low oil pressure FORD FIESTA 2007 Owner's Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2007, Model line: FIESTA, Model: FORD FIESTA 2007Pages: 1226, PDF Size: 61.26 MB

Page 573 of 1226

Engine - 1.25L Duratec-1 6V (Sigma)ll.4L

Duratec-1 6V (Sigma)ll .6L Duratec-1 6V (Sigma)

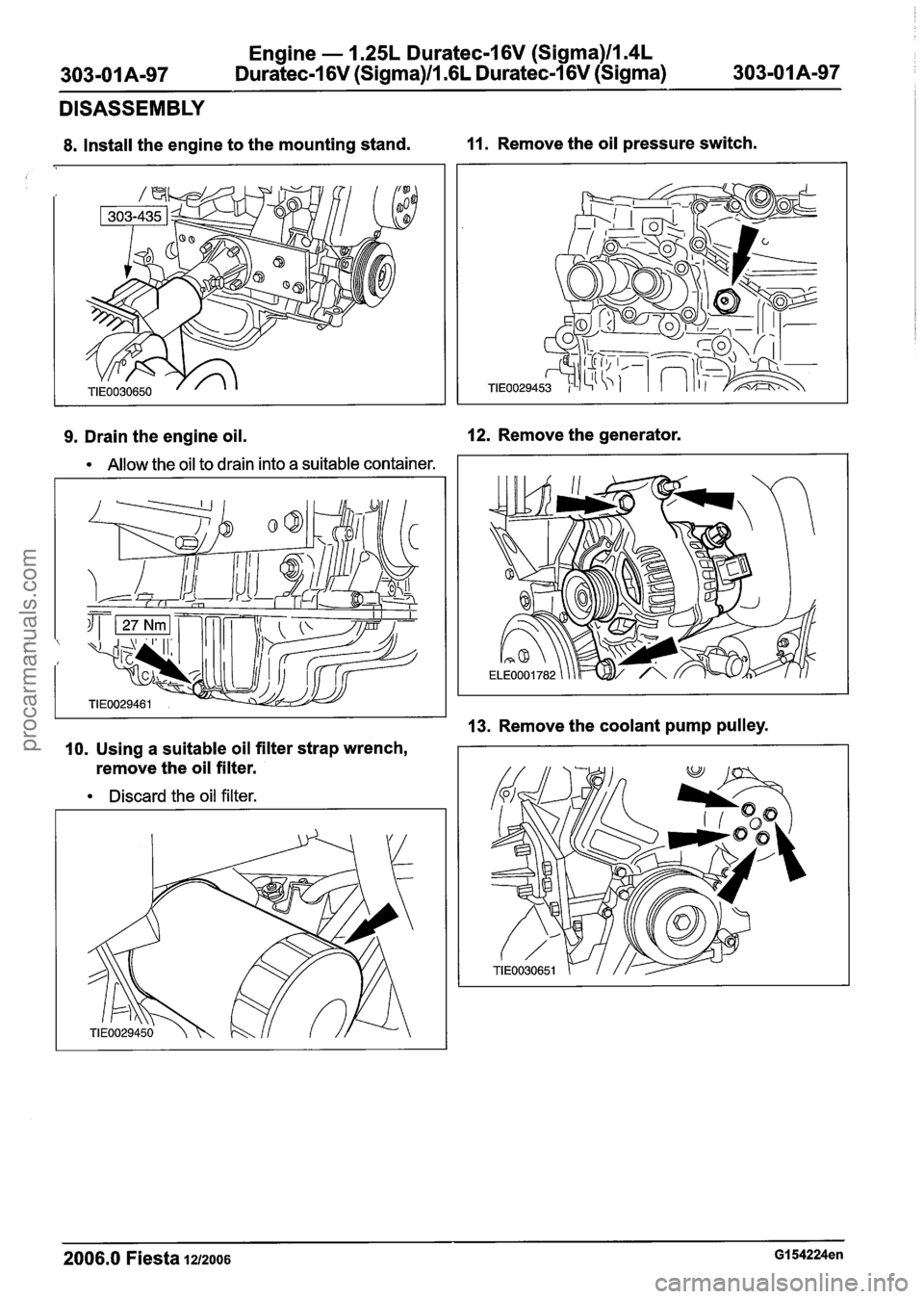

DISASSEMBLY

8. Install the engine to the mounting stand. 11. Remove the oil pressure switch.

9. Drain the engine oil. 12. Remove the generator.

Allow the oil to drain into a suitable container.

13. Remove the coolant pump pulley.

10. Using a suitable oil filter strap wrench,

remove the oil filter.

Discard the oil filter.

2006.0 Fiesta 1212006 GI 54224en

procarmanuals.com

Page 605 of 1226

303-01 A-I 29 Engine

- 1.25L Duratec-I

6V (Sigma)ll.4L

Duratec-I 6V (Sigma)/l .6L Duratec-1 6V (Sigma) 303-01A-129

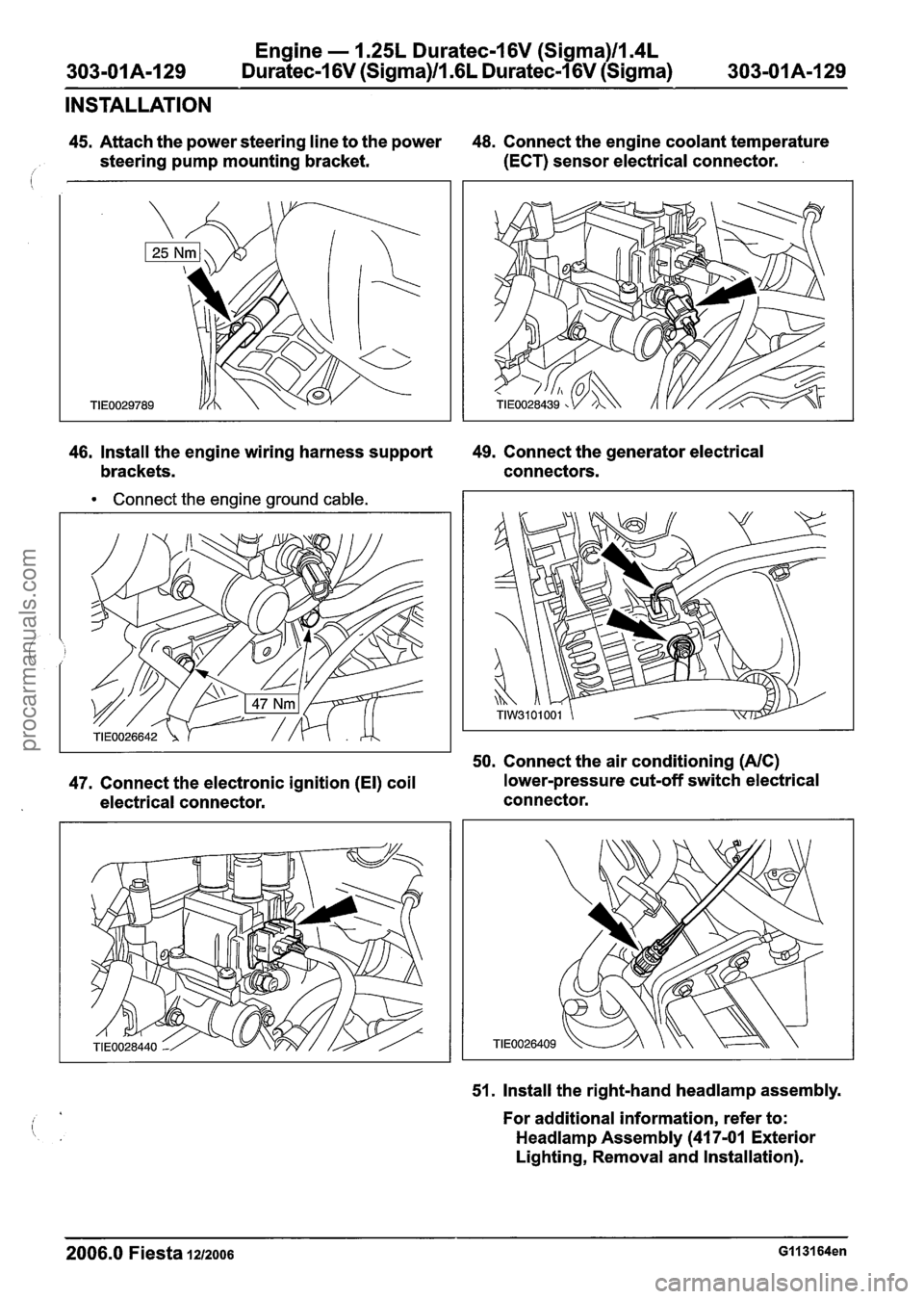

INSTALLATION

45. Attach the power steering line to the power 48.

Connect the engine coolant temperature

i steering pump mounting bracket. (ECT) sensor electrical connector.

46, Install the engine wiring harness support 49.

Connect the generator electrical

brackets. connectors.

Connect the engine ground cable.

50. Connect the air conditioning (AIC)

47. Connect the electronic ignition (El) coil lower-pressure

cut-off switch electrical

electrical connector. connector.

51. Install the right-hand

headlamp assembly.

For additional information, refer to:

Headlamp Assembly (41 7-01 Exterior

Lighting, Removal and Installation).

2006.0 Fiesta 1212006 GI 131 64en

procarmanuals.com

Page 625 of 1226

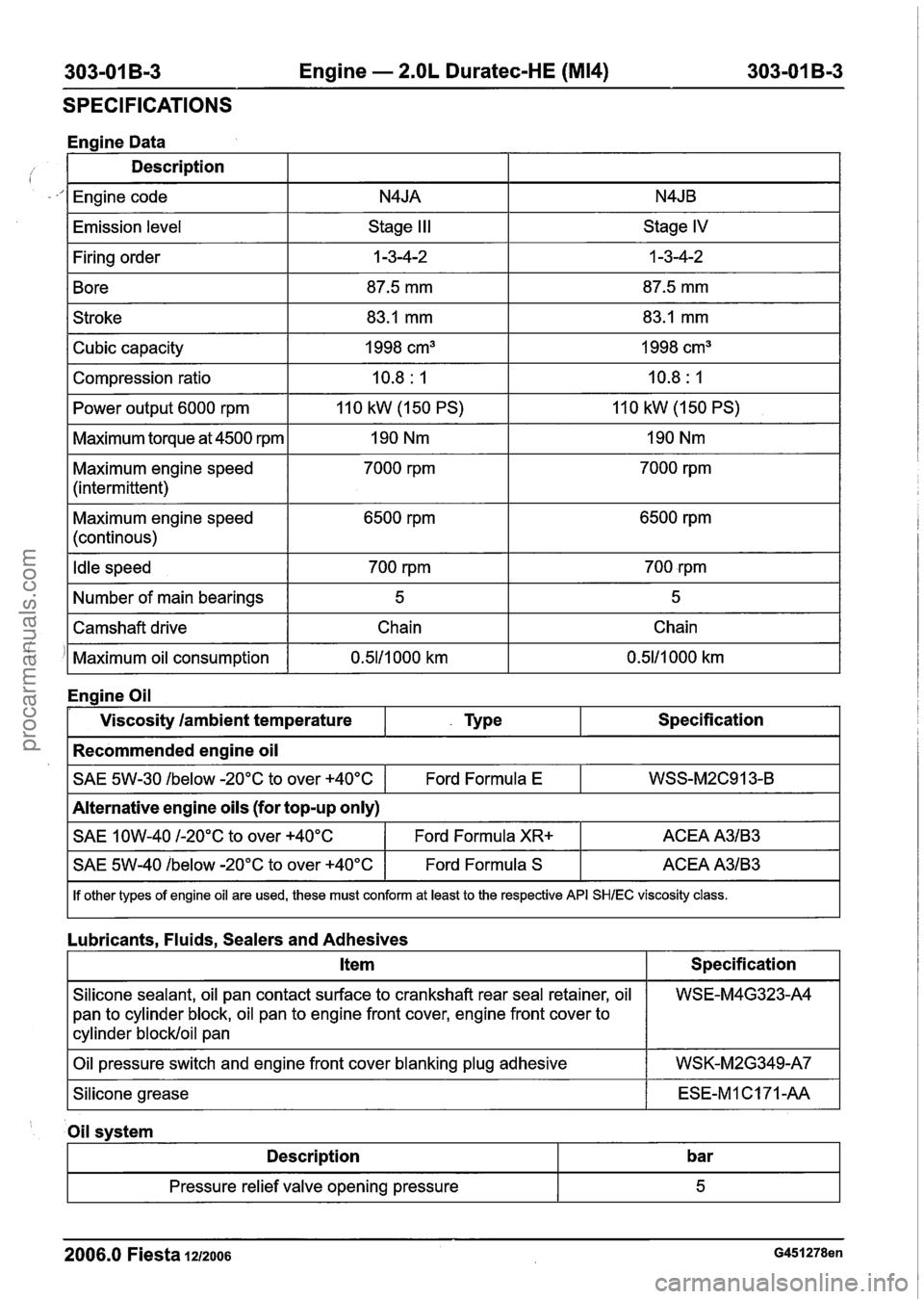

Engine - 2.OL Duratec-HE (M14)

SPECIFICATIONS

Engine Data

Description

I Engine code I N4JA I N4JB I

IEmission level I Stage III I Stage IV I

I Firing order I 1 -3-4-2 I 1 -3-4-2 I

1 Bore I 87.5 mm I 87.5 mm I

1 Stroke I 83.1 mm I 83.1 mm I

I Power output 6000 rpm 1 110 kW (150 PS) I 110 kW (1 50 PS) I

Cubic capacity

Compression ratio

I Maximum torque at 4500 rpm I 190 Nm I 190 Nm I

Maximum engine speed

(intermittent) 1998

cm3

10.8

: I

7000 rprn 1998

cm3

10.8

: 1

7000 rprn

Maximum engine speed

(continous) 6500

rprn 6500 rprn

I Idle speed I 700 rpm I 700 rpm I

I Number of main bearings I 5 I 5 I

!

Engine Oil

I SAE 1 OW-40 I-20°C to over +40°C I Ford Formula XR+ I ACEA A3lB3 I

Camshaft drive

Maximum oil consumption

Viscosity

/ambient temperature

Recommended engine oil

~40%%0w -20°C to over +40°C I Ford Formula S I ACEA A3lB3 I

SAE 5W-30 /below -20°C to over +40°C

I If other types of engine oil are used, these must conform at least to the respective API SHlEC viscosity class.

Chain

0.5111 000 km

- Type

Lubricants, Fluids, Sealers and Adhesives Chain

0.5111 000 km

Specification

Alternative engine oils (for top-up only) Ford Formula

E

I Item I Specification I

WSS-M2C913-B

I Oil pressure switch and engine front cover blanking plug adhesive I WSK-M2G349-A7 I

Silicone sealant, oil pan contact surface to crankshaft rear seal retainer, oil

pan to

cylinder block, oil pan to engine front cover, engine front cover to

cylinder blockloil pan

ISilicohe grease I ESE-MlC171-AA I

WSE-M4G323-A4

' Oil svstem

I Description I bar I

2006.0 Fiesta 1212006 G451278en

- -

Pressure relief valve opening pressure 5

procarmanuals.com

Page 628 of 1226

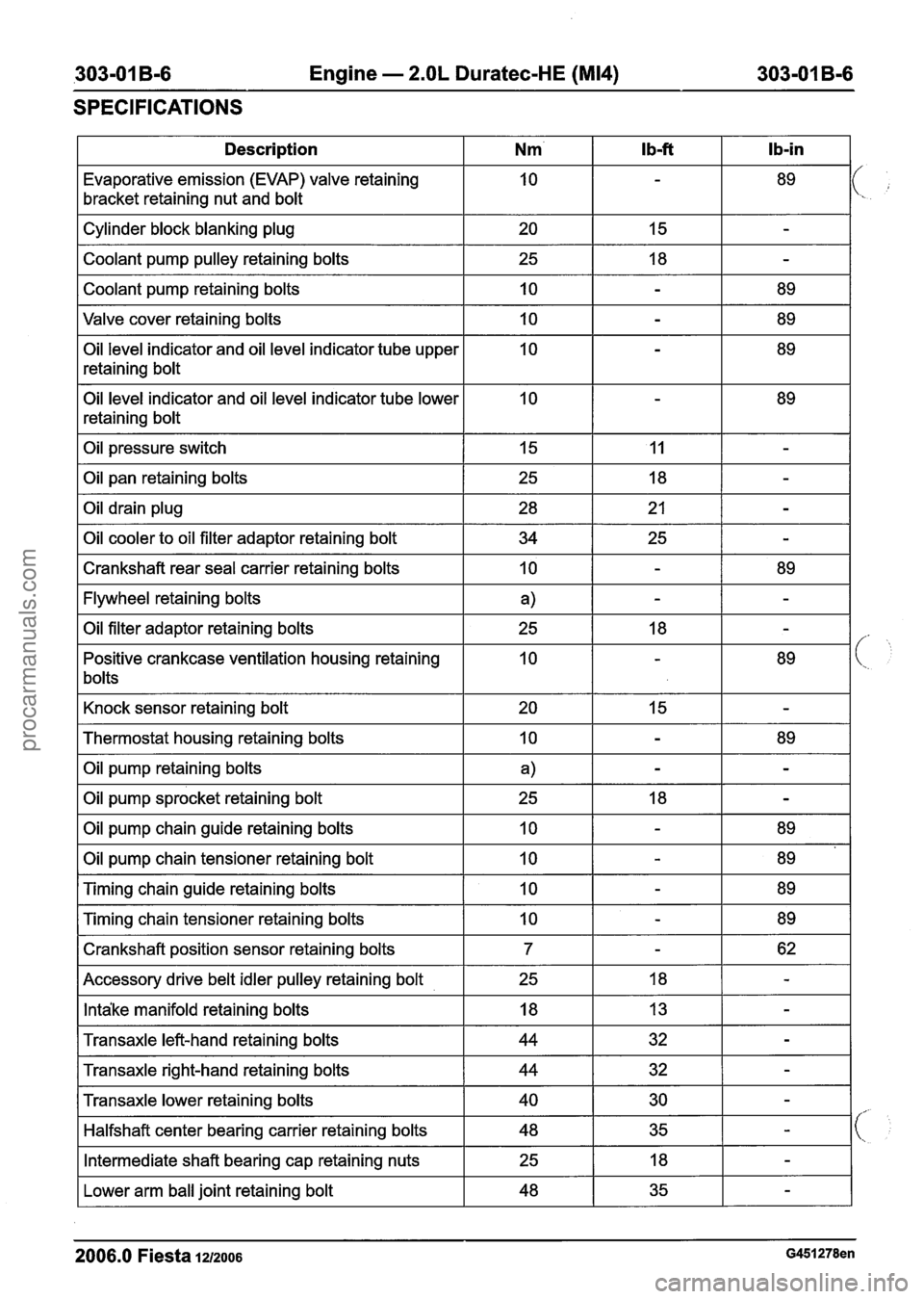

,303-01 B-6 Engine - 2.OL Duratec-HE (M14) 303-01 B-6

SPECIFICATIONS

I Description I Nm' I Ib-ft I Ib-in I

Evaporative emission (EVAP) valve retaining

bracket retaining nut and bolt

Valve cover retaining bolts

I 10 I - I 89 I

Cylinder block blanking plug

Coolant pump pulley retaining bolts

Coolant pump retaining bolts

Oil level indicator and oil level indicator tube upper

retaining bolt

Oil level indicator and oil level indicator tube lower

retaining bolt 20

25

10

Oil pressure switch I 15 I 11 I - I

I Oil pan retaining bolts

15

18

-

-

-

89

I Crankshaft rear seal carrier retaining bolts I 10 I - I 89 I

Oil drain plug

Oil cooler to oil filter adaptor retaining bolt

I Flywheel retaining bolts I a) I - I - I

28

34

I Knock sensor retaining bolt I 20 I 15 I - I

Oil filter adaptor retaining bolts

Positive crankcase ventilation housing retaining

bolts

I Thermostat housing retaining bolts I 10 I - I 89 I

21

25

I Oil pump retaining bolts I a) I - I - I

-

-

25

10

I Oil pump sprocket retaining bolt I 25 I 18 I - I

18

-

-

89

Oil pump chain guide retaining bolts

Oil pump chain tensioner retaining bolt

I Crankshaft position sensor retaining bolts I 7 I - I 62 I

Timing chain guide retaining bolts

Timing chain tensioner retaining bolts

I Accessory drive belt idler pulley retaining bolt I 25 I 18 I - I

10

10

I Intake manifold retaining bolts I 18 I 13 I - I

10

10

I Transaxle left-hand retaining bolts I 44 I 32 I - I

-

-

I Transaxle right-hand retaining bolts I 44 I 32 I - I

89

89

-

-

89

89

Transaxle lower retaining bolts

Halfshaft center bearing carrier retaining bolts

I Lower arm ball joint retaining bolt I 48 I 35 I - I

Intermediate shaft bearing cap retaining nuts

2006.0 Fiesta 1212006 G451278en

40

48

25 30

35 -

-

18 -

procarmanuals.com

Page 678 of 1226

303-01 B-56 Engine - 2.OL Duratec-HE (M14) 303-01 B-56

IN-VEHICLE

REPAIR

Crankshaft Rear Seal(21 468 4)

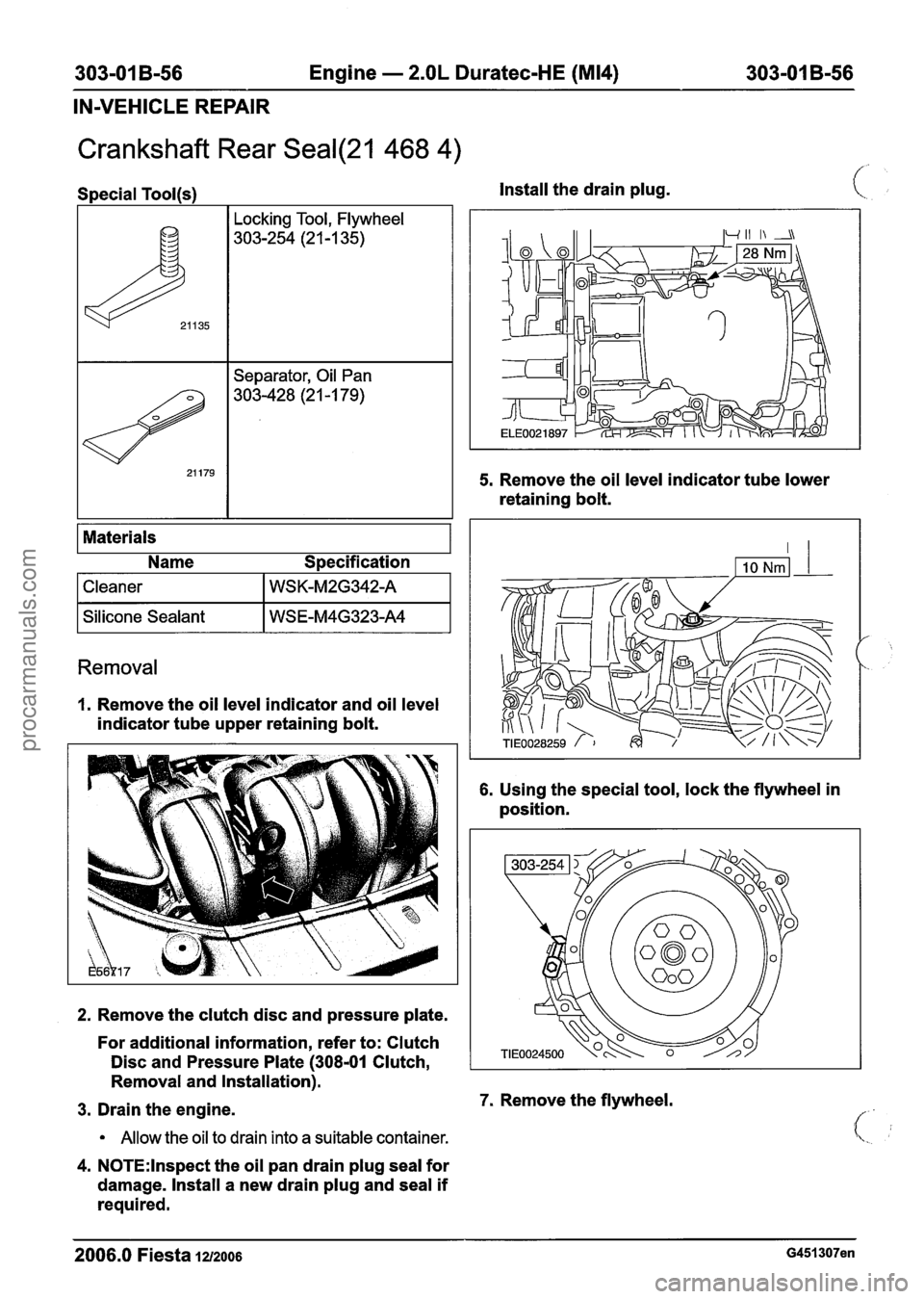

Special Tool(s) Install the drain plug.

Materials Name

S~ecification

1 Cleaner I WSK-M2G342-A I

5. Remove the oil level indicator tube lower

retaining bolt.

- -

d 21 135

4 21 179

I Silicone Sealant I WSE-M4G323-A4 I

Locking Tool, Flywheel

303-254 (2 1 -1 35)

Separator, Oil Pan

303-428 (21 -1

79)

Removal

1. Remove the oil level indicator and oil level

indicator tube upper retaining bolt.

2. Remove the clutch disc and pressure plate.

For additional information, refer to: Clutch

Disc and Pressure Plate

(308-01 Clutch,

Removal and Installation).

3. Drain the engine.

Allow the oil to drain into a suitable container.

4. N0TE:lnspect the oil pan drain plug seal for

damage. Install a new drain plug and seal

if

required.

6. Using the special tool, lock the flywheel in

position.

7. Remove the flywheel.

2006.0 Fiesta 1212006 G451307en

procarmanuals.com

Page 681 of 1226

303-01 B-59 Engine - 2.OL Duratec-HE (M14) 303-01 B-59

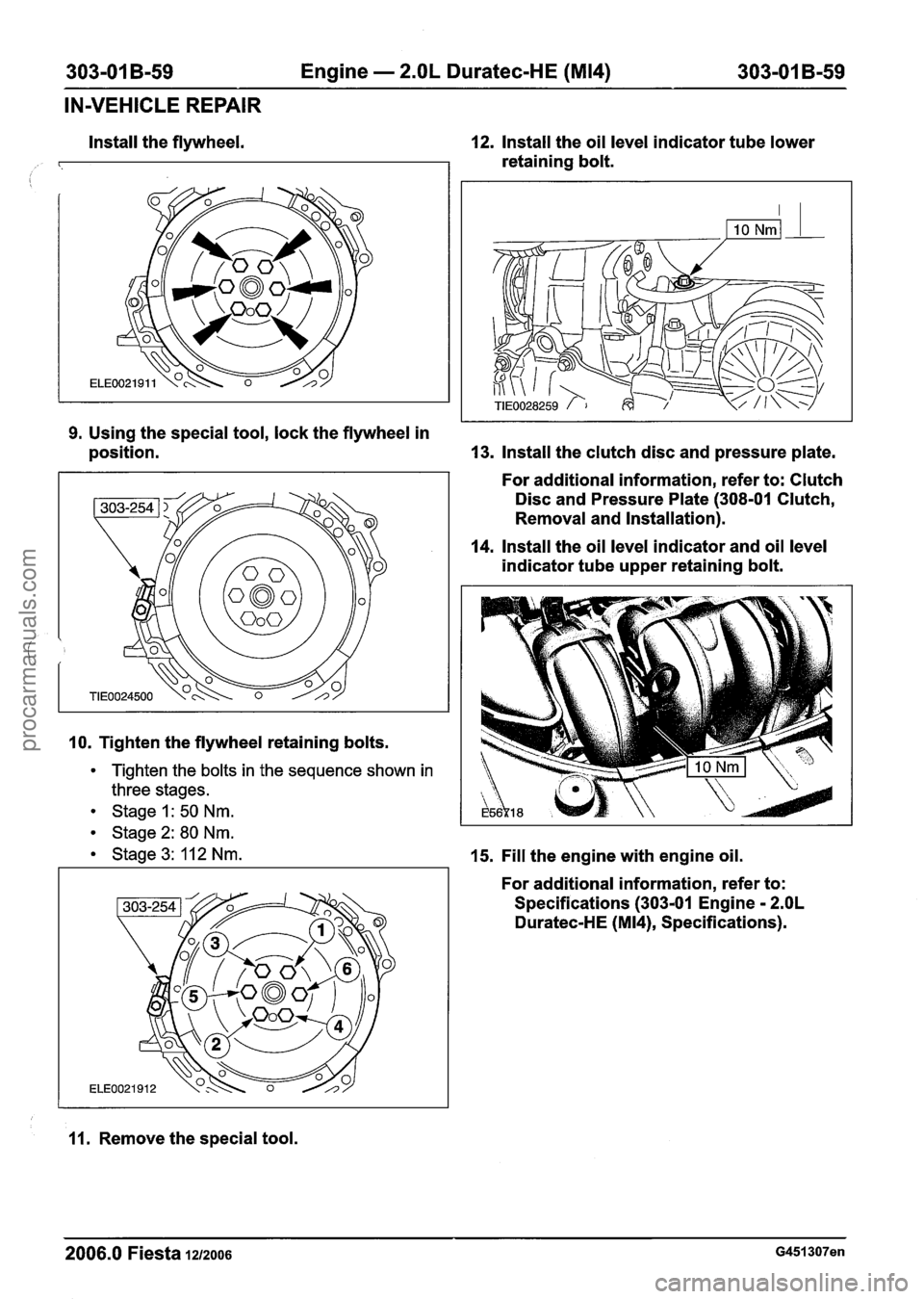

IN-VEHICLE REPAIR

Install the flywheel. 12. Install the oil level indicator tube lower

retaining bolt.

9. Using the special tool, lock the flywheel in

position. 13.

Install the clutch disc and pressure plate.

10. Tighten the flywheel retaining bolts. For

additional information, refer to: Clutch

Disc and Pressure Plate (308-01 Clutch,

Removal and installation).

14. Install the oil level indicator and oil level

indicator tube upper retaining bolt.

Tighten the bolts in the sequence shown in

three stages.

Stage I: 50 Nm.

Stage2: 80 Nm.

Stage 3: 112 Nm. 15. Fill the engine with engine oil.

11. Remove the special tool. For

additional information, refer to:

Specifications

(303-01 Engine - 2.OL

Duratec-HE (M14), Specifications).

2006.0 Fiesta 1212006 G451307en

procarmanuals.com

Page 709 of 1226

303-01 B-87 Engine - 2.OL Duratec-HE (M14) 303-01 B-87

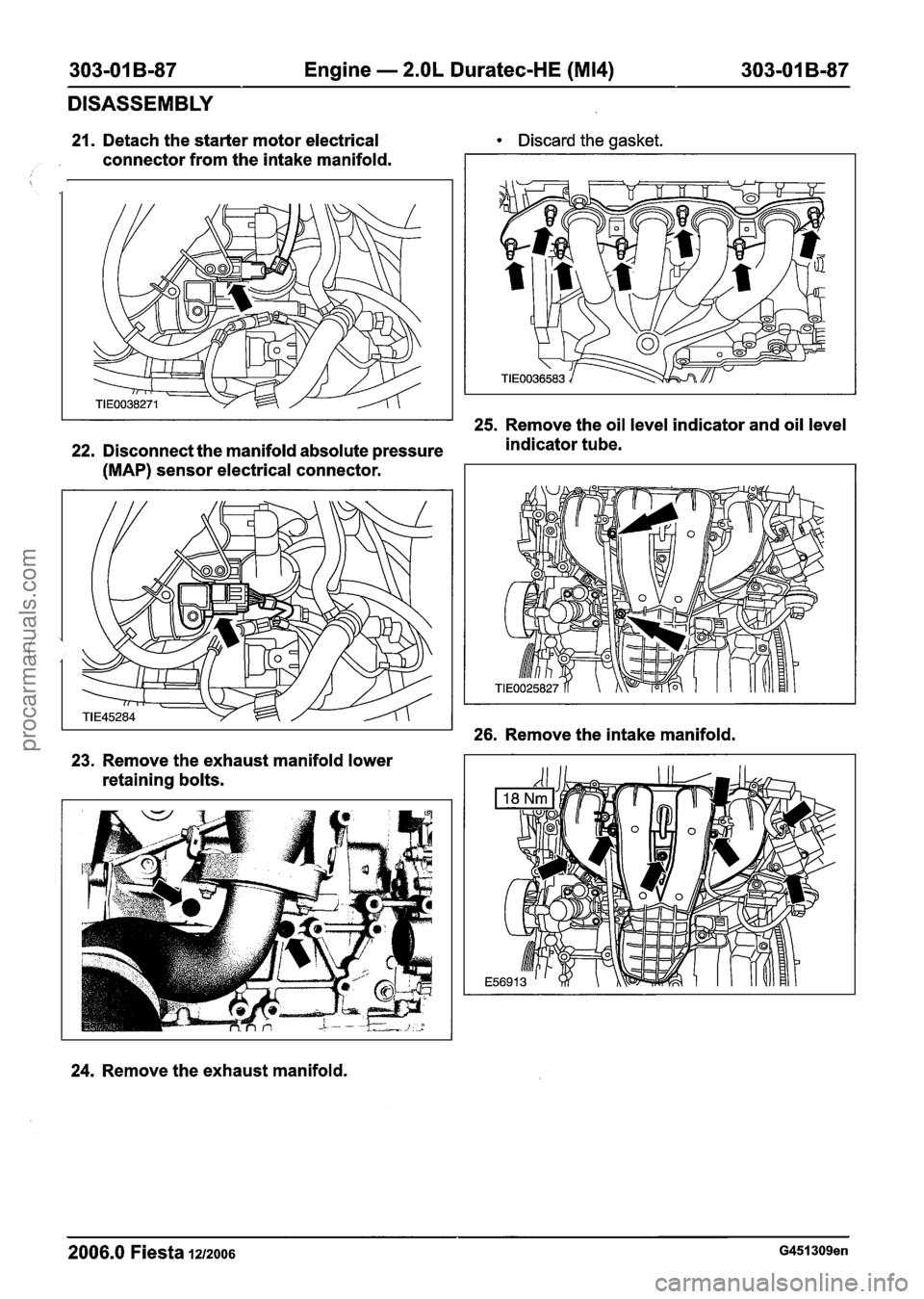

DISASSEMBLY

21. Detach the starter motor electrical

connector from the intake manifold. Discard the

gasket.

25. Remove the oil level indicator and oil level

22. Disconnect the manifold absolute pressure indicator

tube.

(MAP) sensor electrical connector.

26. Remove the intake manifold.

23. Remove the exhaust manifold lower

retaining bolts.

24. Remove the exhaust manifold.

2006.0 Fiesta 1212006 G451309en

procarmanuals.com

Page 759 of 1226

Engine Cooling - I .3L Duratec-8V

(Rocam)llm25L Duratec-1 6V (Sigma)ll.4L

303-03A-17 Duratec-1 6V (Sigma)/lm6L Duratec-1 6V (Sigma) 303-03A-17

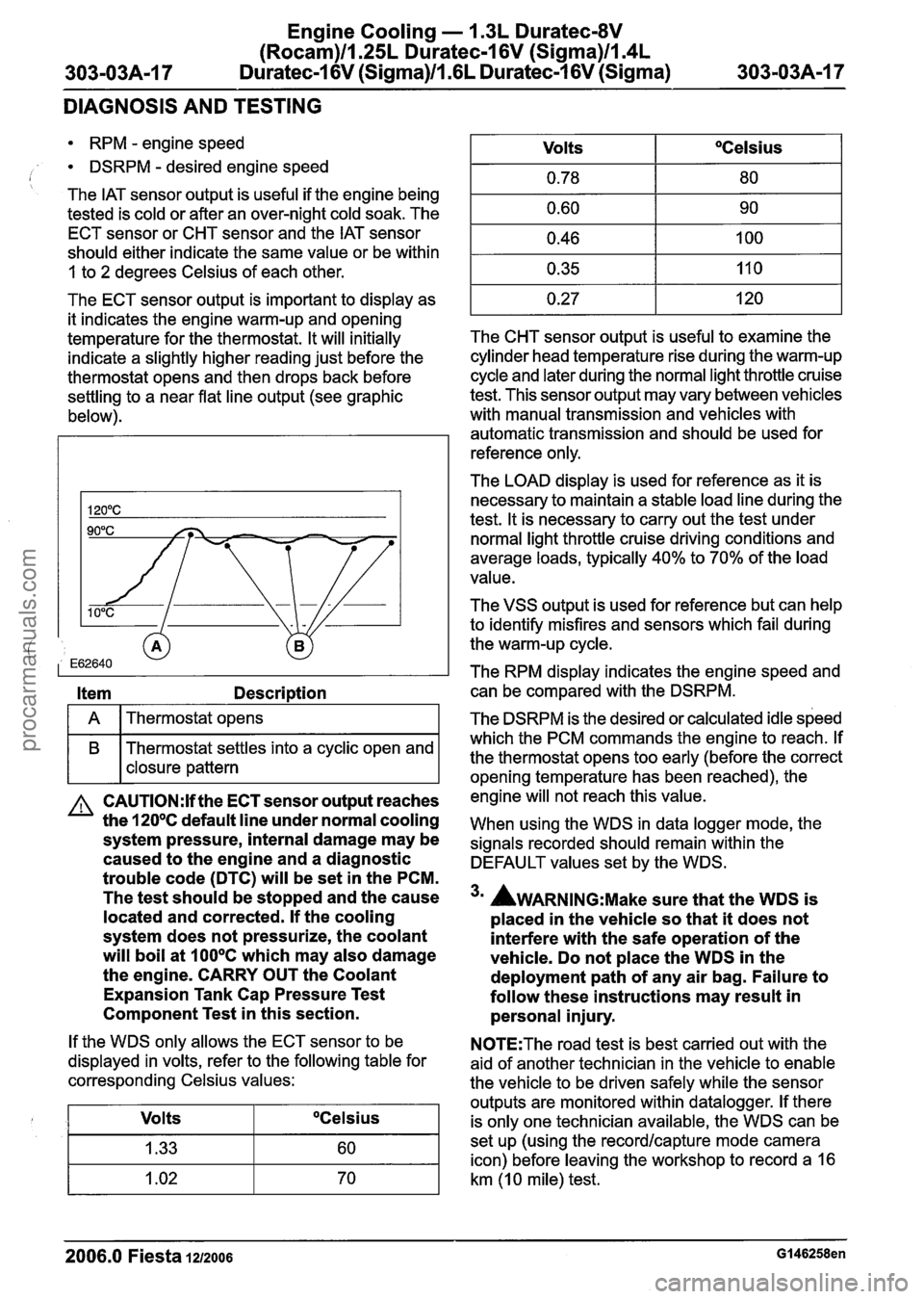

DIAGNOSIS AND TESTING

RPM - engine speed

i DSRPM - desired engine speed

The IAT sensor output is useful if the engine being

tested is cold or after an over-night cold soak. The

ECT sensor or CHT sensor and the IAT sensor

should either indicate the same value or be within

1 to 2 degrees Celsius of each other.

The ECT sensor output is important to display as

it indicates the engine warm-up and opening

temperature for the thermostat. It will initially

indicate a slightly higher reading just before the

thermostat opens and then drops back before

settling to a near flat line output (see graphic

below).

Item Description

I A I Thermostat opens I

B Thermostat settles into a cyclic open and

I I closure pattern

A CAUTI0N:lf the ECT sensor output reaches

the

120°C default line under normal cooling

system pressure, internal damage may be

caused to the engine and a diagnostic

trouble code (DTC) will be set in the PCM.

The test should be stopped and the cause

located and corrected. If the cooling

system does not pressurize, the coolant

will boil at

100°C which may also damage

the engine. CARRY OUT the Coolant

Expansion Tank Cap Pressure Test

Component Test in this section.

If the WDS only allows the ECT sensor to be

displayed in volts, refer to the following table for

corresponding Celsius values:

Volts

OCelsius

The CHT sensor output is useful to examine the

cylinder head temperature rise during the warm-up

cycle and later during the normal light throttle cruise

test. This sensor output may vary between vehicles

with manual transmission and vehicles with

automatic transmission and should be used for

reference only.

Volts

0.78

0.60

0.46

0.35

0.27

The

LOAD display is used for reference as it is

necessary to maintain a stable load line during the

test. It is necessary to carry out the test under

normal light throttle cruise driving conditions and

average loads, typically

40% to 70% of the load

value.

OCelsius

80

90

100

11 0

120

The VSS output is used for reference but can help

to identify misfires and sensors which fail during

the warm-up cycle.

The RPM display indicates the engine speed and can be compared with the DSRPM.

The DSRPM is the desired or calculated idle speed

which the PCM commands the engine to reach. If

the thermostat opens too early (before the correct

opening temperature has been reached), the

engine will not reach this value.

When using the WDS in data logger mode, the

signals recorded should remain within the

DEFAULT values set by the WDS.

3m AWARNING:M~~~ sure that the WDS is

placed in the vehicle so that it does not

interfere with the safe operation of the

vehicle. Do not place the WDS in the

deployment path of any air bag. Failure to

follow these instructions may result in personal injury.

N0TE:The road test is best carried out with the

aid of another technician in the vehicle to enable

the vehicle to be driven safely while the sensor

outputs are monitored within datalogger. If there

is only one technician available, the WDS can be

set up (using the

recordlcapture mode camera

icon) before leaving the workshop to record a

16

km (1 0 mile) test.

2006.0 Fiesta 1212006 GI 46258en

procarmanuals.com

Page 777 of 1226

303-03B-7 Engine Cooling - 2.OL Duratec-HE (M14) 303-03B-7

DESCRIPTION AND OPERATION

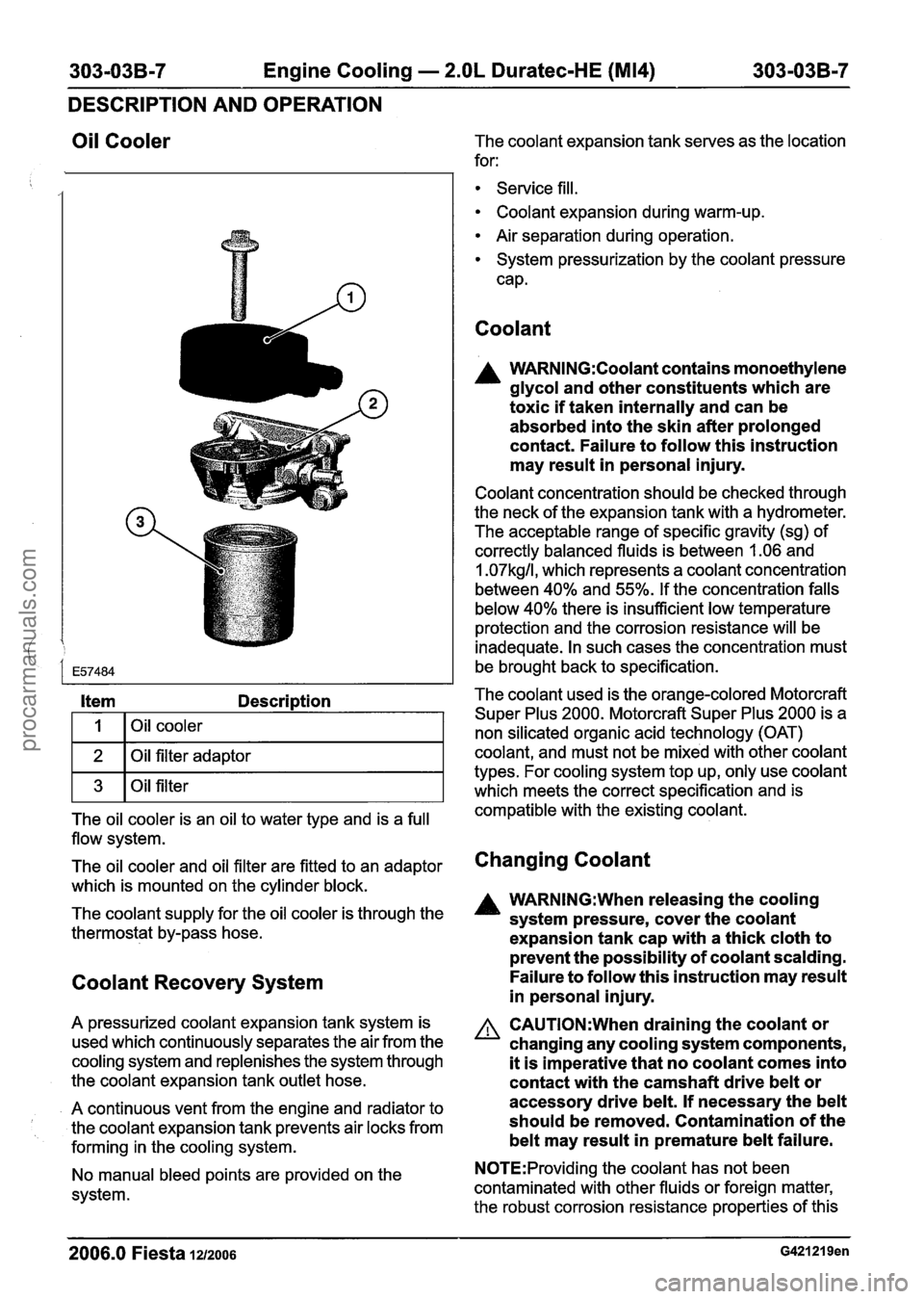

Oil Cooler

Item Description

I I I Oil cooler I

1 2 1 Oil filter adaptor I

1 3 1 Oil filter I

The oil cooler is an oil to water type and is a full

flow system.

The oil cooler and oil filter are fitted to an adaptor

which is mounted on the cylinder block.

The coolant supply for the oil cooler is through the

thermostat by-pass hose.

Coolant Recovery System

A pressurized coolant expansion tank system is

used which continuously separates the air from the

cooling system and replenishes the system through

the coolant expansion tank outlet hose.

A continuous vent from the engine and radiator to

I the coolant expansion tank prevents air locks from

forming in the cooling system.

No manual bleed points are provided on the

system. The coolant expansion tank serves

as the location

for:

Service fill.

Coolant expansion during warm-up.

Air separation during operation.

System pressurization by the coolant pressure

cap.

Coolant

A WARN1NG:Coolant contains monoethylene

glycol and other constituents which are

toxic if taken internally and can be

absorbed into the skin after prolonged

contact. Failure to follow this instruction

may result in personal injury.

Coolant concentration should be checked through

the neck of the expansion tank with a hydrometer.

The acceptable range of specific gravity (sg) of

correctly balanced fluids is between

1.06 and

1.07kg/l, which represents a coolant concentration

between 40% and 55%. If the concentration falls

below 40% there is insufficient low temperature

protection and the corrosion resistance will be

inadequate. In such cases the concentration must

be brought back to specification.

The coolant used is the orange-colored Motorcraft

Super Plus 2000. Motorcraft Super Plus 2000 is a

non silicated organic acid technology (OAT)

coolant, and must not be mixed with other coolant

types. For cooling system top up, only use coolant

which meets the correct specification and is

compatible with the existing coolant.

Changing Coolant

A WARN1NG:When releasing the cooling

system pressure, cover the coolant

expansion tank cap with a thick cloth to

prevent the possibility of coolant scalding.

Failure to follow this instruction may result

in personal injury.

A CAUTI0N:When draining the coolant or

changing any cooling system components,

it is imperative that no coolant comes into

contact with the camshaft drive belt or

accessory drive belt. If necessary the belt

should be removed. Contamination of the

belt may result in premature belt failure.

N0TE:Providing the coolant has not been

contaminated with other fluids or foreign matter,

the robust corrosion resistance properties of this

2006.0 Fiesta 1212006 G421219en

procarmanuals.com

Page 785 of 1226

303-03B-15 Engine Cooling - 2.OL Duratec-HE (M14) 303-03B-15

DIAGNOSIS AND TESTING

A CAUTI0N:lf the ECT sensor output reaches

the

120°C default line under normal cooling

system pressure, internal damage may be

caused to the engine and a diagnostic

trouble code (DTC) will be set in the PCM.

The test should be stopped and the cause

located and corrected. If the cooling

system does not pressurize, the coolant

will boil at

1 OO°C which may also damage

the engine. CARRY

OUT the Coolant

Expansion Tank Cap Pressure Test

Component Test in this section.

If the WDS only allows the ECT sensor to be

displayed in volts, refer to the following table for

corresponding Celsius values:

The CHT sensor output is useful to examine the

cylinder head temperature rise during the warm-up

cycle and later during the normal light throttle cruise

test. This sensor output may vary between vehicles

with manual transmission and vehicles with automatic transmission and should be used for

reference only.

Volts

1.33

1.02

0.78

0.60

0.46

0.35 0.27

The LOAD display is used for reference as it is

necessary to maintain a stable load line during the

test. It is necessary to carry out the test under

normal light throttle cruise driving conditions and

average loads, typically 40% to 70% of the load

value.

OCelsius

60

70

80

90

100

110

120 '

The VSS output is used for reference but can help

to identify misfires and sensors which fail during

the warm-up cycle.

The RPM display indicates the engine speed and

can be compared with the DSRPM.

The DSRPM is the desired or calculated idle speed

which the PCM commands the engine to reach. If

the thermostat opens too early (before the correct

opening temperature has been reached), the

engine will not reach this value. When

using the WDS in data logger mode, the

signals recorded should remain within the

DEFAULT values set by the WDS.

3m AWARNING:M~~~ sure that the WDS is

placed in the vehicle so that it does not

interfere with the safe operation of the

vehicle. Do not place the WDS in the

deployment path of any air bag. Failure to

follow these instructions may result in personal injury.

N0TE:The road test is best carried out with the

aid of another technician in the vehicle to enable

the vehicle to be driven safely while the sensor

outputs are monitored within datalogger. If there

is only one technician available, the WDS can be

set up (using the

recordlcapture mode camera

icon) before leaving the workshop to record a 16

km (1 0 mile) test.

N0TE:The results from the test are more

conclusive if the engine is cold when the test is

started.

Carry out a road test.

REFER to:

RoadIRoller Testing (1 00-00 General

Information, Description and Operation).

4. Drive the vehicle at a constant throttle opening

and set speed until the ECT value settles into

a shallow rise and fall signal, close to a straight

line. This indicates that the thermostat is

functioning correctly.

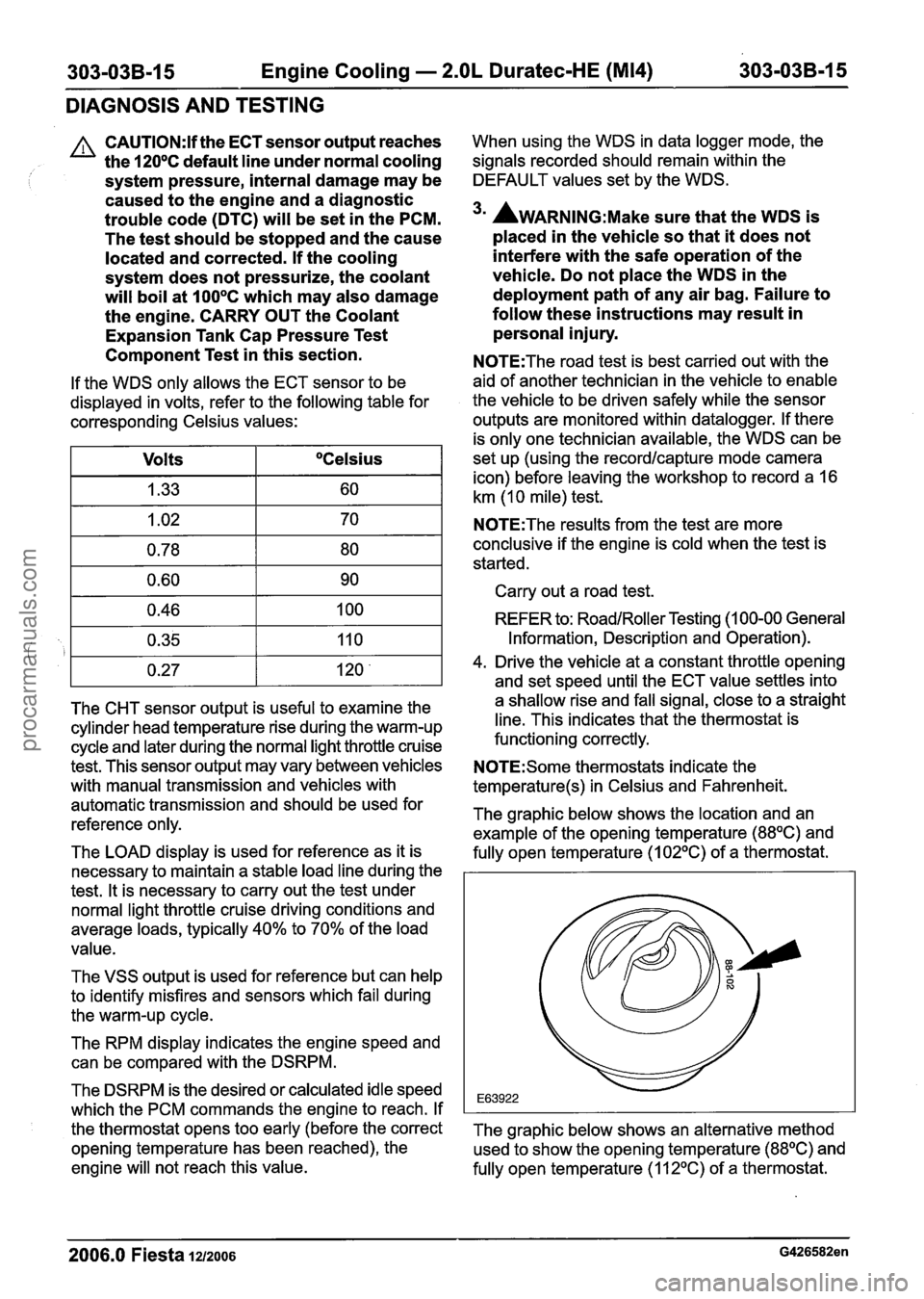

N0TE:Some thermostats indicate the

temperature(s) in Celsius and Fahrenheit.

The graphic below shows the location and an

example of the opening temperature

(88OC) and

fully open temperature (1

02OC) of a thermostat.

The graphic below shows an alternative method used to show the opening temperature

(88OC) and

fully open temperature

(112OC) of a thermostat.

2006.0 Fiesta 1212006 G426582en

procarmanuals.com