brake rotor FORD GRANADA 1985 Service Repair Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1985, Model line: GRANADA, Model: FORD GRANADA 1985Pages: 255, PDF Size: 14.98 MB

Page 3 of 255

1•2

Every 12 000 miles (20 000 km) or

12 months – whichever comes sooner

m mCheck operation of latches, check straps and locks; lubricate if

necessary (Section 19)

m mCheck condition and tension of auxiliary drivebelt(s); adjust or

renew as necessary (Section 21)

m mCheck tightness of battery terminals, clean and neutralise

corrosion if necessary (Section 22)

m mCheck engine valve clearances (Section 23) m

mCheck tightness of inlet manifold bolts (V6 only) (Section 24) m

mRenew spark plugs (Section 20) m

mClean air conditioning condenser fins (when applicable)

(Section 25)

m mCheck air conditioning refrigerant charge (when applicable)

(Section 26)

m mCheck manual gearbox oil level (Section 18) m

mCheck final drive oil level (Section 27) m

mLubricate automatic transmission selector/kickdown linkage

(Section 28)

m mCheck security and condition of steering and suspension

components, gaiters and boots (Section 29)

m mCheck condition and security of driveshaft joints (Section 30) m

mInspect underbody and panels for corrosion or other damage

(Section 31)

m mInspect brake pipes and hoses (Section 32) m

mClean idle speed control linkage at throttle (when applicable)

(Section 33)

m mRoad test and check operation of ABS (Section 34)m

mCheck automatic transmission fluid level (engine hot)

(Section 17)

m mCheck engine for satisfactory hot starting (Section 37)m

mCheck that automatic choke is fully off with engine hot (not fuel-

injection models) (Section 36)

m mCheck power steering fluid level (when applicable) (Section 35)

Every 24 000 miles (40 000 km) or

2 years - whichever comes sooner

m

mRenew air cleaner element (Section 38) m

mClean and inspect distributor cap, rotor arm, HT leads and coil

tower (Section 39)

m mAdjust automatic transmission brake bands (Section 40)m

mRenew fuel filter (fuel-injection models only) (Section 41) m

mRenew crankcase ventilation vent valve (carburettor models)

(Section 42)

Every 36 000 miles (60 000 km) or

3 years - whichever comes sooner

m

mRenew brake hydraulic system seals and hoses if necessary

(Section 43)

m mRenew brake hydraulic fluid (Section 44) m

mRenew camshaft drivebelt on SOHC models - recommended as

a precautionary measure (Section 45)

Every 2 years - regardless of mileage

m

mRenew coolant (Section 46)

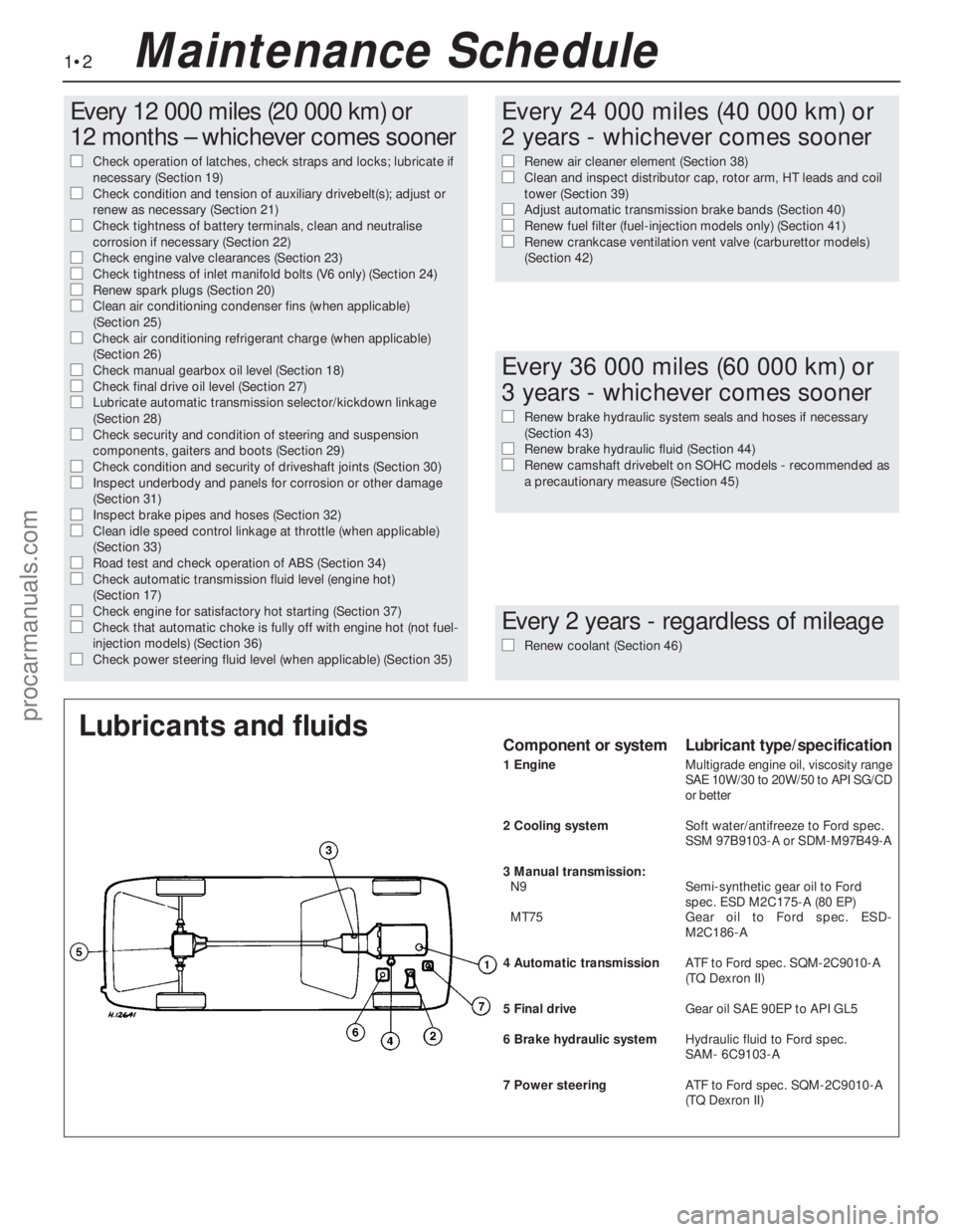

Lubricants and fluidsComponent or systemLubricant type/specification

1 EngineMultigrade engine oil, viscosity range

SAE 10W/30 to 20W/50 to API SG/CD

or better

2 Cooling systemSoft water/antifreeze to Ford spec.

SSM 97B9103-A or SDM-M97B49-A

3 Manual transmission:

N9Semi-synthetic gear oil to Ford

spec. ESD M2C175-A (80 EP)

MT75Gear oil to Ford spec. ESD-

M2C186-A

4 Automatic transmissionATF to Ford spec. SQM-2C9010-A

(TQ Dexron II)

5 Final driveGear oil SAE 90EP to APIGL5

6 Brake hydraulic systemHydraulic fluid to Ford spec.

SAM- 6C9103-A

7 Power steeringATFto Ford spec. SQM-2C9010-A

(TQDexron II)

Maintenance Schedule

procarmanuals.com

Page 20 of 255

the previous sub Section.

27Refitting is a reversal of removal, ensuring

that the rotor arm is pushed fully home on the

rotor shaft. Make sure that the HT leads are

fitted to their correct cylinders. Note that the

rotor arm will only fit in one position.

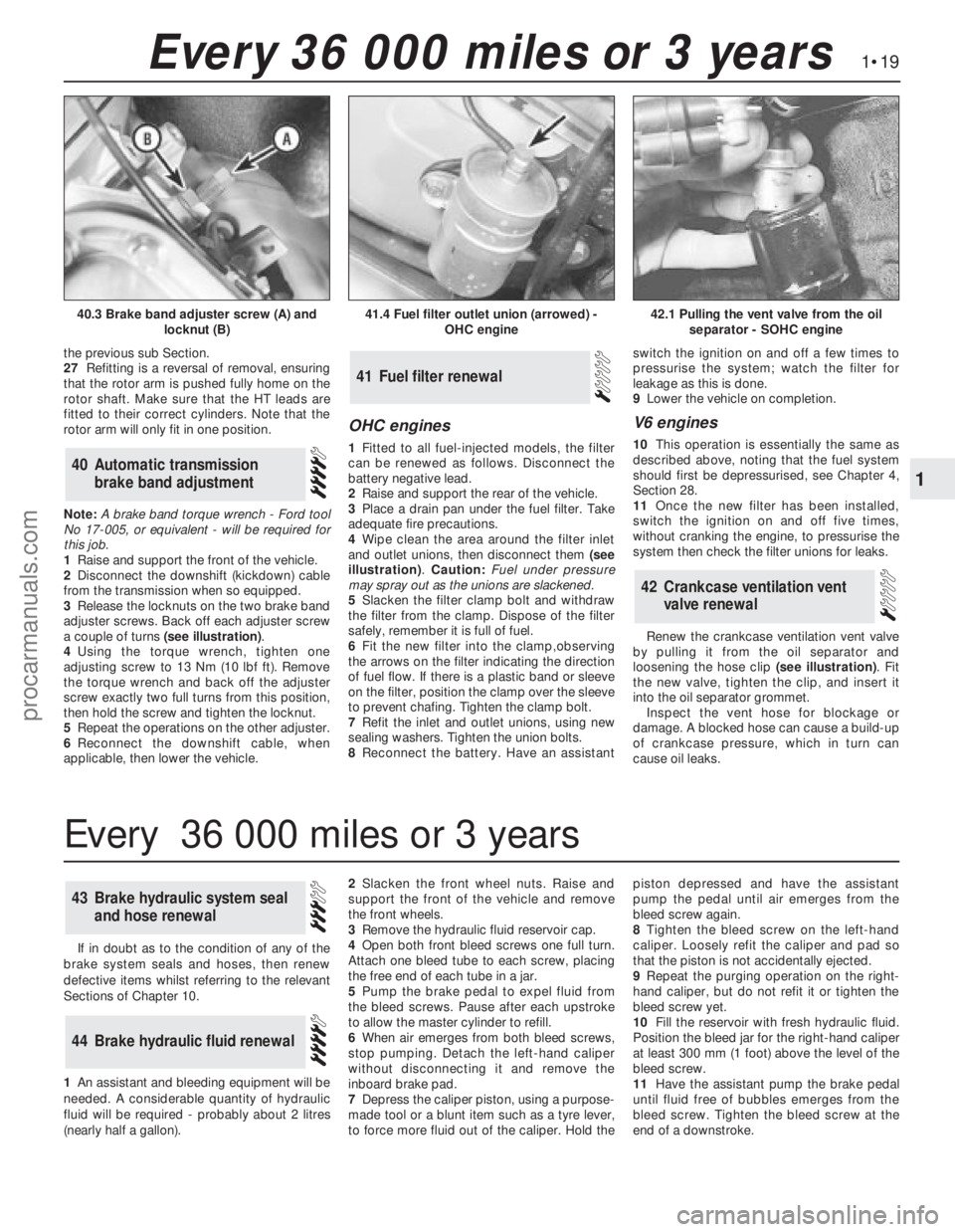

Note: A brake band torque wrench - Ford tool

No 17-005, or equivalent - will be required for

this job.

1Raise and support the front of the vehicle.

2Disconnect the downshift (kickdown) cable

from the transmission when so equipped.

3Release the locknuts on the two brake band

adjuster screws. Back off each adjuster screw

a couple of turns (see illustration).

4Using the torque wrench, tighten one

adjusting screw to 13 Nm (10 lbf ft). Remove

the torque wrench and back off the adjuster

screw exactly two full turns from this position,

then hold the screw and tighten the locknut.

5Repeat the operations on the other adjuster.

6Reconnect the downshift cable, when

applicable, then lower the vehicle.

OHC engines

1Fitted to all fuel-injected models, the filter

can be renewed as follows. Disconnect the

battery negative lead.

2Raise and support the rear of the vehicle.

3Place a drain pan under the fuel filter. Take

adequate fire precautions.

4Wipe clean the area around the filter inlet

and outlet unions, then disconnect them (see

illustration). Caution: Fuel under pressure

may spray out as the unions are slackened.

5Slacken the filter clamp bolt and withdraw

the filter from the clamp. Dispose of the filter

safely, remember it is full of fuel.

6Fit the new filter into the clamp,observing

the arrows on the filter indicating the direction

of fuel flow. If there is a plastic band or sleeve

on the filter, position the clamp over the sleeve

to prevent chafing. Tighten the clamp bolt.

7Refit the inlet and outlet unions, using new

sealing washers. Tighten the union bolts.

8Reconnect the battery. Have an assistantswitch the ignition on and off a few times to

pressurise the system; watch the filter for

leakage as this is done.

9Lower the vehicle on completion.

V6 engines

10This operation is essentially the same as

described above, noting that the fuel system

should first be depressurised, see Chapter 4,

Section 28.

11Once the new filter has been installed,

switch the ignition on and off five times,

without cranking the engine, to pressurise the

system then check the filter unions for leaks.

Renew the crankcase ventilation vent valve

by pulling it from the oil separator and

loosening the hose clip (see illustration). Fit

the new valve, tighten the clip, and insert it

into the oil separator grommet.

Inspect the vent hose for blockage or

damage. A blocked hose can cause a build-up

of crankcase pressure, which in turn can

cause oil leaks.

42Crankcase ventilation vent

valve renewal

41Fuel filter renewal

40Automatic transmission

brake band adjustment

1•19

1

Every 36 000 miles or 3 years

41.4 Fuel filter outlet union (arrowed) -

OHC engine42.1 Pulling the vent valve from the oil

separator - SOHC engine40.3 Brake band adjuster screw (A) and

locknut (B)

If in doubt as to the condition of any of the

brake system seals and hoses, then renew

defective items whilst referring to the relevant

Sections of Chapter 10.

1An assistant andbleeding equipment will be

needed. A considerable quantity of hydraulic

fluid will be required - probably about 2 litres

(nearly half a gallon).2Slacken the front wheel nuts. Raise and

support the front of the vehicle andremove

the front wheels.

3Remove the hydraulic fluid reservoir cap.

4Open both front bleed screws one full turn.

Attach one bleed tube to each screw, placing

the free end of each tube in a jar.

5Pump the brake pedal to expel fluid from

the bleed screws. Pause after each upstroke

to allow the master cylinder to refill.

6When air emerges from both bleed screws,

stop pumping. Detach the left-hand caliper

without disconnecting it and remove the

inboard brake pad.

7Depress the caliper piston, using a purpose-

made tool or a blunt item such as a tyre lever,

to force more fluid out of the caliper. Hold thepiston depressed and have the assistant

pump the pedal until air emerges from the

bleed screw again.

8Tighten the bleed screw on the left-hand

caliper. Loosely refit the caliper and pad so

that the piston is not accidentally ejected.

9Repeat the purging operation on the right-

hand caliper, but do not refit it or tighten the

bleed screw yet.

10Fill the reservoir with fresh hydraulic fluid.

Position the bleed jar for the right-hand caliper

at least 300 mm (1 foot) above the level of the

bleed screw.

11Have the assistant pump the brake pedal

until fluid free of bubbles emerges from the

bleed screw. Tighten the bleed screw at the

end of a downstroke.

44Brake hydraulic fluid renewal

43Brake hydraulic system seal

and hose renewal

Every 36 000 miles or 3 years

procarmanuals.com

Page 54 of 255

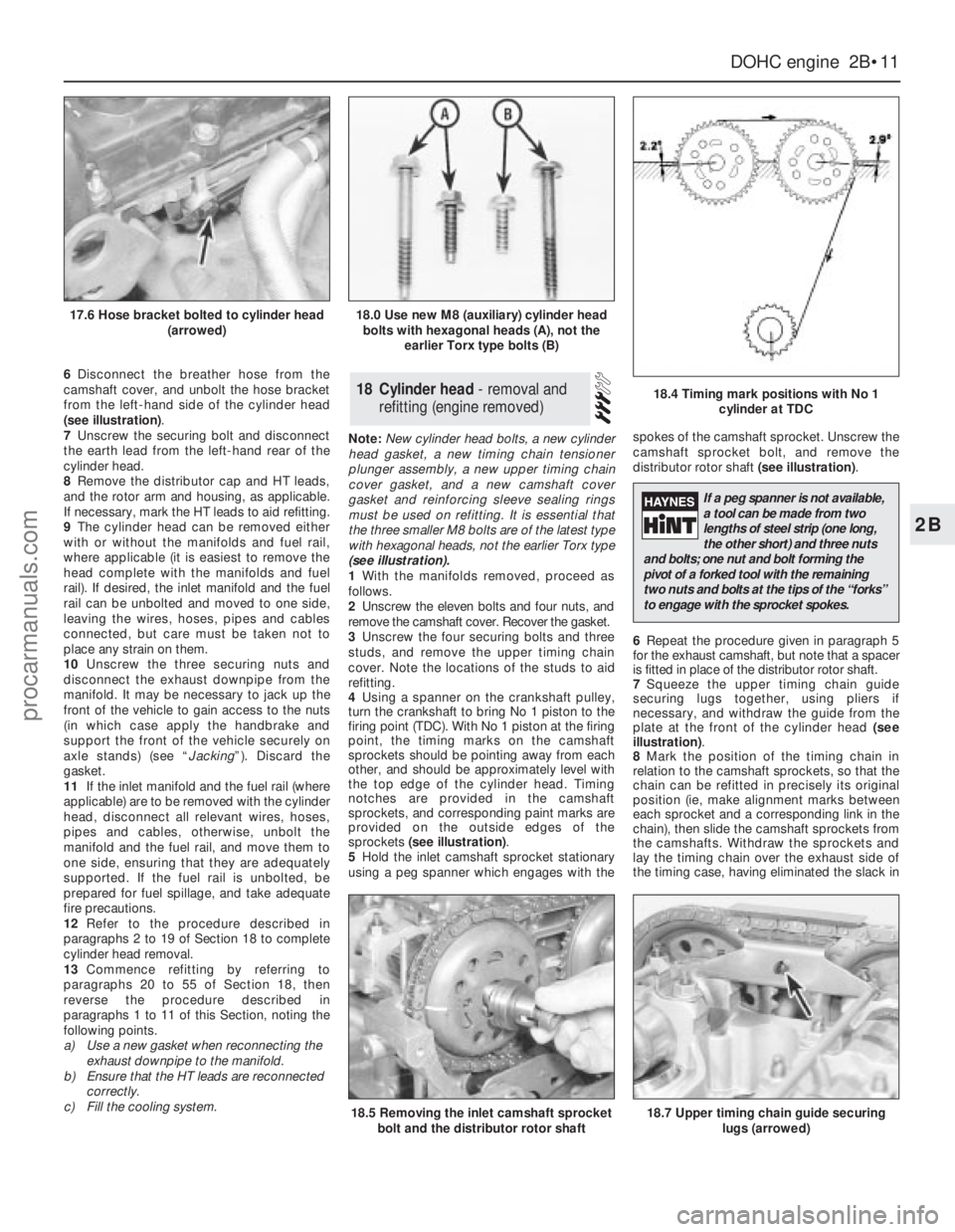

6Disconnect the breather hose from the

camshaft cover, and unbolt the hose bracket

from the left-hand side of the cylinder head

(see illustration).

7Unscrew the securing bolt and disconnect

the earth lead from the left-hand rear of the

cylinder head.

8Remove the distributor cap and HT leads,

and the rotor arm and housing, as applicable.

If necessary, mark the HT leads to aid refitting.

9The cylinder head can be removed either

with or without the manifolds and fuel rail,

where applicable (it is easiest to remove the

head complete with the manifolds and fuel

rail). If desired, the inlet manifold and the fuel

rail can be unbolted and moved to one side,

leaving the wires, hoses, pipes and cables

connected, but care must be taken not to

place any strain on them.

10Unscrew the three securing nuts and

disconnect the exhaust downpipe from the

manifold. It may be necessary to jack up the

front of the vehicle to gain access to the nuts

(in which case apply the handbrake and

support the front of the vehicle securely on

axle stands) (see “Jacking”). Discard the

gasket.

11If the inlet manifold and the fuel rail (where

applicable) are to be removed with the cylinder

head, disconnect all relevant wires, hoses,

pipes and cables, otherwise, unbolt the

manifold and the fuel rail, and move them to

one side, ensuring that they are adequately

supported. If the fuel rail is unbolted, be

prepared for fuel spillage, and take adequate

fire precautions.

12Refer to the procedure described in

paragraphs 2 to 19 of Section 18 to complete

cylinder head removal.

13Commence refitting by referring to

paragraphs 20 to 55 of Section 18, then

reverse the procedure described in

paragraphs 1 to 11 of this Section, noting the

following points.

a)Use a new gasket when reconnecting the

exhaust downpipe to the manifold.

b)Ensure that the HT leads are reconnected

correctly.

c)Fill the cooling system.Note: New cylinder head bolts, a new cylinder

head gasket, a new timing chain tensioner

plunger assembly, a new upper timing chain

cover gasket, and a new camshaft cover

gasket and reinforcing sleeve sealing rings

must be used on refitting. It is essential that

the three smaller M8 bolts are of the latest type

with hexagonal heads, not the earlier Torx type

(see illustration).

1With the manifolds removed, proceed as

follows.

2Unscrew the eleven bolts and four nuts, and

remove the camshaft cover. Recover the gasket.

3Unscrew the four securing bolts and three

studs, and remove the upper timing chain

cover. Note the locations of the studs to aid

refitting.

4Using a spanner on the crankshaft pulley,

turn the crankshaft to bring No 1 piston to the

firing point (TDC). With No 1 piston at the firing

point, the timing marks on the camshaft

sprockets should be pointing away from each

other, and should be approximately level with

the top edge of the cylinder head. Timing

notches are provided in the camshaft

sprockets, and corresponding paint marks are

provided on the outside edges of the

sprockets (see illustration).

5Hold the inlet camshaft sprocket stationary

using a peg spanner which engages with thespokes of the camshaft sprocket. Unscrew the

camshaft sprocket bolt, and remove the

distributor rotor shaft (see illustration).

6Repeat the procedure given in paragraph 5

for the exhaust camshaft, but note that a spacer

is fitted in place of the distributor rotor shaft.

7Squeeze the upper timing chain guide

securing lugs together, using pliers if

necessary, and withdraw the guide from the

plate at the front of the cylinder head (see

illustration).

8Mark the position of the timing chain in

relation to the camshaft sprockets, so that the

chain can be refitted in precisely its original

position (ie, make alignment marks between

each sprocket and a corresponding link in the

chain), then slide the camshaft sprockets from

the camshafts. Withdraw the sprockets and

lay the timing chain over the exhaust side of

the timing case, having eliminated the slack in18Cylinder head - removal and

refitting (engine removed)

DOHCengine 2B•11

2B

17.6 Hose bracket bolted to cylinder head

(arrowed)18.0 Use new M8 (auxiliary) cylinder head

bolts with hexagonal heads (A), not the

earlier Torx type bolts (B)

18.4 Timing mark positions with No 1

cylinder at TDC

18.5 Removing the inlet camshaft sprocket

bolt and the distributor rotor shaft18.7 Upper timing chain guide securing

lugs (arrowed)

If a peg spanner is not available,

a tool can be made from two

lengths of steel strip (one long,

the other short) and three nuts

and bolts; one nut and bolt forming the

pivot of a forked tool with the remaining

two nuts and bolts at the tips of the “forks”

to engage with the sprocket spokes.

procarmanuals.com

Page 58 of 255

d)Disconnect the breather hose from the

camshaft cover.

e)Remove the distributor cap and HT leads,

and the rotor arm and housing. If

necessary, mark the HT leads to aid

refitting.

2Proceed as described in paragraphs 2 to 15

inclusive of Section 18.

3Examine the surfaces of the camshaft

journals and lobes and the contact surfaces of

the cam followers for wear. If wear is

excessive, considerable noise would have

been noticed from the top of the engine when

running, and new camshafts and followers

must be fitted. It is unlikely that this level of

wear will occur unless a considerable mileage

has been covered. Note that the cam followers

cannot be dismantled for renewal of individual

components.

4Check the camshaft bearing surfaces in the

cylinder head and the bearing caps for wear. If

excessive wear is evident, the only course of

action available is to renew the cylinder head

complete with bearing caps.

5Check the cam follower bores in the

cylinder head for wear. If excessive wear is

evident, the cylinder head must be renewed.

6Check the cam follower oil grooves and the

oil ports in the cylinder head for obstructions.

7Refit the cam followers and the camshafts as

described in paragraphs 27 to 55 of Section 18.

8If the engine is in the vehicle, reverse the

operations given in paragraph 1.

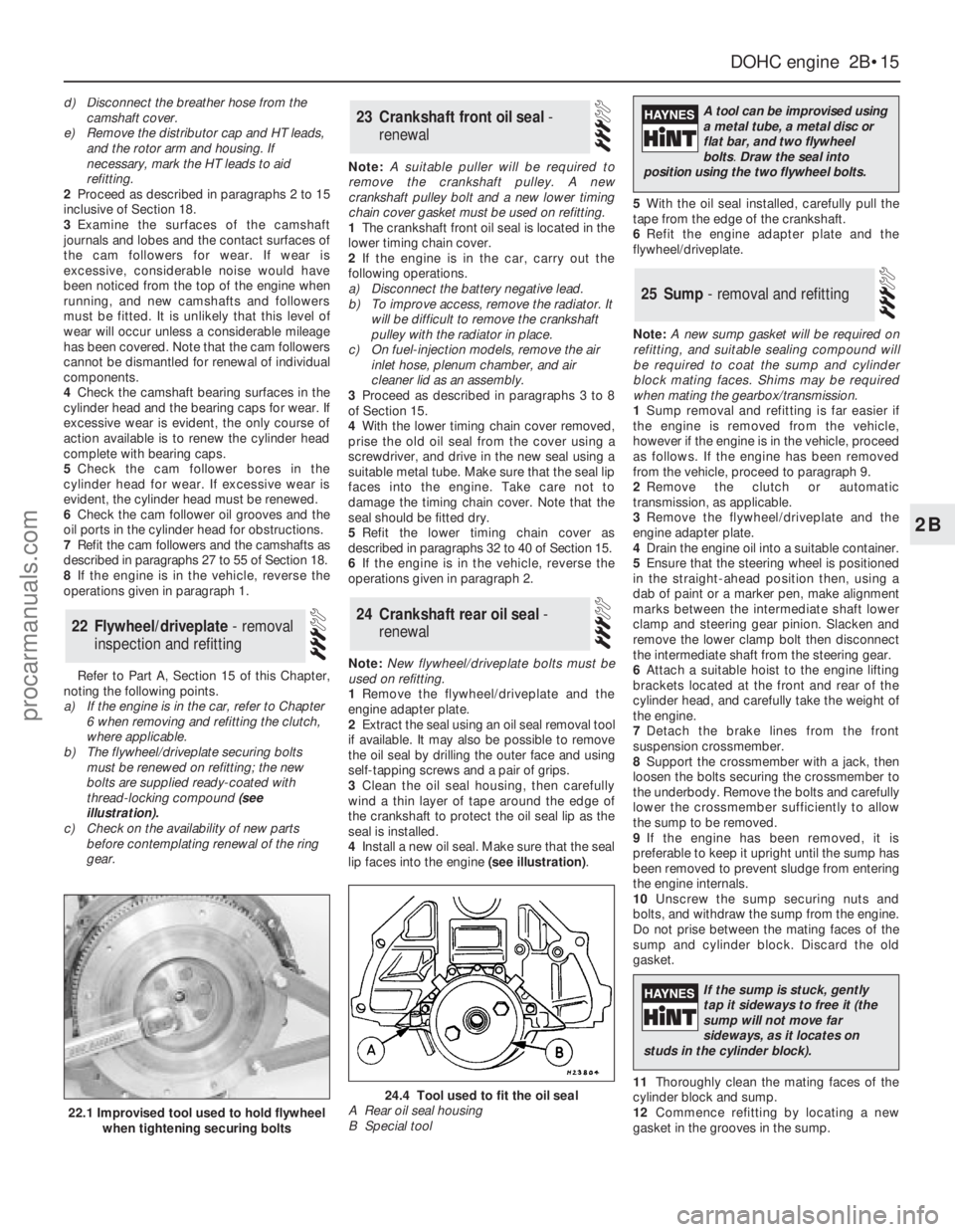

Refer to Part A, Section 15 of this Chapter,

noting the following points.

a)If the engine is in the car, refer to Chapter

6 when removing and refitting the clutch,

where applicable.

b)The flywheel/driveplate securing bolts

must be renewed on refitting; the new

bolts are supplied ready-coated with

thread-locking compound (see

illustration).

c)Check on the availability of new parts

before contemplating renewal of the ring

gear.Note: A suitable puller will be required to

remove the crankshaft pulley. A new

crankshaft pulley bolt and a new lower timing

chain cover gasket must be used on refitting.

1The crankshaft front oil seal is located in the

lower timing chain cover.

2If the engine is in the car, carry out the

following operations.

a)Disconnect the battery negative lead.

b)To improve access, remove the radiator. It

will be difficult to remove the crankshaft

pulley with the radiator in place.

c)On fuel-injection models, remove the air

inlet hose, plenum chamber, and air

cleaner lid as an assembly.

3Proceed as described in paragraphs 3 to 8

of Section 15.

4With the lower timing chain cover removed,

prise the old oil seal from the cover using a

screwdriver, and drive in the new seal using a

suitable metal tube. Make sure that the seal lip

faces into the engine. Take care not to

damage the timing chain cover. Note that the

seal should be fitted dry.

5Refit the lower timing chain cover as

described in paragraphs 32 to 40 of Section 15.

6If the engine is in the vehicle, reverse the

operations given in paragraph 2.

Note: New flywheel/driveplate bolts must be

used on refitting.

1Remove the flywheel/driveplate and the

engine adapter plate.

2Extract the seal using an oil seal removal tool

if available. It may also be possible to remove

the oil seal by drilling the outer face and using

self-tapping screws and a pair of grips.

3Clean the oil seal housing, then carefully

wind a thin layer of tape around the edge of

the crankshaft to protect the oil seal lip as the

seal is installed.

4Install a new oil seal. Make sure that the seal

lip faces into the engine (see illustration).5With the oil seal installed, carefully pull the

tape from the edge of the crankshaft.

6Refit the engine adapter plate and the

flywheel/driveplate.

Note: A new sump gasket will be required on

refitting, and suitable sealing compound will

be required to coat the sump and cylinder

block mating faces. Shims may be required

when mating the gearbox/transmission.

1Sump removal and refitting is far easier if

the engine is removed from the vehicle,

however if the engine is in the vehicle, proceed

as follows. If the engine has been removed

from the vehicle, proceed to paragraph 9.

2Remove the clutch or automatic

transmission, as applicable.

3Remove the flywheel/driveplate and the

engine adapter plate.

4Drain the engine oil into a suitable container.

5Ensure that the steering wheel is positioned

in the straight-ahead position then, using a

dab of paint or a marker pen, make alignment

marks between the intermediate shaft lower

clamp and steering gear pinion. Slacken and

remove the lower clamp bolt then disconnect

the intermediate shaft from the steering gear.

6Attach a suitable hoist to the engine lifting

brackets located at the front and rear of the

cylinder head, and carefully take the weight of

the engine.

7Detach the brake lines from the front

suspension crossmember.

8Support the crossmember with a jack, then

loosen the bolts securing the crossmember to

the underbody. Remove the bolts and carefully

lower the crossmember sufficiently to allow

the sump to be removed.

9If the engine has been removed, it is

preferable to keep it upright until the sump has

been removed to prevent sludge from entering

the engine internals.

10Unscrew the sump securing nuts and

bolts, and withdraw the sump from the engine.

Do not prise between the mating faces of the

sump and cylinder block. Discard the old

gasket.

11Thoroughly clean the mating faces of the

cylinder block and sump.

12Commence refitting by locating a new

gasket in the grooves in the sump.

25Sump - removal and refitting

24Crankshaft rear oil seal -

renewal

23Crankshaft front oil seal -

renewal

22Flywheel/driveplate - removal

inspection and refitting

DOHCengine 2B•15

2B

22.1 Improvised tool used to hold flywheel

when tightening securing bolts

24.4 Tool used to fit the oil seal

A Rear oil seal housing

B Special tool

A tool can be improvised using

a metal tube, a metal disc or

flat bar, and two flywheel

bolts.Draw the seal into

position using the two flywheel bolts.

If the sump is stuck, gently

tap it sideways to free it (the

sump will not move far

sideways, as it locates on

studs in the cylinder block).

procarmanuals.com

Page 71 of 255

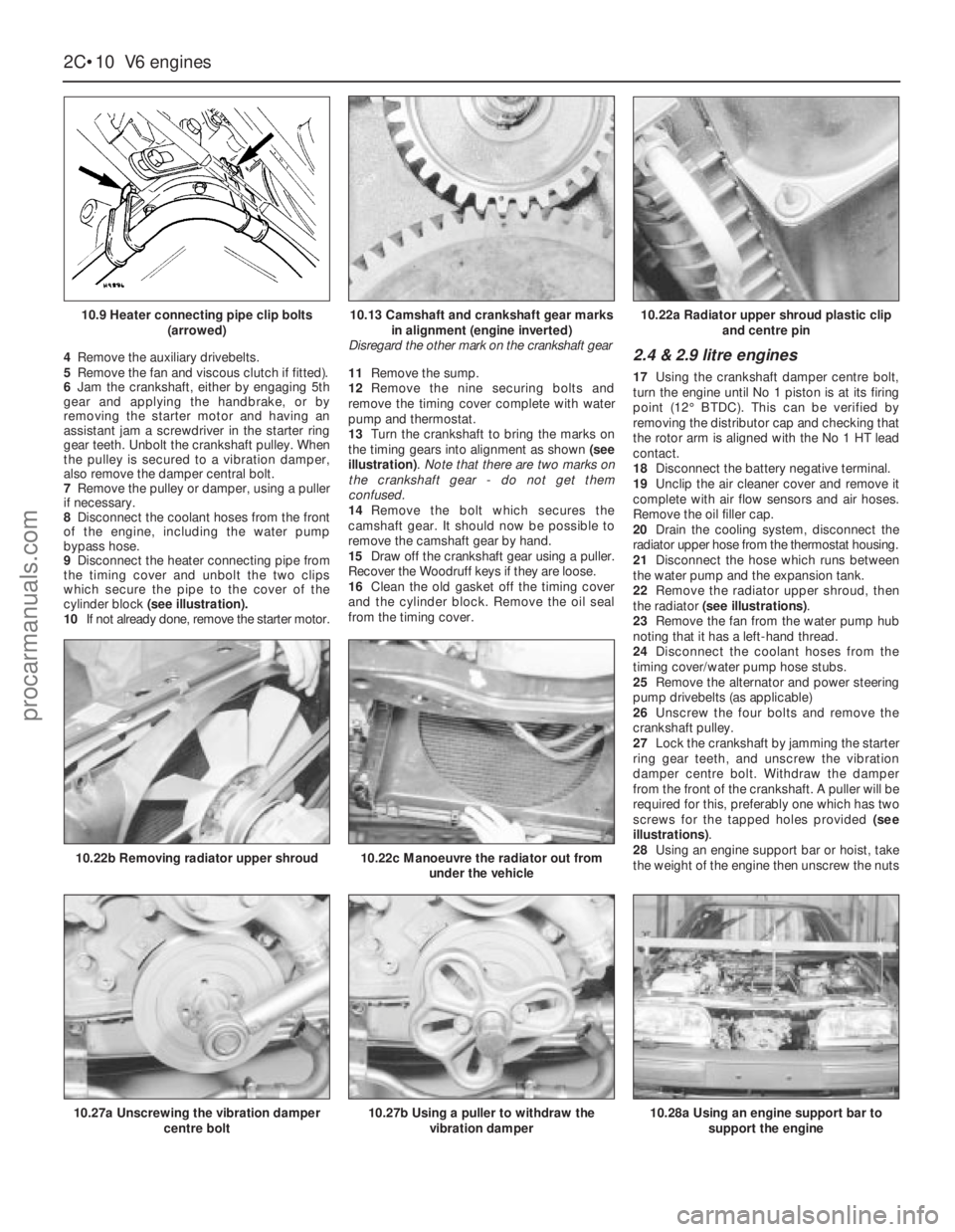

4Remove the auxiliary drivebelts.

5Remove the fan and viscous clutch if fitted).

6Jam the crankshaft, either by engaging 5th

gear and applying the handbrake, or by

removing the starter motor and having an

assistant jam a screwdriver in the starter ring

gear teeth. Unbolt the crankshaft pulley. When

the pulley is secured to a vibration damper,

also remove the damper central bolt.

7Remove the pulley or damper, using a puller

if necessary.

8Disconnect the coolant hoses from the front

of the engine, including the water pump

bypass hose.

9Disconnect the heater connecting pipe from

the timing cover and unbolt the two clips

which secure the pipe to the cover of the

cylinder block (see illustration).

10If not already done, remove the starter motor.11Remove the sump.

12Remove the nine securing bolts and

remove the timing cover complete with water

pump and thermostat.

13Turn the crankshaft to bring the marks on

the timing gears into alignment as shown (see

illustration). Note that there are two marks on

the crankshaft gear - do not get them

confused.

14Remove the bolt which secures the

camshaft gear. It should now be possible to

remove the camshaft gear by hand.

15Draw off the crankshaft gear using a puller.

Recover the Woodruff keys if they are loose.

16Clean the old gasket off the timing cover

and the cylinder block. Remove the oil seal

from the timing cover.2.4 & 2.9 litre engines

17Using the crankshaft damper centre bolt,

turn the engine until No 1 piston is at its firing

point (12°BTDC). This can be verified by

removing the distributor cap and checking that

the rotor arm is aligned with the No 1 HT lead

contact.

18Disconnect the battery negative terminal.

19Unclip the air cleaner cover and remove it

complete with air flow sensors and air hoses.

Remove the oil filler cap.

20Drain the cooling system, disconnect the

radiator upper hose from the thermostat housing.

21Disconnect the hose which runs between

the water pump and the expansion tank.

22Remove the radiator upper shroud, then

the radiator (see illustrations).

23Remove the fan from the water pump hub

noting that it has a left-hand thread.

24Disconnect the coolant hoses from the

timing cover/water pump hose stubs.

25Remove the alternator and power steering

pump drivebelts (as applicable)

26Unscrew the four bolts and remove the

crankshaft pulley.

27Lock the crankshaft by jamming the starter

ring gear teeth, and unscrew the vibration

damper centre bolt. Withdraw the damper

from the front of the crankshaft. A puller will be

required for this, preferably one which has two

screws for the tapped holes provided (see

illustrations).

28Using an engine support bar or hoist, take

the weight of the engine then unscrew the nuts

2C•10V6 engines

10.9 Heater connecting pipe clip bolts

(arrowed)

10.27a Unscrewing the vibration damper

centre bolt

10.22b Removing radiator upper shroud10.22c Manoeuvre the radiator out from

under the vehicle

10.27b Using a puller to withdraw the

vibration damper10.28a Using an engine support bar to

support the engine

10.13 Camshaft and crankshaft gear marks

in alignment (engine inverted)

Disregard the other mark on the crankshaft gear10.22a Radiator upper shroud plastic clip

and centre pin

procarmanuals.com

Page 151 of 255

times, then use a proprietary balljoint

separator to break the taper (see illustration).

5Use a stout piece of wood to lever the lower

arm downwards and free the balljoint from the

stub axle carrier.

6Remove the ABS wheel sensor from its

hole.

7Remove the spring clip from one of the

wheel studs and pull the brake disc off the

hub.

8Remove the stub axle carrier pinch-bolt.

Spread the stub axle carrier by carefully

introducing a chisel or blunt instrument into its

slot. Draw the stub axle carrier off the

suspension strut and remove it.

9Refit by reversing the removal operations,

noting the following points:

a)Tighten all fastenings to the specified

torque

b)Use new split pins, when applicable

c)Renew the wheel sensor O-ring if

necessary; clean the sensor and its bore,

and smear them with wheel bearing

grease

Models before August 1989

1Remove the stub axle carrier as described

in the previous Section.

2Screw the wheel nuts onto the studs to

protect the threads. Clamp the stub axle

carrier in a vice by means of the studs and

nuts; do not overtighten.

3Remove the dust cap from the hub nut,

carefully levering it free (see illustration). A

new cap and a new hub nut will be required for

reassembly.

4Undo the hub nut. This nut is very tight. The

right-hand hub nut has a left-handthread,

therefore it is undone in a clockwisedirection.

5Remove the ABS rotor from below the hub

nut.

6Lift the carrier off the stub axle, tapping it

with a mallet if necessary to free it. Remove

the bearing inner race from the carrier.

7Prise the oil seal out of the carrier and

recover the bearing outer race.8Drive the bearing tracks out of the stub axle

carrier using a blunt drift and a hammer. Be

careful not to mark the bearing seats.

9Clean all old grease and debris from the

stub axle carrier.

10New bearing components are matched in

production and must only be fitted as a set.

Only the manufacturer’s approved

components should be used in order to obtain

the required long service life and freedom from

adjustment.

11Drive the new bearing tracks into the

carrier, preferably using a suitable diameter

tube to seat them. Make sure the tracks are

fully seated.

12Work some clean grease into the bearing

races. Use high melting-point lithium-based

grease (to Ford spec. SAMIC-9111A or

equivalent). Make sure all the spaces between

the rollers are filled; do not pack grease into

the space between the inner and outer

bearings however.

13Fit the bearing outer race. Grease the lips

of a new oil seal and fit it to the stub axle

carrier, lips facing inwards. Seat the seal with

a pipe or large socket and a mallet.

14Offer the carrier to the stub axle, tapping it

home if necessary. Fit the bearing inner race

over the stub axle.

15Refit the ABS rotor, dished face

uppermost.

16Fit a new hub nut (left-hand thread on the

right-hand hub) and tighten it to the specified

torque.17Fit a new dust cap and seat it by tapping

round the rim (see illustration).

18Refit the stub axle carrier.

Models from August 1989

19Modified front wheel bearing assemblies

were fitted to all models after 1989. The

modified bearings are of similar design, but

are interference fit type bearings. This was to

reduce the amount of endfloat present at the

wheel hub and to improve bearing preload

tolerances. This was achieved by increasing

the diameter of the stub axle, thus causing the

axle to be an interference fit in the bearing.

Note that the modified bearings can be fitted

to earlier models which were originally

equipped with non-interference fit front wheel

bearings. Note: Due to the design of the

interference fit bearings, a suitable heavy duty

bearing puller and a hydraulic press and

several suitable mandrels will be required to

remove the originalbearing and install the new

one.

20Interference fit front wheel bearings can be

removed and refitted as described above,

noting the following points.

a)It will be necessary to press or draw the

stub axle out of the carrier using a

hydraulic press or a suitable bearing

puller.

b)Draw the outer bearing off the stub axle

using a suitable bearing puller.

c)Press new bearing tracks into the hub

carrier using a suitable tubular spacer

which bears only on the tracks outer edge.

d)Pack the new outer bearing with Ford

grease (SAM-1C9111-A) and press the

bearing into the carrier.

e)Press a new seal into position in the

carrier and pack all cavities with the

specified grease.

f)Position the hub carrier over the stub axle

and press the carrier onto the axle using a

suitable tubular spacer which bears only

on the bearing track outer edge.

g)Pack the new inner bearing with the

specified grease then press the bearing

onto the stub axle, using a suitable tubular

spacer, whilst rotating the hub carrier to

ensure that the bearing is correctly seated.

h)Whilst tightening the hub nut to the

specified torque, rotate the hub carrier to

ensure that the bearing preload is correct

and bearings are correctly seated. Once

the nut is tightened to the specified

torque, rotate the hub carrier 20 times to

settle the bearings in position then

recheck that the hub nut is tightened to

the specified torque. Pack the inner

bearing with the specified grease and fit a

new dust cap.

17Front wheel bearings -

renewal

11•8Steering and suspension

16.4 Slackening the front suspension lower

arm balljoint nut

17.17 Seating the new dust cap17.3 Removing the dust cap from the stub

axle carrier to expose the hub nut

procarmanuals.com

Page 249 of 255

REF•14Glossary of Technical Terms

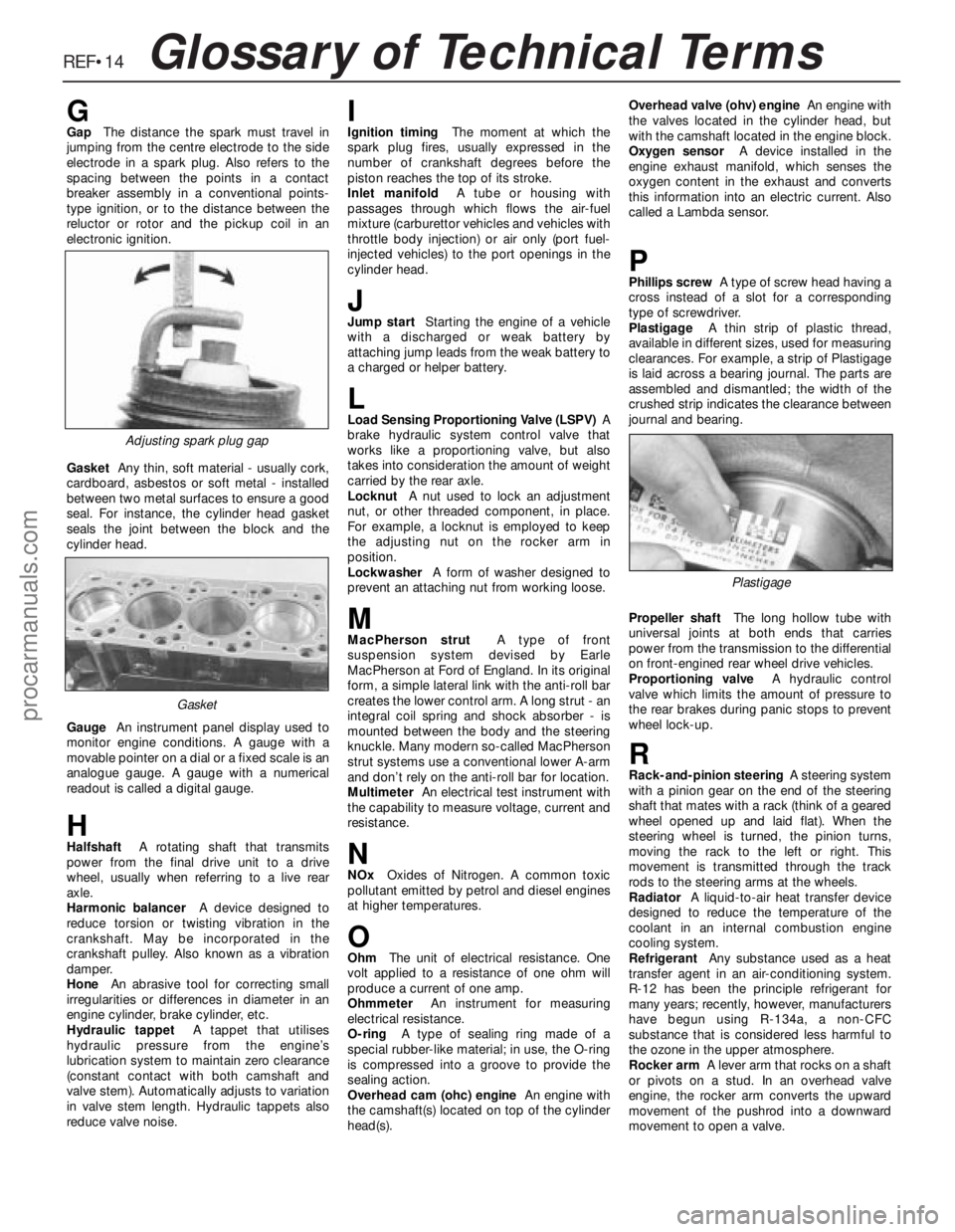

GGapThe distance the spark must travel in

jumping from the centre electrode to the side

electrode in a spark plug. Also refers to the

spacing between the points in a contact

breaker assembly in a conventional points-

type ignition, or to the distance between the

reluctor or rotor and the pickup coil in an

electronic ignition.

GasketAny thin, soft material - usually cork,

cardboard, asbestos or soft metal - installed

between two metal surfaces to ensure a good

seal. For instance, the cylinder head gasket

seals the joint between the block and the

cylinder head.

GaugeAn instrument panel display used to

monitor engine conditions. A gauge with a

movable pointer on a dial or a fixed scale is an

analogue gauge. A gauge with a numerical

readout is called a digital gauge.

HHalfshaftA rotating shaft that transmits

power from the final drive unit to a drive

wheel, usually when referring to a live rear

axle.

Harmonic balancerA device designed to

reduce torsion or twisting vibration in the

crankshaft. May be incorporated in the

crankshaft pulley. Also known as a vibration

damper.

HoneAn abrasive tool for correcting small

irregularities or differences in diameter in an

engine cylinder, brake cylinder, etc.

Hydraulic tappetA tappet that utilises

hydraulic pressure from the engine’s

lubrication system to maintain zero clearance

(constant contact with both camshaft and

valve stem). Automatically adjusts to variation

in valve stem length. Hydraulic tappets also

reduce valve noise.

IIgnition timingThe moment at which the

spark plug fires, usually expressed in the

number of crankshaft degrees before the

piston reaches the top of its stroke.

Inlet manifoldA tube or housing with

passages through which flows the air-fuel

mixture (carburettor vehicles and vehicles with

throttle body injection) or air only (port fuel-

injected vehicles) to the port openings in the

cylinder head.

JJump startStarting the engine of a vehicle

with a discharged or weak battery by

attaching jump leads from the weak battery to

a charged or helper battery.

LLoad Sensing Proportioning Valve (LSPV)A

brake hydraulic system control valve that

works like a proportioning valve, but also

takes into consideration the amount of weight

carried by the rear axle.

LocknutA nut used to lock an adjustment

nut, or other threaded component, in place.

For example, a locknut is employed to keep

the adjusting nut on the rocker arm in

position.

LockwasherA form of washer designed to

prevent an attaching nut from working loose.

MMacPherson strutA type of front

suspension system devised by Earle

MacPherson at Ford of England. In its original

form, a simple lateral link with the anti-roll bar

creates the lower control arm. A long strut - an

integral coil spring and shock absorber - is

mounted between the body and the steering

knuckle. Many modern so-called MacPherson

strut systems use a conventional lower A-arm

and don’t rely on the anti-roll bar for location.

MultimeterAn electrical test instrument with

the capability to measure voltage, current and

resistance.

NNOxOxides of Nitrogen. A common toxic

pollutant emitted by petrol and diesel engines

at higher temperatures.

OOhmThe unit of electrical resistance. One

volt applied to a resistance of one ohm will

produce a current of one amp.

OhmmeterAn instrument for measuring

electrical resistance.

O-ringA type of sealing ring made of a

special rubber-like material; in use, the O-ring

is compressed into a groove to provide the

sealing action.

Overhead cam (ohc) engineAn engine with

the camshaft(s) located on top of the cylinder

head(s).Overhead valve (ohv) engineAn engine with

the valves located in the cylinder head, but

with the camshaft located in the engine block.

Oxygen sensorA device installed in the

engine exhaust manifold, which senses the

oxygen content in the exhaust and converts

this information into an electric current. Also

called a Lambda sensor.

PPhillips screwA type of screw head having a

cross instead of a slot for a corresponding

type of screwdriver.

PlastigageA thin strip of plastic thread,

available in different sizes, used for measuring

clearances. For example, a strip of Plastigage

is laid across a bearing journal. The parts are

assembled and dismantled; the width of the

crushed strip indicates the clearance between

journal and bearing.

Propeller shaftThe long hollow tube with

universal joints at both ends that carries

power from the transmission to the differential

on front-engined rear wheel drive vehicles.

Proportioning valveA hydraulic control

valve which limits the amount of pressure to

the rear brakes during panic stops to prevent

wheel lock-up.

RRack-and-pinion steeringA steering system

with a pinion gear on the end of the steering

shaft that mates with a rack (think of a geared

wheel opened up and laid flat). When the

steering wheel is turned, the pinion turns,

moving the rack to the left or right. This

movement is transmitted through the track

rods to the steering arms at the wheels.

RadiatorA liquid-to-air heat transfer device

designed to reduce the temperature of the

coolant in an internal combustion engine

cooling system.

RefrigerantAny substance used as a heat

transfer agent in an air-conditioning system.

R-12 has been the principle refrigerant for

many years; recently, however, manufacturers

have begun using R-134a, a non-CFC

substance that is considered less harmful to

the ozone in the upper atmosphere.

Rocker armA lever arm that rocks on a shaft

or pivots on a stud. In an overhead valve

engine, the rocker arm converts the upward

movement of the pushrod into a downward

movement to open a valve.

Adjusting spark plug gap

Plastigage

Gasket

procarmanuals.com