length FORD GRANADA 1985 Service Repair Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1985, Model line: GRANADA, Model: FORD GRANADA 1985Pages: 255, PDF Size: 14.98 MB

Page 13 of 255

1Work around the vehicle, and lubricate the

hinges and locks with a light machine oil.

2Lightly lubricate the bonnet release

mechanism and exposed sections of inner

cable with a smear of grease.

3Check the security and operation of all

hinges, latches and locks, adjusting them

where required. Where applicable, check the

operation of the central locking system.

4Check the condition and operation of the

tailgate struts, renewing them if either is

leaking or is no longer able to support the

tailgate securely when raised.

SOHC and V6 engines

1The correct functioning of the spark plugs is

vital for the correct running and efficiency of

the engine. It is essential that the plugs fitted

are appropriate for the engine.

2Make sure that the ignition is switched off

before inspecting the HT leads to see if they

carry their cylinder numbers - if not, number

each lead using sticky tape or paint.

3Pull the HT lead connectors off the plugs.

Pull on the connectors, not on the leads.

4Blow away any dirt from around the spark

plug recesses in the cylinder head(s).

5Unscrew and remove the plugs, using a

proprietary plug spanner or a spark plug

socket, extension and ratchet.

6The condition of the plugs will tell much

about the overall condition of the engine. If the

insulator nose of the spark plug is clean and

white, with no deposits, this is indicative of a

weak mixture or too hot a plug (a hot plug

transfers heat away from the electrode slowly,

a cold plug transfers heat away quickly).

7If the tip and insulator nose are covered with

hard black-looking deposits, then this is

indicative that the mixture is too rich. Should

the plug be black and oily, then it is likely that

the engine is fairly worn, as well as the mixture

being too rich.

8If the insulator nose is covered with light tan

to greyish-brown deposits, then the mixture is

correct, and it is likely that the engine is in

good condition.

9Apply a smear of anti-seize compound to

the threads of the new plugs. Make sure that

theinsulators are clean and that the screwed

HT lead adapters are tight. Pay particular

attention to the plug seating surfaces on OHC

engines, since these plugs have no sealing

washers (“taper seat” type) and any dirt will

cause a bad seal.

10Screw each plug into its hole by hand. If a

plug is reluctant to go in, do not force it with a

spanner, but unscrew it and try again. If the

plug is cross-threaded, it is the cylinder head

which will be damaged.11Final tightening of the spark plugs should

ideally be carried out using a torque wrench.

The tightening torques are given in the

Specifications. If a torque wrench is not

available, tighten the plugs beyond the point

where they contact the head as follows:

OHC (taper seat plugs) - One-sixteenth of a

turn maximum

V6 (plugs with washers) - One-quarter of a

turn maximum

12If the taper seat type of plug is

overtightened, the sealing faces will bite

together and removal will be very difficult.

13Refit the HT leads to the plugs, paying

attention to the cylinder numbers. Push each

connector firmly onto its plug.

14Run the engine to verify that the HT leads

have been refitted correctly.

DOHC engines

15Proceed as described above whilst noting

the following points.

a)Remove the air cleaner as described in

Chapter 4.

b)The minimal length of number 3 HT lead

makes removal from the spark plug

difficult. It is advisable to remove this lead

from the distributor prior to removing it

from the spark plug.

c)The spark plugs are deeply recessed in

the cylinder head and it will be necessary

to use a spark plug socket with a long

extension bar. If possible, use a spark plug

socket with a rubber grip inside as this will

hold onto the spark plug once loosened

and will enable the spark plugs to be

withdrawn and refitted more easily.

SOHC and all V6 engines

1All of these engines have one or two

drivebelts which drive the water pump and

alternator from the crankshaft pulley. When

power steering is fitted, the same belts drive

the steering pump. The air conditioning

compressor, when fitted, is driven

independently.

2Periodically inspect the drivebelt(s) for

fraying, cracks, glazing or other damage. Turn

the engine so that the full length of the belt(s)

can be viewed. Renew belts which are in poor

condition. When twin drivebelts are fitted, both

must be renewed together, even if only one is

damaged.

3Check the tension of the drivebelt(s) by

pressing firmly with the fingers in the middle of

the longest belt run (engine stopped). Tension

is correct when the belt can be deflected by

10 mm (0.4 in) under firm finger pressure (see

illustration).

4Renewal and adjustment procedures for

models with power steering are given in

Chapter 11. For other models proceed as

follows.

5Disconnect the battery negative lead.

6On models with air conditioning, remove the

compressor drivebelt.

7Slacken the alternator pivot and adjusting

bolts. Swing the alternator towards the engine

and slip the belt(s) off the pulleys.

8Fit the new belt(s) over the pulleys. Move

the alternator away from the engine until the

belt tension is correct, then tighten the

alternator adjusting strap and pivot bolts. If it

is necessary to lever against the alternator to

achieve the correct tension, only do so using a

wooden or plastic lever(seeillustration).

9Refit and tension the air conditioning

compressor drivebelt, when applicable.

10Reconnect the battery. If a new drivebelt

has been fitted, run the engine for a few

minutes, then stop it and recheck the tension.

11Check the tension of new belts again after

a few hundred miles.

21Auxiliary drivebelt check

20Spark plug renewal

19Hinge and lock check and

lubrication

1•12Every 12 000 miles or 12 months

21.3 Checking drivebelt tension

It is very often difficult to insert spark

plugs into their holes without cross-

threading them. To avoid this

possibility, fit a short length of 5/16-

inch internal diameter rubber hose over

the end of the spark plug. The flexible

hose acts as a universal joint to help

align the plug with the plug hole.

Should the plug begin to cross-thread,

the hose will slip on the spark plug,

preventing thread damage to the

aluminium cylinder head. Remove the

rubber hose, and tighten the plug to the

specified torque using the spark plug

socket and a torque wrench. Fit the

remaining spark plugs in the same

manner.

procarmanuals.com

Page 25 of 255

2A•2SOHCengines

Oil pump

Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Bi-rotor

Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .From auxiliary shaft

Operating clearances:

Outer rotor-to-housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.15 to 0.30 mm

Inner-to-outer rotor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.05 to 0.20 mm

Rotor endfloat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.04 to 0.10 mm

Cylinder block1.8 (REC)2.0 (NEL and NRA)

Cast identification mark . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18S20S

Bore diameter:

Standard grade 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86.180 to 86.190 mm90.800 to 90.810 mm

Standard grade 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86.190 to 86.200 mm90.810 to 90.820 mm

Standard grade 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86.200 to 86.210 mm90.820 to 90.830 mm

Standard grade 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86.210 to 86.220 mm90.830 to 90.840 mm

Oversize grade 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86.690 to 86.700 mm91.310 to 91.320 mm

Oversize grade B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86.700 to 86.710 mm91.320 to 91.330 mm

Oversize grade C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86.710 to 86.720 mm91.330 to 91.340 mm

Standard service grade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Not stated90.830 to 90.840 mm

Oversize 0.5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Not stated91.330 to 91.340 mm

Oversize 1.0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Not stated91.830 to 91.840 mm

Crankshaft

Number of main bearings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Main bearing journal diameter:

Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56.970 to 56.990 mm

Undersize 0.25 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56.720 to 56.740 mm

Undersize 0.50 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56.470 to 56.490 mm

Undersize 0.75 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56.220 to 56.240 mm

Undersize 1.00 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55.970 to 55.990 mm

Main bearing running clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.010 to 0.064 mm

Big-end bearing journal diameter:

Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51.980 to 52.000 mm

Undersize 0.25 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51.730 to 51.750 mm

Undersize 0.50 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51.480 to 51.500 mm

Undersize 0.75 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51.230 to 51.250 mm

Undersize 1.00 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50.980 to 51.000 mm

Big-end bearing running clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.006 to 0.060 mm

Thrustwasher thickness:

Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.30 to 2.35 mm

Oversize . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.50 to 2.55 mm

Crankshaft endfloat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.08 to 0.28 mm

Connecting rods

Big-end parent bore diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55.000 to 55.020 mm

Small-end bush internal diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23.964 to 23.976 mm

Pistons1.8 (REC)2.0 (NEL and NRA)

Diameter:

Standard grade 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86.145 to 86.155 mm90.765 to 90.775 mm

Standard grade 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86.155 to 86.165 mm90.775 to 90.785 mm

Standard grade 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86.165 to 86.175 mm90.785 to 90.795 mm

Standard grade 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86.175 to 86.185 mm90.795 to 90.805 mm

Service standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86.170 to 86.195 mm90.790 to 90.815 mm

Oversize 0.5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86.670 to 86.695 mm91.290 to 91.315 mm

Oversize 1.0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87.170 to 87.195 mm91.790 to 91.815 mm

Clearance in bore . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.015 to 0.050 mm0.015 to 0.050 mm

Piston ring end gaps:

Top and centre . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.3 to 0.5 mm0.4 to 0.6 mm

Bottom . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.4 to 1.4 mm0.4 to 1.4 mm

Gudgeon pins

Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68.0 to 68.8 mm

Diameter:

Red . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23.994 to 23.997 mm

Blue . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23.997 to 24.000 mm

Yellow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24.000 to 24.003 mm

Clearance in piston . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.008 to 0.014 mm

Interference in connecting rod . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.018 to 0.039 mm

procarmanuals.com

Page 26 of 255

SOHCengines 2A•3

2A

Cylinder head

Identification mark:

1.8 (REC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

2.0 (NEL and NRA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0

Valve seat angle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44°30’ to 45°00’

Valve seat width . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.5 to 2.0 mm

Valve guide bore:

Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8.063 to 8.088 mm

Oversize 0.2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8.263 to 8.288 mm

Oversize 0.4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8.463 to 8.488 mm

Camshaft bearing parent bores:

Front . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45.072 to 45.102 mm

Centre . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47.692 to 47.722 mm

Rear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48.072 to 48.102 mm

Auxiliary shaft

Endfloat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.050 to 0.204 mm

Camshaft

Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Toothed belt

Thrust plate thickness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3.98 to 4.01 mm

Endfloat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.104 to 0.204 mm

Cam lift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6.3323 mm

Cam length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36.26 to 36.60 mm

Valve timing:

Inlet opens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24°BTDC

Inlet closes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64°ABDC

Exhaust opens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70°BBDC

Exhaust closes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18°ATDC

Bearing journal diameter:

Front . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41.987 to 42.013 mm

Centre . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44.607 to 44.633 mm

Rear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44.987 to 45.013 mm

Bearing bush internal diameter:

Front . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42.035 to 42.055 mm

Centre . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44.655 to 44.675 mm

Rear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45.035 to 45.055 mm

Valve clearances (cold)

Inlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.20 ±0.03 mm (0.008 ±0.001 in)

Exhaust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.25 ±0.03 mm (0.010 ±0.001 in)

Inlet valves

Length:

1.8 (REC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .111.75 to 112.75 mm

2.0 (NEL and NRA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .110.65 to 111.65 mm

Head diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41.80 to 42.20 mm

Stem diameter:

Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8.025 to 8.043 mm

Oversizes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .+0.2, 0.4, 0.6 and 0.8 mm

Stem-to-guide clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.020 to 0.063 mm

Exhaust valves

Length:

1.8 (REC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .111.15 to 112.15 mm

2.0 (NEL) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .110.05 to 111.05 mm

2.0 (NRA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .110.75 to 111.75 mm

Head diameter:

1.8 (REL) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34.00 to 34.40 mm

2.0 (NEL and NRA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35.80 to 36.20 mm

Stem diameter:

Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7.999 to 8.017 mm

Oversizes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .+0.2, 0.4, 0.6 and 0.8 mm

Stem-to-guide clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.046 to 0.089 mm

Valve springs

Free length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47.0 mm

Inside diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23.45 to 23.95 mm

Wire diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3.87 to 3.93 mm

Number of turns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4.7

procarmanuals.com

Page 45 of 255

2B•2DOHCengine

Cylinder block

Bore diameter:

Standard grade 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86.000 to 86.010 mm

Standard grade 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86.010 to 86.020 mm

Oversize 0.15 grade A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86.150 to 86.160 mm

Oversize 0.15 grade B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86.160 to 86.170 mm

Oversize 0.5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86.500 to 86.510 mm

Crankshaft

Endfloat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.090 to 0.300 mm

Main bearing running clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.011 to 0.048 mm

Main bearing journal diameter:

Standard (yellow) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54.980 to 54.990 mm

Standard (red) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54.990 to 55.000 mm

Undersize 0.25 (green) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54.730 to 54.750 mm

Main bearing thrustwasher thickness:

Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.301 to 2.351 mm

Oversize 0.38 (yellow) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.491 to 2.541 mm

Big-end bearing running clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.006 to 0.060 mm

Big-end bearing journal diameter:

Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50.890 to 50.910 mm

Undersize 0.25 (green) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50.640 to 50.660 mm

Pistons and piston rings

Piston diameter:

Standard 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85.970 to 85.980 mm

Standard 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85.980 to 85.990 mm

Standard service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85.980 to 86.000 mm

Oversize 0.15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86.130 to 86.150 mm

Oversize 0.50 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86.470 to 86.490 mm

Piston ring end gap:

Top . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.300 to 0.600 mm

Centre . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.500 to 0.800 mm

Bottom (oil control) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.400 to 1.500 mm

Cylinder head

Valve guide bore . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7.063 to 7.094 mm

Camshaft bearing parent bore diameter . . . . . . . . . . . . . . . . . . . . . . . . .26.000 to 26.030 mm

Camshafts

Endfloat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.020 to 0.260 mm

Valves and valve springs - general

Valve timing:

Carburettor engine:

Inlet opens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13°BTDC

Inlet closes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39°ABDC

Exhaust opens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43°BBDC

Exhaust closes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13°ATDC

Fuel-injection engines:

Inlet opens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13°BTDC

Inlet closes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51°ABDC

Exhaust opens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43°BBDC

Exhaust closes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13°ATDC

Valve spring free length:

Inner spring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48.200 mm

Outer spring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46.800 mm

Inlet valve stem diameter:

Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7.025 to 7.043 mm

Oversize 0.2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7.225 to 7.243 mm

Oversize 0.4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7.425 to 7.443 mm

Oversize 0.6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7.625 to 7.643 mm

Oversize 0.8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7.825 to 7.843 mm

Exhaust valve stem diameter:

Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6.999 to 7.017 mm

Oversize 0.2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7.199 to 7.217 mm

Oversize 0.4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7.399 to 7.417 mm

Oversize 0.6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7.599 to 7.617 mm

Oversize 0.8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7.799 to 7.817 mm

procarmanuals.com

Page 54 of 255

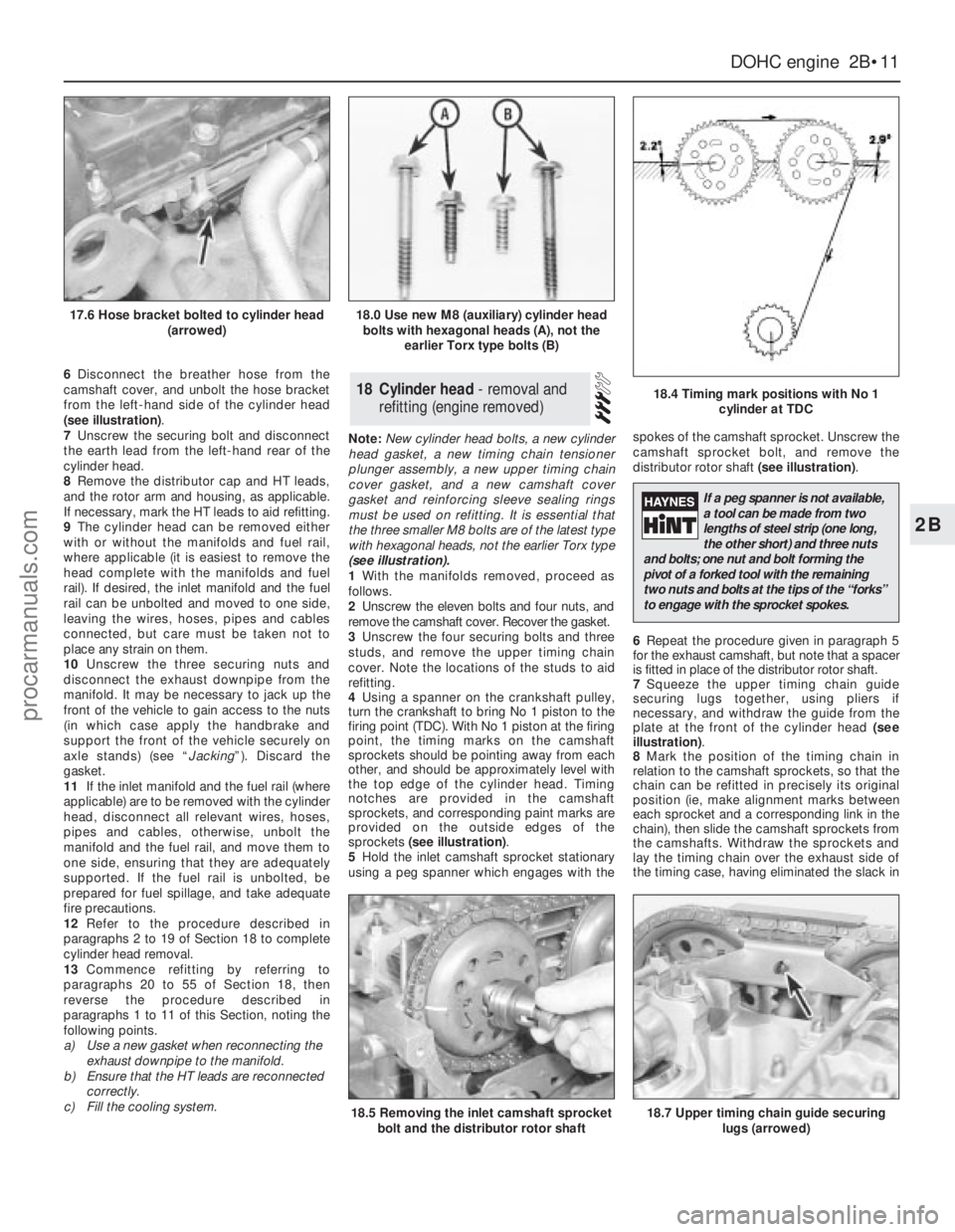

6Disconnect the breather hose from the

camshaft cover, and unbolt the hose bracket

from the left-hand side of the cylinder head

(see illustration).

7Unscrew the securing bolt and disconnect

the earth lead from the left-hand rear of the

cylinder head.

8Remove the distributor cap and HT leads,

and the rotor arm and housing, as applicable.

If necessary, mark the HT leads to aid refitting.

9The cylinder head can be removed either

with or without the manifolds and fuel rail,

where applicable (it is easiest to remove the

head complete with the manifolds and fuel

rail). If desired, the inlet manifold and the fuel

rail can be unbolted and moved to one side,

leaving the wires, hoses, pipes and cables

connected, but care must be taken not to

place any strain on them.

10Unscrew the three securing nuts and

disconnect the exhaust downpipe from the

manifold. It may be necessary to jack up the

front of the vehicle to gain access to the nuts

(in which case apply the handbrake and

support the front of the vehicle securely on

axle stands) (see “Jacking”). Discard the

gasket.

11If the inlet manifold and the fuel rail (where

applicable) are to be removed with the cylinder

head, disconnect all relevant wires, hoses,

pipes and cables, otherwise, unbolt the

manifold and the fuel rail, and move them to

one side, ensuring that they are adequately

supported. If the fuel rail is unbolted, be

prepared for fuel spillage, and take adequate

fire precautions.

12Refer to the procedure described in

paragraphs 2 to 19 of Section 18 to complete

cylinder head removal.

13Commence refitting by referring to

paragraphs 20 to 55 of Section 18, then

reverse the procedure described in

paragraphs 1 to 11 of this Section, noting the

following points.

a)Use a new gasket when reconnecting the

exhaust downpipe to the manifold.

b)Ensure that the HT leads are reconnected

correctly.

c)Fill the cooling system.Note: New cylinder head bolts, a new cylinder

head gasket, a new timing chain tensioner

plunger assembly, a new upper timing chain

cover gasket, and a new camshaft cover

gasket and reinforcing sleeve sealing rings

must be used on refitting. It is essential that

the three smaller M8 bolts are of the latest type

with hexagonal heads, not the earlier Torx type

(see illustration).

1With the manifolds removed, proceed as

follows.

2Unscrew the eleven bolts and four nuts, and

remove the camshaft cover. Recover the gasket.

3Unscrew the four securing bolts and three

studs, and remove the upper timing chain

cover. Note the locations of the studs to aid

refitting.

4Using a spanner on the crankshaft pulley,

turn the crankshaft to bring No 1 piston to the

firing point (TDC). With No 1 piston at the firing

point, the timing marks on the camshaft

sprockets should be pointing away from each

other, and should be approximately level with

the top edge of the cylinder head. Timing

notches are provided in the camshaft

sprockets, and corresponding paint marks are

provided on the outside edges of the

sprockets (see illustration).

5Hold the inlet camshaft sprocket stationary

using a peg spanner which engages with thespokes of the camshaft sprocket. Unscrew the

camshaft sprocket bolt, and remove the

distributor rotor shaft (see illustration).

6Repeat the procedure given in paragraph 5

for the exhaust camshaft, but note that a spacer

is fitted in place of the distributor rotor shaft.

7Squeeze the upper timing chain guide

securing lugs together, using pliers if

necessary, and withdraw the guide from the

plate at the front of the cylinder head (see

illustration).

8Mark the position of the timing chain in

relation to the camshaft sprockets, so that the

chain can be refitted in precisely its original

position (ie, make alignment marks between

each sprocket and a corresponding link in the

chain), then slide the camshaft sprockets from

the camshafts. Withdraw the sprockets and

lay the timing chain over the exhaust side of

the timing case, having eliminated the slack in18Cylinder head - removal and

refitting (engine removed)

DOHCengine 2B•11

2B

17.6 Hose bracket bolted to cylinder head

(arrowed)18.0 Use new M8 (auxiliary) cylinder head

bolts with hexagonal heads (A), not the

earlier Torx type bolts (B)

18.4 Timing mark positions with No 1

cylinder at TDC

18.5 Removing the inlet camshaft sprocket

bolt and the distributor rotor shaft18.7 Upper timing chain guide securing

lugs (arrowed)

If a peg spanner is not available,

a tool can be made from two

lengths of steel strip (one long,

the other short) and three nuts

and bolts; one nut and bolt forming the

pivot of a forked tool with the remaining

two nuts and bolts at the tips of the “forks”

to engage with the sprocket spokes.

procarmanuals.com

Page 64 of 255

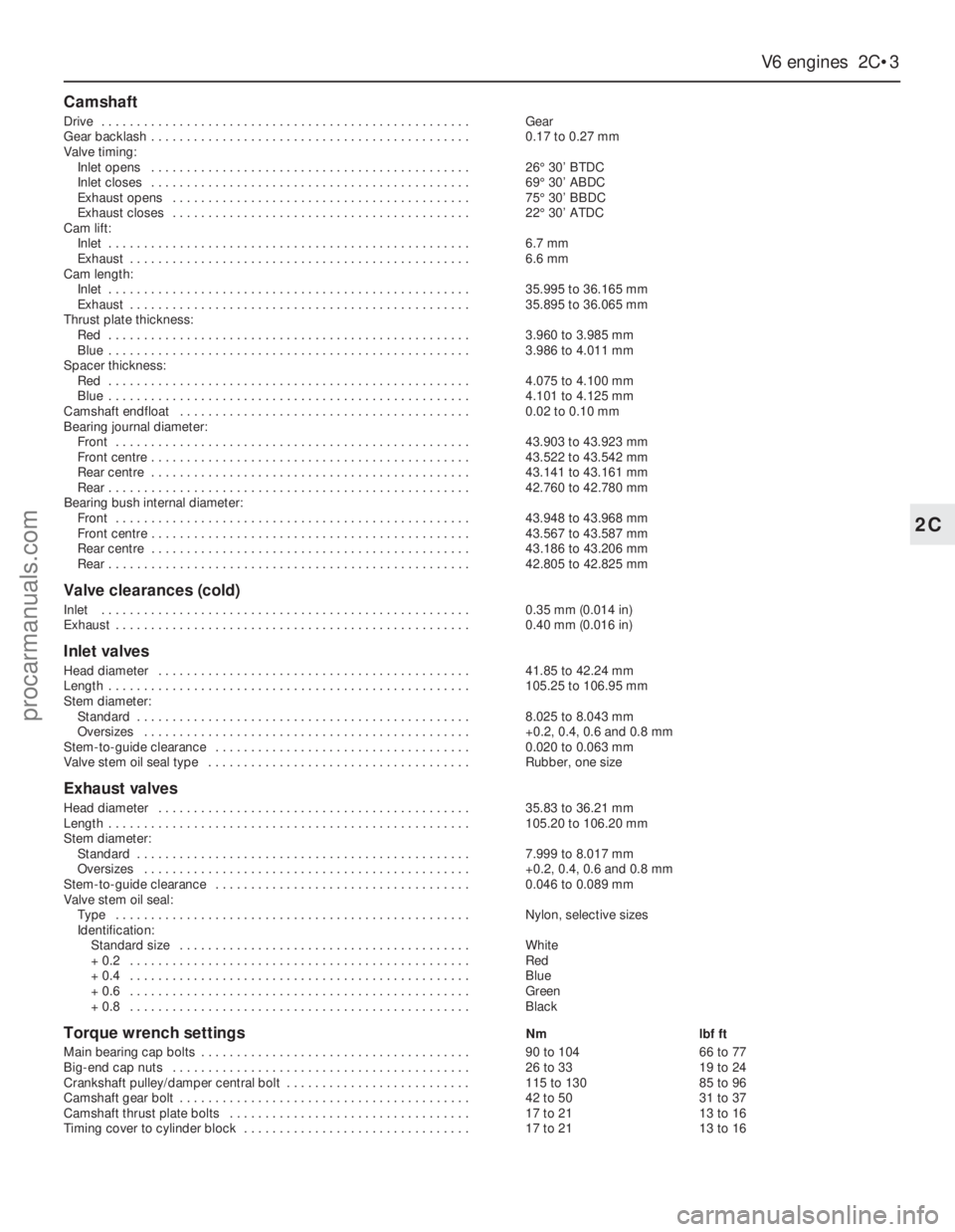

V6 engines 2C•3

2C

Camshaft

Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Gear

Gear backlash . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.17 to 0.27 mm

Valve timing:

Inlet opens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26°30’ BTDC

Inlet closes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69°30’ ABDC

Exhaust opens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75°30’ BBDC

Exhaust closes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22°30’ ATDC

Cam lift:

Inlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6.7 mm

Exhaust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6.6 mm

Cam length:

Inlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35.995 to 36.165 mm

Exhaust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35.895 to 36.065 mm

Thrust plate thickness:

Red . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3.960 to 3.985 mm

Blue . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3.986 to 4.011 mm

Spacer thickness:

Red . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4.075 to 4.100 mm

Blue . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4.101 to 4.125 mm

Camshaft endfloat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.02 to 0.10 mm

Bearing journal diameter:

Front . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43.903 to 43.923 mm

Front centre . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43.522 to 43.542 mm

Rear centre . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43.141 to 43.161 mm

Rear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42.760 to 42.780 mm

Bearing bush internal diameter:

Front . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43.948 to 43.968 mm

Front centre . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43.567 to 43.587 mm

Rear centre . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43.186 to 43.206 mm

Rear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42.805 to 42.825 mm

Valve clearances (cold)

Inlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.35 mm (0.014 in)

Exhaust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.40 mm (0.016 in)

Inlet valves

Head diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41.85 to 42.24 mm

Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .105.25 to 106.95 mm

Stem diameter:

Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8.025 to 8.043 mm

Oversizes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .+0.2, 0.4, 0.6 and 0.8 mm

Stem-to-guide clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.020 to 0.063 mm

Valve stem oil seal type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Rubber, one size

Exhaust valves

Head diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35.83 to 36.21 mm

Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .105.20 to 106.20 mm

Stem diameter:

Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7.999 to 8.017 mm

Oversizes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .+0.2, 0.4, 0.6 and 0.8 mm

Stem-to-guide clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.046 to 0.089 mm

Valve stem oil seal:

Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Nylon, selective sizes

Identification:

Standard size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .White

+ 0.2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Red

+ 0.4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Blue

+ 0.6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Green

+ 0.8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Black

Torque wrench settingsNmlbf ft

Main bearing cap bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90 to 10466 to 77

Big-end cap nuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26 to 3319 to 24

Crankshaft pulley/damper central bolt . . . . . . . . . . . . . . . . . . . . . . . . . .115 to 13085 to 96

Camshaft gear bolt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42 to 5031 to 37

Camshaft thrust plate bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17 to 2113 to 16

Timing cover to cylinder block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17 to 2113 to 16

procarmanuals.com

Page 66 of 255

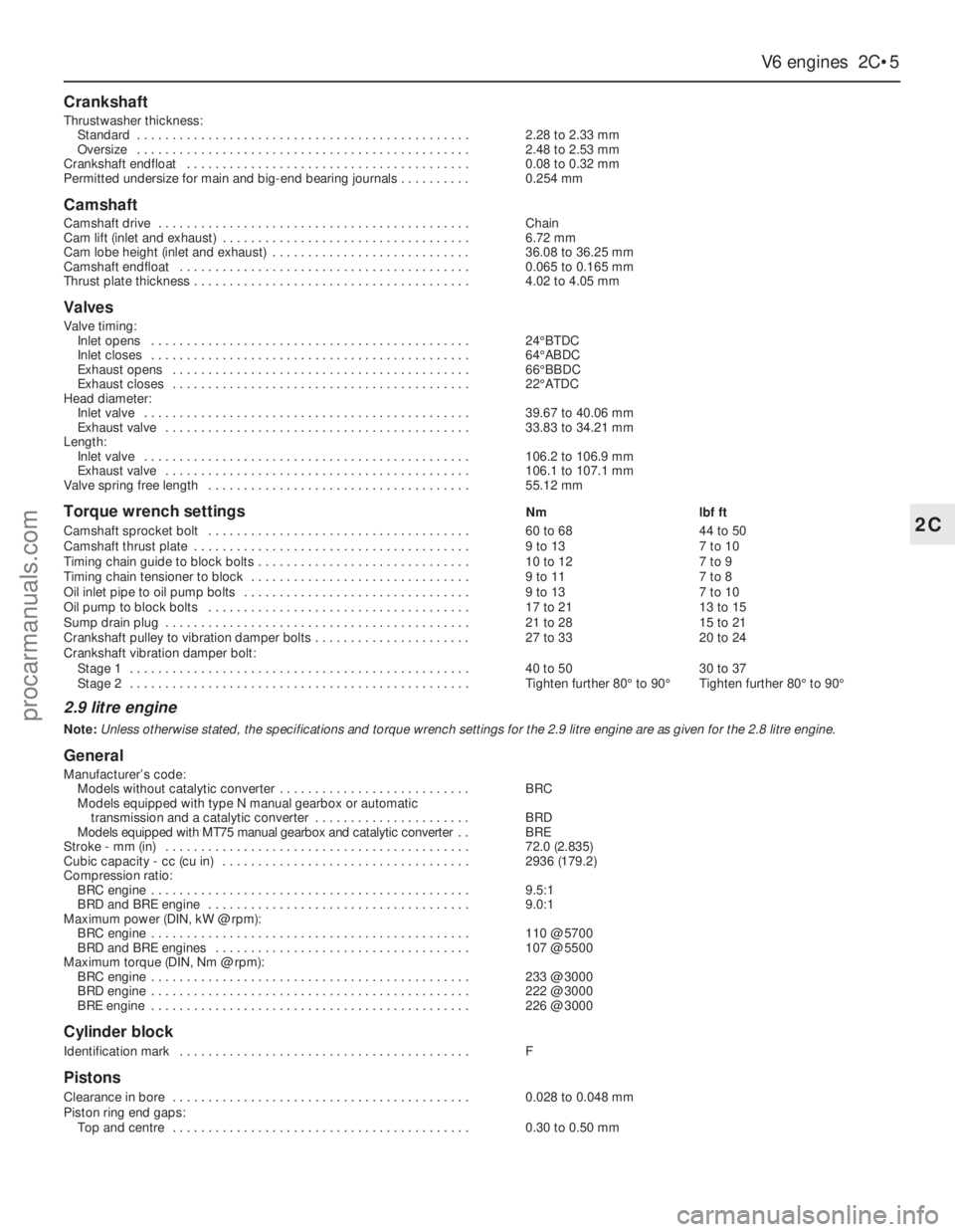

V6 engines 2C•5

2C

Crankshaft

Thrustwasher thickness:

Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.28 to 2.33 mm

Oversize . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.48 to 2.53 mm

Crankshaft endfloat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.08to 0.32 mm

Permitted undersize for main and big-end bearing journals . . . . . . . . . .0.254 mm

Camshaft

Camshaft drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Chain

Cam lift (inlet and exhaust) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6.72 mm

Cam lobe height (inlet and exhaust) . . . . . . . . . . . . . . . . . . . . . . . . . . . .36.08 to 36.25 mm

Camshaft endfloat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.065 to 0.165 mm

Thrust plate thickness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4.02 to 4.05 mm

Valves

Valve timing:

Inlet opens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24°BTDC

Inlet closes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64°ABDC

Exhaust opens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66°BBDC

Exhaust closes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22°ATDC

Head diameter:

Inlet valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39.67 to 40.06 mm

Exhaust valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33.83 to 34.21 mm

Length:

Inlet valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .106.2 to 106.9 mm

Exhaust valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .106.1 to 107.1 mm

Valve spring free length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55.12 mm

Torque wrench settingsNmlbf ft

Camshaft sprocket bolt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60 to 6844 to 50

Camshaft thrust plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 to 137 to 10

Timing chain guide to block bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10 to 127 to 9

Timing chain tensioner to block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 to 117 to 8

Oil inlet pipe to oil pump bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 to 137 to 10

Oil pump to block bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17 to 2113 to 15

Sump drain plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21 to 2815to 21

Crankshaft pulley to vibration damper bolts . . . . . . . . . . . . . . . . . . . . . .27 to 3320 to 24

Crankshaft vibration damper bolt:

Stage 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40 to 5030 to 37

Stage 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Tighten further 80°to 90°Tighten further 80°to 90°

2.9 litre engine

Note: Unless otherwise stated, the specifications and torque wrench settings for the 2.9 litre engine are as given for the 2.8 litre engine.

General

Manufacturer’s code:

Models without catalytic converter . . . . . . . . . . . . . . . . . . . . . . . . . . .BRC

Models equipped with type N manual gearbox or automatic

transmission and a catalytic converter . . . . . . . . . . . . . . . . . . . . . .BRD

Models equipped with MT75 manual gearbox and catalytic converter . .BRE

Stroke - mm (in) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72.0 (2.835)

Cubic capacity - cc (cu in) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2936 (179.2)

Compression ratio:

BRC engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9.5:1

BRD and BRE engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9.0:1

Maximum power (DIN, kW @ rpm):

BRC engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .110 @ 5700

BRD and BRE engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .107 @ 5500

Maximum torque (DIN, Nm @ rpm):

BRC engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .233 @ 3000

BRD engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .222 @ 3000

BRE engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .226 @ 3000

Cylinder block

Identification mark . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .F

Pistons

Clearance in bore . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.028 to 0.048 mm

Piston ring end gaps:

Top and centre . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.30 to 0.50 mm

procarmanuals.com

Page 67 of 255

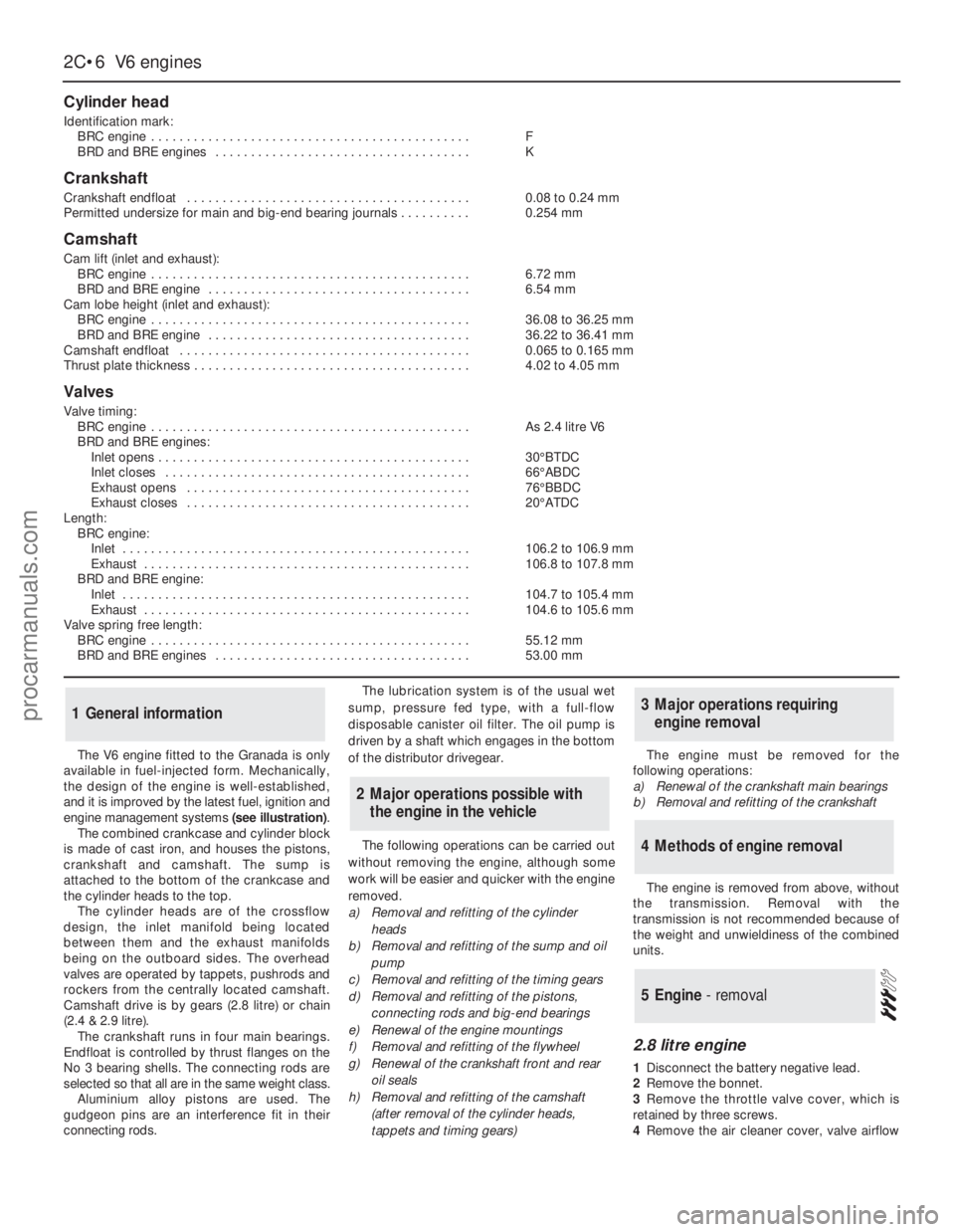

The V6 engine fitted to the Granada is only

available in fuel-injected form. Mechanically,

the design of the engine is well-established,

and it is improved by the latest fuel, ignition and

engine management systems (see illustration).

The combined crankcase and cylinder block

is made of cast iron, and houses the pistons,

crankshaft and camshaft. The sump is

attached to the bottom of the crankcase and

the cylinder heads to the top.

The cylinder heads are of the crossflow

design, the inlet manifold being located

between them and the exhaust manifolds

being on the outboard sides. The overhead

valves are operated by tappets, pushrods and

rockers from the centrally located camshaft.

Camshaft drive is by gears (2.8 litre) or chain

(2.4 & 2.9 litre).

The crankshaft runs in four main bearings.

Endfloat is controlled by thrust flanges on the

No 3 bearing shells. The connecting rods are

selected so that all are in the same weight class.

Aluminium alloy pistons are used. The

gudgeon pins are an interference fit in their

connecting rods.The lubrication system is of the usual wet

sump, pressure fed type, with a full-flow

disposable canister oil filter. The oil pump is

driven by a shaft which engages in the bottom

of the distributor drivegear.

The following operations can be carried out

without removing the engine, although some

work will be easier and quicker with the engine

removed.

a)Removal and refitting of the cylinder

heads

b)Removal and refitting of the sump and oil

pump

c)Removal and refitting of the timing gears

d)Removal and refitting of the pistons,

connecting rods and big-end bearings

e)Renewal of the engine mountings

f)Removal and refitting of the flywheel

g)Renewal of the crankshaft front and rear

oil seals

h)Removal and refitting of the camshaft

(after removal of the cylinder heads,

tappets and timing gears)The engine must be removed for the

following operations:

a)Renewal of the crankshaft main bearings

b)Removal and refitting of the crankshaft

The engine is removed from above, without

the transmission. Removal with the

transmission is not recommended because of

the weight and unwieldiness of the combined

units.

2.8 litre engine

1Disconnect the battery negative lead.

2Remove the bonnet.

3Remove the throttle valve cover, which is

retained by three screws.

4Remove the air cleaner cover, valve airflow

5Engine - removal

4Methods of engine removal

3Major operations requiring

engine removal

2Major operations possible with

the engine in the vehicle

1General information

2C•6V6 engines

Cylinder head

Identification mark:

BRC engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .F

BRD and BRE engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .K

Crankshaft

Crankshaft endfloat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.08 to 0.24 mm

Permitted undersize for main and big-end bearing journals . . . . . . . . . .0.254 mm

Camshaft

Cam lift (inlet and exhaust):

BRC engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6.72mm

BRD and BRE engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6.54 mm

Cam lobe height (inlet and exhaust):

BRC engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36.08 to 36.25 mm

BRD and BRE engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36.22 to 36.41 mm

Camshaft endfloat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.065 to 0.165 mm

Thrust plate thickness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4.02 to 4.05 mm

Valves

Valve timing:

BRC engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .As 2.4 litre V6

BRD and BRE engines:

Inlet opens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30°BTDC

Inlet closes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66°ABDC

Exhaust opens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .76°BBDC

Exhaust closes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20°ATDC

Length:

BRC engine:

Inlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .106.2 to 106.9 mm

Exhaust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .106.8 to 107.8 mm

BRD and BRE engine:

Inlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .104.7 to 105.4 mm

Exhaust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .104.6 to 105.6 mm

Valve spring free length:

BRC engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55.12 mm

BRD and BRE engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53.00 mm

procarmanuals.com

Page 75 of 255

9Inspect the valve springs, if possible

comparing their free length with new springs.

Renew the springs anyway if they have been in

use for 20 000 miles (32 000 km) or more.

10Use a straight-edge and feeler blades to

check that the cylinder head mating faces are

not distorted. If they are, have the heads

resurfaced by an engineering works.

11Commence reassembly by oiling a valve

stem and inserting the valve into its guide.

Cover the collet grooves with adhesive tape

and press the new valve stem oil seal down

the stem, using a suitable tube to press the

seals home. Note that the inlet valve seals are

rubber and the exhaust seals nylon. On the 2.8

litre engine, oversize exhaust valve seals must

be used when valves with oversize stems are

fitted. Remove the adhesive tape.

12Fit the valve spring and spring retainer.

Compress the spring and fit the collets, using

a dab of grease to hold them in position.

Carefully release the compressor.

13Tap the valve stem smartly with a mallet to

seat the components.

14Repeat the process on the remaining valves.

Refer to Part A, Section 28 of this Chapter.

The main bearing caps should be fitted, and

their bolts tightened to the specified torque,

when making bore measurements.

Refer to Part A, Section 29 of this Chapter.

1Refer to Part A, Section 27 of this Chapter for

the examination procedure. Note that regrinding

of this crankshaft is not permitted, so if significant

journal wear is present, a new crankshaft (and

new bearing shells) must be fitted.

2As with the SOHC engine, oversize main

bearing parent bores may be encountered.

These are marked with paint stripes on the

bearing caps, corresponding paint marks on

the bearing shells and identification codes on

the backs of the bearing shells.

3On the 2.4 litre engine, separate

thrustwashers are used to control crankshaft

endfloat. On the 2.9 litre engine, No 3 main

bearing shells have integral thrust flanges.

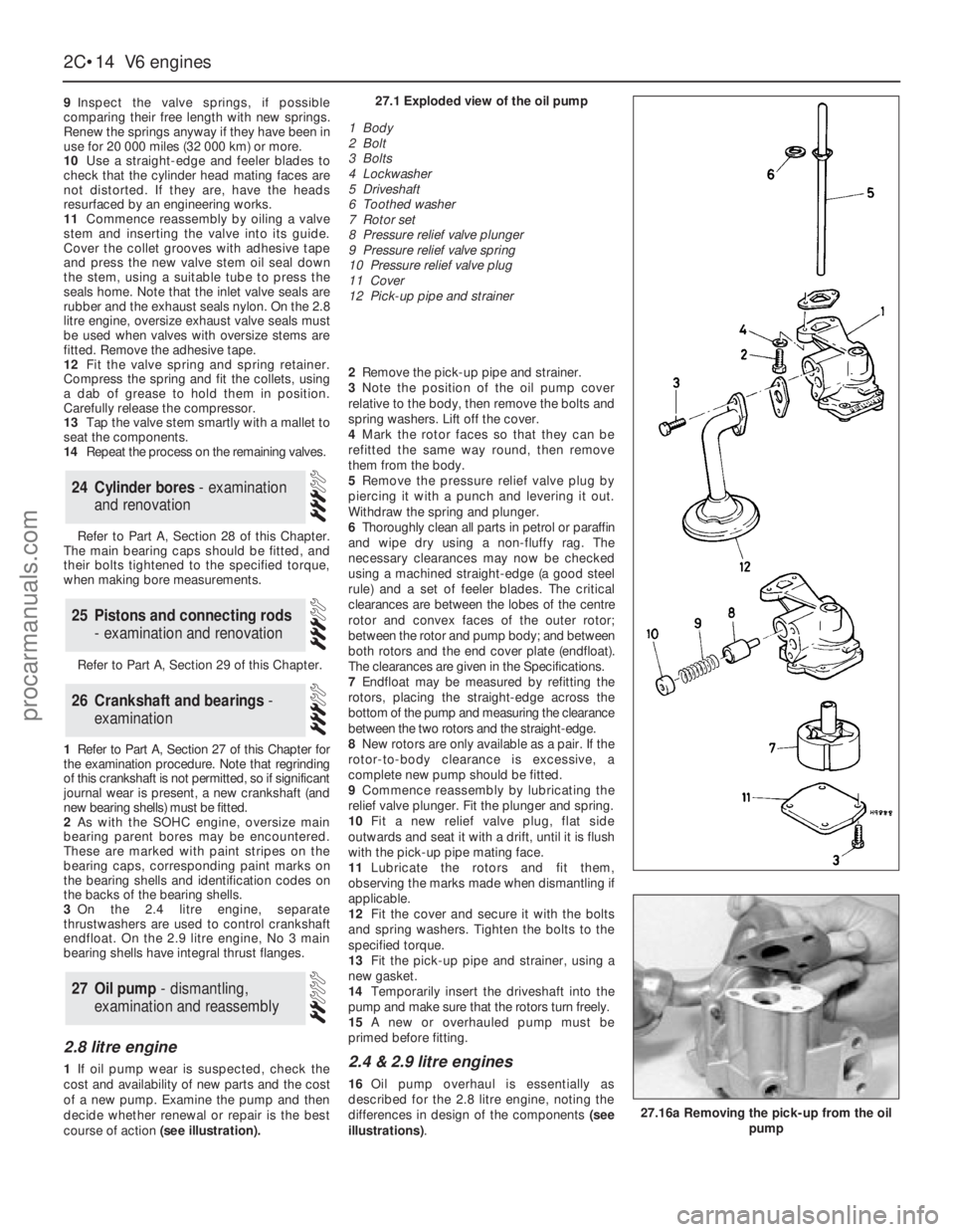

2.8 litre engine

1If oil pump wear is suspected, check the

cost and availability of new parts and the cost

of a new pump. Examine the pump and then

decide whether renewal or repair is the best

course of action (see illustration).2Remove the pick-up pipe and strainer.

3Note the position of the oil pump cover

relative to the body, then remove the bolts and

spring washers. Lift off the cover.

4Mark the rotor faces so that they can be

refitted the same way round, then remove

them from the body.

5Remove the pressure relief valve plug by

piercing it with a punch and levering it out.

Withdraw the spring and plunger.

6Thoroughly clean all parts in petrol or paraffin

and wipe dry using a non-fluffy rag. The

necessary clearances may now be checked

using a machined straight-edge (a good steel

rule) and a set of feeler blades. The critical

clearances are between the lobes of the centre

rotor and convex faces of the outer rotor;

between the rotor and pump body; and between

both rotors and the end cover plate (endfloat).

The clearances are given in the Specifications.

7Endfloat may be measured by refitting the

rotors, placing the straight-edge across the

bottom of the pump and measuring the clearance

between the two rotors and the straight-edge.

8New rotors are only available as a pair. If the

rotor-to-body clearance is excessive, a

complete new pump should be fitted.

9Commence reassembly by lubricating the

relief valve plunger. Fit the plunger and spring.

10Fit a new relief valve plug, flat side

outwards and seat it with a drift, until it is flush

with the pick-up pipe mating face.

11Lubricate the rotors and fit them,

observing the marks made when dismantling if

applicable.

12Fit the cover and secure it with the bolts

and spring washers. Tighten the bolts to the

specified torque.

13Fit the pick-up pipe and strainer, using a

new gasket.

14Temporarily insert the driveshaft into the

pump and make sure that the rotors turn freely.

15A new or overhauled pump must be

primed before fitting.2.4 & 2.9 litre engines

16Oil pump overhaul is essentially as

described for the 2.8 litre engine, noting the

differences in design of the components (see

illustrations).

27Oil pump - dismantling,

examination and reassembly

26Crankshaft and bearings -

examination

25Pistons and connecting rods

- examination and renovation

24Cylinder bores - examination

and renovation

2C•14V6 engines

27.16a Removing the pick-up from the oil

pump

27.1 Exploded view of the oil pump

1 Body

2 Bolt

3 Bolts

4 Lockwasher

5 Driveshaft

6 Toothed washer

7 Rotor set

8 Pressure relief valve plunger

9 Pressure relief valve spring

10 Pressure relief valve plug

11 Cover

12 Pick-up pipe and strainer

procarmanuals.com

Page 78 of 255

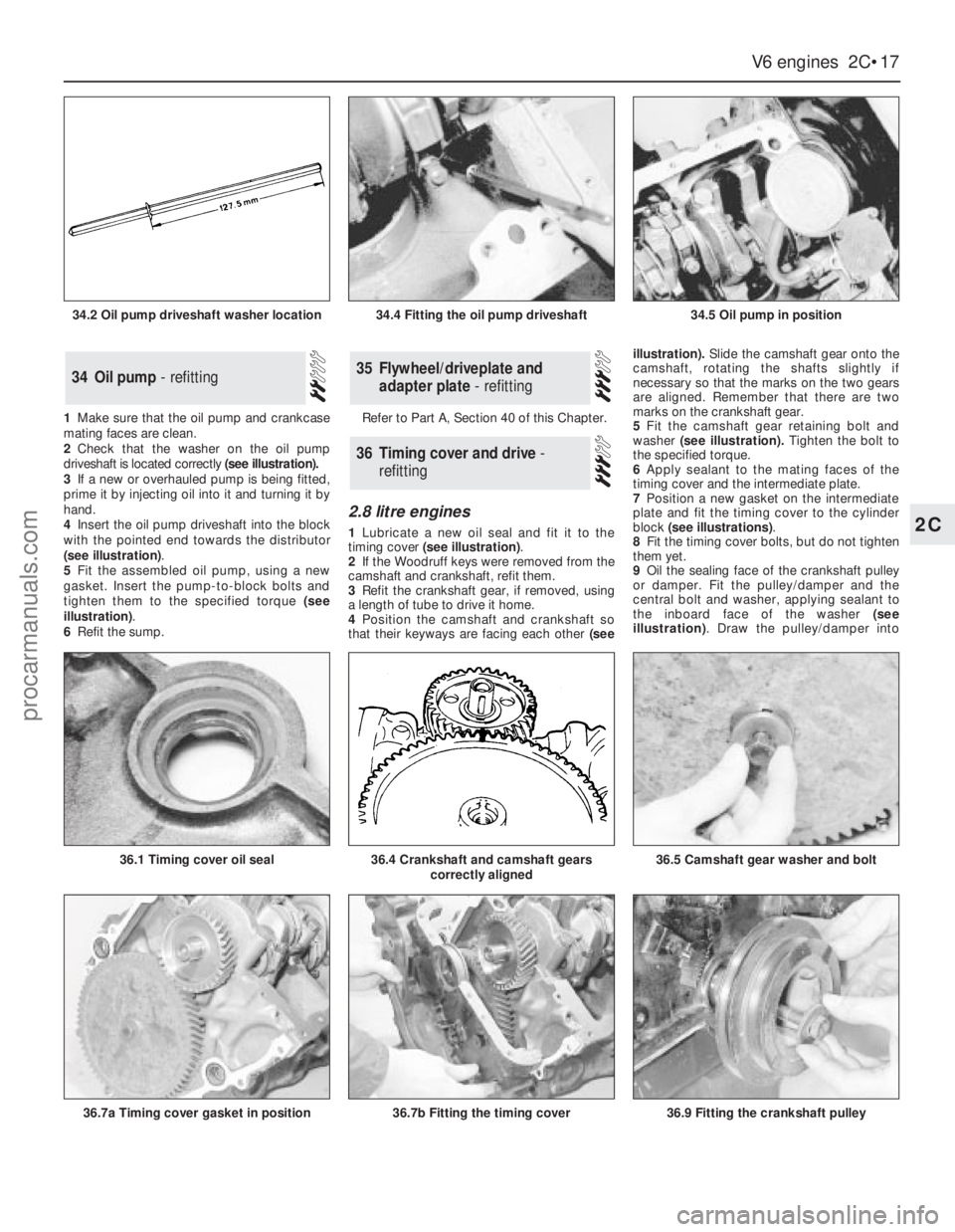

1Make sure that the oil pump and crankcase

mating faces are clean.

2Check that the washer on the oil pump

driveshaft is located correctly (see illustration).

3If a new or overhauled pump is being fitted,

prime it by injecting oil into it and turning it by

hand.

4Insert the oil pump driveshaft into the block

with the pointed end towards the distributor

(see illustration).

5Fit the assembled oil pump, using a new

gasket. Insert the pump-to-block bolts and

tighten them to the specified torque (see

illustration).

6Refit the sump.Refer to Part A, Section 40 of this Chapter.

2.8 litre engines

1Lubricate a new oil seal and fit it to the

timing cover (see illustration).

2If the Woodruff keys were removed from the

camshaft and crankshaft, refit them.

3Refit the crankshaft gear, if removed, using

a length of tube to drive it home.

4Position the camshaft and crankshaft so

that their keyways are facing each other(seeillustration).Slide the camshaft gear onto the

camshaft, rotating the shafts slightly if

necessary so that the marks on the two gears

are aligned. Remember that there are two

marks on the crankshaft gear.

5Fit the camshaft gear retaining bolt and

washer(see illustration).Tighten the bolt to

the specified torque.

6Apply sealant to the mating faces of the

timing cover and the intermediate plate.

7Position a new gasket on the intermediate

plate and fit the timing cover to the cylinder

block (see illustrations).

8Fit the timing cover bolts, but do not tighten

them yet.

9Oil the sealing face of the crankshaft pulley

or damper. Fit the pulley/damper and the

central bolt and washer, applying sealant to

the inboard face of the washer (see

illustration). Draw the pulley/damper into

36Timing cover and drive -

refitting

35Flywheel/driveplate and

adapter plate - refitting34Oil pump - refitting

V6 engines 2C•17

2C

34.2 Oil pump driveshaft washer location34.4 Fitting the oil pump driveshaft34.5 Oil pump in position

36.7a Timing cover gasket in position

36.1 Timing cover oil seal36.5 Camshaft gear washer and bolt36.4 Crankshaft and camshaft gears

correctly aligned

36.7b Fitting the timing cover36.9 Fitting the crankshaft pulley

procarmanuals.com