ECO mode FORD KUGA 2011 1.G Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2011, Model line: KUGA, Model: FORD KUGA 2011 1.GPages: 2057

Page 1851 of 2057

select-shift switch module transmits a downshift

signal to the TCM.

If you move the gear selector lever backwards (+),

an upshift signal is transmitted to the TCM. In the

instrument cluster, the symbol when the selector

lever is in the 'S' position changes from 'D' to the

current gear, for example 3.

The TCM transmits a signal to the select-shift

switch module to switch on the light emitting diode

for 'S' and to switch off all other light emitting

diodes. The TCM decides whether the shift process

is possible.

If the shift process is permitted, then the various

valves are activated according to the intended

combination for each gear.

In certain situations however, the TCM determines

the gear shifting. The following applies:

• If the vehicle is stationary, only 1st, 2nd and 3rdgears can be selected. 4th gear can be selected

at speeds over 30 km/h and 5th gear at speeds

over 40 km/h.

• The kickdown function is only available in the automatic transmission range 'D'

• Automatic gear changes into the next higher or next lower gear occur at fixed vehicle speeds

and fixed engine speeds

• The permitted engine speed for manual change down agree with that for the kickdown change

up, i.e. an engine speed of approximately 6000

rpm.

• If the temperature inside the transmission rises too high, the TCM takes control of the shift

decisions in order to select a gear in which

activation of torque converter lockup at the

current speed is possible

• Torque converter lockup is possible in 3rd, 4th and 5th gear. (1st and 2nd gears do not have

torque converter lockup)

The signal that specifies the position of the lever

to the select-shift switch module is generated as

follows in the selector lever position 'S': there is a

Hall sensor at the printed circuit board for the

module for each of the three selector lever

positions. A permanent magnet on the cover in the

selector lever affects the output signals to the

control module from the sensors. The control

module recognizes the position of the lever by the

differences in the signal properties.Selector lever from 'N' to 'R' position

The TCM only permits shifting to reverse gear if

the vehicle speed is less than 4.35 mph.

If the vehicle speed is greater than 7 km/h (approx.

4.35 mph), the clutch (C2) and the multi-plate brake

(B3) are not activated and the gearshift is thus

prevented.

Self-test and Diagnosis

The TCM monitors all the transaxle sensors and

electronic components including the PCM. If a fault

occurs, the driver is informed via a warning

indicator and a text message in the instrument

cluster. Faults are stored as DTCs in the fault

memory of the TCM and can be read out and

cleared using the IDS.

Temperature controlled torque converter

lockup

If heavy load and high ambient temperatures cause

an abnormal rise in the transmission temperature,

torque converter lockup is activated as often as

possible (temperature controlled lockup).

This reduces the slip and the heat developed in

the transmission. When the temperature drops

below +20 °C, torque converter lockup is not used.

Slip locking

When changing gear this function makes it possible

for the gears to engage more smoothly with

reduced vibration and less noise. In this mode, the

torque converter clutch is activated but not fully

locked.

The following conditions must be met for the

function to activate:

• Gear selector lever in position D or S.

• Gear 3, 4 or 5.

• The transmission input speed is 1100 rpm or more and the throttle plate opening 20 - 35%.

• The transmission fluid temperature is 40 - 120 °C.

Hill climbing

The TCM can change the shift pattern slightly when

driving uphill to avoid changing gear too often.

G1163605en2008.50 Kuga8/2011

307-01- 30

Automatic Transmission/Transaxle

— Vehicles With:

5-Speed Automatic Transaxle - AW55 AWD

307-01- 30

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1856 of 2057

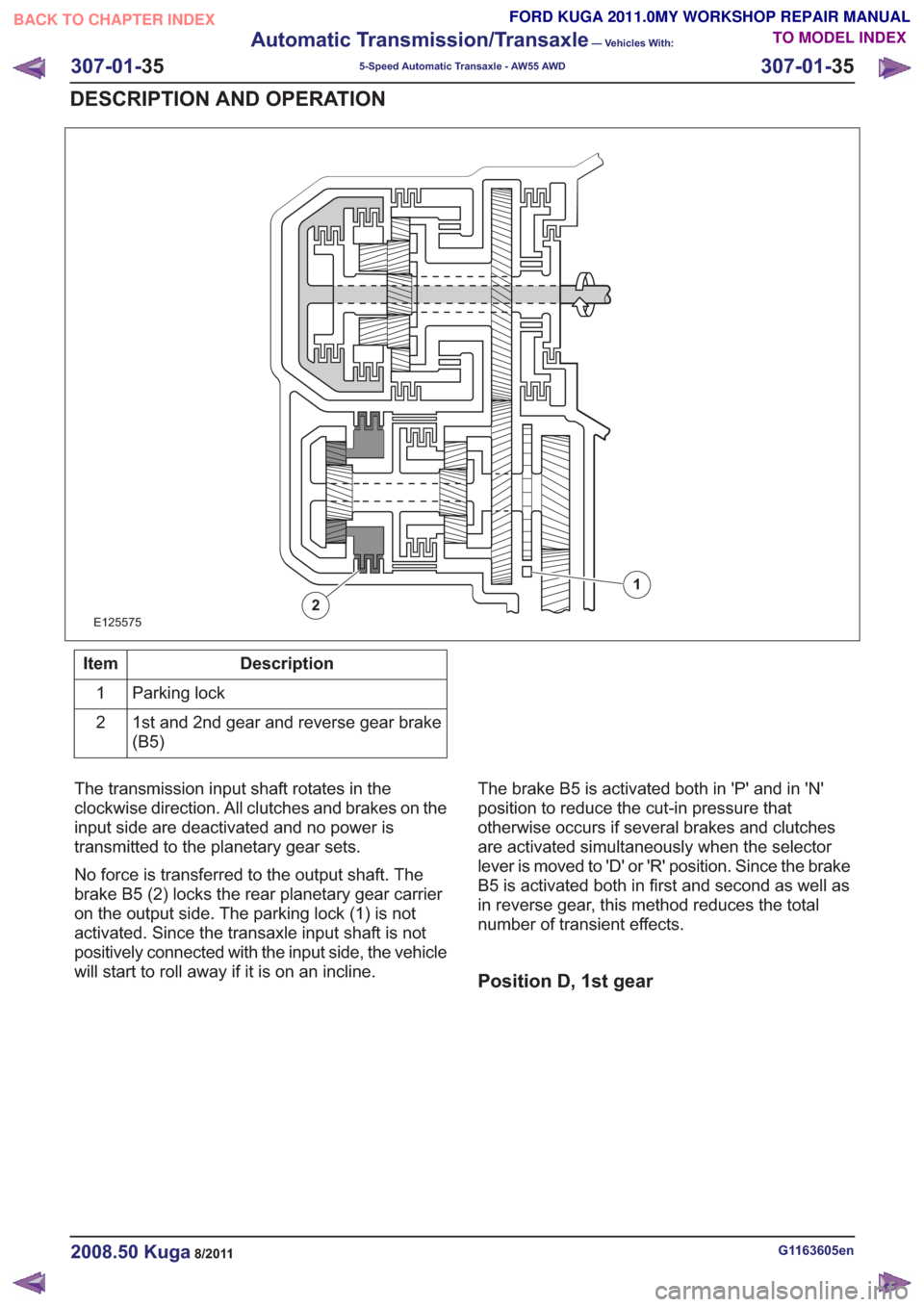

E125575

1

2

Description

Item

Parking lock

1

1st and 2nd gear and reverse gear brake

(B5)

2

The transmission input shaft rotates in the

clockwise direction. All clutches and brakes on the

input side are deactivated and no power is

transmitted to the planetary gear sets.

No force is transferred to the output shaft. The

brake B5 (2) locks the rear planetary gear carrier

on the output side. The parking lock (1) is not

activated. Since the transaxle input shaft is not

positively connected with the input side, the vehicle

will start to roll away if it is on an incline. The brake B5 is activated both in 'P' and in 'N'

position to reduce the cut-in pressure that

otherwise occurs if several brakes and clutches

are activated simultaneously when the selector

lever is moved to 'D' or 'R' position. Since the brake

B5 is activated both in first and second as well as

in reverse gear, this method reduces the total

number of transient effects.

Position D, 1st gear

G1163605en2008.50 Kuga8/2011

307-01-

35

Automatic Transmission/Transaxle

— Vehicles With:

5-Speed Automatic Transaxle - AW55 AWD

307-01- 35

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1857 of 2057

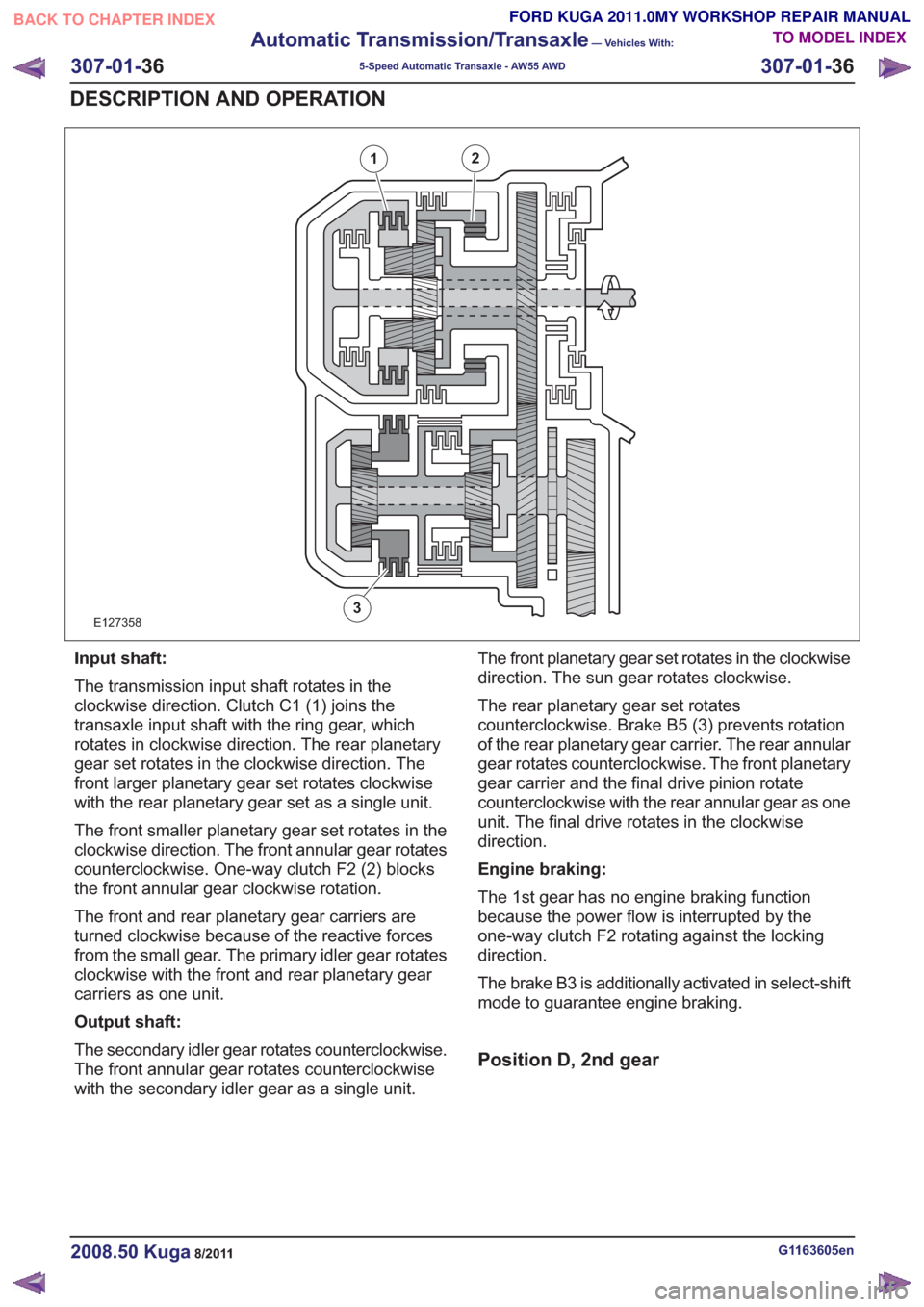

E127358

21

3

Input shaft:

The transmission input shaft rotates in the

clockwise direction. Clutch C1 (1) joins the

transaxle input shaft with the ring gear, which

rotates in clockwise direction. The rear planetary

gear set rotates in the clockwise direction. The

front larger planetary gear set rotates clockwise

with the rear planetary gear set as a single unit.

The front smaller planetary gear set rotates in the

clockwise direction. The front annular gear rotates

counterclockwise. One-way clutch F2 (2) blocks

the front annular gear clockwise rotation.

The front and rear planetary gear carriers are

turned clockwise because of the reactive forces

from the small gear. The primary idler gear rotates

clockwise with the front and rear planetary gear

carriers as one unit.

Output shaft:

The secondary idler gear rotates counterclockwise.

The front annular gear rotates counterclockwise

with the secondary idler gear as a single unit.The front planetary gear set rotates in the clockwise

direction. The sun gear rotates clockwise.

The rear planetary gear set rotates

counterclockwise. Brake B5 (3) prevents rotation

of the rear planetary gear carrier. The rear annular

gear rotates counterclockwise. The front planetary

gear carrier and the final drive pinion rotate

counterclockwise with the rear annular gear as one

unit. The final drive rotates in the clockwise

direction.

Engine braking:

The 1st gear has no engine braking function

because the power flow is interrupted by the

one-way clutch F2 rotating against the locking

direction.

The brake B3 is additionally activated in select-shift

mode to guarantee engine braking.

Position D, 2nd gear

G1163605en2008.50 Kuga8/2011

307-01-

36

Automatic Transmission/Transaxle

— Vehicles With:

5-Speed Automatic Transaxle - AW55 AWD

307-01- 36

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1858 of 2057

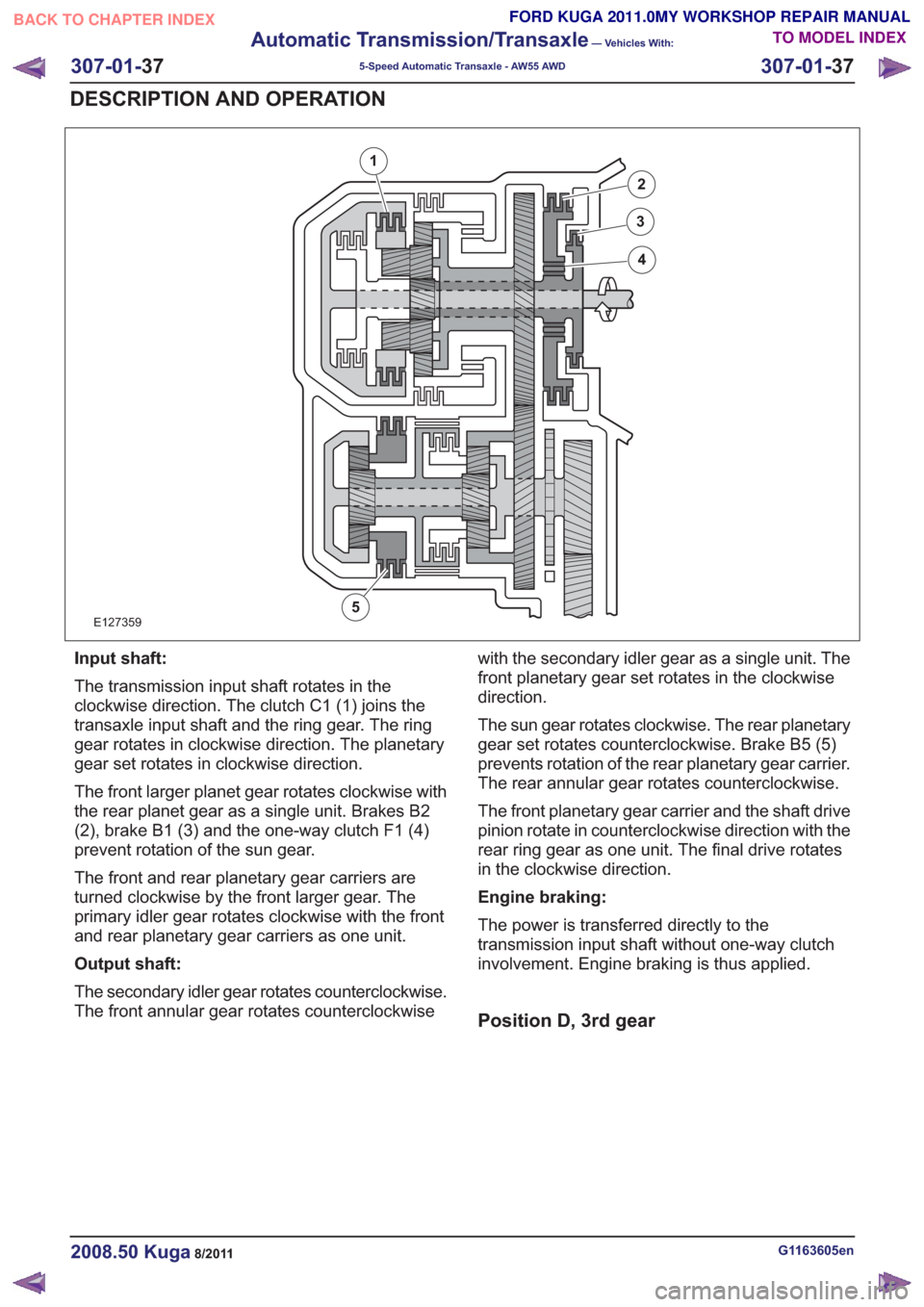

E127359

1

2

3

4

5

Input shaft:

The transmission input shaft rotates in the

clockwise direction. The clutch C1 (1) joins the

transaxle input shaft and the ring gear. The ring

gear rotates in clockwise direction. The planetary

gear set rotates in clockwise direction.

The front larger planet gear rotates clockwise with

the rear planet gear as a single unit. Brakes B2

(2), brake B1 (3) and the one-way clutch F1 (4)

prevent rotation of the sun gear.

The front and rear planetary gear carriers are

turned clockwise by the front larger gear. The

primary idler gear rotates clockwise with the front

and rear planetary gear carriers as one unit.

Output shaft:

The secondary idler gear rotates counterclockwise.

The front annular gear rotates counterclockwisewith the secondary idler gear as a single unit. The

front planetary gear set rotates in the clockwise

direction.

The sun gear rotates clockwise. The rear planetary

gear set rotates counterclockwise. Brake B5 (5)

prevents rotation of the rear planetary gear carrier.

The rear annular gear rotates counterclockwise.

The front planetary gear carrier and the shaft drive

pinion rotate in counterclockwise direction with the

rear ring gear as one unit. The final drive rotates

in the clockwise direction.

Engine braking:

The power is transferred directly to the

transmission input shaft without one-way clutch

involvement. Engine braking is thus applied.

Position D, 3rd gear

G1163605en2008.50 Kuga8/2011

307-01-

37

Automatic Transmission/Transaxle

— Vehicles With:

5-Speed Automatic Transaxle - AW55 AWD

307-01- 37

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1859 of 2057

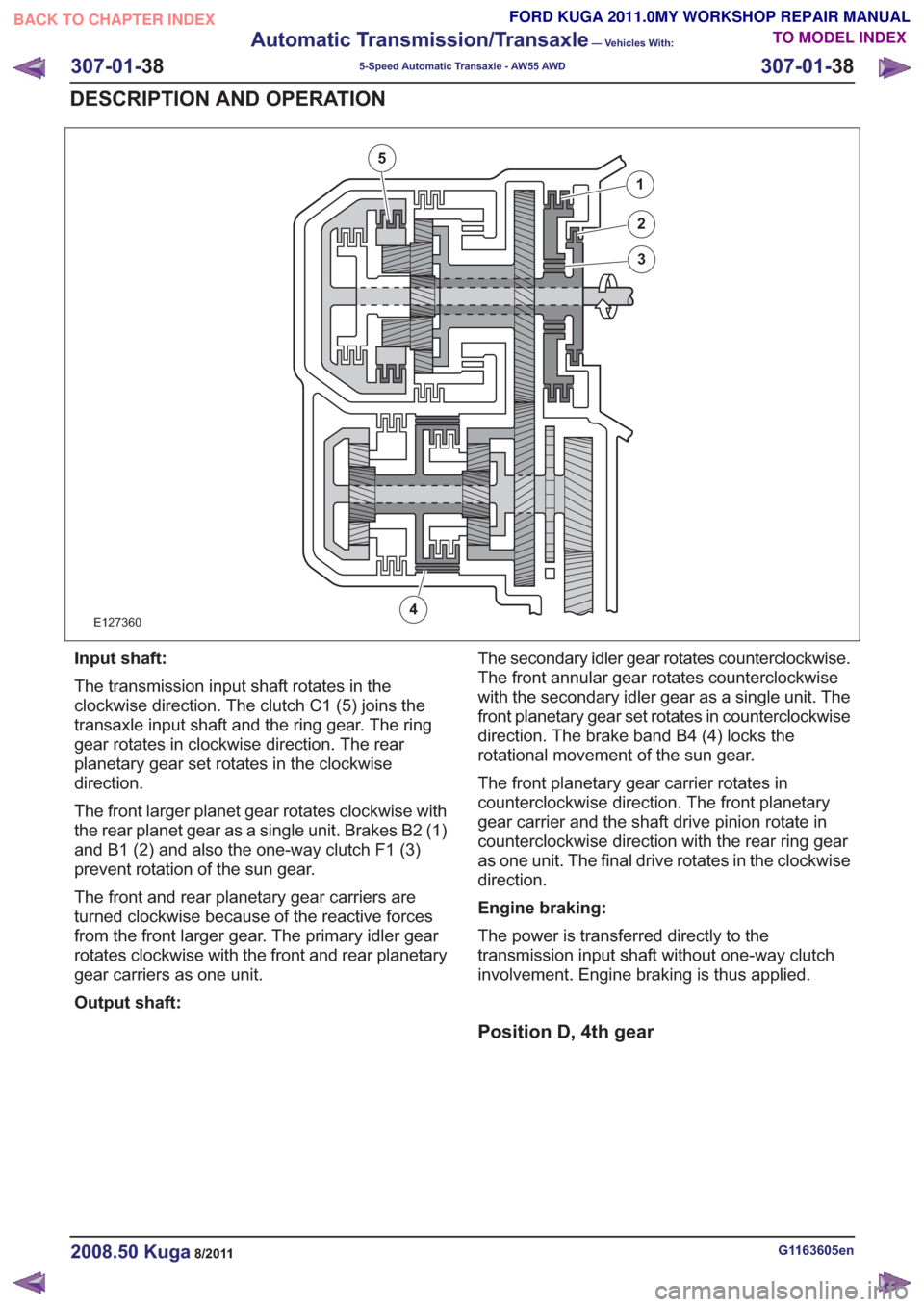

E127360

1

2

3

4

5

Input shaft:

The transmission input shaft rotates in the

clockwise direction. The clutch C1 (5) joins the

transaxle input shaft and the ring gear. The ring

gear rotates in clockwise direction. The rear

planetary gear set rotates in the clockwise

direction.

The front larger planet gear rotates clockwise with

the rear planet gear as a single unit. Brakes B2 (1)

and B1 (2) and also the one-way clutch F1 (3)

prevent rotation of the sun gear.

The front and rear planetary gear carriers are

turned clockwise because of the reactive forces

from the front larger gear. The primary idler gear

rotates clockwise with the front and rear planetary

gear carriers as one unit.

Output shaft:The secondary idler gear rotates counterclockwise.

The front annular gear rotates counterclockwise

with the secondary idler gear as a single unit. The

front planetary gear set rotates in counterclockwise

direction. The brake band B4 (4) locks the

rotational movement of the sun gear.

The front planetary gear carrier rotates in

counterclockwise direction. The front planetary

gear carrier and the shaft drive pinion rotate in

counterclockwise direction with the rear ring gear

as one unit. The final drive rotates in the clockwise

direction.

Engine braking:

The power is transferred directly to the

transmission input shaft without one-way clutch

involvement. Engine braking is thus applied.

Position D, 4th gear

G1163605en2008.50 Kuga8/2011

307-01-

38

Automatic Transmission/Transaxle

— Vehicles With:

5-Speed Automatic Transaxle - AW55 AWD

307-01- 38

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1860 of 2057

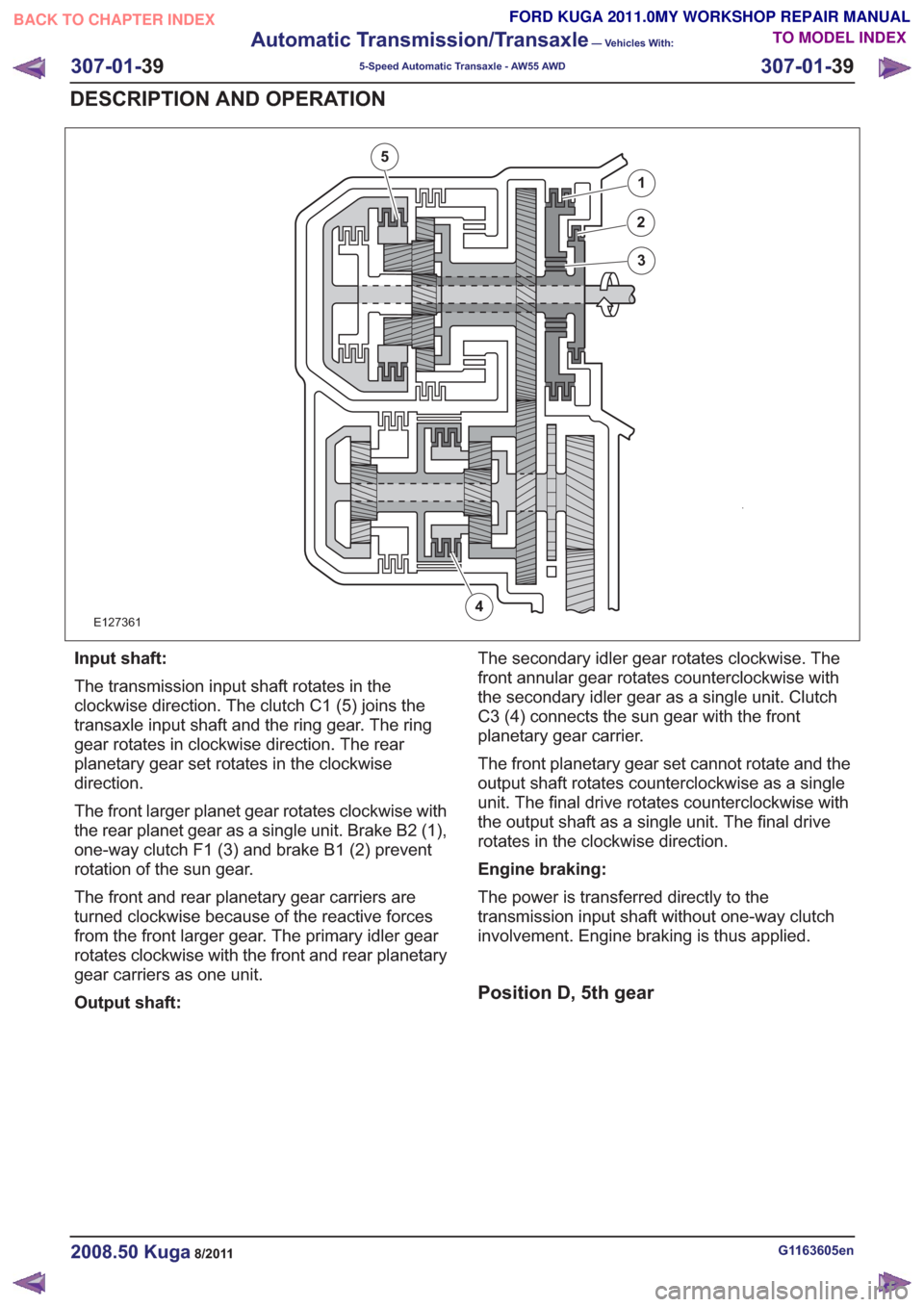

E127361

1

2

3

4

5

Input shaft:

The transmission input shaft rotates in the

clockwise direction. The clutch C1 (5) joins the

transaxle input shaft and the ring gear. The ring

gear rotates in clockwise direction. The rear

planetary gear set rotates in the clockwise

direction.

The front larger planet gear rotates clockwise with

the rear planet gear as a single unit. Brake B2 (1),

one-way clutch F1 (3) and brake B1 (2) prevent

rotation of the sun gear.

The front and rear planetary gear carriers are

turned clockwise because of the reactive forces

from the front larger gear. The primary idler gear

rotates clockwise with the front and rear planetary

gear carriers as one unit.

Output shaft:The secondary idler gear rotates clockwise. The

front annular gear rotates counterclockwise with

the secondary idler gear as a single unit. Clutch

C3 (4) connects the sun gear with the front

planetary gear carrier.

The front planetary gear set cannot rotate and the

output shaft rotates counterclockwise as a single

unit. The final drive rotates counterclockwise with

the output shaft as a single unit. The final drive

rotates in the clockwise direction.

Engine braking:

The power is transferred directly to the

transmission input shaft without one-way clutch

involvement. Engine braking is thus applied.

Position D, 5th gear

G1163605en2008.50 Kuga8/2011

307-01-

39

Automatic Transmission/Transaxle

— Vehicles With:

5-Speed Automatic Transaxle - AW55 AWD

307-01- 39

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1861 of 2057

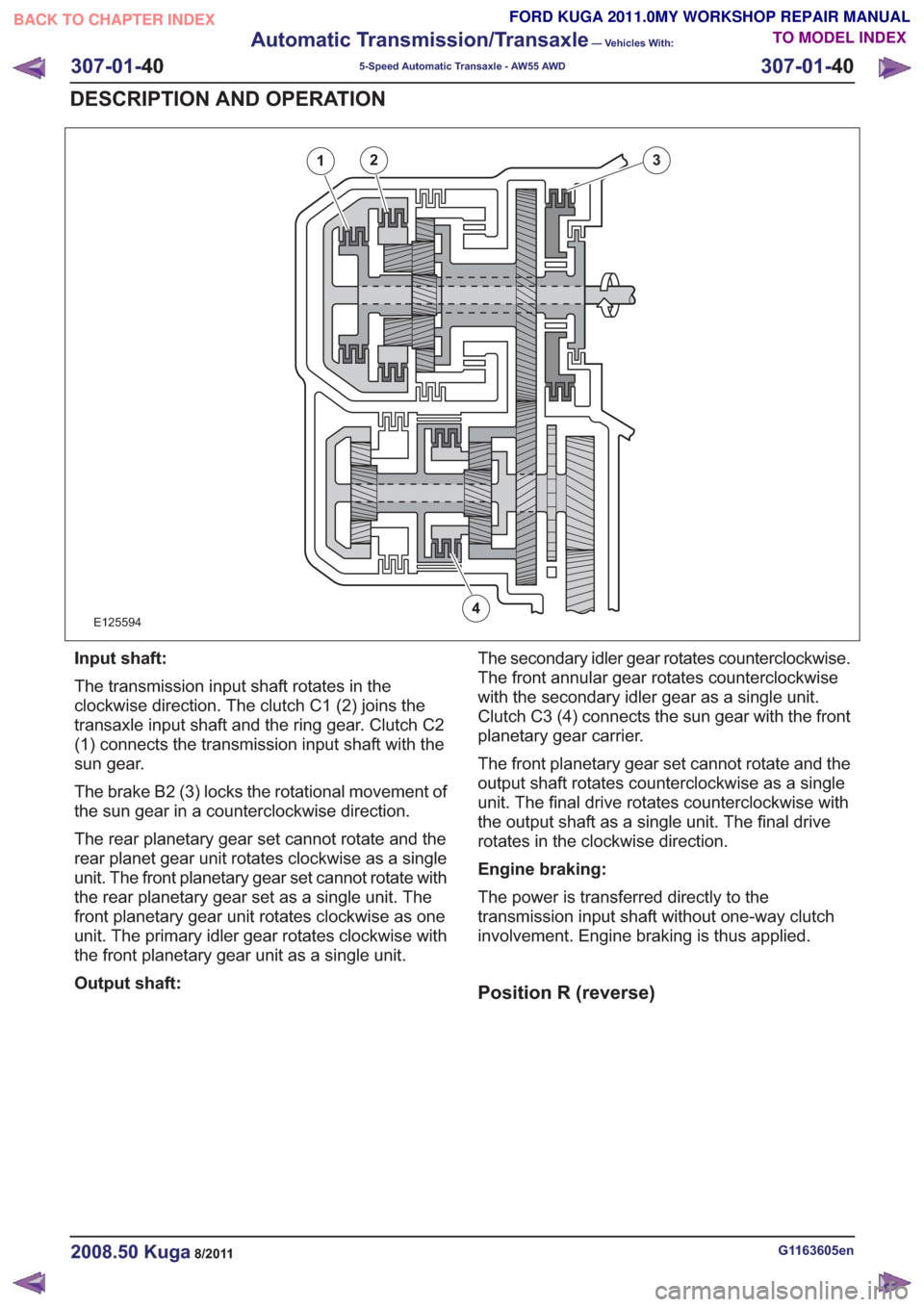

E125594

12

4

3

Input shaft:

The transmission input shaft rotates in the

clockwise direction. The clutch C1 (2) joins the

transaxle input shaft and the ring gear. Clutch C2

(1) connects the transmission input shaft with the

sun gear.

The brake B2 (3) locks the rotational movement of

the sun gear in a counterclockwise direction.

The rear planetary gear set cannot rotate and the

rear planet gear unit rotates clockwise as a single

unit. The front planetary gear set cannot rotate with

the rear planetary gear set as a single unit. The

front planetary gear unit rotates clockwise as one

unit. The primary idler gear rotates clockwise with

the front planetary gear unit as a single unit.

Output shaft:The secondary idler gear rotates counterclockwise.

The front annular gear rotates counterclockwise

with the secondary idler gear as a single unit.

Clutch C3 (4) connects the sun gear with the front

planetary gear carrier.

The front planetary gear set cannot rotate and the

output shaft rotates counterclockwise as a single

unit. The final drive rotates counterclockwise with

the output shaft as a single unit. The final drive

rotates in the clockwise direction.

Engine braking:

The power is transferred directly to the

transmission input shaft without one-way clutch

involvement. Engine braking is thus applied.

Position R (reverse)

G1163605en2008.50 Kuga8/2011

307-01-

40

Automatic Transmission/Transaxle

— Vehicles With:

5-Speed Automatic Transaxle - AW55 AWD

307-01- 40

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1862 of 2057

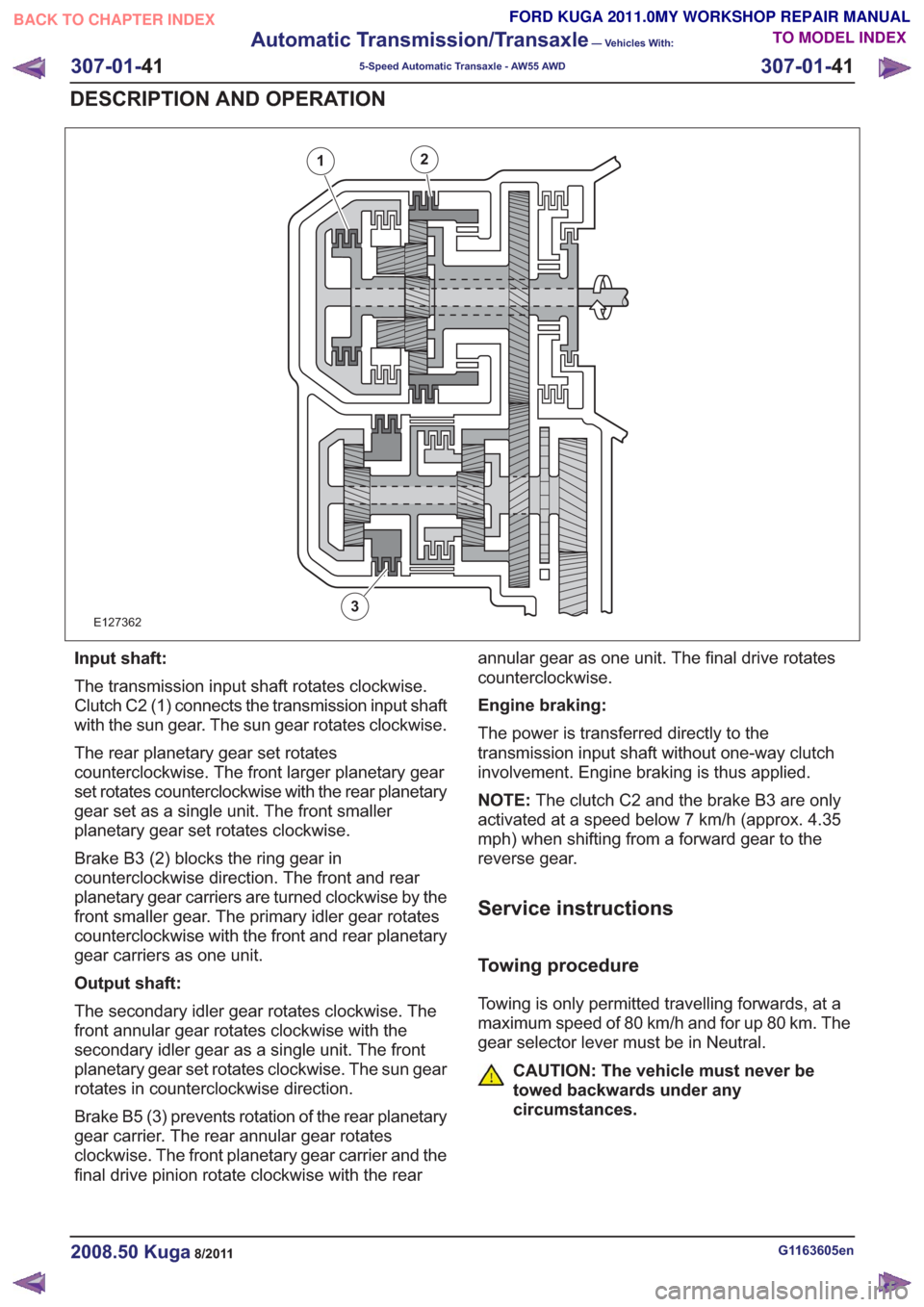

E127362

12

3

Input shaft:

The transmission input shaft rotates clockwise.

Clutch C2 (1) connects the transmission input shaft

with the sun gear. The sun gear rotates clockwise.

The rear planetary gear set rotates

counterclockwise. The front larger planetary gear

set rotates counterclockwise with the rear planetary

gear set as a single unit. The front smaller

planetary gear set rotates clockwise.

Brake B3 (2) blocks the ring gear in

counterclockwise direction. The front and rear

planetary gear carriers are turned clockwise by the

front smaller gear. The primary idler gear rotates

counterclockwise with the front and rear planetary

gear carriers as one unit.

Output shaft:

The secondary idler gear rotates clockwise. The

front annular gear rotates clockwise with the

secondary idler gear as a single unit. The front

planetary gear set rotates clockwise. The sun gear

rotates in counterclockwise direction.

Brake B5 (3) prevents rotation of the rear planetary

gear carrier. The rear annular gear rotates

clockwise. The front planetary gear carrier and the

final drive pinion rotate clockwise with the rearannular gear as one unit. The final drive rotates

counterclockwise.

Engine braking:

The power is transferred directly to the

transmission input shaft without one-way clutch

involvement. Engine braking is thus applied.

NOTE:

The clutch C2 and the brake B3 are only

activated at a speed below 7 km/h (approx. 4.35

mph) when shifting from a forward gear to the

reverse gear.

Service instructions

Towing procedure

Towing is only permitted travelling forwards, at a

maximum speed of 80 km/h and for up 80 km. The

gear selector lever must be in Neutral.

CAUTION: The vehicle must never be

towed backwards under any

circumstances.

G1163605en2008.50 Kuga8/2011

307-01- 41

Automatic Transmission/Transaxle

— Vehicles With:

5-Speed Automatic Transaxle - AW55 AWD

307-01- 41

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1863 of 2057

Reset adaptation data

Adaptation values are stored in the software of the

TCM:

• Adaptation should be reset after an internalcomponent has been exchanged or the whole

transmission has been changed.

The adaptation of the transmission is reset via IDS.

Limp home mode

The TCM software contains functions which take

control of the transmission if serious faults occur.

The fault characteristic decides which strategies

are to be used.

The vehicle remains capable of restricted

operation.

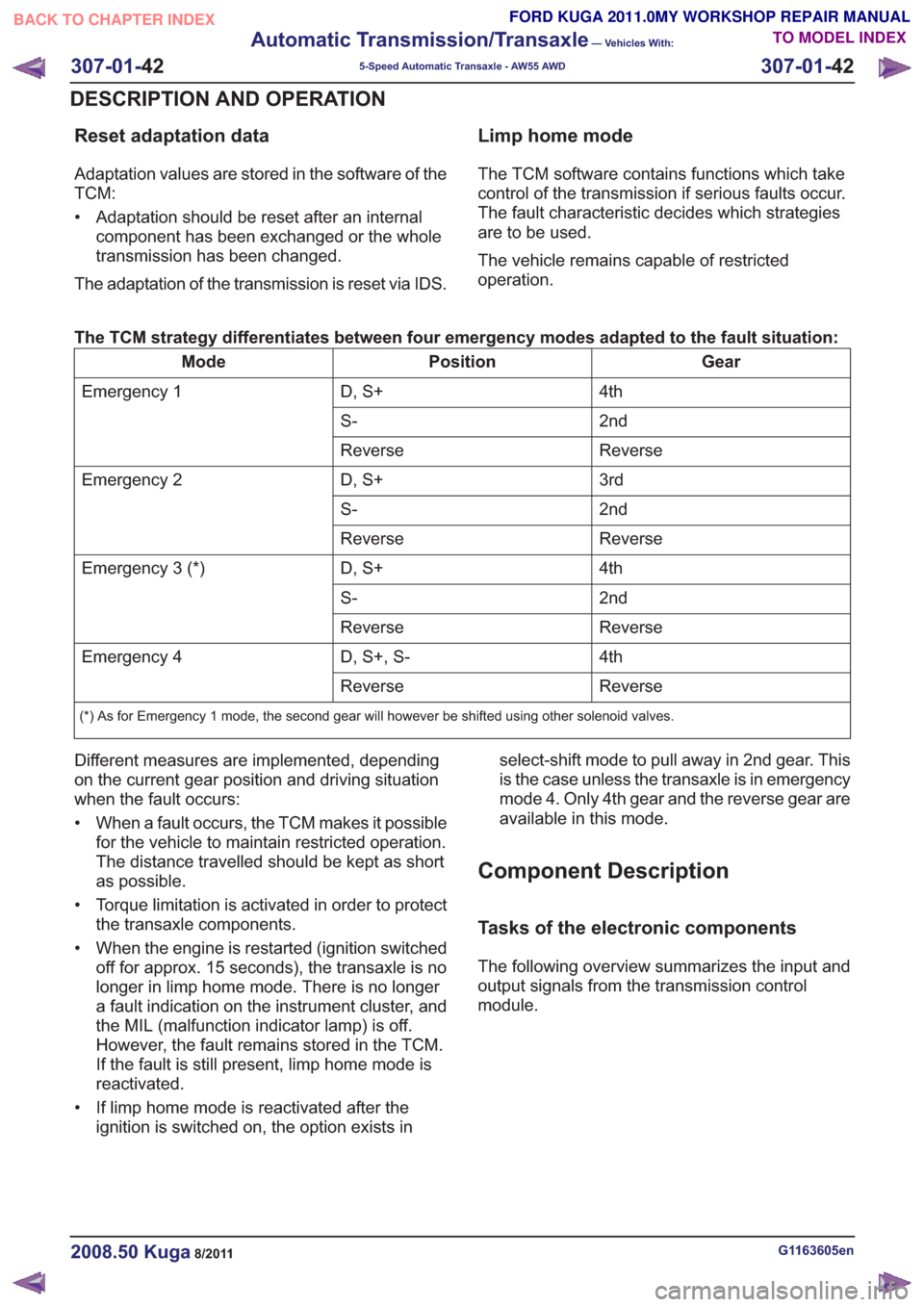

The TCM strategy differentiates between four emergency modes adapted to the fault situation:

Gear

Position

Mode

4th

D, S+

Emergency 1

2nd

S-

Reverse

Reverse

3rd

D, S+

Emergency 2

2nd

S-

Reverse

Reverse

4th

D, S+

Emergency 3 (*)

2nd

S-

Reverse

Reverse

4th

D, S+, S-

Emergency 4

Reverse

Reverse

(*) As for Emergency 1 mode, the second gear will however be shifted using other solenoid valves.

Different measures are implemented, depending

on the current gear position and driving situation

when the fault occurs:

• When a fault occurs, the TCM makes it possible

for the vehicle to maintain restricted operation.

The distance travelled should be kept as short

as possible.

• Torque limitation is activated in order to protect the transaxle components.

• When the engine is restarted (ignition switched off for approx. 15 seconds), the transaxle is no

longer in limp home mode. There is no longer

a fault indication on the instrument cluster, and

the MIL (malfunction indicator lamp) is off.

However, the fault remains stored in the TCM.

If the fault is still present, limp home mode is

reactivated.

• If limp home mode is reactivated after the ignition is switched on, the option exists in select-shift mode to pull away in 2nd gear. This

is the case unless the transaxle is in emergency

mode 4. Only 4th gear and the reverse gear are

available in this mode.

Component Description

Tasks of the electronic components

The following overview summarizes the input and

output signals from the transmission control

module.

G1163605en2008.50 Kuga8/2011

307-01-

42

Automatic Transmission/Transaxle

— Vehicles With:

5-Speed Automatic Transaxle - AW55 AWD

307-01- 42

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1866 of 2057

Output signals

Hard wired

• Item 8: PCM– Start inhibitor. Supplies the PCM with a signalthat indicates whether the engine can be

started or not.

• Item 9: Selector lever module (select-shift module)

– Controls the solenoid switch in the selectorlever unit.

• Position 10: PWM solenoid valve – shift pressure (SLS)

– Matches the line pressure to a shift pressureand is activated for certain gears.

• Position 11: PWM solenoid valve – main line pressure (SLT)

– Adjusts the linear line pressure for gearchanges without jolts.

• Position 12: PWM- solenoid valve – TCC (SLU) – Matches the line pressure to a torqueconverter lock-up pressure. Is also used for

certain gearshifts.

• Items 13 - 17: Shift solenoids S1 – S5 – The TCM checks which gear is engaged asthe solenoids become active in different

patterns.

Via the LIN data bus

• Item 7: Selector lever module (select-shift module)

– The TCM transmits a signal to the selectorlever module which activates the LED (light

emitting diode) in the selector mechanism

assembly according to the selector lever

position. Via the CAN data bus

• Item 2: GEM

– The selector lever module transmits a signalvia the TCM, which indicates that the selector

lever is locked in position P. The GEM uses

this information to control the ignition switch

key inhibit function.

– The TCM transmits a signal via the GEM to activate the back-up lamps.

• Item 3: Instrument Cluster – Current selector lever position. Used toindicate the selector lever position in the

instrument cluster.

– Check the warning lamps via the GEM. In the event of a fault, the general warning lamp

lights.

– Text messages in the instrument cluster via the GEM. The driver receives various

malfunction messages from the TCM.

– The TCM transmits signals on the CAN data bus to the PCM so that the MIL lights up in

the event of emissions-related faults.

• Item 4: PCM – Transmission fluid temperature, used tocompensate for increased loads at low fluid

temperatures.

– Gear selected, used by the engine so that it can compensate for different loads.

– Torque converter lockup, used by the engine so that it can compensate for different loads.

– Next gear planned by the TCM, used by the engine to compensate for different loads.

– Requirement for a reduced engine torque during gear shifts, the engine reduces the

engine torque during gear shifts.

– Torque limiting requirement, the engine limits the engine torque according to the gear

engaged.

• Item 5: ABS module – Current gear, used to transmit a signal, notfor shift control.

– Vehicle speed, used as reserve.

Control valve assembly

G1163605en2008.50 Kuga8/2011

307-01- 45

Automatic Transmission/Transaxle

— Vehicles With:

5-Speed Automatic Transaxle - AW55 AWD

307-01- 45

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL