check engine light FORD GRANADA 1985 Service User Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 1985, Model line: GRANADA, Model: FORD GRANADA 1985Pages: 255, PDF Size: 14.98 MB

Page 37 of 255

(1.0 in) either side of the spreader gap. Fit the

tapered lower compression ring with the TOP

mark towards the top of the piston and the gap

150°from the spreader gap, then fit the upper

compression ring with the gap 150°on the

other side of the spreader gap. Note that the

compression rings are coated with a

molybdenum skin which must not be damaged.

7Note that the compression rings are made

of cast iron, and will snap if expanded too far.

Examine the surface of the camshaft

journals and lobes and the cam followers for

wear. If excessive, considerable noise would

have been noticed from the top of the engine

and a new camshaft and followers must be

fitted.

Check the camshaft bearings for wear and if

necessary have them renewed by a Ford

garage.

Check the camshaft lubrication tube for

obstructions and make sure that the jet holes

are clear. Obstruction of the holes can be due

to sludge build-up which occurs when regular

oil changes have been neglected.

Examine the auxiliary shaft for wear and

damage and renew it if necessary.

If the auxiliary shaft endfloat is outside the

limits given in the Specifications fit a new

thrust plate. If this does not bring the endfloat

within limits, renew the shaft.

Whenever the timing belt is removed it is

worthwhile renewing it, especially if it has

covered a high mileage. This is more important

on the 2.0 litre engine where stripped teeth on

the timing belt can cause the pistons to foul

the valves.If the ring gear is badly worn or has missing

teeth, it should be renewed. The old ring can

be removed from the flywheel by cutting a

notch between two teeth with a hacksaw and

then splitting it with a cold chisel. Wear eye

protection when doing this.

To fit a new ring gear requires heating the

ring to 204°C (400°F). This can be done by

polishing four equal sections of the gear,

laying it on a suitable heat resistant surface

(such as fire bricks) and heating it evenly with

a blow lamp or torch until the polished areas

turn a light yellow tinge. Do not overheat or the

hard wearing properties will be lost. The gear

has a chamfered inner edge which should go

against the shoulder when put on the flywheel.

When hot enough place the gear in position

quickly, tapping it home if necessary and let it

cool naturally, without quenching.

1This operation will normally only be required

at comparatively high mileages. However, if

persistent pinking occurs and performance

has deteriorated even though the engine

adjustments are correct, decarbonising and

valve grinding may be required.

2With the cylinder head removed, use a

scraper to remove the carbon from the

combustion chambers and ports. Remove all

traces of gasket from the cylinder head

surface, then wash it thoroughly with paraffin.

3Use a straight-edge and feeler blade to

check that the cylinder head surface is not

distorted. If it is, it must be resurfaced by a

suitably equipped engineering works.

4If the engine is still in the car, clean the

piston crowns and cylinder bore upper edges,

but make sure that no carbon drops between

the pistons and bores. To do this, locate two

of the pistons at the top of their bores and seal

off the remaining bores with paper and

masking tape. Press a little grease between

the two pistons and their bores to collect any

carbon dust; this can be wiped away when the

piston is lowered.5Examine the heads of the valves for pitting

and burning, especially the exhaust valve

heads. Renew any valve which is badly burnt.

Examine the valve seats at the same time. If

the pitting is very slight, it can be removed by

grinding the valve heads and seats together

with coarse, then fine, grinding paste.

6Where excessive pitting has occurred, the

valve seats must be recut or renewed by a

suitably equipped engineering works.

7Valve grinding is carried out as follows.

Place the cylinder head upside down on a

bench on blocks of wood.

8Smear a trace of coarse carborundum paste

on the seat face and press a suction grinding

tool onto the valve head. With a semi-rotary

action, grind the valve head to its seat, lifting

the valve occasionally to redistribute the

grinding paste. When a dull matt even surface

is produced on both the valve seat and the

valve, wipe off the paste and repeat the

process with fine carborundum paste as

before. A light spring placed under the valve

head will greatly ease this operation. When a

smooth unbroken ring of light grey matt finish

is produced on both the valve and seat, the

grinding operation is complete.

9Scrape away all carbon from the valve head

and stem, and clean away all traces of

grinding compound. Clean the valves and

seats with a paraffin soaked rag, then wipe

with a clean rag.

10If the guides are worn they will need

reboring for oversize valves or for fitting guide

inserts. The valve seats will also need

recutting to ensure that they are concentric

with the stems. This work should be given to

your Ford dealer or local engineering works.

11If the valve springs have been in use

for 20 000 miles (32 000 km) or more, renew

them. Always renew the valve stem oil seals

when the valves are removed.

1To ensure maximum life with minimum

trouble from a rebuilt engine, not only must

everything be correctly assembled, but it must

also be spotlessly clean. All oilways must be

clear, and locking washers and spring washers

must be fitted where indicated. Oil all bearings

and other working surfaces thoroughly with

engine oil during assembly.

2Before assembly begins, renew any bolts or

studs with damaged threads.

3Gather together a torque wrench, oil can,

clean rag, and a set of engine gaskets and oil

seals, together with a new oil filter.

4If they have been removed, new cylinder

head bolts and flywheel bolts will also be

required.

35Engine reassembly - general

information

34Cylinder head - decarbonising,

valve grinding and renovation

33Flywheel ring gear -

examination and renovation

32Timing belt - examination and

renovation

31Auxiliary shaft - examination

and renovation

30Camshaft and cam followers

- examination and renovation

2A•14SOHCengines

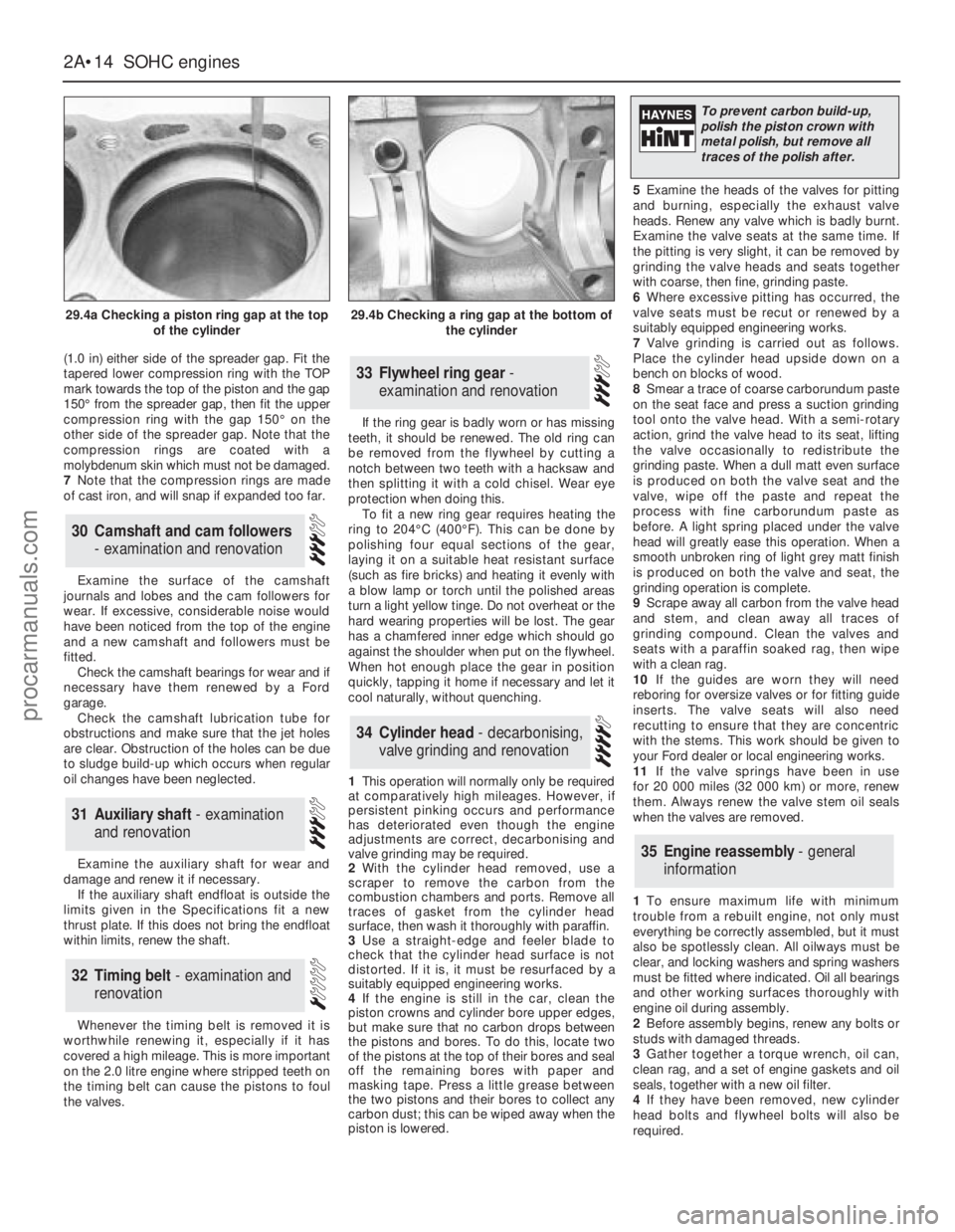

29.4a Checking a piston ring gap at the top

of the cylinder29.4b Checking a ring gap at the bottom of

the cylinder

To prevent carbon build-up,

polish the piston crown with

metal polish, but remove all

traces of the polish after.

procarmanuals.com

Page 38 of 255

1Wipe the bearing shell locations in the

crankcase with a soft, non-fluffy rag.

2Wipe the crankshaft journals with a soft,

non-fluffy rag.

3Fit the five upper half main bearing shells to

their locations in the crankcase. If the old

shells are being re-used, make sure they are

refitted to their old locations.

4Identify each main bearing cap and place in

order. The number is cast onto the cap and on

intermediate caps an arrow is also marked

which should point towards front of engine.

5Wipe the cap bearing shell location with a

soft non-fluffy rag.

6Fit the bearing half shell onto each main

bearing cap.

7Apply a little grease to each side of the

centre main bearing so as to retain the

thrustwasher.

8Fit the upper halves of the thrustwashers

into their grooves either side of the main

bearing. The slots must face outwards.

9Lubricate the crankshaft journals and the

upper and lower main bearing shells with

engine oil and locate the rear oil seal (with lip

lubricated) on the rear of the crankshaft.

10Carefully lower the crankshaft into the

crankcase.

11Lubricate the crankshaft main bearing

journals again and then fit No 1 bearing cap. Fit

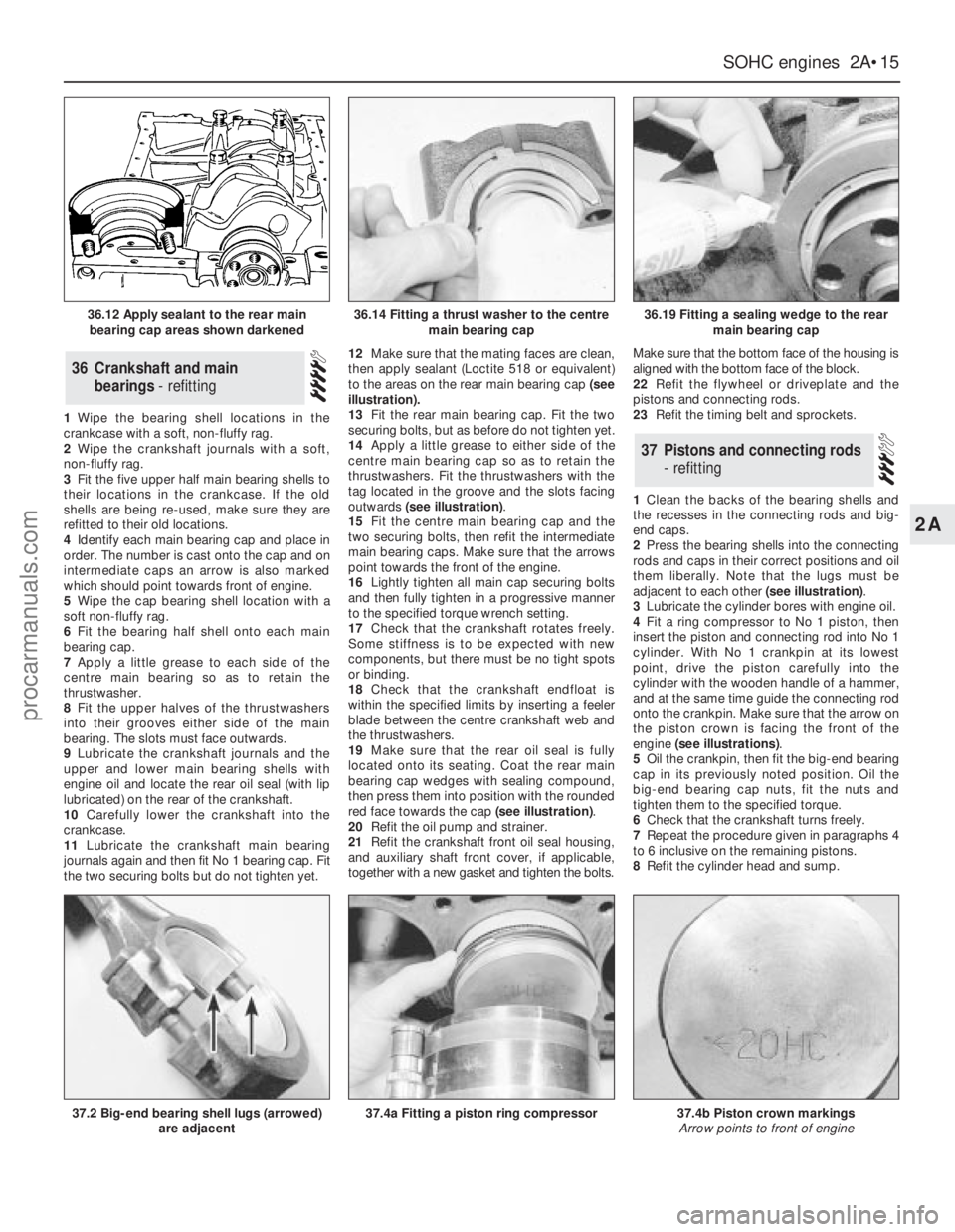

the two securing bolts but do not tighten yet.12Make sure that the mating faces are clean,

then apply sealant (Loctite 518 or equivalent)

to the areas on the rear main bearing cap (see

illustration).

13Fit the rear main bearing cap. Fit the two

securing bolts, but as before do not tighten yet.

14Apply a little grease to either side of the

centre main bearing cap so as to retain the

thrustwashers. Fit the thrustwashers with the

tag located in the groove and the slots facing

outwards (see illustration).

15Fit the centre main bearing cap and the

two securing bolts, then refit the intermediate

main bearing caps. Make sure that the arrows

point towards the front of the engine.

16Lightly tighten all main cap securing bolts

and then fully tighten in a progressive manner

to the specified torque wrench setting.

17Check that the crankshaft rotates freely.

Some stiffness is to be expected with new

components, but there must be no tight spots

or binding.

18Check that the crankshaft endfloat is

within the specified limits by inserting a feeler

blade between the centre crankshaft web and

the thrustwashers.

19Make sure that the rear oil seal is fully

located onto its seating. Coat the rear main

bearing cap wedges with sealing compound,

then press them into position with the rounded

red face towards the cap (see illustration).

20Refit the oil pump and strainer.

21Refit the crankshaft front oil seal housing,

and auxiliary shaft front cover, if applicable,

together with a new gasket and tighten the bolts.Make sure that the bottom face of the housing is

aligned with the bottom face of the block.

22Refit the flywheel or driveplate and the

pistons and connecting rods.

23Refit the timing belt and sprockets.

1Clean the backs of the bearing shells and

the recesses in the connecting rods and big-

end caps.

2Press the bearing shells into the connecting

rods and caps in their correct positions and oil

them liberally. Note that the lugs must be

adjacent to each other (see illustration).

3Lubricate the cylinder bores with engine oil.

4Fit a ring compressor to No 1 piston, then

insert the piston and connecting rod into No 1

cylinder. With No 1 crankpin at its lowest

point, drive the piston carefully into the

cylinder with the wooden handle of a hammer,

and at the same time guide the connecting rod

onto the crankpin. Make sure that the arrow on

the piston crown is facing the front of the

engine (see illustrations).

5Oil the crankpin, then fit the big-end bearing

cap in its previously noted position. Oil the

big-end bearing cap nuts, fit the nuts and

tighten them to the specified torque.

6Check that the crankshaft turns freely.

7Repeat the procedure given in paragraphs 4

to 6 inclusive on the remaining pistons.

8Refit the cylinder head and sump.

37Pistons and connecting rods

- refitting

36Crankshaft and main

bearings - refitting

SOHCengines 2A•15

2A

36.12 Apply sealant to the rear main

bearing cap areas shown darkened36.14 Fitting a thrust washer to the centre

main bearing cap36.19 Fitting a sealing wedge to the rear

main bearing cap

37.2 Big-end bearing shell lugs (arrowed)

are adjacent37.4a Fitting a piston ring compressor37.4b Piston crown markings

Arrow points to front of engine

procarmanuals.com

Page 40 of 255

1Refit the thermostat and housing.

2Refit the timing belt tensioner if it was

removed, but do not tighten the bolts yet.

3If applicable, screw the cam follower ball-

pins in their correct locations (see

illustration).

4Oil the valve stems and insert the valves in

their correct guides.

5Wrap some adhesive tape over the collet

groove of each valve, then oil the oil seals and

slide them over the valve onto the guides. Use

a suitable metal tube if necessary to press

them onto the guides. Remove the adhesive

tape.

6Working on each valve in turn, fit the valve

spring and cap, then compress the spring with

the compressor and insert the split collets.

Release the compressor and remove it. Tap

the end of the valve stem with a non-metallic

mallet to settle the collets. If tool 21-005-A is

being used, first locate the camshaft in its

bearings.

7Refit the camshaft.1Drive the new oil seal into the camshaft front

bearing location on the cylinder head using a

suitable metal tube or socket (see

illustration). Smear the lip with engine oil.

2Lubricate the bearings with hypoid

SAE 80/90 oil, then carefully insert the camshaft.

3Locate the thrust plate in the camshaft

groove, then insert and tighten the bolts.

4Using feeler blades check that the endfloat

is as given in the Specifications.

5Lubricate the ball-pins with hypoid

SAE 80/90 oil, then fit the cam followers in

their correct locations and retain with the

spring clips. It will be necessary to rotate the

camshaft during this operation.

6Fit the oil supply tube and tighten the bolts.

7Fit the camshaft sprocket backplate and

sprocket. Insert and tighten the bolt while

holding the camshaft stationary with a spanner

on the lug (see illustration).

8Refit the cylinder head.

1Adjust the valve clearances. This work is

easier to carry out on the bench rather than in

the car.

2Turn the engine so that No 1 piston is

approximately 2 cm (0.8 in) before top deadcentre. This precaution will prevent any

damage to open valves.

3Make sure that the faces of the cylinder

block and cylinder head are perfectly clean,

then locate the new gasket on the block

making sure that all the internal holes are

aligned (see illustration). Do not use jointing

compound.

4Turn the camshaft so that the TDC pointer is

aligned with the indentation on the front of the

cylinder head.

5Lower the cylinder head onto the gasket.

The help of an assistant will ensure that the

gasket is not dislodged. Alternatively, make a

couple of guide studs by sawing the heads off

two old cylinder head bolts; remove the studs

when the head is in position.

6Lightly oil the heads and threads of the new

head bolts and insert them into their holes.

7Using the Torx key, tighten the bolts

progressively to the Stage 1 specified torque

in the indicated sequence(see illustration).

8In the same sequence tighten the bolts to

the Stage 2 specified torque.

9Wait five minutes, then tighten the bolts

through the angle specified for Stage 3, still

following the same sequence. (If the engine is

on the bench, it may be preferable to leave this

final stage until after refitting the engine, when

the problem of holding it still will not arise.)

10Refit the rocker cover, using a new gasket.

Make sure that the dovetail sections of the

gasket engage correctly (see illustration).

11Fit the rocker cover bolts and reinforcing

plates. Tighten the bolts as follows, referring to

44Cylinder head - refitting

43Camshaft - refitting42Cylinder head - reassembly

SOHCengines 2A•17

2A

41.3a Driving out the auxiliary shaft cover

oil seal41.3b Fitting a new oil seal in the auxiliary

shaft cover42.3 Cam follower ball-pins and spring

clips fitted

43.1 Fitting the camshaft front bearing oil

seal43.7 Fitting the camshaft sprocket

backplate44.3 Fitting a new cylinder head gasket

A dab of grease on the collets

will keep them in position on

the valve stem

procarmanuals.com

Page 42 of 255

If the crankcase ventilation oil separator was

removed, apply a liquid locking agent to its

tube before pressing it into the cylinder block.

1Make sure that the clutch is centred.

2Apply a smear of grease or anti-seize

compound to the gearbox input shaft splines.

3With the aid of an assistant, offer the

gearbox to the engine. If the input shaft is

reluctant to enter the clutch, rock the gearbox

slightly or turn the crankshaft back and forth.

Support the gearbox until it is engaged with

the dowels on the engine - do not leave it

hanging on the input shaft.4Refit the engine-to-bellhousing bolts, the

bracing strap and the starter motor.

1Sling the engine/gearbox unit so that it

hangs at an angle of approximately 45°.

2Lower the unit into the engine bay, at the

same time moving it towards the rear of the

vehicle. Have an assistant watch as the unit is

lowered to check that no pipes, wires etc are

fouled or trapped.

3Raise the gearbox as the engine is lowered

until the unit takes up its correct position.

Secure the engine bearers to the mountings

and refit the gearbox crossmember.

4The remainder of refitting is a reversal of the

removal procedure. Refer to Section 6. Also

refer to Section 49, paragraph 9.

5Before starting the engine, refer to Section 51.

1On manual gearbox models, check that the

clutch is centred correctly. Apply a smear of

grease or anti-seize compound to the gearbox

input shaft.

2On automatic transmission models, check

that the torque converter is fully engaged with

the transmission oil pump.

3Sling the engine so that it is roughly horizontal.Lift it and position it over the engine bay.

4Lower the engine into place. Have an

assistant watch as the unit is lowered to check

that no pipes, wires etc are fouled or trapped.

5Guide the engine onto the transmission,

raising or lowering the transmission slightly if

necessary. Do not place any weight on the

transmission input shaft. With manual gearbox

models, rock the engine gently from side to

side to encourage the input shaft to enter the

clutch.

6When the engine and transmission are fully

engaged, refit the engine-to-bellhousing bolts.

Do not overlook the earth strap.

7Lower the engine so that the engine bearers

engage with the mountings. Fit the mounting

nuts and remove the lifting tackle.

8On automatic transmission models, bolt the

torque converter to the driveplate.

9The remainder of refitting is a reversal of the

removal procedure. Note the following

additional points:

a)Refill the engine with oil

b)Check the transmission oil level if

necessary

c)Adjust the tension of the accessory

drivebelts

d)Adjust the throttle cable

e)Adjust the downshift cable when

applicable

f)Refill the cooling system

10Before starting the engine, see Section 51

49Engine - refitting without

gearbox/transmission

48Engine - refitting with manual

gearbox

47Engine and gearbox -

reconnection

SOHCengines 2A•19

2A

45.16 Holding the crankshaft pulley with

two bolts and a lever while tightening the

central bolt

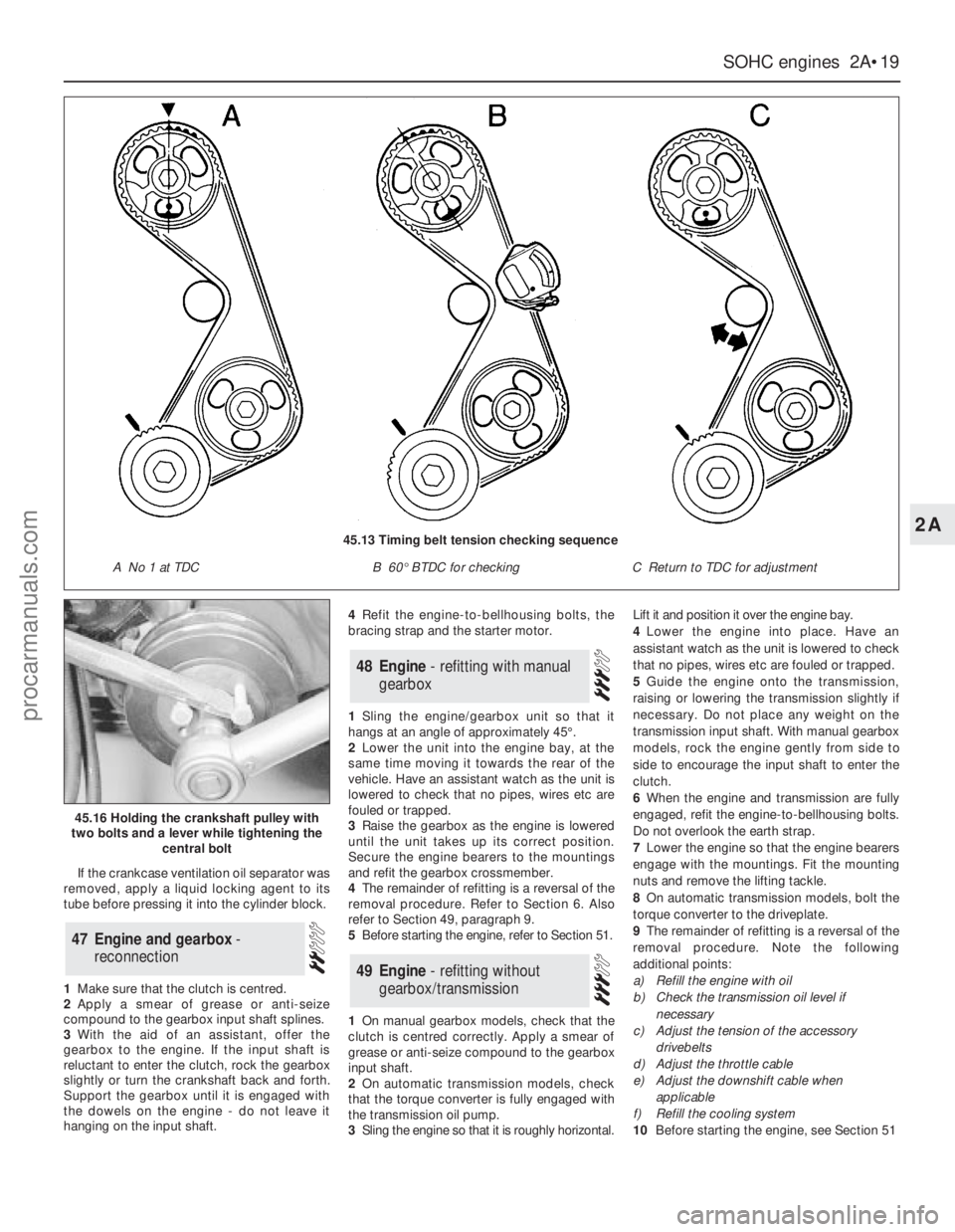

45.13 Timing belt tension checking sequence

A No 1 at TDCB 60°BTDC for checkingC Return to TDC for adjustment

procarmanuals.com

Page 43 of 255

See Chapter 1, Section 23.

1Make a final check to ensure that everything

has been reconnected to the engine and that no

rags or tools have been left in the engine bay.

2Check that oil and coolant levels are

correct.

3Start the engine. This may take a little longer

than usual as fuel is pumped up to the engine.

4Check that the oil pressure light goes out

when the engine starts.

5Run the engine at a fast tickover and check

for leaks of oil, fuel and coolant. Also check

power steering and transmission fluid cooler

unions, when applicable. Some smoke and

odd smells may be experienced as assembly

lubricant burns off the exhaust manifold and

other components.6Bring the engine to operating temperature.

Check the ignition timing then adjust the idle

speed (if applicable) and mixture.

7Stop the engine and allow it to cool, then re-

check the oil and coolant levels.

8If new bearings, pistons etc have been

fitted, the engine should be run in at reduced

speeds and loads for the first 500 miles (800

km) or so. It is beneficial to change the engine

oil and filter after this mileage.

1When engine performance is down, or if

misfiring occurs which cannot be attributed to

the ignition or fuel system, a compression test

can provide diagnostic clues. If the test is

performed regularly it can give warning of

trouble before any other symptoms become

apparent.

2The engine must be at operating

temperature, the battery must be fully charged

and the spark plugs must be removed. The

services of an assistant will also be required.

3Disable the ignition system by dismantlingthe coil LT feed. Fit the compression tester to

No 1 spark plug hole. (The type of tester which

screws into the spark plug hole is to be

preferred.)

4Have the assistant hold the throttle wide

open and crank the engine on the starter.

Record the highest reading obtained on the

compression tester.

5Repeat the test on the remaining cylinders,

recording the pressure developed in each.

6Desired pressures are given in the

Specifications. If the pressure in any cylinder

is low, introduce a teaspoonful of clean engine

oil into the spark plug hole and repeat the test.

7If the addition of oil temporarily improves

the compression pressure, this indicates that

bore or piston wear was responsible for the

pressure loss. No improvement suggests that

leaking or burnt valves, or a blown head

gasket, may be to blame.

8A low reading from two adjacent cylinders is

almost certainly due to the head gasket

between them having blown.

9On completion of the test, refit the spark

plugs and reconnect the coil LT feed.

52Compression test -

description and interpretation

51Initial start-up after overhaul

or major repair

50Valve clearances - checking

and adjustment

2A•20SOHCengines

procarmanuals.com

Page 49 of 255

Note: Refer to Part A, Section 4 of this Chapter

and to the warning that appears at the start of

Section 5 before proceeding. A hoist and lifting

tackle will be required for this operation.

1Proceed as described in paragraphs 1 to 21

of Section 5.

2Unscrew the securing bolt, and disconnect

the earth lead from the rear left-hand side of

the cylinder head.

3Unscrew the nuts securing the engine

mountings to the engine mounting brackets.

4Jack up the vehicle and support it securely

on axle stands (see “Jacking”). Ensure that

there is enough working room beneath the

vehicle.

5To improve access, disconnect the exhaust

downpipe from the manifold and remove the

exhaust system.

6Drain the engine oil into a suitable container.

7On models fitted with a catalytic converter,

release the securing clips and withdraw the

exhaust heat shield from under the vehicle for

access to the propeller shaft.

8Remove the propeller shaft.

9Where applicable, bend back the locktabs,

then unscrew the two bolts in each case

securing the two anti-roll bar mounting clamps

to the vehicle underbody. Lower the anti-roll

bar as far as possible.

10Proceed as described in paragraphs 30

and 31 of Section 5.

11Support the gearbox with a trolley jack,

using a block of wood between the jack and

the gearbox to spread the load.

12Unscrew the four nuts securing the

gearbox crossmember to the vehicle

underbody. Unscrew the central bolt securing

the crossmember to the gearbox, and remove

the crossmember. Note the position of the

earth strap, where applicable. Recover the

mounting cup, and the exhaust mounting

bracket and heat shield (as applicable).

13Lower the gearbox slightly on the jack,

then remove the circlip, and disconnect the

speedometer drive cable from the gearbox.

14Disconnect the wiring from the reversing

lamp switch, and on models with fuel-injection,

disconnect the wiring from the vehicle speed

sensor mounted in the side of the gearbox.

15Slacken and remove the two bolts and

washers (one either side) securing the gear

linkage support bracket to the gearbox.

16Using a pin punch, drive out the roll pin

securing the gearchange rod to the gear linkage.

17Attach a hoist to the engine lifting brackets

located at the front and rear of the cylinder head,

and slowly take the weight of the engine. Arrange

the lifting tackle so that the engine/gearbox

assembly will assume a steep angle of

approximately 40°to 45°as it is being removed.

18To improve clearance in the engine

compartment when lifting the engine, unboltthe engine mounting brackets from the

cylinder block, and remove them.

19Ensure that the steering wheel is positioned

in the straight-ahead position then, using a dab

of paint or a marker pen, make alignment marks

between the intermediate shaft lower clamp

and steering gear pinion. Slacken and remove

the lower clamp bolt then disconnect the

intermediate shaft from the steering gear.

20Detach the brake lines from the front

suspension crossmember.

21Support the crossmember with a jack (do not

remove the jack from under the gearbox), then

loosen the bolts securing the crossmember to the

underbody. Remove the crossmember securing

bolts, and carefully lower the crossmember to

allow sufficient room for the engine sump to clear

the steering rack and crossmember as the

engine/gearbox assembly is removed.

22Make a final check to ensure that all

relevant wires, pipes and hoses have been

disconnected to facilitate removal of the

engine/gearbox assembly.

23Raise the engine/gearbox, at the same

time lowering the trolley jack which is

supporting the gearbox.

24Place a suitable rod across the vehicle

underbody to support the gear linkage support

bracket whilst the gearbox is removed.

25Tilt the engine/gearbox assembly using

the hoist and the trolley jack, until the

assembly can be lifted from the vehicle. Take

care not to damage surrounding components.

26If the vehicle is to be moved, with the

engine/gearbox assembly removed, temporarily

refit the suspension crossmember and the anti-

roll bar to the underbody, and reconnect the

steering column to the intermediate shaft.

27To separate the engine from the gearbox,

proceed as follows.

28Remove the starter motor.

29Support the engine and gearbox

horizontally on blocks of wood.

30Unscrew the engine-to-gearbox bolts,

noting the locations of the bolts, and the

positions of the earth strap and any wiring clips

attached to the bolts. Recover any shims fitted

between the sump and the gearbox when

removing the lower engine-to-gearbox bolts.

31Unscrew the bolt from the engine adapter

plate.

32Pull the engine and gearbox apart, taking

care not to strain the gearbox input shaft. It

may be necessary to rock the units slightly to

separate them.

Note: Refer to Part A, Section 4 of this

Chapter and to the warning that appears at the

start of Section 5 before proceeding. A

suitable hoist and lifting tackle will be required

for this operation. Any suspected faults in the

automatic transmission should be referred to a

Ford dealer or automatic transmissionspecialist before removal of unit, as the

specialist fault diagnosis equipment is

designed to operate with the transmission in

the vehicle.

1Proceed as described in paragraphs 1 to 21

of Section 5.

2Unscrew the securing bolt, and disconnect

the earth lead from the rear left-hand side of

the cylinder head.

3Unscrew the nuts securing the engine

mountings to the engine mounting brackets.

4Jack up the vehicle and support it securely

on axle stands (see “Jacking”). Ensure that

there is enough working room beneath the

vehicle.

5To improve access, disconnect the exhaust

downpipe from the manifold and remove the

exhaust system .

6Drain the engine oil into a suitable container.

7On models fitted with a catalytic converter,

release the securing clips and withdraw the

exhaust heat shield from under the vehicle for

access to the propeller shaft.

8Remove the propeller shaft.

9Where applicable, bend back the locktabs,

then unscrew the two bolts in each case

securing the two anti-roll bar mounting clamps

to the vehicle underbody. Lower the anti-roll

bar as far as possible.

10Support the transmission with a trolley

jack, using a block of wood between the jack

and the transmission to spread the load.

11Unscrew the four bolts securing the

transmission crossmember to the vehicle

underbody. Unscrew the central bolt securing

the crossmember to the transmission, and

remove the crossmember. Note the position of

the earth strap, where applicable. Recover the

mounting cup, and the exhaust mounting

bracket and heat shield (as applicable).

12Lower the transmission slightly on the jack.

13Unscrew the unions and disconnect the

fluid cooler pipes from the transmission. Plug

the open ends of the pipes and the

transmission to prevent dirt ingress and fluid

leakage. Where applicable, detach the fluid

cooler pipe bracket from the engine mounting

bracket, and move it to one side.

14Remove the two clips securing the

selector rod, and detach the selector rod from

the manual selector lever, and the selector

lever on the transmission.

15Disconnect the wiring from the starter

inhibitor switch, downshift solenoid, lock-up

clutch, reversing lamp switch, and where

applicable, the 3rd/4th gearchange solenoid.

16Remove the securing screw, and

disconnect the speedometer cable (where

fitted) from the transmission extension

housing. Plug the opening in the transmission

to prevent dirt ingress.

17Proceed as described in paragraphs 17 to 26

of Section 7, substituting transmission for

gearbox and ignoring paragraph 24.

18To separate the engine from the

transmission, proceed as follows.

19Remove the starter motor.

20Support the engine and transmission

horizontally on blocks of wood.

8Engine/automatic

transmission assembly -

removal and separation

7Engine/manual gearbox

assembly - removal and

separation

2B•6DOHCengine

procarmanuals.com

Page 50 of 255

21Working through the starter motor

aperture, unscrew the four torque converter-

to-driveplate nuts. It will be necessary to turn

the crankshaft using a spanner on the

crankshaft pulley bolt in order to gain access

to each nut in turn through the aperture.

22Where applicable, remove the bolt

securing the transmission fluid dipstick tube to

the left-hand side of the cylinder block.

23Unscrew the engine-to-transmission bolts,

noting the locations of the bolts, and the

positions of the earth strap and any wiring

clips attached to the bolts. Recover any shims

fitted between the sump and the transmission

when removing the lower engine-to-

transmission bolts.

24Unscrew the bolt from the engine adapter

plate and, where applicable, pull the blanking

plug from the adapter plate.

25Pull the engine and the transmission apart,

ensuring that the torque converter is held firmly

in place in the transmission housing, otherwise

it could fall out resulting in fluid spillage and

possible damage. It may be necessary to rock

the units slightly to separate them.

1Reverse the procedure described in

paragraphs 1 to 40 ofSection 5, noting the

following points.

2Before attempting to refit the engine, check

that the clutch friction disc is centralised.

3Check that the clutch release arm and

bearing are correctly fitted, and lightly grease

the input shaft splines.

4Check that the engine adapter plate is

correctly positioned on the locating dowels. If

necessary, a cable-tie can be used to

temporarily secure the adapter plate in

position on the cylinder block using one of the

engine-to-gearbox bolt holes.

5If shims were fitted between the sump and

the gearbox, refit them in their original

locations when mating the engine to the

gearbox. If the engine has been overhauled,

where applicable fit the relevant shims as

calculated during engine reassembly .

6Reconnect the clutch cable to the release arm,

ensuring that it is routed as noted during removal.

7Ensure that the roadwheels and the steering

wheel are in the straight-ahead position then

align the marks made on removal and reconnect

the intermediate shaft to the steering gearing.

Tighten the clamp bolt to the specified torque.

8Refit the exhaust downpipe.

9Fill the engine with the correct grade and

quantity of oil.

10Check the throttle cable adjustment. Where

necessary, also adjust the speed control cable

in the same way so that there is only a small

amount of slack present in the cable.

11Reconnect the coolant hoses to the water

pump housing.

12Fill the cooling system .

13Tighten all fixings to the specified torque,

where applicable.1Reverse the procedure described in Section 6,

noting the following points.

2Check that the engine adapter plate is

correctly positioned on the locating dowels. If

necessary, a cable-tie can be used to

temporarily secure the adapter plate in

position on the cylinder block using one of the

engine-to-transmission bolt holes.

3As the torque converter is only loosely

engaged in the transmission, care must be taken

to prevent the torque converter from falling out

forwards. When the torque converter hub is fully

engaged with the fluid pump drivegear in the

transmission, distance A (see illustration 2.20 in

Chapter 7B)must be as specified. Incorrect

installation of the torque converter will result in

damageto the transmission.

4If shims were fitted between the sump and

the transmission, refit them in their original

locations when mating the engine to the

transmission. If the engine has been

overhauled, where applicable fit the relevant

shims as calculated during engine reassembly.

5As the engine is installed, guide the torque

converter studs through the holes in the

driveplate. When the engine is positioned flush

with the engine adapter plate and the

transmission housing, check that the torque

converter is free to move axially a small

amount before refitting and tightening the

engine-to-transmission bolts.

6Do not tighten the torque converter-to-

driveplate nuts until the lower engine-to-

transmission bolts have been fitted and

tightened.

7Ensure that the roadwheels and the steering

wheel are in the straight-ahead position then

align the marks made on removal and

reconnect the intermediate shaft to the

steering gearing. Tighten the clamp bolt to the

specified torque.

8Refit the exhaust downpipe.

9Fill the engine with the correct grade and

quantity of oil.

10Check the throttle cable adjustment. Where

necessary, also adjust the speed control cable

in the same way so that there is only a small

amount of slack present in the cable.

11Reconnect the coolant hoses to the water

pump housing.

12Fill the cooling system.

13Tighten all fixings to the specified torque,

where applicable.

1Reverse the procedure described in Section 7,

noting the following points.

2Before attempting to reconnect the engine

to the gearbox, check that the clutch friction

disc is centralised.

3Check that the clutch release arm andbearing are correctly fitted, and lightly grease

the input shaft splines.

4Check that the engine adapter plate is

correctly positioned on the locating dowels. If

necessary, a cable-tie can be used to

temporarily secure the adapter plate in

position on the cylinder block using one of the

engine-to-gearbox bolt holes.

5If shims were fitted between the sump and

the gearbox, refit them in their original

locations when mating the engine to the

gearbox. If the engine has been overhauled,

where applicable fit the relevant shims as

calculated during engine reassembly.

6Ensure that the roadwheels and the steering

wheel are in the straight-ahead position then

align the marks made on removal and

reconnect the intermediate shaft to the

steering gearing. Tighten the clamp bolt to the

specified torque.

7Reconnect the clutch cable to the release

arm, ensuring that it is routed as noted during

removal.

8Refit the propeller shaft.

9Refit the exhaust system.

10Fill the engine with the correct grade and

quantity of oil.

11Check the throttle cable adjustment. Where

necessary, also adjust the speed control cable

in the same way so that there is only a small

amount of slack present in the cable.

12Reconnect the coolant hoses to the water

pump housing.

13Fill the cooling system.

14Check and if necessary top-up the

gearbox oil level.

15Tighten all fixings to the specified torque,

where applicable.

1Reverse the procedure described in Section 8,

noting the following points.

2Check that the engine adapter plate is

correctly positioned on the locating dowels. If

necessary, a cable-tie can be used to

temporarily secure the adapter plate in

position on the cylinder block using one of the

engine-to-transmission bolt holes.

3As the torque converter is only loosely

engaged in the transmission, care must be taken

to prevent the torque converter from falling out

forwards. When the torque converter hub is fully

engaged with the fluid pump drivegear in the

transmission, distance A (see illustration 2.20 in

Chapter 7B)must be as specified. Incorrect

installation of the torque converter will result in

damage to the transmission.

4If shims were fitted between the sump and

the transmission, refit them in their original

locations when mating the engine to the

transmission. If the engine has been

overhauled, where applicable fit the relevant

shims as calculated during engine reassembly.

5As the engine and transmission are mated

12Engine/automatic

transmission assembly -

reconnection and refitting

11Engine/manual gearbox

assembly - reconnection and

refitting

10Engine - refitting (automatic

transmission in vehicle)

9Engine - refitting (manual

gearbox in vehicle)

DOHCengine 2B•7

2B

procarmanuals.com

Page 57 of 255

camshaft sprocket, aligning the marks made

previously on the chain and the sprocket.

40Fit the sprocket to the inlet camshaft, with

the camshaft in the TDC position (ie with the

inlet camshaft sprocket timing mark in line

with the top edge of the cylinder head,

pointing to the inlet side of the engine see

paragraph 4). Again, turn the camshaft if

necessary to enable the sprocket to be fitted.

41With the sprocket fitted, fit the distributor

rotor shaft to the end of the camshaft, and

tighten the securing bolt finger-tight. Note that

it is acceptable for the timing chain to sag

slightly between the two pulleys.

42Fit a new upper timing chain guide to the

plate at the front of the cylinder head.

43Turn the crankshaft clockwise until the

inlet camshaft begins to turn.

44If the chain tensioner plunger piston

protrudes from the cylinder, unlatch the piston by

pressing the chain tensioner arm down by hand.

45If the plunger piston is below the top

surface of the cylinder, a tool must be

fabricated to unlatch the piston (see

illustration). It is suggested that 2.5 mm

diameter welding rod is used to manufacture

the tool. Use the tool to release the piston as

follows.

46Carefully lift the chain tensioner arm with a

screwdriver, and insert the tool between the

tensioner arm and the piston. Remove the

screwdriver, and release the piston by

pressing the tensioner arm down by hand.

Carefully withdraw the tool once the piston

has been released.

47Tighten the camshaft sprocket securing

bolts to the specified torque, holding the

sprockets stationary as during removal.

48Turn the crankshaft clockwise through two

complete revolutions, and check that the

timing marks on the camshaft sprockets are

still aligned with the top face of the cylinder

head as described in paragraph 4.

49Turn the crankshaft clockwise through

another complete revolution, and check that

the timing marks on the camshaft sprockets

are facing each other, directly in line with the

top face of the cylinder head.

50If the timing marks do not align as

described, the timing chain has been

incorrectly fitted (probably one chain link awayfrom the correct position on one of the

camshaft sprockets), and the chain should be

removed from the sprockets and fitted in the

correct position.

51Inspect the oil seal in the upper timing

chain cover. If the oil seal is in good condition,

the cover can be refitted as follows, but if the

seal is damaged, or has been leaking, a new

seal should be fitted to the cover. If necessary,

carefully prise the old oil seal from the cover

using a screwdriver, and drive in the new seal

using a suitable metal tube. Make sure that the

seal lip faces into the engine. Take care not to

damage the timing chain cover.

52Fit the upper timing chain cover using a

new rubber gasket. Great care must be taken

to avoid damage to the oil seal when passing

the seal over the end of the inlet camshaft.

Careful manipulation will be required (possibly

using a thin feeler blade) to avoid damage to

the oil seal sealing lip. Note that the oil seal

should be fitted dry.

53Refit the timing chain cover securing bolts

and studs in their original locations and tighten

them to the specified torque (see illustration).

54Remove the reinforcing sleeves from the

camshaft cover, and renew the rubber sealing

rings. Note that the four short reinforcing

sleeves fit at the front of the cover (see

illustration).

55Refit the camshaft cover using a new

gasket, and tighten the securing bolts and

studs to the specified torque.

Note: A valve spring compressor will be

required during this procedure. New valve

stem oil seals should be used on reassembly.

Dismantle the cylinder head as described in

paragraphs 2 to 4, Section 12, PartA of this

Chapterand reassemble the head as

described in paragraphs 4 to 6, Section 42,

Part A of this Chapter, noting the following

points:

a)Ignore the references to the special tool.

b)Double valve springs are used on all the

valves (see illustration).

c)Refer to the following Section if the

cylinder head is to be inspected and

renovated.Refer to Part A, Section 34 of this Chapter,

noting the following points.

a)Valve and valve seat cutting and

regrinding can be carried out using

conventional tools.

b)The cylinder head cannot be resurfaced,

and if the surface distortion exceeds the

specified limits, the cylinder head must be

renewed.

Note: Once the timing chain has been

removed from the camshaft sprockets, do not

turn the crankshaft until the timing chain has

been correctly refitted - this is to prevent

contact between the valves and pistons. A

new timing chain tensioner plunger assembly,

a new upper timing chain cover gasket, and a

new camshaft cover and reinforcing sleeve

sealing rings must be used on refitting.

1If the engine is in the vehicle, carry out the

following operations.

a)Disconnect the battery negative lead.

b)On carburettor models, remove the air

cleaner.

c)On fuel-injection models, remove the air

inlet hose, plenum chamber, and air

cleaner lid as an assembly.

21Camshafts and cam followers

- removal, inspection and

refitting

20Cylinder head - inspection and

renovation

19Cylinder head - dismantling

and reassembly

2B•14DOHCengine

18.45 Fabricated tool used to unlatch

tensioner plunger piston

19.1 Withdrawing the double valve springs

from the cylinder head

18.53 Upper timing chain cover securing

stud locations (arrowed)18.54 Fitting a camshaft cover reinforcing

sleeve and sealing ring

procarmanuals.com

Page 61 of 255

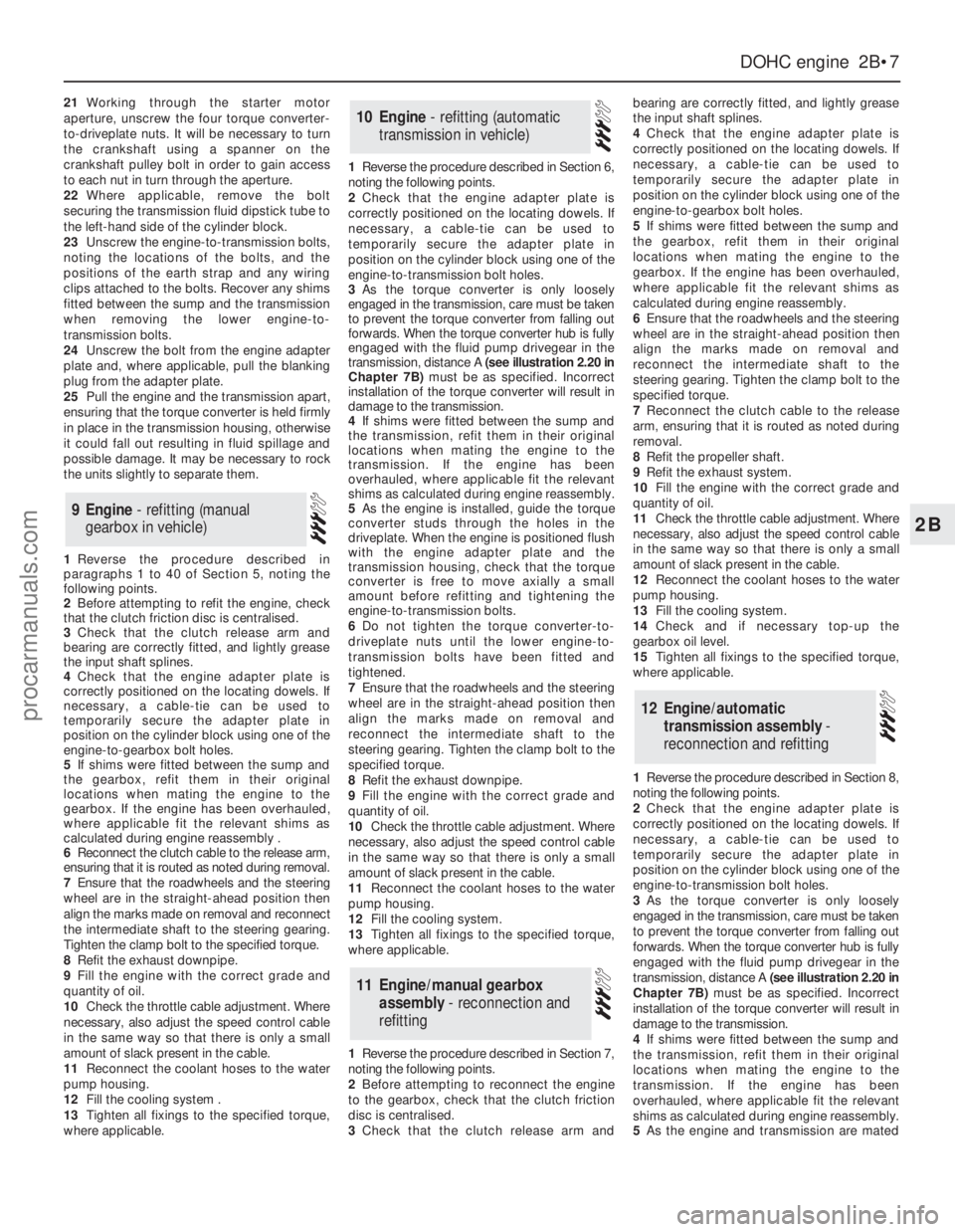

9Extract the bearing shells, and recover the

thrustwashers, keeping them identified for

location.

10The crankshaft and bearings can be

examined and if necessary renovated.

11Commence refitting as follows(see

illustration).

12Wipe the bearing shell locations in the

crankcase, and the crankshaft journals with a

soft non-fluffy rag.

13If the old main bearing shells are to be

renewed (not to do so is a false economy,

unless they are virtually new) fit the five upper

halves of the main bearing shells to their

locations in the crankcase.

14Fit the thrustwashers to the centre main

bearing location, using a little grease to retain

them if necessary. The oil grooves in the

thrustwashers must face outwards (ie facing

the crankshaft webs). Note that where

standard thrustwashers have been fitted in

production, the centre main bearing is

unmarked, but if oversize (0.38 mm)

thrustwashers have been fitted, the centre

main bearing will carry a yellow paint mark.

15Lubricate the crankshaft journals and the

upper and lower main bearing shells with

clean engine oil, then carefully lower the

crankshaft into the crankcase.

16Lubricate the crankshaft main bearing

journals again, and then fit the main bearing caps

in their correct locations, with the arrows on the

caps pointing towards the front of the engine.

17Fit the main bearing cap bolts, noting that

the studded bolts secure bearing caps Nos 3

and 5.

18Lightly tighten all the securing bolts, then

progressively tighten all bolts to the specified

torque.

19Check that the crankshaft rotates freely.

Some stiffness is to be expected with newcomponents, but there must be no tight spots

or binding.

20Check that the crankshaft endfloat is

within the specified limits by inserting a feeler

blade between the centre crankshaft web and

the thrustwashers.

21Refit the sump mounting plate to the front

of the cylinder block, and tighten the securing

bolts to the specified torque.

22Carefully wind a thin layer of tape around

the rear edge of the crankshaft to protect the

oil seal lips as the rear oil seal is installed.

23Refit the crankshaft rear oil seal housing,

using a new gasket, and tighten the securing

bolts to the specified torque.

24Install the new oil seal with reference to

Section 24.

25With the oil seal installed, carefully pull the

tape from the edge of the crankshaft.

26Refit the pistons and connecting rods as

described previously in this Chapter.

27Refit the flywheel/driveplate, and the

timing chain and crankshaft sprocket.

Proceed as described in Part A, Section 27

of this Chapter, noting that the production

bearing undersizes are indicated as follows.

Yellow or red paint marks on crankshaft —

standard diameter main bearing journals.

Green line on crankshaft front counterweight

— main bearing journals 0.25 mm

undersize.

Green spot on counterweight — big-end

bearing journals 0.25 mm undersize.

Refer to Part A, Section 25 of this Chapter,

but note that the connecting rod bolts should

be renewed on reassembly, and when

renewing the cylinder head bolts, the latest

type bolts with hexagonal heads should

always be used.

Proceed as described in Part A, Section 35

of this Chapter, noting the following points.

a)If the cylinder head has been removed,

pay particular attention to the note at the

beginning of Section 18.

b)If removed during any dismantling

operations, new flywheel driveplate bolts

and connecting rod bolts must be used.

c)After reassembling the main engine

components, refer to paragraph 3 of

Section 14 and refit the ancillary

components listed.Refer to Part A, Section 51 of this Chapter,

but note that when the engine is first started, a

metallic tapping noise may be heard. This is

due to the timing chain tensioner plunger

assembly taking time to pressurize with oil,

resulting in a temporarily slack chain. The

noise should stop after a short time, once oil

pressure has built up.

1When engine performance is down, or if

misfiring occurs which cannot be attributed to

the ignition or fuel system, a compression test

can provide diagnostic clues. If the test is

performed regularly it can give warning of

trouble before any other symptoms become

apparent.

2The engine must be at operating

temperature, the battery must be fully charged

and the spark plugs must be removed. The

services of an assistant will also be required.

3Disable the ignition system by dismantling

the coil LT feed. Fit the compression tester to

No 1 spark plug hole. (The type of tester which

screws into the spark plug hole is to be

preferred.)

4Have the assistant hold the throttle wide

open and crank the engine on the starter.

Record the highest reading obtained on the

compression tester.

5Repeat the test on the remaining cylinders,

recording the pressure developed in each.

6Desired pressures are given in the

Specifications. If the pressure in any cylinder

is low, introduce a teaspoonful of clean engine

oil into the spark plug hole and repeat the test.

7If the addition of oil temporarily improves

the compression pressure, this indicates that

bore or piston wear was responsible for the

pressure loss. No improvement suggests that

leaking or burnt valves, or a blown head

gasket, may be to blame.

8A low reading from two adjacent cylinders is

almost certainly due to the head gasket

between them having blown.

9On completion of the test, refit the spark

plugs and reconnect the coil LT feed.

35Compression test -

description and interpretation

34Initial start-up after overhaul

or major repair

33Engine reassembly - general

information

32Examination and renovation -

general information

31Crankshaft and bearings -

examination and renovation

2B•18DOHCengine

30.11 Crankshaft main bearings and

associated components

1 Bearing cap

2 Thrustwasher

3 Stud for oil baffle

4 Identification markings

5 Bearing shell without oil groove

6 Bearing shell with oil groove

7 Bearing seat in cylinder block

procarmanuals.com

Page 62 of 255

Chapter 2 Part C:

2.4, 2.8 and 2.9 litre V6 engines

Ancillary components - refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Ancillary components - removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Camshaft and bearings - examination and renovation . . . . . . . . . .22

Camshaft and intermediate plate - refitting . . . . . . . . . . . . . . . . . . .32

Camshaft and intermediate plate - removal . . . . . . . . . . . . . . . . . . .14

Compression test - description and interpretation . . . . . . . . . . . . .43

Crankcase ventilation system - general information . . . . . . . . . . . .29

Crankshaft and bearings - examination . . . . . . . . . . . . . . . . . . . . . .26

Crankshaft and main bearings - refitting . . . . . . . . . . . . . . . . . . . . .31

Crankshaft and main bearings - removal . . . . . . . . . . . . . . . . . . . . .15

Crankshaft front oil seal - renewal . . . . . . . . . . . . . . . . . . . . . . . . . .17

Crankshaft rear oil seal - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Cylinder bores - examination and renovation . . . . . . . . . . . . . . . . .24

Cylinder heads - overhaul . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Cylinder heads - refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Cylinder heads - removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Engine - refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Engine - removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Engine dismantling - general . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Engine mountings - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Engine reassembly - general information . . . . . . . . . . . . . . . . . . . . .30

Examination and renovation - general infomation . . . . . . . . . . . . . .19Flywheel/driveplate and adapter plate - refitting . . . . . . . . . . . . . . .35

Flywheel/driveplate and adapter plate - removal . . . . . . . . . . . . . . .11

Flywheel ring gear - examination and renovation . . . . . . . . . . . . . . 28

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Initial start-up after overhaul or major repair . . . . . . . . . . . . . . . . . .42

Major operations possible with the engine in the vehicle . . . . . . . . .2

Major operations requiring engine removal . . . . . . . . . . . . . . . . . . . .3

Methods of engine removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Oil pump - dismantling, examination and reassembly . . . . . . . . . . .27

Oil pump - refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Oil pump - removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Pistons and connecting rods - examination and renovation . . . . . .25

Pistons and connecting rods - refitting . . . . . . . . . . . . . . . . . . . . . .33

Pistons and connecting rods - removal . . . . . . . . . . . . . . . . . . . . . .13

Rocker shaft - dismantling, examination and reassembly . . . . . . . .20

Sump - refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Sump - removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Tappets and pushrods - examination . . . . . . . . . . . . . . . . . . . . . . .21

Timing cover and drive - refitting . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Timing cover and drive - removal . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Valve clearances - checking and adjustment . . . . . . . . . . . . . . . . . .39

2.8 litre engine

General

Manufacturer’s code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . PRE

Bore - mm (in) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93.0 (3.66)

Stroke - mm (in) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68.5 (2.70)

Cubic capacity - cc (cu in) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2792 (170)

Compression ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.2:1

Compression pressure at cranking speed . . . . . . . . . . . . . . . . . . . . . . . 11.5 to 12.5 bar (167 to 181 lbf/in

2)

Maximum power (DIN, kW @ rpm) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110 @ 5800

Maximum torque (DIN, Nm @ rpm) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 216 @ 3000

Lubrication system

Oil type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . See “Lubricants and fluids”

Oil capacity (drain and refill, including filter) . . . . . . . . . . . . . . . . . . . . . . 4.25 litres (7.5 pints) approx

Oil pressure (SAE 10W/30 oil at 80°C/176°F):

At 750 rpm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.0 bar

At 2000 rpm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.5 bar

Oil pressure relief valve opening pressure . . . . . . . . . . . . . . . . . . . . . . . 4.0 to 4.7 bar

Oil pressure warning light switch setting . . . . . . . . . . . . . . . . . . . . . . . . 0.3 to 0.5 bar

2C•1

Easy,suitable for

novice with little

experienceFairly easy,suitable

for beginner with

some experienceFairly difficult,

suitable for competent

DIY mechanicDifficult,suitable for

experienced DIY

mechanicVery difficult,

suitable for expert

DIY or professional

Degrees of difficulty

Specifications Contents

2C

procarmanuals.com