start FORD KUGA 2011 1.G Owners Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2011, Model line: KUGA, Model: FORD KUGA 2011 1.GPages: 2057

Page 1879 of 2057

transaxle output shaft. The frequency of the

square-wave signal increases with the speed of

the transmission output shaft.

The OSS sensor picks up the speed at the gear of

the parking lock.

The TCM uses the information from the OSS

sensor for the following parameters:

• Calculation of the degree of torque reductionthat needs to be requested by the PCM during

shifting.

• Calculation of the shift points.

• Calculation of the engaging and disengaging point for the TCC (lock-up function).

• Calculation of the current gear ratios by comparison of the TSS sensor signal.

Consequences of signal failure

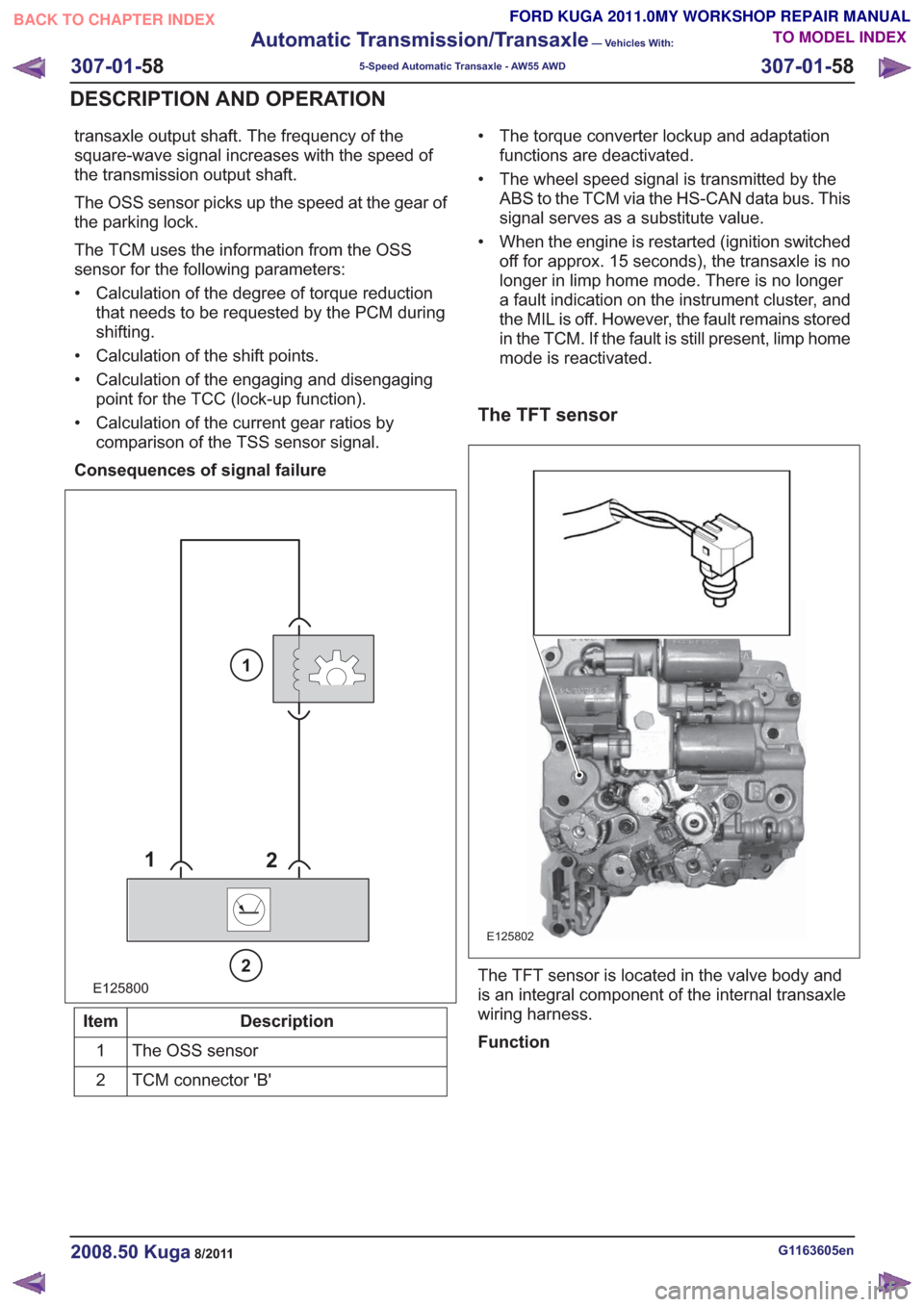

E125800

1 2

2

1

Description

Item

The OSS sensor

1

TCM connector 'B'

2 • The torque converter lockup and adaptation

functions are deactivated.

• The wheel speed signal is transmitted by the ABS to the TCM via the HS-CAN data bus. This

signal serves as a substitute value.

• When the engine is restarted (ignition switched off for approx. 15 seconds), the transaxle is no

longer in limp home mode. There is no longer

a fault indication on the instrument cluster, and

the MIL is off. However, the fault remains stored

in the TCM. If the fault is still present, limp home

mode is reactivated.

The TFT sensor

E125802

The TFT sensor is located in the valve body and

is an integral component of the internal transaxle

wiring harness.

Function

G1163605en2008.50 Kuga8/2011

307-01- 58

Automatic Transmission/Transaxle

— Vehicles With:

5-Speed Automatic Transaxle - AW55 AWD

307-01- 58

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1880 of 2057

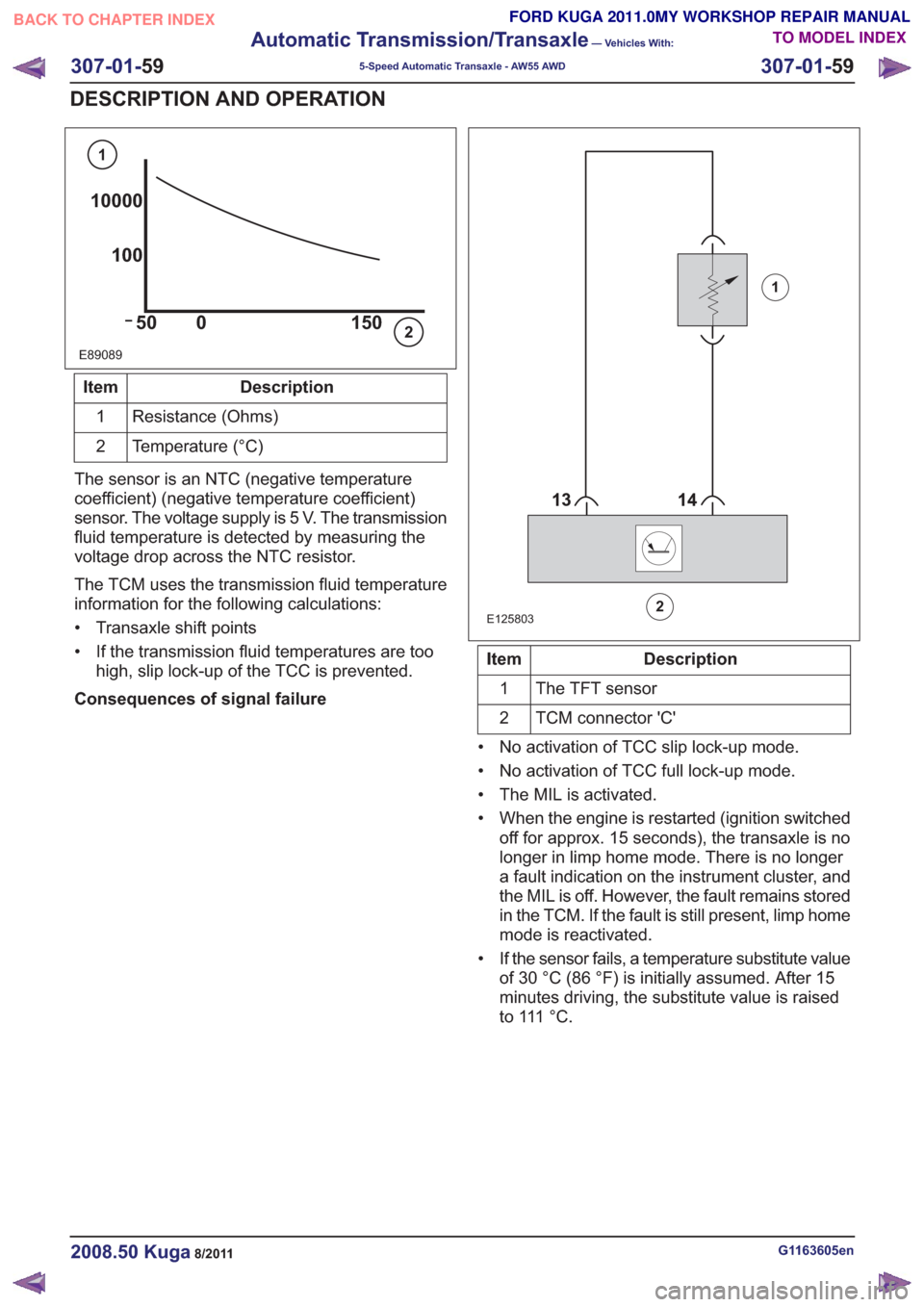

E89089

10000100

50 0 150

1

2

Description

Item

Resistance (Ohms)

1

Temperature (°C)

2

The sensor is an NTC (negative temperature

coefficient) (negative temperature coefficient)

sensor. The voltage supply is 5 V. The transmission

fluid temperature is detected by measuring the

voltage drop across the NTC resistor.

The TCM uses the transmission fluid temperature

information for the following calculations:

• Transaxle shift points

• If the transmission fluid temperatures are too high, slip lock-up of the TCC is prevented.

Consequences of signal failure

88

E125803

1

2

Description

Item

The TFT sensor

1

TCM connector 'C'

2

• No activation of TCC slip lock-up mode.

• No activation of TCC full lock-up mode.

• The MIL is activated.

• When the engine is restarted (ignition switched off for approx. 15 seconds), the transaxle is no

longer in limp home mode. There is no longer

a fault indication on the instrument cluster, and

the MIL is off. However, the fault remains stored

in the TCM. If the fault is still present, limp home

mode is reactivated.

• If the sensor fails, a temperature substitute value of 30 °C (86 °F) is initially assumed. After 15

minutes driving, the substitute value is raised

t o 111 ° C .

G1163605en2008.50 Kuga8/2011

307-01- 59

Automatic Transmission/Transaxle

— Vehicles With:

5-Speed Automatic Transaxle - AW55 AWD

307-01- 59

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1881 of 2057

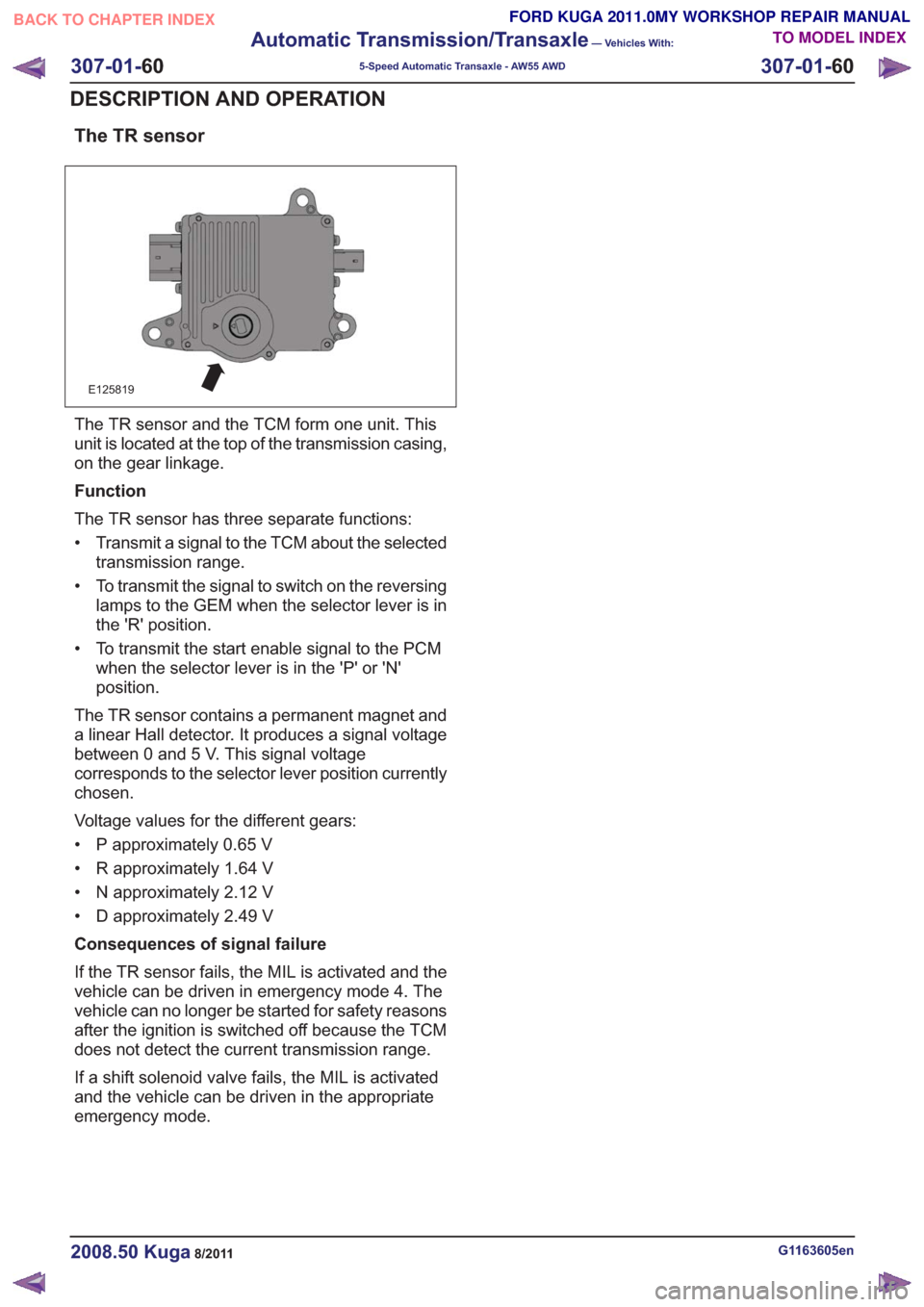

The TR sensor

E125819

The TR sensor and the TCM form one unit. This

unit is located at the top of the transmission casing,

on the gear linkage.

Function

The TR sensor has three separate functions:

• Transmit a signal to the TCM about the selectedtransmission range.

• To transmit the signal to switch on the reversing lamps to the GEM when the selector lever is in

the 'R' position.

• To transmit the start enable signal to the PCM when the selector lever is in the 'P' or 'N'

position.

The TR sensor contains a permanent magnet and

a linear Hall detector. It produces a signal voltage

between 0 and 5 V. This signal voltage

corresponds to the selector lever position currently

chosen.

Voltage values for the different gears:

• P approximately 0.65 V

• R approximately 1.64 V

• N approximately 2.12 V

• D approximately 2.49 V

Consequences of signal failure

If the TR sensor fails, the MIL is activated and the

vehicle can be driven in emergency mode 4. The

vehicle can no longer be started for safety reasons

after the ignition is switched off because the TCM

does not detect the current transmission range.

If a shift solenoid valve fails, the MIL is activated

and the vehicle can be driven in the appropriate

emergency mode.

G1163605en2008.50 Kuga8/2011

307-01- 60

Automatic Transmission/Transaxle

— Vehicles With:

5-Speed Automatic Transaxle - AW55 AWD

307-01- 60

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1882 of 2057

Transmission Fluid Level Check

General EquipmentFord Diagnostic Equipment

Materials

Specification

Name

WSS-M2C924-A / 4U7J-

M2C924-AA

Automatic Transmission

Oil E-AW

Inspection

1.

Refer to: Health and Safety Precautions (100-00

General Information, Description and

Operation).

2. Connect the Ford diagnostic equipment.

General Equipment: Ford Diagnostic Equipment

3. Make sure that the transmission is not in

emergency operation mode.

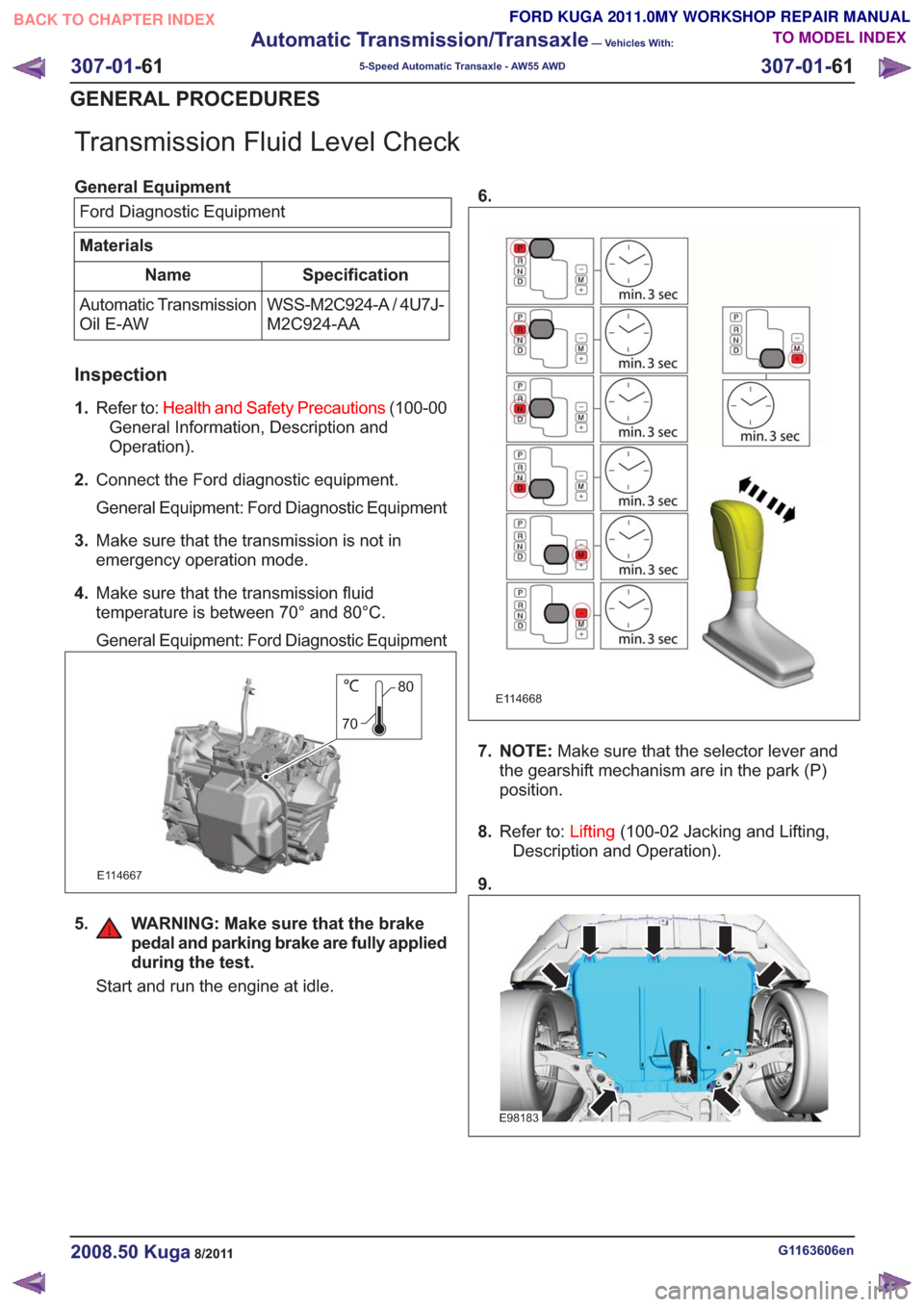

4. Make sure that the transmission fluid

temperature is between 70° and 80°C.

General Equipment: Ford Diagnostic Equipment

80

70

E114667

5. WARNING: Make sure that the brake pedal and parking brake are fully applied

during the test.

Start and run the engine at idle. 6.

E114668

7. NOTE:

Make sure that the selector lever and

the gearshift mechanism are in the park (P)

position.

8. Refer to: Lifting(100-02 Jacking and Lifting,

Description and Operation).

9.

E98183

G1163606en2008.50 Kuga8/2011

307-01- 61

Automatic Transmission/Transaxle

— Vehicles With:

5-Speed Automatic Transaxle - AW55 AWD

307-01- 61

GENERAL PROCEDURES

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1885 of 2057

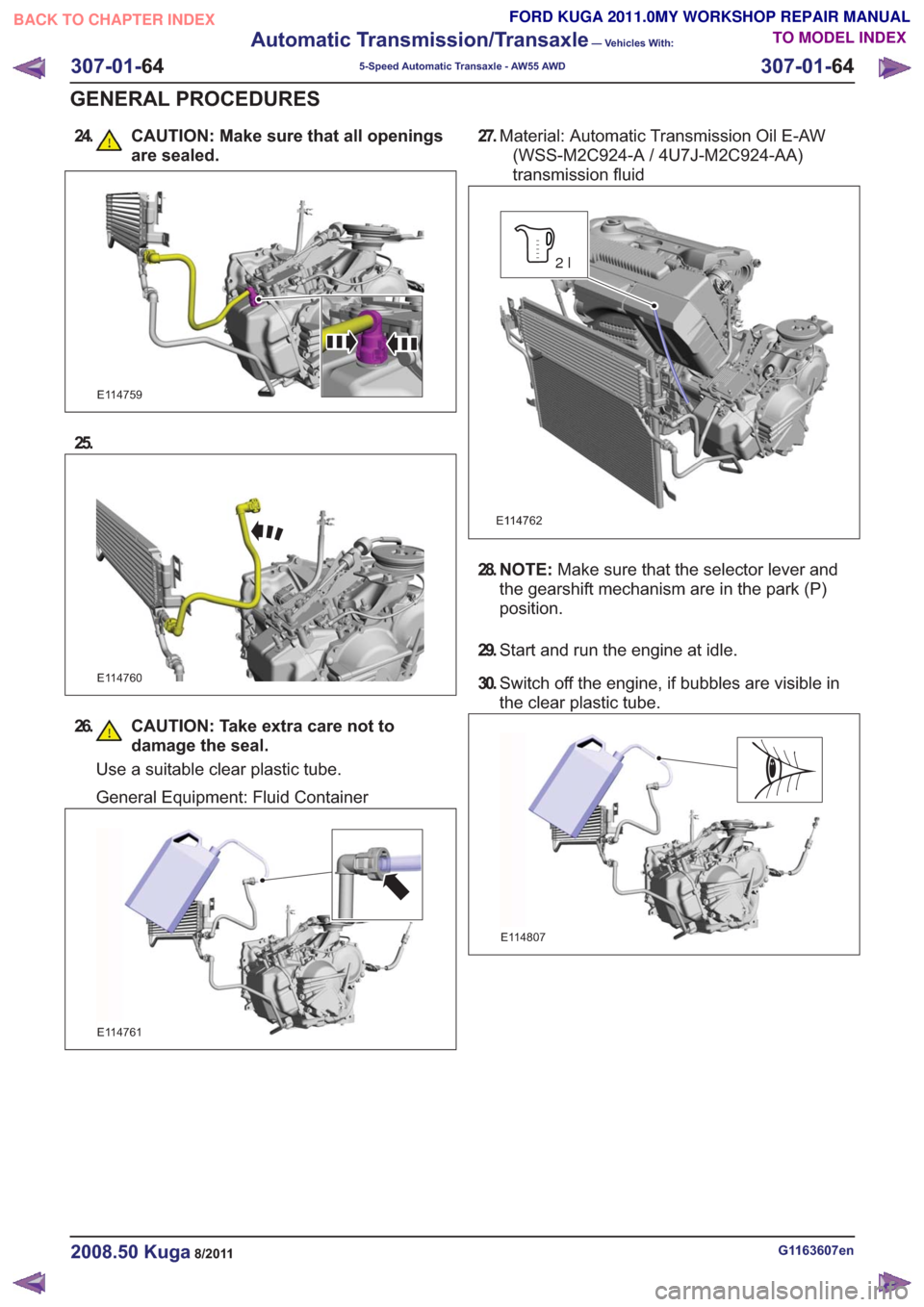

24. CAUTION: Make sure that all openingsare sealed.

E114759

25.

E114760

26. CAUTION: Take extra care not todamage the seal.

Use a suitable clear plastic tube.

General Equipment: Fluid Container

E114761

27.Material: Automatic Transmission Oil E-AW

(WSS-M2C924-A / 4U7J-M2C924-AA)

transmission fluid

E114762

2l

28. N O T E : Make sure that the selector lever and

the gearshift mechanism are in the park (P)

position.

29. Start and run the engine at idle.

30. Switch off the engine, if bubbles are visible in

the clear plastic tube.

E114807

G1163607en2008.50 Kuga8/2011

307-01- 64

Automatic Transmission/Transaxle

— Vehicles With:

5-Speed Automatic Transaxle - AW55 AWD

307-01- 64

GENERAL PROCEDURES

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1886 of 2057

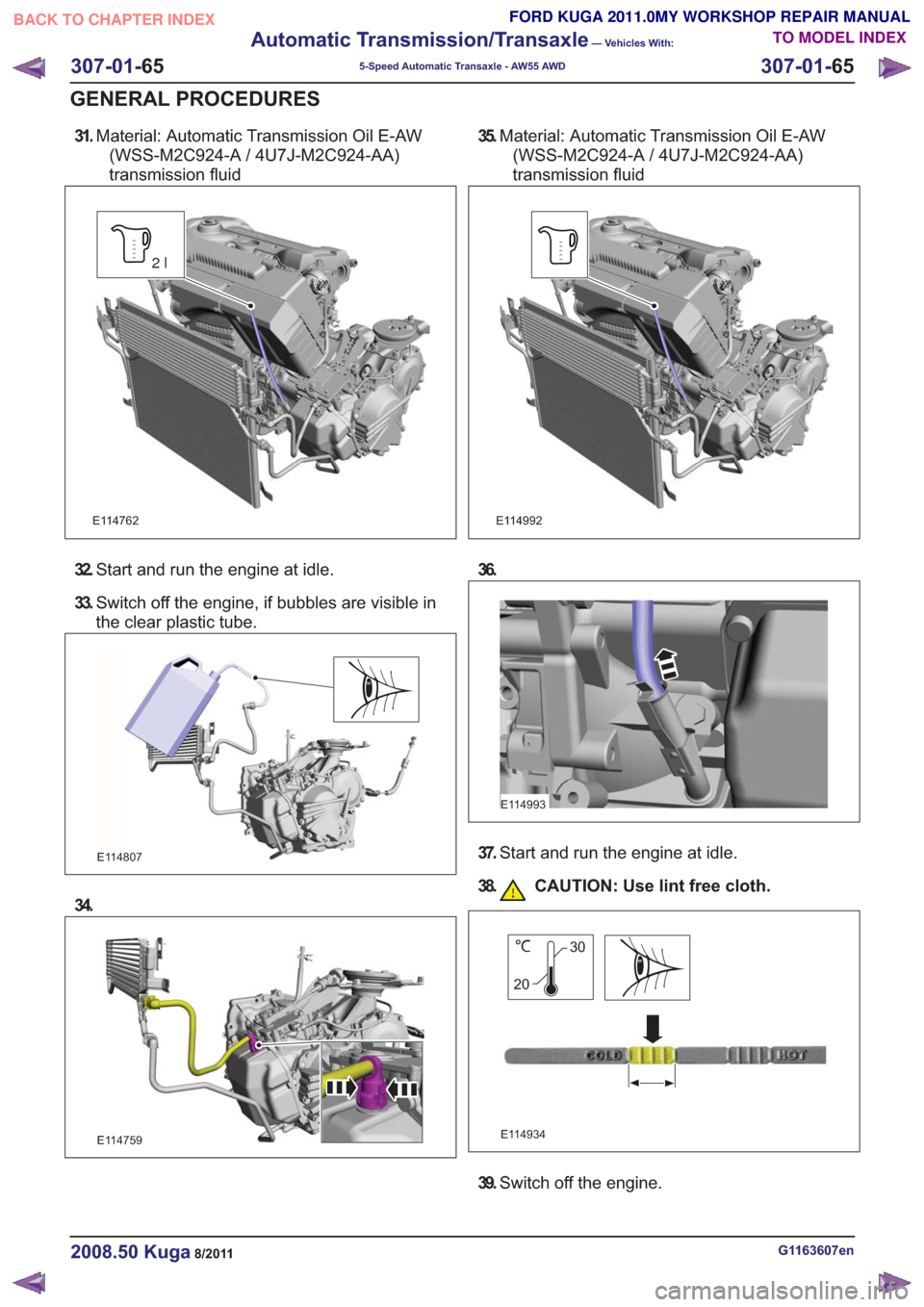

31.Material: Automatic Transmission Oil E-AW

(WSS-M2C924-A / 4U7J-M2C924-AA)

transmission fluid

E114762

2l

32. Start and run the engine at idle.

33. Switch off the engine, if bubbles are visible in

the clear plastic tube.

E114807

34.

E114759

35.Material: Automatic Transmission Oil E-AW

(WSS-M2C924-A / 4U7J-M2C924-AA)

transmission fluid

E114992

36.

E114993

37. Start and run the engine at idle.

38. CAUTION: Use lint free cloth.

E114934

30

20

39. Switch off the engine.

G1163607en2008.50 Kuga8/2011

307-01- 65

Automatic Transmission/Transaxle

— Vehicles With:

5-Speed Automatic Transaxle - AW55 AWD

307-01- 65

GENERAL PROCEDURES

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1934 of 2057

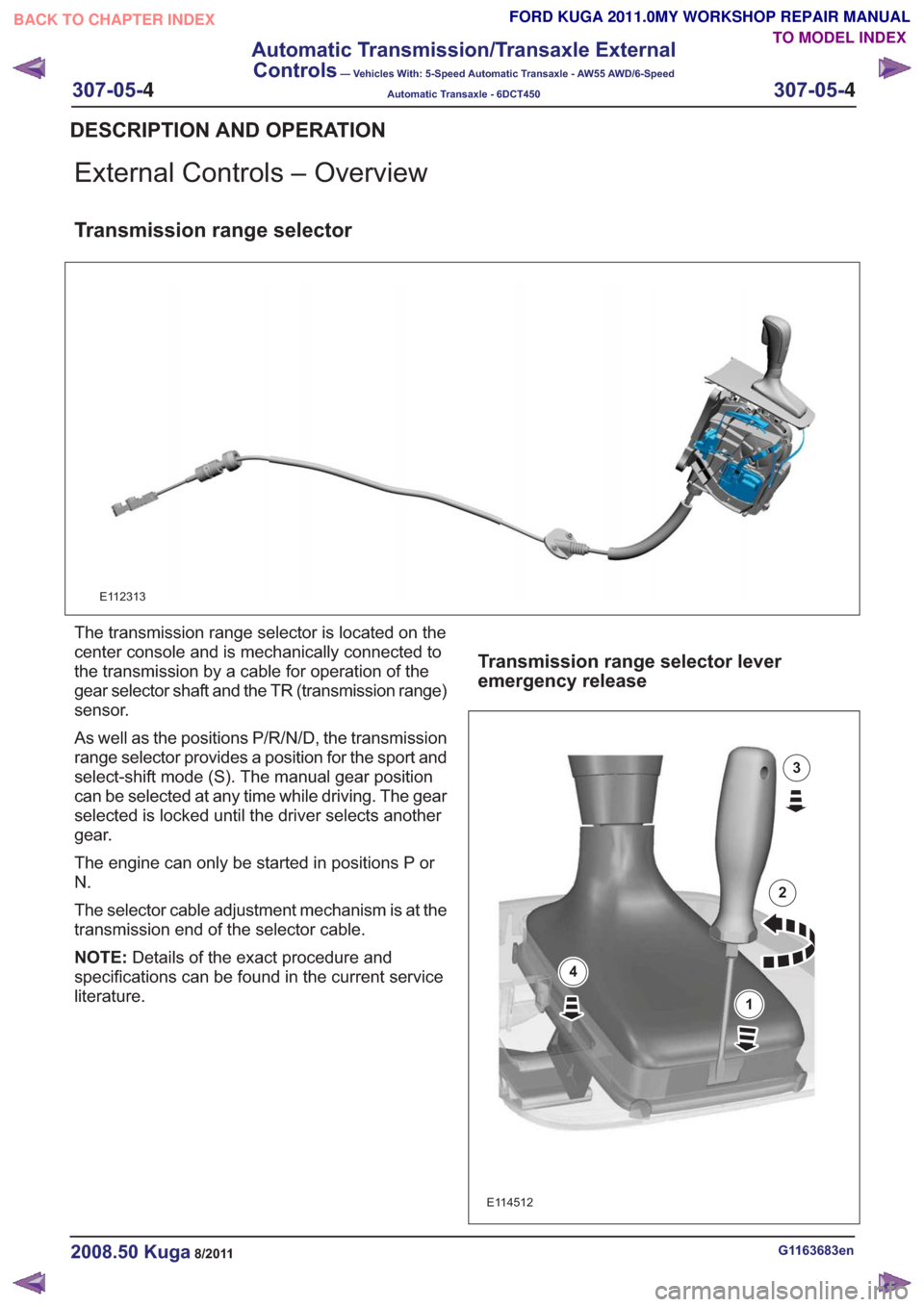

External Controls – Overview

Transmission range selector

E112313

The transmission range selector is located on the

center console and is mechanically connected to

the transmission by a cable for operation of the

gear selector shaft and the TR (transmission range)

sensor.

As well as the positions P/R/N/D, the transmission

range selector provides a position for the sport and

select-shift mode (S). The manual gear position

can be selected at any time while driving. The gear

selected is locked until the driver selects another

gear.

The engine can only be started in positions P or

N.

The selector cable adjustment mechanism is at the

transmission end of the selector cable.

NOTE:Details of the exact procedure and

specifications can be found in the current service

literature.

Transmission range selector lever

emergency release

E114512

1

2

3

4

G1163683en2008.50 Kuga8/2011

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

307-05-

4

Automatic Transmission/Transaxle External

Controls

— Vehicles With: 5-Speed Automatic Transaxle - AW55 AWD/6-Speed

Automatic Transaxle - 6DCT450

307-05-4

.

Page 1936 of 2057

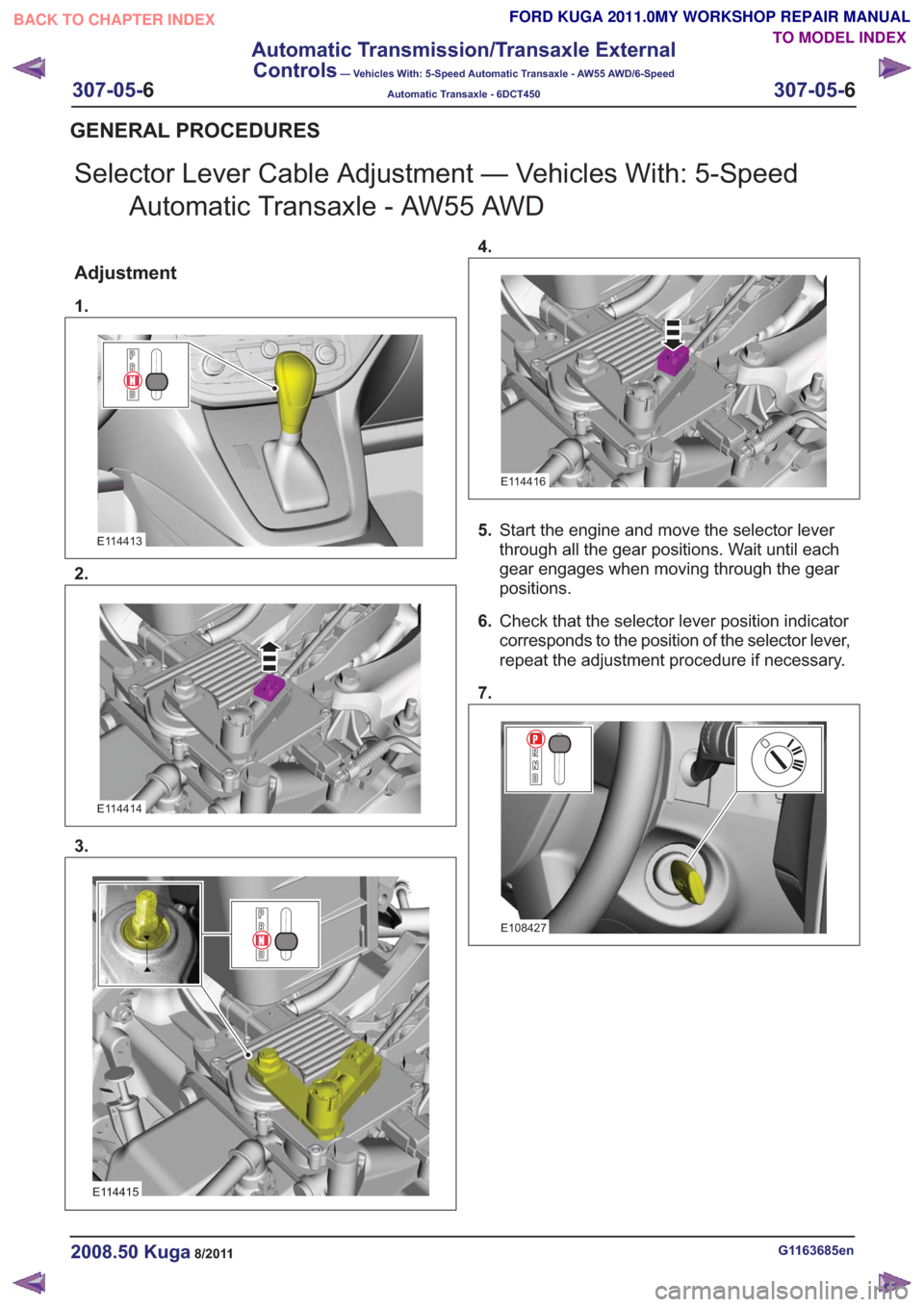

Selector Lever Cable Adjustment — Vehicles With: 5-SpeedAutomatic Transaxle - AW55 AWD

Adjustment

1.

E114413

2.

E114414

3.

E114415

4.

E114416

5.Start the engine and move the selector lever

through all the gear positions. Wait until each

gear engages when moving through the gear

positions.

6. Check that the selector lever position indicator

corresponds to the position of the selector lever,

repeat the adjustment procedure if necessary.

7.

E108427

G1163685en2008.50 Kuga8/2011

GENERAL PROCEDURES

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

307-05-

6

Automatic Transmission/Transaxle External

Controls

— Vehicles With: 5-Speed Automatic Transaxle - AW55 AWD/6-Speed

Automatic Transaxle - 6DCT450

307-05-6

.

Page 1950 of 2057

Transfer Case – System Operation and Component Description

System Operation

1

2

3

E103728

Description

Item

Hollow shaft

1

Output shaft

2

Output drive flange

3

NOTE: From the start of series production, the

transfer box will be subject to a "Black Box Phase"

and will therefore not be repaired.

To realise the all-wheel drive, a transfer box has

been flange-mounted to the manual transaxle. The

transfer box is designed as an angular gear to

transfer the torque from the transaxle to the rear

axle. The hollow shaft of the transfer box is inserted

in a tooth on the gear case. From the hollow shaft,

torque is transferred to the driveshaft through the

output shaft/output flange via crown gear and

differential pinion gear.

G1164987en2008.50 Kuga8/2011

307-07- 8

Transfer Case

— Vehicles With: 5-Speed Automatic Transaxle - AW55

AWD/6-Speed Automatic Transaxle - 6DCT450

307-07- 8

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1970 of 2057

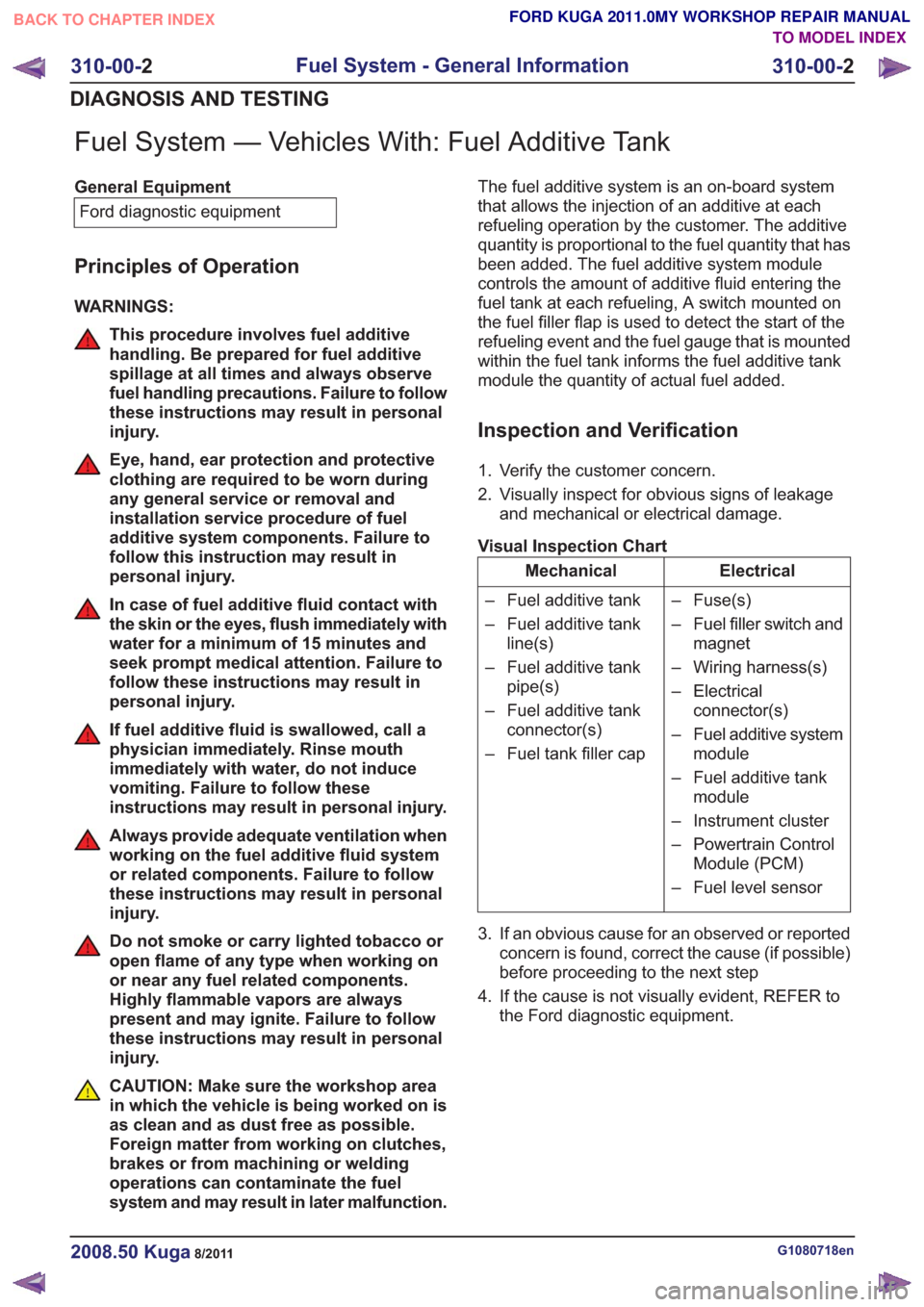

Fuel System — Vehicles With: Fuel Additive Tank

General EquipmentFord diagnostic equipment

Principles of Operation

WARNINGS:

This procedure involves fuel additive

handling. Be prepared for fuel additive

spillage at all times and always observe

fuel handling precautions. Failure to follow

these instructions may result in personal

injury.

Eye, hand, ear protection and protective

clothing are required to be worn during

any general service or removal and

installation service procedure of fuel

additive system components. Failure to

follow this instruction may result in

personal injury.

In case of fuel additive fluid contact with

the skin or the eyes, flush immediately with

water for a minimum of 15 minutes and

seek prompt medical attention. Failure to

follow these instructions may result in

personal injury.

If fuel additive fluid is swallowed, call a

physician immediately. Rinse mouth

immediately with water, do not induce

vomiting. Failure to follow these

instructions may result in personal injury.

Always provide adequate ventilation when

working on the fuel additive fluid system

or related components. Failure to follow

these instructions may result in personal

injury.

Do not smoke or carry lighted tobacco or

open flame of any type when working on

or near any fuel related components.

Highly flammable vapors are always

present and may ignite. Failure to follow

these instructions may result in personal

injury.

CAUTION: Make sure the workshop area

in which the vehicle is being worked on is

as clean and as dust free as possible.

Foreign matter from working on clutches,

brakes or from machining or welding

operations can contaminate the fuel

system and may result in later malfunction. The fuel additive system is an on-board system

that allows the injection of an additive at each

refueling operation by the customer. The additive

quantity is proportional to the fuel quantity that has

been added. The fuel additive system module

controls the amount of additive fluid entering the

fuel tank at each refueling, A switch mounted on

the fuel filler flap is used to detect the start of the

refueling event and the fuel gauge that is mounted

within the fuel tank informs the fuel additive tank

module the quantity of actual fuel added.

Inspection and Verification

1. Verify the customer concern.

2. Visually inspect for obvious signs of leakage

and mechanical or electrical damage.

Visual Inspection Chart

Electrical

Mechanical

– Fuse(s)

– Fuel filler switch andmagnet

– Wiring harness(s)

– Electrical connector(s)

– Fuel additive system module

– Fuel additive tank module

– Instrument cluster

– Powertrain Control Module (PCM)

– Fuel level sensor

– Fuel additive tank

– Fuel additive tank

line(s)

– Fuel additive tank pipe(s)

– Fuel additive tank connector(s)

– Fuel tank filler cap

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible)

before proceeding to the next step

4. If the cause is not visually evident, REFER to the Ford diagnostic equipment.

G1080718en2008.50 Kuga8/2011

310-00- 2

Fuel System - General Information

310-00- 2

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL