stop start FORD GRANADA 1985 Service Owner's Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1985, Model line: GRANADA, Model: FORD GRANADA 1985Pages: 255, PDF Size: 14.98 MB

Page 178 of 255

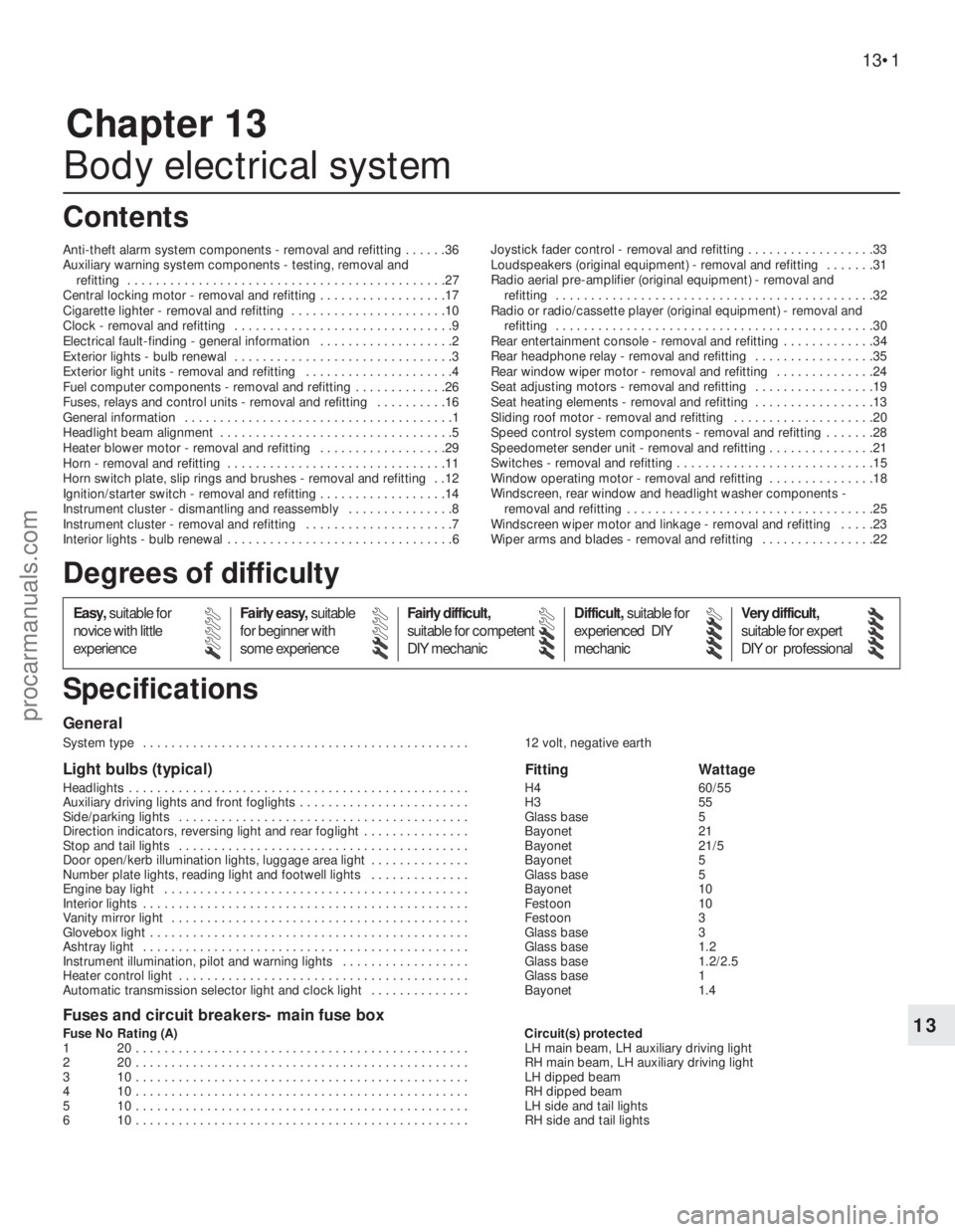

Chapter 13

Body electrical system

Anti-theft alarm system components - removal and refitting . . . . . .36

Auxiliary warning system components - testing, removal and

refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Central locking motor - removal and refitting . . . . . . . . . . . . . . . . . .17

Cigarette lighter - removal and refitting . . . . . . . . . . . . . . . . . . . . . .10

Clock - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Electrical fault-finding - general information . . . . . . . . . . . . . . . . . . .2

Exterior lights - bulb renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Exterior light units - removal and refitting . . . . . . . . . . . . . . . . . . . . .4

Fuel computer components - removal and refitting . . . . . . . . . . . . .26

Fuses, relays and control units - removal and refitting . . . . . . . . . .16

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Headlight beam alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Heater blower motor - removal and refitting . . . . . . . . . . . . . . . . . .29

Horn - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Horn switch plate, slip rings and brushes - removal and refitting . .12

Ignition/starter switch - removal and refitting . . . . . . . . . . . . . . . . . .14

Instrument cluster - dismantling and reassembly . . . . . . . . . . . . . . .8

Instrument cluster - removal and refitting . . . . . . . . . . . . . . . . . . . . .7

Interior lights - bulb renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6Joystick fader control - removal and refitting . . . . . . . . . . . . . . . . . .33

Loudspeakers (original equipment) - removal and refitting . . . . . . .31

Radio aerial pre-amplifier (original equipment) - removal and

refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Radio or radio/cassette player (original equipment) - removal and

refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Rear entertainment console - removal and refitting . . . . . . . . . . . . .34

Rear headphone relay - removal and refitting . . . . . . . . . . . . . . . . .35

Rear window wiper motor - removal and refitting . . . . . . . . . . . . . .24

Seat adjusting motors - removal and refitting . . . . . . . . . . . . . . . . .19

Seat heating elements - removal and refitting . . . . . . . . . . . . . . . . .13

Sliding roof motor - removal and refitting . . . . . . . . . . . . . . . . . . . .20

Speed control system components - removal and refitting . . . . . . .28

Speedometer sender unit - removal and refitting . . . . . . . . . . . . . . .21

Switches - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Window operating motor - removal and refitting . . . . . . . . . . . . . . .18

Windscreen, rear window and headlight washer components -

removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Windscreen wiper motor and linkage - removal and refitting . . . . .23

Wiper arms and blades - removal and refitting . . . . . . . . . . . . . . . .22

General

System type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 volt, negative earth

Light bulbs (typical)Fitting Wattage

Headlights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . H4 60/55

Auxiliary driving lights and front foglights . . . . . . . . . . . . . . . . . . . . . . . . H3 55

Side/parking lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Glass base 5

Direction indicators, reversing light and rear foglight . . . . . . . . . . . . . . . Bayonet 21

Stop and tail lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Bayonet 21/5

Door open/kerb illumination lights, luggage area light . . . . . . . . . . . . . . Bayonet 5

Number plate lights, reading light and footwell lights . . . . . . . . . . . . . . Glass base 5

Engine bay light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Bayonet 10

Interior lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Festoon 10

Vanity mirror light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Festoon 3

Glovebox light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Glass base 3

Ashtray light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Glass base 1.2

Instrument illumination, pilot and warning lights . . . . . . . . . . . . . . . . . . Glass base 1.2/2.5

Heater control light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Glass base 1

Automatic transmission selector light and clock light . . . . . . . . . . . . . . Bayonet 1.4

Fuses and circuit breakers- main fuse box

Fuse No Rating (A) Circuit(s) protected

1 20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . LH main beam, LH auxiliary driving light

2 20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . RH main beam, LH auxiliary driving light

3 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . LH dipped beam

4 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . RH dipped beam

5 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . LH side and tail lights

6 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . RH side and tail lights

13•1

Easy,suitable for

novice with little

experienceFairly easy,suitable

for beginner with

some experienceFairly difficult,

suitable for competent

DIY mechanicDifficult,suitable for

experienced DIY

mechanicVery difficult,

suitable for expert

DIY or professional

Degrees of difficulty

Specifications Contents

13

procarmanuals.com

Page 240 of 255

The vehicle owner who does his or her own maintenance according

to the recommended service schedules should not have to use this

section of the manual very often. Modern component reliability is such

that, provided those items subject to wear or deterioration are

inspected or renewed at the specified intervals, sudden failure is

comparatively rare. Faults do not usually just happen as a result of

sudden failure, but develop over a period of time. Major mechanical

failures in particular are usually preceded by characteristic symptoms

over hundreds or even thousands of miles. Those components which

do occasionally fail without warning are often small and easily carried

in the vehicle.With any fault-finding, the first step is to decide where to begin

investigations. Sometimes this is obvious, but on other occasions, a

little detective work will be necessary. The owner who makes half a

dozen haphazard adjustments or replacements may be successful in

curing a fault (or its symptoms), but will be none the wiser if the fault

recurs, and ultimately may have spent more time and money than was

necessary. A calm and logical approach will be found to be more

satisfactory in the long run. Always take into account any warning

signs or abnormalities that may have been noticed in the period

preceding the fault - power loss, high or low gauge readings, unusual

smells, etc - and remember that failure of components such as fuses or

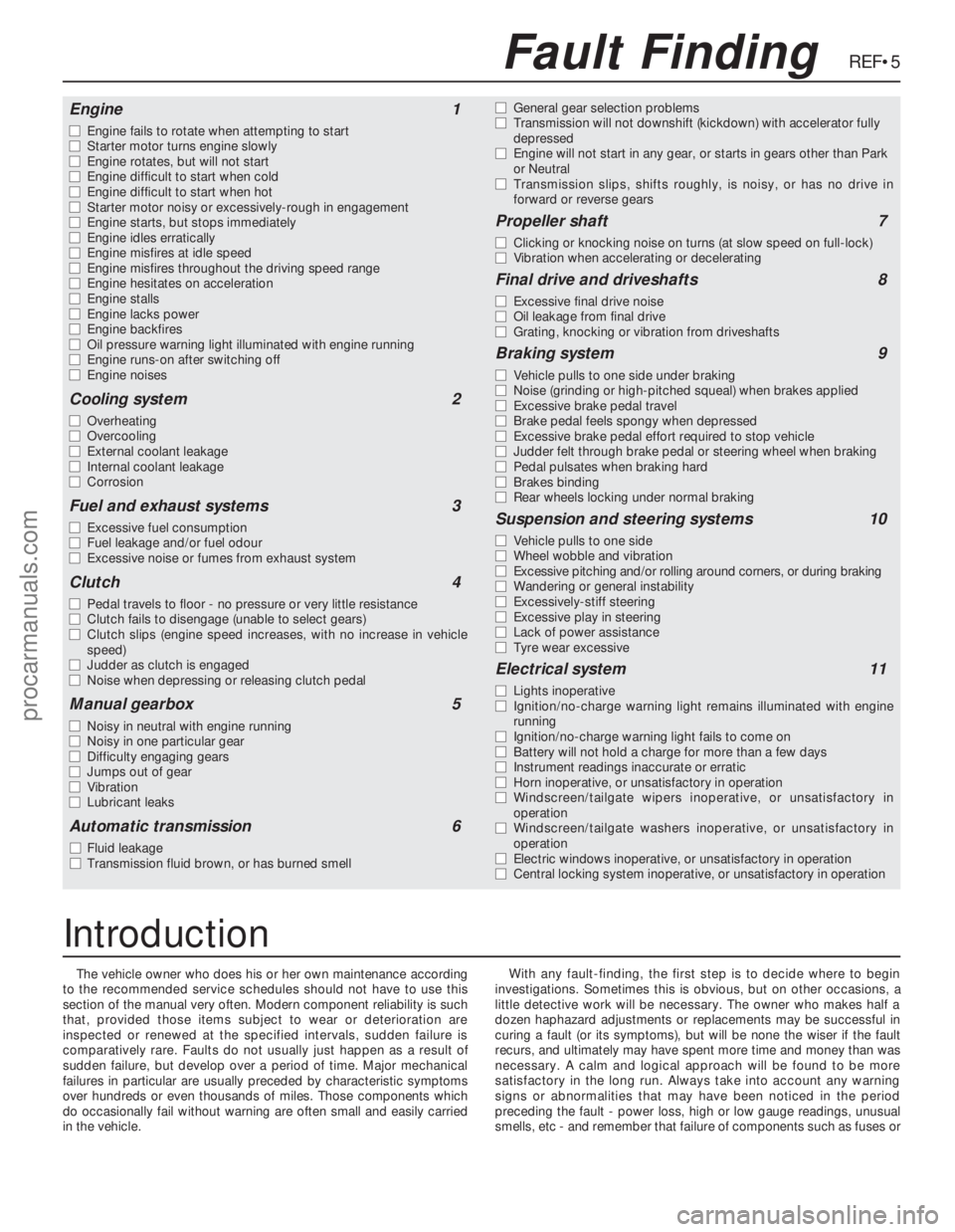

REF•5Fault Finding

Engine1

m mEngine fails to rotate when attempting to start

m mStarter motor turns engine slowly

m mEngine rotates, but will not start

m mEngine difficult to start when cold

m mEngine difficult to start when hot

m mStarter motor noisy or excessively-rough in engagement

m mEngine starts, but stops immediately

m mEngine idles erratically

m mEngine misfires at idle speed

m mEngine misfires throughout the driving speed range

m mEngine hesitates on acceleration

m mEngine stalls

m mEngine lacks power

m mEngine backfires

m mOil pressure warning light illuminated with engine running

m mEngine runs-on after switching off

m mEngine noises

Cooling system2

m

mOverheating

m mOvercooling

m mExternal coolant leakage

m mInternal coolant leakage

m mCorrosion

Fuel and exhaust systems3

m

mExcessive fuel consumption

m mFuel leakage and/or fuel odour

m mExcessive noise or fumes from exhaust system

Clutch4

m

mPedal travels to floor - no pressure or very little resistance

m mClutch fails to disengage (unable to select gears)

m mClutch slips (engine speed increases, with no increase in vehicle

speed)

m mJudder as clutch is engaged

m mNoise when depressing or releasing clutch pedal

Manual gearbox5

m

mNoisy in neutral with engine running

m mNoisy in one particular gear

m mDifficulty engaging gears

m mJumps out of gear

m mVibration

m mLubricant leaks

Automatic transmission6

m

mFluid leakage

m mTransmission fluid brown, or has burned smellm mGeneral gear selection problems

m mTransmission will not downshift (kickdown) with accelerator fully

depressed

m mEngine will not start in any gear, or starts in gears other than Park

or Neutral

m mTransmission slips, shifts roughly, is noisy, or has no drive in

forward or reverse gears

Propeller shaft7

m

mClicking or knocking noise on turns (at slow speed on full-lock)

m mVibration when accelerating or decelerating

Final drive and driveshafts8

m

mExcessive final drive noise

m mOil leakage from final drive

m mGrating, knocking or vibration from driveshafts

Braking system9

m

mVehicle pulls to one side under braking

m mNoise (grinding or high-pitched squeal) when brakes applied

m mExcessive brake pedal travel

m mBrake pedal feels spongy when depressed

m mExcessive brake pedal effort required to stop vehicle

m mJudder felt through brake pedal or steering wheel when braking

m mPedal pulsates when braking hard

m mBrakes binding

m mRear wheels locking under normal braking

Suspension and steering systems10

m

mVehicle pulls to one side

m mWheel wobble and vibration

m mExcessive pitching and/or rolling around corners, or during braking

m mWandering or general instability

m mExcessively-stiff steering

m mExcessive play in steering

m mLack of power assistance

m mTyre wear excessive

Electrical system11

m

mLights inoperative

m mIgnition/no-charge warning light remains illuminated with engine

running

m mIgnition/no-charge warning light fails to come on

m mBattery will not hold a charge for more than a few days

m mInstrument readings inaccurate or erratic

m mHorn inoperative, or unsatisfactory in operation

m mWindscreen/tailgate wipers inoperative, or unsatisfactory in

operation

m mWindscreen/tailgate washers inoperative, or unsatisfactory in

operation

m mElectric windows inoperative, or unsatisfactory in operation

m mCentral locking system inoperative, or unsatisfactory in operation

Introduction

procarmanuals.com

Page 241 of 255

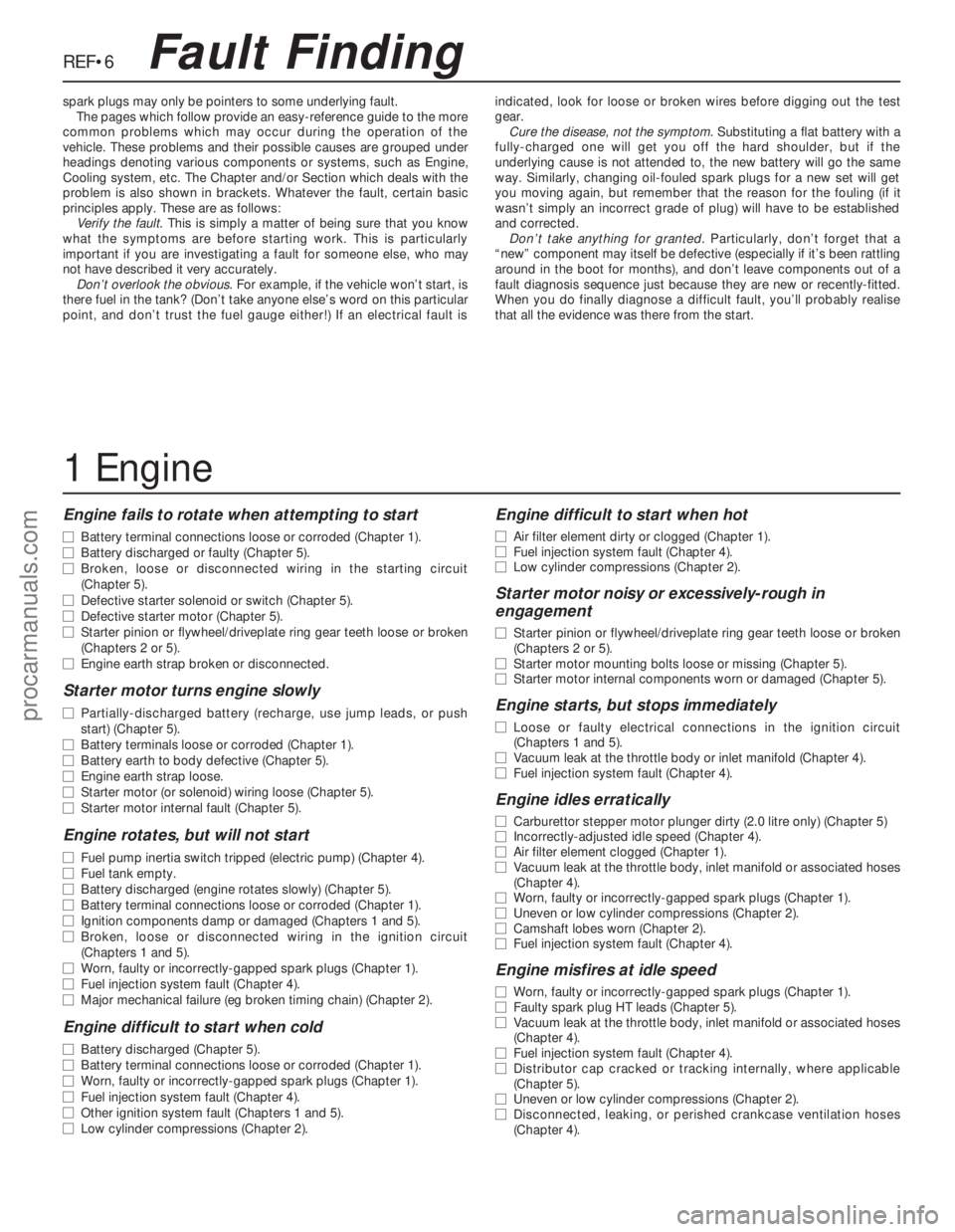

REF•6

Engine fails to rotate when attempting to start

m mBattery terminal connections loose or corroded (Chapter 1).

m mBattery discharged or faulty (Chapter 5).

m mBroken, loose or disconnected wiring in the starting circuit

(Chapter 5).

m mDefective starter solenoid or switch (Chapter 5).

m mDefective starter motor (Chapter 5).

m mStarter pinion or flywheel/driveplate ring gear teeth loose or broken

(Chapters 2 or 5).

m mEngine earth strap broken or disconnected.

Starter motor turns engine slowly

m

mPartially-discharged battery (recharge, use jump leads, or push

start) (Chapter 5).

m mBattery terminals loose or corroded (Chapter 1).

m mBattery earth to body defective (Chapter 5).

m mEngine earth strap loose.

m mStarter motor (or solenoid) wiring loose (Chapter 5).

m mStarter motor internal fault (Chapter 5).

Engine rotates, but will not start

m

mFuel pump inertia switch tripped (electric pump) (Chapter 4).

m mFuel tank empty.

m mBattery discharged (engine rotates slowly) (Chapter 5).

m mBattery terminal connections loose or corroded (Chapter 1).

m mIgnition components damp or damaged (Chapters 1 and 5).

m mBroken, loose or disconnected wiring in the ignition circuit

(Chapters 1 and 5).

m mWorn, faulty or incorrectly-gapped spark plugs (Chapter 1).

m mFuel injection system fault (Chapter 4).

m mMajor mechanical failure (eg broken timing chain) (Chapter 2).

Engine difficult to start when cold

m

mBattery discharged (Chapter 5).

m mBattery terminal connections loose or corroded (Chapter 1).

m mWorn, faulty or incorrectly-gapped spark plugs (Chapter 1).

m mFuel injection system fault (Chapter 4).

m mOther ignition system fault (Chapters 1 and 5).

m mLow cylinder compressions (Chapter 2).

Engine difficult to start when hot

m

mAir filter element dirty or clogged (Chapter 1).

m mFuel injection system fault (Chapter 4).

m mLow cylinder compressions (Chapter 2).

Starter motor noisy or excessively-rough in

engagement

m mStarter pinion or flywheel/driveplate ring gear teeth loose or broken

(Chapters 2 or 5).

m mStarter motor mounting bolts loose or missing (Chapter 5).

m mStarter motor internal components worn or damaged (Chapter 5).

Engine starts, but stops immediately

m

mLoose or faulty electrical connections in the ignition circuit

(Chapters 1 and 5).

m mVacuum leak at the throttle body or inlet manifold (Chapter 4).

m mFuel injection system fault (Chapter 4).

Engine idles erratically

m

mCarburettor stepper motor plunger dirty (2.0 litre only) (Chapter 5)

m mIncorrectly-adjusted idle speed (Chapter 4).

m mAir filter element clogged (Chapter 1).

m mVacuum leak at the throttle body, inlet manifold or associated hoses

(Chapter 4).

m mWorn, faulty or incorrectly-gapped spark plugs (Chapter 1).

m mUneven or low cylinder compressions (Chapter 2).

m mCamshaft lobes worn (Chapter 2).

m mFuel injection system fault (Chapter 4).

Engine misfires at idle speed

m

mWorn, faulty or incorrectly-gapped spark plugs (Chapter 1).

m mFaulty spark plug HT leads (Chapter 5).

m mVacuum leak at the throttle body, inlet manifold or associated hoses

(Chapter 4).

m mFuel injection system fault (Chapter 4).

m mDistributor cap cracked or tracking internally, where applicable

(Chapter 5).

m mUneven or low cylinder compressions (Chapter 2).

m mDisconnected, leaking, or perished crankcase ventilation hoses

(Chapter 4).

Fault Finding

spark plugs may only be pointers to some underlying fault.

The pages which follow provide an easy-reference guide to the more

common problems which may occur during the operation of the

vehicle. These problems and their possible causes are grouped under

headings denoting various components or systems, such as Engine,

Cooling system, etc. The Chapter and/or Section which deals with the

problem is also shown in brackets. Whatever the fault, certain basic

principles apply. These are as follows:

Verify the fault. This is simply a matter of being sure that you know

what the symptoms are before starting work. This is particularly

important if you are investigating a fault for someone else, who may

not have described it very accurately.

Don’t overlook the obvious. For example, if the vehicle won’t start, is

there fuel in the tank? (Don’t take anyone else’s word on this particular

point, and don’t trust the fuel gauge either!) If an electrical fault isindicated, look for loose or broken wires before digging out the test

gear.

Cure the disease, not the symptom. Substituting a flat battery with a

fully-charged one will get you off the hard shoulder, but if the

underlying cause is not attended to, the new battery will go the same

way. Similarly, changing oil-fouled spark plugs for a new set will get

you moving again, but remember that the reason for the fouling (if it

wasn’t simply an incorrect grade of plug) will have to be established

and corrected.

Don’t take anything for granted. Particularly, don’t forget that a

“new” component may itself be defective (especially if it’s been rattling

around in the boot for months), and don’t leave components out of a

fault diagnosis sequence just because they are new or recently-fitted.

When you do finally diagnose a difficult fault, you’ll probably realise

that all the evidence was there from the start.

1 Engine

procarmanuals.com

Page 244 of 255

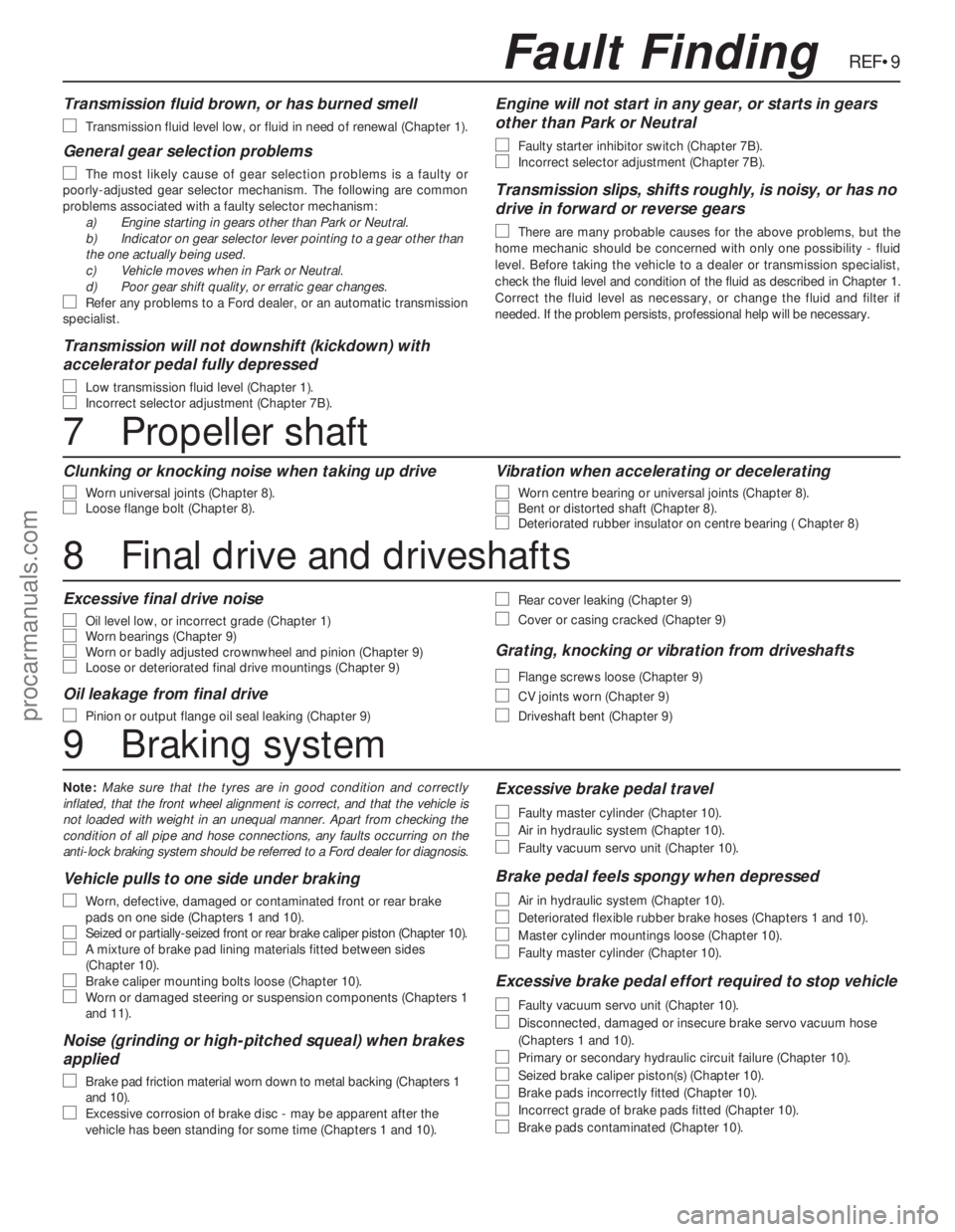

Transmission fluid brown, or has burned smell

m m

Transmission fluid level low, or fluid in need of renewal (Chapter 1).

General gear selection problems

m m

The most likely cause of gear selection problems is a faulty or

poorly-adjusted gear selector mechanism. The following are common

problems associated with a faulty selector mechanism:

a)Engine starting in gears other than Park or Neutral.

b)Indicator on gear selector lever pointing to a gear other than

the one actually being used.

c)Vehicle moves when in Park or Neutral.

d)Poor gear shift quality, or erratic gear changes.

m

mRefer any problems to a Ford dealer, or an automatic transmission

specialist.

Transmission will not downshift (kickdown) with

accelerator pedal fully depressed

m m

Low transmission fluid level (Chapter 1).

m

mIncorrect selector adjustment (Chapter 7B).

Engine will not start in any gear, or starts in gears

other than Park or Neutral

m m

Faulty starter inhibitor switch (Chapter 7B).

m

mIncorrect selector adjustment (Chapter 7B).

Transmission slips, shifts roughly, is noisy, or has no

drive in forward or reverse gears

m m

There are many probable causes for the above problems, but the

home mechanic should be concerned with only one possibility - fluid

level. Before taking the vehicle to a dealer or transmission specialist,

check the fluid level and condition of the fluid as described in Chapter 1.

Correct the fluid level as necessary, or change the fluid and filter if

needed. If the problem persists, professional help will be necessary.

REF•9Fault Finding

7Propeller shaft

Clunking or knocking noise when taking up drive

m m

Worn universal joints (Chapter 8).m

mLoose flange bolt (Chapter 8).

Vibration when accelerating or decelerating

m m

Worn centre bearing or universal joints (Chapter 8).m

mBent or distorted shaft (Chapter 8).m

mDeteriorated rubber insulator on centre bearing ( Chapter 8)

8Final drive and driveshafts

Excessive final drive noise

m m

Oil level low, or incorrect grade (Chapter 1)m

mWorn bearings (Chapter 9)m

mWorn or badly adjusted crownwheel and pinion (Chapter 9)m

mLoose or deteriorated final drive mountings (Chapter 9)

Oil leakage from final drive

m m

Pinion or output flange oil seal leaking (Chapter 9)

m

mRear cover leaking (Chapter 9)

m

mCover or casing cracked (Chapter 9)

Grating, knocking or vibration from driveshafts

m m

Flange screws loose (Chapter 9)

m

mCV joints worn (Chapter 9)

m

mDriveshaft bent (Chapter 9)

9Braking system

Note:Make sure that the tyres are in good condition and correctly

inflated, that the front wheel alignment is correct, and that the vehicle is

not loaded with weight in an unequal manner. Apart from checking the

condition of all pipe and hose connections, any faults occurring on the

anti-lock braking system should be referred to a Ford dealer for diagnosis.

Vehicle pulls to one side under braking

m m

Worn, defective, damaged or contaminated front or rear brake

pads on one side (Chapters 1 and 10).

m mSeized or partially-seized front or rear brake caliper piston (Chapter 10).m

mA mixture of brake pad lining materials fitted between sides

(Chapter 10).

m mBrake caliper mounting bolts loose (Chapter 10).m

mWorn or damaged steering or suspension components (Chapters 1

and 11).

Noise (grinding or high-pitched squeal) when brakes

applied

m m

Brake pad friction material worn down to metal backing (Chapters 1

and 10).

m mExcessive corrosion of brake disc - may be apparent after the

vehicle has been standing for some time (Chapters 1 and 10).

Excessive brake pedal travel

m m

Faulty master cylinder (Chapter 10).

m

mAir in hydraulic system (Chapter 10).

m

mFaulty vacuum servo unit (Chapter 10).

Brake pedal feels spongy when depressed

m m

Air in hydraulic system (Chapter 10).

m

mDeteriorated flexible rubber brake hoses (Chapters 1 and 10).

m

mMaster cylinder mountings loose (Chapter 10).

m

mFaulty master cylinder (Chapter 10).

Excessive brake pedal effort required to stop vehicle

m m

Faulty vacuum servo unit (Chapter 10).

m

mDisconnected, damaged or insecure brake servo vacuum hose

(Chapters 1 and 10).

m mPrimary or secondary hydraulic circuit failure (Chapter 10).

m

mSeized brake caliper piston(s) (Chapter 10).

m

mBrake pads incorrectly fitted (Chapter 10).

m

mIncorrect grade of brake pads fitted (Chapter 10).

m

mBrake pads contaminated (Chapter 10).

procarmanuals.com

Page 249 of 255

REF•14Glossary of Technical Terms

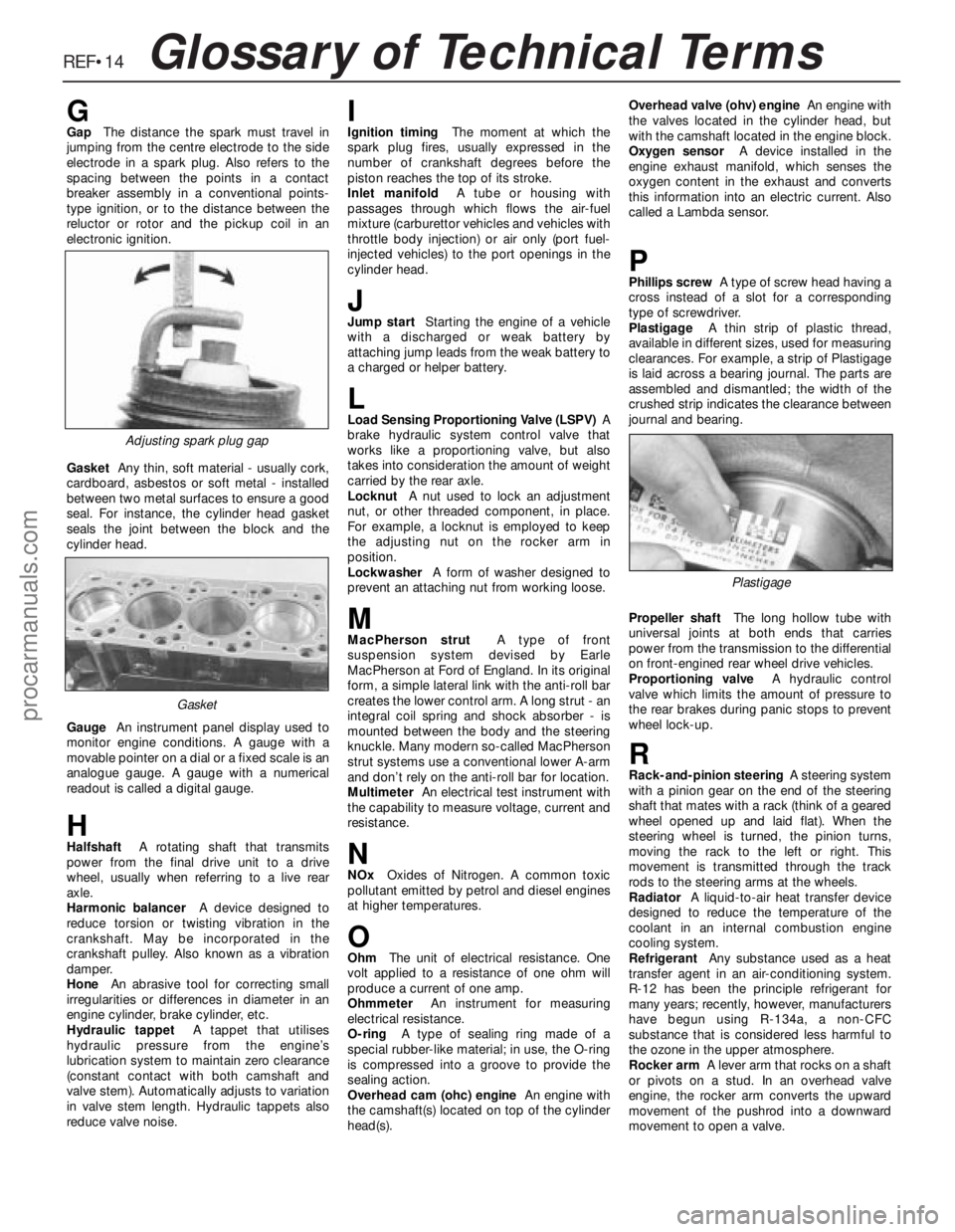

GGapThe distance the spark must travel in

jumping from the centre electrode to the side

electrode in a spark plug. Also refers to the

spacing between the points in a contact

breaker assembly in a conventional points-

type ignition, or to the distance between the

reluctor or rotor and the pickup coil in an

electronic ignition.

GasketAny thin, soft material - usually cork,

cardboard, asbestos or soft metal - installed

between two metal surfaces to ensure a good

seal. For instance, the cylinder head gasket

seals the joint between the block and the

cylinder head.

GaugeAn instrument panel display used to

monitor engine conditions. A gauge with a

movable pointer on a dial or a fixed scale is an

analogue gauge. A gauge with a numerical

readout is called a digital gauge.

HHalfshaftA rotating shaft that transmits

power from the final drive unit to a drive

wheel, usually when referring to a live rear

axle.

Harmonic balancerA device designed to

reduce torsion or twisting vibration in the

crankshaft. May be incorporated in the

crankshaft pulley. Also known as a vibration

damper.

HoneAn abrasive tool for correcting small

irregularities or differences in diameter in an

engine cylinder, brake cylinder, etc.

Hydraulic tappetA tappet that utilises

hydraulic pressure from the engine’s

lubrication system to maintain zero clearance

(constant contact with both camshaft and

valve stem). Automatically adjusts to variation

in valve stem length. Hydraulic tappets also

reduce valve noise.

IIgnition timingThe moment at which the

spark plug fires, usually expressed in the

number of crankshaft degrees before the

piston reaches the top of its stroke.

Inlet manifoldA tube or housing with

passages through which flows the air-fuel

mixture (carburettor vehicles and vehicles with

throttle body injection) or air only (port fuel-

injected vehicles) to the port openings in the

cylinder head.

JJump startStarting the engine of a vehicle

with a discharged or weak battery by

attaching jump leads from the weak battery to

a charged or helper battery.

LLoad Sensing Proportioning Valve (LSPV)A

brake hydraulic system control valve that

works like a proportioning valve, but also

takes into consideration the amount of weight

carried by the rear axle.

LocknutA nut used to lock an adjustment

nut, or other threaded component, in place.

For example, a locknut is employed to keep

the adjusting nut on the rocker arm in

position.

LockwasherA form of washer designed to

prevent an attaching nut from working loose.

MMacPherson strutA type of front

suspension system devised by Earle

MacPherson at Ford of England. In its original

form, a simple lateral link with the anti-roll bar

creates the lower control arm. A long strut - an

integral coil spring and shock absorber - is

mounted between the body and the steering

knuckle. Many modern so-called MacPherson

strut systems use a conventional lower A-arm

and don’t rely on the anti-roll bar for location.

MultimeterAn electrical test instrument with

the capability to measure voltage, current and

resistance.

NNOxOxides of Nitrogen. A common toxic

pollutant emitted by petrol and diesel engines

at higher temperatures.

OOhmThe unit of electrical resistance. One

volt applied to a resistance of one ohm will

produce a current of one amp.

OhmmeterAn instrument for measuring

electrical resistance.

O-ringA type of sealing ring made of a

special rubber-like material; in use, the O-ring

is compressed into a groove to provide the

sealing action.

Overhead cam (ohc) engineAn engine with

the camshaft(s) located on top of the cylinder

head(s).Overhead valve (ohv) engineAn engine with

the valves located in the cylinder head, but

with the camshaft located in the engine block.

Oxygen sensorA device installed in the

engine exhaust manifold, which senses the

oxygen content in the exhaust and converts

this information into an electric current. Also

called a Lambda sensor.

PPhillips screwA type of screw head having a

cross instead of a slot for a corresponding

type of screwdriver.

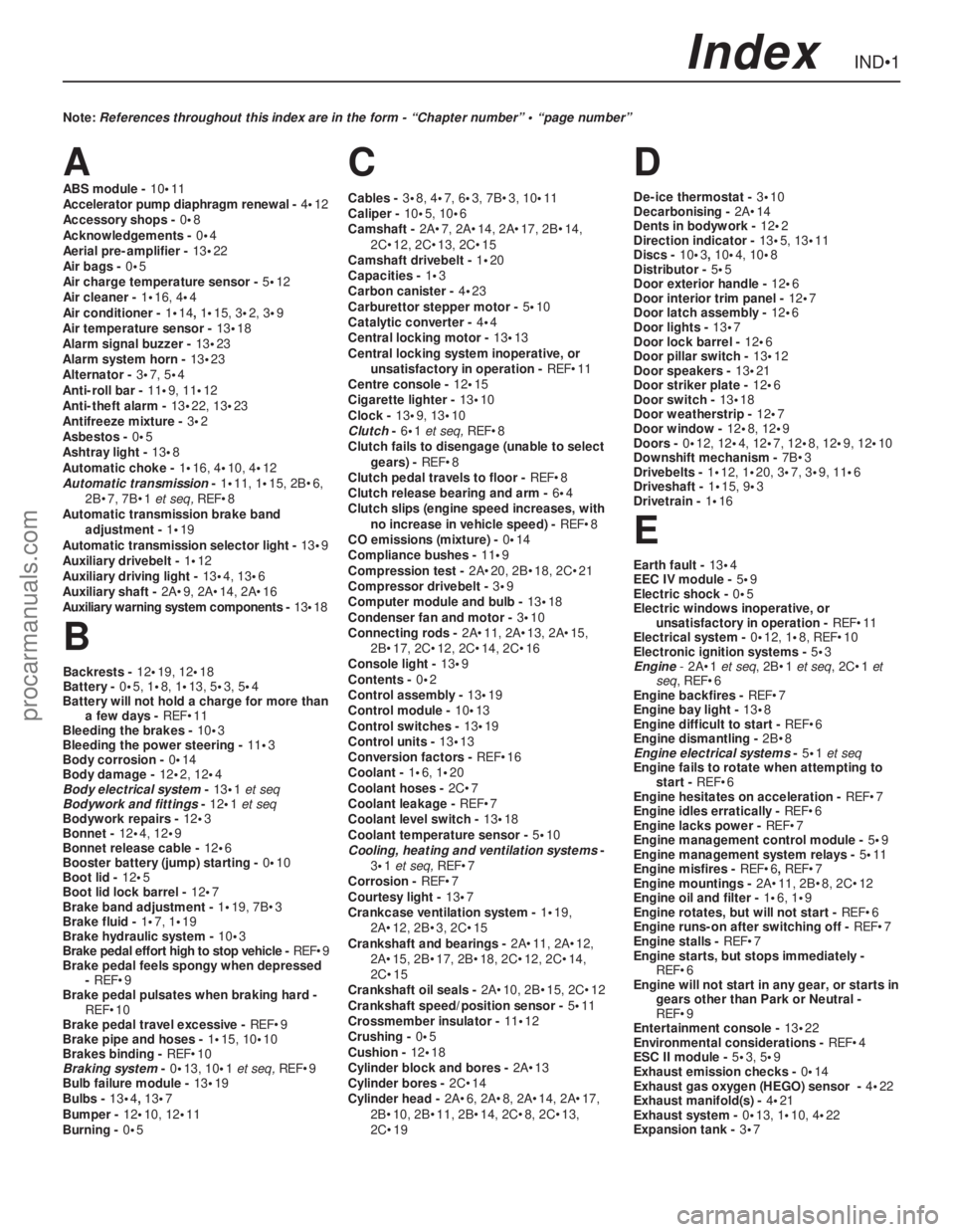

PlastigageA thin strip of plastic thread,

available in different sizes, used for measuring

clearances. For example, a strip of Plastigage

is laid across a bearing journal. The parts are

assembled and dismantled; the width of the

crushed strip indicates the clearance between

journal and bearing.

Propeller shaftThe long hollow tube with

universal joints at both ends that carries

power from the transmission to the differential

on front-engined rear wheel drive vehicles.

Proportioning valveA hydraulic control

valve which limits the amount of pressure to

the rear brakes during panic stops to prevent

wheel lock-up.

RRack-and-pinion steeringA steering system

with a pinion gear on the end of the steering

shaft that mates with a rack (think of a geared

wheel opened up and laid flat). When the

steering wheel is turned, the pinion turns,

moving the rack to the left or right. This

movement is transmitted through the track

rods to the steering arms at the wheels.

RadiatorA liquid-to-air heat transfer device

designed to reduce the temperature of the

coolant in an internal combustion engine

cooling system.

RefrigerantAny substance used as a heat

transfer agent in an air-conditioning system.

R-12 has been the principle refrigerant for

many years; recently, however, manufacturers

have begun using R-134a, a non-CFC

substance that is considered less harmful to

the ozone in the upper atmosphere.

Rocker armA lever arm that rocks on a shaft

or pivots on a stud. In an overhead valve

engine, the rocker arm converts the upward

movement of the pushrod into a downward

movement to open a valve.

Adjusting spark plug gap

Plastigage

Gasket

procarmanuals.com

Page 250 of 255

REF•15Glossary of Technical Terms

RotorIn a distributor, the rotating device

inside the cap that connects the centre

electrode and the outer terminals as it turns,

distributing the high voltage from the coil

secondary winding to the proper spark plug.

Also, that part of an alternator which rotates

inside the stator. Also, the rotating assembly

of a turbocharger, including the compressor

wheel, shaft and turbine wheel.

RunoutThe amount of wobble (in-and-out

movement) of a gear or wheel as it’s rotated.

The amount a shaft rotates “out-of-true.” The

out-of-round condition of a rotating part.

SSealantA liquid or paste used to prevent

leakage at a joint. Sometimes used in

conjunction with a gasket.

Sealed beam lampAn older headlight design

which integrates the reflector, lens and

filaments into a hermetically-sealed one-piece

unit. When a filament burns out or the lens

cracks, the entire unit is simply replaced.

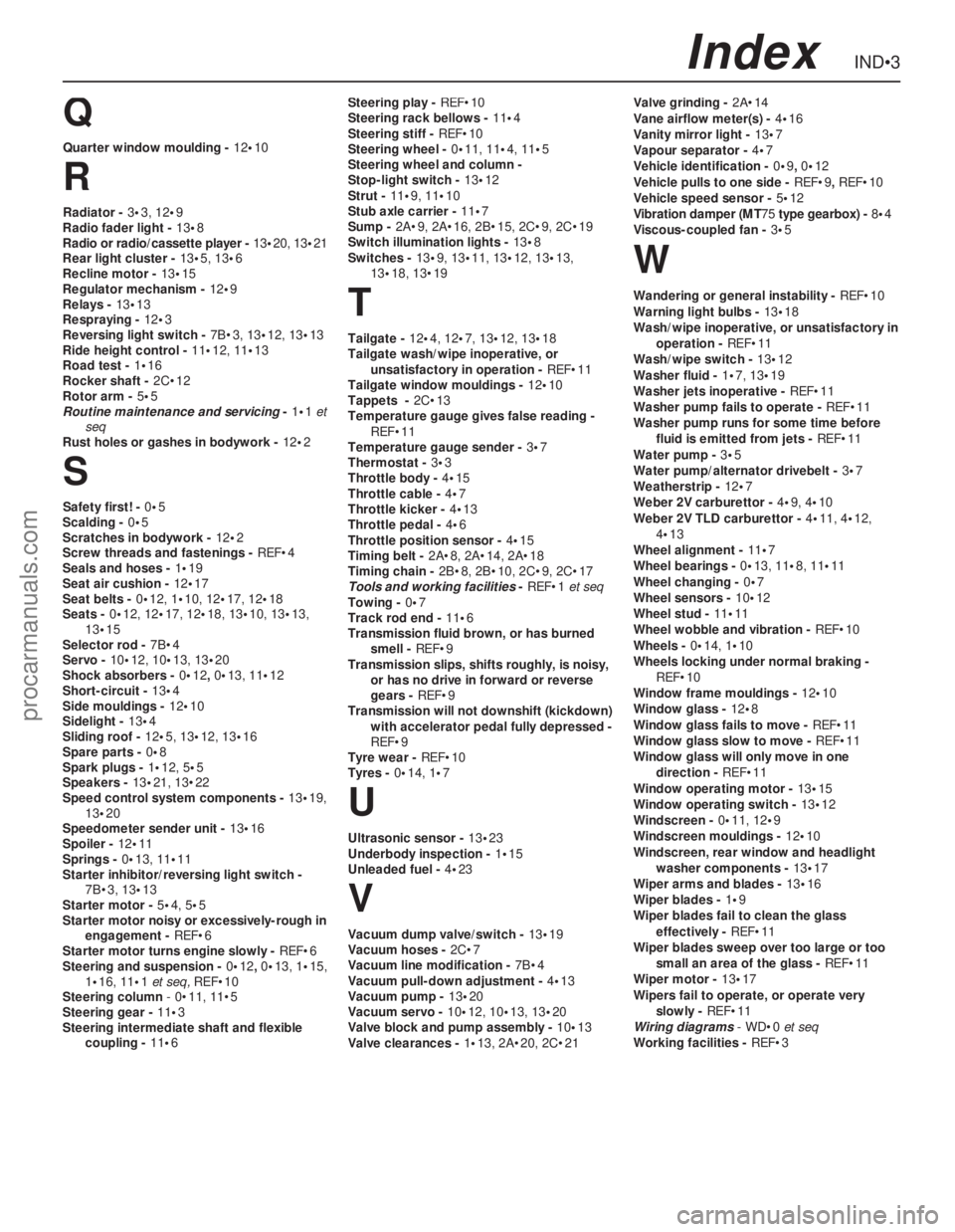

Serpentine drivebeltA single, long, wide

accessory drivebelt that’s used on some

newer vehicles to drive all the accessories,

instead of a series of smaller, shorter belts.

Serpentine drivebelts are usually tensioned by

an automatic tensioner.

ShimThin spacer, commonly used to adjust

the clearance or relative positions between

two parts. For example, shims inserted into or

under bucket tappets control valve

clearances. Clearance is adjusted by

changing the thickness of the shim.

Slide hammerA special puller that screws

into or hooks onto a component such as a

shaft or bearing; a heavy sliding handle on the

shaft bottoms against the end of the shaft to

knock the component free.SprocketA tooth or projection on the

periphery of a wheel, shaped to engage with a

chain or drivebelt. Commonly used to refer to

the sprocket wheel itself.

Starter inhibitor switchOn vehicles with an

automatic transmission, a switch that

prevents starting if the vehicle is not in Neutral

or Park.

StrutSee MacPherson strut.

TTappetA cylindrical component which

transmits motion from the cam to the valve

stem, either directly or via a pushrod and

rocker arm. Also called a cam follower.

ThermostatA heat-controlled valve that

regulates the flow of coolant between the

cylinder block and the radiator, so maintaining

optimum engine operating temperature. A

thermostat is also used in some air cleaners in

which the temperature is regulated.

Thrust bearingThe bearing in the clutch

assembly that is moved in to the release

levers by clutch pedal action to disengage the

clutch. Also referred to as a release bearing.

Timing beltA toothed belt which drives the

camshaft. Serious engine damage may result

if it breaks in service.

Timing chainA chain which drives the

camshaft.

Toe-inThe amount the front wheels are

closer together at the front than at the rear. On

rear wheel drive vehicles, a slight amount of

toe-in is usually specified to keep the front

wheels running parallel on the road by

offsetting other forces that tend to spread the

wheels apart.

Toe-outThe amount the front wheels are

closer together at the rear than at the front. On

front wheel drive vehicles, a slight amount of

toe-out is usually specified.

ToolsFor full information on choosing and

using tools, refer to the Haynes Automotive

Tools Manual.

TracerA stripe of a second colour applied to

a wire insulator to distinguish that wire from

another one with the same colour insulator.

Tune-upA process of accurate and careful

adjustments and parts replacement to obtain

the best possible engine performance.TurbochargerA centrifugal device, driven by

exhaust gases, that pressurises the intake air.

Normally used to increase the power output

from a given engine displacement, but can

also be used primarily to reduce exhaust

emissions (as on VW’s “Umwelt” Diesel

engine).

UUniversal joint or U-jointA double-pivoted

connection for transmitting power from a

driving to a driven shaft through an angle. A

U-joint consists of two Y-shaped yokes and a

cross-shaped member called the spider.

VValveA device through which the flow of

liquid, gas, vacuum, or loose material in bulk

may be started, stopped, or regulated by a

movable part that opens, shuts, or partially

obstructs one or more ports or passageways.

A valve is also the movable part of such a

device.

Valve clearanceThe clearance between the

valve tip (the end of the valve stem) and the

rocker arm or tappet. The valve clearance is

measured when the valve is closed.

Vernier caliperA precision measuring

instrument that measures inside and outside

dimensions. Not quite as accurate as a

micrometer, but more convenient.

ViscosityThe thickness of a liquid or its

resistance to flow.

VoltA unit for expressing electrical

“pressure” in a circuit. One volt that will

produce a current of one ampere through a

resistance of one ohm.

WWeldingVarious processes used to join metal

items by heating the areas to be joined to a

molten state and fusing them together. For

more information refer to the Haynes

Automotive Welding Manual.

Wiring diagramA drawing portraying the

components and wires in a vehicle’s electrical

system, using standardised symbols. For

more information refer to the Haynes

Automotive Electrical and Electronic Systems

Manual.

Serpentine drivebelt

procarmanuals.com

Page 252 of 255

A

ABS module - 10•11

Accelerator pump diaphragm renewal - 4•12

Accessory shops - 0•8

Acknowledgements - 0•4

Aerial pre-amplifier - 13•22

Air bags - 0•5

Air charge temperature sensor - 5•12

Air cleaner - 1•16, 4•4

Air conditioner - 1•14, 1•15, 3•2, 3•9

Air temperature sensor - 13•18

Alarm signal buzzer - 13•23

Alarm system horn - 13•23

Alternator - 3•7, 5•4

Anti-roll bar - 11•9, 11•12

Anti-theft alarm - 13•22, 13•23

Antifreeze mixture - 3•2

Asbestos - 0•5

Ashtray light - 13•8

Automatic choke - 1•16, 4•10, 4•12

Automatic transmission- 1•11, 1•15, 2B•6,

2B•7, 7B•1et seq, REF•8

Automatic transmission brake band

adjustment - 1•19

Automatic transmission selector light - 13•9

Auxiliary drivebelt - 1•12

Auxiliary driving light - 13•4, 13•6

Auxiliary shaft - 2A•9, 2A•14, 2A•16

Auxiliary warning system components - 13•18

B

Backrests - 12•19, 12•18

Battery - 0•5, 1•8, 1•13, 5•3, 5•4

Battery will not hold a charge for more than

a few days - REF•11

Bleeding the brakes - 10•3

Bleeding the power steering - 11•3

Body corrosion - 0•14

Body damage - 12•2, 12•4

Body electrical system- 13•1et seq

Bodywork and fittings- 12•1et seq

Bodywork repairs - 12•3

Bonnet - 12•4, 12•9

Bonnet release cable - 12•6

Booster battery (jump) starting - 0•10

Boot lid - 12•5

Boot lid lock barrel - 12•7

Brake band adjustment - 1•19, 7B•3

Brake fluid - 1•7, 1•19

Brake hydraulic system - 10•3

Brake pedal effort high to stop vehicle - REF•9

Brake pedal feels spongy when depressed

- REF•9

Brake pedal pulsates when braking hard -

REF•10

Brake pedal travel excessive - REF•9

Brake pipe and hoses - 1•15, 10•10

Brakes binding - REF•10

Braking system- 0•13, 10•1et seq, REF•9

Bulb failure module - 13•19

Bulbs - 13•4, 13•7

Bumper - 12•10, 12•11

Burning - 0•5

C

Cables - 3•8, 4•7, 6•3, 7B•3, 10•11

Caliper - 10•5, 10•6

Camshaft - 2A•7, 2A•14, 2A•17, 2B•14,

2C•12, 2C•13, 2C•15

Camshaft drivebelt - 1•20

Capacities - 1•3

Carbon canister - 4•23

Carburettor stepper motor - 5•10

Catalytic converter - 4•4

Central locking motor - 13•13

Central locking system inoperative, or

unsatisfactory in operation - REF•11

Centre console - 12•15

Cigarette lighter - 13•10

Clock - 13•9, 13•10

Clutch- 6•1et seq, REF•8

Clutch fails to disengage (unable to select

gears) - REF•8

Clutch pedal travels to floor - REF•8

Clutch release bearing and arm - 6•4

Clutch slips (engine speed increases, with

no increase in vehicle speed) - REF•8

CO emissions (mixture) - 0•14

Compliance bushes - 11•9

Compression test - 2A•20, 2B•18, 2C•21

Compressor drivebelt - 3•9

Computer module and bulb - 13•18

Condenser fan and motor - 3•10

Connecting rods - 2A•11, 2A•13, 2A•15,

2B•17, 2C•12, 2C•14, 2C•16

Console light - 13•9

Contents - 0•2

Control assembly - 13•19

Control module - 10•13

Control switches - 13•19

Control units - 13•13

Conversion factors - REF•16

Coolant - 1•6, 1•20

Coolant hoses - 2C•7

Coolant leakage - REF•7

Coolant level switch - 13•18

Coolant temperature sensor - 5•10

Cooling, heating and ventilation systems-

3•1 et seq, REF•7

Corrosion - REF•7

Courtesy light - 13•7

Crankcase ventilation system - 1•19,

2A•12, 2B•3, 2C•15

Crankshaft and bearings - 2A•11, 2A•12,

2A•15, 2B•17, 2B•18, 2C•12, 2C•14,

2C•15

Crankshaft oil seals - 2A•10, 2B•15, 2C•12

Crankshaft speed/position sensor - 5•11

Crossmember insulator - 11•12

Crushing - 0•5

Cushion - 12•18

Cylinder block and bores - 2A•13

Cylinder bores - 2C•14

Cylinder head - 2A•6, 2A•8, 2A•14, 2A•17,

2B•10, 2B•11, 2B•14, 2C•8, 2C•13,

2C•19

D

De-ice thermostat - 3•10

Decarbonising - 2A•14

Dents in bodywork - 12•2

Direction indicator - 13•5, 13•11

Discs - 10•3, 10•4, 10•8

Distributor - 5•5

Door exterior handle - 12•6

Door interior trim panel - 12•7

Door latch assembly - 12•6

Door lights - 13•7

Door lock barrel - 12•6

Door pillar switch - 13•12

Door speakers - 13•21

Door striker plate - 12•6

Door switch - 13•18

Door weatherstrip - 12•7

Door window - 12•8, 12•9

Doors - 0•12, 12•4, 12•7, 12•8, 12•9, 12•10

Downshift mechanism - 7B•3

Drivebelts - 1•12, 1•20, 3•7, 3•9, 11•6

Driveshaft - 1•15, 9•3

Drivetrain - 1•16

E

Earth fault - 13•4

EEC IV module - 5•9

Electric shock - 0•5

Electric windows inoperative, or

unsatisfactory in operation - REF•11

Electrical system - 0•12, 1•8, REF•10

Electronic ignition systems - 5•3

Engine- 2A•1 et seq, 2B•1 et seq, 2C•1 et

seq, REF•6

Engine backfires - REF•7

Engine bay light - 13•8

Engine difficult to start - REF•6

Engine dismantling - 2B•8

Engine electrical systems- 5•1et seq

Engine fails to rotate when attempting to

start - REF•6

Engine hesitates on acceleration - REF•7

Engine idles erratically - REF•6

Engine lacks power - REF•7

Engine management control module - 5•9

Engine management system relays - 5•11

Engine misfires - REF•6, REF•7

Engine mountings - 2A•11, 2B•8, 2C•12

Engine oil and filter - 1•6, 1•9

Engine rotates, but will not start - REF•6

Engine runs-on after switching off - REF•7

Engine stalls - REF•7

Engine starts, but stops immediately -

REF•6

Engine will not start in any gear, or starts in

gears other than Park or Neutral -

REF•9

Entertainment console - 13•22

Environmental considerations - REF•4

ESC II module - 5•3, 5•9

Exhaust emission checks - 0•14

Exhaust gas oxygen (HEGO) sensor - 4•22

Exhaust manifold(s) - 4•21

Exhaust system - 0•13, 1•10, 4•22

Expansion tank - 3•7

IND•1Index

Note: References throughout this index are in the form - “Chapter number” • “page number”

procarmanuals.com

Page 254 of 255

Q

Quarter window moulding - 12•10

R

Radiator - 3•3, 12•9

Radio fader light - 13•8

Radio or radio/cassette player - 13•20, 13•21

Rear light cluster - 13•5, 13•6

Recline motor - 13•15

Regulator mechanism - 12•9

Relays - 13•13

Respraying - 12•3

Reversing light switch - 7B•3, 13•12, 13•13

Ride height control - 11•12, 11•13

Road test - 1•16

Rocker shaft - 2C•12

Rotor arm - 5•5

Routine maintenance and servicing- 1•1et

seq

Rust holes or gashes in bodywork - 12•2

S

Safety first! - 0•5

Scalding - 0•5

Scratches in bodywork - 12•2

Screw threads and fastenings - REF•4

Seals and hoses - 1•19

Seat air cushion - 12•17

Seat belts - 0•12, 1•10, 12•17, 12•18

Seats - 0•12, 12•17, 12•18, 13•10, 13•13,

13•15

Selector rod - 7B•4

Servo - 10•12, 10•13, 13•20

Shock absorbers - 0•12, 0•13, 11•12

Short-circuit - 13•4

Side mouldings - 12•10

Sidelight - 13•4

Sliding roof - 12•5, 13•12, 13•16

Spare parts - 0•8

Spark plugs - 1•12, 5•5

Speakers - 13•21, 13•22

Speed control system components - 13•19,

13•20

Speedometer sender unit - 13•16

Spoiler - 12•11

Springs - 0•13, 11•11

Starter inhibitor/reversing light switch -

7B•3, 13•13

Starter motor - 5•4, 5•5

Starter motor noisy or excessively-rough in

engagement - REF•6

Starter motor turns engine slowly - REF•6

Steering and suspension - 0•12, 0•13, 1•15,

1•16, 11•1et seq,REF•10

Steering column- 0•11, 11•5

Steering gear - 11•3

Steering intermediate shaft and flexible

coupling - 11•6Steering play - REF•10

Steering rack bellows - 11•4

Steering stiff - REF•10

Steering wheel - 0•11, 11•4, 11•5

Steering wheel and column -

Stop-light switch - 13•12

Strut - 11•9, 11•10

Stub axle carrier - 11•7

Sump - 2A•9, 2A•16, 2B•15, 2C•9, 2C•19

Switch illumination lights - 13•8

Switches - 13•9, 13•11, 13•12, 13•13,

13•18, 13•19

T

Tailgate - 12•4, 12•7, 13•12, 13•18

Tailgate wash/wipe inoperative, or

unsatisfactory in operation - REF•11

Tailgate window mouldings - 12•10

Tappets - 2C•13

Temperature gauge gives false reading -

REF•11

Temperature gauge sender - 3•7

Thermostat - 3•3

Throttle body - 4•15

Throttle cable - 4•7

Throttle kicker - 4•13

Throttle pedal - 4•6

Throttle position sensor - 4•15

Timing belt - 2A•8, 2A•14, 2A•18

Timing chain - 2B•8, 2B•10, 2C•9, 2C•17

Tools and working facilities- REF•1et seq

Towing - 0•7

Track rod end - 11•6

Transmission fluid brown, or has burned

smell - REF•9

Transmission slips, shifts roughly, is noisy,

or has no drive in forward or reverse

gears - REF•9

Transmission will not downshift (kickdown)

with accelerator pedal fully depressed -

REF•9

Tyre wear - REF•10

Tyres - 0•14, 1•7

U

Ultrasonic sensor - 13•23

Underbody inspection - 1•15

Unleaded fuel - 4•23

V

Vacuum dump valve/switch - 13•19

Vacuum hoses - 2C•7

Vacuum line modification - 7B•4

Vacuum pull-down adjustment - 4•13

Vacuum pump - 13•20

Vacuum servo - 10•12, 10•13, 13•20

Valve block and pump assembly - 10•13

Valve clearances - 1•13, 2A•20, 2C•21Valve grinding - 2A•14

Vane airflow meter(s) - 4•16

Vanity mirror light - 13•7

Vapour separator - 4•7

Vehicle identification - 0•9, 0•12

Vehicle pulls to one side - REF•9, REF•10

Vehicle speed sensor - 5•12

Vibration damper (MT75type gearbox) - 8•4

Viscous-coupled fan - 3•5

W

Wandering or general instability - REF•10

Warning light bulbs - 13•18

Wash/wipe inoperative, or unsatisfactory in

operation - REF•11

Wash/wipe switch - 13•12

Washer fluid - 1•7, 13•19

Washer jets inoperative - REF•11

Washer pump fails to operate - REF•11

Washer pump runs for some time before

fluid is emitted from jets - REF•11

Water pump - 3•5

Water pump/alternator drivebelt - 3•7

Weatherstrip - 12•7

Weber 2V carburettor - 4•9, 4•10

Weber 2V TLD carburettor - 4•11, 4•12,

4•13

Wheel alignment - 11•7

Wheel bearings - 0•13, 11•8, 11•11

Wheel changing - 0•7

Wheel sensors - 10•12

Wheel stud - 11•11

Wheel wobble and vibration - REF•10

Wheels - 0•14, 1•10

Wheels locking under normal braking -

REF•10

Window frame mouldings - 12•10

Window glass - 12•8

Window glass fails to move - REF•11

Window glass slow to move - REF•11

Window glass will only move in one

direction - REF•11

Window operating motor - 13•15

Window operating switch - 13•12

Windscreen - 0•11, 12•9

Windscreen mouldings - 12•10

Windscreen, rear window and headlight

washer components - 13•17

Wiper arms and blades - 13•16

Wiper blades - 1•9

Wiper blades fail to clean the glass

effectively - REF•11

Wiper blades sweep over too large or too

small an area of the glass - REF•11

Wiper motor - 13•17

Wipers fail to operate, or operate very

slowly - REF•11

Wiring diagrams- WD•0 et seq

Working facilities - REF•3

IND•3Index

procarmanuals.com