air con FORD FIESTA 2007 Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2007, Model line: FIESTA, Model: FORD FIESTA 2007Pages: 1226, PDF Size: 61.26 MB

Page 852 of 1226

303-05-1 4 Accessory Drive 303-05-1 4

DIAGNOSIS AND TESTING

Symptom

N0TE:Squeal is defined as a

continuous shriek, most noticeable

when the engine is being acceler-

ated or with electrical load.

Accessory drive belt squeal

N0TE:Whine is defined as a

continuous noise at the same

frequency, generally associated

with plastic pulleys.

Accessory drive belt whine

Possible Sources Action

Accessory drive belt tensioner

worn, damaged or contamin-

ated with oil.

Poor surface finish on

accessory drive belt idler pulley

flat

surface(s).

CHECK the accessory drive

belt tensioner for correct opera

tion, damage or contamination.

REFER to the Accessory Drive

Belt Tensioner Component

Test in this procedure.

INSTALL a new accessory

drive belt tensioner as neces-

sary.

REFER to: Accessory Drive

Belt Tensioner

- 1.6L

Duratorq-TDCi (DV) Diesel,

Vehicles With: Air Condi-

tioning (303-05, Removal and

Installation)

1 Accessory Drive Belt

Tensioner

- I .6L Duratorq-

TDCi (DV) Diesel (303-05

Accessory Drive, Removal and Installation).

TEST the system for normal

operation.

REMOVE the accessory drive

belt.

REFER to: Accessory Drive

Belt

- 1.3L Duratec-8V

(Rocam) (303-05 Accessory

Drive, Removal and Installa-

tion)

1 Accessory Drive Belt - 1.4L

Duratorq-TDCi (DV) Diesel

(303-05 Accessory Drive,

Removal and Installation)

1 Accessory Drive Belt Tensioner

- 1.6L Duratorq-

TDCi (DV) Diesel (303-05

Accessory Drive, Removal

and Installation)

I Accessory Drive Belt - 2.OL

Duratec-H E (M14) (303-05

Accessory Drive, Removal

and Installation).

INSPECT the idler

pulley(s) for

surface finish. INSTALL a new

idler

pulley(s) as necessary.

TEST the system for normal

operation.

2006.0 Fiesta 1212006 G346263en

procarmanuals.com

Page 854 of 1226

303-05-1 6 Accessory Drive 303-05-1 6

DIAGNOSIS AND TESTING

Symptom

N0TE:Rattle is defined as a

metallic knocking noise

Accessory drive belt rattle

Accessory drive belt fraying

Possible Sources Action

Accessory drive belt tensioner

hitting the end stops.

Loose components or hard-

ware.

Accessory drive belt.

CHECK the accessory drive

belt tensioner for correct

operaJ

tion or damage. REFER to the

Accessory Drive Belt Tensioner

Component Test in this

procedure. INSTALL a new

accessory drive belt tensioner

as necessary.

REFER to: Accessory Drive

Belt Tensioner

- 1.6L

Duratorq-TDCi (DV) Diesel,

Vehicles With: Air Condi-

tioning (303-05, Removal and

Installation)

1 Accessory Drive Belt

Tensioner

- I .6L Duratorq-

TDCi (DV) Diesel (303-05

Accessory Drive, Removal and Installation).

TEST the system for normal

operation.

CHECK the components or

hardware for correct installation

and tighten as necessary.

TEST the system for normal

operation.

CHECK the extent of the

fraying by referring to the illus-

trations shown in the Visual

lnspection section. Only

INSTALL a new accessory

drive belt if the fraying is within

the criteria quoted in the Visual

lnspection section. TEST the

system for normal operation.

CHECK the pulley(s) for

damage, freedom of rotation

and alignment. INSTALL new

components as necessary.

TEST the system for normal

operation.

Component Tests 1. Inspect the area surrounding the accessory

drive belt tensioner for lubricant or other

contamination. Rectify any leaks before

Accessory Drive Belt Tensioner - Static installing a new accessory drive belt tensioner.

Check If the accessory drive belt tensioner is

contaminated, do not attempt to clean it as

the(

The accessory drive belt tensioner may be checked

damping mechanism inside may be damaged.

statically as follows:

INSTALL a new accessory drive belt tensioner

as necessary.

2006.0 Fiesta 1212006 G346263en

procarmanuals.com

Page 855 of 1226

303-05-1 7 Accessory Drive 303-05-1 7

DIAGNOSIS AND TESTING

REFER to: Accessory Drive Belt Tensioner -

1.6L Duratorq-TDCi (DV) Diesel, Vehicles i With: Air Conditioning (303-05, Removal and

Installation).

REFER to: Accessory Drive Belt Tensioner

-

1.6L Duratorq-TDCi (DV) Diesel (303-05

Accessory Drive, Removal and lnstallation).

TEST the system for normal operation.

2. Detach the accessory drive belt in the area of

the accessory drive belt tensioner.

3. N0TE:The accessory drive belt tensioner

has a damping feature, which is usually a

friction device, therefore some friction within

the system is normal.

Using the correct tool, move the accessory drive

belt tensioner from its relaxed position through

its full stroke and back to the relaxed position

to make sure there is no excessive stick, grab

or bind, and to make sure there is tension on

the accessory drive belt tensioner spring.

4. Rotate the accessory drive belt tensioner pulley

and check for damage, freedom of rotation and

alignment. INSTALL a new accessory drive belt

tensioner as necessary.

Accessory Drive Belt Tensioner - Dynamic

Check

The accessory drive belt tensioner may be checked

dynamically as follows:

1. With the engine running, observe the accessory

drive belt tensioner movement. The accessory

drive belt tensioner should move (respond)

when the engine is accelerated rapidly or when

the

A/C clutch cycles ON and OFF (the degree

of movement can be up to 4 mm). If the

accessory drive belt tensioner movement is not

constant without engine acceleration or

A/C

clutch cycling, a pulley or shaft is possibly bent,

out of round, or the damping mechanism inside

the accessory drive belt tensioner may be

damaged. INSTALL a new accessory drive belt

tensioner as necessary.

REFER to: Accessory Drive Belt Tensioner

-

1.6L Duratorq-TDCi (DV) Diesel, Vehicles

With: Air Conditioning (303-05, Removal and

Installation).

REFER to: Accessory Drive Belt Tensioner -

1.6L Duratorq-TDCi (DV) Diesel (303-05

Accessory Drive, Removal and lnstallation).

( :I. REFER to: Accessory Drive Belt Tensioner - TEST the system for normal operation.

1.6L Duratorq-TDCi (DV) Diesel, Vehicles

2. Excessive accessory drive belt rideout (uneven

With: Air Conditioning (303-05, Removal and

depth of grooves in the accessory drive belt)

Installation). may cause excessive accessory drive belt

REFER to: Accessory Drive Belt Tensioner

- tensioner movement. Check the condition by

1.6L Duratorq-TDCi (DV) Diesel (303-05

installing a new accessory drive belt.

Accessory Drive, Removal and

installation). . REFER to: Accessory Drive Belt - 1.3~

TEST the system for normal operation. Duratec-8V (Rocam) (303-05 Accessory

Drive,

5. If the accessory drive belt tensioner meets the

above criteria, proceed to test the accessory

drive belt tensioner dynamically. If the accessory

drive belt tensioner does not meet the above

criteria, INSTALL a new accessory drive belt

tensioner.

REFER to: Accessory Drive Belt Tensioner

-

1.6L Duratorq-TDCi (DV) Diesel, Vehicles

With: Air Conditioning (303-05, Removal and

Installation).

REFER to: Accessory Drive Belt Tensioner

-

1.6L Duratorq-TDCi (DV) Diesel (303-05

Accessory Drive, Removal and Installation).

TEST the system for normal operation. Removal and Installation).

REFER to: Accessory Drive Belt

- 1.4L

Duratorq-TDCi (DV) Diesel (303-05 Accessory

Drive, Removal and Installation).

REFER to: Accessory Drive Belt - 1.6L

Duratorq-TDCi (DV) Diesel (303-05 Accessory

Drive, Removal and Installation).

REFER to: Accessory Drive Belt

- 2.OL

Duratec-H E (M 14) (303-05 Accessory Drive,

Removal and Installation).

TEST the system for normal operation.

2006.0 Fiesta 12/2006 G346263en

procarmanuals.com

Page 856 of 1226

303-05-1 8 Accessory Drive 303-05-1 8

REMOVAL AND INSTALLATION

Accessory Drive Belt - 1.4L Duratec-1 6V (Sigma)/l .6L

Duratec-1

6V (Sigma), Vehicles With: Air

Conditioning(21 567 0)

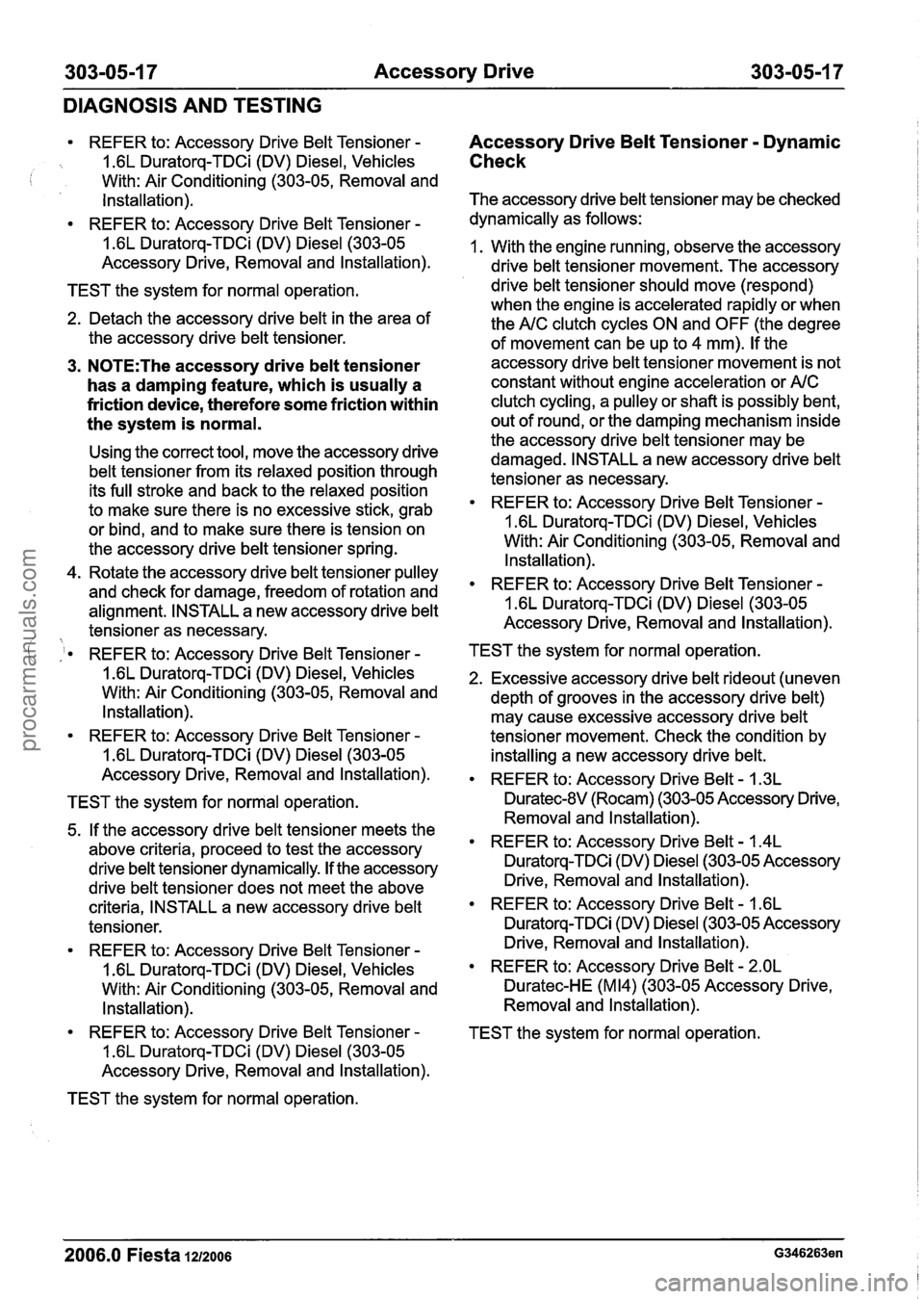

General Equipment 2. Using paint or typing correction fluid, mark

Knife the crankshaft pulley at the 6 o'clock

position.

i

Removal

A CAUTI0N:The accessory drive belt must

not be reused as it is designed to be

stretched onto the pulleys only once.

Failure to follow this instruction may lead

to premature failure of the belt.

I. Raise and support the vehicle. For additional

information, refer to Section

100-02 [Jacking

and Lifting].

2. Detach the power steering line and remove

the crankshaft pulley splash shield.

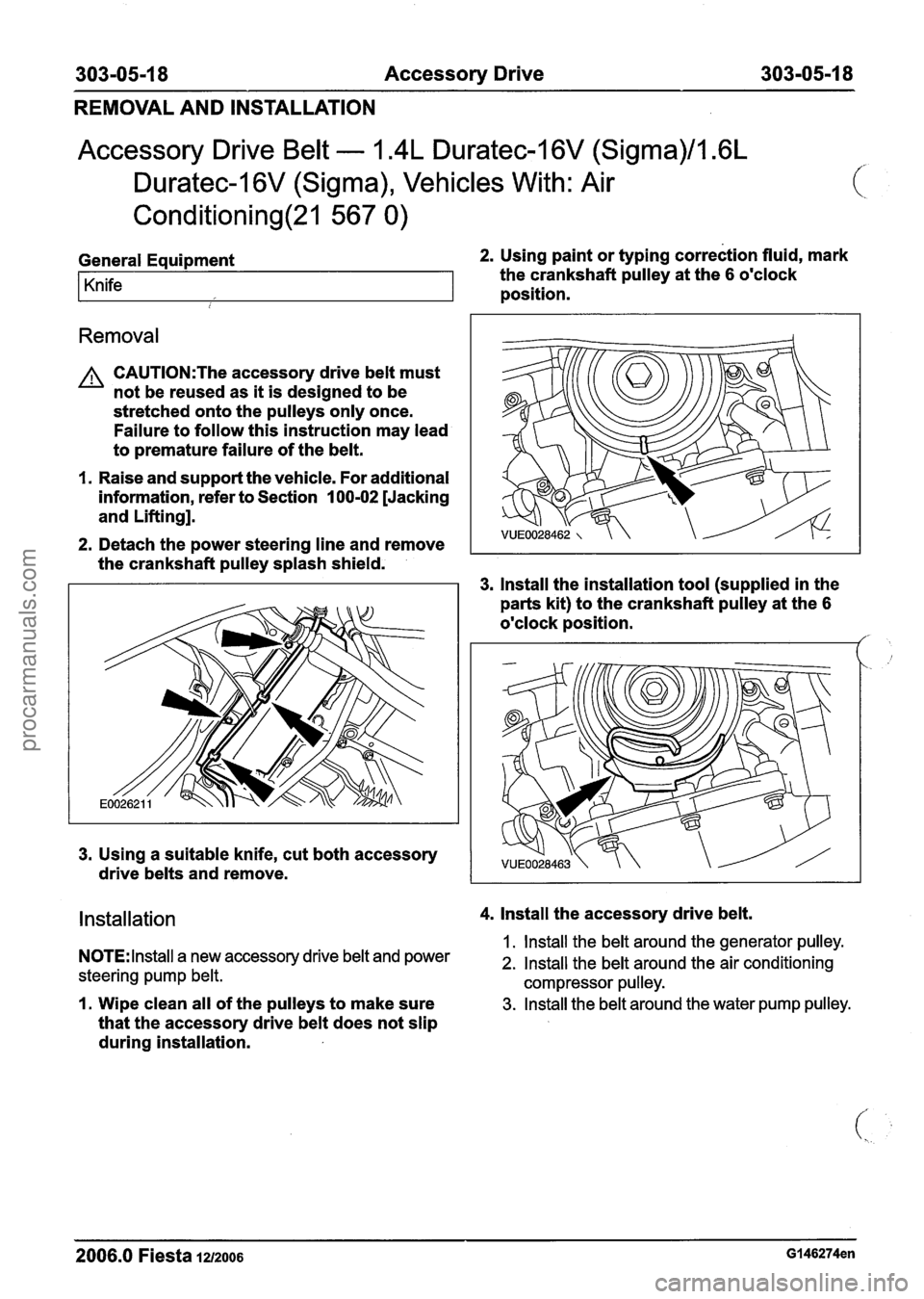

3. lnstall the installation tool (supplied in the

parts kit) to the crankshaft pulley at the

6

o'clock position. /'

3. Using a suitable knife, cut both accessory

drive belts and remove.

Installation 4. lnstall the accessory drive belt.

1. lnstall the belt around the generator pulley. NOTE: Install a new accessory drive belt and power 2. Install the belt around the air conditioning

steering pump belt. compressor pulley.

I. Wipe clean all of the pulleys to make sure 3. Install the belt around the water pump pulley.

that the accessory drive belt does not slip

during installation.

2006.0 Fiesta 1212006 GI 46274en

procarmanuals.com

Page 859 of 1226

303-05-21 Accessory Drive 303-05-21

REMOVAL AND INSTALLATION

Accessory Drive Belt - 1.4L Duratec-I 6V (Sigma)/l .6L

Duratec-1 6V (Sigma), Vehicles Without: Air

Conditioning(21 567 0)

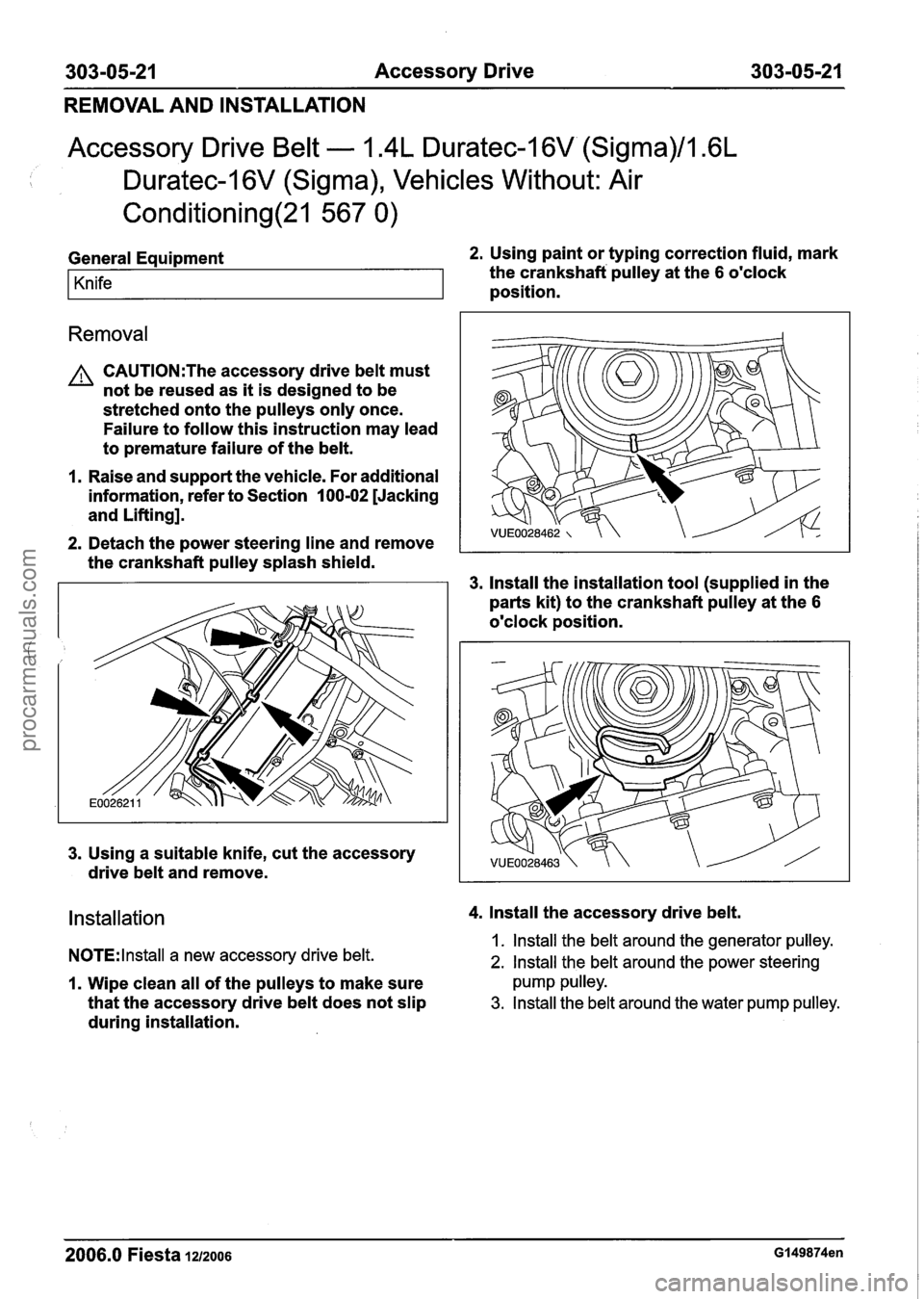

General Equipment 2. Using paint or typing correction fluid, mark

Knife the crankshaft pulley at the 6 o'clock

position.

Removal

A CAUTI0N:The accessory drive belt must

not be reused as it is designed to be

stretched onto the pulleys only once.

Failure to follow this instruction may lead

to premature failure of the belt.

1. Raise and support the vehicle. For additional

information, refer to Section

I 00-02 [Jacking

and Lifting].

2. Detach the power steering line and remove

the crankshaft pulley splash shield.

3. lnstall the installation tool (supplied in the

parts kit) to the crankshaft pulley at the

6

o'clock position.

3. Using a suitable knife, cut the accessory

drive belt and remove.

Installation 4. lnstall the accessory drive belt.

NOTE:

lnstall a new accessory drive belt. 1. lnstall the belt around the generator pulley.

2. lnstall the belt around the power steering

1. Wipe clean all of the pulleys to make sure pump pulley.

that the accessory drive belt does not slip 3. Install the belt around the water pump pulley.

during installation.

2006.0 Fiesta 1212006 Gl49874en

procarmanuals.com

Page 862 of 1226

303-05-24 Accessory Drive 303-05-24

REMOVAL AND INSTALLATION

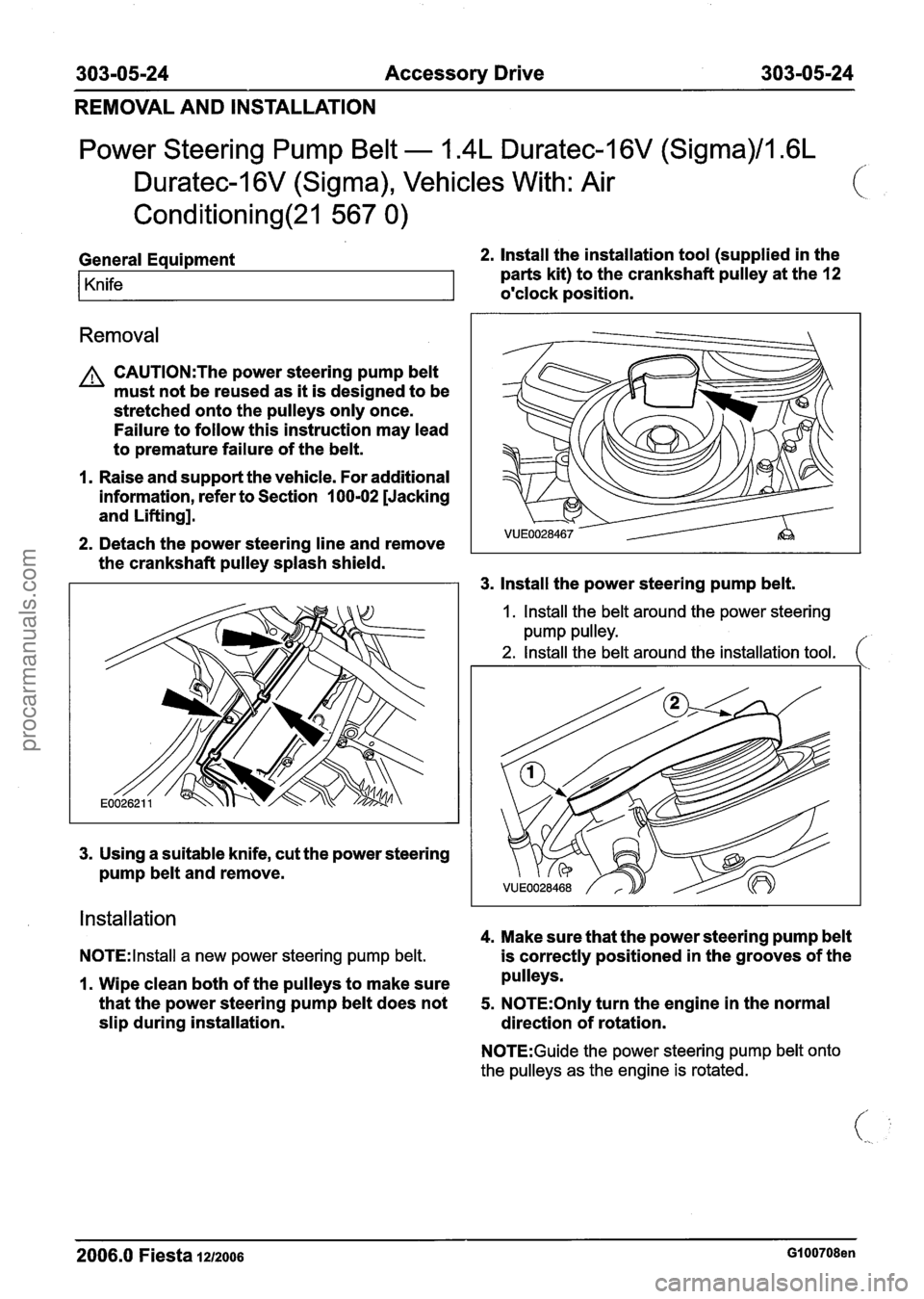

Power Steering Pump Belt - 1.4L Duratec-1 6V (Sigma)/l .6L

Duratec-1 6V (Sigma), Vehicles With: Air

Conditioning(21 567 0)

General Equipment 2. Install the installation tool (supplied in the

Knife parts kit) to the crankshaft pulley at the 12

o'clock position.

Removal

A CAUTI0N:The power steering pump belt

must not be reused as it is designed to be

stretched onto the pulleys only once.

Failure to follow this instruction may lead

to premature failure of the belt.

1. Raise and support the vehicle. For additional

information, refer to Section

100-02 [Jacking

and Lifting].

2. Detach the power steering line and remove

the crankshaft pulley splash shield.

3. Install the power steering pump belt.

I. Install the belt around the power steering

pump pulley.

2. Install the belt around the installation tool. (

Installation

4. Make sure that the power steering pump belt

N0TE:lnstall a new power steering pump belt. is correctly positioned in the grooves of the

1. Wipe clean both of the pulleys to make sure pulleys.

that the power steering pump belt does not

5. N0TE:Only turn the engine in the normal

slip during installation.

direction of rotation.

N0TE:Guide the power steering pump belt onto

the pulleys as the engine is rotated.

2006.0 Fiesta 1212006 GI 00708en

procarmanuals.com

Page 871 of 1226

303-06-7 Starting System 303-06-7

DIAGNOSIS AND TESTING

TEST CONDITIONS DETAILSIRESU LTSIACTIONS

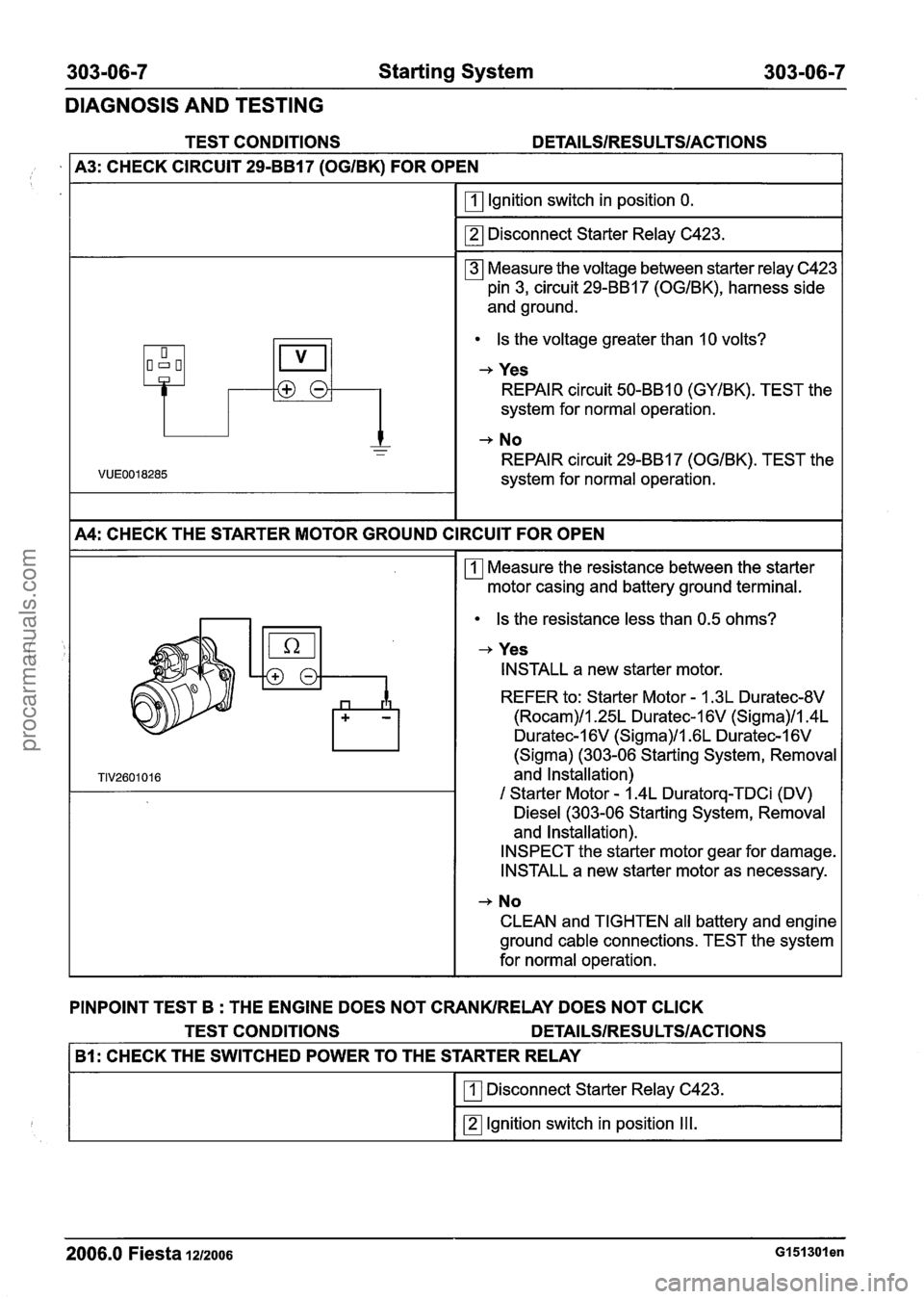

I A3: CHECK CIRCUIT 29-BB17 (OGIBK) FOR OPEN I

I Ignition switch in position 0. I

I rn Disconnect Starter Relay C423. I

Measure the voltage between starter relay C423

pin 3, circuit

29-8817 (OGIBK), harness side

Is the voltage greater than 10 volts?

+ Yes

REPAIR circuit 50-BB10 (GYIBK). TEST the

system for normal operation.

+ No

REPAIR circuit 29-BB17 (OGIBK). TEST the

system for normal operation.

I A4: CHECK THE STARTER MOTOR GROUND CIRCUIT FOR OPEN I - - --

Measure the resistance between the starter

motor casing and battery

1 ground terminal.

Is the resistance less than 0.5 ohms?

+ Yes

INSTALL a new starter motor.

REFER to: Starter Motor

- 1.3L Duratec-8V

(Rocam)/l.25L Duratec-1 6V (Sigma)/l.4L

Duratec-1 6V (Sigma)ll .6L Duratec-1 6V

(Sigma) (303-06 Starting System, Removal

and Installation)

I Starter Motor - 1.4L Duratorq-TDCi (DV)

Diesel (303-06 Starting System, Removal

and

Installation).

INSPECT the starter motor gear for damage.

INSTALL a new starter motor as necessary.

+ No

CLEAN and TIGHTEN all battery and engine

ground cable connections. TEST the system

for normal operation.

PINPOINT TEST B : THE ENGINE DOES NOT CRANKIRELAY DOES NOT CLICK

TEST CONDITIONS

DETAILSIRESU LTSIACTIONS

B1: CHECK THE SWITCHED POWER TO THE STARTER RELAY

Disconnect Starter Relay C423.

rn lgnition switch in position Ill.

2006.0 Fiesta 1212006 GI 51 301 en

procarmanuals.com

Page 872 of 1226

303-06-8 Starting System 303-06-8

DIAGNOSIS AND TESTING

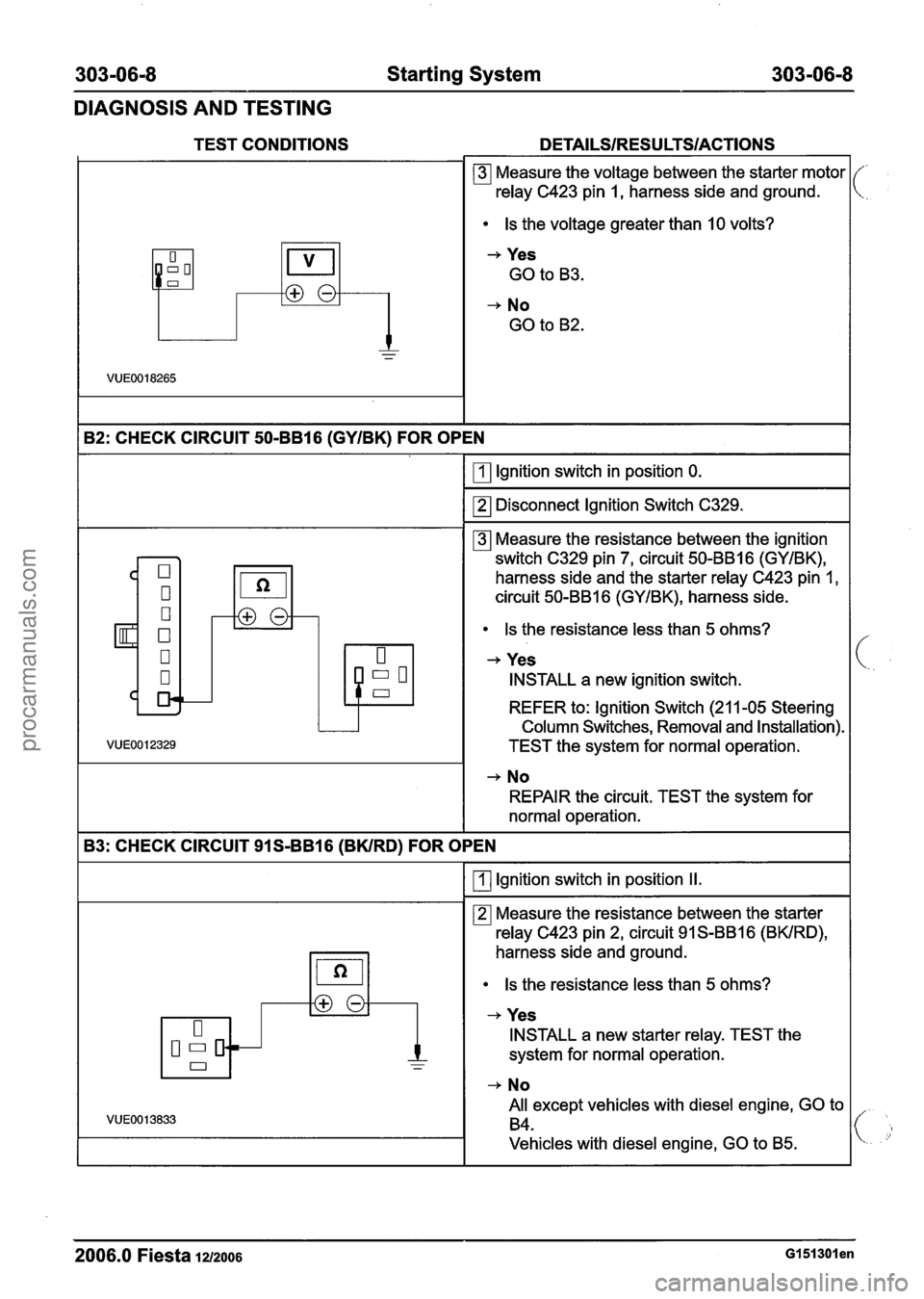

1 82: CHECK CIRCUIT 50-BB16 (GYIBK) FOR OPEN I

TEST CONDITIONS DETAILSIRESULTSIACTIONS

lgnition switch in position 0.

0 - -

VU E0018265

rn Disconnect lgnition Switch C329.

Measure the voltage between the starter motor

relay C423 pin

1, harness side and ground.

Is the voltage greater than

10 volts?

-+ Yes

GO to B3.

-+ No

GO to B2.

Measure the resistance between the ignition

switch C329 pin

7, circuit 50-BB16 (GYIBK),

harness side and the starter relay C423 pin

1,

circuit 50-BB16 (GYIBK), harness side.

Is the resistance less than 5 ohms?

-+ Yes

INSTALL a new ignition switch.

REFER to: lgnition Switch (21 1-05 Steering

Column Switches, Removal and Installation).

TEST the system for normal operation.

-+ No

REPAIR the circuit. TEST the system for

normal operation.

I B3: CHECK CIRCUIT 91s-BB16 (BKIRD) FOR OPEN I

I Ignition switch in position II. I

rn Measure the resistance between the starter

relay C423 pin 2, circuit 91 S-BB16 (BWRD),

harness side and ground.

Is the resistance less than 5 ohms?

-+ Yes

INSTALL a new starter relay. TEST the

system for normal operation.

-+ No

All except vehicles with diesel engine, GO to

B4.

Vehicles with diesel engine, GO to B5.

2006.0 Fiesta 1212006 GI 51 301 en

procarmanuals.com

Page 873 of 1226

303-06-9 Starting System 303-06-9 -- -

DIAGNOSIS AND TESTING

TEST CONDITIONS DETAILSIRESU LTSIACTIONS

PINPOINT TEST C : THE ENGINE CRANKS SLOWLY

TEST CONDITIONS

DETAILSIRESULTSIACTIONS

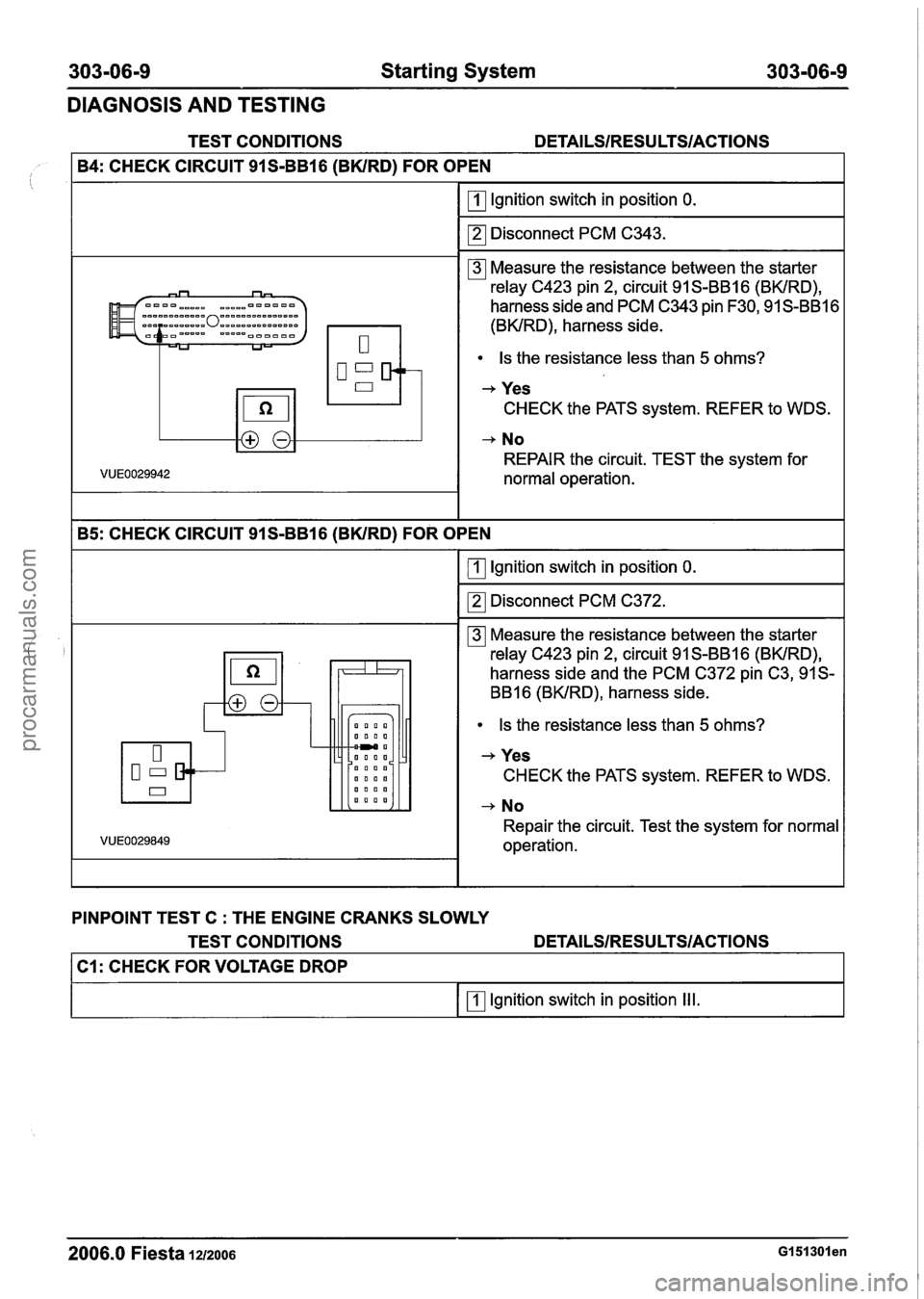

B4: CHECK CIRCUIT 91s-BB16 (BWRD) FOR OPEN

C1: CHECK FOR VOLTAGE DROP

rn lgnition switch in position Ill.

VU E0029942

2006.0 Fiesta 1212006 GI 51 301 en

lgnition switch in position 0.

Disconnect PCM C343.

rn Measure the resistance between the starter

relay C423 pin 2, circuit 91 S-BB16 (BWRD),

harness side and PCM C343 pin

F30,91 S-BBI 6

(BWRD), harness side.

Is the resistance less than 5 ohms?

+ Yes

CHECK the PATS system. REFER to WDS.

-, No

REPAIR the circuit. TEST the system for

normal operation.

B5: CHECK CIRCUIT 91s-BB16 (BWRD) FOR OPEN

Inl

I I It I

-0 @

-

0

lY2't

VUE0029849

lgnition switch in position 0.

Disconnect PCM C372.

rn Measure the resistance between the starter

relay C423 pin 2, circuit 91 S-BB16 (B WRD),

harness side and the PCM C372 pin

C3,91S-

BB16 (BWRD), harness side.

Is the resistance less than 5 ohms?

+ Yes

CHECK the PATS system. REFER to WDS.

-, No

Repair the circuit. Test the system for normal

operation.

procarmanuals.com

Page 892 of 1226

Engine Emission Control - 1.3L Duratec-8V

(Rocam)ll.25L Duratec-1 6V (Sigma)ll.4L

Duratec-1 6V (Sigma)ll .6L Duratec-I 6V (Sigma)

DIAGNOSIS AND TESTING

Engine Emission Control

lnspection and Verification

1. Verify the customer concern.

2. Visually inspect for obvious signs of mechanical

damage.

3. If an obvious cause for an observed or reported

Visual lnspection Chart

I 1 concern is found, correct the cause (if possible)

I Mechanical I before proceeding to the next step.

. -

Symptom Chart

Positive crankcase ventilation (PCV) valve

PCV separator

Symptom Chart

Symptom

Excessive crankcase pressure

4. If the cause is not visually evident, verify the

symptom and refer to the Symptom Chart.

Oil in the air intake system Possible

Sources

Blocked PCV valve.

Blocked PCV separator.

Blocked PCV hose.

Restriction in PCV separator.

PCV valve permanently open. Action

CLEAN

or INSTALL new PCV

components as necessary.

TEST the system for normal

operation. If the concern

persists, REFER to

Section 303-00 [Engine

System

- General Information].

CLEAN or INSTALL a new

PCV separator. TEST the

system for normal operation.

-

INSTALL a new PCV valve.

TEST the system for normal

operation.

2006.0 Fiesta 1212006 Gl48220en

procarmanuals.com