Page 83 to 93 FORD KUGA 2010 1.G Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2010, Model line: KUGA, Model: FORD KUGA 2010 1.GPages: 226, PDF Size: 8.07 MB

Page 146 of 226

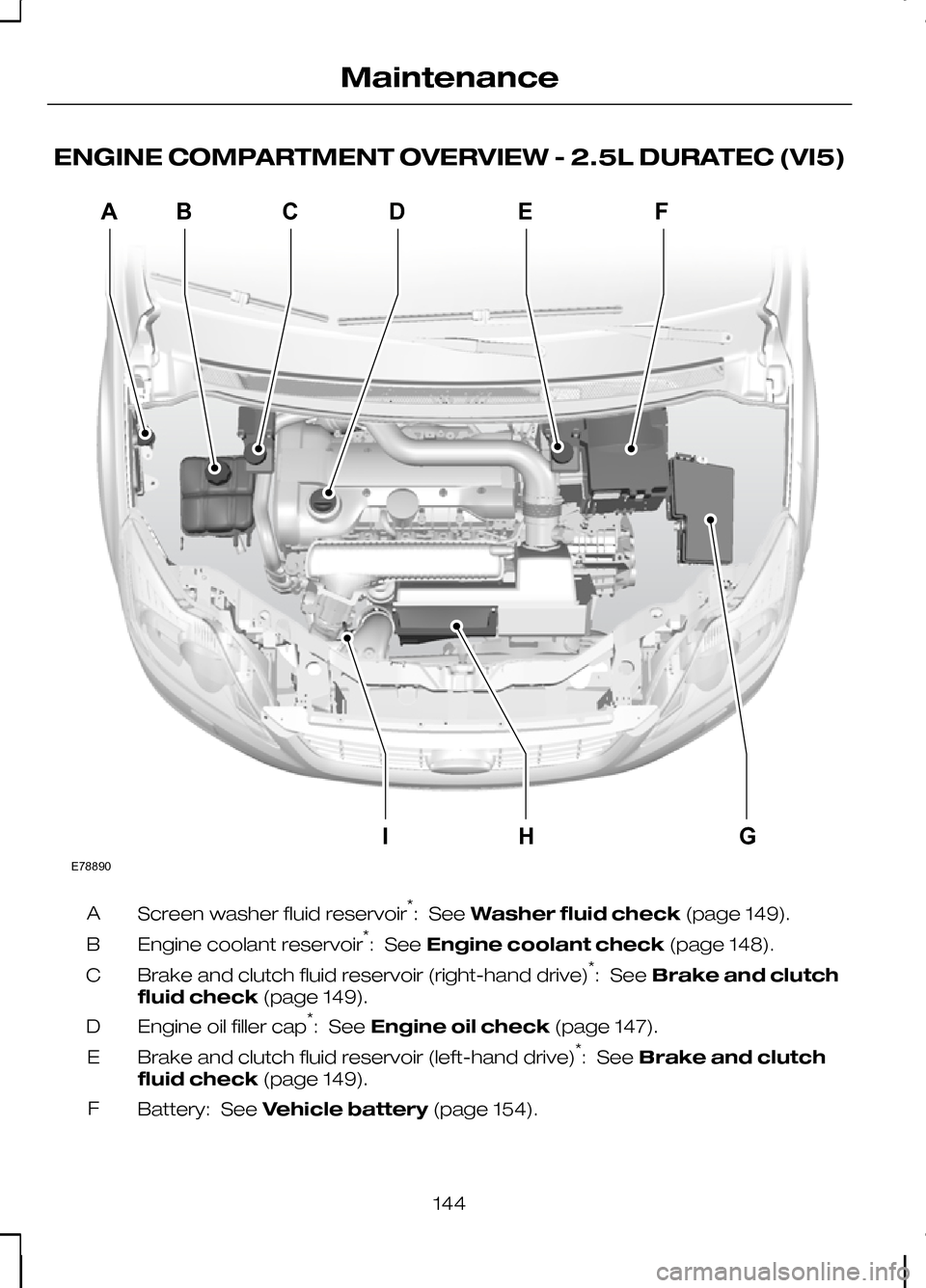

ENGINE COMPARTMENT OVERVIEW - 2.5L DURATEC (VI5)

Screen washer fluid reservoir

*

: See Washer fluid check (page 149).

A

Engine coolant reservoir *

: See Engine coolant check (page 148).

B

Brake and clutch fluid reservoir (right-hand drive) *

: See Brake and clutch

fluid check (page 149).

C

Engine oil filler cap *

: See Engine oil check (page 147).

D

Brake and clutch fluid reservoir (left-hand drive) *

: See Brake and clutch

fluid check (page 149).

E

Battery: See Vehicle battery (page 154).

F

144

MaintenanceE78890IFEDCBAHG

Page 147 of 226

Engine compartment fuse box: See

Fuses(page 134).

G

Air cleaner: No maintenance necessary.

H

Engine oil dipstick *

: See Engine oil check (page 147).

I

* For easy identification, filler caps and the engine oil dipstick are marked in colour.

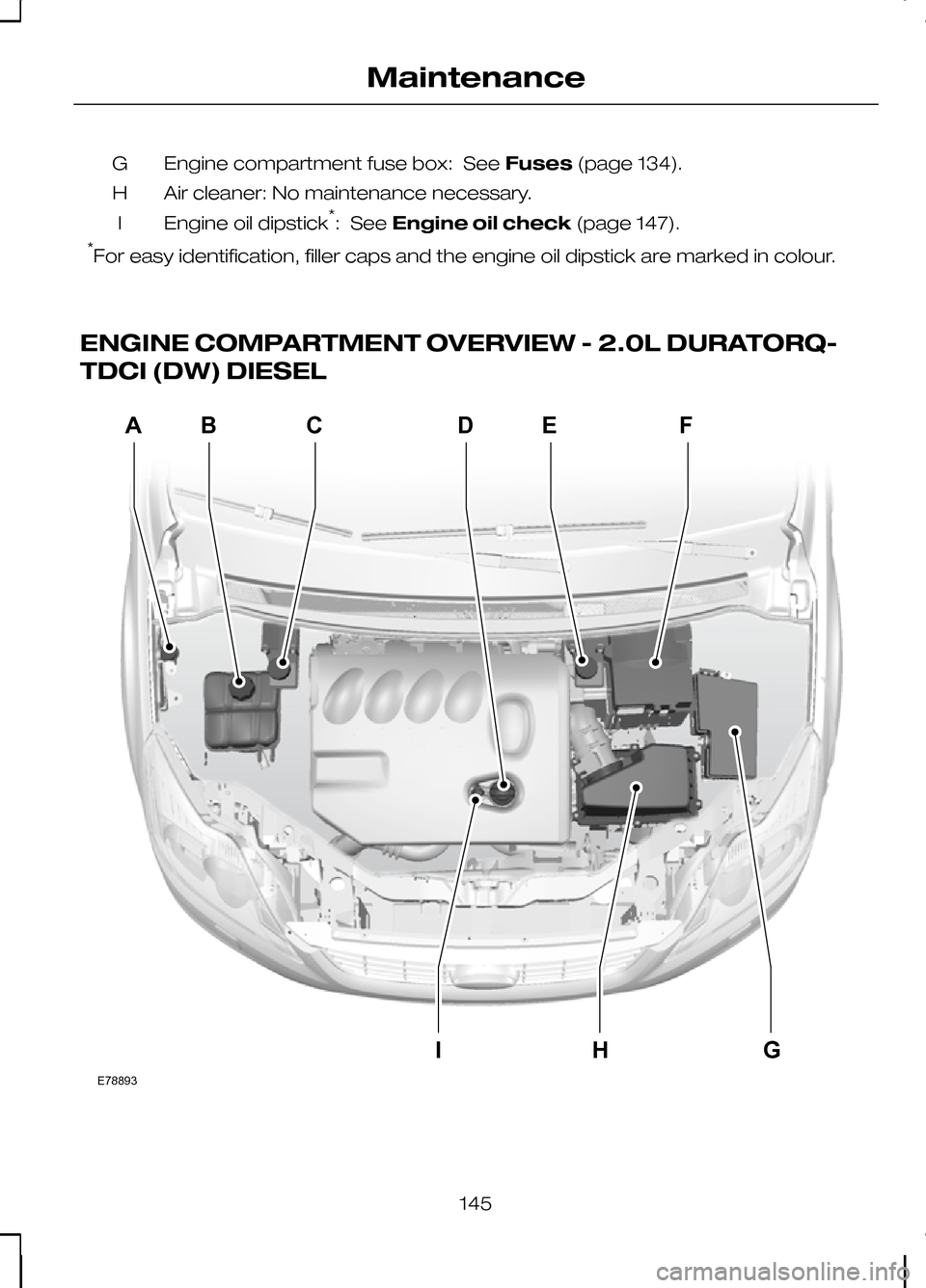

ENGINE COMPARTMENT OVERVIEW - 2.0L DURATORQ-

TDCI (DW) DIESEL 145

MaintenanceE78893IFEDCBAHG

Page 148 of 226

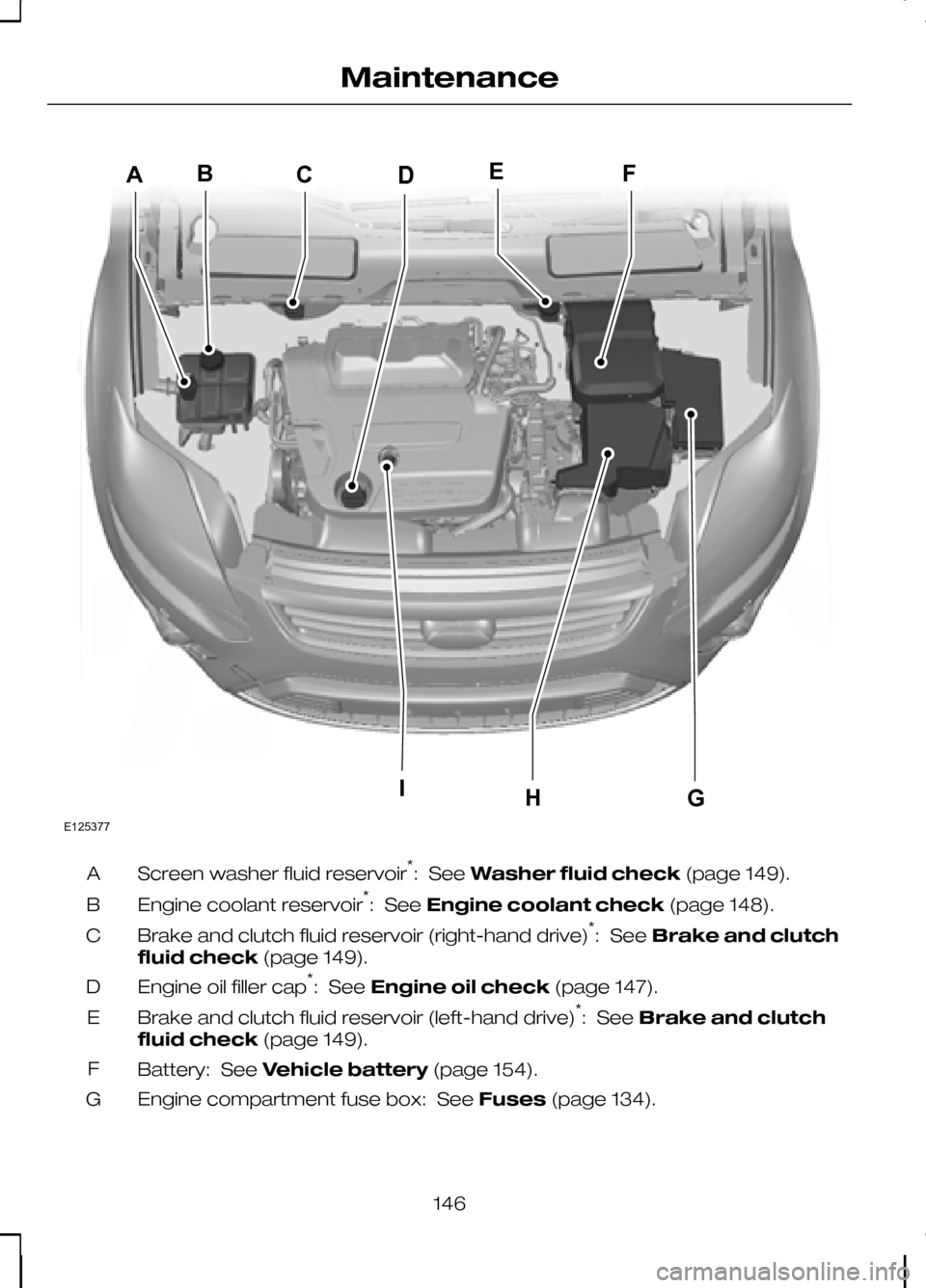

Screen washer fluid reservoir

*

: See Washer fluid check (page 149).

A

Engine coolant reservoir *

: See Engine coolant check (page 148).

B

Brake and clutch fluid reservoir (right-hand drive) *

: See Brake and clutch

fluid check (page 149).

C

Engine oil filler cap *

: See Engine oil check (page 147).

D

Brake and clutch fluid reservoir (left-hand drive) *

: See Brake and clutch

fluid check (page 149).

E

Battery: See Vehicle battery (page 154).

F

Engine compartment fuse box: See Fuses(page 134).

G

146

MaintenanceIFEDCBAHGE125377

Page 149 of 226

Air cleaner: No maintenance necessary.

H

Engine oil dipstick *

: See Engine oil check (page 147).

I

* For easy identification, filler caps and the engine oil dipstick are marked in colour.

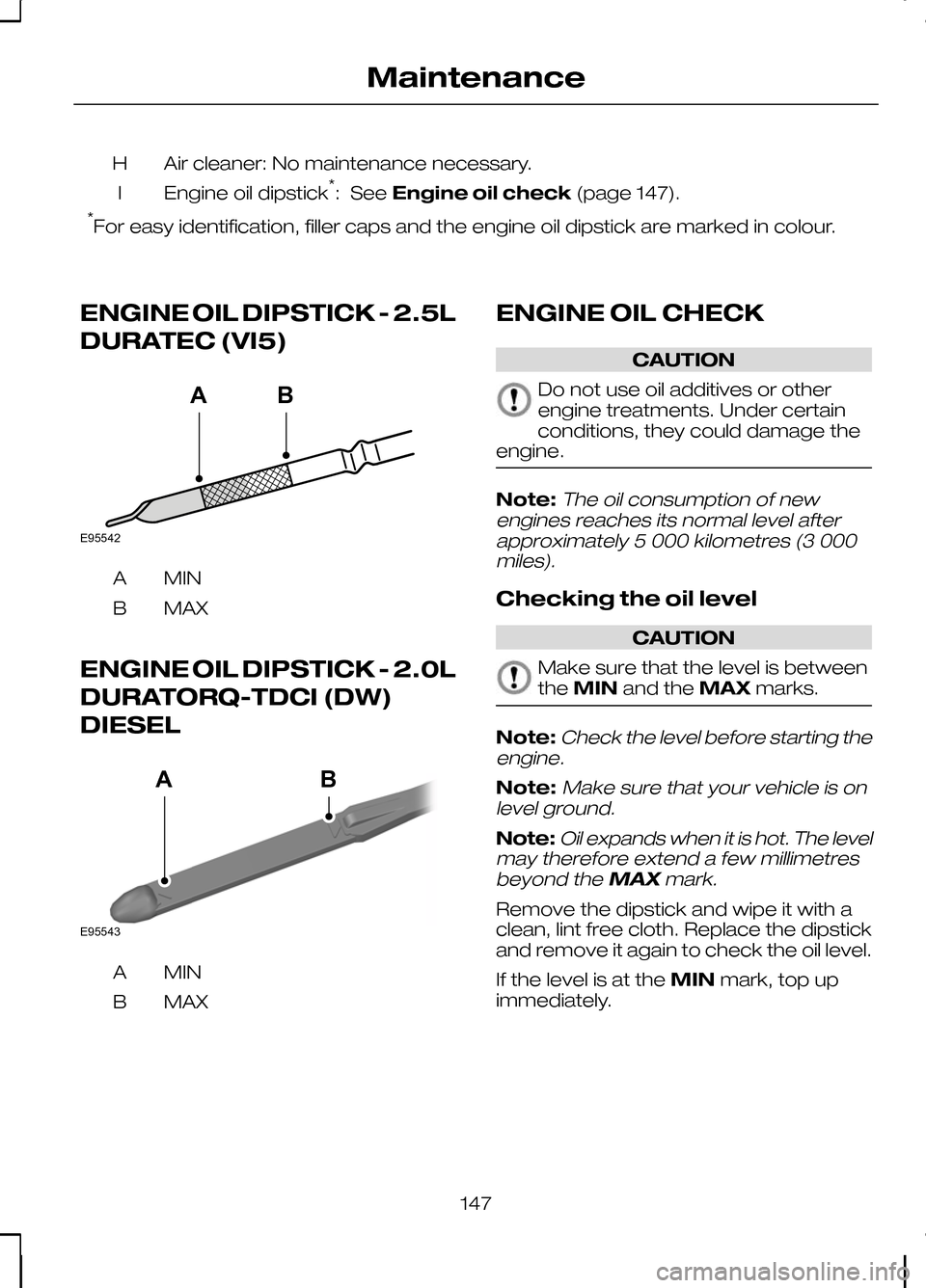

ENGINE OIL DIPSTICK - 2.5L

DURATEC (VI5) MINA

MAX

B

ENGINE OIL DIPSTICK - 2.0L

DURATORQ-TDCI (DW)

DIESEL MINA

MAX

B ENGINE OIL CHECK CAUTION

Do not use oil additives or other

engine treatments. Under certain

conditions, they could damage the

engine. Note:The oil consumption of new

engines reaches its normal level after approximately 5 000 kilometres (3 000miles).

Checking the oil level CAUTION

Make sure that the level is between

the

MIN and the MAXmarks. Note:

Check the level before starting the

engine.

Note:Make sure that your vehicle is on

level ground.

Note:Oil expands when it is hot. The level

may therefore extend a few millimetres

beyond the MAXmark.

Remove the dipstick and wipe it with a

clean, lint free cloth. Replace the dipstick

and remove it again to check the oil level.

If the level is at the MINmark, top up

immediately.

147

MaintenanceE95542BA E95543BA

Page 150 of 226

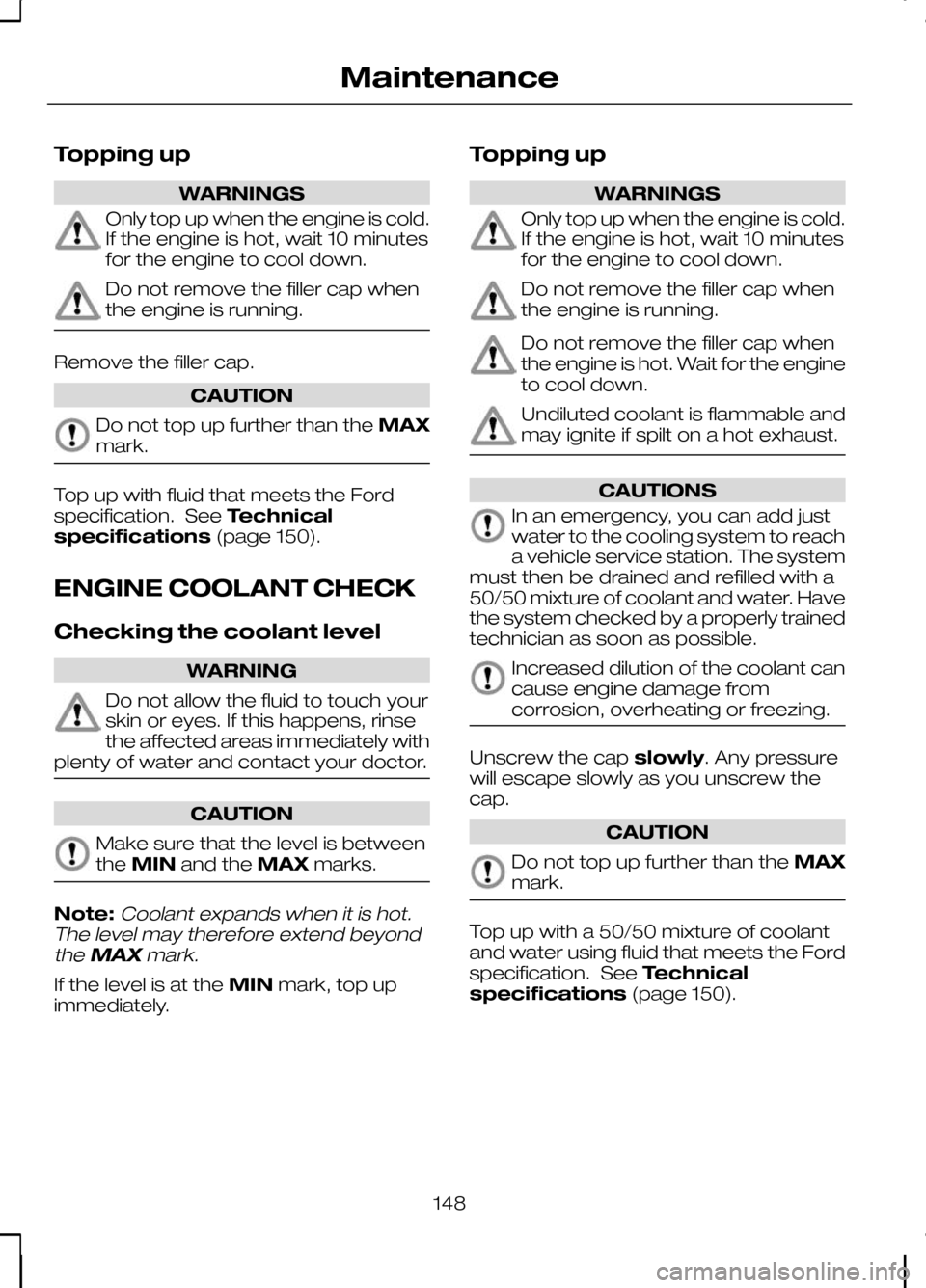

Topping up

WARNINGS

Only top up when the engine is cold.

If the engine is hot, wait 10 minutes

for the engine to cool down.

Do not remove the filler cap when

the engine is running.

Remove the filler cap.

CAUTION

Do not top up further than the

MAX

mark. Top up with fluid that meets the Ford

specification. See

Technical

specifications (page 150).

ENGINE COOLANT CHECK

Checking the coolant level WARNING

Do not allow the fluid to touch your

skin or eyes. If this happens, rinse

the affected areas immediately with

plenty of water and contact your doctor. CAUTION

Make sure that the level is between

the

MIN and the MAXmarks.Note:Coolant expands when it is hot.

The level may therefore extend beyond

the MAX mark.

If the level is at the MINmark, top up

immediately. Topping up WARNINGS

Only top up when the engine is cold.

If the engine is hot, wait 10 minutes

for the engine to cool down.

Do not remove the filler cap when

the engine is running.

Do not remove the filler cap when

the engine is hot. Wait for the engine

to cool down.

Undiluted coolant is flammable and

may ignite if spilt on a hot exhaust.

CAUTIONS

In an emergency, you can add just

water to the cooling system to reach

a vehicle service station. The system

must then be drained and refilled with a

50/50 mixture of coolant and water. Have

the system checked by a properly trained

technician as soon as possible. Increased dilution of the coolant can

cause engine damage from

corrosion, overheating or freezing.

Unscrew the cap

slowly. Any pressure

will escape slowly as you unscrew the

cap. CAUTION

Do not top up further than the

MAX

mark. Top up with a 50/50 mixture of coolant

and water using fluid that meets the Ford

specification. See

Technical

specifications (page 150).

148

Maintenance

Page 151 of 226

BRAKE AND CLUTCH FLUID

CHECK

WARNINGS

Do not allow the fluid to touch your

skin or eyes. If this happens, rinse

the affected areas immediately with

plenty of water and contact your doctor. If the level is at the

MINmark, have

the system checked by a properly

trained technician as soon as

possible. Note:The brake and the clutch systems

are supplied from the same reservoir.

Top up with fluid that meets the Ford

specification. See Technical

specifications (page 150).

POWER STEERING FLUID

CHECK WARNING

Do not allow the fluid to touch your

skin or eyes. If this happens, rinse

the affected areas immediately with

plenty of water and contact your doctor. CAUTION

Make sure that the level is between

the

MIN and the MAXmarks. If the level is at the

MINmark, top up

immediately.

Topping up

Remove the filler cap. CAUTION

Do not top up further than the

MAX

mark. Top up with fluid that meets the Ford

specification. See

Technical

specifications (page 150).

WASHER FLUID CHECK

The front and rear washer systems are

supplied from the same reservoir.

149

Maintenance

Page 162 of 226

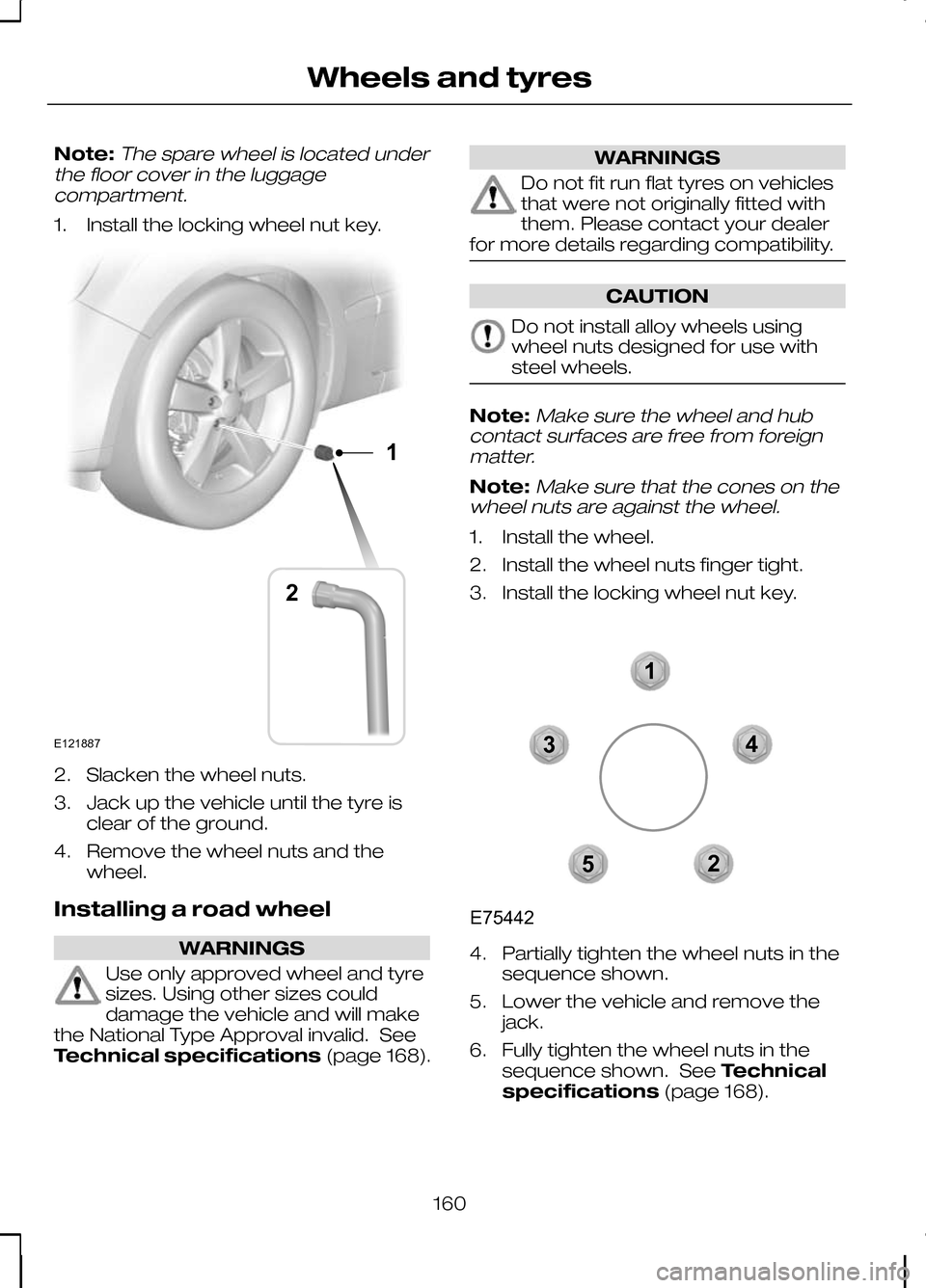

Note:The spare wheel is located under

the floor cover in the luggage compartment.

1. Install the locking wheel nut key. 2. Slacken the wheel nuts.

3. Jack up the vehicle until the tyre is

clear of the ground.

4. Remove the wheel nuts and the wheel.

Installing a road wheel WARNINGS

Use only approved wheel and tyre

sizes. Using other sizes could

damage the vehicle and will make

the National Type Approval invalid. See

Technical specifications (page 168). WARNINGS

Do not fit run flat tyres on vehicles

that were not originally fitted with

them. Please contact your dealer

for more details regarding compatibility. CAUTION

Do not install alloy wheels using

wheel nuts designed for use with

steel wheels.

Note:

Make sure the wheel and hub

contact surfaces are free from foreign matter.

Note:Make sure that the cones on the

wheel nuts are against the wheel.

1. Install the wheel.

2. Install the wheel nuts finger tight.

3. Install the locking wheel nut key. 4. Partially tighten the wheel nuts in the

sequence shown.

5. Lower the vehicle and remove the jack.

6. Fully tighten the wheel nuts in the sequence shown. See Technical

specifications (page 168).

160

Wheels and tyresE12188712 12345E75442

Page 163 of 226

7. Install the wheel trim using the ball of

your hand. WARNING

Have the wheel nuts checked for

tightness and the tyre pressure

checked as soon as possible.

Note:If the spare wheel is different in size

or construction to the road wheels, have this replaced as soon as possible.

TYRE REPAIR KIT

Your vehicle is not equipped with a spare

tyre, but does include an emergency tyre

repair kit that can be used to repair one

flat tyre.

The tyre repair kit is located in the

underfloor storage compartment. See

Storage compartments (page 98).

General information WARNINGS

Depending on the type and extent

of tyre damage, some tyres can

only be partially sealed or not sealed

at all. Loss of tyre pressure can affect

vehicle handling, leading to loss of vehicle

control. Do not use the tyre repair kit if the

tyre has already been damaged as

a result of being driven under

inflated. Do not use the tyre repair kit on run

flat tyres.

Do not try to seal damage other

than that located within the visible

tread of the tyre.

Do not try to seal damage to the

tyre’s sidewall. The tyre repair kit seals most tyre

punctures [with a diameter of up to six

millimetres (1/4 inch)] to temporarily

restore mobility.

Observe the following rules when using

the kit:

•

Drive with caution and avoid

making sudden steering or

driving manoeuvres, especially if

the vehicle is heavily loaded or you are

towing a trailer.

• The kit will provide you with an

emergency temporary repair, enabling

you to continue your journey to the

next vehicle or tyre dealer, or to drive

a maximum distance of

200 kilometres (125 miles).

• Do not exceed a

maximum speed

of 80 km/h (50 mph).

• Keep the kit out of the reach of

children.

• Only use the kit when the ambient

temperature is between –30°C (-22°F)

and +70°C (+158°F).

Using the tyre repair kit WARNINGS

Compressed air can act as an

explosive or propellant.

Never leave the tyre repair kit

unattended while in use.

CAUTION

Do not keep the compressor

operating for more than 10 minutes.

Note:

Use the tyre repair kit only for the

vehicle with which it was supplied.

161

Wheels and tyres

Page 165 of 226

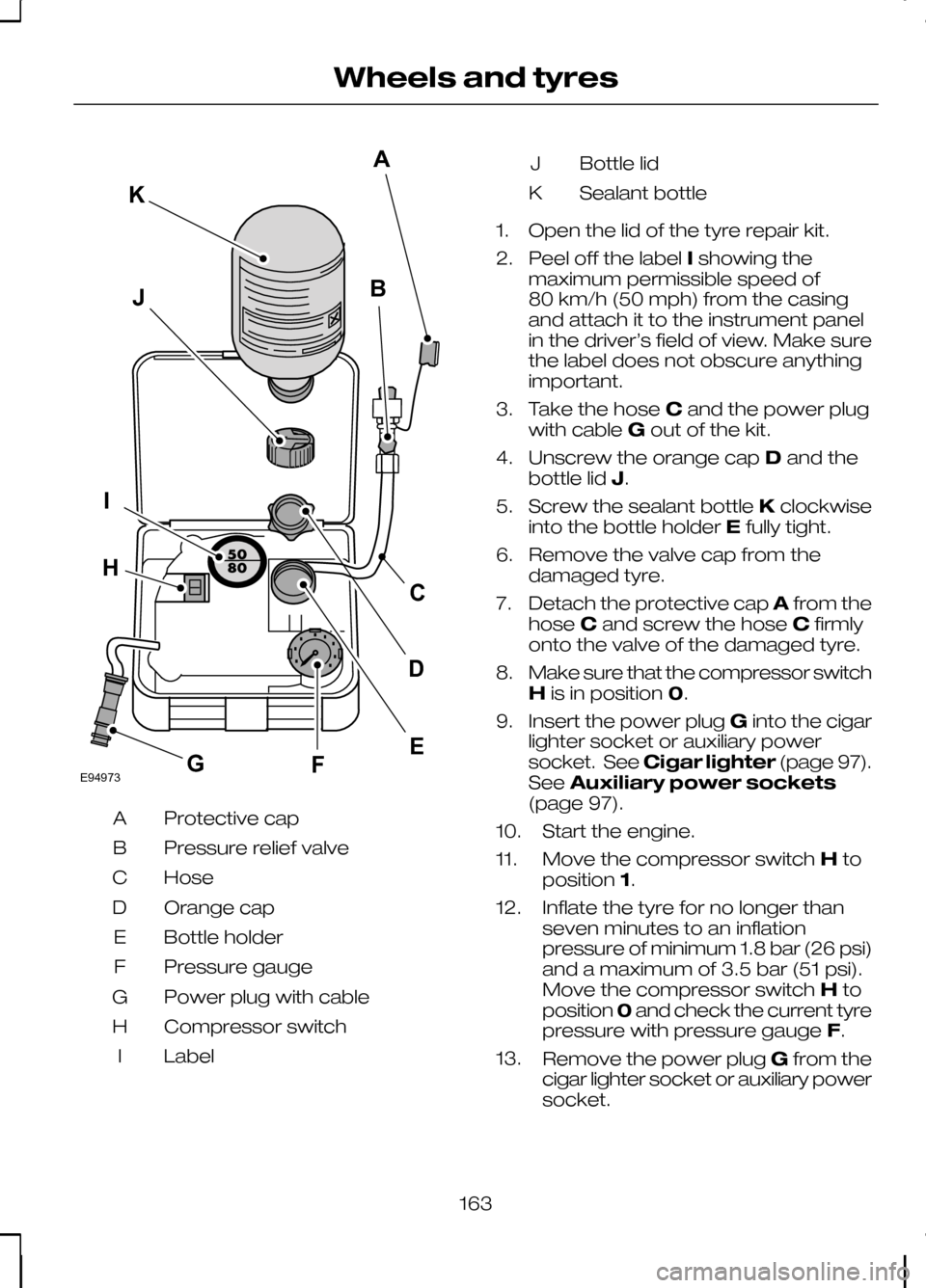

Protective cap

A

Pressure relief valve

B

Hose

C

Orange cap

D

Bottle holder

E

Pressure gauge

F

Power plug with cable

G

Compressor switch

H

Label

I Bottle lid

J

Sealant bottle

K

1. Open the lid of the tyre repair kit.

2. Peel off the label Ishowing the

maximum permissible speed of

80 km/h (50 mph) from the casing

and attach it to the instrument panel

in the driver’s field of view. Make sure

the label does not obscure anything

important.

3. Take the hose Cand the power plug

with cable Gout of the kit.

4. Unscrew the orange cap Dand the

bottle lid J.

5. Screw the sealant bottle Kclockwise

into the bottle holder Efully tight.

6. Remove the valve cap from the damaged tyre.

7. Detach the protective cap Afrom the

hose Cand screw the hose Cfirmly

onto the valve of the damaged tyre.

8. Make sure that the compressor switch

His in position 0.

9. Insert the power plug Ginto the cigar

lighter socket or auxiliary power

socket. See Cigar lighter (page 97).

See Auxiliary power sockets

(page 97).

10. Start the engine.

11. Move the compressor switch Hto

position 1.

12. Inflate the tyre for no longer than seven minutes to an inflation

pressure of minimum 1.8 bar (26 psi)

and a maximum of 3.5 bar (51 psi).

Move the compressor switch Hto

position 0and check the current tyre

pressure with pressure gauge F.

13. Remove the power plug Gfrom the

cigar lighter socket or auxiliary power

socket.

163

Wheels and tyresE94973BJIFECKAGHD

Page 166 of 226

14.

Quickly unscrew the hose Cfrom

the tyre valve and replace the

protective cap A. Fasten the valve

cap again.

15. Leave the sealant bottle Kin the

bottle holder E.

16. Make sure the kit, the bottle lid and the orange cap are stored safely, but

still easily accessible in the vehicle.

The kit will be required again when

you check the tyre pressure.

17. Immediately drive approximately three kilometres (two miles) so that

the sealant can seal the damaged

area.

Note:When pumping in the sealant

through the tyre valve, the pressure may rise up to 6 bar (87 psi) but will drop againafter about 30 seconds. WARNING

If you experience heavy vibrations,

unsteady steering behaviour or

noises while driving, reduce your

speed and drive with caution to a place

where it is safe for you to stop the vehicle.

Recheck the tyre and its pressure. If the

tyre pressure is less than 1.3 bar (19 psi)

or if there are any cracks, bumps or similar

damage visible, do not continue driving

with this tyre. Checking the tyre pressure

1. Stop the vehicle after driving

approximately three kilometres

(two miles). Check, and where

necessary, adjust the pressure of the

damaged tyre.

2. Attach the kit and read the tyre pressure from the pressure gauge F.

3. If the pressure of the sealant-filled tyre

is 1.3 bar (19 psi) or more, adjust it to

the specified pressure. See

Technical specifications (page

168). 4. Follow the inflation procedure once

again to top up the tyre.

5. Check the tyre pressure again from the pressure gauge F. If the tyre

pressure is too high, deflate the tyre

to the specified pressure using the

pressure relief valve B.

6. Once you have inflated the tyre to its correct tyre pressure, move the

compressor switch Hto position 0,

remove the power plug Gfrom the

socket, unscrew the hose C, fasten

the valve cap and replace the

protective cap A.

7. Leave the sealant bottle Kin the bottle

holder Eand store the kit away safely

in its original location.

8. Drive to the nearest tyre specialist to get the damaged tyre replaced.

Before the tyre is removed from the

rim, inform your tyre dealer that the

tyre contains sealant. Renew the kit

as soon as possible after it has been

used once.

Note:

Remember that emergency

roadside tyre repair kits only provide temporary mobility. Regulationsconcerning tyre repair after usage of tyrerepair kit may differ from country tocountry. You should consult a tyrespecialist for advice. WARNING

Before driving, make sure the tyre

is adjusted to the recommended

inflation pressure. See

Technical

specifications (page 168). Monitor the

tyre pressure until the sealed tyre is

replaced. Empty sealant bottles can be disposed

of together with normal household waste.

Return remains of sealant to your dealer

or dispose of it in compliance with local

waste disposal regulations.

164

Wheels and tyres