light FORD GRANADA 1985 Service Service Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1985, Model line: GRANADA, Model: FORD GRANADA 1985Pages: 255, PDF Size: 14.98 MB

Page 132 of 255

Note: Hydraulic fluid is poisonous; wash off

immediately and thoroughly in the case of skin

contact and seek immediate medical advice if

any fluid is swallowed or gets into the eyes.

Certain types of hydraulic fluid are inflammable

and may ignite when allowed into contact with

hot components; when servicing any hydraulic

system it is safest to assume that the fluid is

inflammable and to take precautions against

the risk of fire as though it is petrol that is

being handled. Finally, it is hygroscopic (it

absorbs moisture from the air) old fluid may be

contaminated and unfit for further use. When

topping-up or renewing the fluid, always use

the recommended type and ensure that it

comes from a freshly-opened sealed container

1Bleeding is necessary whenever air has

entered the hydraulic system - for instance

after component renewal. Because the

hydraulic circuits are split, if only the front or

rear circuit has been disturbed it will normally

only be necessary to bleed the front or rear

calipers. If the hydraulic unit has been

disturbed or the fluid level has been allowed to

fall so low that air has entered the system,

both front and rear circuits must be bled,

starting with the front

2The services of an assistant will be required.

As far as is known, pressure bleeding or other

“one-man” equipment cannot be used. In

addition a supply of fresh brake fluid of the

correct type will be needed, together with a

length of flexible tube to fit the bleed screws

and a clean glass or plastic container.

3Do not allow the hydraulic unit pump motor

to run for more than two minutes at a time. The

motor must be allowed to cool (with the

ignition off) for at least ten minutes after each

two minute spell of running.

4Remember that brake fluid is poisonous and

that the rear brake hydraulic system may be

under considerable pressure. Take care not to

allow hydraulic fluid to spray into the face or

eyes.

5Keep the reservoir topped up to the MAX

mark during bleeding.

6Discard the fluid bled out of the system as it

is unfit for re-use.

Models before April 1992

Front brakes

7Remove the dust cap (if fitted) from the left-

hand caliper bleed screw. Slacken the bleed

screw, then nip it up again. Make sure that the

ignition is off.8Fit the bleed tube over the bleed screw.

Place the other end of the tube in the bleed jar

(glass or plastic container). Pour sufficient

brake fluid into the jar to cover the end of the

tube.

9Open the bleed screw one full turn. Have

the assistant depress the brake pedal as far as

it will go, and hold it depressed. Tighten the

bleed screw, then tell the assistant to release

the pedal.

10Repeat paragraph 9 until clean fluid, free

of air bubbles, flows from the bleed screw

during the downstrokes. Remember to keep

the fluid reservoir topped up.

11Repeat the operations on the right-hand

caliper. Refit the bleed screw dust caps (if

applicable) on completion.

Rear brakes

12Remove the dust cap (if fitted) from the

rear left-hand caliper bleed screw. Open the

bleed screw one full turn.

13Fit the bleed tube over the bleed screw.

Place the other end of the tube in the bleed jar

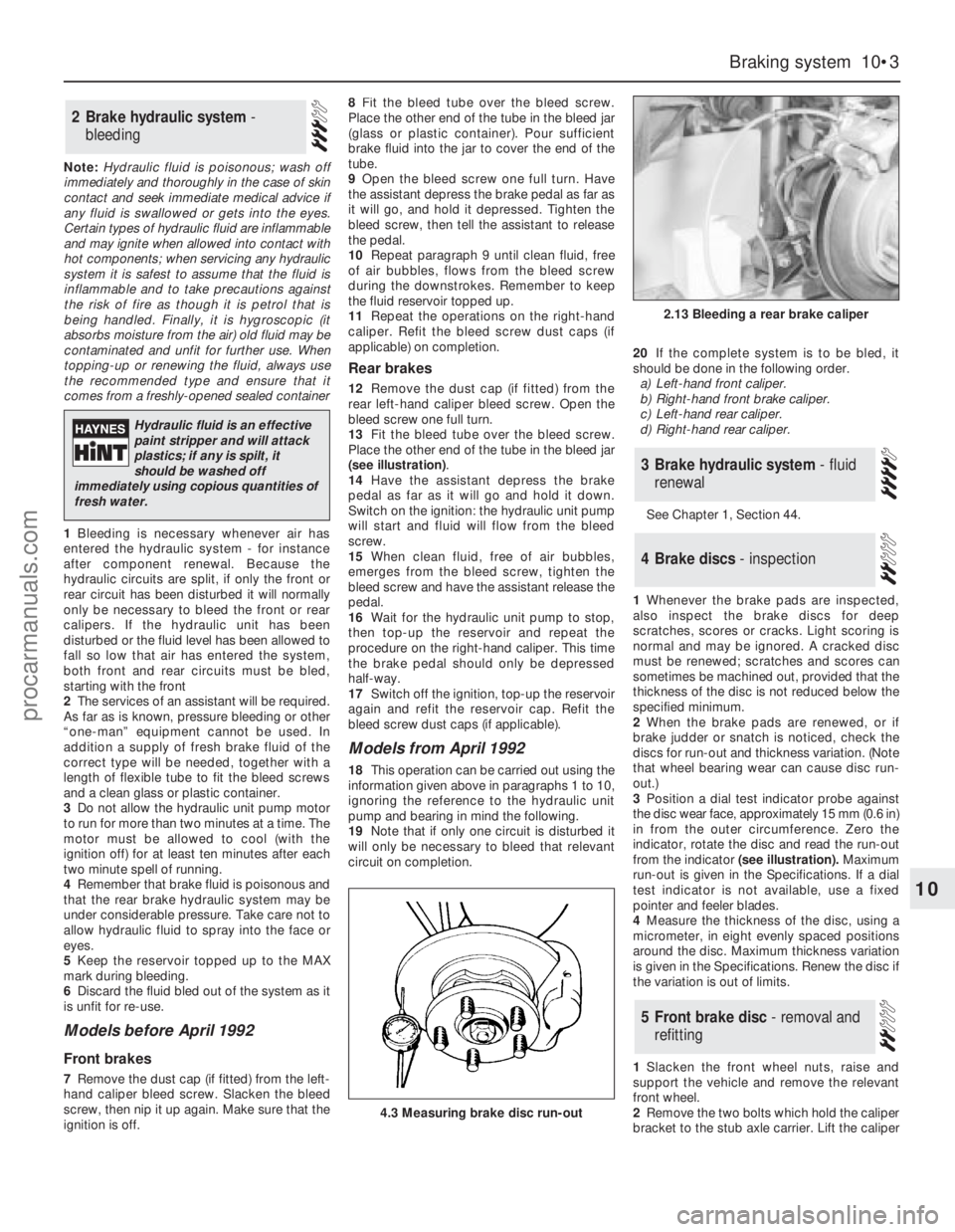

(see illustration).

14Have the assistant depress the brake

pedal as far as it will go and hold it down.

Switch on the ignition: the hydraulic unit pump

will start and fluid will flow from the bleed

screw.

15When clean fluid, free of air bubbles,

emerges from the bleed screw, tighten the

bleed screw and have the assistant release the

pedal.

16Wait for the hydraulic unit pump to stop,

then top-up the reservoir and repeat the

procedure on the right-hand caliper. This time

the brake pedal should only be depressed

half-way.

17Switch off the ignition, top-up the reservoir

again and refit the reservoir cap. Refit the

bleed screw dust caps (if applicable).

Models from April 1992

18This operation can be carried out using the

information given above inparagraphs 1 to 10,

ignoring the reference to the hydraulic unit

pump and bearing in mind the following.

19Note that if only one circuit is disturbed it

will only be necessary to bleed that relevant

circuit on completion.20If the complete system is to be bled, it

should be done in the following order.

a)Left-hand front caliper.

b)Right-hand front brake caliper.

c)Left-hand rear caliper.

d)Right-hand rear caliper.

See Chapter 1, Section 44.

1Whenever the brake pads are inspected,

also inspect the brake discs for deep

scratches, scores or cracks. Light scoring is

normal and may be ignored. A cracked disc

must be renewed; scratches and scores can

sometimes be machined out, provided that the

thickness of the disc is not reduced below the

specified minimum.

2When the brake pads are renewed, or if

brake judder or snatch is noticed, check the

discs for run-out and thickness variation. (Note

that wheel bearing wear can cause disc run-

out.)

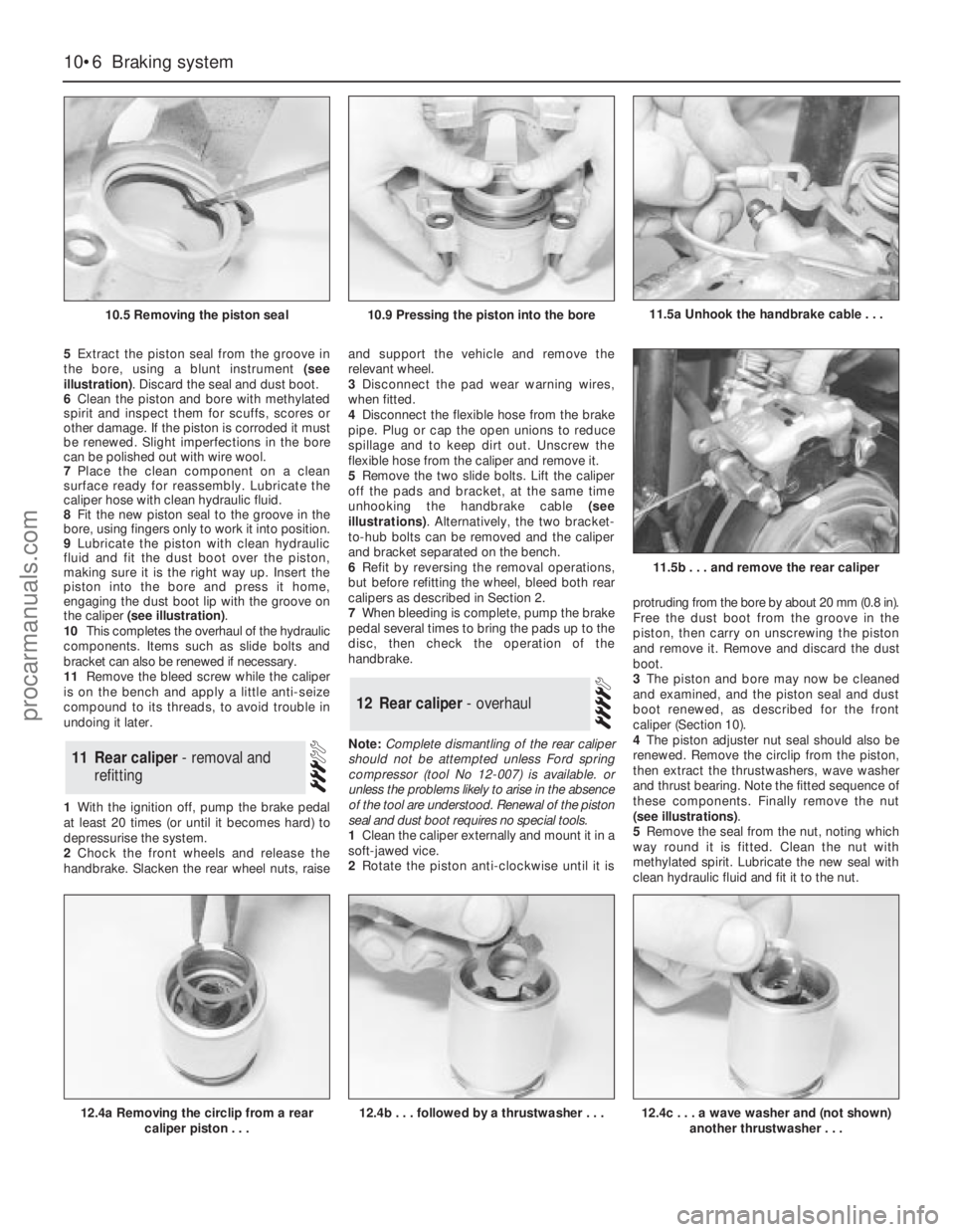

3Position a dial test indicator probe against

the disc wear face, approximately 15 mm (0.6 in)

in from the outer circumference. Zero the

indicator, rotate the disc and read the run-out

from the indicator(see illustration).Maximum

run-out is given in the Specifications. If a dial

test indicator is not available, use a fixed

pointer and feeler blades.

4Measure the thickness of the disc, using a

micrometer, in eight evenly spaced positions

around the disc. Maximum thickness variation

is given in the Specifications. Renew the disc if

the variation is out of limits.

1Slacken the front wheel nuts, raise and

support the vehicle and remove the relevant

front wheel.

2Remove the two bolts which hold the caliper

bracket to the stub axle carrier. Lift the caliper

5Front brake disc - removal and

refitting

4Brake discs - inspection

3Brake hydraulic system - fluid

renewal

2Brake hydraulic system -

bleeding

Braking system 10•3

10

2.13 Bleeding a rear brake caliper

4.3 Measuring brake disc run-out

Hydraulic fluid is an effective

paint stripper and will attack

plastics; if any is spilt, it

should be washed off

immediately using copious quantities of

fresh water.

procarmanuals.com

Page 135 of 255

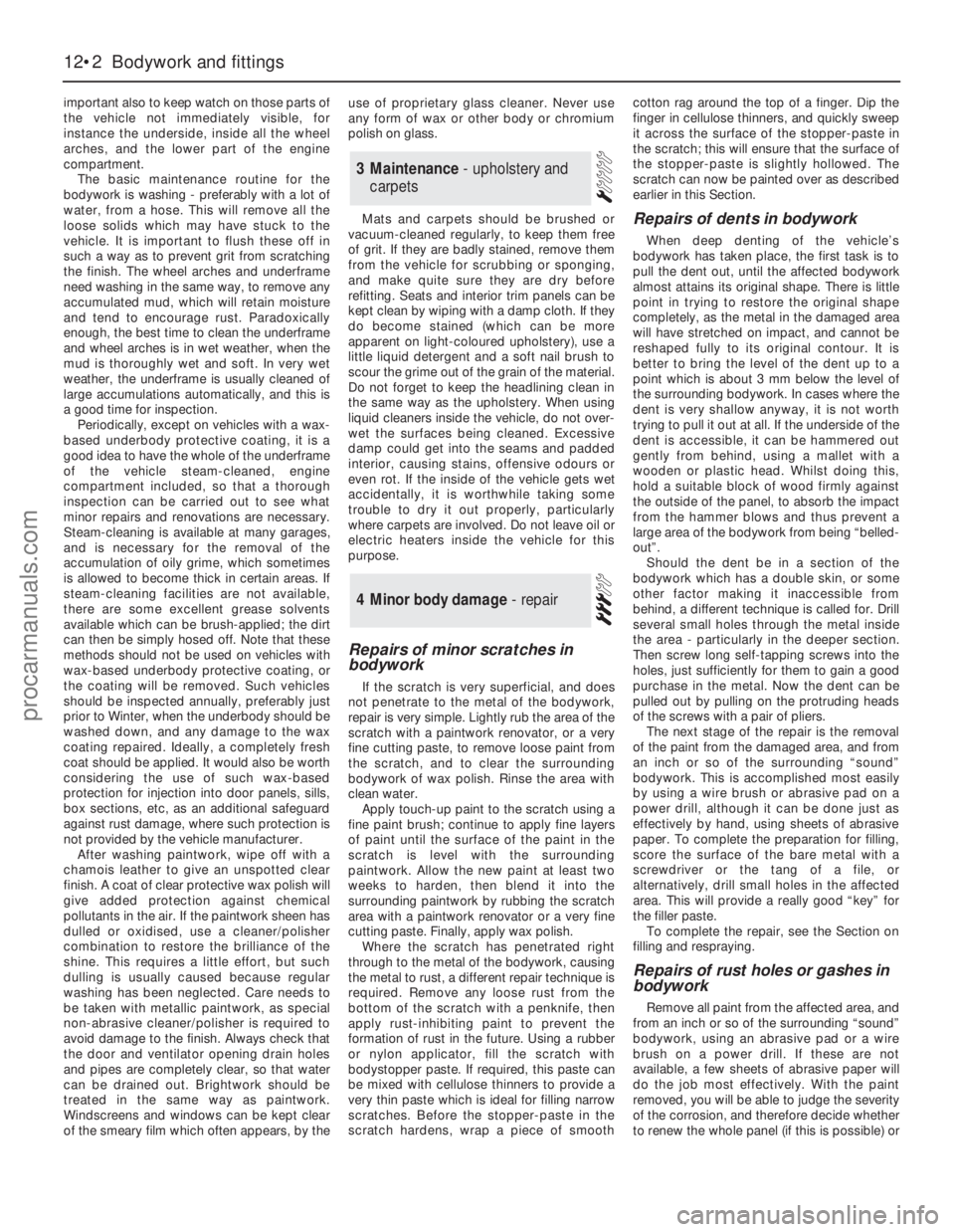

5Extract the piston seal from the groove in

the bore, using a blunt instrument (see

illustration). Discard the seal and dust boot.

6Clean the piston and bore with methylated

spirit and inspect them for scuffs, scores or

other damage. If the piston is corroded it must

be renewed. Slight imperfections in the bore

can be polished out with wire wool.

7Place the clean component on a clean

surface ready for reassembly. Lubricate the

caliper hose with clean hydraulic fluid.

8Fit the new piston seal to the groove in the

bore, using fingers only to work it into position.

9Lubricate the piston with clean hydraulic

fluid and fit the dust boot over the piston,

making sure it is the right way up. Insert the

piston into the bore and press it home,

engaging the dust boot lip with the groove on

the caliper (see illustration).

10This completes the overhaul of the hydraulic

components. Items such as slide bolts and

bracket can also be renewed if necessary.

11Remove the bleed screw while the caliper

is on the bench and apply a little anti-seize

compound to its threads, to avoid trouble in

undoing it later.

1With the ignition off, pump the brake pedal

at least 20 times (or until it becomes hard) to

depressurise the system.

2Chock the front wheels and release the

handbrake. Slacken the rear wheel nuts, raiseand support the vehicle and remove the

relevant wheel.

3Disconnect the pad wear warning wires,

when fitted.

4Disconnect the flexible hose from the brake

pipe. Plug or cap the open unions to reduce

spillage and to keep dirt out. Unscrew the

flexible hose from the caliper and remove it.

5Remove the two slide bolts. Lift the caliper

off the pads and bracket, at the same time

unhooking the handbrake cable (see

illustrations). Alternatively, the two bracket-

to-hub bolts can be removed and the caliper

and bracket separated on the bench.

6Refit by reversing the removal operations,

but before refitting the wheel, bleed both rear

calipers as described in Section 2.

7When bleeding is complete, pump the brake

pedal several times to bring the pads up to the

disc, then check the operation of the

handbrake.

Note: Complete dismantling of the rear caliper

should not be attempted unless Ford spring

compressor (tool No 12-007) is available. or

unless the problems likely to arise in the absence

of the tool are understood. Renewal of the piston

seal and dust boot requires no special tools.

1Clean the caliper externally and mount it in a

soft-jawed vice.

2Rotate the piston anti-clockwise until it isprotruding from the bore by about 20 mm (0.8 in).

Free the dust boot from the groove in the

piston, then carry on unscrewing the piston

and remove it. Remove and discard the dust

boot.

3The piston and bore may now be cleaned

and examined, and the piston seal and dust

boot renewed, as described for the front

caliper (Section 10).

4The piston adjuster nut seal should also be

renewed. Remove the circlip from the piston,

then extract the thrustwashers, wave washer

and thrust bearing. Note the fitted sequence of

these components. Finally remove the nut

(see illustrations).

5Remove the seal from the nut, noting which

way round it is fitted. Clean the nut with

methylated spirit. Lubricate the new seal with

clean hydraulic fluid and fit it to the nut.

12Rear caliper - overhaul

11Rear caliper - removal and

refitting

10•6Braking system

10.5 Removing the piston seal

12.4a Removing the circlip from a rear

caliper piston . . .12.4b . . . followed by a thrustwasher . . .

11.5b . . . and remove the rear caliper

10.9 Pressing the piston into the bore11.5a Unhook the handbrake cable . . .

12.4c . . . a wave washer and (not shown)

another thrustwasher . . .

procarmanuals.com

Page 137 of 255

17Refit the washer, spring and spring cover.

Compress the spring and refit the circlip, then

release the spring compressor.

18Lubricate the caliper bore with clean

hydraulic fluid and fit a new piston seal.

19Reassemble the piston components.

Lubricate the contact face of the adjuster nut

with a little brake grease, then fit the adjuster

nut (with new seal), thrust bearing,

thrustwasher, wave washer and the second

thrustwasher. Secure with the circlip.

20Fit a new dust boot. The manufacturers

recommend that it be fitted to the caliper

groove and the piston fitted afterwards; it is

also possible to fit the boot to the piston first

and engage it in the caliper groove afterwards.

Either way it is a fiddly business.

21Refit the piston and screw it into the

caliper, then fit whichever lip of the dust boot

was left free (see illustration).22Renew the slide pin gaiters and apply a

little anti-seize compound to the slide pins

when reassembling the caliper to the bracket.

The splash shield is retained by the rear hub

bolts. Proceed as described in Chapter 11 for

removal and refitting of the rear hub.

1Disconnect the battery negative lead.

2Depressurise the hydraulic system by

pumping the brake pedal at least 20 times, or

until it becomes hard.

3Remove the under-dash trim on the driver’s

side.

4Remove the spring clip which secures the

hydraulic unit pushrod to the brake pedal. Also

remove the clip from the brake pedal shaft

(see illustration).

5Withdraw the brake pedal shaft towards the

left of the vehicle - through the clutch pedal,

when applicable - until the brake pedal is free.

6Remove the pedal, noting the fitted

sequence of bushes, spacers and washers.

7Refit by reversing the removal operations.

Check the correct functioning of the stop-light

and (if applicable) cruise control switches

before refitting the trim. See Chapter 13.1Disconnect the battery negative lead.

2Depressurise the hydraulic system by

pumping the brake pedal at least 20 times, or

until it becomes hard.

3Disconnect the six multi-plugs from the

hydraulic unit. They are all different, so there is

no need to label them. When a plug has a

spring clip retainer, lift the clip before pulling

out the plug. To release the pump plug, pull

back the rubber boot and the plug sleeve (see

illustrations).

4Unbolt the earth strap from the unit (see

illustration).

5Make arrangements to catch spilt hydraulic

15Hydraulic unit - removal and

refitting

14Brake pedal - removal and

refitting

13Rear disc splash shield -

removal and refitting

10•8Braking system

12.21 Dust boot fitted to caliper and piston

15.3d Disconnecting the pressure switch

multi-plug15.3e Disconnecting the pump motor plug15.4 Earth strap (arrowed) bolted to

hydraulic unit

14.4 Pushrod spring clip (A) and brake

pedal shaft clip (B)

15.3a Disconnect the valve block multi-

plug. Lift the clip and pull off the plug15.3b Disconnecting a fluid level sensor

plug15.3c Disconnecting the main valve plug

procarmanuals.com

Page 159 of 255

important also to keep watch on those parts of

the vehicle not immediately visible, for

instance the underside, inside all the wheel

arches, and the lower part of the engine

compartment.

The basic maintenance routine for the

bodywork is washing - preferably with a lot of

water, from a hose. This will remove all the

loose solids which may have stuck to the

vehicle. It is important to flush these off in

such a way as to prevent grit from scratching

the finish. The wheel arches and underframe

need washing in the same way, to remove any

accumulated mud, which will retain moisture

and tend to encourage rust. Paradoxically

enough, the best time to clean the underframe

and wheel arches is in wet weather, when the

mud is thoroughly wet and soft. In very wet

weather, the underframe is usually cleaned of

large accumulations automatically, and this is

a good time for inspection.

Periodically, except on vehicles with a wax-

based underbody protective coating, it is a

good idea to have the whole of the underframe

of the vehicle steam-cleaned, engine

compartment included, so that a thorough

inspection can be carried out to see what

minor repairs and renovations are necessary.

Steam-cleaning is available at many garages,

and is necessary for the removal of the

accumulation of oily grime, which sometimes

is allowed to become thick in certain areas. If

steam-cleaning facilities are not available,

there are some excellent grease solvents

available which can be brush-applied; the dirt

can then be simply hosed off. Note that these

methods should not be used on vehicles with

wax-based underbody protective coating, or

the coating will be removed. Such vehicles

should be inspected annually, preferably just

prior to Winter, when the underbody should be

washed down, and any damage to the wax

coating repaired. Ideally, a completely fresh

coat should be applied. It would also be worth

considering the use of such wax-based

protection for injection into door panels, sills,

box sections, etc, as an additional safeguard

against rust damage, where such protection is

not provided by the vehicle manufacturer.

After washing paintwork, wipe off with a

chamois leather to give an unspotted clear

finish. A coat of clear protective wax polish will

give added protection against chemical

pollutants in the air. If the paintwork sheen has

dulled or oxidised, use a cleaner/polisher

combination to restore the brilliance of the

shine. This requires a little effort, but such

dulling is usually caused because regular

washing has been neglected. Care needs to

be taken with metallic paintwork, as special

non-abrasive cleaner/polisher is required to

avoid damage to the finish. Always check that

the door and ventilator opening drain holes

and pipes are completely clear, so that water

can be drained out. Brightwork should be

treated in the same way as paintwork.

Windscreens and windows can be kept clear

of the smeary film which often appears, by theuse of proprietary glass cleaner. Never use

any form of wax or other body or chromium

polish on glass.

Mats and carpets should be brushed or

vacuum-cleaned regularly, to keep them free

of grit. If they are badly stained, remove them

from the vehicle for scrubbing or sponging,

and make quite sure they are dry before

refitting. Seats and interior trim panels can be

kept clean by wiping with a damp cloth. If they

do become stained (which can be more

apparent on light-coloured upholstery), use a

little liquid detergent and a soft nail brush to

scour the grime out of the grain of the material.

Do not forget to keep the headlining clean in

the same way as the upholstery. When using

liquid cleaners inside the vehicle, do not over-

wet the surfaces being cleaned. Excessive

damp could get into the seams and padded

interior, causing stains, offensive odours or

even rot. If the inside of the vehicle gets wet

accidentally, it is worthwhile taking some

trouble to dry it out properly, particularly

where carpets are involved. Do not leave oil or

electric heaters inside the vehicle for this

purpose.

Repairs of minor scratches in

bodywork

If the scratch is very superficial, and does

not penetrate to the metal of the bodywork,

repair is very simple. Lightly rub the area of the

scratch with a paintwork renovator, or a very

fine cutting paste, to remove loose paint from

the scratch, and to clear the surrounding

bodywork of wax polish. Rinse the area with

clean water.

Apply touch-up paint to the scratch using a

fine paint brush; continue to apply fine layers

of paint until the surface of the paint in the

scratch is level with the surrounding

paintwork. Allow the new paint at least two

weeks to harden, then blend it into the

surrounding paintwork by rubbing the scratch

area with a paintwork renovator or a very fine

cutting paste. Finally, apply wax polish.

Where the scratch has penetrated right

through to the metal of the bodywork, causing

the metal to rust, a different repair technique is

required. Remove any loose rust from the

bottom of the scratch with a penknife, then

apply rust-inhibiting paint to prevent the

formation of rust in the future. Using a rubber

or nylon applicator, fill the scratch with

bodystopper paste. If required, this paste can

be mixed with cellulose thinners to provide a

very thin paste which is ideal for filling narrow

scratches. Before the stopper-paste in the

scratch hardens, wrap a piece of smoothcotton rag around the top of a finger. Dip the

finger in cellulose thinners, and quickly sweep

it across the surface of the stopper-paste in

the scratch; this will ensure that the surface of

the stopper-paste is slightly hollowed. The

scratch can now be painted over as described

earlier in this Section.

Repairs of dents in bodywork

When deep denting of the vehicle’s

bodywork has taken place, the first task is to

pull the dent out, until the affected bodywork

almost attains its original shape. There is little

point in trying to restore the original shape

completely, as the metal in the damaged area

will have stretched on impact, and cannot be

reshaped fully to its original contour. It is

better to bring the level of the dent up to a

point which is about 3 mm below the level of

the surrounding bodywork. In cases where the

dent is very shallow anyway, it is not worth

trying to pull it out at all. If the underside of the

dent is accessible, it can be hammered out

gently from behind, using a mallet with a

wooden or plastic head. Whilst doing this,

hold a suitable block of wood firmly against

the outside of the panel, to absorb the impact

from the hammer blows and thus prevent a

large area of the bodywork from being “belled-

out”.

Should the dent be in a section of the

bodywork which has a double skin, or some

other factor making it inaccessible from

behind, a different technique is called for. Drill

several small holes through the metal inside

the area - particularly in the deeper section.

Then screw long self-tapping screws into the

holes, just sufficiently for them to gain a good

purchase in the metal. Now the dent can be

pulled out by pulling on the protruding heads

of the screws with a pair of pliers.

The next stage of the repair is the removal

of the paint from the damaged area, and from

an inch or so of the surrounding “sound”

bodywork. This is accomplished most easily

by using a wire brush or abrasive pad on a

power drill, although it can be done just as

effectively by hand, using sheets of abrasive

paper. To complete the preparation for filling,

score the surface of the bare metal with a

screwdriver or the tang of a file, or

alternatively, drill small holes in the affected

area. This will provide a really good “key” for

the filler paste.

To complete the repair, see the Section on

filling and respraying.

Repairs of rust holes or gashes in

bodywork

Remove all paint from the affected area, and

from an inch or so of the surrounding “sound”

bodywork, using an abrasive pad or a wire

brush on a power drill. If these are not

available, a few sheets of abrasive paper will

do the job most effectively. With the paint

removed, you will be able to judge the severity

of the corrosion, and therefore decide whether

to renew the whole panel (if this is possible) or

4Minor body damage - repair

3Maintenance - upholstery and

carpets

12•2Bodywork and fittings

procarmanuals.com

Page 160 of 255

to repair the affected area. New body panels

are not as expensive as most people think,

and it is often quicker and more satisfactory to

fit a new panel than to attempt to repair large

areas of corrosion.

Remove all fittings from the affected area,

except those which will act as a guide to the

original shape of the damaged bodywork (eg

headlight shells etc). Then, using tin snips or a

hacksaw blade, remove all loose metal and

any other metal badly affected by corrosion.

Hammer the edges of the hole inwards, in

order to create a slight depression for the filler

paste.

Wire-brush the affected area to remove the

powdery rust from the

surface of the remaining metal. Paint the

affected area with rust-inhibiting paint, if the

back of the rusted area is accessible, treat this

also.

Before filling can take place, it will be

necessary to block the hole in some way. This

can be achieved by the use of aluminium or

plastic mesh, or aluminium tape.

Aluminium or plastic mesh, or glass-fibre

matting, is probably the best material to use

for a large hole. Cut a piece to the

approximate size and shape of the hole to be

filled, then position it in the hole so that its

edges are below the level of the surrounding

bodywork. It can be retained in position by

several blobs of filler paste around its

periphery.

Aluminium tape should be used for small or

very narrow holes. Pull a piece off the roll, trim

it to the approximate size and shape required,

then pull off the backing paper (if used) and

stick the tape over the hole; it can be

overlapped if the thickness of one piece is

insufficient. Burnish down the edges of the

tape with the handle of a screwdriver or

similar, to ensure that the tape is securely

attached to the metal underneath.

Bodywork repairs - filling and

respraying

Before using this Section, see the Sections

on dent, deep scratch, rust holes and gash

repairs.

Many types of bodyfiller are available, but

generally speaking, those proprietary kits

which contain a tin of filler paste and a tube of

resin hardener are best for this type of repair.

A wide, flexible plastic or nylon applicator will

be found invaluable for imparting a smooth

and well-contoured finish to the surface of the

filler.

Mix up a little filler on a clean piece of card

or board - measure the hardener carefully

(follow the maker’s instructions on the pack),

otherwise the filler will set too rapidly or too

slowly. Using the applicator, apply the filler

paste to the prepared area; draw the

applicator across the surface of the filler to

achieve the correct contour and to level the

surface. As soon as a contour that

approximates to the correct one is achieved,

stop working the paste - if you carry on too

long, the paste will become sticky and begin

to “pick-up” on the applicator. Continue to

add thin layers of filler paste at 20-minuteintervals, until the level of the filler is just proud

of the surrounding bodywork.

Once the filler has hardened, the excess can

be removed using a metal plane or file. From

then on, progressively-finer grades of abrasive

paper should be used, starting with a 40-

grade production paper, and finishing with a

400-grade wet-and-dry paper. Always wrap

the abrasive paper around a flat rubber, cork,

or wooden block - otherwise the surface of the

filler will not be completely flat. During the

smoothing of the filler surface, the wet-and-

dry paper should be periodically rinsed in

water. This will ensure that a very smooth

finish is imparted to the filler at the final stage.

At this stage, the “dent” should be

surrounded by a ring of bare metal, which in

turn should be encircled by the finely

“feathered” edge of the good paintwork. Rinse

the repair area with clean water, until all of the

dust produced by the rubbing-down operation

has gone.

Spray the whole area with a light coat of

primer - this will show up any imperfections in

the surface of the filler. Repair these

imperfections with fresh filler paste or

bodystopper, and once more smooth the

surface with abrasive paper. Repeat this

spray-and-repair procedure until you are

satisfied that the surface of the filler, and the

feathered edge of the paintwork, are perfect.

Clean the repair area with clean water, and

allow to dry fully.

The repair area is now ready for final

spraying. Paint spraying must be carried out in

a warm, dry, windless and dust-free

atmosphere. This condition can be created

artificially if you have access to a large indoor

working area, but if you are forced to work in

the open, you will have to pick your day very

carefully. If you are working indoors, dousing

the floor in the work area with water will help

to settle the dust which would otherwise be in

the atmosphere. If the repair area is confined

to one body panel, mask off the surrounding

panels; this will help to minimise the effects of

a slight mis-match in paint colours. Bodywork

fittings (eg chrome strips, door handles etc)

will also need to be masked off. Use genuine

masking tape, and several thicknesses of

newspaper, for the masking operations.

Before commencing to spray, agitate the

aerosol can thoroughly, then spray a test area

(an old tin, or similar) until the technique is

mastered. Cover the repair area with a thick

coat of primer; the thickness should be built

up using several thin layers of paint, rather

than one thick one. Using 400-grade wet-and-

dry paper, rub down the surface of the primer

until it is really smooth. While doing this, the

work area should be thoroughly doused with

water, and the wet-and-dry paper periodically

rinsed in water. Allow to dry before spraying

on more paint.

Spray on the top coat, again building up thethickness by using several thin layers of paint.

Start spraying at one edge of the repair area,

and then, using a side-to-side motion, work

until the whole repair area and about 2 inches

of the surrounding original paintwork is

covered. Remove all masking material 10 to 15

minutes after spraying on the final coat of

paint.

Allow the new paint at least two weeks to

harden, then, using a paintwork renovator, or a

very fine cutting paste, blend the edges of the

paint into the existing paintwork. Finally, apply

wax polish.

Plastic components

With the use of more and more plastic body

components by the vehicle manufacturers (eg

bumpers. spoilers, and in some cases major

body panels), rectification of more serious

damage to such items has become a matter of

either entrusting repair work to a specialist in

this field, or renewing complete components.

Repair of such damage by the DIY owner is

not really feasible, owing to the cost of the

equipment and materials required for effecting

such repairs. The basic technique involves

making a groove along the line of the crack in

the plastic, using a rotary burr in a power drill.

The damaged part is then welded back

together, using a hot-air gun to heat up and

fuse a plastic filler rod into the groove. Any

excess plastic is then removed, and the area

rubbed down to a smooth finish. It is important

that a filler rod of the correct plastic is used, as

body components can be made of a variety of

different types (eg polycarbonate, ABS,

polypropylene).

Damage of a less serious nature (abrasions,

minor cracks etc) can be repaired by the DIY

owner using a two-part epoxy filler repair

material. Once mixed in equal proportions, this

is used in similar fashion to the bodywork filler

used on metal panels. The filler is usually

cured in twenty to thirty minutes, ready for

sanding and painting.

If the owner is renewing a complete

component himself, or if he has repaired it with

epoxy filler, he will be left with the problem of

finding a suitable paint for finishing which is

compatible with the type of plastic used. At

one time, the use of a universal paint was not

possible, owing to the complex range of

plastics encountered in body component

applications. Standard paints, generally

speaking, will not bond to plastic or rubber

satisfactorily. However, it is now possible to

obtain a plastic body parts finishing kit which

consists of a pre-primer treatment, a primer

and coloured top coat. Full instructions are

normally supplied with a kit, but basically, the

method of use is to first apply the pre-primer

to the component concerned, and allow it to

dry for up to 30 minutes. Then the primer is

applied, and left to dry for about an hour

before finally applying the special-coloured

top coat. The result is a correctly-coloured

component, where the paint will flex with the

plastic or rubber, a property that standard

paint does not normally posses.

Bodywork and fittings 12•3

12

If bodystopper is used, it can be

mixed with cellulose thinners,

to form a thin paste which is

ideal for filling small holes.

procarmanuals.com

Page 161 of 255

Where serious damage has occurred or

large areas need renewal due to neglect, it

means certainly that completely new sections

or panels will need welding in and this is best

left to professionals. If the damage is due to

impact, it will also be necessary to completely

check the alignment of the bodyshell

structure. Due to the principle of construction,

the strength and shape of the whole car can

be affected by damage to one part. In such

instances the services of a Ford agent with

specialist checking jigs are essential. If a body

is left misaligned, it is first of all dangerous as

the car will not handle properly, and secondly

uneven stresses will be imposed on the

steering, engine and transmission, causing

abnormal wear or complete failure. Tyre wear

may also be excessive.

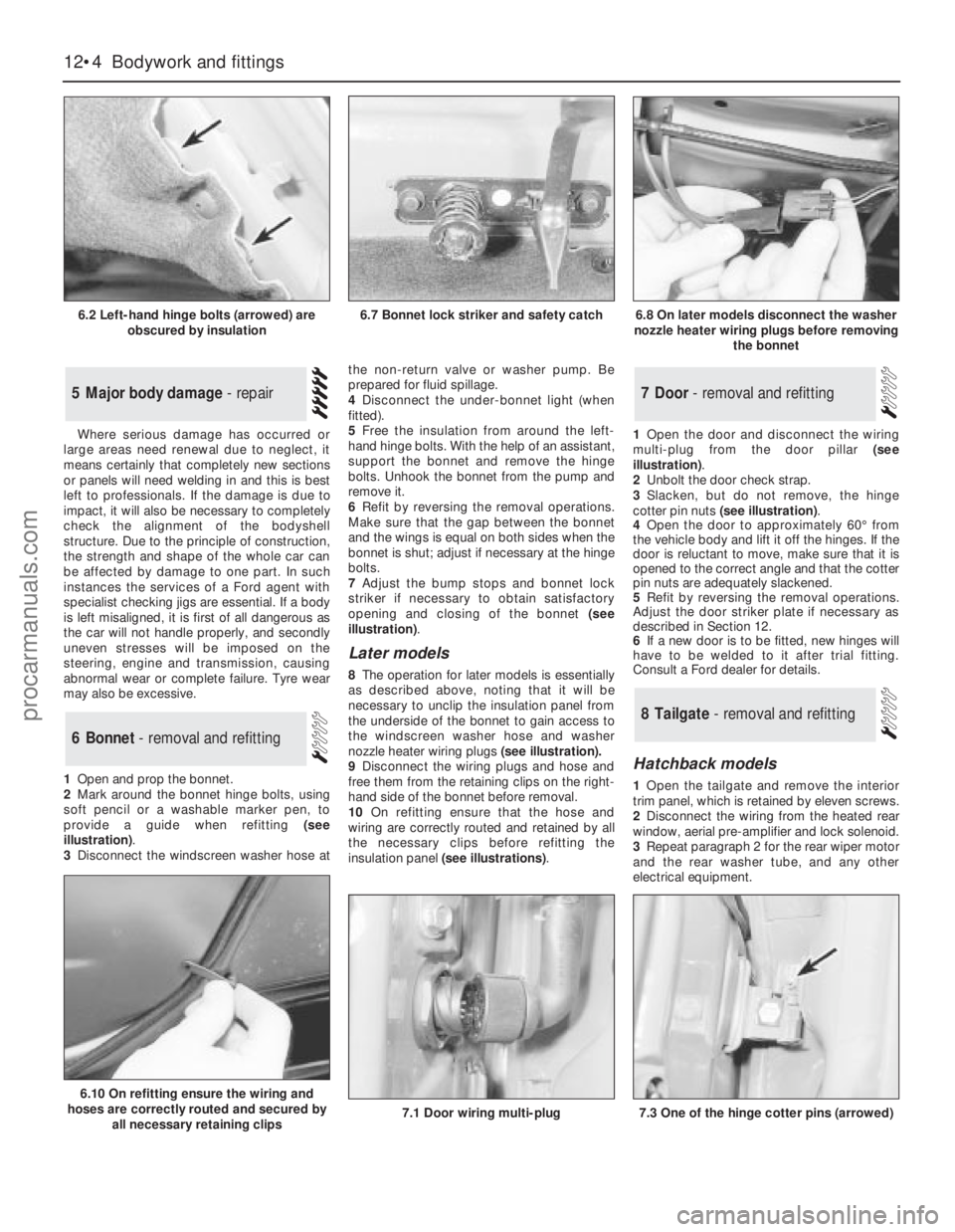

1Open and prop the bonnet.

2Mark around the bonnet hinge bolts, using

soft pencil or a washable marker pen, to

provide a guide when refitting (see

illustration).

3Disconnect the windscreen washer hose atthe non-return valve or washer pump. Be

prepared for fluid spillage.

4Disconnect the under-bonnet light (when

fitted).

5Free the insulation from around the left-

hand hinge bolts. With the help of an assistant,

support the bonnet and remove the hinge

bolts. Unhook the bonnet from the pump and

remove it.

6Refit by reversing the removal operations.

Make sure that the gap between the bonnet

and the wings is equal on both sides when the

bonnet is shut; adjust if necessary at the hinge

bolts.

7Adjust the bump stops and bonnet lock

striker if necessary to obtain satisfactory

opening and closing of the bonnet (see

illustration).

Later models

8The operation for later models is essentially

as described above, noting thatit will be

necessary to unclip the insulation panel from

the underside of the bonnet to gain access to

the windscreen washer hose and washer

nozzle heater wiring plugs (see illustration).

9Disconnect the wiring plugs and hose and

free them from the retaining clips on the right-

hand side of the bonnet before removal.

10On refitting ensure that the hose and

wiring are correctly routed and retained by all

the necessary clips before refitting the

insulation panel (see illustrations).1Open the door and disconnect the wiring

multi-plug from the door pillar (see

illustration).

2Unbolt the door check strap.

3Slacken, but do not remove, the hinge

cotter pin nuts (see illustration).

4Open the door to approximately 60°from

the vehicle body and lift it off the hinges. If the

door is reluctant to move, make sure that it is

opened to the correct angle and that the cotter

pin nuts are adequately slackened.

5Refit by reversing the removal operations.

Adjust the door striker plate if necessary as

described in Section 12.

6If a new door is to be fitted, new hinges will

have to be welded to it after trial fitting.

Consult a Ford dealer for details.

Hatchback models

1Open the tailgate and remove the interior

trim panel, which is retained by eleven screws.

2Disconnect the wiring from the heated rear

window, aerial pre-amplifier and lock solenoid.

3Repeat paragraph 2 for the rear wiper motor

and the rear washer tube, and any other

electrical equipment.

8Tailgate - removal and refitting

7Door - removal and refitting

6Bonnet - removal and refitting

5Major body damage - repair

12•4Bodywork and fittings

6.2 Left-hand hinge bolts (arrowed) are

obscured by insulation

6.10 On refitting ensure the wiring and

hoses are correctly routed and secured by

all necessary retaining clips

7.1 Door wiring multi-plug7.3 One of the hinge cotter pins (arrowed)

6.7 Bonnet lock striker and safety catch6.8 On later models disconnect the washer

nozzle heater wiring plugs before removing

the bonnet

procarmanuals.com

Page 166 of 255

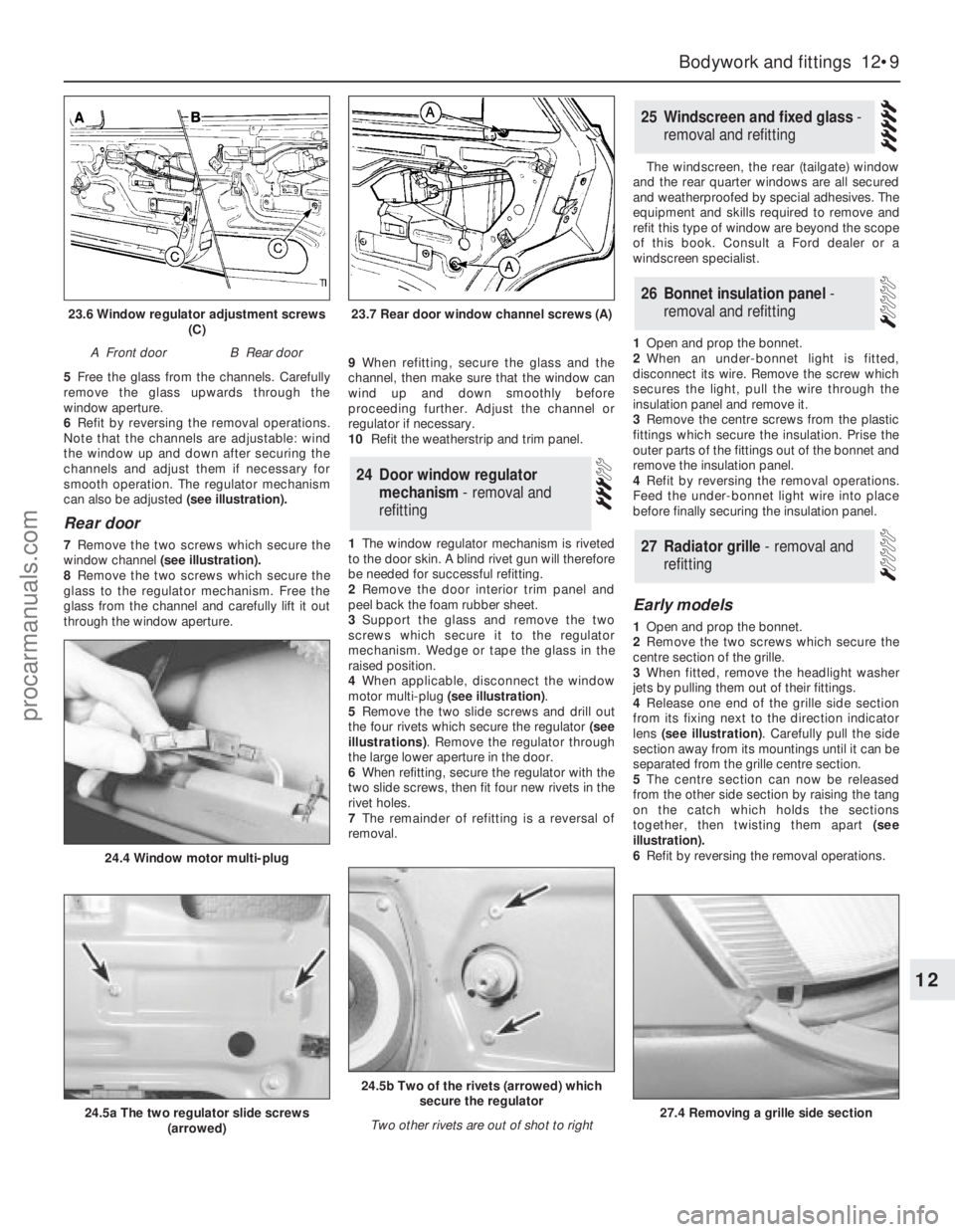

5Free the glass from the channels. Carefully

remove the glass upwards through the

window aperture.

6Refit by reversing the removal operations.

Note that the channels are adjustable: wind

the window up and down after securing the

channels and adjust them if necessary for

smooth operation. The regulator mechanism

can also be adjusted (see illustration).

Rear door

7Remove the two screws which secure the

window channel (see illustration).

8Remove the two screws which secure the

glass to the regulator mechanism. Free the

glass from the channel and carefully lift it out

through the window aperture.9When refitting, secure the glass and the

channel, then make sure that the window can

wind up and down smoothly before

proceeding further. Adjust the channel or

regulator if necessary.

10Refit the weatherstrip and trim panel.

1The window regulator mechanism is riveted

to the door skin. A blind rivet gun will therefore

be needed for successful refitting.

2Remove the door interior trim panel and

peel back the foam rubber sheet.

3Support the glass and remove the two

screws which secure it to the regulator

mechanism. Wedge or tape the glass in the

raised position.

4When applicable, disconnect the window

motor multi-plug (see illustration).

5Remove the two slide screws and drill out

the four rivets which secure the regulator (see

illustrations). Remove the regulator through

the large lower aperture in the door.

6When refitting, secure the regulator with the

two slide screws, then fit four new rivets in the

rivet holes.

7The remainder of refitting is a reversal of

removal.The windscreen, the rear (tailgate) window

and the rear quarter windows are all secured

and weatherproofed by special adhesives. The

equipment and skills required to remove and

refit this type of window are beyond the scope

of this book. Consult a Ford dealer or a

windscreen specialist.

1Open and prop the bonnet.

2When an under-bonnet light is fitted,

disconnect its wire. Remove the screw which

secures the light, pull the wire through the

insulation panel and remove it.

3Remove the centre screws from the plastic

fittings which secure the insulation. Prise the

outer parts of the fittings out of the bonnet and

remove the insulation panel.

4Refit by reversing the removal operations.

Feed the under-bonnet light wire into place

before finally securing the insulation panel.

Early models

1Open and prop the bonnet.

2Remove the two screws which secure the

centre section of the grille.

3When fitted, remove the headlight washer

jets by pulling them out of their fittings.

4Release one end of the grille side section

from its fixing next to the direction indicator

lens (see illustration). Carefully pull the side

section away from its mountings until it can be

separated from the grille centre section.

5The centre section can now be released

from the other side section by raising the tang

on the catch which holds the sections

together, then twisting them apart (see

illustration).

6Refit by reversing the removal operations.

27Radiator grille - removal and

refitting

26Bonnet insulation panel -

removal and refitting

25Windscreen and fixed glass -

removal and refitting

24Door window regulator

mechanism - removal and

refitting

Bodywork and fittings 12•9

12

23.6 Window regulator adjustment screws

(C)

A Front doorB Rear door

23.7 Rear door window channel screws (A)

24.5a The two regulator slide screws

(arrowed)

24.4 Window motor multi-plug

24.5b Two of the rivets (arrowed) which

secure the regulator

Two other rivets are out of shot to right

27.4 Removing a grille side section

procarmanuals.com

Page 170 of 255

6Disconnect the glovebox arms and hinges.

Withdraw the hinge pins and remove the lid.

7Slide the auxiliary fuse panel off its

mounting and remove the glovebox light

(when fitted).

8Remove the ABS and ESC/EEC modules

(Chapter 13). Remove the two nuts and

washers from inside the glovebox.

9Remove the radio, stowage box or graphic

equaliser, ashtray, cigarette lighter panel and

(when applicable) the gear lever gaiter.

10Remove the centre console, disconnecting

switches, rear heater controls etc as

necessary.

11Remove the six screws which secure the

passenger’s side lower panel. Remove the

panel. 12Refit by reversing the removal operations,

transferring the brackets, captive nuts or other

fittings to any new panels being fitted.

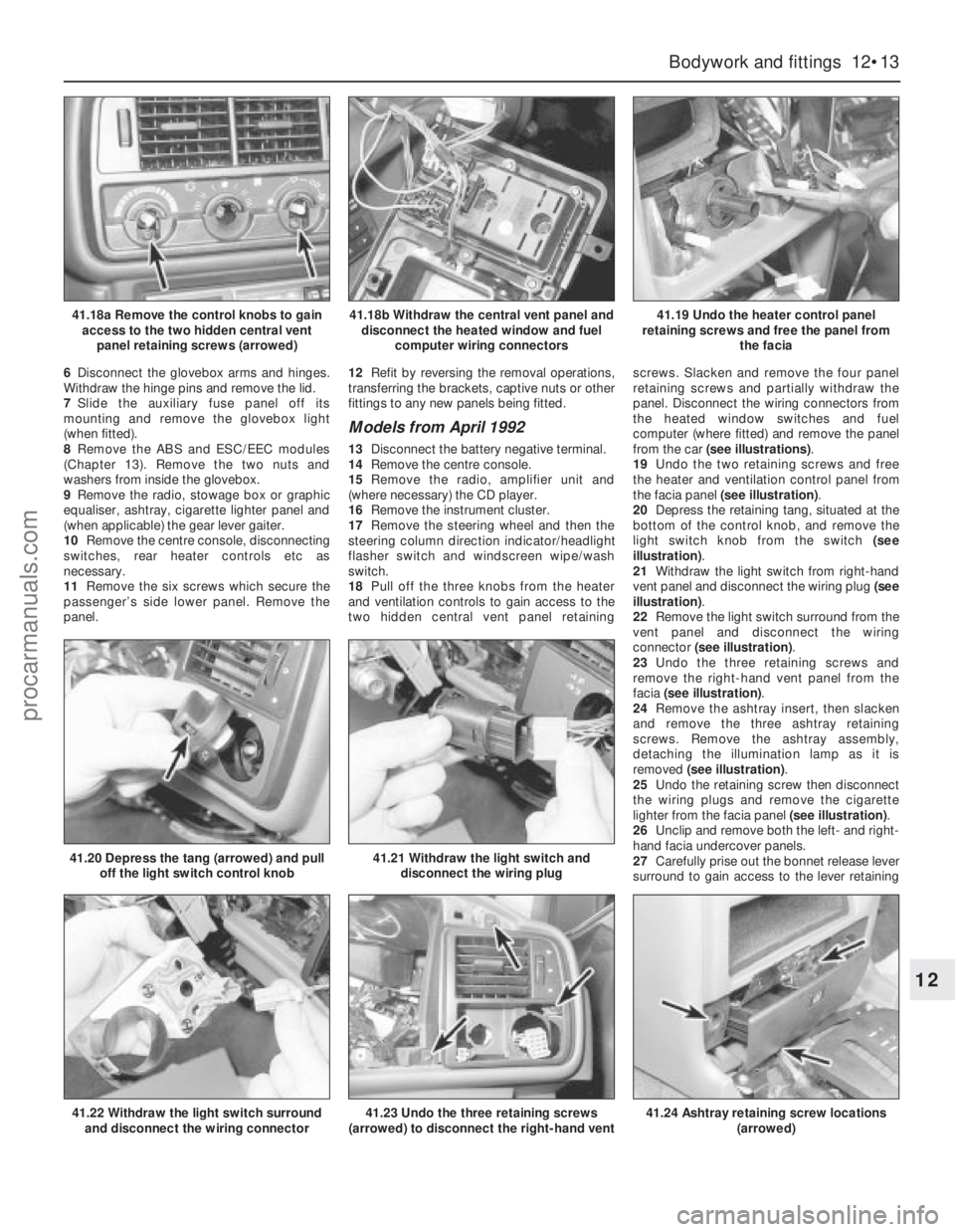

Models from April 1992

13Disconnect the battery negative terminal.

14Remove the centre console.

15Remove the radio, amplifier unit and

(where necessary) the CD player.

16Remove the instrument cluster.

17Remove the steering wheel and then the

steering column direction indicator/headlight

flasher switch and windscreen wipe/wash

switch.

18Pull off the three knobs from the heater

and ventilation controls to gain access to the

two hidden central vent panel retainingscrews. Slacken and remove the four panel

retaining screws and partially withdraw the

panel. Disconnect the wiring connectors from

the heated window switches and fuel

computer (where fitted) and remove the panel

from the car (see illustrations).

19Undo the two retaining screws and free

the heater and ventilation control panel from

the facia panel (see illustration).

20Depress the retaining tang, situated at the

bottom of the control knob, and remove the

light switch knob from the switch (see

illustration).

21Withdraw the light switch from right-hand

vent panel and disconnect the wiring plug (see

illustration).

22Remove the light switch surround from the

vent panel and disconnect the wiring

connector (see illustration).

23Undo the three retaining screws and

remove the right-hand vent panel from the

facia (see illustration).

24Remove the ashtray insert, then slacken

and remove the three ashtray retaining

screws. Remove the ashtray assembly,

detaching the illumination lamp as it is

removed (see illustration).

25Undo the retaining screw then disconnect

the wiring plugs and remove the cigarette

lighter from the facia panel (see illustration).

26Unclip and remove both the left- and right-

hand facia undercover panels.

27Carefully prise out the bonnet release lever

surround to gain access to the lever retaining

Bodywork and fittings 12•13

12

41.18a Remove the control knobs to gain

access to the two hidden central vent

panel retaining screws (arrowed)41.18b Withdraw the central vent panel and

disconnect the heated window and fuel

computer wiring connectors41.19 Undo the heater control panel

retaining screws and free the panel from

the facia

41.22 Withdraw the light switch surround

and disconnect the wiring connector

41.20 Depress the tang (arrowed) and pull

off the light switch control knob41.21 Withdraw the light switch and

disconnect the wiring plug

41.23 Undo the three retaining screws

(arrowed) to disconnect the right-hand vent41.24 Ashtray retaining screw locations

(arrowed)

procarmanuals.com

Page 171 of 255

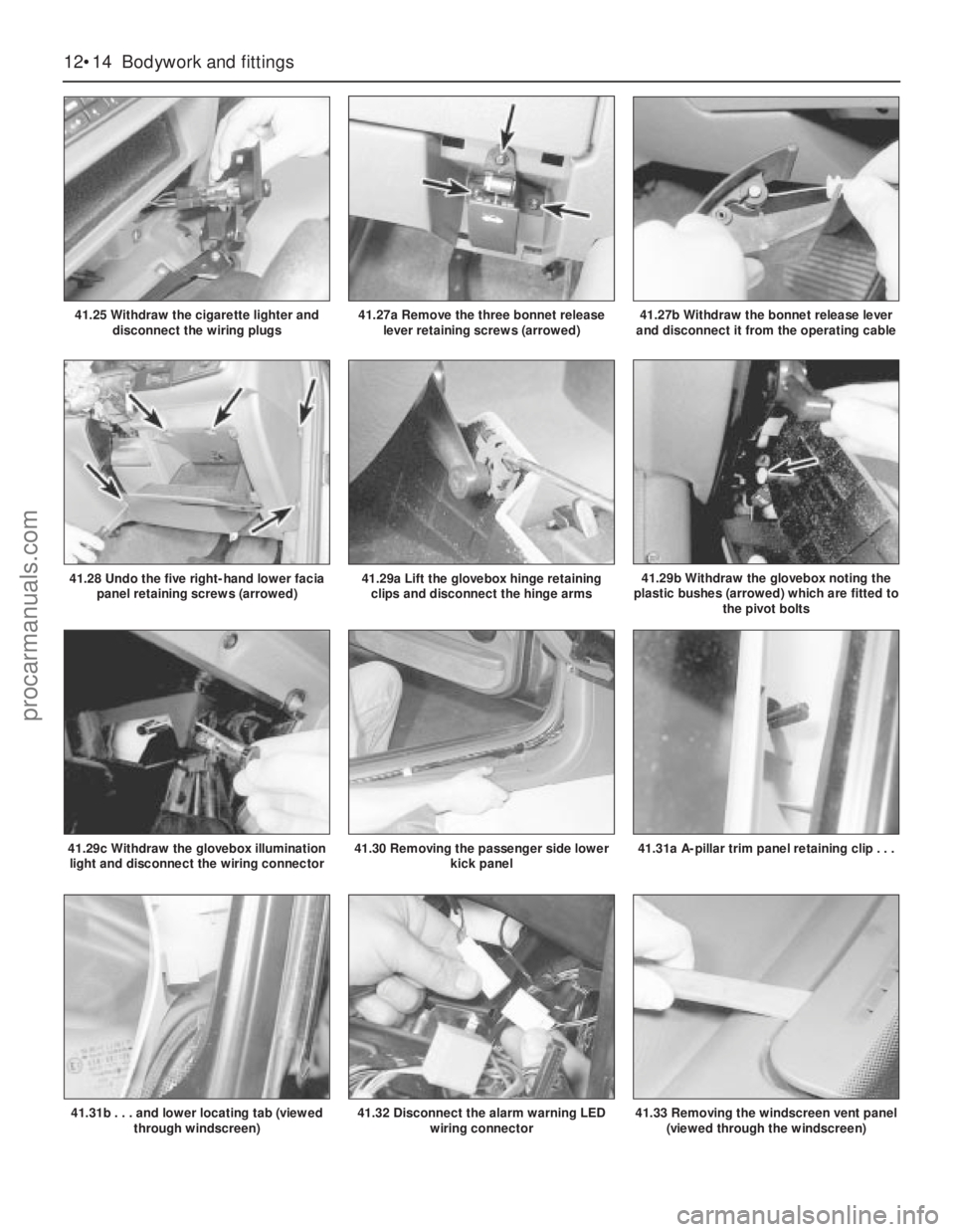

12•14Bodywork and fittings

41.25 Withdraw the cigarette lighter and

disconnect the wiring plugs

41.30 Removing the passenger side lower

kick panel

41.29a Lift the glovebox hinge retaining

clips and disconnect the hinge arms41.29b Withdraw the glovebox noting the

plastic bushes (arrowed) which are fitted to

the pivot bolts

41.29c Withdraw the glovebox illumination

light and disconnect the wiring connector

41.28 Undo the five right-hand lower facia

panel retaining screws (arrowed)

41.31a A-pillar trim panel retaining clip . . .

41.31b . . . and lower locating tab (viewed

through windscreen)

41.27a Remove the three bonnet release

lever retaining screws (arrowed)41.27b Withdraw the bonnet release lever

and disconnect it from the operating cable

41.32 Disconnect the alarm warning LED

wiring connector41.33 Removing the windscreen vent panel

(viewed through the windscreen)

procarmanuals.com

Page 172 of 255

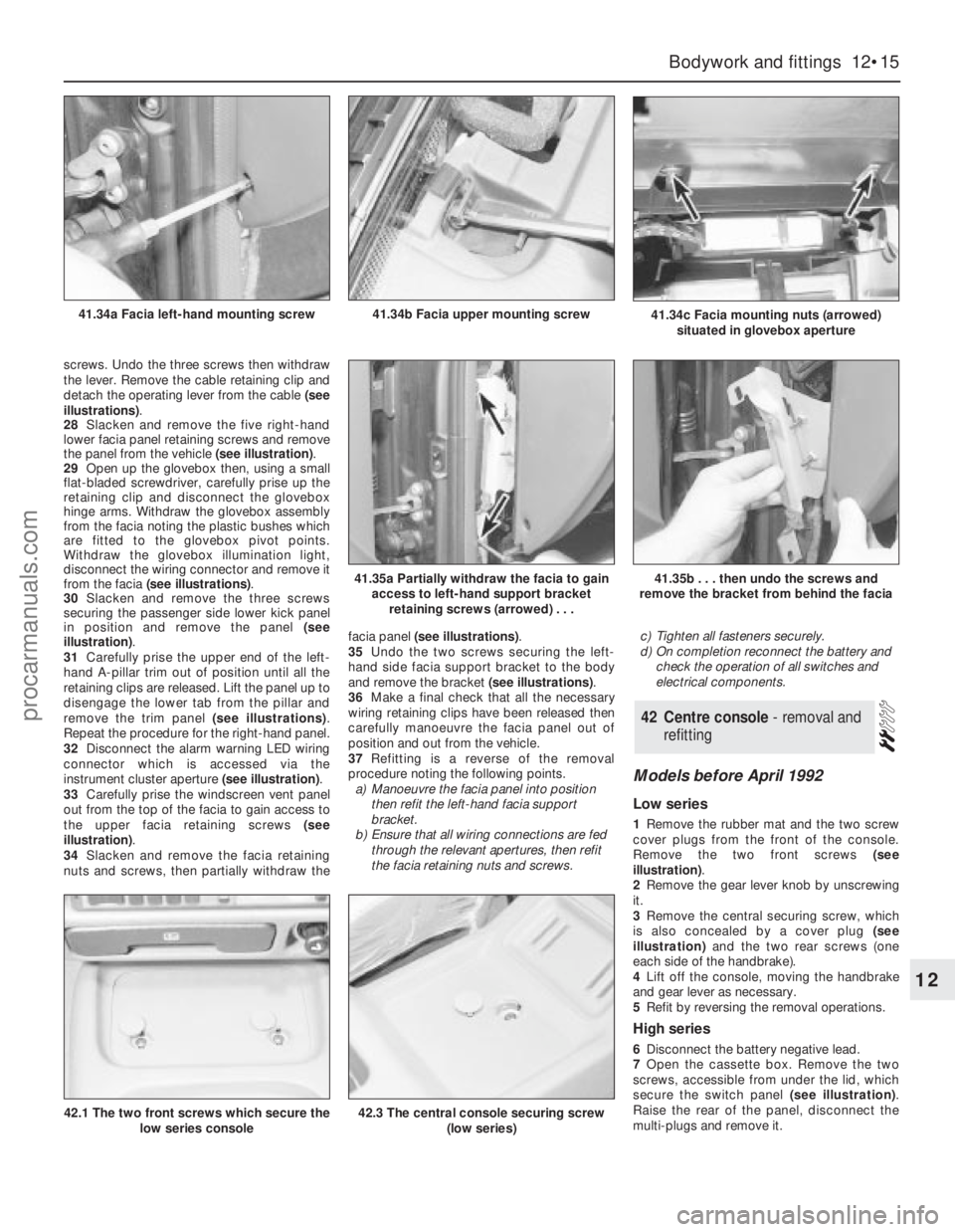

screws. Undo the three screws then withdraw

the lever. Remove the cable retaining clip and

detach the operating lever from the cable (see

illustrations).

28Slacken and remove the five right-hand

lower facia panel retaining screws and remove

the panel from the vehicle (see illustration).

29Open up the glovebox then, using a small

flat-bladed screwdriver, carefully prise up the

retaining clip and disconnect the glovebox

hinge arms. Withdraw the glovebox assembly

from the facia noting the plastic bushes which

are fitted to the glovebox pivot points.

Withdraw the glovebox illumination light,

disconnect the wiring connector and remove it

from the facia (see illustrations).

30Slacken and remove the three screws

securing the passenger side lower kick panel

in position and remove the panel (see

illustration).

31Carefully prise the upper end of the left-

hand A-pillar trim out of position until all the

retaining clips are released. Lift the panel up to

disengage the lower tab from the pillar and

remove the trim panel (see illustrations).

Repeat the procedure for the right-hand panel.

32Disconnect the alarm warning LED wiring

connector which is accessed via the

instrument cluster aperture (see illustration).

33Carefully prise the windscreen vent panel

out from the top of the facia to gain access to

the upper facia retaining screws (see

illustration).

34Slacken and remove the facia retaining

nuts and screws, then partially withdraw thefacia panel (see illustrations).

35Undo the two screws securing the left-

hand side facia support bracket to the body

and remove the bracket (see illustrations).

36Make a final check that all the necessary

wiring retaining clips have been released then

carefully manoeuvre the facia panel out of

position and out from the vehicle.

37Refitting is a reverse of the removal

procedure noting the following points.

a)Manoeuvre the facia panel into position

then refit the left-hand facia support

bracket.

b)Ensure that all wiring connections are fed

through the relevant apertures, then refit

the facia retaining nuts and screws.c)Tighten all fasteners securely.

d)On completion reconnect the battery and

check the operation of all switches and

electrical components.

Models before April 1992

Low series

1Remove the rubber mat and the two screw

cover plugs from the front of the console.

Remove the two front screws (see

illustration).

2Remove the gear lever knob by unscrewing

it.

3Remove the central securing screw, which

is also concealed by a cover plug (see

illustration)and the two rear screws (one

each side of the handbrake).

4Lift off the console, moving the handbrake

and gear lever as necessary.

5Refit by reversing the removal operations.

High series

6Disconnect the battery negative lead.

7Open the cassette box. Remove the two

screws, accessible from under the lid, which

secure the switch panel (see illustration).

Raise the rear of the panel, disconnect the

multi-plugs and remove it.

42Centre console - removal and

refitting

Bodywork and fittings 12•15

12

41.34c Facia mounting nuts (arrowed)

situated in glovebox aperture41.34b Facia upper mounting screw41.34a Facia left-hand mounting screw

41.35a Partially withdraw the facia to gain

access to left-hand support bracket

retaining screws (arrowed) . . .41.35b . . . then undo the screws and

remove the bracket from behind the facia

42.1 The two front screws which secure the

low series console42.3 The central console securing screw

(low series)

procarmanuals.com