fuel FORD GRANADA 1985 Service Owner's Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 1985, Model line: GRANADA, Model: FORD GRANADA 1985Pages: 255, PDF Size: 14.98 MB

Page 59 of 255

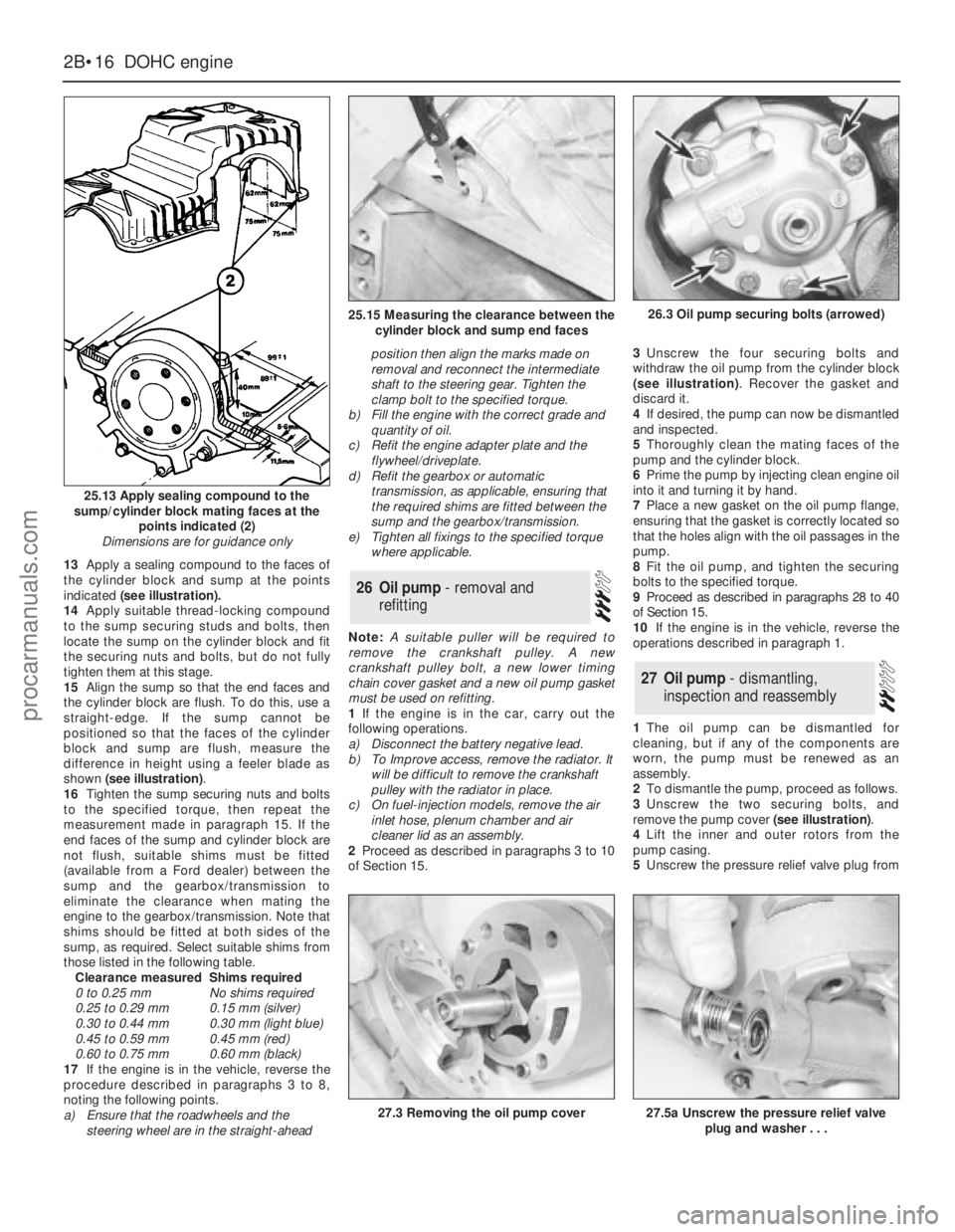

13Apply a sealing compound to the faces of

the cylinder block and sump at the points

indicated(see illustration).

14Apply suitable thread-locking compound

to the sump securing studs and bolts, then

locate the sump on the cylinder block and fit

the securing nuts and bolts, but do not fully

tighten them at this stage.

15Align the sump so that the end faces and

the cylinder block are flush. To do this, use a

straight-edge. If the sump cannot be

positioned so that the faces of the cylinder

block and sump are flush, measure the

difference in height using a feeler blade as

shown (see illustration).

16Tighten the sump securing nuts and bolts

to the specified torque, then repeat the

measurement made in paragraph 15. If the

end faces of the sump and cylinder block are

not flush, suitable shims must be fitted

(available from a Ford dealer) between the

sump and the gearbox/transmission to

eliminate the clearance when mating the

engine to the gearbox/transmission. Note that

shims should be fitted at both sides of the

sump, as required. Select suitable shims from

those listed in the following table.

Clearance measuredShims required

0 to 0.25 mmNo shims required

0.25 to 0.29 mm0.15 mm (silver)

0.30 to 0.44 mm0.30 mm (light blue)

0.45 to 0.59 mm0.45 mm (red)

0.60 to 0.75 mm0.60 mm (black)

17If the engine is in the vehicle, reverse the

procedure described in paragraphs 3 to 8,

noting the following points.

a)Ensure that the roadwheels and the

steering wheel are in the straight-aheadposition then align the marks made on

removal and reconnect the intermediate

shaft to the steering gear. Tighten the

clamp bolt to the specified torque.

b)Fill the engine with the correct grade and

quantity of oil.

c)Refit the engine adapter plate and the

flywheel/driveplate.

d)Refit the gearbox or automatic

transmission, as applicable, ensuring that

the required shims are fitted between the

sump and the gearbox/transmission.

e)Tighten all fixings to the specified torque

where applicable.

Note: A suitable puller will be required to

remove the crankshaft pulley. A new

crankshaft pulley bolt, a new lower timing

chain cover gasket and a new oil pump gasket

must be used on refitting.

1If the engine is in the car, carry out the

following operations.

a)Disconnect the battery negative lead.

b)To Improve access, remove the radiator. It

will be difficult to remove the crankshaft

pulley with the radiator in place.

c)On fuel-injection models, remove the air

inlet hose, plenum chamber and air

cleaner lid as an assembly.

2Proceed as described in paragraphs 3 to 10

of Section 15.3Unscrew the four securing bolts and

withdraw the oil pump from the cylinder block

(see illustration). Recover the gasket and

discard it.

4If desired, the pump can now be dismantled

and inspected.

5Thoroughly clean the mating faces of the

pump and the cylinder block.

6Prime the pump by injecting clean engine oil

into it and turning it by hand.

7Place a new gasket on the oil pump flange,

ensuring that the gasket is correctly located so

that the holes align with the oil passages in the

pump.

8Fit the oil pump, and tighten the securing

bolts to the specified torque.

9Proceed as described in paragraphs 28 to 40

of Section 15.

10If the engine is in the vehicle, reverse the

operations described in paragraph 1.

1The oil pump can be dismantled for

cleaning, but if any of the components are

worn, the pump must be renewed as an

assembly.

2To dismantle the pump, proceed as follows.

3Unscrew the two securing bolts, and

remove the pump cover (see illustration).

4Lift the inner and outer rotors from the

pump casing.

5Unscrew the pressure relief valve plug from

27Oil pump - dismantling,

inspection and reassembly

26Oil pump - removal and

refitting

2B•16DOHCengine

25.13 Apply sealing compound to the

sump/cylinder block mating faces at the

points indicated (2)

Dimensions are for guidance only

27.3 Removing the oil pump cover27.5a Unscrew the pressure relief valve

plug and washer . . .

25.15 Measuring the clearance between the

cylinder block and sump end faces26.3 Oil pump securing bolts (arrowed)

procarmanuals.com

Page 61 of 255

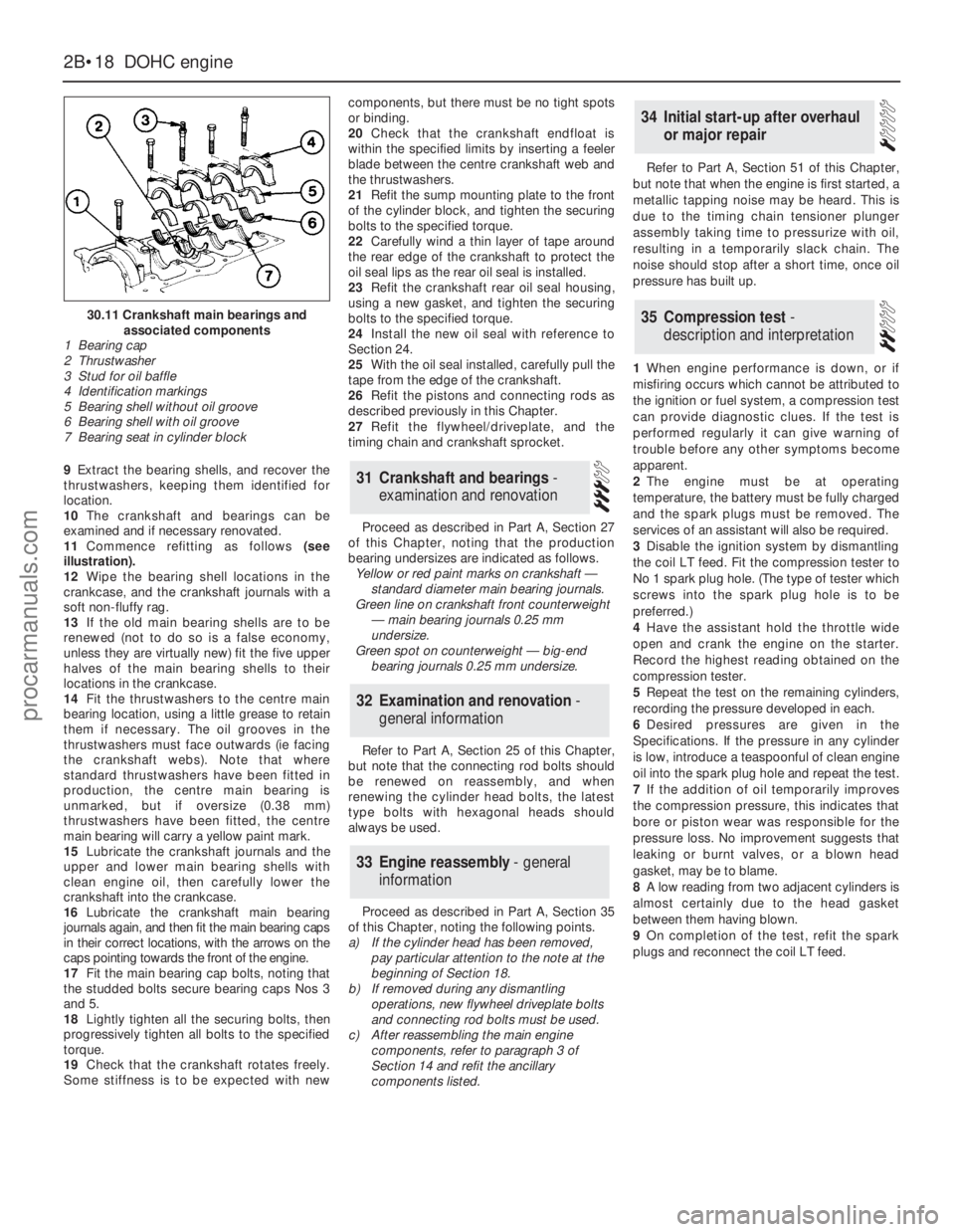

9Extract the bearing shells, and recover the

thrustwashers, keeping them identified for

location.

10The crankshaft and bearings can be

examined and if necessary renovated.

11Commence refitting as follows(see

illustration).

12Wipe the bearing shell locations in the

crankcase, and the crankshaft journals with a

soft non-fluffy rag.

13If the old main bearing shells are to be

renewed (not to do so is a false economy,

unless they are virtually new) fit the five upper

halves of the main bearing shells to their

locations in the crankcase.

14Fit the thrustwashers to the centre main

bearing location, using a little grease to retain

them if necessary. The oil grooves in the

thrustwashers must face outwards (ie facing

the crankshaft webs). Note that where

standard thrustwashers have been fitted in

production, the centre main bearing is

unmarked, but if oversize (0.38 mm)

thrustwashers have been fitted, the centre

main bearing will carry a yellow paint mark.

15Lubricate the crankshaft journals and the

upper and lower main bearing shells with

clean engine oil, then carefully lower the

crankshaft into the crankcase.

16Lubricate the crankshaft main bearing

journals again, and then fit the main bearing caps

in their correct locations, with the arrows on the

caps pointing towards the front of the engine.

17Fit the main bearing cap bolts, noting that

the studded bolts secure bearing caps Nos 3

and 5.

18Lightly tighten all the securing bolts, then

progressively tighten all bolts to the specified

torque.

19Check that the crankshaft rotates freely.

Some stiffness is to be expected with newcomponents, but there must be no tight spots

or binding.

20Check that the crankshaft endfloat is

within the specified limits by inserting a feeler

blade between the centre crankshaft web and

the thrustwashers.

21Refit the sump mounting plate to the front

of the cylinder block, and tighten the securing

bolts to the specified torque.

22Carefully wind a thin layer of tape around

the rear edge of the crankshaft to protect the

oil seal lips as the rear oil seal is installed.

23Refit the crankshaft rear oil seal housing,

using a new gasket, and tighten the securing

bolts to the specified torque.

24Install the new oil seal with reference to

Section 24.

25With the oil seal installed, carefully pull the

tape from the edge of the crankshaft.

26Refit the pistons and connecting rods as

described previously in this Chapter.

27Refit the flywheel/driveplate, and the

timing chain and crankshaft sprocket.

Proceed as described in Part A, Section 27

of this Chapter, noting that the production

bearing undersizes are indicated as follows.

Yellow or red paint marks on crankshaft —

standard diameter main bearing journals.

Green line on crankshaft front counterweight

— main bearing journals 0.25 mm

undersize.

Green spot on counterweight — big-end

bearing journals 0.25 mm undersize.

Refer to Part A, Section 25 of this Chapter,

but note that the connecting rod bolts should

be renewed on reassembly, and when

renewing the cylinder head bolts, the latest

type bolts with hexagonal heads should

always be used.

Proceed as described in Part A, Section 35

of this Chapter, noting the following points.

a)If the cylinder head has been removed,

pay particular attention to the note at the

beginning of Section 18.

b)If removed during any dismantling

operations, new flywheel driveplate bolts

and connecting rod bolts must be used.

c)After reassembling the main engine

components, refer to paragraph 3 of

Section 14 and refit the ancillary

components listed.Refer to Part A, Section 51 of this Chapter,

but note that when the engine is first started, a

metallic tapping noise may be heard. This is

due to the timing chain tensioner plunger

assembly taking time to pressurize with oil,

resulting in a temporarily slack chain. The

noise should stop after a short time, once oil

pressure has built up.

1When engine performance is down, or if

misfiring occurs which cannot be attributed to

the ignition or fuel system, a compression test

can provide diagnostic clues. If the test is

performed regularly it can give warning of

trouble before any other symptoms become

apparent.

2The engine must be at operating

temperature, the battery must be fully charged

and the spark plugs must be removed. The

services of an assistant will also be required.

3Disable the ignition system by dismantling

the coil LT feed. Fit the compression tester to

No 1 spark plug hole. (The type of tester which

screws into the spark plug hole is to be

preferred.)

4Have the assistant hold the throttle wide

open and crank the engine on the starter.

Record the highest reading obtained on the

compression tester.

5Repeat the test on the remaining cylinders,

recording the pressure developed in each.

6Desired pressures are given in the

Specifications. If the pressure in any cylinder

is low, introduce a teaspoonful of clean engine

oil into the spark plug hole and repeat the test.

7If the addition of oil temporarily improves

the compression pressure, this indicates that

bore or piston wear was responsible for the

pressure loss. No improvement suggests that

leaking or burnt valves, or a blown head

gasket, may be to blame.

8A low reading from two adjacent cylinders is

almost certainly due to the head gasket

between them having blown.

9On completion of the test, refit the spark

plugs and reconnect the coil LT feed.

35Compression test -

description and interpretation

34Initial start-up after overhaul

or major repair

33Engine reassembly - general

information

32Examination and renovation -

general information

31Crankshaft and bearings -

examination and renovation

2B•18DOHCengine

30.11 Crankshaft main bearings and

associated components

1 Bearing cap

2 Thrustwasher

3 Stud for oil baffle

4 Identification markings

5 Bearing shell without oil groove

6 Bearing shell with oil groove

7 Bearing seat in cylinder block

procarmanuals.com

Page 65 of 255

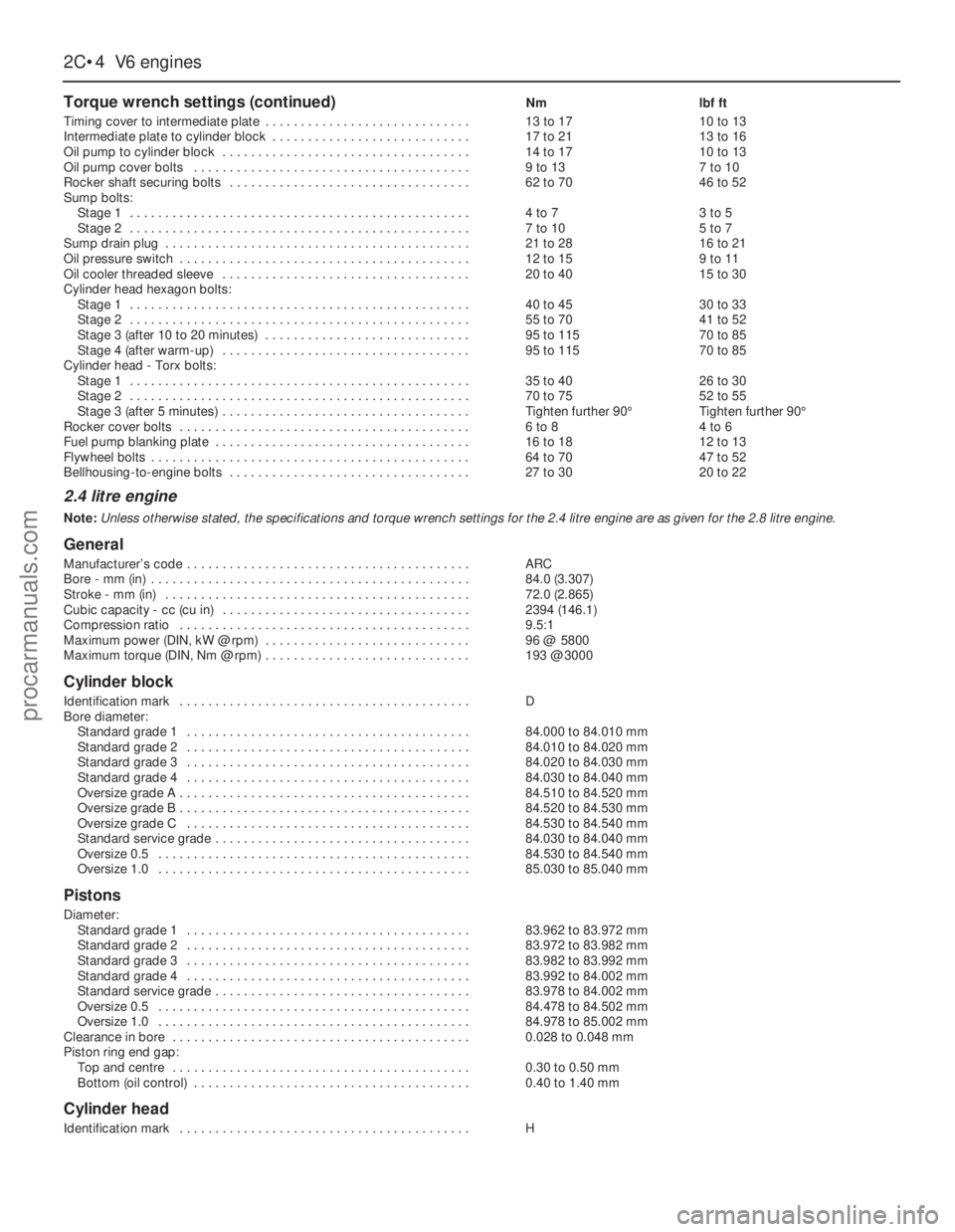

2C•4V6 engines

Torque wrench settings (continued)Nmlbf ft

Timing cover to intermediate plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13 to 1710 to 13

Intermediate plate to cylinder block . . . . . . . . . . . . . . . . . . . . . . . . . . . .17 to 2113 to 16

Oil pump to cylinder block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14 to 1710 to 13

Oil pump cover bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 to 137 to 10

Rocker shaft securing bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62 to 7046 to 52

Sump bolts:

Stage 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 to 73 to 5

Stage 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7 to 105 to 7

Sump drain plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21 to 2816 to 21

Oil pressure switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12 to 159 to 11

Oil cooler threaded sleeve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20 to 4015 to 30

Cylinder head hexagon bolts:

Stage 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40 to 4530 to 33

Stage 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55 to 7041 to 52

Stage 3 (after 10 to 20 minutes) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .95 to 11570 to 85

Stage 4 (after warm-up) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .95 to 11570 to 85

Cylinder head - Torx bolts:

Stage 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35 to 4026 to 30

Stage 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70 to 7552 to 55

Stage 3 (after 5 minutes) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Tighten further 90°Tighten further 90°

Rocker cover bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 to 84 to 6

Fuel pump blanking plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16 to 1812 to 13

Flywheel bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64 to 7047 to 52

Bellhousing-to-engine bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27 to 3020 to 22

2.4 litre engine

Note: Unless otherwise stated, the specifications and torque wrench settings for the 2.4 litre engine are as given for the 2.8 litre engine.

General

Manufacturer’s code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ARC

Bore - mm (in) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84.0 (3.307)

Stroke - mm (in) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72.0 (2.865)

Cubic capacity - cc (cu in) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2394 (146.1)

Compression ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9.5:1

Maximum power (DIN, kW @ rpm) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .96 @ 5800

Maximum torque (DIN, Nm @ rpm) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .193 @ 3000

Cylinder block

Identification mark . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D

Bore diameter:

Standard grade 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84.000 to 84.010 mm

Standard grade 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84.010 to 84.020 mm

Standard grade 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84.020 to 84.030 mm

Standard grade 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84.030 to 84.040 mm

Oversize grade A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84.510 to 84.520 mm

Oversize grade B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84.520 to 84.530 mm

Oversize grade C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84.530 to 84.540 mm

Standard service grade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84.030 to 84.040 mm

Oversize 0.5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84.530 to 84.540 mm

Oversize 1.0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85.030 to 85.040 mm

Pistons

Diameter:

Standard grade 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83.962 to 83.972 mm

Standard grade 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83.972 to 83.982 mm

Standard grade 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83.982 to 83.992 mm

Standard grade 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83.992 to 84.002 mm

Standard service grade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83.978 to 84.002 mm

Oversize 0.5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84.478 to 84.502 mm

Oversize 1.0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84.978 to 85.002 mm

Clearance in bore . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.028 to 0.048 mm

Piston ring end gap:

Top and centre . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.30 to 0.50 mm

Bottom (oil control) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.40 to 1.40 mm

Cylinder head

Identification mark . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .H

procarmanuals.com

Page 67 of 255

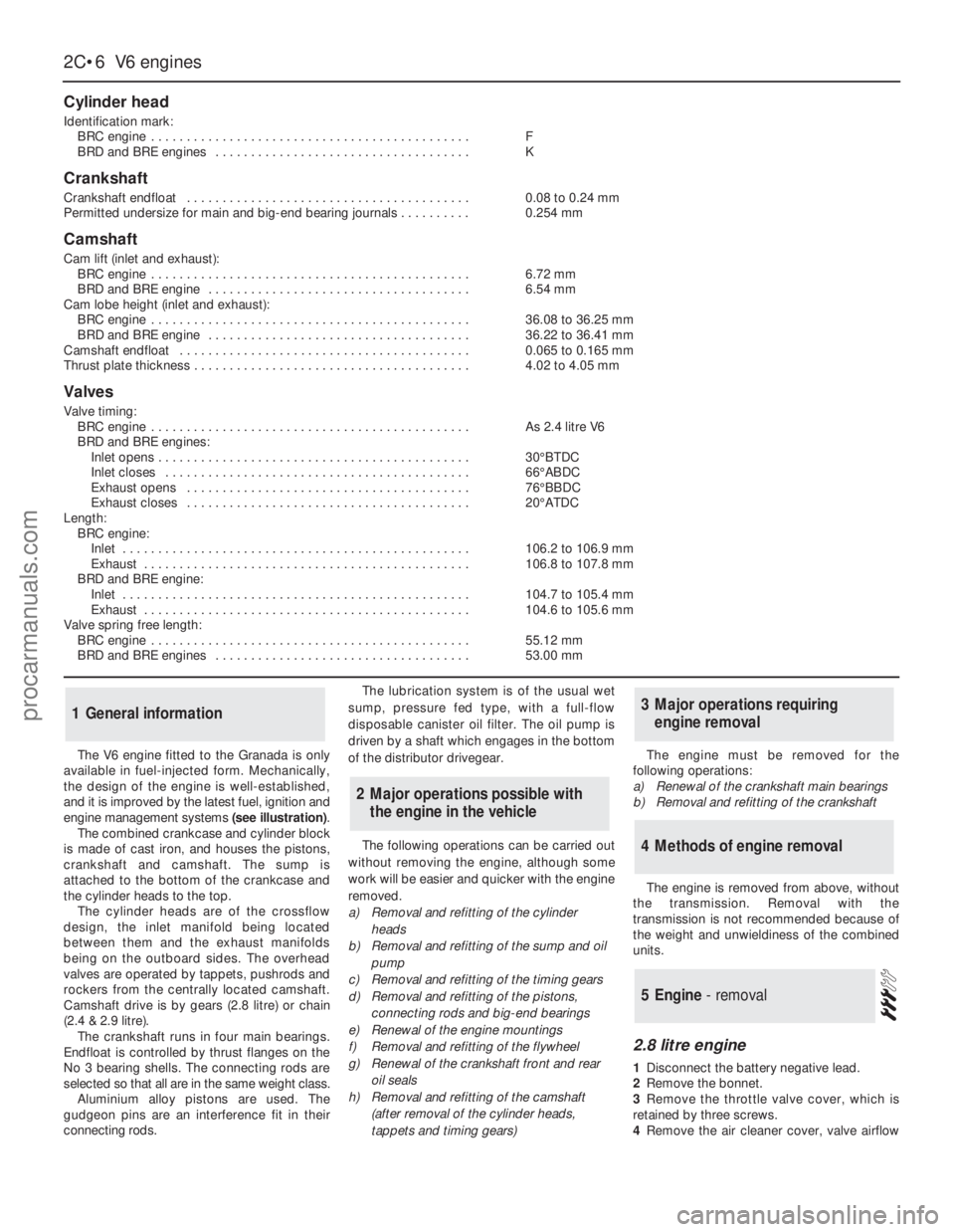

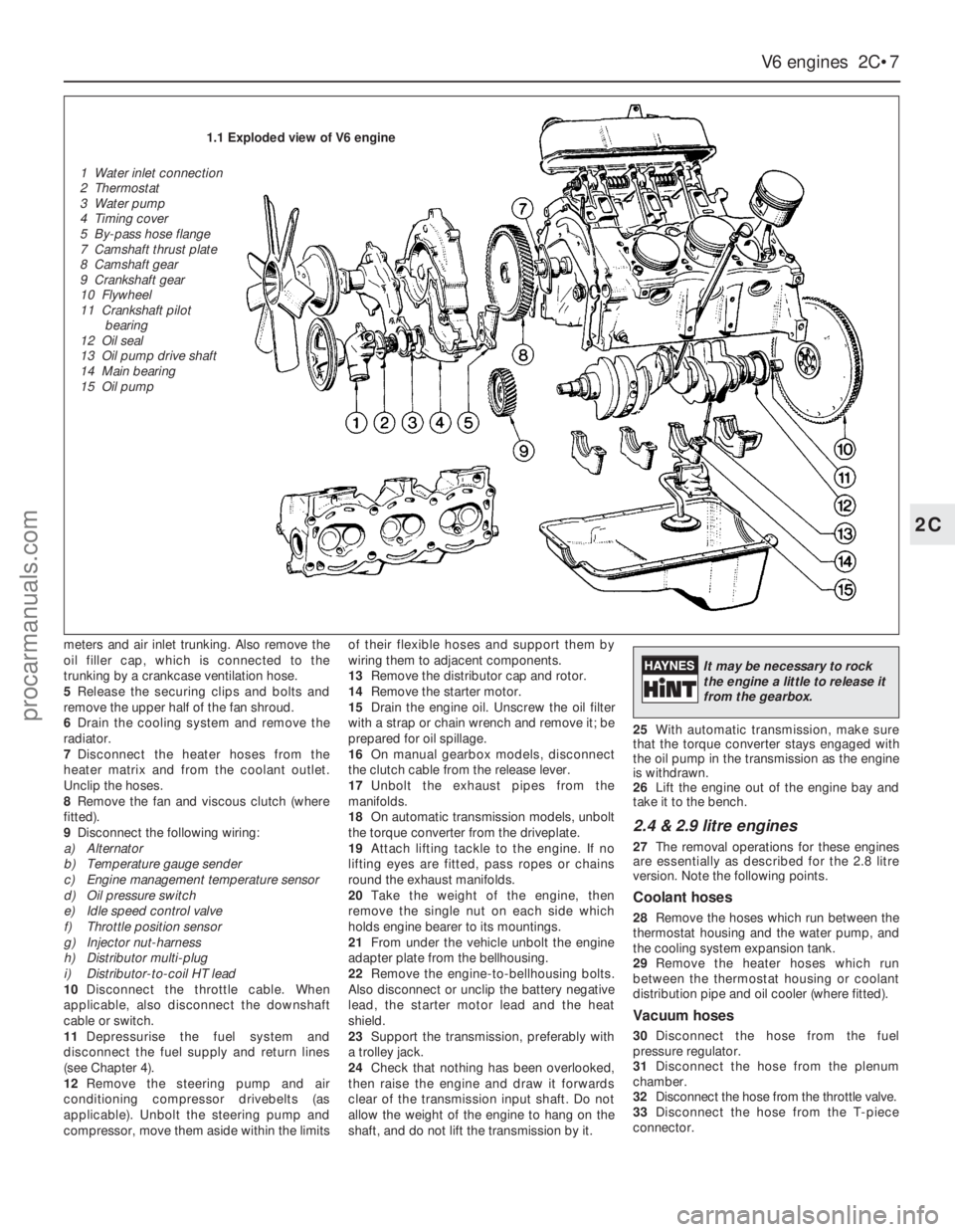

The V6 engine fitted to the Granada is only

available in fuel-injected form. Mechanically,

the design of the engine is well-established,

and it is improved by the latest fuel, ignition and

engine management systems (see illustration).

The combined crankcase and cylinder block

is made of cast iron, and houses the pistons,

crankshaft and camshaft. The sump is

attached to the bottom of the crankcase and

the cylinder heads to the top.

The cylinder heads are of the crossflow

design, the inlet manifold being located

between them and the exhaust manifolds

being on the outboard sides. The overhead

valves are operated by tappets, pushrods and

rockers from the centrally located camshaft.

Camshaft drive is by gears (2.8 litre) or chain

(2.4 & 2.9 litre).

The crankshaft runs in four main bearings.

Endfloat is controlled by thrust flanges on the

No 3 bearing shells. The connecting rods are

selected so that all are in the same weight class.

Aluminium alloy pistons are used. The

gudgeon pins are an interference fit in their

connecting rods.The lubrication system is of the usual wet

sump, pressure fed type, with a full-flow

disposable canister oil filter. The oil pump is

driven by a shaft which engages in the bottom

of the distributor drivegear.

The following operations can be carried out

without removing the engine, although some

work will be easier and quicker with the engine

removed.

a)Removal and refitting of the cylinder

heads

b)Removal and refitting of the sump and oil

pump

c)Removal and refitting of the timing gears

d)Removal and refitting of the pistons,

connecting rods and big-end bearings

e)Renewal of the engine mountings

f)Removal and refitting of the flywheel

g)Renewal of the crankshaft front and rear

oil seals

h)Removal and refitting of the camshaft

(after removal of the cylinder heads,

tappets and timing gears)The engine must be removed for the

following operations:

a)Renewal of the crankshaft main bearings

b)Removal and refitting of the crankshaft

The engine is removed from above, without

the transmission. Removal with the

transmission is not recommended because of

the weight and unwieldiness of the combined

units.

2.8 litre engine

1Disconnect the battery negative lead.

2Remove the bonnet.

3Remove the throttle valve cover, which is

retained by three screws.

4Remove the air cleaner cover, valve airflow

5Engine - removal

4Methods of engine removal

3Major operations requiring

engine removal

2Major operations possible with

the engine in the vehicle

1General information

2C•6V6 engines

Cylinder head

Identification mark:

BRC engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .F

BRD and BRE engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .K

Crankshaft

Crankshaft endfloat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.08 to 0.24 mm

Permitted undersize for main and big-end bearing journals . . . . . . . . . .0.254 mm

Camshaft

Cam lift (inlet and exhaust):

BRC engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6.72mm

BRD and BRE engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6.54 mm

Cam lobe height (inlet and exhaust):

BRC engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36.08 to 36.25 mm

BRD and BRE engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36.22 to 36.41 mm

Camshaft endfloat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.065 to 0.165 mm

Thrust plate thickness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4.02 to 4.05 mm

Valves

Valve timing:

BRC engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .As 2.4 litre V6

BRD and BRE engines:

Inlet opens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30°BTDC

Inlet closes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66°ABDC

Exhaust opens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .76°BBDC

Exhaust closes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20°ATDC

Length:

BRC engine:

Inlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .106.2 to 106.9 mm

Exhaust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .106.8 to 107.8 mm

BRD and BRE engine:

Inlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .104.7 to 105.4 mm

Exhaust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .104.6 to 105.6 mm

Valve spring free length:

BRC engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55.12 mm

BRD and BRE engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53.00 mm

procarmanuals.com

Page 68 of 255

meters and air inlet trunking. Also remove the

oil filler cap, which is connected to the

trunking by a crankcase ventilation hose.

5Release the securing clips and bolts and

remove the upper half of the fan shroud.

6Drain the cooling system and remove the

radiator.

7Disconnect the heater hoses from the

heater matrix and from the coolant outlet.

Unclip the hoses.

8Remove the fan and viscous clutch (where

fitted).

9Disconnect the following wiring:

a)Alternator

b)Temperature gauge sender

c)Engine management temperature sensor

d)Oil pressure switch

e)Idle speed control valve

f)Throttle position sensor

g)Injector nut-harness

h)Distributor multi-plug

i)Distributor-to-coil HT lead

10Disconnect the throttle cable. When

applicable, also disconnect the downshaft

cable or switch.

11Depressurise the fuel system and

disconnect the fuel supply and return lines

(see Chapter 4).

12Remove the steering pump and air

conditioning compressor drivebelts (as

applicable). Unbolt the steering pump and

compressor, move them aside within the limitsof their flexible hoses and support them by

wiring them to adjacent components.

13Remove the distributor cap and rotor.

14Remove the starter motor.

15Drain the engine oil. Unscrew the oil filter

with a strap or chain wrench and remove it; be

prepared for oil spillage.

16On manual gearbox models, disconnect

the clutch cable from the release lever.

17Unbolt the exhaust pipes from the

manifolds.

18On automatic transmission models, unbolt

the torque converter from the driveplate.

19Attach lifting tackle to the engine. If no

lifting eyes are fitted, pass ropes or chains

round the exhaust manifolds.

20Take the weight of the engine, then

remove the single nut on each side which

holds engine bearer to its mountings.

21From under the vehicle unbolt the engine

adapter plate from the bellhousing.

22Remove the engine-to-bellhousing bolts.

Also disconnect or unclip the battery negative

lead, the starter motor lead and the heat

shield.

23Support the transmission, preferably with

a trolley jack.

24Check that nothing has been overlooked,

then raise the engine and draw it forwards

clear of the transmission input shaft. Do not

allow the weight of the engine to hang on the

shaft, and do not lift the transmission by it.25With automatic transmission, make sure

that the torque converter stays engaged with

the oil pump in the transmission as the engine

is withdrawn.

26Lift the engine out of the engine bay and

take it to the bench.

2.4 & 2.9 litre engines

27The removal operations for these engines

are essentially as described for the 2.8 litre

version. Note the following points.

Coolant hoses

28Remove the hoses which run between the

thermostat housing and the water pump, and

the cooling system expansion tank.

29Remove the heater hoses which run

between the thermostat housing or coolant

distribution pipe and oil cooler (where fitted).

Vacuum hoses

30Disconnect the hose from the fuel

pressure regulator.

31Disconnect the hose from the plenum

chamber.

32Disconnect the hose from the throttle valve.

33Disconnect the hose from the T-piece

connector.

V6 engines 2C•7

2C

1.1 Exploded view of V6 engine

1 Water inlet connection

2 Thermostat

3 Water pump

4 Timing cover

5 By-pass hose flange

7 Camshaft thrust plate

8 Camshaft gear

9 Crankshaft gear

10 Flywheel

11 Crankshaft pilot

bearing

12 Oil seal

13 Oil pump drive shaft

14 Main bearing

15 Oil pump

It may be necessary to rock

the engine a little to release it

from the gearbox.

procarmanuals.com

Page 69 of 255

Other items

34Disconnect the throttle cable from the

operating lever and bracket.

35Disconnect the right-hand exhaust

downpipe from the manifold then remove the

starter motor, the oil filter, and disconnect the

left-hand exhaust downpipe, in that order.

Refer to Part A, Section 8, paragraphs 1 to 8

of this Chapter.

Cylinder head bolts on the V6 engine may

be conventional (hexagon-headed) or Torx

type. The appropriate Torx key will be needed

to deal with the latter.

Before dismantling the engine into its main

components, the following ancillaries can be

removed. The actual items removed, and the

sequence of removal, will depend on the work

to be done.

Distributor and bracket

Spark plugs

Inlet manifold and associated items

Exhaust manifolds

Clutch

Alternator and bracket

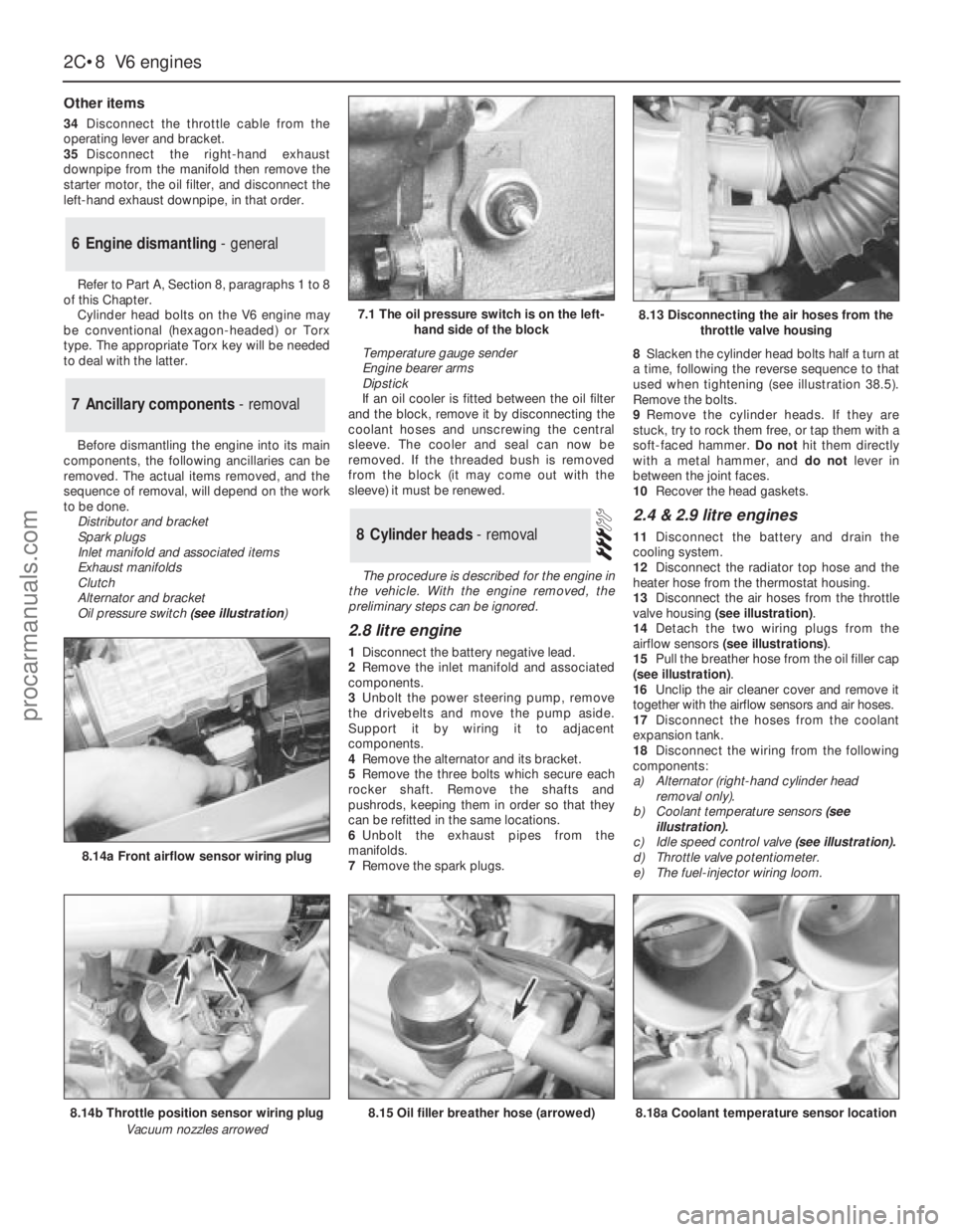

Oil pressure switch(see illustration) Temperature gauge sender

Engine bearer arms

Dipstick

If an oil cooler is fitted between the oil filter

and the block, remove it by disconnecting the

coolant hoses and unscrewing the central

sleeve. The cooler and seal can now be

removed. If the threaded bush is removed

from the block (it may come out with the

sleeve) it must be renewed.

The procedure is described for the engine in

the vehicle. With the engine removed, the

preliminary steps can be ignored.

2.8 litre engine

1Disconnect the battery negative lead.

2Remove the inlet manifold and associated

components.

3Unbolt the power steering pump, remove

the drivebelts and move the pump aside.

Support it by wiring it to adjacent

components.

4Remove the alternator and its bracket.

5Remove the three bolts which secure each

rocker shaft. Remove the shafts and

pushrods, keeping them in order so that they

can be refitted in the same locations.

6Unbolt the exhaust pipes from the

manifolds.

7Remove the spark plugs.8Slacken the cylinder head bolts half a turn at

a time, following the reverse sequence to that

used when tightening (see illustration 38.5).

Remove the bolts.

9Remove the cylinder heads. If they are

stuck, try to rock them free, or tap them with a

soft-faced hammer. Do nothit them directly

with a metal hammer, and do notlever in

between the joint faces.

10Recover the head gaskets.

2.4 & 2.9 litre engines

11Disconnect the battery and drain the

cooling system.

12Disconnect the radiator top hose and the

heater hose from the thermostat housing.

13Disconnect the air hoses from the throttle

valve housing (see illustration).

14Detach the two wiring plugs from the

airflow sensors (see illustrations).

15Pull the breather hose from the oil filler cap

(see illustration).

16Unclip the air cleaner cover and remove it

together with the airflow sensors and air hoses.

17Disconnect the hoses from the coolant

expansion tank.

18Disconnect the wiring from the following

components:

a)Alternator (right-hand cylinder head

removal only).

b)Coolant temperature sensors(see

illustration).

c)Idle speed control valve (see illustration).

d)Throttle valve potentiometer.

e)The fuel-injector wiring loom.8Cylinder heads - removal

7Ancillary components - removal

6Engine dismantling - general

2C•8V6 engines

7.1 The oil pressure switch is on the left-

hand side of the block

8.14b Throttle position sensor wiring plug

Vacuum nozzles arrowed

8.14a Front airflow sensor wiring plug

8.15 Oil filler breather hose (arrowed)8.18a Coolant temperature sensor location

8.13 Disconnecting the air hoses from the

throttle valve housing

procarmanuals.com

Page 70 of 255

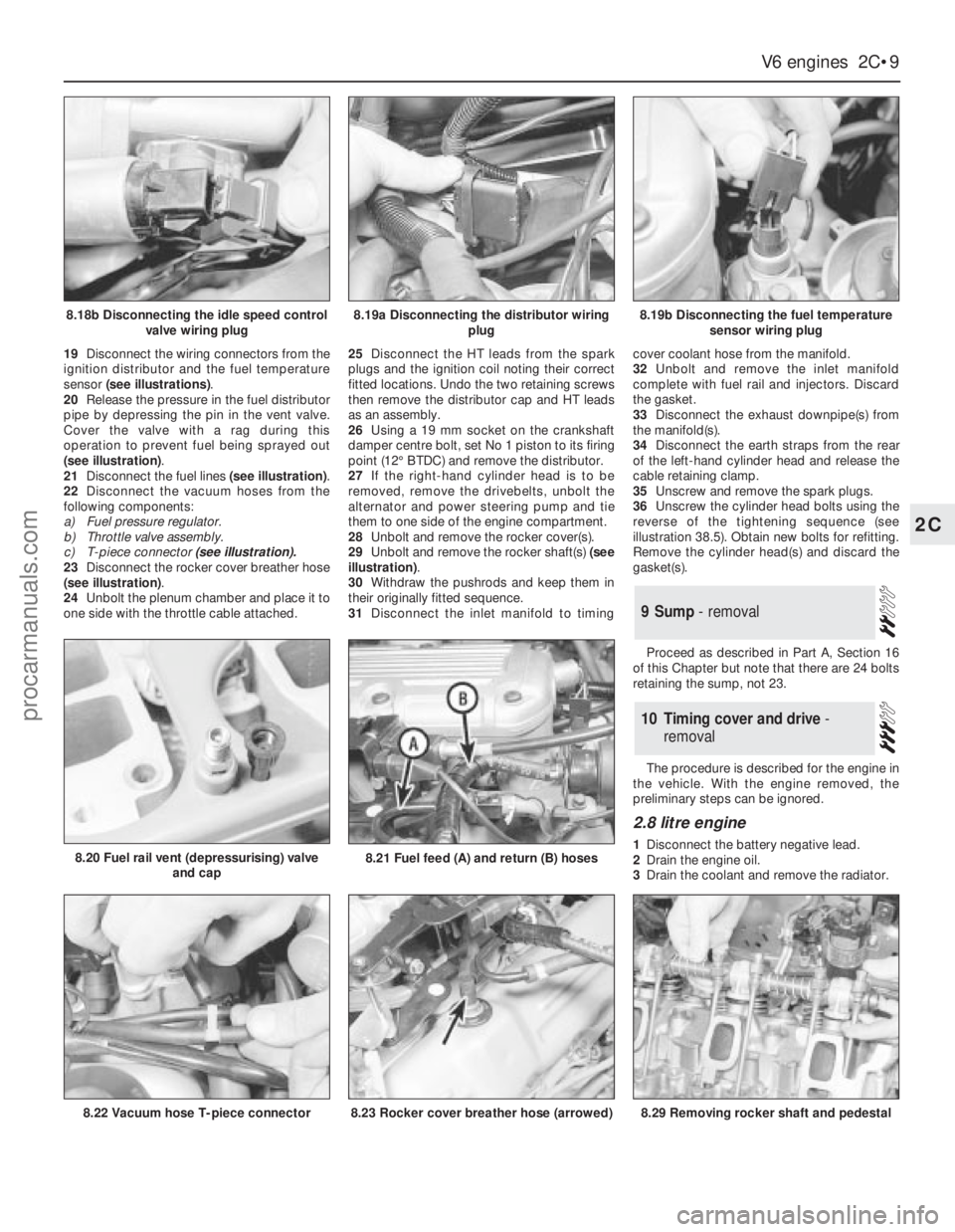

19Disconnect the wiring connectors from the

ignition distributor and the fuel temperature

sensor (see illustrations).

20Release the pressure in the fuel distributor

pipe by depressing the pin in the vent valve.

Cover the valve with a rag during this

operation to prevent fuel being sprayed out

(see illustration).

21Disconnect the fuel lines (see illustration).

22Disconnect the vacuum hoses from the

following components:

a)Fuel pressure regulator.

b)Throttle valve assembly.

c)T-piece connector (see illustration).

23Disconnect the rocker cover breather hose

(see illustration).

24Unbolt the plenum chamber and place it to

one side with the throttle cable attached.25Disconnect the HT leads from the spark

plugs and the ignition coil noting their correct

fitted locations. Undo the two retaining screws

then remove the distributor cap and HT leads

as an assembly.

26Using a 19 mm socket on the crankshaft

damper centre bolt, set No 1 piston to its firing

point (12°BTDC) and remove the distributor.

27If the right-hand cylinder head is to be

removed, remove the drivebelts, unbolt the

alternator and power steering pump and tie

them to one side of the engine compartment.

28Unbolt and remove the rocker cover(s).

29Unbolt and remove the rocker shaft(s) (see

illustration).

30Withdraw the pushrods and keep them in

their originally fitted sequence.

31Disconnect the inlet manifold to timingcover coolant hose from the manifold.

32Unbolt and remove the inlet manifold

complete with fuel rail and injectors. Discard

the gasket.

33Disconnect the exhaust downpipe(s) from

the manifold(s).

34Disconnect the earth straps from the rear

of the left-hand cylinder head and release the

cable retaining clamp.

35Unscrew and remove the spark plugs.

36Unscrew the cylinder head bolts using the

reverse of the tightening sequence (see

illustration 38.5). Obtain new bolts for refitting.

Remove the cylinder head(s) and discard the

gasket(s).

Proceed as described in Part A, Section 16

of this Chapter but note that there are 24 bolts

retaining the sump, not 23.

The procedure is described for the engine in

the vehicle. With the engine removed, the

preliminary steps can be ignored.

2.8 litre engine

1Disconnect the battery negative lead.

2Drain the engine oil.

3Drain the coolant and remove the radiator.

10Timing cover and drive -

removal

9Sump - removal

V6 engines 2C•9

2C

8.18b Disconnecting the idle speed control

valve wiring plug8.19a Disconnecting the distributor wiring

plug8.19b Disconnecting the fuel temperature

sensor wiring plug

8.22 Vacuum hose T-piece connector

8.20 Fuel rail vent (depressurising) valve

and cap8.21 Fuel feed (A) and return (B) hoses

8.23 Rocker cover breather hose (arrowed)8.29 Removing rocker shaft and pedestal

procarmanuals.com

Page 81 of 255

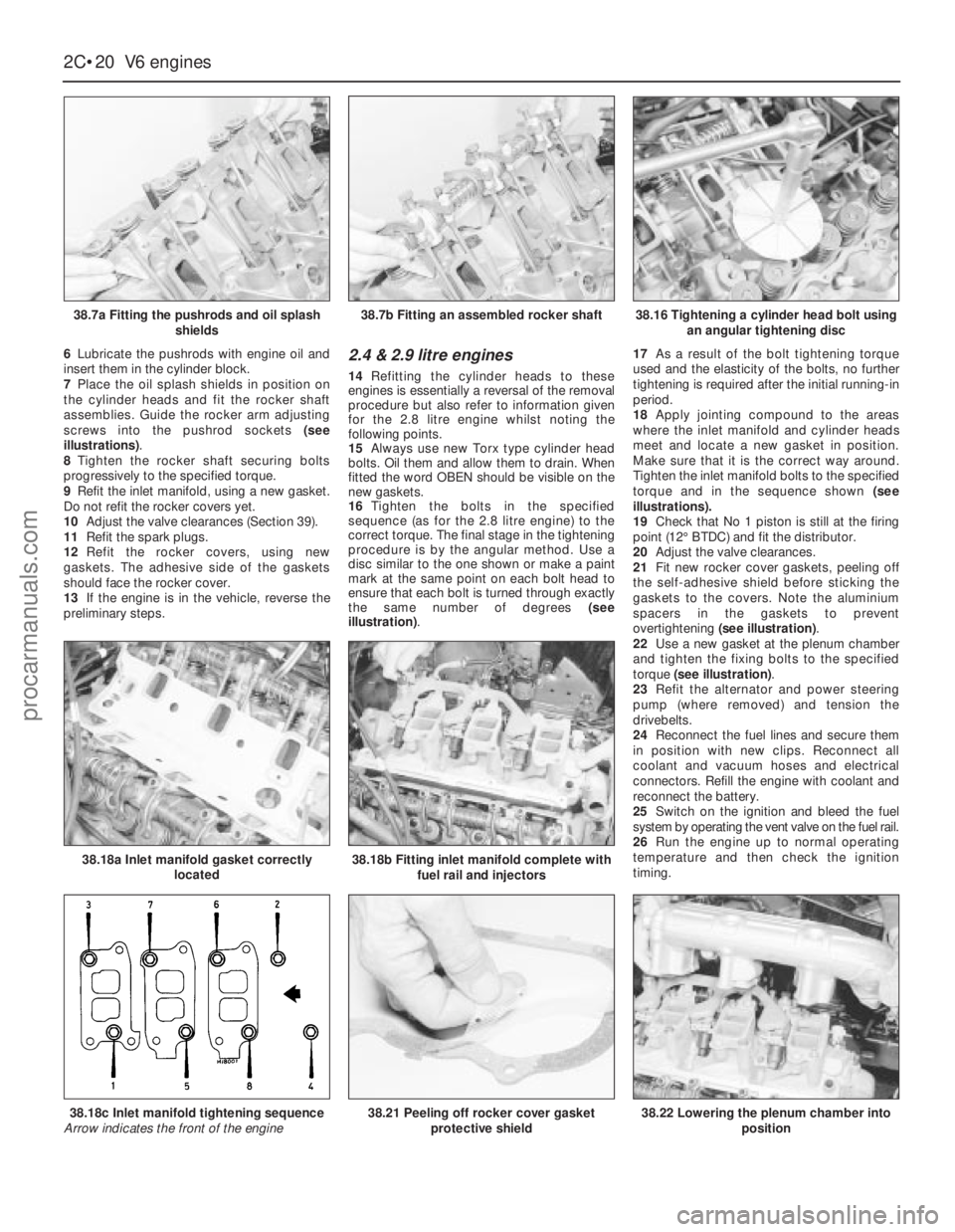

6Lubricate the pushrods with engine oil and

insert them in the cylinder block.

7Place the oil splash shields in position on

the cylinder heads and fit the rocker shaft

assemblies. Guide the rocker arm adjusting

screws into the pushrod sockets (see

illustrations).

8Tighten the rocker shaft securing bolts

progressively to the specified torque.

9Refit the inlet manifold, using a new gasket.

Do not refit the rocker covers yet.

10Adjust the valve clearances (Section 39).

11Refit the spark plugs.

12Refit the rocker covers, using new

gaskets. The adhesive side of the gaskets

should face the rocker cover.

13If the engine is in the vehicle, reverse the

preliminary steps.2.4 & 2.9 litre engines

14Refitting the cylinder heads to these

engines is essentially a reversal of the removal

procedure but also refer to information given

for the 2.8 litre engine whilstnoting the

following points.

15Always use new Torx type cylinder head

bolts. Oil them and allow them to drain. When

fitted the word OBEN should be visible on the

new gaskets.

16Tighten the bolts in the specified

sequence (as for the 2.8 litre engine) to the

correct torque. The final stage in the tightening

procedure is by the angular method. Use a

disc similar to the one shown or make a paint

mark at the same point on each bolt head to

ensure that each bolt is turned through exactly

the same number of degrees (see

illustration).17As a result of the bolt tightening torque

used and the elasticity of the bolts, no further

tightening is required after the initial running-in

period.

18Apply jointing compound to the areas

where the inlet manifold and cylinder heads

meet and locate a new gasket in position.

Make sure that it is the correct way around.

Tighten the inlet manifold bolts to the specified

torque and in the sequence shown (see

illustrations).

19Check that No 1 piston is still at the firing

point (12°BTDC) and fit the distributor.

20Adjust the valve clearances.

21Fit new rocker cover gaskets, peeling off

the self-adhesive shield before sticking the

gaskets to the covers. Note the aluminium

spacers in the gaskets to prevent

overtightening (see illustration).

22Use a new gasket at the plenum chamber

and tighten the fixing bolts to the specified

torque (see illustration).

23Refit the alternator and power steering

pump (where removed) and tension the

drivebelts.

24Reconnect the fuel lines and secure them

in position with new clips. Reconnect all

coolant and vacuum hoses and electrical

connectors. Refill the engine with coolant and

reconnect the battery.

25Switch on the ignition and bleed the fuel

system by operating the vent valve on the fuel rail.

26Run the engine up to normal operating

temperature and then check the ignition

timing.

2C•20V6 engines

38.7a Fitting the pushrods and oil splash

shields

38.18a Inlet manifold gasket correctly

located38.18b Fitting inlet manifold complete with

fuel rail and injectors

38.22 Lowering the plenum chamber into

position38.18c Inlet manifold tightening sequence

Arrow indicates the front of the engine38.21 Peeling off rocker cover gasket

protective shield

38.7b Fitting an assembled rocker shaft38.16 Tightening a cylinder head bolt using

an angular tightening disc

procarmanuals.com

Page 82 of 255

27The inlet manifold bolts should be

retightened to the specified torque in the correct

sequence. This will mean disconnecting the air

hoses from the throttle valve housing, the

vacuum hose from the left-hand rocker cover,

and the wiring connector from the idle speed

control valve and throttle valve potentiometer.

Remove the plenum chamber, place it to one

side, then release the fuel rail bolts but do not

disconnect the fuel pipes. It may also be

necessary to remove the distributor again to

gain access to one of the bolts.

See Chapter 1, Section 23.

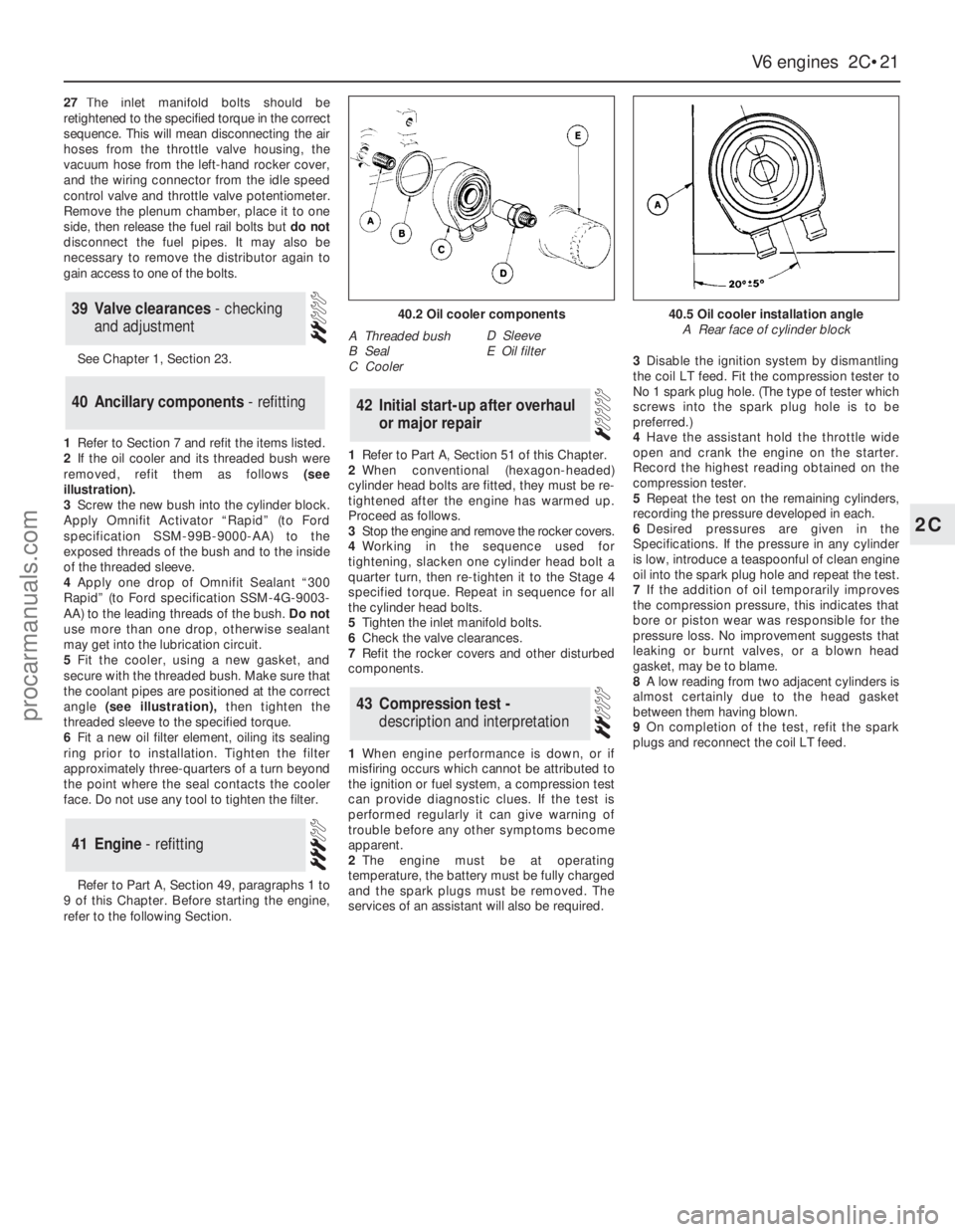

1Refer to Section 7 and refit the items listed.

2If the oil cooler and its threaded bush were

removed, refit them as follows (see

illustration).

3Screw the new bush into the cylinder block.

Apply Omnifit Activator “Rapid” (to Ford

specification SSM-99B-9000-AA) to the

exposed threads of the bush and to the inside

of the threaded sleeve.

4Apply one drop of Omnifit Sealant “300

Rapid” (to Ford specification SSM-4G-9003-

AA) to the leading threads of the bush.Do not

use more than one drop, otherwise sealant

may get into the lubrication circuit.

5Fit the cooler, using a new gasket, and

secure with the threaded bush. Make sure that

the coolant pipes are positioned at the correct

angle (see illustration),then tighten the

threaded sleeve to the specified torque.

6Fit a new oil filter element, oiling its sealing

ring prior to installation. Tighten the filter

approximately three-quarters of a turn beyond

the point where the seal contacts the cooler

face. Do not use any tool to tighten the filter.

Refer to Part A, Section 49, paragraphs 1 to

9 of this Chapter. Before starting the engine,

refer to the following Section.1Refer to Part A, Section 51 of this Chapter.

2When conventional (hexagon-headed)

cylinder head bolts are fitted, they must be re-

tightened after the engine has warmed up.

Proceed as follows.

3Stop the engine and remove the rocker covers.

4Working in the sequence used for

tightening, slacken one cylinder head bolt a

quarter turn, then re-tighten it to the Stage 4

specified torque. Repeat in sequence for all

the cylinder head bolts.

5Tighten the inlet manifold bolts.

6Check the valve clearances.

7Refit the rocker covers and other disturbed

components.

1When engine performance is down, or if

misfiring occurs which cannot be attributed to

the ignition or fuel system, a compression test

can provide diagnostic clues. If the test is

performed regularly it can give warning of

trouble before any other symptoms become

apparent.

2The engine must be at operating

temperature, the battery must be fully charged

and the spark plugs must be removed. The

services of an assistant will also be required.3Disable the ignition system by dismantling

the coil LT feed. Fit the compression tester to

No 1 spark plug hole. (The type of tester which

screws into the spark plug hole is to be

preferred.)

4Have the assistant hold the throttle wide

open and crank the engine on the starter.

Record the highest reading obtained on the

compression tester.

5Repeat the test on the remaining cylinders,

recording the pressure developed in each.

6Desired pressures are given in the

Specifications. If the pressure in any cylinder

is low, introduce a teaspoonful of clean engine

oil into the spark plug hole and repeat the test.

7If the addition of oil temporarily improves

the compression pressure, this indicates that

bore or piston wear was responsible for the

pressure loss. No improvement suggests that

leaking or burnt valves, or a blown head

gasket, may be to blame.

8A low reading from two adjacent cylinders is

almost certainly due to the head gasket

between them having blown.

9On completion of the test, refit the spark

plugs and reconnect the coil LT feed.

43Compression test -

description and interpretation

42Initial start-up after overhaul

or major repair

41Engine - refitting

40Ancillary components - refitting

39Valve clearances - checking

and adjustment

V6 engines 2C•21

2C

40.2 Oil cooler components

A Threaded bush

B Seal

C CoolerD Sleeve

E Oil filter

40.5 Oil cooler installation angle

A Rear face of cylinder block

procarmanuals.com

Page 84 of 255

Chapter 3

Cooling, heating and ventilation systems

Air conditioning system - component renewal . . . . . . . . . . . . . . . . .22

Cooling fan switch - removal and refitting . . . . . . . . . . . . . . . . . . . .16

Cooling system - draining . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Cooling system - filling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Cooling system - flushing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Electric cooling fan(s) - removal and refitting . . . . . . . . . . . . . . . . . .10

Expansion tank - removal and refitting . . . . . . . . . . . . . . . . . . . . . . .14

General information and precautions . . . . . . . . . . . . . . . . . . . . . . . . .1

Heater assembly - removal and refitting . . . . . . . . . . . . . . . . . . . . .19

Heater control cables - removal and refitting . . . . . . . . . . . . . . . . . .18

Heater controls - removal and refitting . . . . . . . . . . . . . . . . . . . . . . .17

Heater coolant valve - removal and refitting . . . . . . . . . . . . . . . . . .21Heater matrix - dismantling and reassembly . . . . . . . . . . . . . . . . . .20

Radiator - inspection and repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Radiator - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Temperature gauge sender - removal and refitting . . . . . . . . . . . . .15

Thermostat - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Thermostat - testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Viscous-coupled fan - removal and refitting . . . . . . . . . . . . . . . . . . .9

Water pump/alternator drivebelt(s) - inspection, renewal and

adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Water pump/alternator drivebelt tensioner - removal and refitting .13

Water pump - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . .11

General

System type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Sealed, pressurised, thermostatically controlled

Fan type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Mechanical temperature-sensitive viscous clutch, or electric

(DOHC)

Coolant

Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . See “Lubricants and fluids”

Capacity:

SOHC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8.0 litres (14.1 pints) approx

DOHC:

Carburettor models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.9 litres (13.9 pints) approx

Fuel injection models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.3 litres (12.8 pints) approx

V6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8.5 litres (15.0 pints) approx

Specific gravity at 45 to 50% antifreeze concentration . . . . . . . . . . . . . 1.069 to 1.077

Expansion tank cap

Opening pressure:

SOHC and V6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.85 to 1.10 bar

DOHC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.0 to 1.4 bar

Thermostat

Nominal rating:.

SOHC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88°C (190°F)

DOHC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102°C (216°F)

V6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82°C (180°F)

Actual opening temperature:

SOHC and DOHC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85° to 89°C (185° to 192°F)

V6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79° to 83°C (174° to 181°F)

Water pump drivebelt

Deflection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 mm (0.4 in) approx under normal fingertip pressure at mid-

point of longest run

3•1

Easy,suitable for

novice with little

experienceFairly easy,suitable

for beginner with

some experienceFairly difficult,

suitable for competent

DIY mechanicDifficult,suitable for

experienced DIY

mechanicVery difficult,

suitable for expert

DIY or professional

Degrees of difficulty

Specifications Contents

3

procarmanuals.com