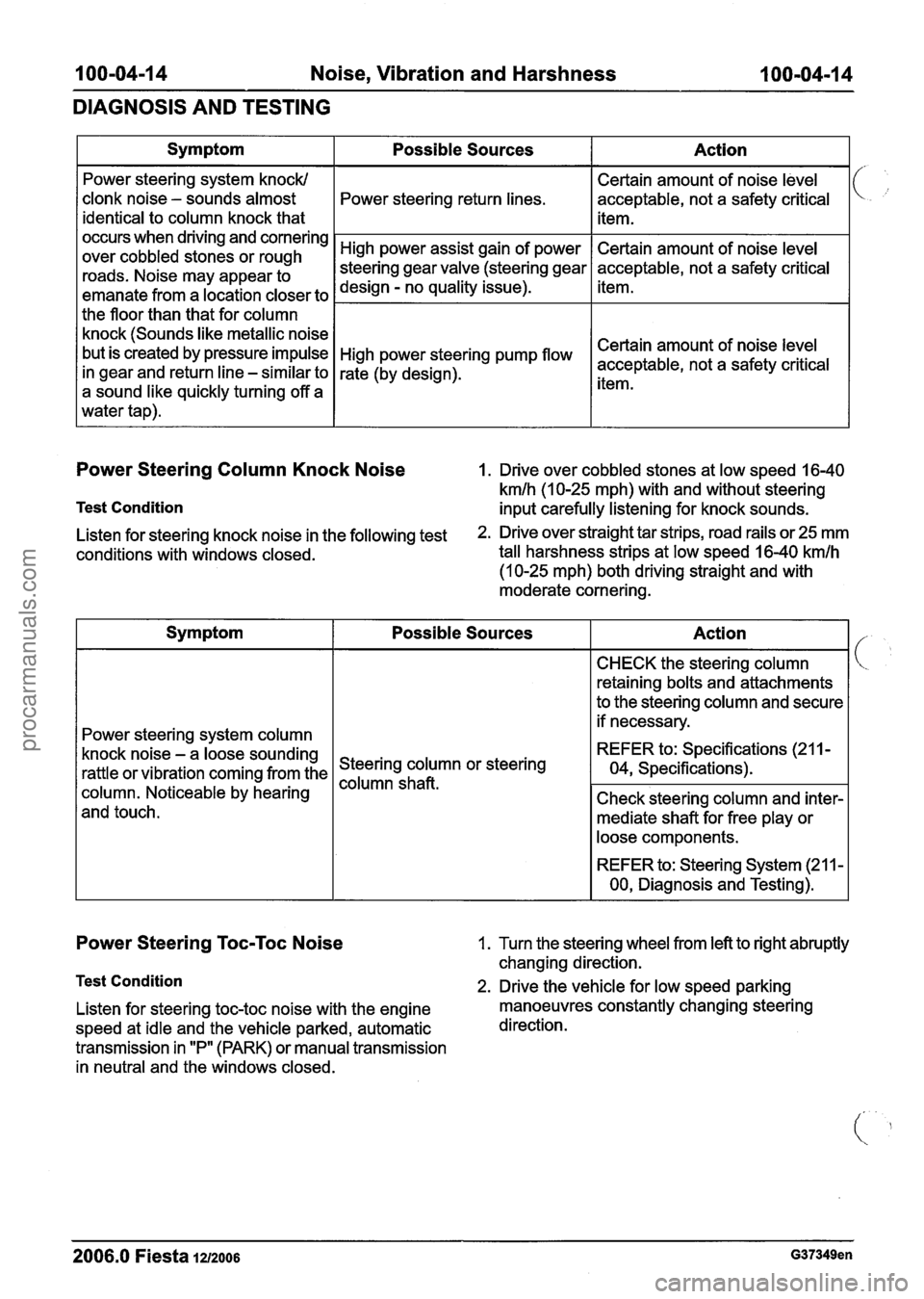

100-04-14 Noise, Vibration and Harshness 100-04-14

DIAGNOSIS AND TESTING

Power Steering Column Knock Noise I. Drive over cobbled stones at low speed 16-40

kmlh (1 0-25 mph) with and without steering

Test Condition input carefully listening for knock sounds.

Symptom

Power steering system knock1

clonk noise - sounds almost

identical to column knock that

occurs when driving and cornering

over cobbled stones or rough

roads. Noise may appear to

emanate from a location closer to

the floor than that for column

knock (Sounds like metallic noise

but is created by pressure impulse

in gear and return line

- similar to

a sound like quickly turning off a

water tap).

Listen for steering knock noise in the following test 2. Drive over straight tar strips, road rails or 25 mm

conditions with windows closed. tall

harshness strips at low speed 16-40

kmlh

(10-25 mph) both driving straight and with

moderate cornering.

Possible Sources

Power steering return lines.

High power assist gain of power

steering gear valve (steering gear

design

- no quality issue).

High power steering pump

flow

rate (by design).

Power Steering Toc-Toc Noise 1. Turn the steering wheel from left to right abruptly

changing direction.

Test Condition 2. Drive the vehicle for low speed parking

Listen for steering

toc-toc noise with the engine manoeuvres constantly changing steering

speed at idle and the vehicle parked, automatic direction.

transmission in "P" (PARK) or manual transmission

in neutral and the windows closed.

Action

Certain amount of noise level

acceptable, not a safety critical

item.

Certain amount of noise level

acceptable, not a safety critical

item.

Certain amount of noise level

acceptable, not a safety critical

item.

Symptom

Power steering system column

knock noise

- a loose sounding

rattle or vibration coming from the

column. Noticeable by hearing

and touch.

2006.0 Fiesta 1212006 G37349en

Possible Sources

Steering column or steering

column

Action

CHECK the steering column

retaining bolts and attachments

to the steering column and secure

if necessary.

REFER to: Specifications (21 1

-

04, Specifications).

Check steering column and inter- mediate shaft for free play or

loose components.

REFER to: Steering System (2 11

-

00, Diagnosis and Testing).

procarmanuals.com

Page 175 of 1226

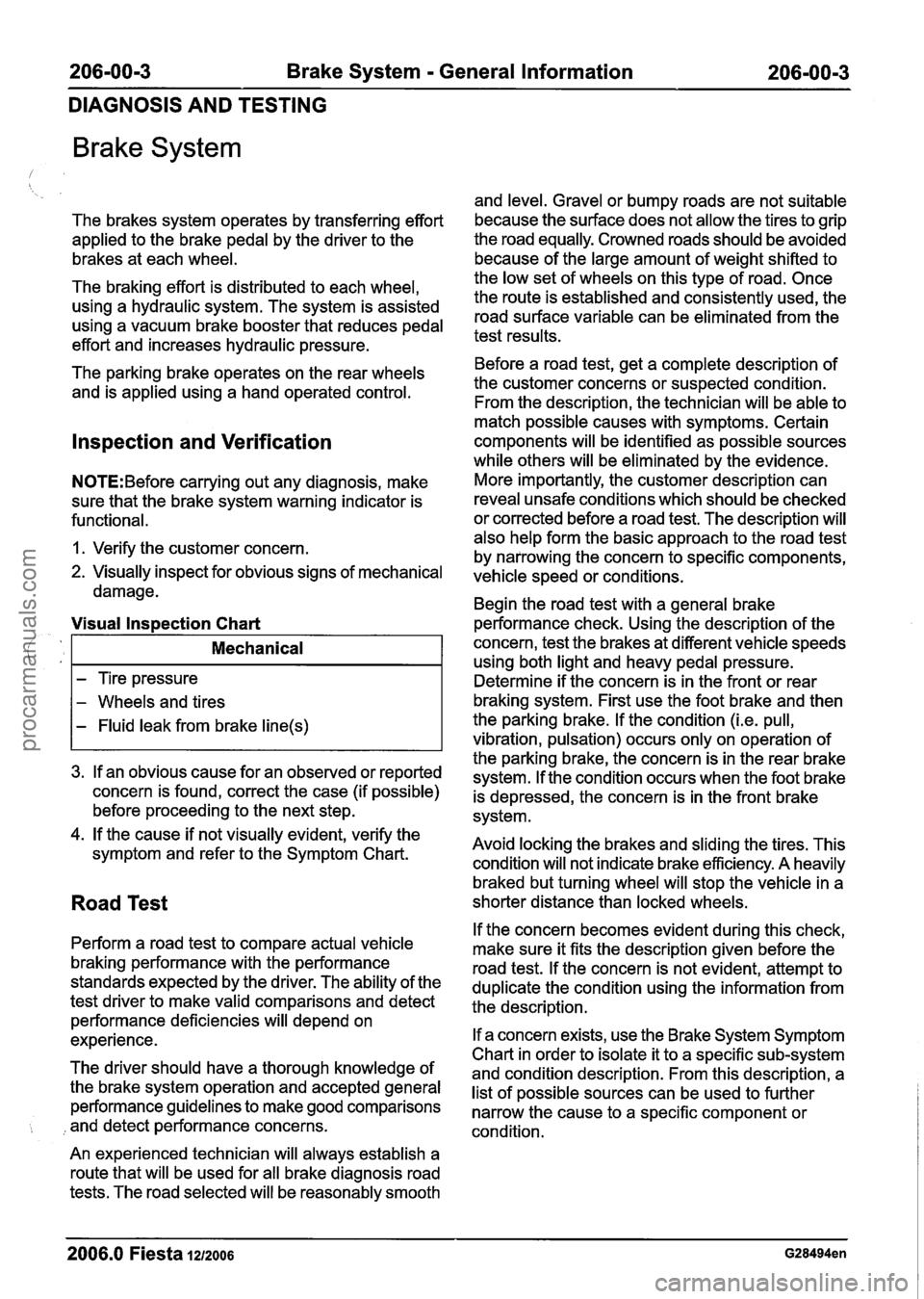

206-00-3 Brake System - General Information 206-00-3

DIAGNOSIS AND TESTING

Brake System

The brakes system operates by transferring effort

applied to the brake pedal by the driver to the

brakes at each wheel.

The braking effort is distributed to each wheel,

using a hydraulic system. The system is assisted

using a vacuum brake booster that reduces pedal

effort and increases hydraulic pressure.

The parking brake operates on the rear wheels

and is applied using a hand operated control.

lnspection and Verification

N0TE:Before carrying out any diagnosis, make

sure that the brake system warning indicator is

functional.

1. Verify the customer concern.

2. Visually inspect for obvious signs of mechanical

damage.

3. If an obvious cause for an observed or reported

concern is found, correct the case (if possible)

before proceeding to the next step.

4. If the cause if not visually evident, verify the

symptom and refer to the Symptom Chart.

Visual lnspection Chart

Road Test

1.

Perform a road test to compare actual vehicle

braking performance with the performance

standards expected by the driver. The ability of the

test driver to make valid comparisons and detect

performance deficiencies will depend on

experience.

Mechanical

- Tire pressure

- Wheels and tires

- Fluid leak from brake line(s)

The driver should have a thorough knowledge of

the brake system operation and accepted general

performance guidelines to make good comparisons

, and detect performance concerns.

An experienced technician will always establish a

route that will be used for all brake diagnosis road

tests. The road selected will be reasonably smooth and level. Gravel

or bumpy roads are not suitable

because the surface does not allow the tires to grip

the road equally. Crowned roads should be avoided

because of the large amount of weight shifted to

the low set of wheels on this type of road. Once

the route is established and consistently used, the

road surface variable can be eliminated from the

test results.

Before a road test, get a complete description of

the customer concerns or suspected condition.

From the description, the technician will be able to

match possible causes with symptoms. Certain

components will be identified as possible sources

while others will be eliminated by the evidence.

More importantly, the customer description can

reveal unsafe conditions which should be checked

or corrected before a road test. The description will

also help form the basic approach to the road test

by narrowing the concern to specific components,

vehicle speed or conditions.

Begin the road test with a general brake

performance check. Using the description of the

concern, test the brakes at different vehicle speeds

using both light and heavy pedal pressure.

Determine if the concern is in the front or rear

braking system. First use the foot brake and then

the parking brake. If the condition

(i.e. pull,

vibration, pulsation) occurs only on operation of

the parking brake, the concern is in the rear brake

system.

If the condition occurs when the foot brake

is depressed, the concern is in the front brake

system.

Avoid locking the brakes and sliding the tires. This

condition will not indicate brake efficiency. A heavily

braked but turning wheel will stop the vehicle in a

shorter distance than locked wheels.

If the concern becomes evident during this check,

make sure it fits the description given before the

road test. If the concern is not evident, attempt to

duplicate the condition using the information from

the description.

If a concern exists, use the Brake System Symptom

Chart in order to isolate it to a specific sub-system

and condition description. From this description, a

list of possible sources can be used to further

narrow the cause to a specific component or

condition.

- -

2006.0 Fiesta 1212006 G28494en

procarmanuals.com

Page 201 of 1226

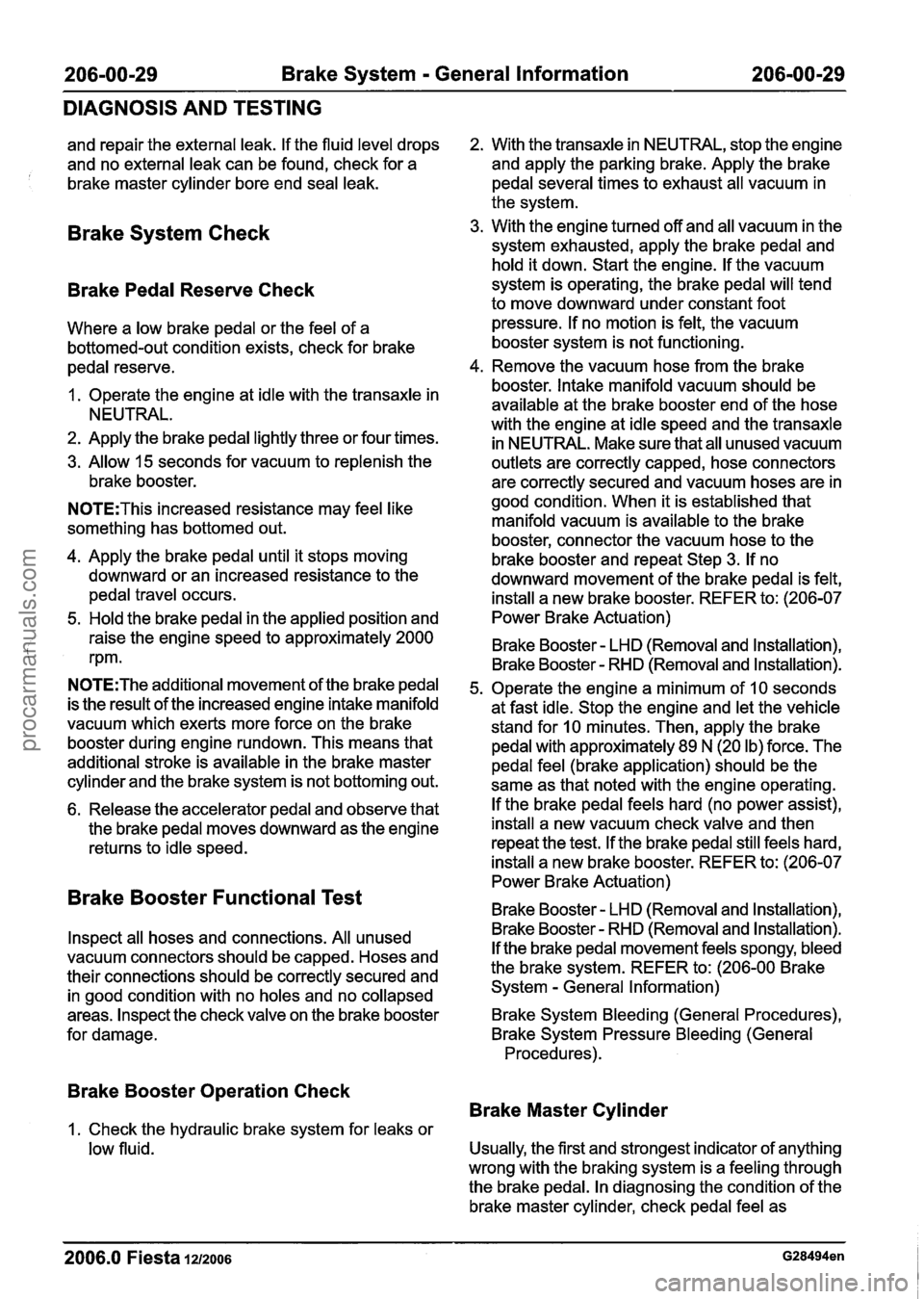

206-00-29 Brake System - General Information 206-00-29

DIAGNOSIS AND TESTING

and repair the external leak. If the fluid level drops

and no external leak can be found, check for a

brake master cylinder bore end seal leak.

Brake System Check

Brake Pedal Reserve Check

Where a low brake pedal or the feel of a

bottomed-out condition exists, check for brake

pedal reserve.

1. Operate the engine at idle with the transaxle in

NEUTRAL.

2. Apply the brake pedal lightly three or four times.

3. Allow 15 seconds for vacuum to replenish the

brake booster.

N0TE:This increased resistance may feel like

something has bottomed out.

4. Apply the brake pedal until it stops moving

downward or an increased resistance to the

pedal travel occurs.

5. Hold the brake pedal in the applied position and

raise the engine speed to approximately 2000

rpm.

N0TE:The additional movement of the brake pedal

is the result of the increased engine intake manifold

vacuum which exerts more force on the brake

booster during engine rundown. This means that

additional stroke is available in the brake master

cylinder and the brake system is not bottoming out.

6. Release the accelerator pedal and observe that

the brake pedal moves downward as the engine

returns to idle speed.

Brake Booster Functional Test

lnspect all hoses and connections. All unused

vacuum connectors should be capped. Hoses and

their connections should be correctly secured and

in good condition with no holes and no collapsed 2.

With the transaxle in NEUTRAL, stop the engine

and apply the parking brake. Apply the brake

pedal several times to exhaust all vacuum in

the system.

3. With the engine turned off and all vacuum in the

system exhausted, apply the brake pedal and hold it down. Start the engine. If the vacuum

system is operating, the brake pedal will tend

to move downward under constant foot

pressure. If no motion is felt, the vacuum

booster system is not functioning.

4. Remove the vacuum hose from the brake

booster.

Intake manifold vacuum should be

available at the brake booster end of the hose

with the engine at idle speed and the transaxle

in NEUTRAL. Make sure that all unused vacuum

outlets are correctly capped, hose connectors

are correctly secured and vacuum hoses are in

good condition. When it is established that

manifold vacuum is available to the brake

booster, connector the vacuum hose to the

brake booster and repeat Step

3. If no

downward movement of the brake pedal is felt,

install a new brake booster. REFER to: (206-07

Power Brake Actuation)

Brake Booster

- LHD (Removal and lnstallation),

Brake Booster

- RHD (Removal and lnstallation).

5. Operate the engine a minimum of 10 seconds

at fast idle. Stop the engine and let the vehicle

stand for

10 minutes. Then, apply the brake

pedal with approximately 89

N (20 lb) force. The

pedal feel (brake application) should be the

same as that noted with the engine operating.

If the brake pedal feels hard (no power assist),

install a new vacuum check valve and then

repeat the test. If the brake pedal still feels hard,

install a new brake booster. REFER to: (206-07

Power Brake Actuation)

Brake Booster

- LHD (Removal and Installation),

Brake Booster

- RHD e em oval and installation).

If the brake pedal movement feels spongy, bleed

the brake system. REFER to: (206-00 Brake

System

- General Information)

areas. Inspect the check valve on the brake booster Brake System Bleeding (General Procedures),

for damage. Brake

System Pressure Bleeding (General

Procedures).

Brake Booster Operation Check

Brake Master Cylinder

1. Check the hydraulic brake system for leaks or

low fluid. Usually,

the first and strongest indicator of anything

wrong with the braking system is a feeling through

the brake pedal. In diagnosing the condition of the

brake master cylinder, check pedal feel as

2006.0 Fiesta 1212006 G28494en I

i

procarmanuals.com

Page 325 of 1226

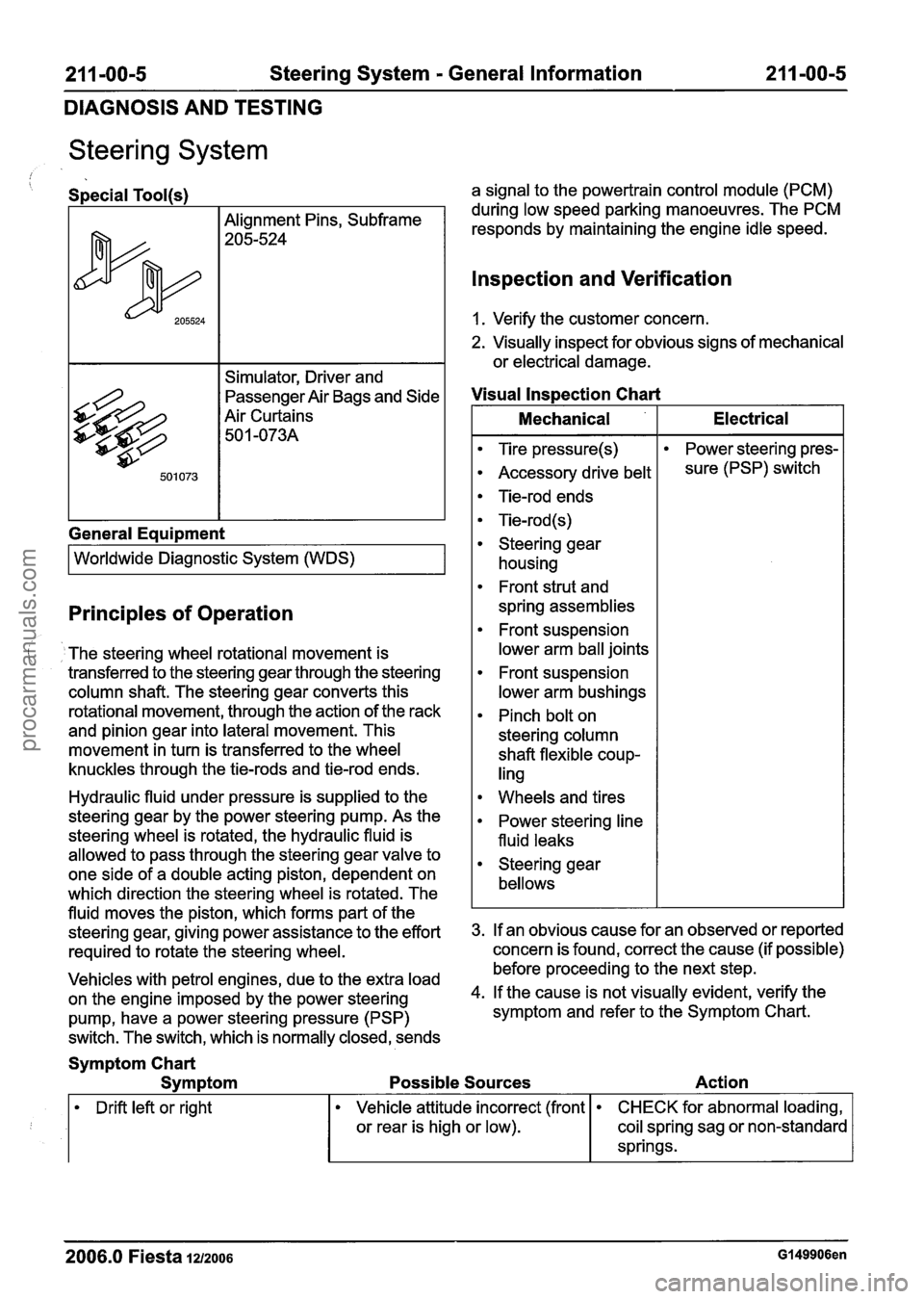

211 -00-5 Steering System - General Information 211 -00-5

DIAGNOSIS AND TESTING

Steering System

/ Special Tool(s)

Alignment Pins, Subframe

205-524

Simulator, Driver and

passenger ~ir Bags and Side

Air Curtains 50

1 -073A

General Eaui~ment

I Worldwide Diagnostic System (WDS) I

Principles of Operation

The steering wheel rotational movement is

transferred to the steering gear through the steering

column shaft. The steering gear converts this

rotational movement, through the action of the rack

and pinion gear into lateral movement. This

movement in turn is transferred to the wheel

knuckles through the tie-rods and tie-rod ends.

Hydraulic fluid under pressure is supplied to the

steering gear by the power steering pump. As the

steering wheel is rotated, the hydraulic fluid is

allowed to pass through the steering gear valve to

one side of a double acting piston, dependent on

which direction the steering wheel is rotated. The

fluid moves the piston, which forms part of the

steering gear, giving power assistance to the effort

required to rotate the steering wheel.

Vehicles with petrol engines, due to the extra load

on the engine imposed by the power steering

pump, have a power steering pressure (PSP)

switch. The switch, which is normally closed, sends a signal

to the powertrain control module (PCM)

during low speed parking manoeuvres. The PCM

responds by maintaining the engine idle speed.

lnspection and Verification

1. Verify the customer concern.

2. Visually inspect for obvious signs of mechanical

or electrical damage.

Visual lnspection Chart

I Mechanical I Electrical I

Tire pressure(s)

Accessory drive belt

Tie-rod ends

Tie-rod (s)

Steering gear housing

Front strut and

spring assemblies

Front suspension

lower arm ball joints

Front suspension

lower arm bushings

Pinch bolt on

steering column

shaft flexible coup-

ling Power

steering pres-

sure (PSP) switch

Wheels and tires

Power steering line

fluid leaks

Steering gear

bellows

3. If an obvious cause for an observed or reported

concern is found, correct the cause (if possible)

before proceeding to the next step.

4. If the cause is not visually evident, verify the

symptom and refer to the Symptom Chart.

Symptom Chart

Symptom Possible Sources Action

Drift left or right

2006.0 Fiesta 1212006 Gl49906en

Vehicle attitude incorrect (front

or rear is high or low). CHECK for abnormal loading,

coil spring sag or non-standard

springs.

procarmanuals.com