Engine control FORD KUGA 2011 1.G Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2011, Model line: KUGA, Model: FORD KUGA 2011 1.GPages: 2057

Page 1816 of 2057

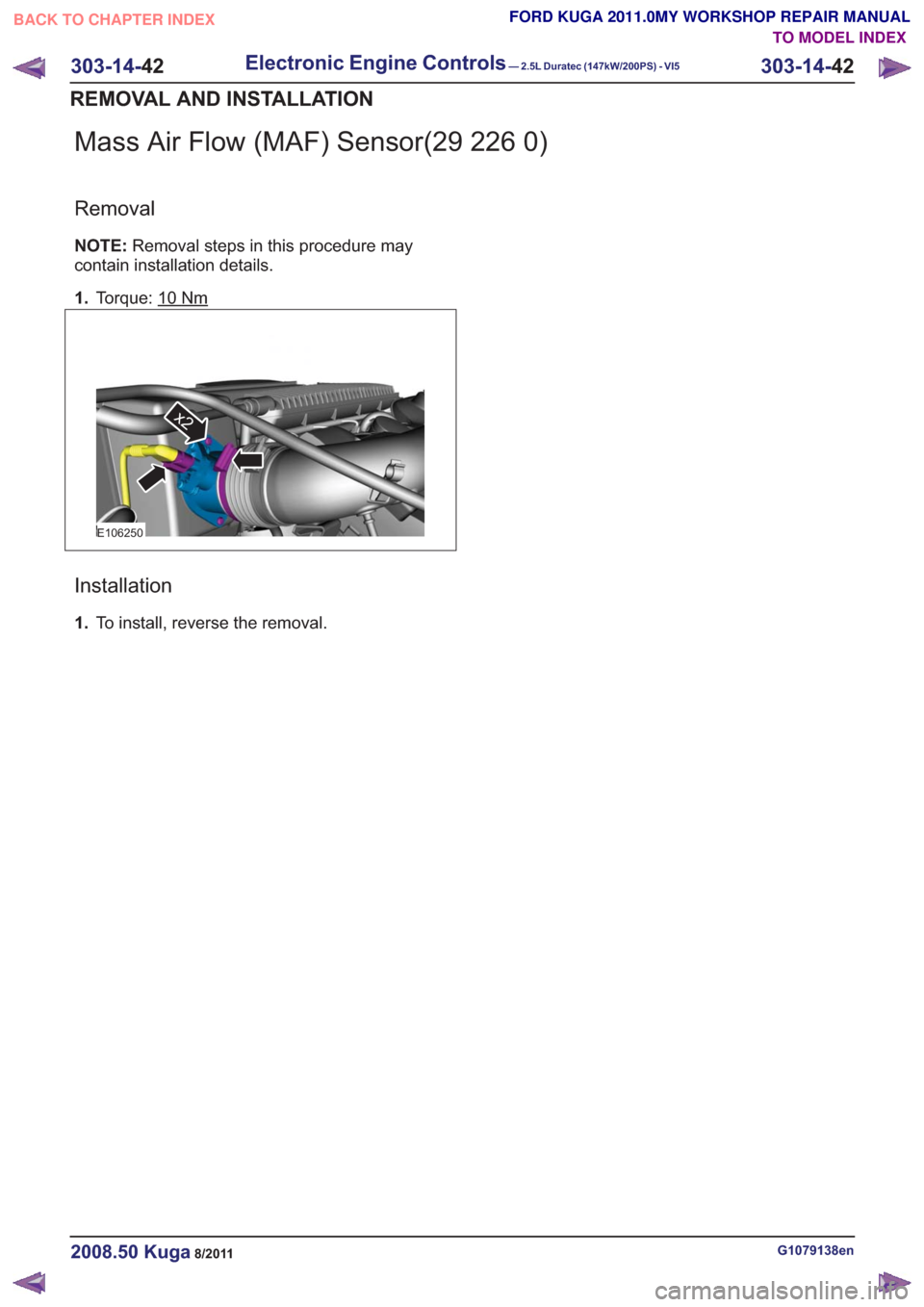

Mass Air Flow (MAF) Sensor(29 226 0)

Removal

NOTE:Removal steps in this procedure may

contain installation details.

1. Torque: 10

Nm

E106250

x2

Installation

1.To install, reverse the removal.

G1079138en2008.50 Kuga8/2011

303-14- 42

Electronic Engine Controls— 2.5L Duratec (147kW/200PS) - VI5303-14-

42

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1817 of 2057

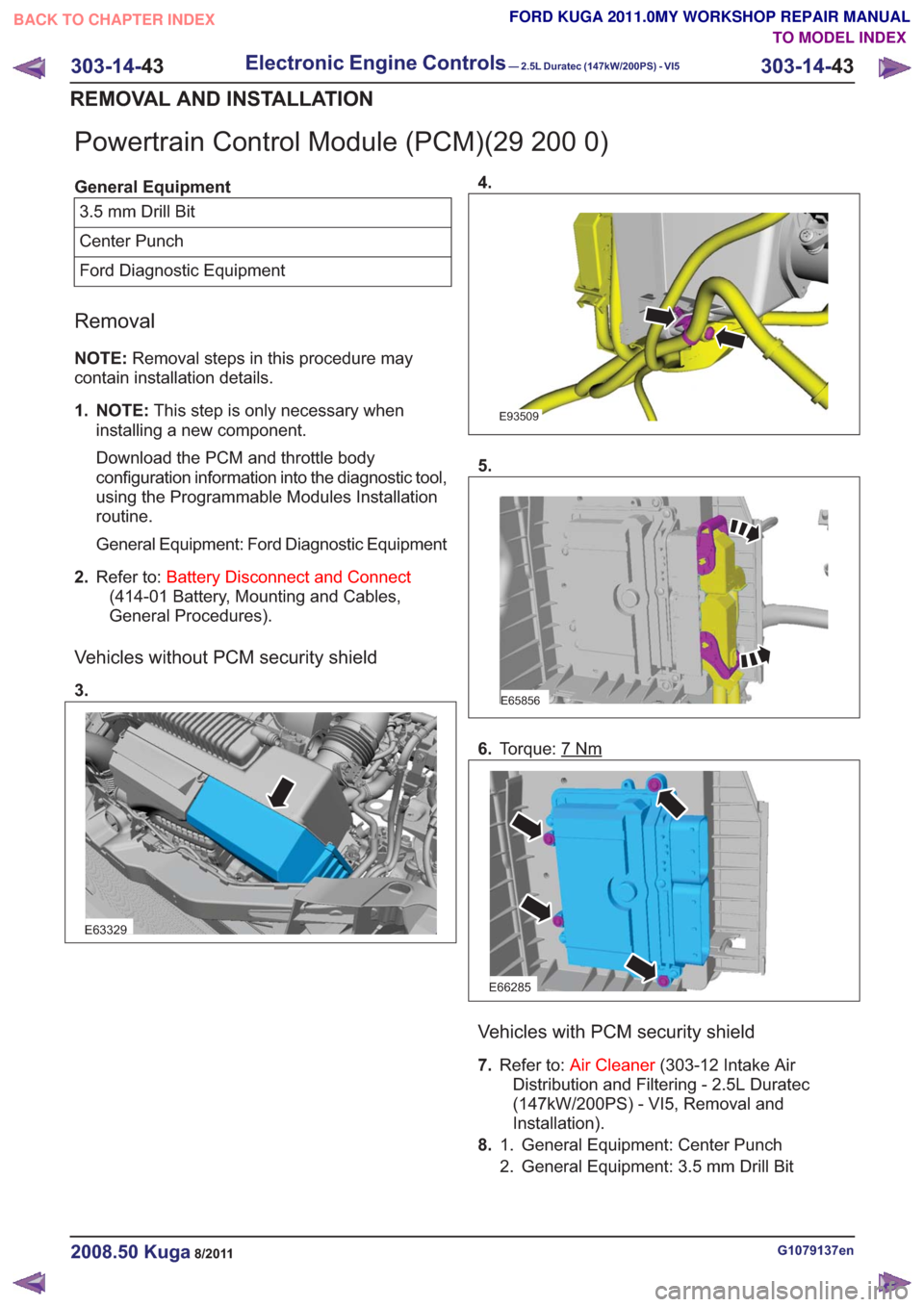

Powertrain Control Module (PCM)(29 200 0)

General Equipment3.5 mm Drill Bit

Center Punch

Ford Diagnostic Equipment

Removal

NOTE: Removal steps in this procedure may

contain installation details.

1. NOTE: This step is only necessary when

installing a new component.

Download the PCM and throttle body

configuration information into the diagnostic tool,

using the Programmable Modules Installation

routine.

General Equipment: Ford Diagnostic Equipment

2. Refer to: Battery Disconnect and Connect

(414-01 Battery, Mounting and Cables,

General Procedures).

Vehicles without PCM security shield

3.

E63329

4.

E93509

5.

E65856

6. Torque: 7Nm

E66285

Vehicles with PCM security shield

7.Refer to: Air Cleaner (303-12 Intake Air

Distribution and Filtering - 2.5L Duratec

(147kW/200PS) - VI5, Removal and

Installation).

8. General Equipment: Center Punch

1.

2. General Equipment: 3.5 mm Drill Bit

G1079137en2008.50 Kuga8/2011

303-14- 43

Electronic Engine Controls— 2.5L Duratec (147kW/200PS) - VI5303-14-

43

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1818 of 2057

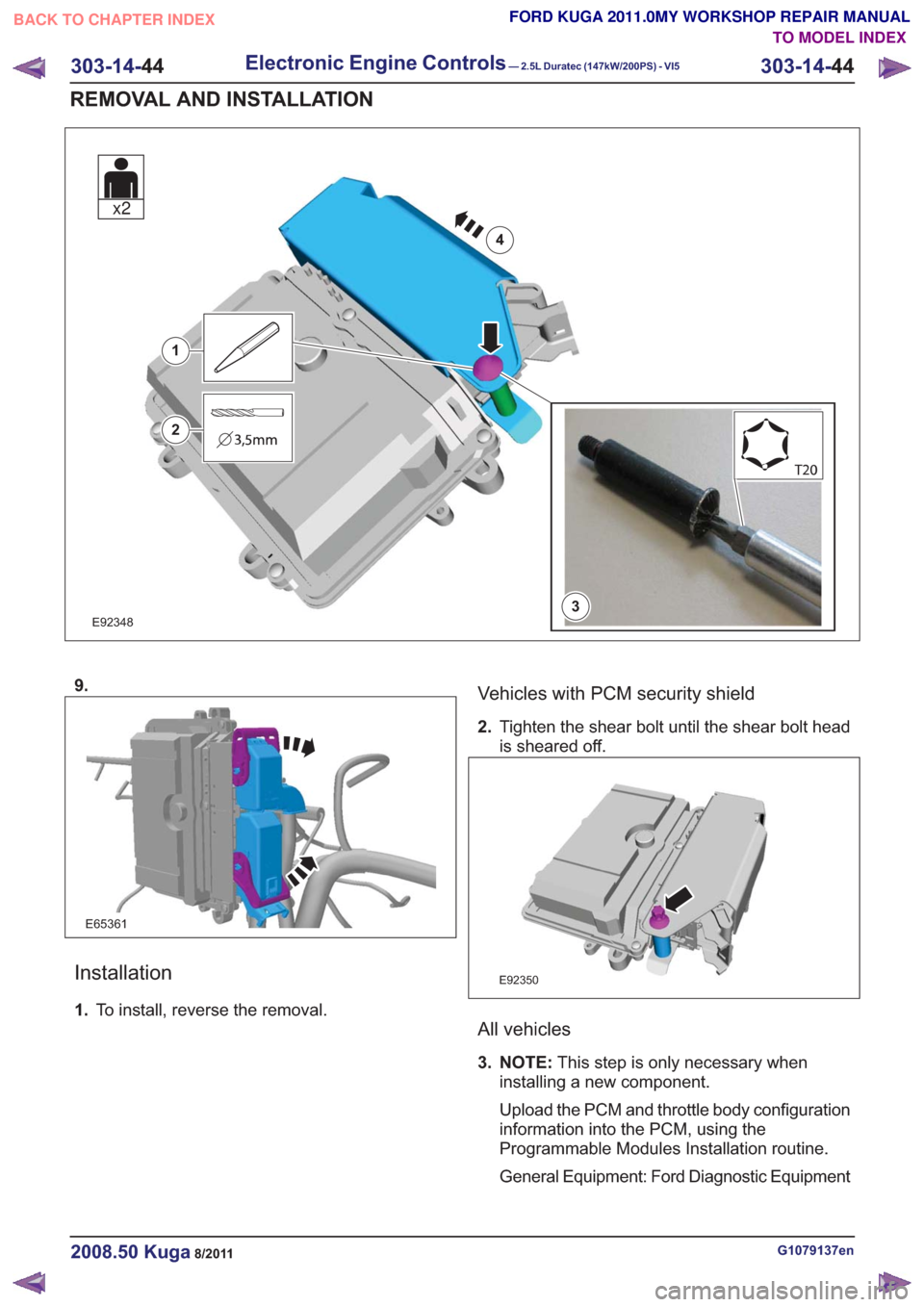

E923483

1

2

4

x2

9.

E65361

Installation

1.To install, reverse the removal.

Vehicles with PCM security shield

2.Tighten the shear bolt until the shear bolt head

is sheared off.

E92350

All vehicles

3. NOTE: This step is only necessary when

installing a new component.

Upload the PCM and throttle body configuration

information into the PCM, using the

Programmable Modules Installation routine.

General Equipment: Ford Diagnostic Equipment

G1079137en2008.50 Kuga8/2011

303-14- 44

Electronic Engine Controls— 2.5L Duratec (147kW/200PS) - VI5303-14-

44

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1819 of 2057

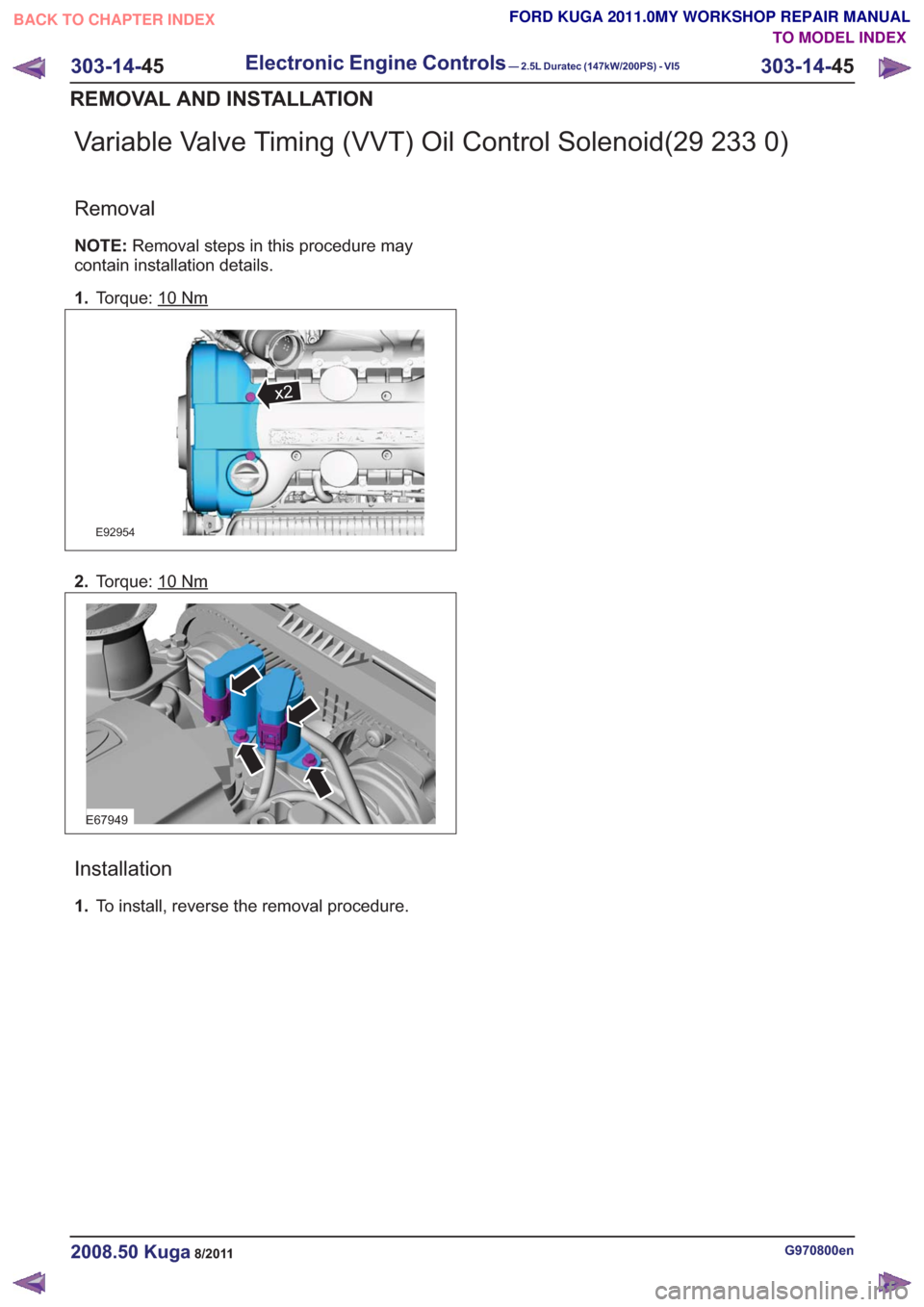

Variable Valve Timing (VVT) Oil Control Solenoid(29 233 0)

Removal

NOTE:Removal steps in this procedure may

contain installation details.

1. Torque: 10

Nm

x2x2

E92954

2.Torque: 10Nm

E67949

Installation

1.To install, reverse the removal procedure.

G970800en2008.50 Kuga8/2011

303-14- 45

Electronic Engine Controls— 2.5L Duratec (147kW/200PS) - VI5303-14-

45

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1820 of 2057

Brake Pedal Position (BPP) Switch(33 502 0)

Removal

1. CAUTION: Make sure that the brakepedal remains in the rest position.

E101878

Installation

1.CAUTION: Make sure that the brake

pedal remains in the rest position.

To install, reverse the removal procedure.

G1065472en2008.50 Kuga8/2011

303-14- 46

Electronic Engine Controls— 2.5L Duratec (147kW/200PS) - VI5303-14-

46

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1821 of 2057

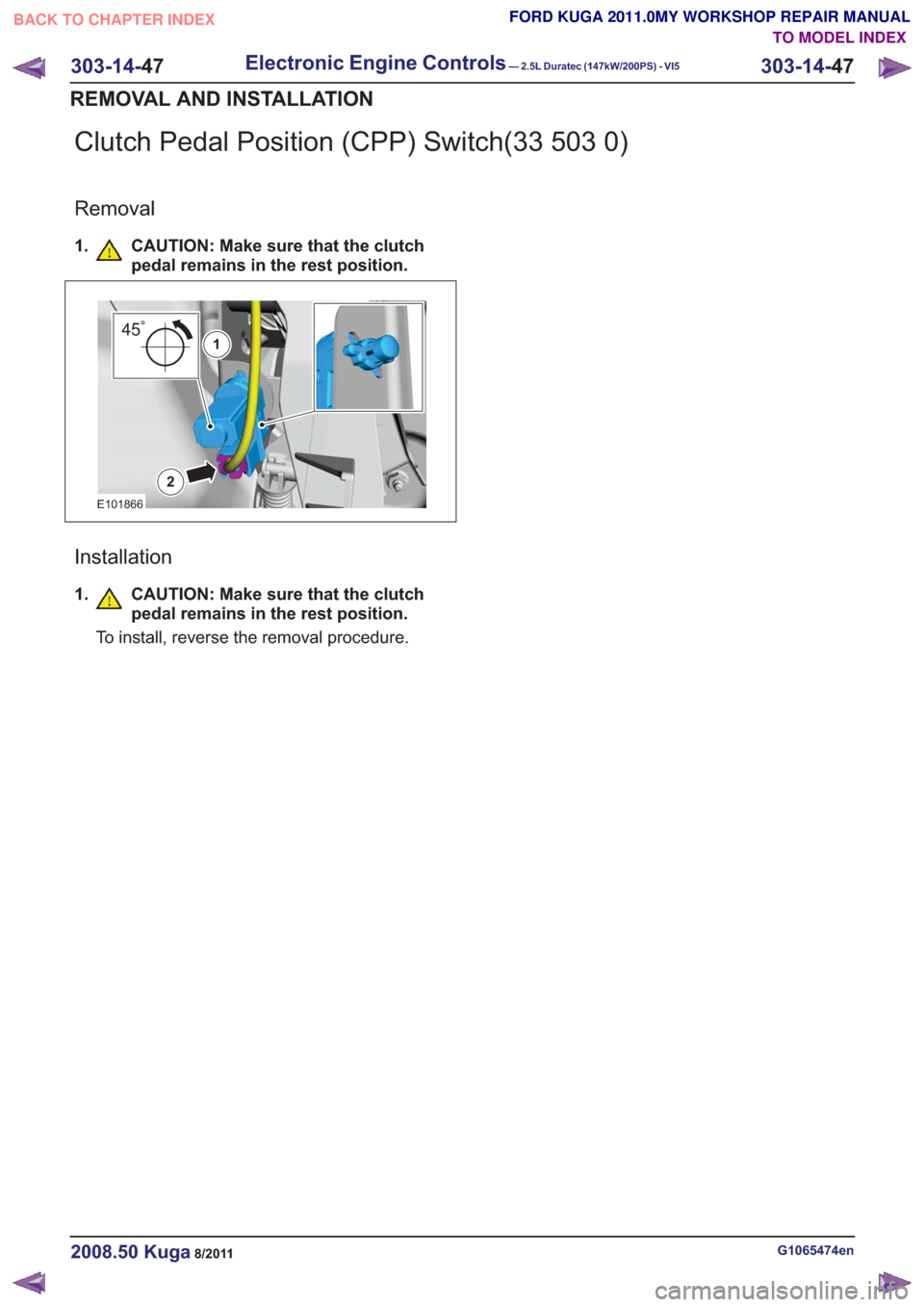

Clutch Pedal Position (CPP) Switch(33 503 0)

Removal

1. CAUTION: Make sure that the clutchpedal remains in the rest position.

2

451

E101866

Installation

1.CAUTION: Make sure that the clutch

pedal remains in the rest position.

To install, reverse the removal procedure.

G1065474en2008.50 Kuga8/2011

303-14- 47

Electronic Engine Controls— 2.5L Duratec (147kW/200PS) - VI5303-14-

47

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1830 of 2057

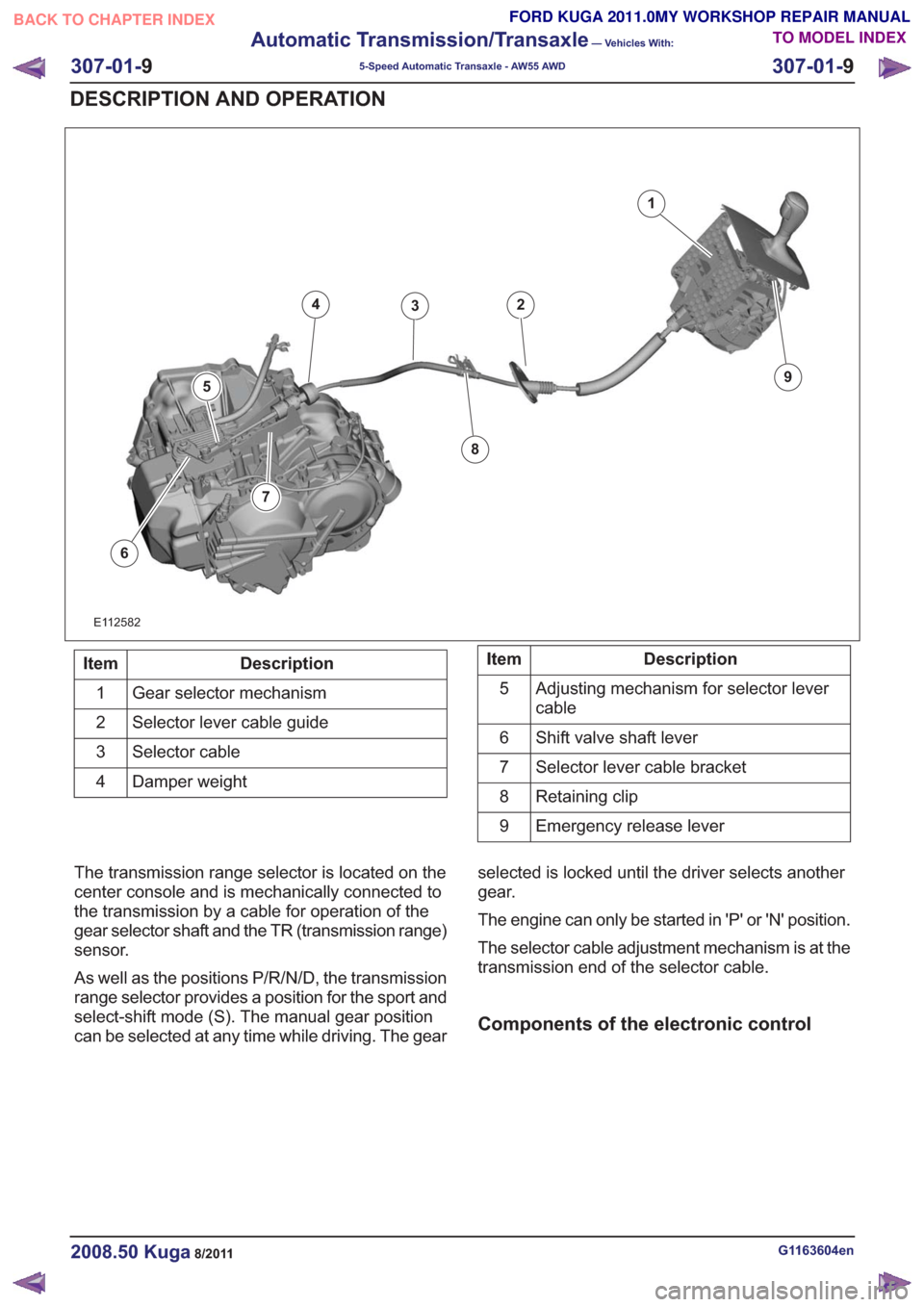

1

234

5

6

8

9

7

E112582

Description

Item

Gear selector mechanism

1

Selector lever cable guide

2

Selector cable

3

Damper weight

4Description

Item

Adjusting mechanism for selector lever

cable

5

Shift valve shaft lever

6

Selector lever cable bracket

7

Retaining clip

8

Emergency release lever

9

The transmission range selector is located on the

center console and is mechanically connected to

the transmission by a cable for operation of the

gear selector shaft and the TR (transmission range)

sensor.

As well as the positions P/R/N/D, the transmission

range selector provides a position for the sport and

select-shift mode (S). The manual gear position

can be selected at any time while driving. The gear selected is locked until the driver selects another

gear.

The engine can only be started in 'P' or 'N' position.

The selector cable adjustment mechanism is at the

transmission end of the selector cable.

Components of the electronic control

G1163604en2008.50 Kuga8/2011

307-01-

9

Automatic Transmission/Transaxle

— Vehicles With:

5-Speed Automatic Transaxle - AW55 AWD

307-01- 9

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1831 of 2057

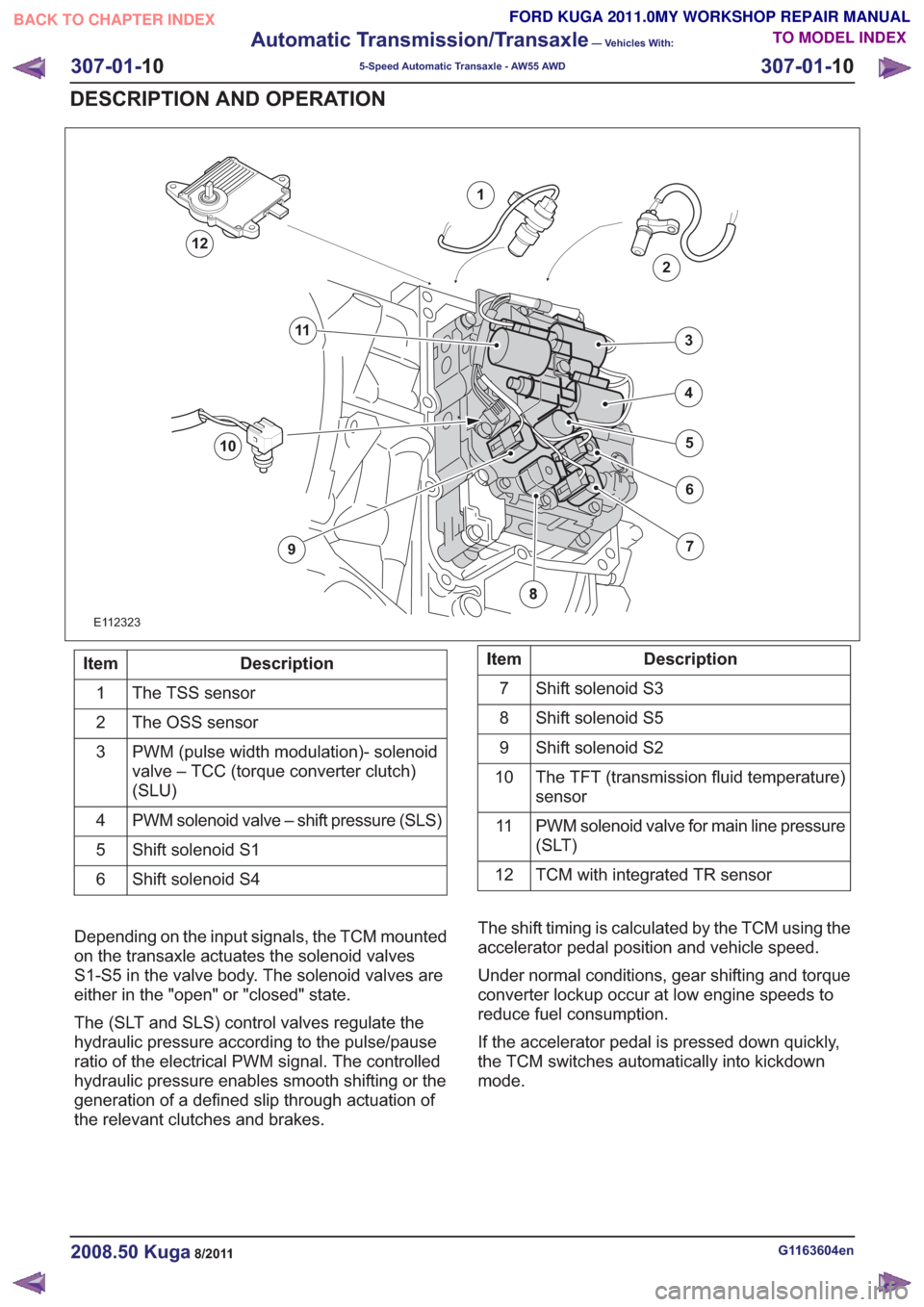

E112323

1

2

7

6

4

5

3

10

9

11

12

Description

Item

The TSS sensor

1

The OSS sensor

2

PWM (pulse width modulation)- solenoid

valve – TCC (torque converter clutch)

(SLU)

3

PWM solenoid valve – shift pressure (SLS)

4

Shift solenoid S1

5

Shift solenoid S4

6Description

Item

Shift solenoid S3

7

Shift solenoid S5

8

Shift solenoid S2

9

The TFT (transmission fluid temperature)

sensor

10

PWM solenoid valve for main line pressure

(SLT)

11

TCM with integrated TR sensor

12

Depending on the input signals, the TCM mounted

on the transaxle actuates the solenoid valves

S1-S5 in the valve body. The solenoid valves are

either in the "open" or "closed" state.

The (SLT and SLS) control valves regulate the

hydraulic pressure according to the pulse/pause

ratio of the electrical PWM signal. The controlled

hydraulic pressure enables smooth shifting or the

generation of a defined slip through actuation of

the relevant clutches and brakes. The shift timing is calculated by the TCM using the

accelerator pedal position and vehicle speed.

Under normal conditions, gear shifting and torque

converter lockup occur at low engine speeds to

reduce fuel consumption.

If the accelerator pedal is pressed down quickly,

the TCM switches automatically into kickdown

mode.

G1163604en2008.50 Kuga8/2011

307-01-

10

Automatic Transmission/Transaxle

— Vehicles With:

5-Speed Automatic Transaxle - AW55 AWD

307-01- 10

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1835 of 2057

Description

Item

ABS (anti-lock brake system)

5

Speed control

6

Select-shift switch module

7

PCM

8

Selector lever lock

9

PWM solenoid valve – shift pressure (SLS)

10

PWM solenoid valve for main line pressure

(SLT)

11

PWM- solenoid valve – TCC (SLU)

12Description

Item

Shift solenoid S1 (open when dormant)

13

Shift solenoid S2 (closed when dormant)

14

Shift solenoid S3 (closed when dormant)

15

Shift solenoid S4 (open when dormant)

16

Shift solenoid S5 (closed when dormant)

17

The TSS sensor

18

The OSS sensor

19

The TFT sensor

20

TR sensor in TCM

21

Knowing and Understanding Customer

Concerns

Knowing and understanding customer concerns is

necessary in order to perform diagnosis.

First of all, ask the customer under which operating

conditions the problem occurs. If possible, try to

reproduce the concern by road testing the vehicle

with the customer.

You should be familiar with the following operating

conditions:

• Engine operating state

– Cold, warm-up phase, or at operatingtemperature

• Ambient temperature – Below 0 °C (32 °F), 0 to 20 °C (32 to 68 °F),or above 20 °C (68 °F)

• Road conditions – Good, poor, or off-road

• Vehicle load status – Unloaded, loaded, or fully loaded

• Transaxle status in manual mode – Upshift, downshift, overrun or acceleration

Testing Possible Causes of Transmission

Control Faults

Before performing a symptom-based diagnosis,

first carry out checks to eliminate various other

potential causes of the fault.

These situations include:

• Battery state of charge

• Defective fuses • Loose or corroded cables or electrical

connectors

• Ground connections to the transmission

• Retrofitted add-on units which are not approved by Ford, such as air conditioning, car telephone,

cruise control

• Unapproved tire sizes

• Incorrect tire size programmed with IDS (Integrated Diagnostic System)

• Engine tuning

IDS Diagnosis

NOTE: Customer concerns relating to the transaxle

can also be caused by engine-related faults.

The transmission control system of the AW55 is

closely linked to the engine management system.

Faults in the engine management system may

affect the transmission control system.

Before repairing the transaxle, it should be ensured

that the fault is not caused by the engine

management system or other non-transaxle

components.

The diagnosis can be performed on the AW55 with

the aid of von IDS.

visual inspection

A thorough visual inspection of the transaxle is

necessary for successful diagnosis.

A visual inspection is made of the following

components:

• Connectors and plug connections

• Ease of operation of the selector lever

G1163604en2008.50 Kuga8/2011

307-01- 14

Automatic Transmission/Transaxle

— Vehicles With:

5-Speed Automatic Transaxle - AW55 AWD

307-01- 14

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1840 of 2057

E77584

NOTE:Due to static charging, measurements

inside the transaxle using a multimeter are

prohibited.

Stored DTCs in the engine management system

may affect transmission control. As a result, faults

in the transmission control system and engine

management system must be rectified in

accordance with the symptom-based diagnosis in

FordEtis IDS.

Applications of IDS Standard include:

• Resetting the counter for fluid change intervals.

• Programming the selector lever position 'N'.

• Resetting the values learned by the TCM.

Resetting the counter for fluid change

intervals.

This function must be performed if the transmission

fluid has been changed or a new automatic

transaxle has been installed with the previous TCM.

This function resets the values stored for the

pollution level of the transmission fluid.

Programming the 'N' position of the TR

sensor

This function must be executed if

• the TCM with integrated TR sensor is renewed,

• a new automatic transaxle is installed with the previous TCM.

• the selector lever cable or the selector mechanism assembly is renewed

• TR have been set due to a fault in the selector lever assembly or in the DTC (diagnostic trouble

code) sensor.

The TCM learns and stores the voltage value in

the 'N' position when this function is executed.

Resetting the values learned by the TCM

This function must be executed if

• a new automatic transaxle is installed with the previous TCM.

• a component of the automatic transaxle has been renewed.

G1163604en2008.50 Kuga8/2011

307-01- 19

Automatic Transmission/Transaxle

— Vehicles With:

5-Speed Automatic Transaxle - AW55 AWD

307-01- 19

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL