engine oil capacity FORD GRANADA 1985 Service Repair Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1985, Model line: GRANADA, Model: FORD GRANADA 1985Pages: 255, PDF Size: 14.98 MB

Page 24 of 255

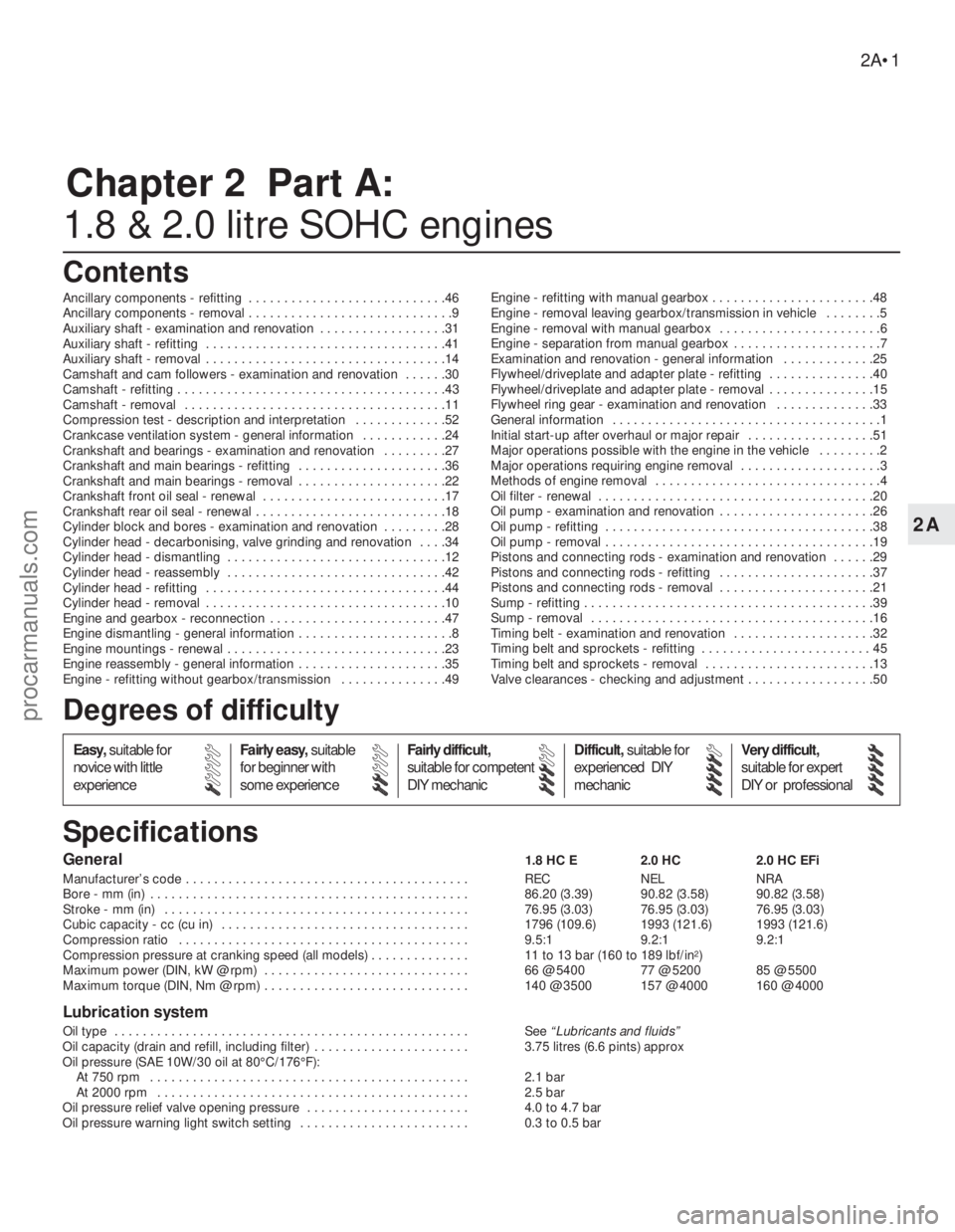

Chapter 2 Part A:

1.8 & 2.0 litre SOHC engines

Ancillary components - refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Ancillary components - removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Auxiliary shaft - examination and renovation . . . . . . . . . . . . . . . . . .31

Auxiliary shaft - refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Auxiliary shaft - removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Camshaft and cam followers - examination and renovation . . . . . .30

Camshaft - refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Camshaft - removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Compression test - description and interpretation . . . . . . . . . . . . .52

Crankcase ventilation system - general information . . . . . . . . . . . .24

Crankshaft and bearings - examination and renovation . . . . . . . . .27

Crankshaft and main bearings - refitting . . . . . . . . . . . . . . . . . . . . .36

Crankshaft and main bearings - removal . . . . . . . . . . . . . . . . . . . . .22

Crankshaft front oil seal - renewal . . . . . . . . . . . . . . . . . . . . . . . . . .17

Crankshaft rear oil seal - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Cylinder block and bores - examination and renovation . . . . . . . . .28

Cylinder head - decarbonising, valve grinding and renovation . . . .34

Cylinder head - dismantling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Cylinder head - reassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Cylinder head - refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Cylinder head - removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Engine and gearbox - reconnection . . . . . . . . . . . . . . . . . . . . . . . . .47

Engine dismantling - general information . . . . . . . . . . . . . . . . . . . . . .8

Engine mountings - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Engine reassembly - general information . . . . . . . . . . . . . . . . . . . . .35

Engine - refitting without gearbox/transmission . . . . . . . . . . . . . . .49Engine - refitting with manual gearbox . . . . . . . . . . . . . . . . . . . . . . .48

Engine - removal leaving gearbox/transmission in vehicle . . . . . . . .5

Engine - removal with manual gearbox . . . . . . . . . . . . . . . . . . . . . . .6

Engine - separation from manual gearbox . . . . . . . . . . . . . . . . . . . . .7

Examination and renovation - general information . . . . . . . . . . . . .25

Flywheel/driveplate and adapter plate - refitting . . . . . . . . . . . . . . .40

Flywheel/driveplate and adapter plate - removal . . . . . . . . . . . . . . .15

Flywheel ring gear - examination and renovation . . . . . . . . . . . . . .33

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Initial start-up after overhaul or major repair . . . . . . . . . . . . . . . . . .51

Major operations possible with the engine in the vehicle . . . . . . . . .2

Major operations requiring engine removal . . . . . . . . . . . . . . . . . . . .3

Methods of engine removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Oil filter - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Oil pump - examination and renovation . . . . . . . . . . . . . . . . . . . . . .26

Oil pump - refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Oil pump - removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Pistons and connecting rods - examination and renovation . . . . . .29

Pistons and connecting rods - refitting . . . . . . . . . . . . . . . . . . . . . .37

Pistons and connecting rods - removal . . . . . . . . . . . . . . . . . . . . . .21

Sump - refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Sump - removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Timing belt - examination and renovation . . . . . . . . . . . . . . . . . . . .32

Timing belt and sprockets - refitting . . . . . . . . . . . . . . . . . . . . . . . . 45

Timing belt and sprockets - removal . . . . . . . . . . . . . . . . . . . . . . . .13

Valve clearances - checking and adjustment . . . . . . . . . . . . . . . . . .50

General1.8 HC E 2.0 HC 2.0 HC EFi

Manufacturer’s code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . REC NEL NRA

Bore - mm (in) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86.20 (3.39) 90.82 (3.58) 90.82 (3.58)

Stroke - mm (in) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76.95 (3.03) 76.95 (3.03) 76.95 (3.03)

Cubic capacity - cc (cu in) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1796 (109.6) 1993 (121.6) 1993 (121.6)

Compression ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.5:1 9.2:1 9.2:1

Compression pressure at cranking speed (all models) . . . . . . . . . . . . . . 11 to 13 bar (160 to 189 lbf/in

2)

Maximum power (DIN, kW @ rpm) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66 @ 5400 77 @ 5200 85 @ 5500

Maximum torque (DIN, Nm @ rpm) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140 @ 3500 157 @ 4000 160 @ 4000

Lubrication system

Oil type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . See“Lubricants and fluids”

Oil capacity (drain and refill, including filter) . . . . . . . . . . . . . . . . . . . . . . 3.75 litres (6.6 pints) approx

Oil pressure (SAE 10W/30 oil at 80°C/176°F):

At 750 rpm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.1 bar

At 2000 rpm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.5 bar

Oil pressure relief valve opening pressure . . . . . . . . . . . . . . . . . . . . . . . 4.0 to 4.7 bar

Oil pressure warning light switch setting . . . . . . . . . . . . . . . . . . . . . . . . 0.3 to 0.5 bar

2A•1

Easy,suitable for

novice with little

experienceFairly easy,suitable

for beginner with

some experienceFairly difficult,

suitable for competent

DIY mechanicDifficult,suitable for

experienced DIY

mechanicVery difficult,

suitable for expert

DIY or professional

Degrees of difficulty

Specifications Contents

2A

procarmanuals.com

Page 44 of 255

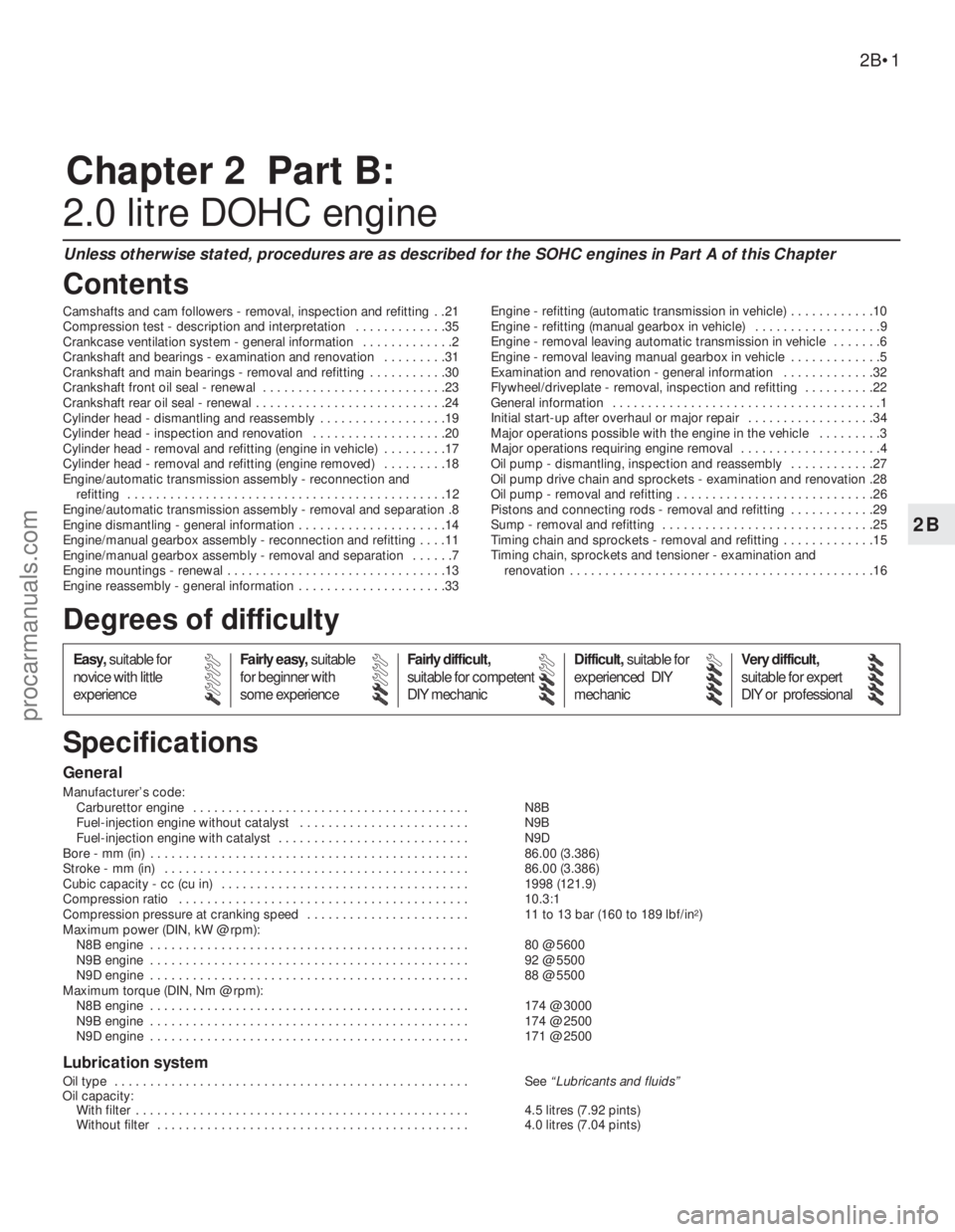

Chapter 2 Part B:

2.0 litre DOHC engine

Unless otherwise stated, procedures are as described for the SOHC engines in Part A of this Chapter

Camshafts and cam followers - removal, inspection and refitting . .21

Compression test - description and interpretation . . . . . . . . . . . . .35

Crankcase ventilation system - general information . . . . . . . . . . . . .2

Crankshaft and bearings - examination and renovation . . . . . . . . .31

Crankshaft and main bearings - removal and refitting . . . . . . . . . . .30

Crankshaft front oil seal - renewal . . . . . . . . . . . . . . . . . . . . . . . . . .23

Crankshaft rear oil seal - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Cylinder head - dismantling and reassembly . . . . . . . . . . . . . . . . . .19

Cylinder head - inspection and renovation . . . . . . . . . . . . . . . . . . .20

Cylinder head - removal and refitting (engine in vehicle) . . . . . . . . .17

Cylinder head - removal and refitting (engine removed) . . . . . . . . .18

Engine/automatic transmission assembly - reconnection and

refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Engine/automatic transmission assembly - removal and separation .8

Engine dismantling - general information . . . . . . . . . . . . . . . . . . . . .14

Engine/manual gearbox assembly - reconnection and refitting . . . .11

Engine/manual gearbox assembly - removal and separation . . . . . .7

Engine mountings - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Engine reassembly - general information . . . . . . . . . . . . . . . . . . . . .33Engine - refitting (automatic transmission in vehicle) . . . . . . . . . . . .10

Engine - refitting (manual gearbox in vehicle) . . . . . . . . . . . . . . . . . .9

Engine - removal leaving automatic transmission in vehicle . . . . . . .6

Engine - removal leaving manual gearbox in vehicle . . . . . . . . . . . . .5

Examination and renovation - general information . . . . . . . . . . . . .32

Flywheel/driveplate - removal, inspection and refitting . . . . . . . . . .22

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Initial start-up after overhaul or major repair . . . . . . . . . . . . . . . . . .34

Major operations possible with the engine in the vehicle . . . . . . . . .3

Major operations requiring engine removal . . . . . . . . . . . . . . . . . . . .4

Oil pump - dismantling, inspection and reassembly . . . . . . . . . . . .27

Oil pump drive chain and sprockets - examination and renovation .28

Oil pump - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Pistons and connecting rods - removal and refitting . . . . . . . . . . . .29

Sump - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Timing chain and sprockets - removal and refitting . . . . . . . . . . . . .15

Timing chain, sprockets and tensioner - examination and

renovation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

General

Manufacturer’s code:

Carburettor engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . N8B

Fuel-injection engine without catalyst . . . . . . . . . . . . . . . . . . . . . . . . N9B

Fuel-injection engine with catalyst . . . . . . . . . . . . . . . . . . . . . . . . . . . N9D

Bore - mm (in) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86.00 (3.386)

Stroke - mm (in) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86.00 (3.386)

Cubic capacity - cc (cu in) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1998 (121.9)

Compression ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.3:1

Compression pressure at cranking speed . . . . . . . . . . . . . . . . . . . . . . . 11 to 13 bar (160 to 189 lbf/in

2)

Maximum power (DIN, kW @ rpm):

N8B engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80 @ 5600

N9B engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92 @ 5500

N9D engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88 @ 5500

Maximum torque (DIN, Nm @ rpm):

N8B engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174 @ 3000

N9B engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174 @ 2500

N9D engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171 @ 2500

Lubrication system

Oil type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . See “Lubricants and fluids”

Oil capacity:

With filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.5 litres (7.92 pints)

Without filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.0 litres (7.04 pints)

2B•1

Easy,suitable for

novice with little

experienceFairly easy,suitable

for beginner with

some experienceFairly difficult,

suitable for competent

DIY mechanicDifficult,suitable for

experienced DIY

mechanicVery difficult,

suitable for expert

DIY or professional

Degrees of difficulty

Specifications Contents

2B

procarmanuals.com

Page 62 of 255

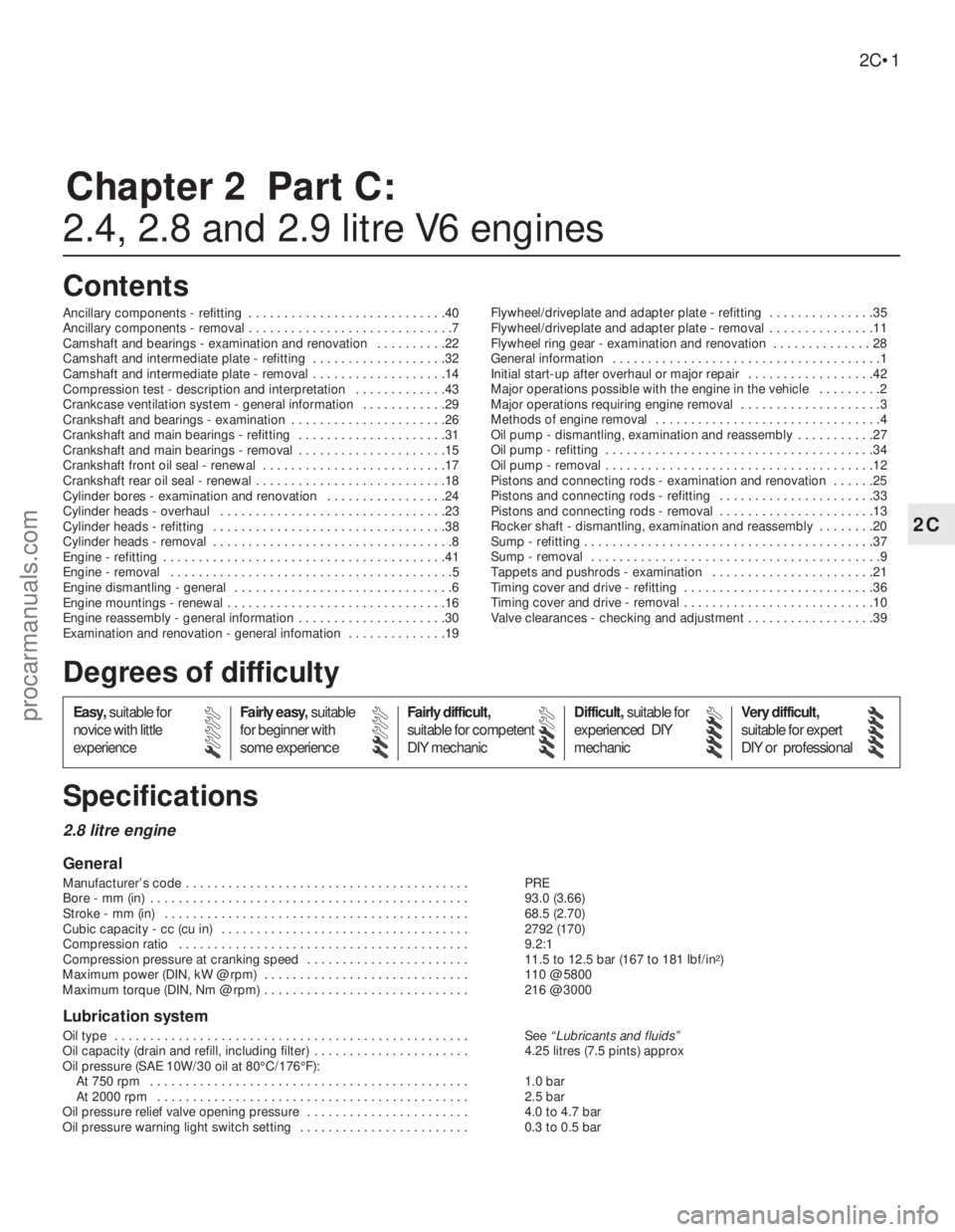

Chapter 2 Part C:

2.4, 2.8 and 2.9 litre V6 engines

Ancillary components - refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Ancillary components - removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Camshaft and bearings - examination and renovation . . . . . . . . . .22

Camshaft and intermediate plate - refitting . . . . . . . . . . . . . . . . . . .32

Camshaft and intermediate plate - removal . . . . . . . . . . . . . . . . . . .14

Compression test - description and interpretation . . . . . . . . . . . . .43

Crankcase ventilation system - general information . . . . . . . . . . . .29

Crankshaft and bearings - examination . . . . . . . . . . . . . . . . . . . . . .26

Crankshaft and main bearings - refitting . . . . . . . . . . . . . . . . . . . . .31

Crankshaft and main bearings - removal . . . . . . . . . . . . . . . . . . . . .15

Crankshaft front oil seal - renewal . . . . . . . . . . . . . . . . . . . . . . . . . .17

Crankshaft rear oil seal - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Cylinder bores - examination and renovation . . . . . . . . . . . . . . . . .24

Cylinder heads - overhaul . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Cylinder heads - refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Cylinder heads - removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Engine - refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Engine - removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Engine dismantling - general . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Engine mountings - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Engine reassembly - general information . . . . . . . . . . . . . . . . . . . . .30

Examination and renovation - general infomation . . . . . . . . . . . . . .19Flywheel/driveplate and adapter plate - refitting . . . . . . . . . . . . . . .35

Flywheel/driveplate and adapter plate - removal . . . . . . . . . . . . . . .11

Flywheel ring gear - examination and renovation . . . . . . . . . . . . . . 28

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Initial start-up after overhaul or major repair . . . . . . . . . . . . . . . . . .42

Major operations possible with the engine in the vehicle . . . . . . . . .2

Major operations requiring engine removal . . . . . . . . . . . . . . . . . . . .3

Methods of engine removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Oil pump - dismantling, examination and reassembly . . . . . . . . . . .27

Oil pump - refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Oil pump - removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Pistons and connecting rods - examination and renovation . . . . . .25

Pistons and connecting rods - refitting . . . . . . . . . . . . . . . . . . . . . .33

Pistons and connecting rods - removal . . . . . . . . . . . . . . . . . . . . . .13

Rocker shaft - dismantling, examination and reassembly . . . . . . . .20

Sump - refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Sump - removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Tappets and pushrods - examination . . . . . . . . . . . . . . . . . . . . . . .21

Timing cover and drive - refitting . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Timing cover and drive - removal . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Valve clearances - checking and adjustment . . . . . . . . . . . . . . . . . .39

2.8 litre engine

General

Manufacturer’s code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . PRE

Bore - mm (in) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93.0 (3.66)

Stroke - mm (in) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68.5 (2.70)

Cubic capacity - cc (cu in) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2792 (170)

Compression ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.2:1

Compression pressure at cranking speed . . . . . . . . . . . . . . . . . . . . . . . 11.5 to 12.5 bar (167 to 181 lbf/in

2)

Maximum power (DIN, kW @ rpm) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110 @ 5800

Maximum torque (DIN, Nm @ rpm) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 216 @ 3000

Lubrication system

Oil type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . See “Lubricants and fluids”

Oil capacity (drain and refill, including filter) . . . . . . . . . . . . . . . . . . . . . . 4.25 litres (7.5 pints) approx

Oil pressure (SAE 10W/30 oil at 80°C/176°F):

At 750 rpm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.0 bar

At 2000 rpm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.5 bar

Oil pressure relief valve opening pressure . . . . . . . . . . . . . . . . . . . . . . . 4.0 to 4.7 bar

Oil pressure warning light switch setting . . . . . . . . . . . . . . . . . . . . . . . . 0.3 to 0.5 bar

2C•1

Easy,suitable for

novice with little

experienceFairly easy,suitable

for beginner with

some experienceFairly difficult,

suitable for competent

DIY mechanicDifficult,suitable for

experienced DIY

mechanicVery difficult,

suitable for expert

DIY or professional

Degrees of difficulty

Specifications Contents

2C

procarmanuals.com

Page 65 of 255

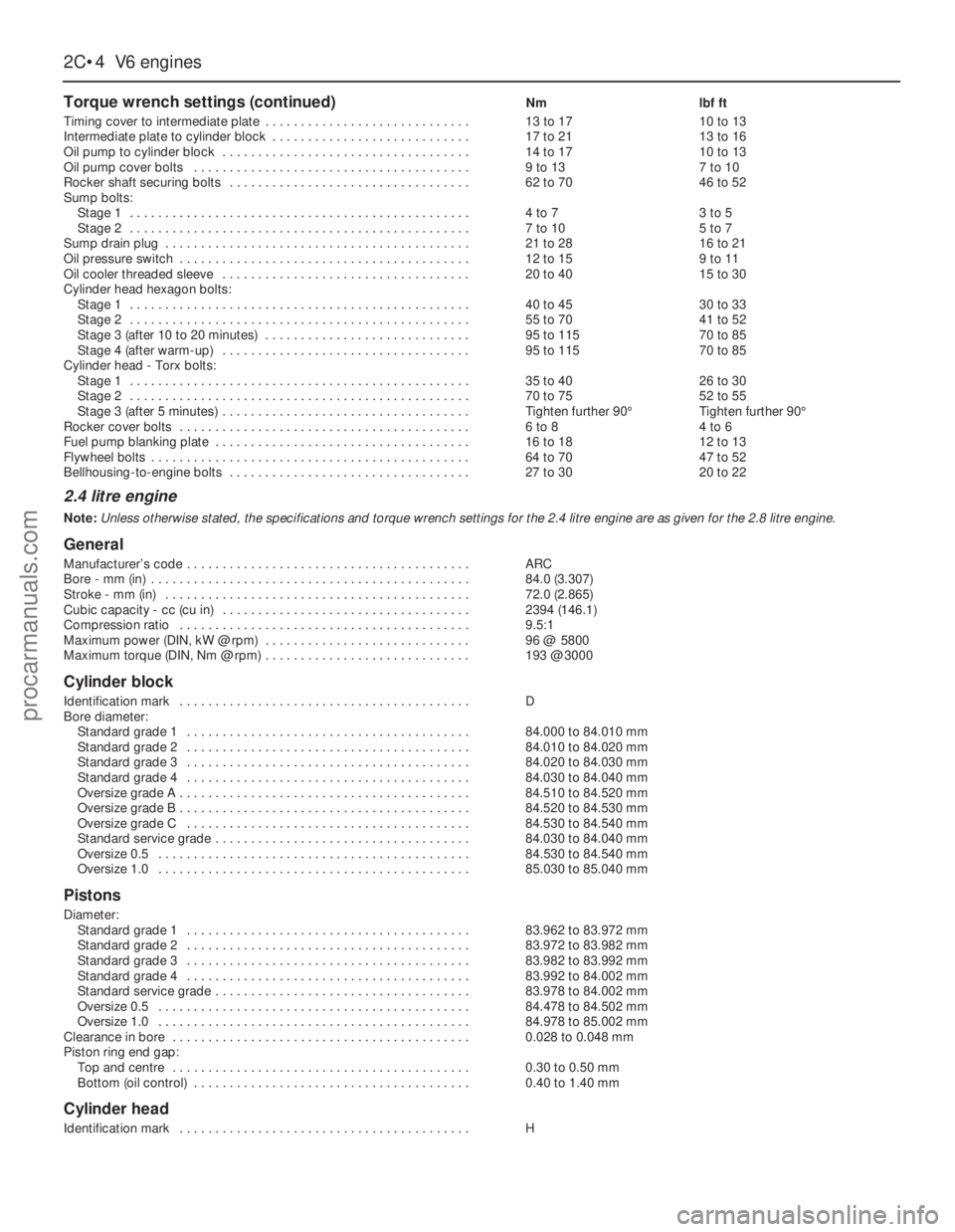

2C•4V6 engines

Torque wrench settings (continued)Nmlbf ft

Timing cover to intermediate plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13 to 1710 to 13

Intermediate plate to cylinder block . . . . . . . . . . . . . . . . . . . . . . . . . . . .17 to 2113 to 16

Oil pump to cylinder block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14 to 1710 to 13

Oil pump cover bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 to 137 to 10

Rocker shaft securing bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62 to 7046 to 52

Sump bolts:

Stage 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 to 73 to 5

Stage 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7 to 105 to 7

Sump drain plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21 to 2816 to 21

Oil pressure switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12 to 159 to 11

Oil cooler threaded sleeve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20 to 4015 to 30

Cylinder head hexagon bolts:

Stage 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40 to 4530 to 33

Stage 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55 to 7041 to 52

Stage 3 (after 10 to 20 minutes) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .95 to 11570 to 85

Stage 4 (after warm-up) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .95 to 11570 to 85

Cylinder head - Torx bolts:

Stage 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35 to 4026 to 30

Stage 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70 to 7552 to 55

Stage 3 (after 5 minutes) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Tighten further 90°Tighten further 90°

Rocker cover bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 to 84 to 6

Fuel pump blanking plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16 to 1812 to 13

Flywheel bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64 to 7047 to 52

Bellhousing-to-engine bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27 to 3020 to 22

2.4 litre engine

Note: Unless otherwise stated, the specifications and torque wrench settings for the 2.4 litre engine are as given for the 2.8 litre engine.

General

Manufacturer’s code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ARC

Bore - mm (in) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84.0 (3.307)

Stroke - mm (in) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72.0 (2.865)

Cubic capacity - cc (cu in) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2394 (146.1)

Compression ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9.5:1

Maximum power (DIN, kW @ rpm) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .96 @ 5800

Maximum torque (DIN, Nm @ rpm) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .193 @ 3000

Cylinder block

Identification mark . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D

Bore diameter:

Standard grade 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84.000 to 84.010 mm

Standard grade 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84.010 to 84.020 mm

Standard grade 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84.020 to 84.030 mm

Standard grade 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84.030 to 84.040 mm

Oversize grade A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84.510 to 84.520 mm

Oversize grade B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84.520 to 84.530 mm

Oversize grade C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84.530 to 84.540 mm

Standard service grade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84.030 to 84.040 mm

Oversize 0.5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84.530 to 84.540 mm

Oversize 1.0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85.030 to 85.040 mm

Pistons

Diameter:

Standard grade 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83.962 to 83.972 mm

Standard grade 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83.972 to 83.982 mm

Standard grade 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83.982 to 83.992 mm

Standard grade 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83.992 to 84.002 mm

Standard service grade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83.978 to 84.002 mm

Oversize 0.5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84.478 to 84.502 mm

Oversize 1.0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84.978 to 85.002 mm

Clearance in bore . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.028 to 0.048 mm

Piston ring end gap:

Top and centre . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.30 to 0.50 mm

Bottom (oil control) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.40 to 1.40 mm

Cylinder head

Identification mark . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .H

procarmanuals.com

Page 66 of 255

V6 engines 2C•5

2C

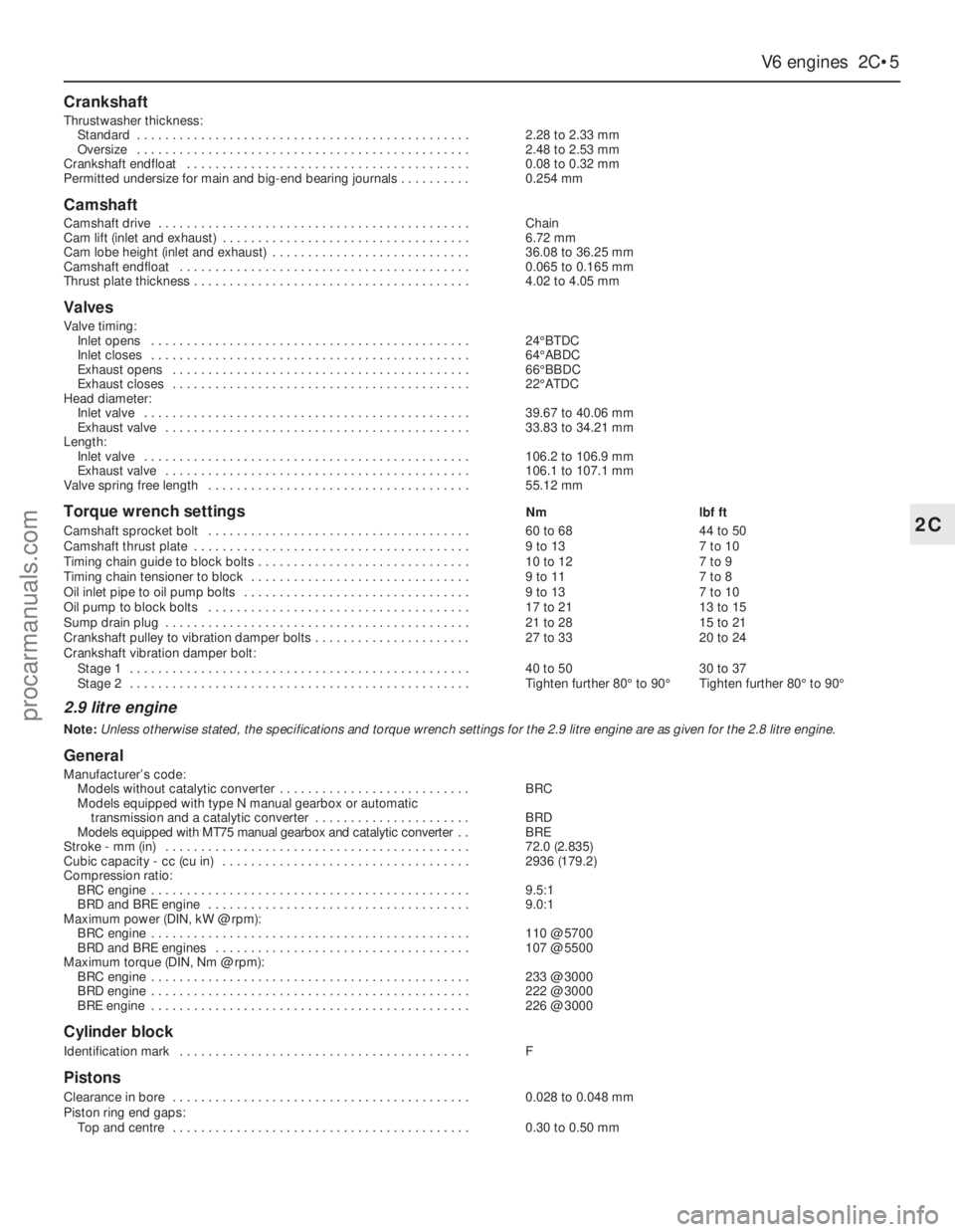

Crankshaft

Thrustwasher thickness:

Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.28 to 2.33 mm

Oversize . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.48 to 2.53 mm

Crankshaft endfloat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.08to 0.32 mm

Permitted undersize for main and big-end bearing journals . . . . . . . . . .0.254 mm

Camshaft

Camshaft drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Chain

Cam lift (inlet and exhaust) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6.72 mm

Cam lobe height (inlet and exhaust) . . . . . . . . . . . . . . . . . . . . . . . . . . . .36.08 to 36.25 mm

Camshaft endfloat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.065 to 0.165 mm

Thrust plate thickness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4.02 to 4.05 mm

Valves

Valve timing:

Inlet opens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24°BTDC

Inlet closes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64°ABDC

Exhaust opens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66°BBDC

Exhaust closes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22°ATDC

Head diameter:

Inlet valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39.67 to 40.06 mm

Exhaust valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33.83 to 34.21 mm

Length:

Inlet valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .106.2 to 106.9 mm

Exhaust valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .106.1 to 107.1 mm

Valve spring free length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55.12 mm

Torque wrench settingsNmlbf ft

Camshaft sprocket bolt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60 to 6844 to 50

Camshaft thrust plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 to 137 to 10

Timing chain guide to block bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10 to 127 to 9

Timing chain tensioner to block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 to 117 to 8

Oil inlet pipe to oil pump bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 to 137 to 10

Oil pump to block bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17 to 2113 to 15

Sump drain plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21 to 2815to 21

Crankshaft pulley to vibration damper bolts . . . . . . . . . . . . . . . . . . . . . .27 to 3320 to 24

Crankshaft vibration damper bolt:

Stage 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40 to 5030 to 37

Stage 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Tighten further 80°to 90°Tighten further 80°to 90°

2.9 litre engine

Note: Unless otherwise stated, the specifications and torque wrench settings for the 2.9 litre engine are as given for the 2.8 litre engine.

General

Manufacturer’s code:

Models without catalytic converter . . . . . . . . . . . . . . . . . . . . . . . . . . .BRC

Models equipped with type N manual gearbox or automatic

transmission and a catalytic converter . . . . . . . . . . . . . . . . . . . . . .BRD

Models equipped with MT75 manual gearbox and catalytic converter . .BRE

Stroke - mm (in) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72.0 (2.835)

Cubic capacity - cc (cu in) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2936 (179.2)

Compression ratio:

BRC engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9.5:1

BRD and BRE engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9.0:1

Maximum power (DIN, kW @ rpm):

BRC engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .110 @ 5700

BRD and BRE engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .107 @ 5500

Maximum torque (DIN, Nm @ rpm):

BRC engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .233 @ 3000

BRD engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .222 @ 3000

BRE engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .226 @ 3000

Cylinder block

Identification mark . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .F

Pistons

Clearance in bore . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.028 to 0.048 mm

Piston ring end gaps:

Top and centre . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.30 to 0.50 mm

procarmanuals.com

Page 238 of 255

REF•3

The following list contains only those tools and

instruments freely available to the public, and not

those special tools produced by the vehicle

manufacturer specifically for its dealer network.

You will find occasional references to these

manufacturer’s special tools in the text of this

manual. Generally, an alternative method of doing

the job without the vehicle manufacturer’s special

tool is given. However, sometimes there is no

alternative to using them. Where this is the case

and the relevant tool cannot be bought or

borrowed, you will have to entrust the work to a

franchised garage.

MValve spring compressor (see illustration)

MValve grinding tool

MPiston ring compressor (see illustration)

MPiston ring removal/installation tool (see

illustration)

MCylinder bore hone (see illustration)

MBalljoint separator

MCoil spring compressors (where applicable)

MTwo/three-legged hub and bearing puller

(see illustration)

MImpact screwdriver

MMicrometer and/or vernier calipers (see

illustrations)

MDial gauge (see illustration)

MStroboscopic timing light (see illustration)

MDwell angle meter/tachometer

MUniversal electrical multi-meter

MCylinder compression gauge (see

illustration)

MHand-operated vacuum pump and gauge

(see illustration)

MClutch plate alignment set (see

illustration)

MBrake shoe steady spring cup removal tool

(see illustration)

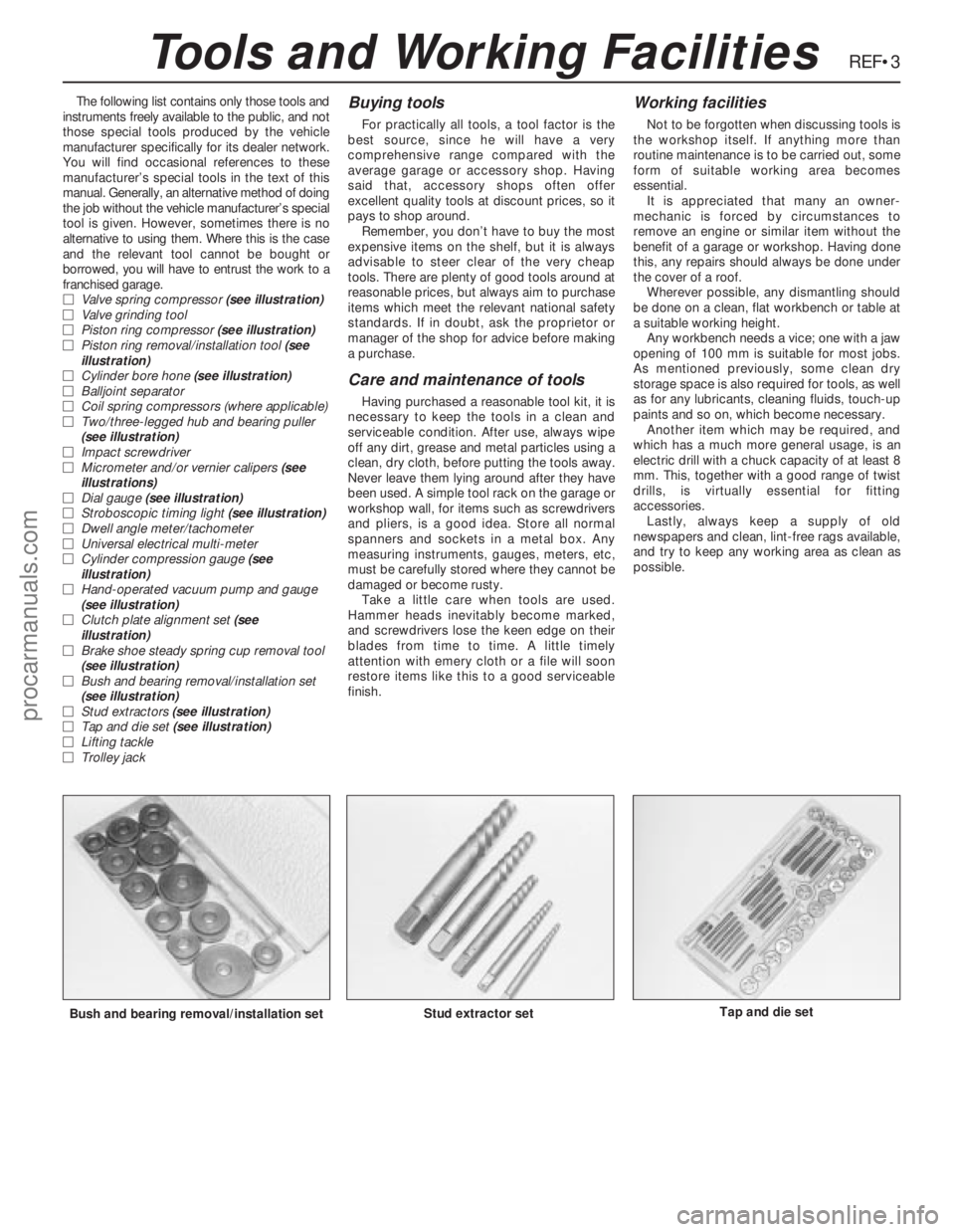

MBush and bearing removal/installation set

(see illustration)

MStud extractors (see illustration)

MTap and die set (see illustration)

MLifting tackle

MTrolley jackBuying tools

For practically all tools, a tool factor is the

best source, since he will have a very

comprehensive range compared with the

average garage or accessory shop. Having

said that, accessory shops often offer

excellent quality tools at discount prices, so it

pays to shop around.

Remember, you don’t have to buy the most

expensive items on the shelf, but it is always

advisable to steer clear of the very cheap

tools. There are plenty of good tools around at

reasonable prices, but always aim to purchase

items which meet the relevant national safety

standards. If in doubt, ask the proprietor or

manager of the shop for advice before making

a purchase.

Care and maintenance of tools

Having purchased a reasonable tool kit, it is

necessary to keep the tools in a clean and

serviceable condition. After use, always wipe

off any dirt, grease and metal particles using a

clean, dry cloth, before putting the tools away.

Never leave them lying around after they have

been used. A simple tool rack on the garage or

workshop wall, for items such as screwdrivers

and pliers, is a good idea. Store all normal

spanners and sockets in a metal box. Any

measuring instruments, gauges, meters, etc,

must be carefully stored where they cannot be

damaged or become rusty.

Take a little care when tools are used.

Hammer heads inevitably become marked,

and screwdrivers lose the keen edge on their

blades from time to time. A little timely

attention with emery cloth or a file will soon

restore items like this to a good serviceable

finish.

Working facilities

Not to be forgotten when discussing tools is

the workshop itself. If anything more than

routine maintenance is to be carried out, some

form of suitable working area becomes

essential.

It is appreciated that many an owner-

mechanic is forced by circumstances to

remove an engine or similar item without the

benefit of a garage or workshop. Having done

this, any repairs should always be done under

the cover of a roof.

Wherever possible, any dismantling should

be done on a clean, flat workbench or table at

a suitable working height.

Any workbench needs a vice; one with a jaw

opening of 100 mm is suitable for most jobs.

As mentioned previously, some clean dry

storage space is also required for tools, as well

as for any lubricants, cleaning fluids, touch-up

paints and so on, which become necessary.

Another item which may be required, and

which has a much more general usage, is an

electric drill with a chuck capacity of at least 8

mm. This, together with a good range of twist

drills, is virtually essential for fitting

accessories.

Lastly, always keep a supply of old

newspapers and clean, lint-free rags available,

and try to keep any working area as clean as

possible.

Bush and bearing removal/installation setStud extractor setTap and die set

Tools and Working Facilities

procarmanuals.com