engine FORD FLEX 2010 1.G Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2010, Model line: FLEX, Model: FORD FLEX 2010 1.GPages: 397

Page 291 of 397

Maintenance and Modifications

The suspension and steering systems on your vehicle have been designed

and tested to provide predictable performance whether loaded or empty

and durable load carrying capability. For this reason, Ford Motor

Company strongly recommends that you do not make modifications such

as adding or removing parts (such as lift kits or stabilizer bars) or by

using replacement parts not equivalent to the original factory equipment.

Any modifications to a vehicle that raise the center of gravity can make

it more likely the vehicle will rollover as a result of a loss of control.

Ford Motor Company recommends that caution be used with any vehicle

equipped with a high load or device (such as ladder or luggage racks).

Failure to maintain your vehicle properly may void the warranty, increase

your repair cost, reduce vehicle performance and operational capabilities

and adversely affect driver and passenger safety. Frequent inspection of

vehicle chassis components is recommended if the vehicle is subjected to

heavy off-highway usage.

DRIVING THROUGH WATER

If driving through deep or standing

water is unavoidable, proceed very

slowly especially when the depth is

not known. Never drive through

water that is higher than the bottom

of the wheel rims (for cars) or the

bottom of the hubs (for trucks).

When driving through water, traction or brake capability may be limited.

Also, water may enter your engine’s air intake and severely damage your

engine or your vehicle may stall.Driving through deep water where

the transmission vent tube is submerged may allow water into the

transmission and cause internal transmission damage.

Once through the water, always dry the brakes by moving your

vehicle slowly while applying light pressure on the brake pedal.

Wet brakes do not stop the vehicle as quickly as dry brakes.

Driving

291

2010 Flex(471)

Owners Guide, 1st Printing

USA(fus)

Page 294 of 397

FUEL PUMP SHUT-OFF

In the event of a moderate to severe collision, this vehicle is equipped

with a fuel pump shut-off feature that stops the flow of fuel to the

engine. Not every impact will cause a shut-off.

Should your vehicle shut off after a collision due to this feature, you may

restart your vehicle by doing the following:

1. Turn the ignition switch to the off position.

2. Turn the ignition switch to the on position.

In some instances the vehicle may not restart the first time you try to

restart and may take one additional attempt.

WARNING:Failure to inspect and if necessary repair fuel leaks

after a collision may increase the risk of fire and serious injury.

Ford Motor Company recommends that the fuel system be inspected

by an authorized dealer after any collision.

FUSES AND RELAYS

Fuses

If electrical components in the

vehicle are not working, a fuse may

have blown. Blown fuses are

identified by a broken wire within

the fuse. Check the appropriate

fuses before replacing any electrical

components.

Note:Always replace a fuse with one that has the specified amperage

rating. Using a fuse with a higher amperage rating can cause severe wire

damage and could start a fire.

15

Roadside Emergencies

294

2010 Flex(471)

Owners Guide, 1st Printing

USA(fus)

Page 298 of 397

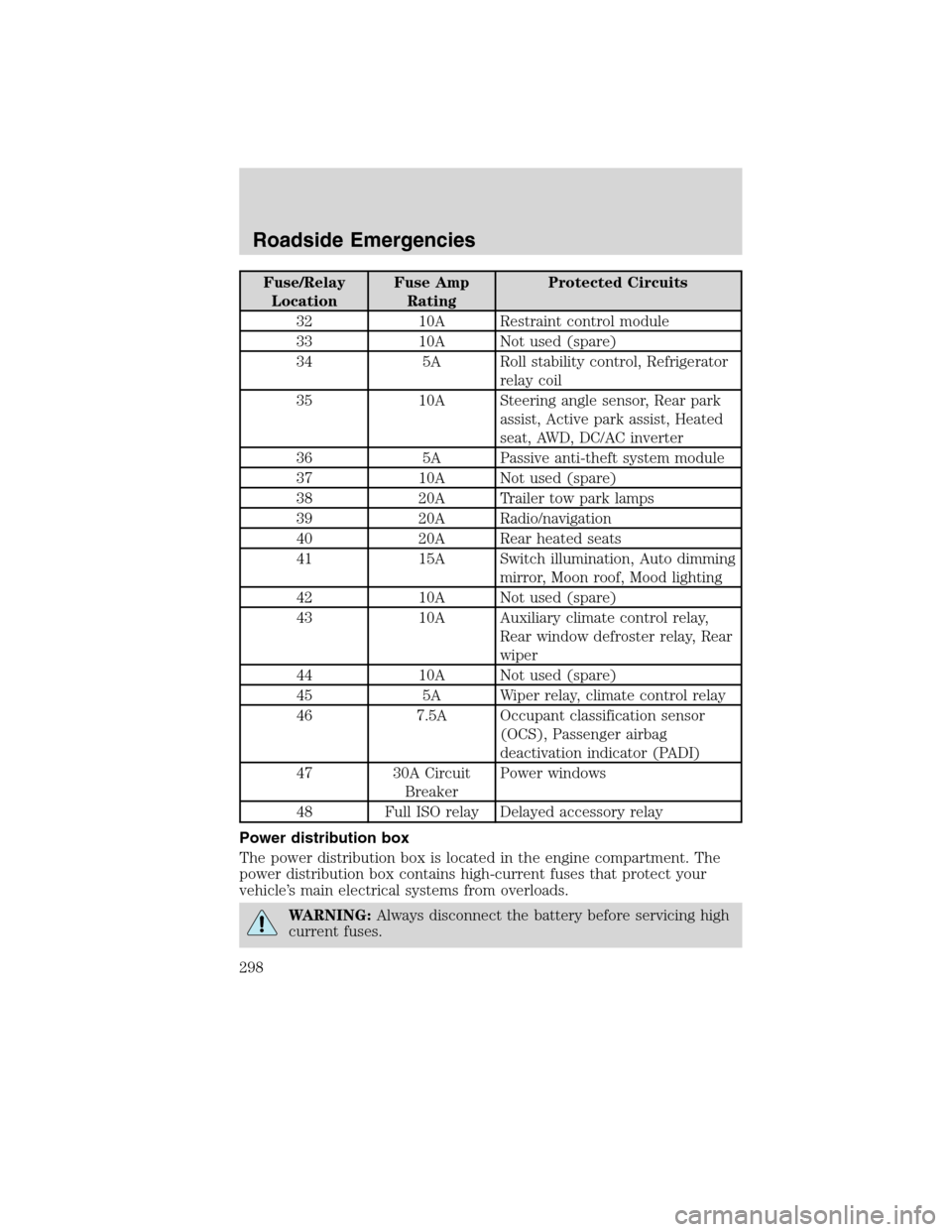

Fuse/Relay

LocationFuse Amp

RatingProtected Circuits

32 10A Restraint control module

33 10A Not used (spare)

34 5A Roll stability control, Refrigerator

relay coil

35 10A Steering angle sensor, Rear park

assist, Active park assist, Heated

seat, AWD, DC/AC inverter

36 5A Passive anti-theft system module

37 10A Not used (spare)

38 20A Trailer tow park lamps

39 20A Radio/navigation

40 20A Rear heated seats

41 15A Switch illumination, Auto dimming

mirror, Moon roof, Mood lighting

42 10A Not used (spare)

43 10A Auxiliary climate control relay,

Rear window defroster relay, Rear

wiper

44 10A Not used (spare)

45 5A Wiper relay, climate control relay

46 7.5A Occupant classification sensor

(OCS), Passenger airbag

deactivation indicator (PADI)

47 30A Circuit

BreakerPower windows

48 Full ISO relay Delayed accessory relay

Power distribution box

The power distribution box is located in the engine compartment. The

power distribution box contains high-current fuses that protect your

vehicle’s main electrical systems from overloads.

WARNING:Always disconnect the battery before servicing high

current fuses.

Roadside Emergencies

298

2010 Flex(471)

Owners Guide, 1st Printing

USA(fus)

Page 301 of 397

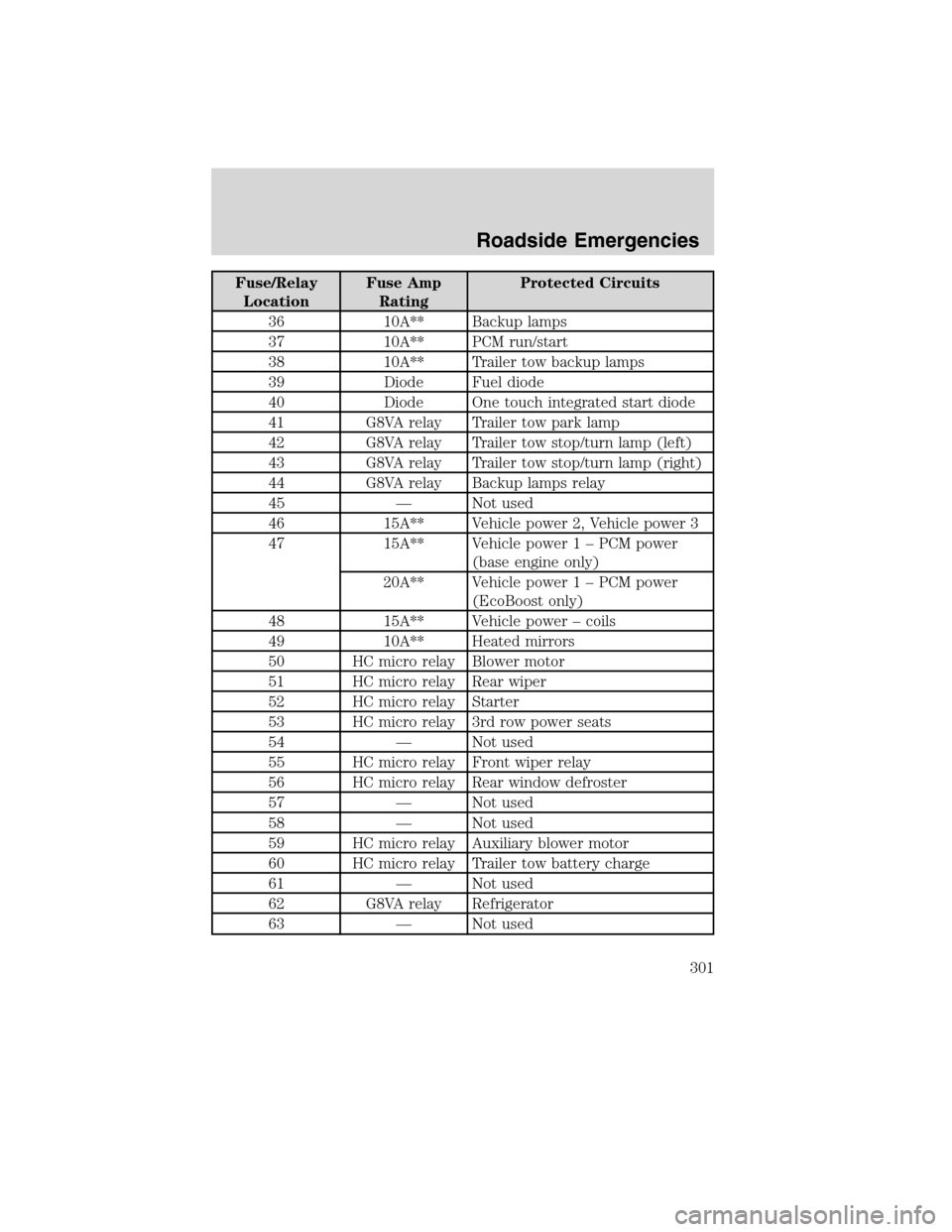

Fuse/Relay

LocationFuse Amp

RatingProtected Circuits

36 10A** Backup lamps

37 10A** PCM run/start

38 10A** Trailer tow backup lamps

39 Diode Fuel diode

40 Diode One touch integrated start diode

41 G8VA relay Trailer tow park lamp

42 G8VA relay Trailer tow stop/turn lamp (left)

43 G8VA relay Trailer tow stop/turn lamp (right)

44 G8VA relay Backup lamps relay

45 — Not used

46 15A** Vehicle power 2, Vehicle power 3

47 15A** Vehicle power 1 – PCM power

(base engine only)

20A** Vehicle power 1 – PCM power

(EcoBoost only)

48 15A** Vehicle power – coils

49 10A** Heated mirrors

50 HC micro relay Blower motor

51 HC micro relay Rear wiper

52 HC micro relay Starter

53 HC micro relay 3rd row power seats

54 — Not used

55 HC micro relay Front wiper relay

56 HC micro relay Rear window defroster

57 — Not used

58 — Not used

59 HC micro relay Auxiliary blower motor

60 HC micro relay Trailer tow battery charge

61 — Not used

62 G8VA relay Refrigerator

63 — Not used

Roadside Emergencies

301

2010 Flex(471)

Owners Guide, 1st Printing

USA(fus)

Page 304 of 397

•Use snow chains on the end of the vehicle with the dissimilar spare

tire/wheel

The usage of a full-size dissimilar spare tire/wheel can lead to

impairment of the following:

•Handling, stability and braking performance

•Comfort and noise

•Ground clearance and parking at curbs

•Winter weather driving capability

•Wet weather driving capability

•All-Wheel driving capability (if applicable)

•Load leveling adjustment (if applicable)

When driving with the full-size dissimilar spare tire/wheel additional

caution should be given to:

•Towing a trailer

•Driving vehicles equipped with a camper body

•Driving vehicles with a load on the cargo rack

Drive cautiously when using a full-size dissimilar spare tire/wheel and

seek service as soon as possible.

Stopping and securing the vehicle

1. Park on a level surface, set the

parking brake and activate hazard

flashers.

2. Place gearshift lever in P (Park)

and turn engine off.

Removing the spare tire and jack

If the 3rd row seat is stowed in the floor, you will need to unstow it to

access the spare tire and jack. Refer toUnstowing the third row seatin

theSeating and Safety Restraintschapter for this procedure.

Roadside Emergencies

304

2010 Flex(471)

Owners Guide, 1st Printing

USA(fus)

Page 311 of 397

•Read the information in theTips for use of the temporary mobility

kitsection to ensure safe operation of the temporary mobility kit and

your vehicle.

Tips for use of the temporary mobility kit

Read the following list of tips to ensure safe operation of the temporary

mobility kit:

•Before operating the temporary mobility kit, make sure your vehicle is

safely off the road and away from moving traffic. Turn on the hazard

lights.

•Always set the parking brake to ensure the vehicle doesn’t move

unexpectedly.

•Do not remove any foreign objects, such as nails or screws, from the

tire.

•When using the temporary mobility kit, leave the engine running

(only if the vehicle is outdoors or in a well-ventilated area)so

the compressor doesn’t drain the vehicle’s battery.

•Do not allow the compressor to operate continuously for more than

15 minutes; this will help prevent the compressor from overheating.

•Never leave the temporary mobility kit unattended when it is

operating.

•Sealant compound contains latex. Make sure that you use the

non-latex gloves provided to avoid an allergic reaction.

•Keep the temporary mobility kit away from children.

•Only use the temporary mobility kit when the ambient temperature is

between -22°F (–30°C) and 158°F (70°C).

•Only use the sealing compound before the use by date. The use by

date is on the lower right hand corner of the label located on the

sealant canister (bottle).Check the use by date regularly and

replace the canister after four years.

•Do not store the temporary mobility kit unsecured inside the

passenger compartment of the vehicle as it may cause injury during a

sudden stop or collision. Always store the kit in its original location.

•After sealant use, the TPMS sensor and valve stem on the wheel must

be replaced by an authorized Ford dealer.

•When inflating a tire or other objects, use the black air hose only. Do

not use the transparent hose which is designed for sealant application

only.

Roadside Emergencies

311

2010 Flex(471)

Owners Guide, 1st Printing

USA(fus)

Page 312 of 397

•Operating the temporary mobility kit could cause an electrical

disturbance in radio and DVD player operation.

What to do when a tire is punctured

A tire puncture within the tire’s tread area can be repaired in two stages

with the temporary mobility kit:

•In the first stage, the tire will be reinflated with a sealing compound

and air. After the tire has been reinflated, you will need to drive the

vehicle a short distance (approximately 4 miles [6 km]) to distribute

the sealant in the tire.

•In the second stage, you will need to check the tire pressure and

adjust, if necessary, to the vehicle’s tire inflation pressure.

First stage: Reinflating the tire with sealing compound and air

Preparation

Park the vehicle in a safe, level and secure area, away from moving

traffic. Turn the hazard lights on. Apply the parking brake and turn the

engine off. Inspect the flat tire for visible damage.

Sealant compound contains latex. To avoid any allergic reactions, use the

non-latex gloves located in the accessory box on the underside of the

temporary mobility kit housing.

Do not remove any foreign object that has pierced the tire. If a puncture

is located in the tire sidewall, stop and call roadside assistance.

1. Remove the valve cap from the tire valve.

2. Unwrap the clear tube from the compressor housing.

3. Remove the tube cap and fasten the metal connector of the tube to

the tire valve, turning clockwise. Make sure the connection is tightly

fastened.

Roadside Emergencies

312

2010 Flex(471)

Owners Guide, 1st Printing

USA(fus)

Page 313 of 397

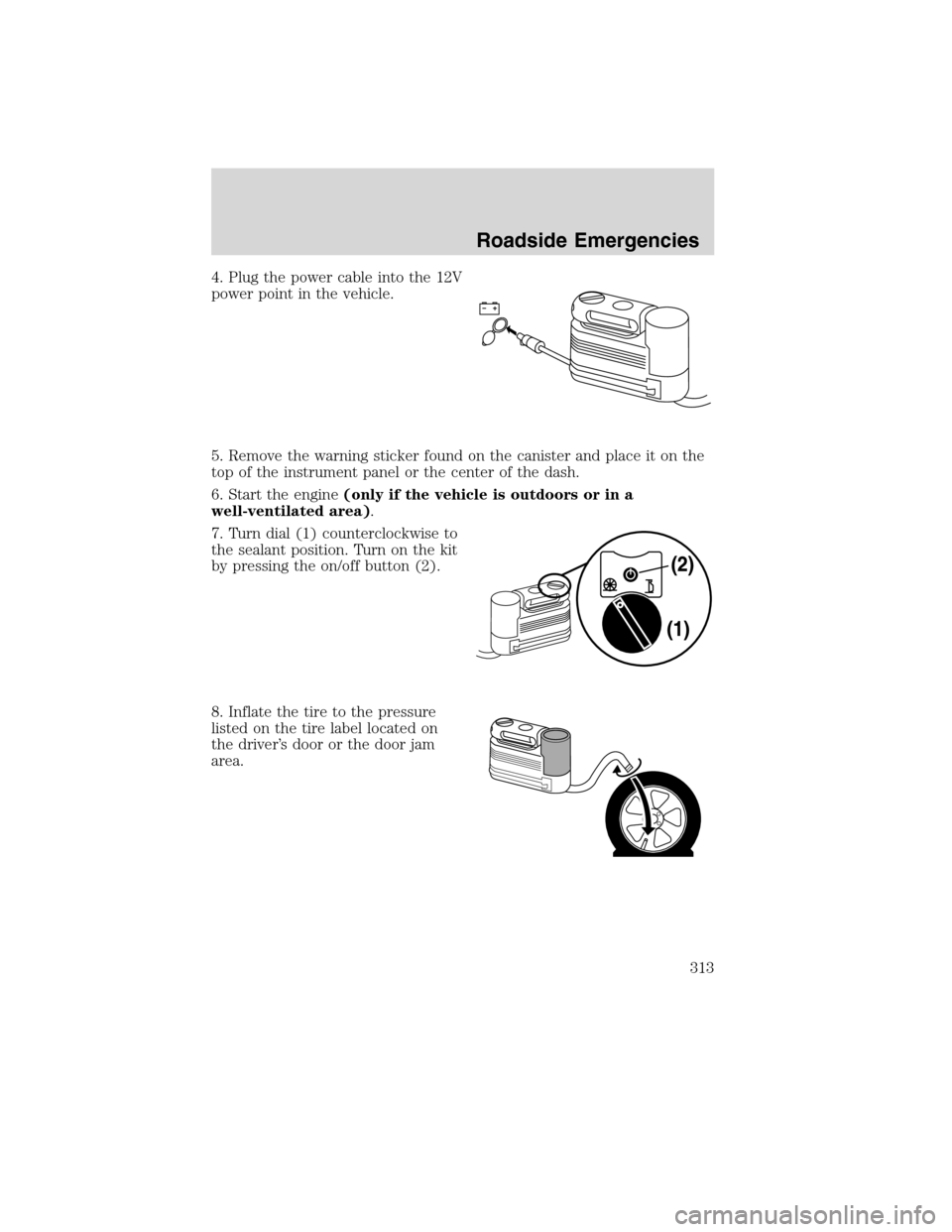

4. Plug the power cable into the 12V

power point in the vehicle.

5. Remove the warning sticker found on the canister and place it on the

top of the instrument panel or the center of the dash.

6. Start the engine(only if the vehicle is outdoors or in a

well-ventilated area).

7. Turn dial (1) counterclockwise to

the sealant position. Turn on the kit

by pressing the on/off button (2).

8. Inflate the tire to the pressure

listed on the tire label located on

the driver’s door or the door jam

area.

Roadside Emergencies

313

2010 Flex(471)

Owners Guide, 1st Printing

USA(fus)

Page 320 of 397

Preparing your vehicle

When the battery is disconnected or a new battery is installed, the

automatic transmission must relearn its shift strategy. As a result, the

transmission may have firm and/or soft shifts. This operation is

considered normal and will not affect function or durability of the

transmission. Over time, the adaptive learning process will fully update

transmission operation.

1.Use only a 12–volt supply to start your vehicle.

2. Do not disconnect the battery of the disabled vehicle as this could

damage the vehicle’s electrical system.

3. Park the booster vehicle close to the hood of the disabled vehicle

making sure the two vehiclesdo nottouch. Set the parking brake on

both vehicles and stay clear of the engine cooling fan and other moving

parts.

4. Check all battery terminals and remove any excessive corrosion before

you attach the battery cables. Ensure that vent caps are tight and level.

5. Turn the heater fan on in both vehicles to protect from any electrical

surges. Turn all other accessories off.

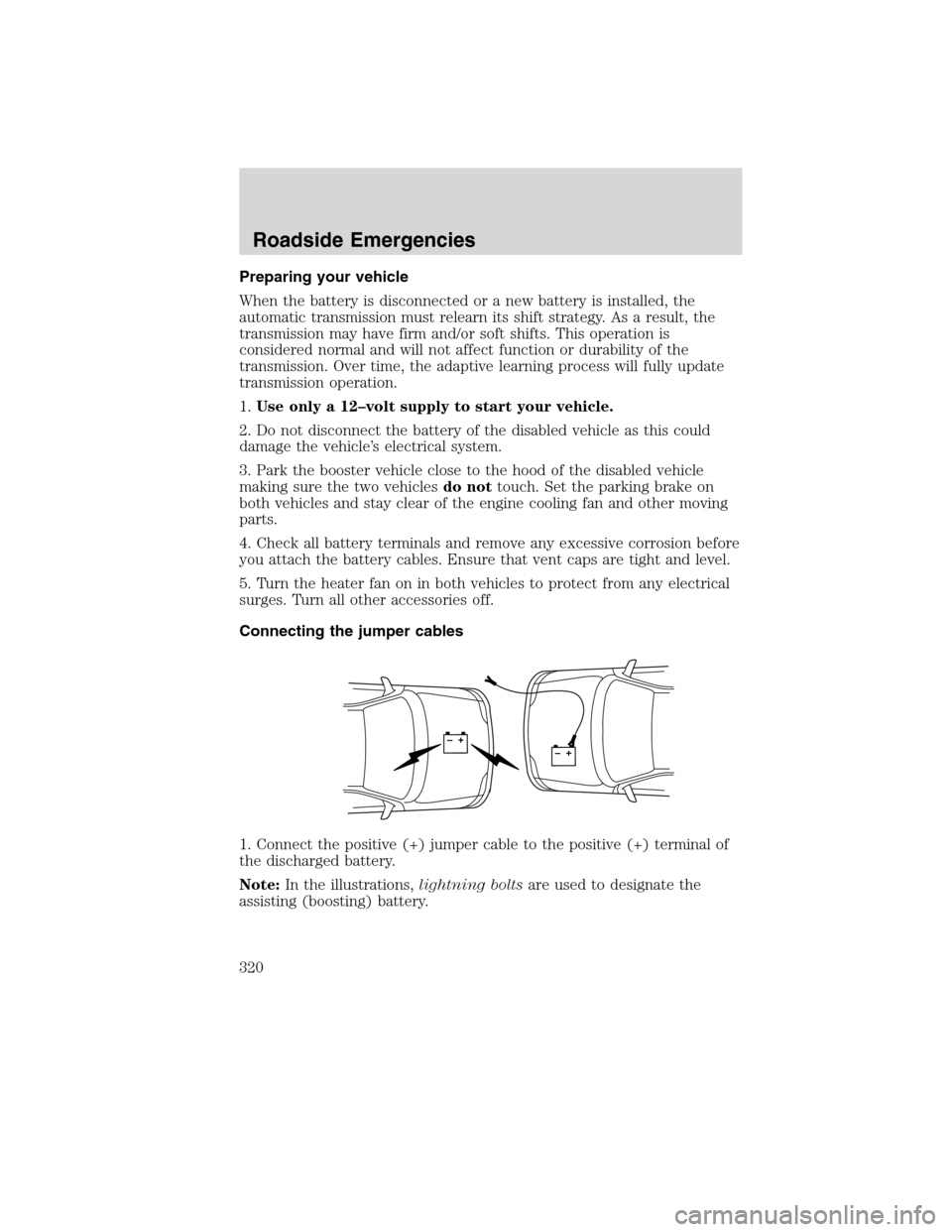

Connecting the jumper cables

1. Connect the positive (+) jumper cable to the positive (+) terminal of

the discharged battery.

Note:In the illustrations,lightning boltsare used to designate the

assisting (boosting) battery.

+–+–

Roadside Emergencies

320

2010 Flex(471)

Owners Guide, 1st Printing

USA(fus)

Page 322 of 397

4. Make the final connection of the negative (-) cable to an exposed

metal part of the stalled vehicle’s engine, away from the battery and the

carburetor/fuel injection system.

Note:Do not attach the negative (-) cable to fuel lines, engine rocker

covers, the intake manifold or electrical components asgrounding

points.

WARNING:Do not connect the end of the second cable to the

negative (-) terminal of the battery to be jumped. A spark may

cause an explosion of the gases that surround the battery.

5. Ensure that the cables are clear of fan blades, belts, moving parts of

both engines, or any fuel delivery system parts.

Jump starting

1. Start the engine of the booster vehicle and run the engine at

moderately increased speed.

2. Start the engine of the disabled vehicle.

3. Once the disabled vehicle has been started, run both engines for an

additional three minutes before disconnecting the jumper cables.

+–+–

Roadside Emergencies

322

2010 Flex(471)

Owners Guide, 1st Printing

USA(fus)