trunk release FORD GRANADA 1985 Service Repair Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1985, Model line: GRANADA, Model: FORD GRANADA 1985Pages: 255, PDF Size: 14.98 MB

Page 17 of 255

Instruments and electrical

equipment

1Check the operation of all instruments and

electrical equipment.

2Make sure that all instruments read

correctly, and switch on all electrical

equipment in turn to check that it functions

properly.

Steering and suspension

3Check for any abnormalities in the steering,

suspension, handling or road “feel”.

4Drive the vehicle, and check that there are

no unusual vibrations or noises.

5Check that the steering feels positive, with

no excessive “sloppiness”, or roughness, and

check for any suspension noises when

cornering, or when driving over bumps.

Drivetrain

6Check the performance of the engine,

clutch, transmission and driveshafts.

7Listen for any unusual noises from the

engine, clutch and transmission.

8Make sure that the engine runs smoothly

when idling, and that there is no hesitation

when accelerating.

9Where applicable, check that the clutch

action is smooth and progressive, that the

drive is taken up smoothly, and that the pedal

travel is not excessive. Also listen for any

noises when the clutch pedal is depressed.

10Check that all gears can be engaged

smoothly, without noise, and that the gear

lever action is not abnormally vague or

“notchy”.

Check the operation and

performance of the braking system

11Make sure that the vehicle does not pull to

one side when braking, and that the wheels do

not lock prematurely when braking hard.

12Check that there is no vibration through

the steering when braking.

13Check that the handbrake operates

correctly, without excessive movement of the

lever, and that it holds the vehicle stationary

on a slope.

14Test the operation of the brake servo unit

as follows. With the engine off, depress the

footbrake four or five times to exhaust the

vacuum. Start the engine, holding the brake

pedal depressed. As the engine starts, there

should be a noticeable “give” in the brake

pedal as vacuum builds up. Allow the engine

to run for at least two minutes, and then

switch it off. If the brake pedal is depressed

now, it should be possible to detect a hiss

from the servo as the pedal is depressed. After

about four or five applications, no further

hissing should be heard, and the pedal should

feel considerably firmer.1The power steering fluid dipstick is

incorporated in the reservoir filler cap. The

reservoir is mounted on the pump. Observe

scrupulous cleanliness when checking the

level or topping-up.

2The system should be at operating

temperature and the engine switched off.

Wipe clean around the reservoir filler cap.

Unscrew the cap, withdraw the dipstick and

wipe it with a clean lint-free rag. Reinsert the

dipstick, screw the cap home, then unscrew it

again and read the level on the dipstick. It

should be up to the MAX or upper HOT mark

(depending on the dipstick markings) (see

illustration).

3Top-up if necessary with clean fluid of the

specified type. Check for leaks if topping-up is

frequently required.

4If the level is checked cold, use the MIN or

FULL COLD mark on the dipstick for reference.

Recheck the level at operating temperature.

On carburettor models, remove the air

cleaner cover and check that the automatic

choke is opening fully when the engine is hot.

Run the engine until it reaches normal

operating temperature. Stop the engine and

immediately restart it. If the engine fails to start

cleanly and immediately then refer to either

Chapters 4 or 5 and check fuel feed

adjustments.

37Hot starting check

36Automatic choke check

35Power steering fluid level

check34Road test

Carburettor models

SOHC engines

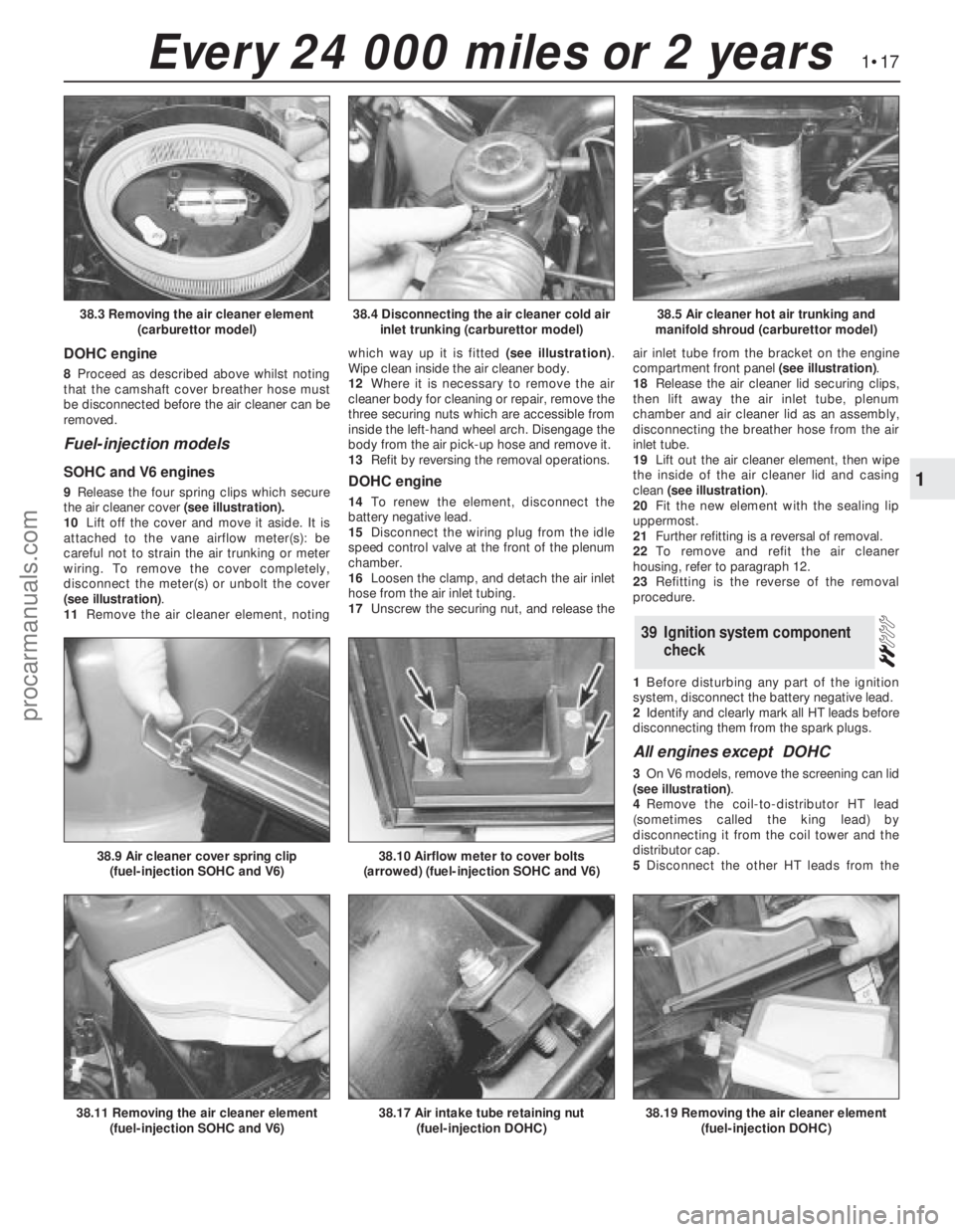

1Remove the screws from the air cleaner

cover(see illustration).

2Release the spring clips (when fitted), then

lift off the cover (see illustration).

3Lift out the air cleaner element(see

illustration). Wipe clean inside the air cleaner

housing, but be careful not to sweep dirt into

the carburettor throat.

4Where it is necessary to remove the air

cleaner body for cleaning or repair, first

disconnect the cold air inlet trunking from the

spout (see illustration). 5Disconnect the vacuum pipe from the inlet

manifold, and the hot air trunking from the

spout or exhaust manifold shroud(see

illustration). 6Remove the remaining screw which secures

the air cleaner to the valve cover, then lift off

the air cleaner.

7Refit by reversing the removal operations.

38Air cleaner filter element

renewal

1•16Every 24 000 miles or 2 years

35.2 Removing the power steering fluid

dipstick

38.2 Releasing an air cleaner cover clip

(carburettor model)38.1 Removing an air cleaner cover screw

(carburettor model)

Every 24 000 miles or 2 years

procarmanuals.com

Page 18 of 255

DOHC engine

8Proceed as described above whilst noting

that the camshaft cover breather hose must

be disconnected before the air cleaner can be

removed.

Fuel-injection models

SOHC and V6 engines

9Release the four spring clips which secure

the air cleaner cover(see illustration).

10Lift off the cover and move it aside. It is

attached to the vane airflow meter(s): be

careful not to strain the air trunking or meter

wiring. To remove the cover completely,

disconnect the meter(s) or unbolt the cover

(see illustration).

11Remove the air cleaner element, notingwhich way up it is fitted (see illustration).

Wipe clean inside the air cleaner body.

12Where it is necessary to remove the air

cleaner body for cleaning or repair, remove the

three securing nuts which are accessible from

inside the left-hand wheel arch. Disengage the

body from the air pick-up hose and remove it.

13Refit by reversing the removal operations.DOHC engine

14To renewthe element, disconnect the

battery negative lead.

15Disconnect the wiring plug from the idle

speed control valve at the front of the plenum

chamber.

16Loosen the clamp, and detach the air inlet

hose from the air inlet tubing.

17Unscrew the securing nut, and release theair inlet tube from the bracket on the engine

compartment front panel (see illustration).

18Release the air cleaner lid securing clips,

then lift away the air inlet tube, plenum

chamber and air cleaner lid as an assembly,

disconnecting the breather hose from the air

inlet tube.

19Lift out the air cleaner element, then wipe

the inside of the air cleaner lid and casing

clean (see illustration).

20Fit the new element with the sealing lip

uppermost.

21Further refitting is a reversal of removal.

22To remove and refit the air cleaner

housing, refer to paragraph 12.

23Refitting is the reverse of the removal

procedure.

1Before disturbing any part of the ignition

system, disconnect the battery negative lead.

2Identify and clearly mark all HT leads before

disconnecting them from the spark plugs.

All engines except DOHC

3On V6 models, remove the screening can lid

(see illustration).

4Remove the coil-to-distributor HT lead

(sometimes called the king lead) by

disconnecting it from the coil tower and the

distributor cap.

5Disconnect the other HT leads from the

39Ignition system component

check

1•17

1

Every 24 000 miles or 2 years

38.4 Disconnecting the air cleaner cold air

inlet trunking (carburettor model)38.5 Air cleaner hot air trunking and

manifold shroud (carburettor model)38.3 Removing the air cleaner element

(carburettor model)

38.17 Air intake tube retaining nut

(fuel-injection DOHC)38.19 Removing the air cleaner element

(fuel-injection DOHC)38.11 Removing the air cleaner element

(fuel-injection SOHC and V6)

38.9 Air cleaner cover spring clip

(fuel-injection SOHC and V6)38.10 Airflow meter to cover bolts

(arrowed) (fuel-injection SOHC and V6)

procarmanuals.com

Page 28 of 255

The cylinder head is of crossflow design

with the inlet manifold mounted on the left-

hand side and the exhaust manifold mounted

on the right-hand side.

Lubrication is by means of a bi-rotor pump

which draws oil through a strainer located

inside the sump, and forces it through a full-

flow filter into the engine oil galleries where it

is distributed to the crankshaft, camshaft and

auxiliary shaft. The big-end bearings are

supplied with oil via internal drillings in the

crankshaft.The undersides of the pistons are

supplied with oil from drillings in the big-ends.

The distributor shaft is intermittently supplied

with oil from the drilled auxiliary shaft. The

camshaft and cam followers are supplied with

oil via a drilled spray tube from the centre

camshaft bearing.

A semi-closed crankcase ventilation system

is employed whereby piston blow-by gases

are drawn into the inlet manifold via an oil

separator and on carburettor models a control

valve.

The following operations can be carried out

without removing the engine, although the

work may be easier and quicker with the

engine removed:

a)Removal and refitting of the cylinder head

b)Removal and refitting of the camshaft

(after removing the cylinder head)

c)Removal and refitting of the timing belt

and sprockets

d)Removal and refitting of the sump and oil

pump

e)Removal and refitting of the pistons,

connecting rods and big-end bearings

f)Renewal of the engine mountings

g)Renewal of the crankshaft oil seals

h)Removal and refitting of the auxiliary shaft

j)Removal and refitting of the flywheel

The engine must be removed from the

vehicle for the following operations:

a)Renewal of the crankshaft main bearings

b)Removal and refitting of the crankshaft

The engine may be lifted out either on its

own or together with the gearbox. Unless work

is also necessary on the gearbox it is

recommended that the engine is removed on

its own. Where automatic transmission is

fitted, the engine should be removed on its

own owing to the additional weight. If the

engine and gearbox are removed together,

they will have to be tilted at a very steep angle;

make sure that the range of the lifting tackle is

adequate.1Disconnect the battery negative lead.

2Remove the bonnet.

3On carburettor models, remove the air

cleaner. On fuel-injection models, remove the

air cleaner cover, vane airflow meter and air

inlet trunking.

4If a splash guard is fitted, remove it.

5Release the securing clips and bolts and

remove the upper half of the fan shroud. On

carburettor models remove the lower half of

the shroud too.

6Drain the cooling system.

7Disconnect the radiator top and bottom

hoses from the thermostat housing and water

pump. Disconnect the top hose spur from the

expansion tank and unclip it.

8Disconnect the heater hoses from the water

pump and from the inlet manifold or automatic

choke housing. Unclip the hoses.

9On models with power steering, remove the

steering pump.

10Disconnect the vacuum pipe(s) from the

inlet manifold, labelling them if there is any

possibility of confusion.

11Disconnect the following wiring, as

applicable:

a)Alternator

b)Temperature gauge sender

c)Engine management temperature sensor

d)Distributor

e)Oil pressure switch

f)Automatic choke and thermo-switch

g)Carburettor stepper motor

h)Fuel-injection system sub-harness

j)Inlet manifold heater

12Disconnect the HT lead from the coil.

13If an oil level sensor is fitted, remove it

(see illustration).

14Unbolt the throttle cable bracket,

disconnect the inner cable and move the cable

and bracket aside. Also disconnect the

downshift cable on automatic transmission

models.

15On carburettor models, disconnect the

fuel lines from the fuel pump (mechanised

type) and from the carburettor. Be prepared

for fuel spillage.

16On fuel-injection models, disconnect the

fuel supply union from the injector rail, and the

fuel return pipe from the fuel pressureregulator. Be prepared for fuel spillage, and

for some spray if the supply side is still

under pressure.

17Unbolt the exhaust downpipe from the

manifold.

18On models with air conditioning, unbolt

the compressor and move it aside without

straining the flexible hoses.

19Remove the starter motor.

20Although not specified by the

manufacturers, the author advises that either

the radiator or the cooling fan be removed, to

reduce the risk of damage.

21Attach the lifting tackle to the two lifting

eyes on the engine, so that when suspended

the engine will be roughly horizontal. Take the

weight of the engine.

22Remove the single nut on each side which

secures each engine bearer to its mounting.

23Working under the vehicle, remove the

bracing strap which connects the engine and

transmission. Unbolt the adapter plate from

the bottom of the transmission bellhousing.

24On automatic transmission models, unbolt

the torque converter from the driveplate.

25Remove the engine-to-bellhousing bolts.

Note the location of the battery earth strap.

26Support the transmission, preferably with

a trolley jack.

27Check that nothing has been overlooked,

then raise the engine and draw it forwards

clear of the transmission input shaft. Do not

allow the weight of the engine to hang on the

shaft, and do not lift the transmission by it.

28On automatic transmission models, make

sure that the torque converter stays engaged

with the oil pump in the transmission as the

engine is withdrawn,

29Lift the engine out of the engine bay and

take it to the bench.

1Engine removal with automatic transmission

is not recommended.

2Proceed as in the previous Section,

paragraphs 1 to 18.

3Disconnect the wiring from the starter

motor, and release the battery earth cable

from its bellhousing bolt.

4Remove the radiator.

5Remove the propeller shaft.

6Disconnect and unclip the reversing light

switch and speedometer sender unit wiring.

7Disconnect the clutch cable.

8Unbolt the anti-roll bar mounting brackets

and lower the anti-roll bar as far as possible.

9From inside the vehicle remove the gear

lever.

10Drain the engine oil.

11Unhook the exhaust system from its

mounting on the gearbox crossmember. Either

support the system or remove it completely.

12Support the gearbox, preferably with a

trolley jack, then unbolt and remove the

gearbox crossmember. Note the earth strap (if

fitted) under one of the crossmember bolts.

13Attach lifting tackle to the two lifting eyes

on the engine so that when suspended it will

be at an angle of approximately 45°.

6Engine - removal with manual

gearbox

5Engine - removal leaving

gearbox/transmission in vehicle

4Methods of engine removal

3Major operations requiring

engine removal

2Major operations possible with

the engine in the vehicle

SOHCengines 2A•5

2A

5.13 Oil level sensor

procarmanuals.com

Page 68 of 255

meters and air inlet trunking. Also remove the

oil filler cap, which is connected to the

trunking by a crankcase ventilation hose.

5Release the securing clips and bolts and

remove the upper half of the fan shroud.

6Drain the cooling system and remove the

radiator.

7Disconnect the heater hoses from the

heater matrix and from the coolant outlet.

Unclip the hoses.

8Remove the fan and viscous clutch (where

fitted).

9Disconnect the following wiring:

a)Alternator

b)Temperature gauge sender

c)Engine management temperature sensor

d)Oil pressure switch

e)Idle speed control valve

f)Throttle position sensor

g)Injector nut-harness

h)Distributor multi-plug

i)Distributor-to-coil HT lead

10Disconnect the throttle cable. When

applicable, also disconnect the downshaft

cable or switch.

11Depressurise the fuel system and

disconnect the fuel supply and return lines

(see Chapter 4).

12Remove the steering pump and air

conditioning compressor drivebelts (as

applicable). Unbolt the steering pump and

compressor, move them aside within the limitsof their flexible hoses and support them by

wiring them to adjacent components.

13Remove the distributor cap and rotor.

14Remove the starter motor.

15Drain the engine oil. Unscrew the oil filter

with a strap or chain wrench and remove it; be

prepared for oil spillage.

16On manual gearbox models, disconnect

the clutch cable from the release lever.

17Unbolt the exhaust pipes from the

manifolds.

18On automatic transmission models, unbolt

the torque converter from the driveplate.

19Attach lifting tackle to the engine. If no

lifting eyes are fitted, pass ropes or chains

round the exhaust manifolds.

20Take the weight of the engine, then

remove the single nut on each side which

holds engine bearer to its mountings.

21From under the vehicle unbolt the engine

adapter plate from the bellhousing.

22Remove the engine-to-bellhousing bolts.

Also disconnect or unclip the battery negative

lead, the starter motor lead and the heat

shield.

23Support the transmission, preferably with

a trolley jack.

24Check that nothing has been overlooked,

then raise the engine and draw it forwards

clear of the transmission input shaft. Do not

allow the weight of the engine to hang on the

shaft, and do not lift the transmission by it.25With automatic transmission, make sure

that the torque converter stays engaged with

the oil pump in the transmission as the engine

is withdrawn.

26Lift the engine out of the engine bay and

take it to the bench.

2.4 & 2.9 litre engines

27The removal operations for these engines

are essentially as described for the 2.8 litre

version. Note the following points.

Coolant hoses

28Remove the hoses which run between the

thermostat housing and the water pump, and

the cooling system expansion tank.

29Remove the heater hoses which run

between the thermostat housing or coolant

distribution pipe and oil cooler (where fitted).

Vacuum hoses

30Disconnect the hose from the fuel

pressure regulator.

31Disconnect the hose from the plenum

chamber.

32Disconnect the hose from the throttle valve.

33Disconnect the hose from the T-piece

connector.

V6 engines 2C•7

2C

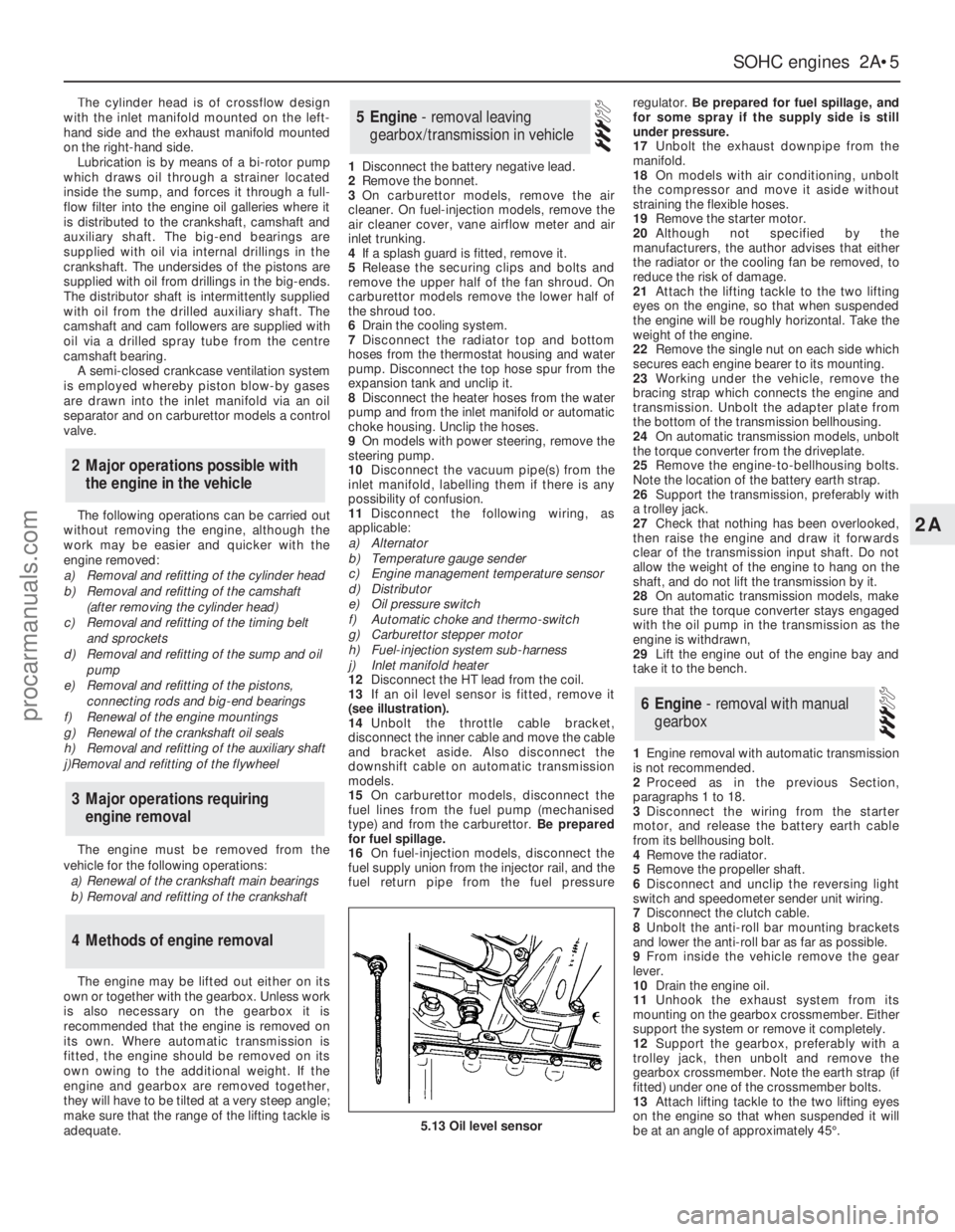

1.1 Exploded view of V6 engine

1 Water inlet connection

2 Thermostat

3 Water pump

4 Timing cover

5 By-pass hose flange

7 Camshaft thrust plate

8 Camshaft gear

9 Crankshaft gear

10 Flywheel

11 Crankshaft pilot

bearing

12 Oil seal

13 Oil pump drive shaft

14 Main bearing

15 Oil pump

It may be necessary to rock

the engine a little to release it

from the gearbox.

procarmanuals.com

Page 91 of 255

panel. Disconnect the wiring connectors from

the heated window switches and fuel

computer (where fitted) and remove the panel

from the car.

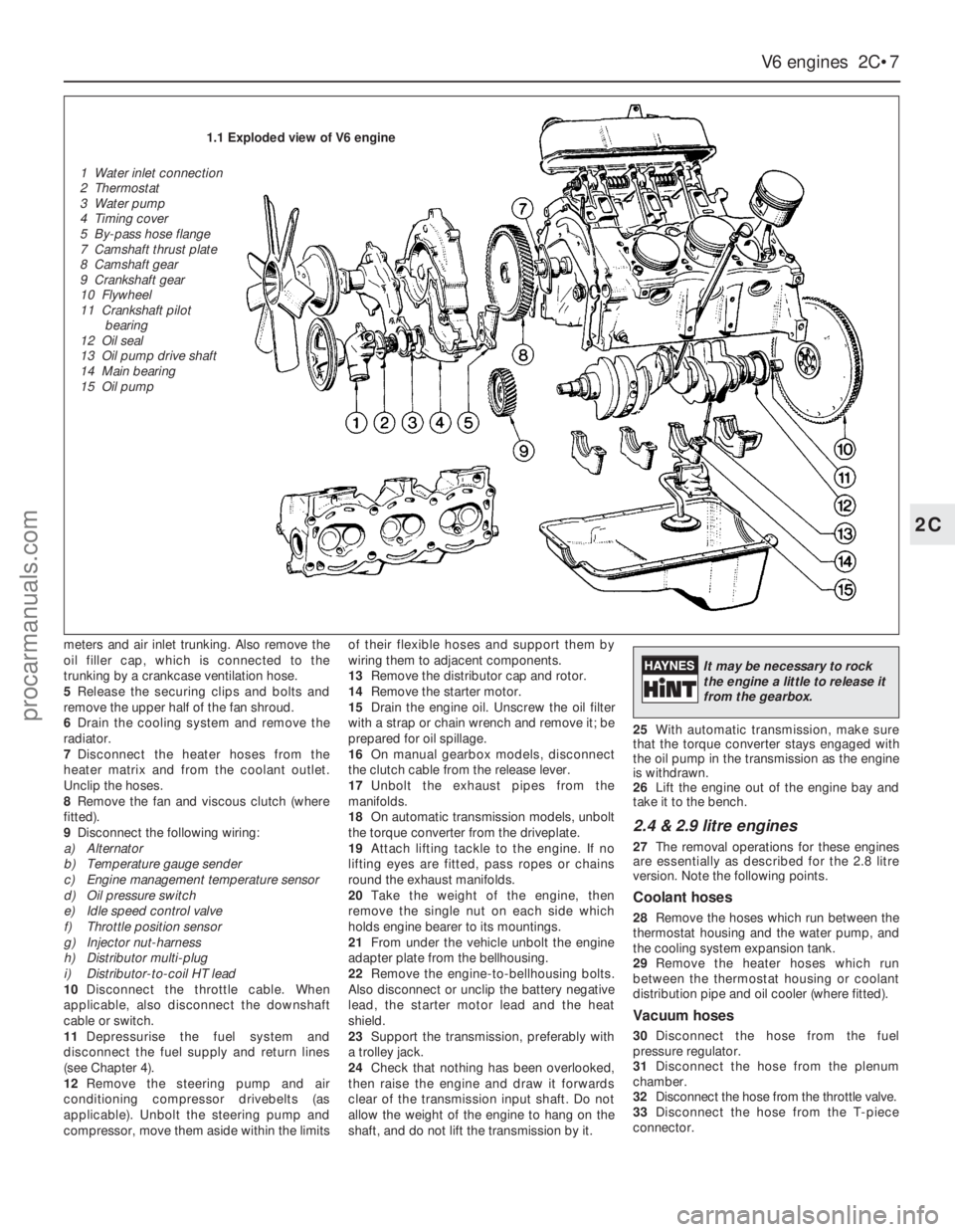

14Undo the two retaining screws then

manoeuvre the control panel out of the facia

and disconnect the wiring connector (see

illustration).

15Unclip the central fan switch from the

panel then, using a small flat-bladed

screwdriver, bend back the retaining tabs and

remove the cover from the panel base plate

(see illustration).

16Cut the cable retaining clips then release

the cables from the toothed guides and

remove the base plate.

17Refitting is a reversal of the removal

procedure securing the cables to the base

plate using new retaining clips.

Models before April 1992

Front

1Remove the heater controls as described in

the previous Section.

2Remove the centre console as described in

Chapter 12. Also remove the console bracket

and the gear lever inner gaiter.

3Unclip the under-dash trim on both sides.

Remove the glovebox lid.

4Remove the radio (Chapter 13).

5Remove the ABS and (when applicable) the

EEC IV modules (Chapters 10 and 13).

6Remove the remaining lower trim on the

passenger side to expose the heater casing.

7Remove the two securing screws and

release the cables from the heater.

8When refitting, place the air distribution and

temperature control valve levers in their

uppermost positions, then connect the cables.

9The remainder of refitting is a reversal of the

removal procedure.

Rear

10Remove the centre console (Chapter 12).

11Remove the front seat on the side

concerned. Also remove the rear seat cushion. 12Remove the front seat belt lower anchor bolt.

13Remove the front scuff plate, which is

secured by three screws. Remove the front

screw from the rear scuff plate.

14Roll back the front carpet from the scuff

plates to expose the heater cable. Release the

cable from its ties and disconnect it from the

control unit and the nozzle (see illustration).

15Refit by reversing the removal operations.

Models from April 1992

16Remove the facia undercovers, the right-

hand lower facia panel and the glovebox .

17Undo the two retaining nuts, then release

the retaining clips and remove the trim panel

from the glovebox aperture.

18Remove the heater control panel.

19Slacken and remove the control cable

retaining screws then release the retaining

clips (one screw and one clip for each cable).

Detach the cables from the heater assembly

and withdraw them from the facia whilst noting

the correct routing (see illustration).

20Refitting is a reverse of the removal

procedure noting the following points.

a)Ensure that the cables are correctly routed

prior to connecting them to the heater

housing.

b)Prior to refitting the glovebox aperture trim

panel, check that the panel controls

function correctly and that the cables

move the relevant operating lever

smoothly from the fully open to the fully

closed position without any trace of undue

friction.

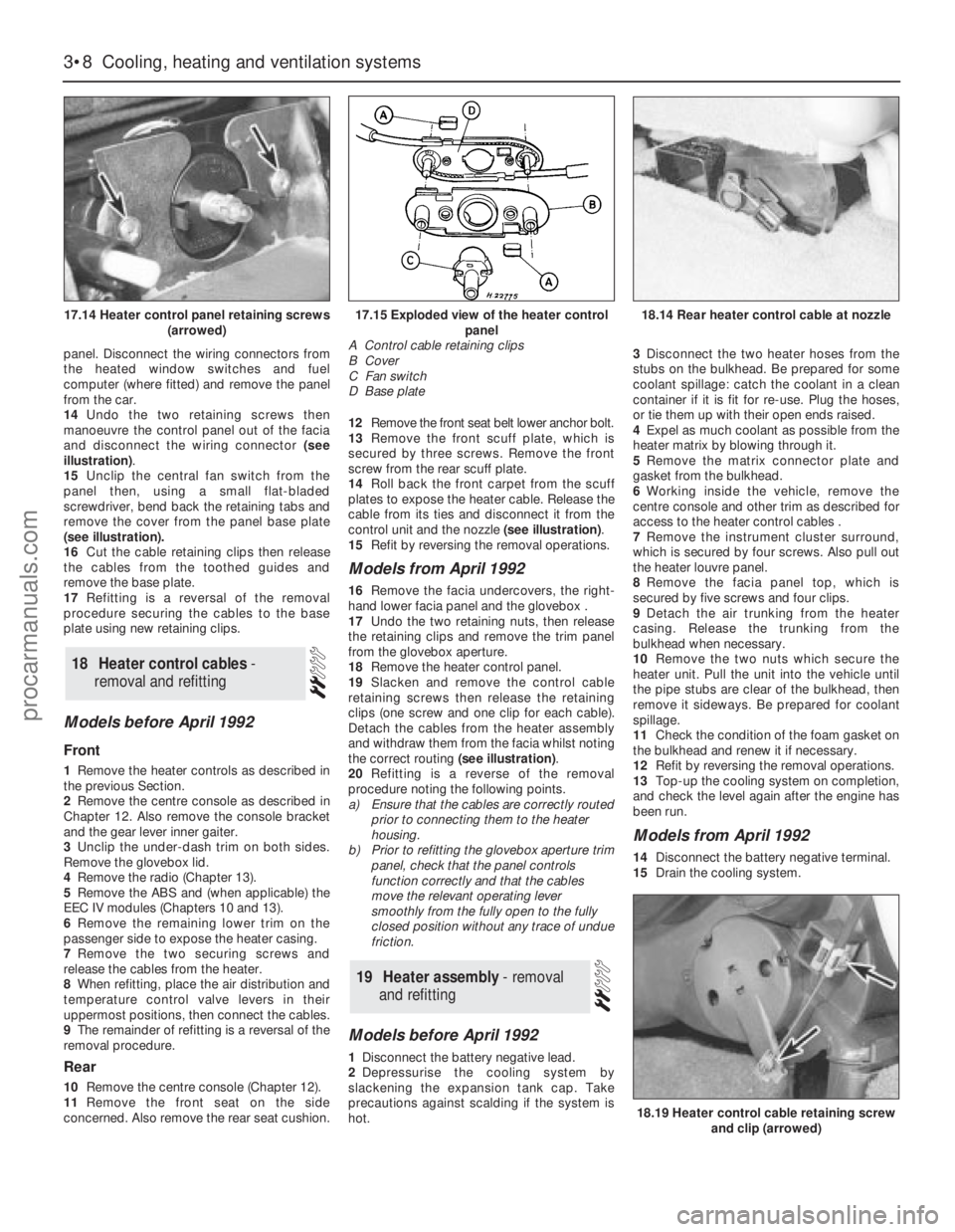

Models before April 1992

1Disconnect the battery negative lead.

2Depressurise the cooling system by

slackening the expansion tank cap. Take

precautions against scalding if the system is

hot.3Disconnect the two heater hoses from the

stubs on the bulkhead. Be prepared for some

coolant spillage: catch the coolant in a clean

container if it is fit for re-use. Plug the hoses,

or tie them up with their open ends raised.

4Expel as much coolant as possible from the

heater matrix by blowing through it.

5Remove the matrix connector plate and

gasket from the bulkhead.

6Working inside the vehicle, remove the

centre console and other trim as described for

access to the heater control cables .

7Remove the instrument cluster surround,

which is secured by four screws. Also pull out

the heater louvre panel.

8Remove the facia panel top, which is

secured by five screws and four clips.

9Detach the air trunking from the heater

casing. Release the trunking from the

bulkhead when necessary.

10Remove the two nuts which secure the

heater unit. Pull the unit into the vehicle until

the pipe stubs are clear of the bulkhead, then

remove it sideways. Be prepared for coolant

spillage.

11Check the condition of the foam gasket on

the bulkhead and renew it if necessary.

12Refit by reversing the removal operations.

13Top-up the cooling system on completion,

and check the level again after the engine has

been run.

Models from April 1992

14Disconnect the battery negative terminal.

15Drain the cooling system.

19Heater assembly - removal

and refitting

18Heater control cables -

removal and refitting

3•8Cooling, heating and ventilation systems

17.14 Heater control panel retaining screws

(arrowed)

18.19 Heater control cable retaining screw

and clip (arrowed)

17.15 Exploded view of the heater control

panel

A Control cable retaining clips

B Cover

C Fan switch

D Base plate18.14 Rear heater control cable at nozzle

procarmanuals.com

Page 98 of 255

4With the engine cold, disconnect the cold

air inlet trunking from the spout. Look into the

spout and check that the flap valve is covering

the hot air inlet.

5Start the engine and allow it to idle. Check

that the flap moves to cover the cold air inlet. If

the flap does not move, check the diaphragm

and heat sensor as follows.

6Stop the engine. Disconnect the diaphragm

vacuum pipe from the heat sensor. Apply

vacuum to the diaphragm, using a vacuum

head pump or by connecting the pipe directly

to manifold vacuum. If the flap now moves, the

heat sensor or vacuum line was faulty. If the

flap still does not move, the diaphragm is

faulty or the flap is jammed.

7On completion reconnect the vacuum pipe

and the cold air trunking.

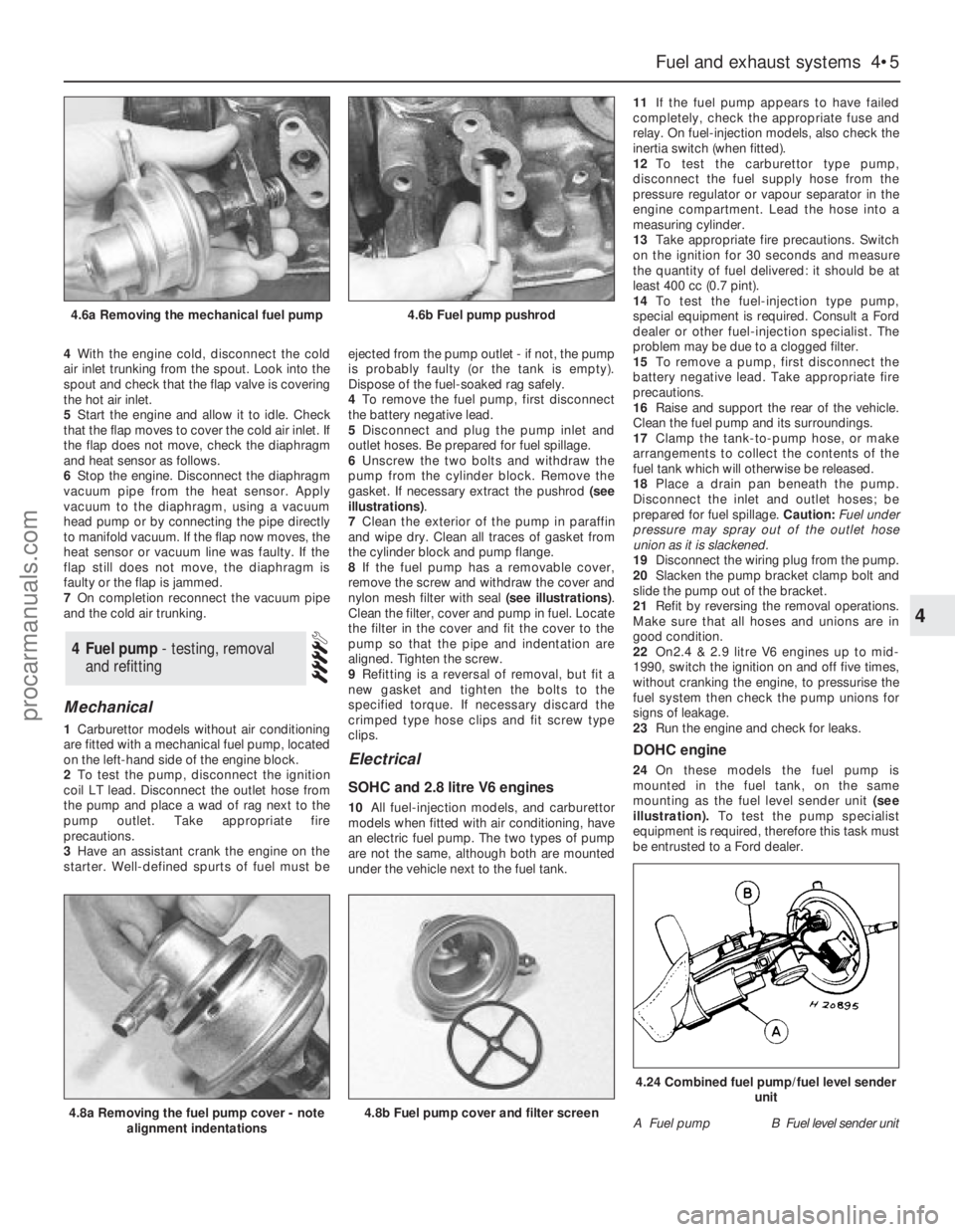

Mechanical

1Carburettor models without air conditioning

are fitted with a mechanical fuel pump, located

on the left-hand side of the engine block.

2To test the pump, disconnect the ignition

coil LT lead. Disconnect the outlet hose from

the pump and place a wad of rag next to the

pump outlet. Take appropriate fire

precautions.

3Have an assistant crank the engine on the

starter. Well-defined spurts of fuel must beejected from the pump outlet - if not, the pump

is probably faulty (or the tank is empty).

Dispose of the fuel-soaked rag safely.

4To remove the fuel pump, first disconnect

the battery negative lead.

5Disconnect and plug the pump inlet and

outlet hoses. Be prepared for fuel spillage.

6Unscrew the two bolts and withdraw the

pump from the cylinder block. Remove the

gasket. If necessary extract the pushrod (see

illustrations).

7Clean the exterior of the pump in paraffin

and wipe dry. Clean all traces of gasket from

the cylinder block and pump flange.

8If the fuel pump has a removable cover,

remove the screw and withdraw the cover and

nylon mesh filter with seal (see illustrations).

Clean the filter, cover and pump in fuel. Locate

the filter in the cover and fit the cover to the

pump so that the pipe and indentation are

aligned. Tighten the screw.

9Refitting is a reversal of removal, but fit a

new gasket and tighten the bolts to the

specified torque. If necessary discard the

crimped type hose clips and fit screw type

clips.

Electrical

SOHC and 2.8 litre V6 engines

10All fuel-injection models, and carburettor

models when fitted with air conditioning, have

an electric fuel pump. The two types of pump

are not the same, although both are mounted

under the vehicle next to the fuel tank.11If the fuel pump appears to have failed

completely, check the appropriate fuse and

relay. On fuel-injection models, also check the

inertia switch (when fitted).

12To test the carburettor type pump,

disconnect the fuel supply hose from the

pressure regulator or vapour separator in the

engine compartment. Lead the hose into a

measuring cylinder.

13Take appropriate fire precautions. Switch

on the ignition for 30 seconds and measure

the quantity of fuel delivered: it should be at

least 400 cc (0.7 pint).

14To test the fuel-injection type pump,

special equipment is required. Consult a Ford

dealer or other fuel-injection specialist. The

problem may be due to a clogged filter.

15To remove a pump, first disconnect the

battery negative lead. Take appropriate fire

precautions.

16Raise and support the rear of the vehicle.

Clean the fuel pump and its surroundings.

17Clamp the tank-to-pump hose, or make

arrangements to collect the contents of the

fuel tank which will otherwise be released.

18Place a drain pan beneath the pump.

Disconnect the inlet and outlet hoses; be

prepared for fuel spillage. Caution: Fuel under

pressure may spray out of the outlet hose

union as it is slackened.

19Disconnect the wiring plug from the pump.

20Slacken the pump bracket clamp bolt and

slide the pump out of the bracket.

21Refit by reversing the removal operations.

Make sure that all hoses and unions are in

good condition.

22On2.4 & 2.9 litre V6 engines up to mid-

1990, switch the ignition on and off five times,

without cranking the engine, to pressurise the

fuel system then check the pump unions for

signs of leakage.

23Run the engine and check for leaks.

DOHC engine

24On these models the fuel pump is

mounted in the fuel tank, on the same

mounting as the fuel level sender unit(see

illustration).To test the pump specialist

equipment is required, therefore this task must

be entrusted to a Ford dealer.

4Fuel pump - testing, removal

and refitting

Fuel and exhaust systems 4•5

4

4.6a Removing the mechanical fuel pump4.6b Fuel pump pushrod

4.8a Removing the fuel pump cover - note

alignment indentations4.8b Fuel pump cover and filter screenA Fuel pumpB Fuel level sender unit

4.24 Combined fuel pump/fuel level sender

unit

procarmanuals.com

Page 109 of 255

9Unscrew the securing nut, and release the

air inlet tube from the bracket on the engine

compartment front panel.

10Disconnect the wiring plug from the idle

speed control valve.

11Release the air cleaner lid securing clips,

then remove the air inlet tube, plenum

chamber, and air cleaner lid as an assembly,

disconnecting the breather hose from the air

inlet tube.

12Unscrew the two securing bolts, and

withdraw the valve from the air inlet tube (see

illustration). Recover the gasket.

13Clean the valve and air inlet tube mating

faces before refitting, taking care not to allow

dirt to enter the air inlet tube.

14Refitting is a reversal of removal, using a

new gasket.15On completion, start the engine and check

that the idle speed is stable - if not, check for

air leaks around the valve. Switch on all

available electrical loads and check that the

idle speed is maintained - if not, suspect a

faulty valve.

OHC engines

1Disconnect the battery negative lead.

2Release the locking clip and disconnect the

multi-plug from the meter (see illustration).

3Release the hose clip and disconnect the air

trunking from the meter.

4Unclip the air cleaner cover and remove it

with the meter. Do not drop or jar it.

5To separate the meter from the cover,

remove the four retaining bolts.

6Refit by reversing the removal operations.

Make sure that the seal in the air cleaner cover

is correctly located and align the hose clip

(seeillustration).

7Check the exhaust CO level on completion.

V6 engines

8Proceed as described above, noting that

there are two meters instead of one.

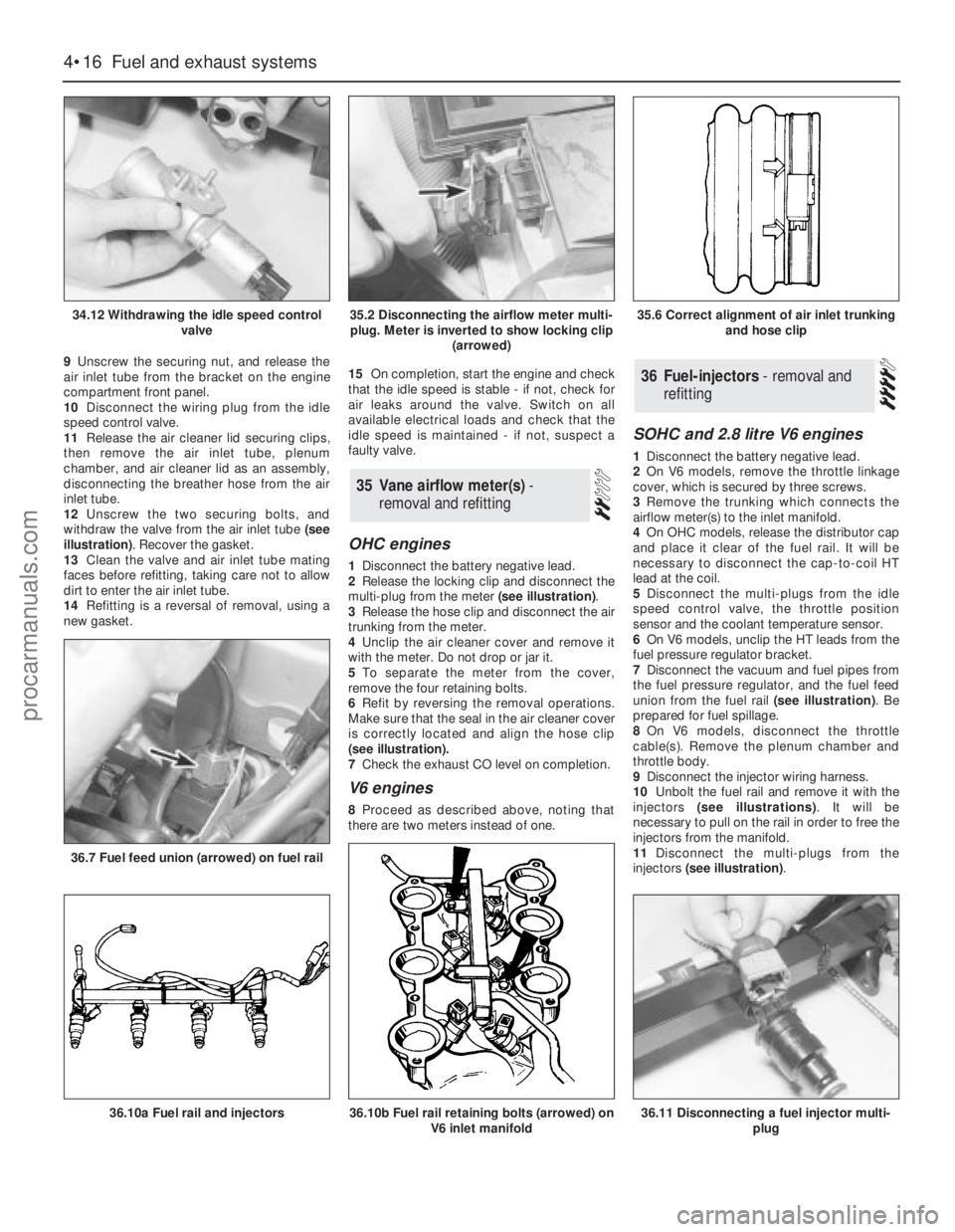

SOHC and 2.8 litre V6 engines

1Disconnect the battery negative lead.

2On V6 models, remove the throttle linkage

cover, which is secured by three screws.

3Remove the trunking which connects the

airflow meter(s) to the inlet manifold.

4On OHCmodels, release the distributor cap

and place it clear of the fuel rail. It will be

necessary to disconnect the cap-to-coil HT

lead at the coil.

5Disconnect the multi-plugs from the idle

speed control valve, the throttle position

sensor and the coolant temperature sensor.

6On V6 models, unclip the HT leads from the

fuel pressure regulator bracket.

7Disconnect the vacuum and fuel pipes from

the fuel pressure regulator, and the fuel feed

union from the fuel rail (see illustration). Be

prepared for fuel spillage.

8On V6 models, disconnect the throttle

cable(s). Remove the plenum chamber and

throttle body.

9Disconnect the injector wiring harness.

10Unbolt the fuel rail and remove it with the

injectors (see illustrations). It will be

necessary to pull on the rail in order to free the

injectors from the manifold.

11Disconnect the multi-plugs from the

injectors (see illustration).

36Fuel-injectors - removal and

refitting

35Vane airflow meter(s) -

removal and refitting

4•16Fuel and exhaust systems

34.12 Withdrawing the idle speed control

valve

36.7 Fuel feed union (arrowed) on fuel rail

36.10a Fuel rail and injectors36.10b Fuel rail retaining bolts (arrowed) on

V6 inlet manifold36.11 Disconnecting a fuel injector multi-

plug

35.2 Disconnecting the airflow meter multi-

plug. Meter is inverted to show locking clip

(arrowed)35.6 Correct alignment of air inlet trunking

and hose clip

procarmanuals.com

Page 112 of 255

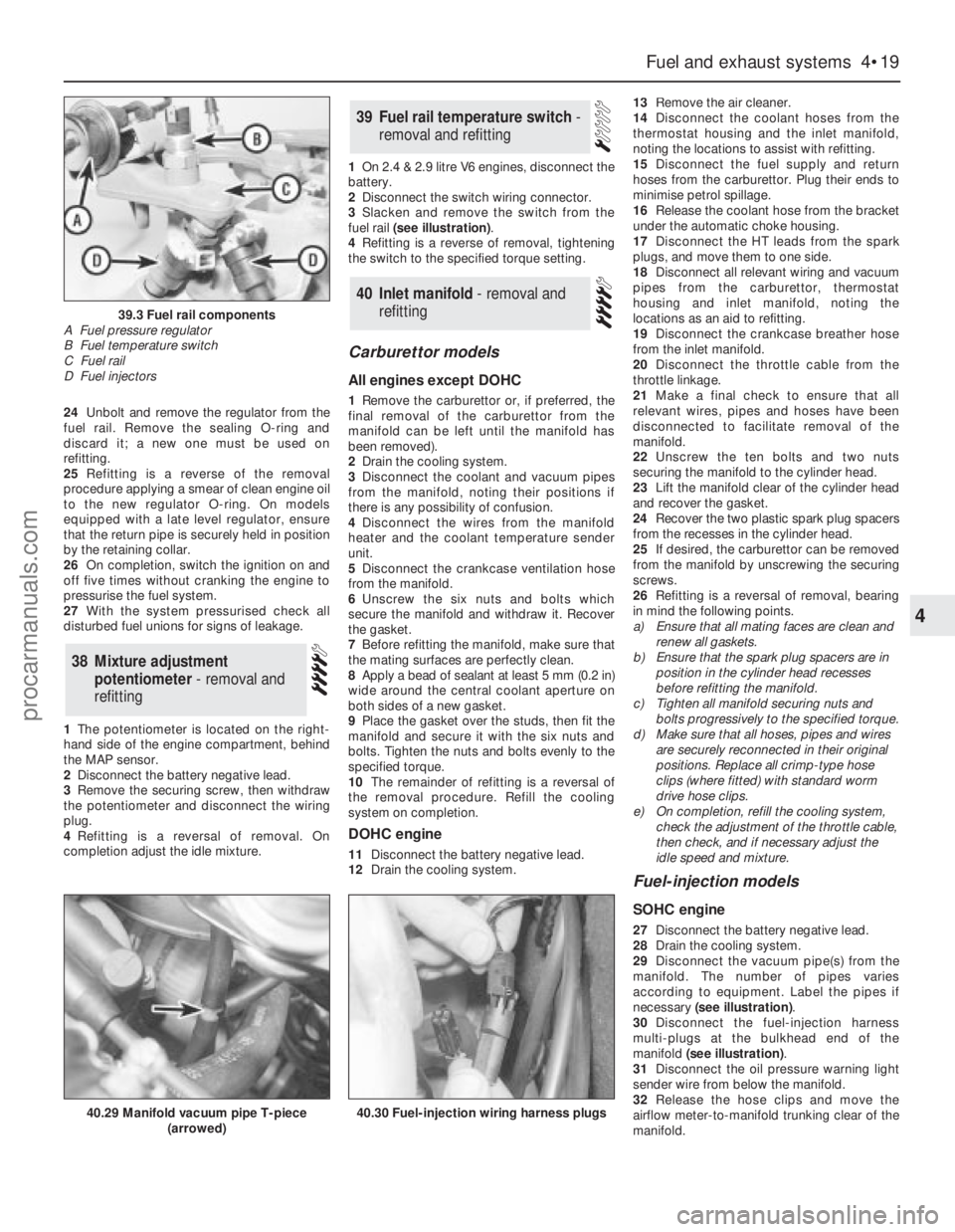

24Unbolt and remove the regulator from the

fuel rail. Remove the sealing O-ring and

discard it; a new one must be used on

refitting.

25Refitting is a reverse of the removal

procedure applying a smear of clean engine oil

to the new regulator O-ring. On models

equipped with a late level regulator, ensure

that the return pipe is securely held in position

by the retaining collar.

26On completion, switch the ignition on and

off five times without cranking the engine to

pressurise the fuel system.

27With the system pressurised check all

disturbed fuel unions for signs of leakage.

1The potentiometer is located on the right-

hand side of the engine compartment, behind

the MAP sensor.

2Disconnect the battery negative lead.

3Remove the securing screw, then withdraw

the potentiometer and disconnect the wiring

plug.

4Refitting is a reversal of removal. On

completion adjust the idle mixture.1On 2.4 & 2.9 litre V6 engines, disconnect the

battery.

2Disconnect the switch wiring connector.

3Slacken and remove the switch from the

fuel rail (see illustration).

4Refitting is a reverse of removal, tightening

the switch to the specified torque setting.

Carburettor models

All engines except DOHC

1Remove the carburettor or, if preferred, the

final removal of the carburettor from the

manifold can be left until the manifold has

been removed).

2Drain the cooling system.

3Disconnect the coolant and vacuum pipes

from the manifold, noting their positions if

there is any possibility of confusion.

4Disconnect the wires from the manifold

heater and the coolant temperature sender

unit.

5Disconnect the crankcase ventilation hose

from the manifold.

6Unscrew the six nuts and bolts which

secure the manifold and withdraw it. Recover

the gasket.

7Before refitting the manifold, make sure that

the mating surfaces are perfectly clean.

8Apply a bead of sealant at least 5 mm (0.2 in)

wide around the central coolant aperture on

both sides of a new gasket.

9Place the gasket over the studs, then fit the

manifold and secure it with the six nuts and

bolts. Tighten the nuts and bolts evenly to the

specified torque.

10The remainder of refitting is a reversal of

the removal procedure. Refill the cooling

system on completion.

DOHC engine

11Disconnect the battery negative lead.

12Drain the cooling system.13Remove the air cleaner.

14Disconnect the coolant hoses from the

thermostat housing and the inlet manifold,

noting the locations to assist with refitting.

15Disconnect the fuel supply and return

hoses from the carburettor. Plug their ends to

minimise petrol spillage.

16Release the coolant hose from the bracket

under the automatic choke housing.

17Disconnect the HT leads from the spark

plugs, and move them to one side.

18Disconnect all relevant wiring and vacuum

pipes from the carburettor, thermostat

housing and inlet manifold, noting the

locations as an aid to refitting.

19Disconnect the crankcase breather hose

from the inlet manifold.

20Disconnect the throttle cable from the

throttle linkage.

21Make a final check to ensure that all

relevant wires, pipes and hoses have been

disconnected to facilitate removal of the

manifold.

22Unscrew the ten bolts and two nuts

securing the manifold to the cylinder head.

23Lift the manifold clear of the cylinder head

and recover the gasket.

24Recover the two plastic spark plug spacers

from the recesses in the cylinder head.

25If desired, the carburettor can be removed

from the manifold by unscrewing the securing

screws.

26Refitting is a reversal of removal, bearing

in mind the following points.

a)Ensure that all mating faces are clean and

renew all gaskets.

b)Ensure that the spark plug spacers are in

position in the cylinder head recesses

before refitting the manifold.

c)Tighten all manifold securing nuts and

bolts progressively to the specified torque.

d)Make sure that all hoses, pipes and wires

are securely reconnected in their original

positions. Replace all crimp-type hose

clips (where fitted) with standard worm

drive hose clips.

e)On completion, refill the cooling system,

check the adjustment of the throttle cable,

then check, and if necessary adjust the

idle speed and mixture.

Fuel-injection models

SOHC engine

27Disconnect the battery negative lead.

28Drain the cooling system.

29Disconnect the vacuum pipe(s) from the

manifold. The number of pipes varies

according to equipment. Label the pipes if

necessary (see illustration).

30Disconnect the fuel-injection harness

multi-plugs at the bulkhead end of the

manifold (see illustration).

31Disconnect the oil pressure warning light

sender wire from below the manifold.

32Release the hose clips and move the

airflow meter-to-manifold trunking clear of the

manifold.

40Inlet manifold - removal and

refitting

39Fuel rail temperature switch -

removal and refitting

38Mixture adjustment

potentiometer - removal and

refitting

Fuel and exhaust systems 4•19

4

39.3 Fuel rail components

A Fuel pressure regulator

B Fuel temperature switch

C Fuel rail

D Fuel injectors

40.29 Manifold vacuum pipe T-piece

(arrowed)40.30 Fuel-injection wiring harness plugs

procarmanuals.com

Page 114 of 255

55Release the throttle position sensor wiring

connector from the clip under the throttle

body, and separate the two halves of the

connector.

56Remove the fuel-injectors.

57Check that all relevant wiring, hoses and

pipes have been disconnected to facilitate

removal of the manifold.

58Unscrew the ten bolts and two nuts

securing the inlet manifold to the cylinder

head, and carefully withdraw the manifold.

Recover the gasket.

59Recover the two plastic spark plug

spacers from the recesses in the cylinder head

(see illustration).

60If desired, the manifold can be dismantled

with reference to the relevant paragraphs of

this Chapter.

61Refitting is a reversal of removal, bearing

in mind the following points.

a)Ensure that the spark plug spacers are in

position in the cylinder head recesses

before refitting the manifold.

b)Ensure manifold and cylinder head mating

surfaces are clean and dry and fit a new

gasket.

c)Tighten the manifold retaining nuts and

bolts evenly and progressively to the

specified torque.

d)Refit the fuel-injectors.

e)Make sure that all hoses, pipes and wires

are securely reconnected in their original

positions.

f)On completion, refill the cooling system.

g)Check the adjustment of the throttle cable

and where necessary, adjust the speed

control cable so that only a small amount

of slack is present in the cable.

h)Where applicable, check and if necessary

adjust the idle speed and mixture.

V6 engines

62Disconnect the battery negative lead.

63Drain the cooling system.

64Remove the throttle linkage cover.

65Release the hose clips and move the

airflow meter-to-manifold trunking aside.

Unclip or remove the crankcase ventilation

hose.

66Disconnect the radiator top hose and the

heater hose from the outlet at the front of the

manifold. Be prepared for some coolant spillage.67Disconnect the multi-plugs from the idle

speed control valve, the temperature gauge

sender unit; the coolant temperature sensor

and the throttle position sensor. Also

disconnect the injector wiring harness.

68Disconnect the throttle cable from the

linkage, unclip it and move it aside. On

automatic transmission models, also

disconnect the downshift cable or multi-plug,

as applicable.

69Disconnect the fuel feed and return pipes.

Be prepared for fuel spillage.

70Remove the HT leads and the distributor.

71Remove the plenum chamber, which is

secured by eight bolts.

72Remove the rocker covers, which are each

secured by seven bolts.

73Disconnect the water pump bypass hose

from the inlet manifold.

74Remove the eight bolts which secure the

inlet manifold to the cylinder heads.

75Lift off the manifold complete with fuel

pressure regulator, fuel rail, throttle body

housing etc. If it is stuck, carefully lever it free.

Do not apply leverage at the mating faces.

Recover the gasket.

76Clean all mating faces, being careful to

keep dirt out of ports and other orifices.

Obtain new gaskets for both the cylinder head

and plenum chamber sides of the manifold,

and for the rocker covers.

77Commence refitting by applying sealant

(Ford part No A70X-19554-BA, or equivalent)

around the ports and coolant passages on the

cylinder head.

78Apply sealant around the apertures on

both sides of the gasket. then fit the gasket to

the cylinder heads.

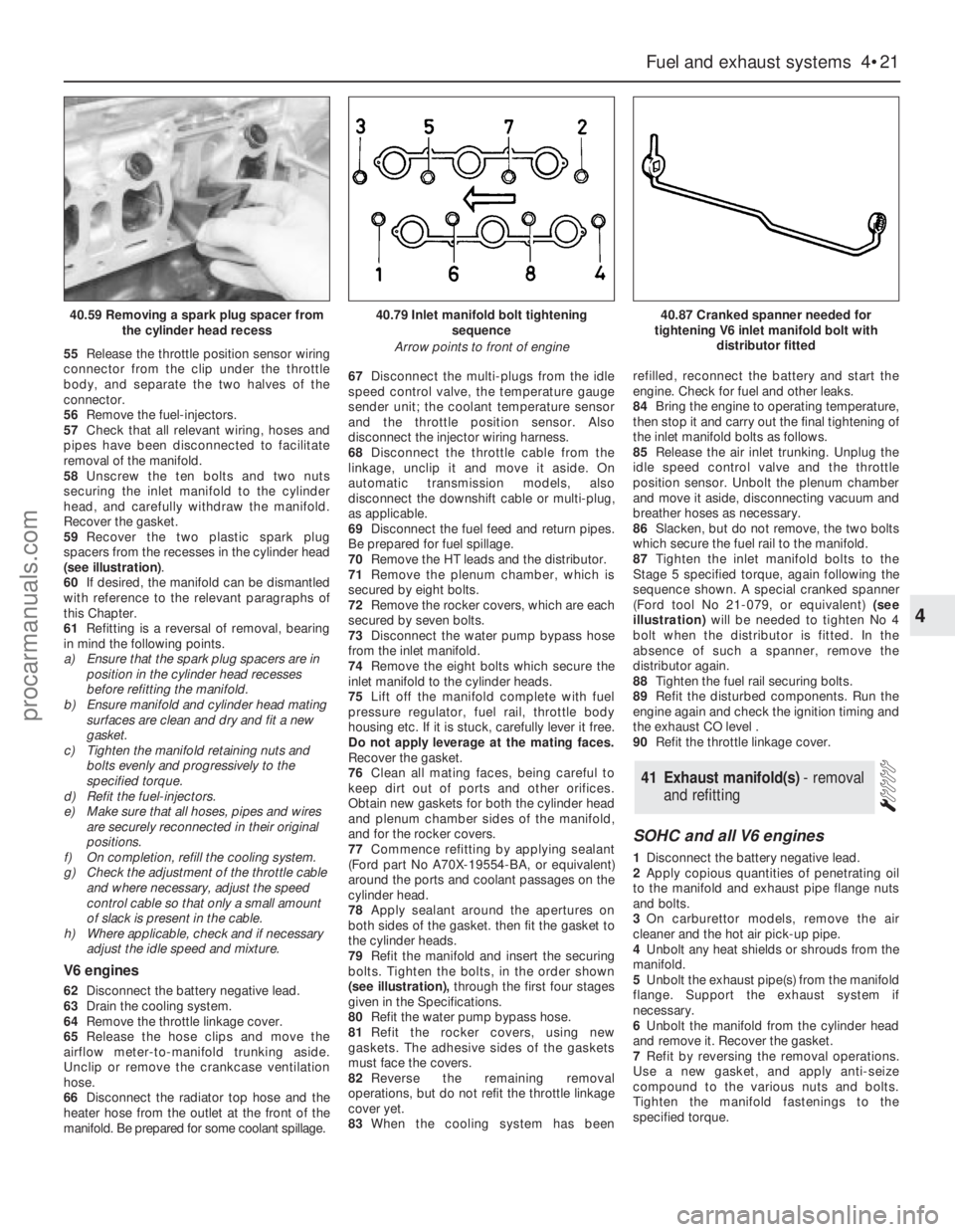

79Refit the manifold and insert the securing

bolts. Tighten the bolts, in the order shown

(see illustration),through the first four stages

given in the Specifications.

80Refit the water pump bypass hose.

81Refit the rocker covers, using new

gaskets. The adhesive sides of the gaskets

must face the covers.

82Reverse the remaining removal

operations, but do not refit the throttle linkage

cover yet.

83When the cooling system has beenrefilled, reconnect the battery and start the

engine. Check for fuel and other leaks.

84Bring the engine to operating temperature,

then stop it and carry out the final tightening of

the inlet manifold bolts as follows.

85Release the air inlet trunking. Unplug the

idle speed control valve and the throttle

position sensor. Unbolt the plenum chamber

and move it aside, disconnecting vacuum and

breather hoses as necessary.

86Slacken, but do not remove, the two bolts

which secure the fuel rail to the manifold.

87Tighten the inlet manifold bolts to the

Stage 5 specified torque, again following the

sequence shown. A special cranked spanner

(Ford tool No 21-079, or equivalent)(see

illustration)will be needed to tighten No 4

bolt when the distributor is fitted. In the

absence of such a spanner, remove the

distributor again.

88Tighten the fuel rail securing bolts.

89Refit the disturbed components. Run the

engine again and check the ignition timing and

the exhaust CO level .

90Refit the throttle linkage cover.

SOHC and all V6 engines

1Disconnect the battery negative lead.

2Apply copious quantities of penetrating oil

to the manifold and exhaust pipe flange nuts

and bolts.

3On carburettor models, remove the air

cleaner and the hot air pick-up pipe.

4Unbolt any heat shields or shrouds from the

manifold.

5Unbolt the exhaust pipe(s) from the manifold

flange. Support the exhaust system if

necessary.

6Unbolt the manifold from the cylinder head

and remove it. Recover the gasket.

7Refit by reversing the removal operations.

Use a new gasket, and apply anti-seize

compound to the various nuts and bolts.

Tighten the manifold fastenings to the

specified torque.

41Exhaust manifold(s) - removal

and refitting

Fuel and exhaust systems 4•21

4

40.59 Removing a spark plug spacer from

the cylinder head recess40.79 Inlet manifold bolt tightening

sequence

Arrow points to front of engine40.87 Cranked spanner needed for

tightening V6 inlet manifold bolt with

distributor fitted

procarmanuals.com