can FORD KUGA 2011 1.G Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2011, Model line: KUGA, Model: FORD KUGA 2011 1.GPages: 2057

Page 1638 of 2057

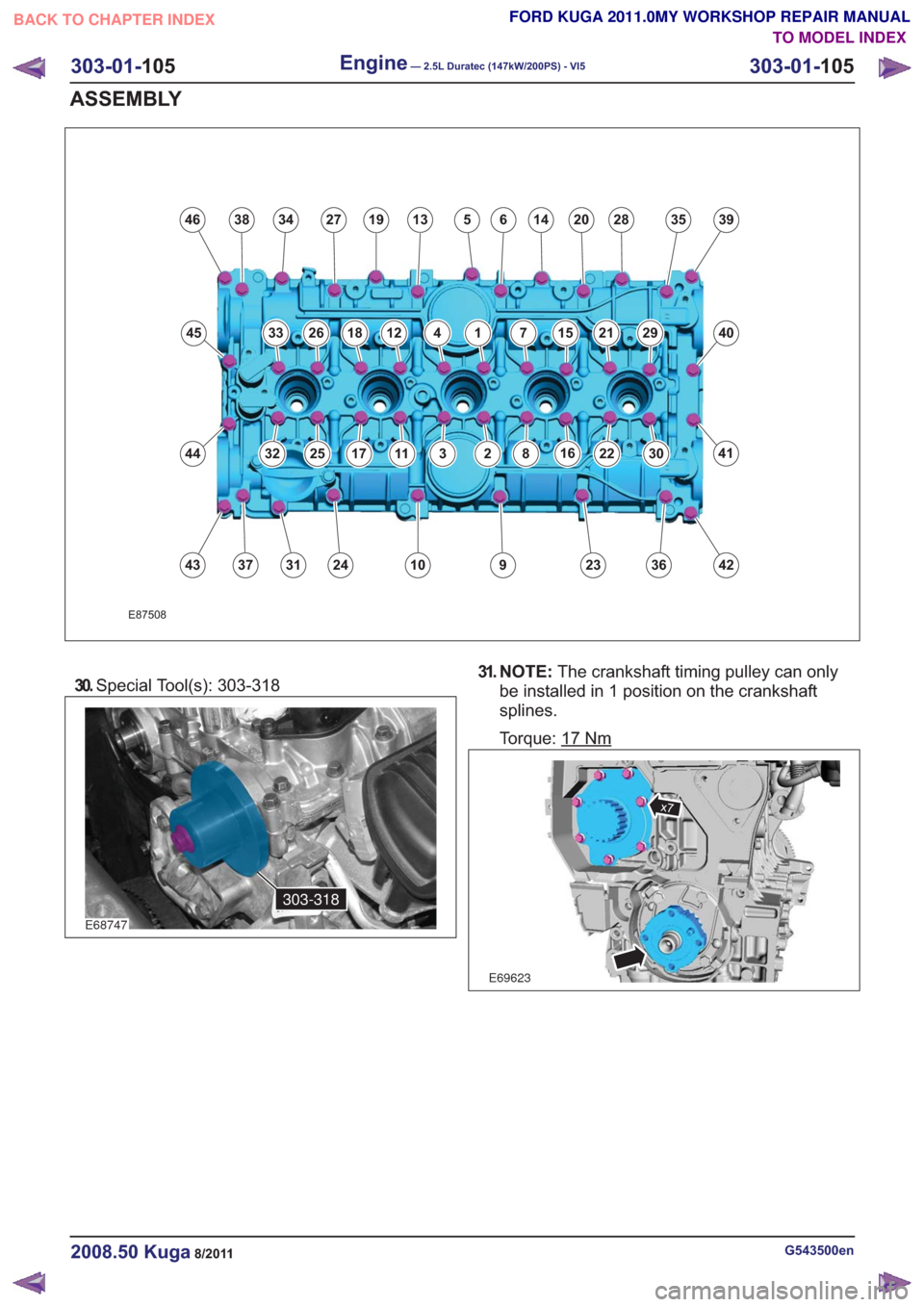

E87508

46

45

44

43

3834271913514202839

40

41

423623910243137

635

29211571412182633

30221682311172532

30.Special Tool(s): 303-318

E68747

303-318

31. N O T E : The crankshaft timing pulley can only

be installed in 1 position on the crankshaft

splines.

Torque: 17

Nm

E69623

x7

G543500en2008.50 Kuga8/2011

303-01- 105

Engine— 2.5L Duratec (147kW/200PS) - VI5303-01-

105

ASSEMBLY

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1681 of 2057

Coolant Pump — 2.5L Duratec (147kW/200PS) - VI5(24 404 0)

General EquipmentTrolley Jack

Removal

NOTE: Removal steps in this procedure may

contain installation details.

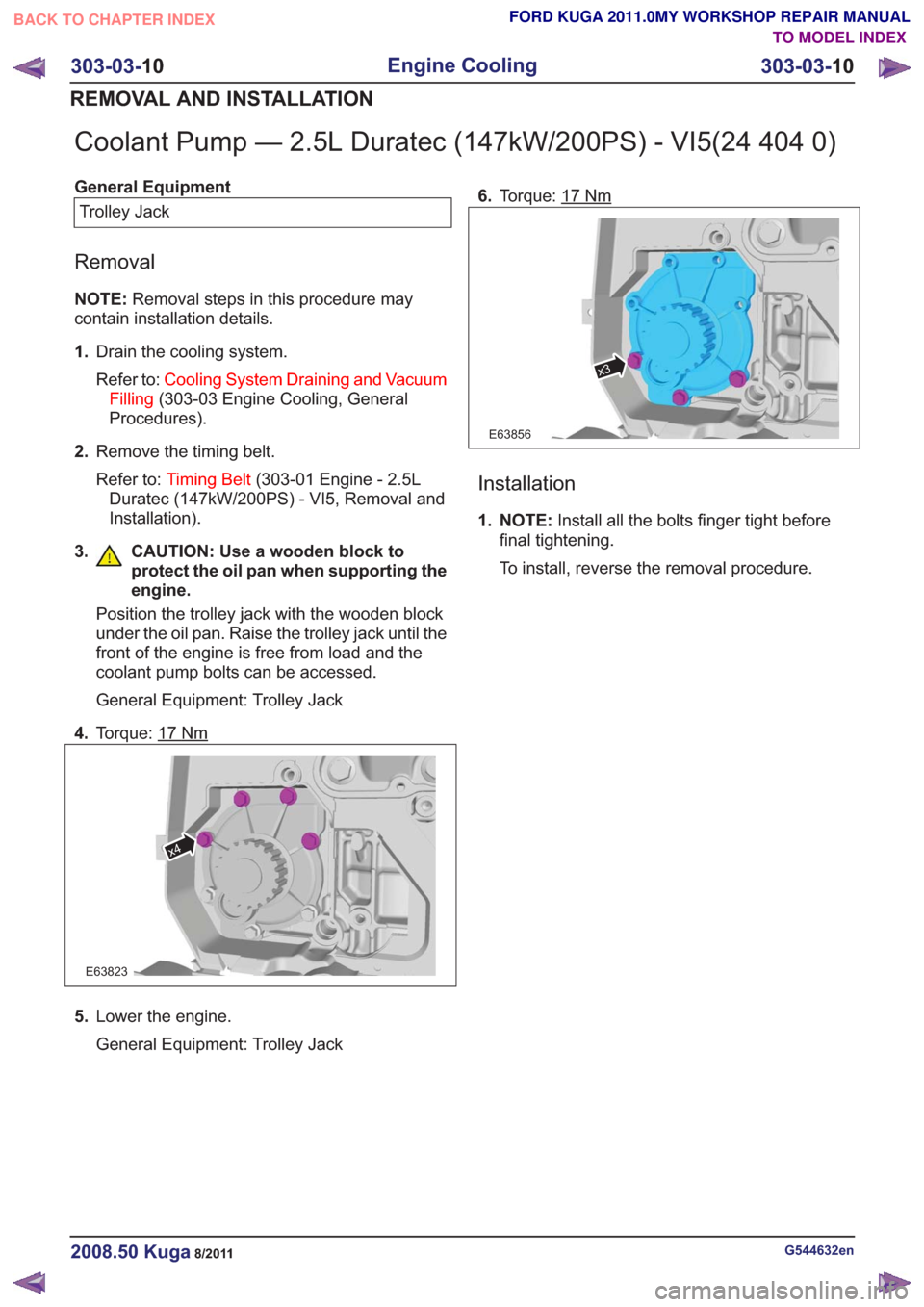

1. Drain the cooling system.

Refer to: Cooling System Draining and Vacuum

Filling (303-03 Engine Cooling, General

Procedures).

2. Remove the timing belt.

Refer to: Timing Belt (303-01 Engine - 2.5L

Duratec (147kW/200PS) - VI5, Removal and

Installation).

3. CAUTION: Use a wooden block to protect the oil pan when supporting the

engine.

Position the trolley jack with the wooden block

under the oil pan. Raise the trolley jack until the

front of the engine is free from load and the

coolant pump bolts can be accessed.

General Equipment: Trolley Jack

4. Torque: 17

Nm

E63823

x4

5.Lower the engine.

General Equipment: Trolley Jack 6.

Torque: 17

Nm

x3

E63856

Installation

1. NOTE: Install all the bolts finger tight before

final tightening.

To install, reverse the removal procedure.

G544632en2008.50 Kuga8/2011

303-03- 10

Engine Cooling

303-03- 10

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1720 of 2057

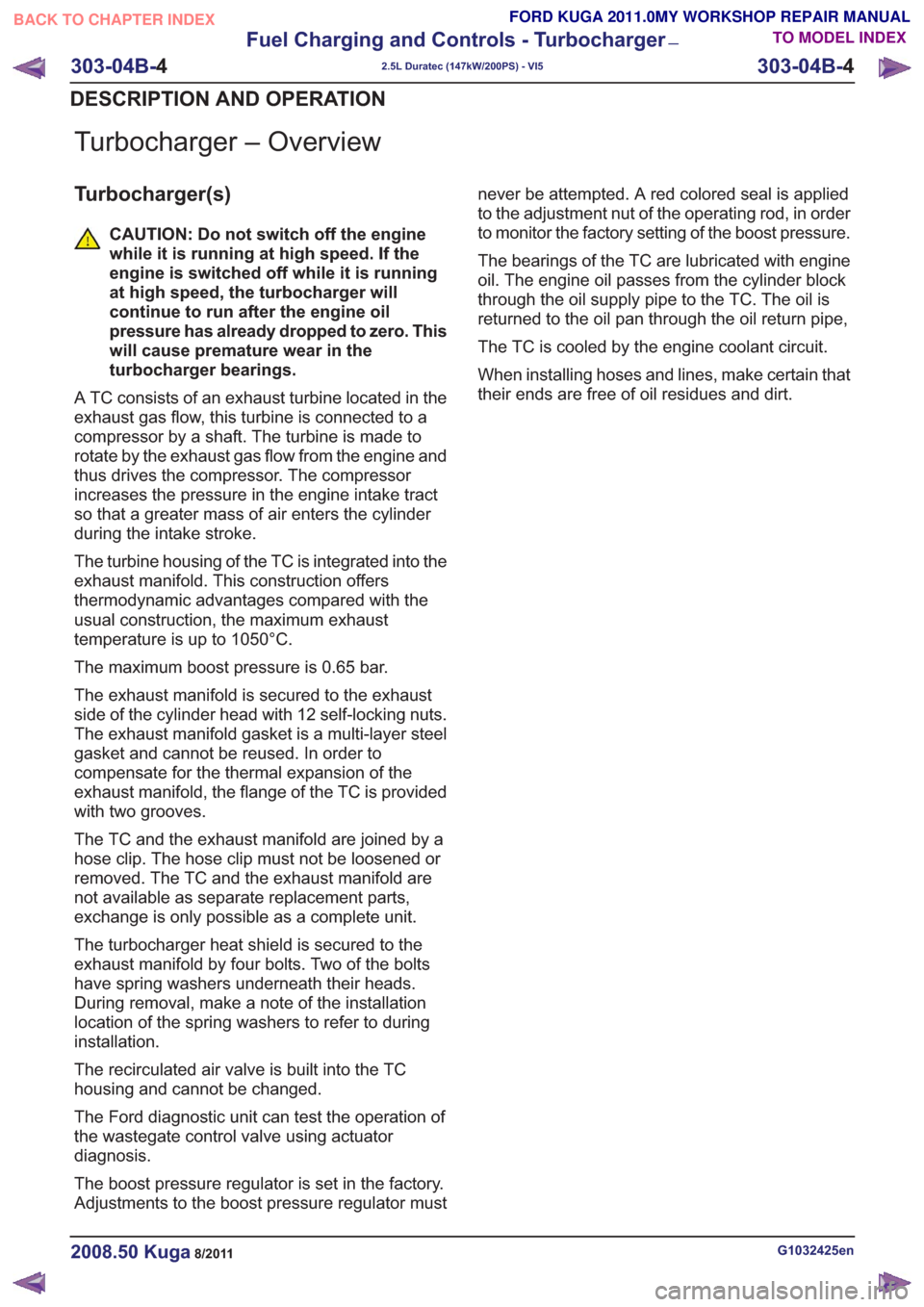

Turbocharger – Overview

Turbocharger(s)

CAUTION: Do not switch off the engine

while it is running at high speed. If the

engine is switched off while it is running

at high speed, the turbocharger will

continue to run after the engine oil

pressure has already dropped to zero. This

will cause premature wear in the

turbocharger bearings.

A TC consists of an exhaust turbine located in the

exhaust gas flow, this turbine is connected to a

compressor by a shaft. The turbine is made to

rotate by the exhaust gas flow from the engine and

thus drives the compressor. The compressor

increases the pressure in the engine intake tract

so that a greater mass of air enters the cylinder

during the intake stroke.

The turbine housing of the TC is integrated into the

exhaust manifold. This construction offers

thermodynamic advantages compared with the

usual construction, the maximum exhaust

temperature is up to 1050°C.

The maximum boost pressure is 0.65 bar.

The exhaust manifold is secured to the exhaust

side of the cylinder head with 12 self-locking nuts.

The exhaust manifold gasket is a multi-layer steel

gasket and cannot be reused. In order to

compensate for the thermal expansion of the

exhaust manifold, the flange of the TC is provided

with two grooves.

The TC and the exhaust manifold are joined by a

hose clip. The hose clip must not be loosened or

removed. The TC and the exhaust manifold are

not available as separate replacement parts,

exchange is only possible as a complete unit.

The turbocharger heat shield is secured to the

exhaust manifold by four bolts. Two of the bolts

have spring washers underneath their heads.

During removal, make a note of the installation

location of the spring washers to refer to during

installation.

The recirculated air valve is built into the TC

housing and cannot be changed.

The Ford diagnostic unit can test the operation of

the wastegate control valve using actuator

diagnosis.

The boost pressure regulator is set in the factory.

Adjustments to the boost pressure regulator must never be attempted. A red colored seal is applied

to the adjustment nut of the operating rod, in order

to monitor the factory setting of the boost pressure.

The bearings of the TC are lubricated with engine

oil. The engine oil passes from the cylinder block

through the oil supply pipe to the TC. The oil is

returned to the oil pan through the oil return pipe,

The TC is cooled by the engine coolant circuit.

When installing hoses and lines, make certain that

their ends are free of oil residues and dirt.

G1032425en2008.50 Kuga8/2011

303-04B-

4

Fuel Charging and Controls - Turbocharger

—

2.5L Duratec (147kW/200PS) - VI5

303-04B- 4

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1722 of 2057

Description

Item

PWM (pulse width modulation) signal

Comments:from PCM (powertrain control module)

5

Atmospheric pressure

6

Turbocharger boost pressure.

7

from air filter

8

Intake air

9Description

Item

Recirculated air valveRefertoComponentDescription:(page

7)

10

Vacuum line, recirculated air valve

11

to intake manifold

12

Throttle plate

13

Compressor

14

Turbine

15

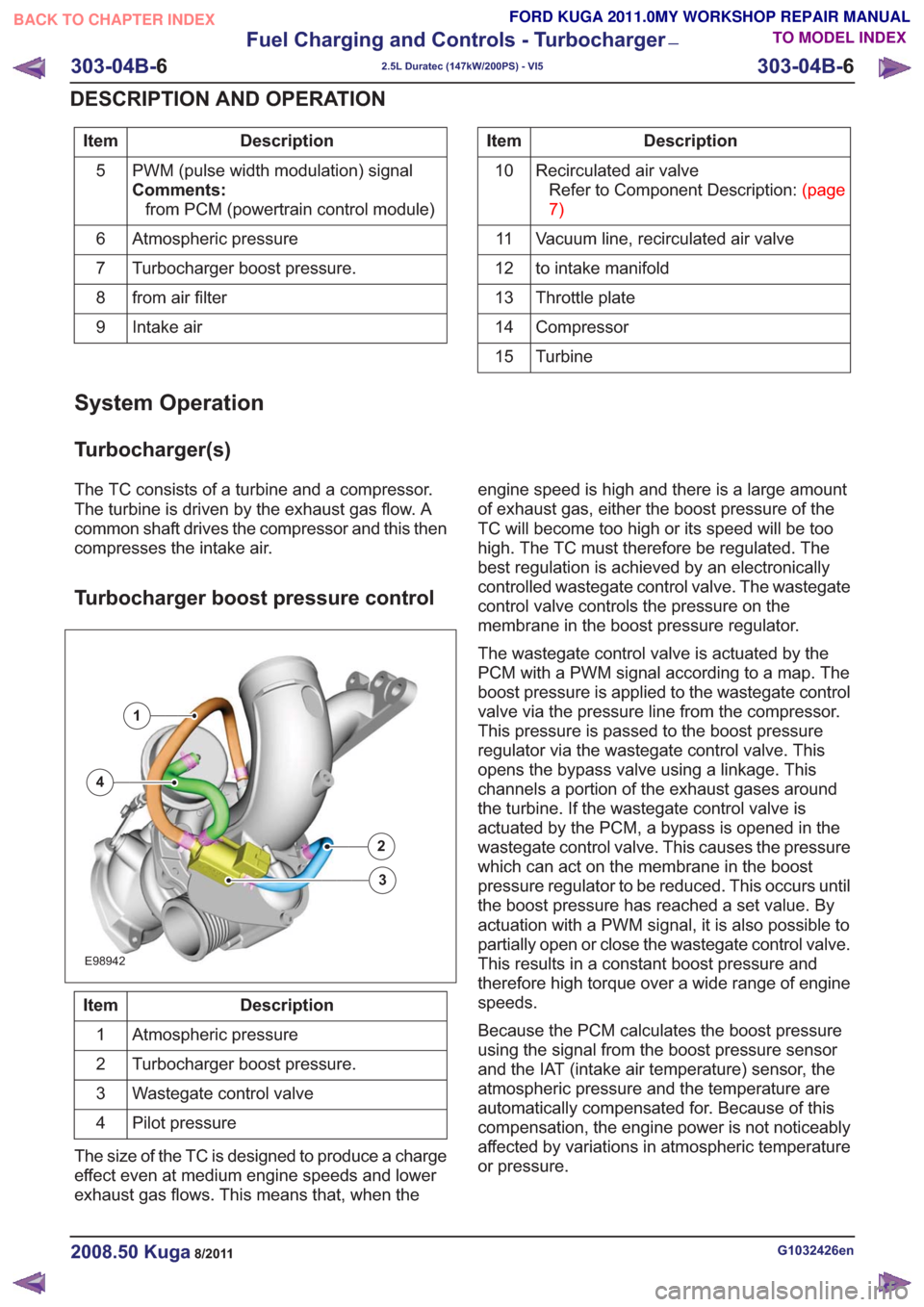

System Operation

Turbocharger(s)

The TC consists of a turbine and a compressor.

The turbine is driven by the exhaust gas flow. A

common shaft drives the compressor and this then

compresses the intake air.

Turbocharger boost pressure control

E98942

1

2

3

4

Description

Item

Atmospheric pressure

1

Turbocharger boost pressure.

2

Wastegate control valve

3

Pilot pressure

4

The size of the TC is designed to produce a charge

effect even at medium engine speeds and lower

exhaust gas flows. This means that, when the engine speed is high and there is a large amount

of exhaust gas, either the boost pressure of the

TC will become too high or its speed will be too

high. The TC must therefore be regulated. The

best regulation is achieved by an electronically

controlled wastegate control valve. The wastegate

control valve controls the pressure on the

membrane in the boost pressure regulator.

The wastegate control valve is actuated by the

PCM with a PWM signal according to a map. The

boost pressure is applied to the wastegate control

valve via the pressure line from the compressor.

This pressure is passed to the boost pressure

regulator via the wastegate control valve. This

opens the bypass valve using a linkage. This

channels a portion of the exhaust gases around

the turbine. If the wastegate control valve is

actuated by the PCM, a bypass is opened in the

wastegate control valve. This causes the pressure

which can act on the membrane in the boost

pressure regulator to be reduced. This occurs until

the boost pressure has reached a set value. By

actuation with a PWM signal, it is also possible to

partially open or close the wastegate control valve.

This results in a constant boost pressure and

therefore high torque over a wide range of engine

speeds.

Because the PCM calculates the boost pressure

using the signal from the boost pressure sensor

and the IAT (intake air temperature) sensor, the

atmospheric pressure and the temperature are

automatically compensated for. Because of this

compensation, the engine power is not noticeably

affected by variations in atmospheric temperature

or pressure.

G1032426en2008.50 Kuga8/2011

303-04B-

6

Fuel Charging and Controls - Turbocharger

—

2.5L Duratec (147kW/200PS) - VI5

303-04B- 6

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1723 of 2057

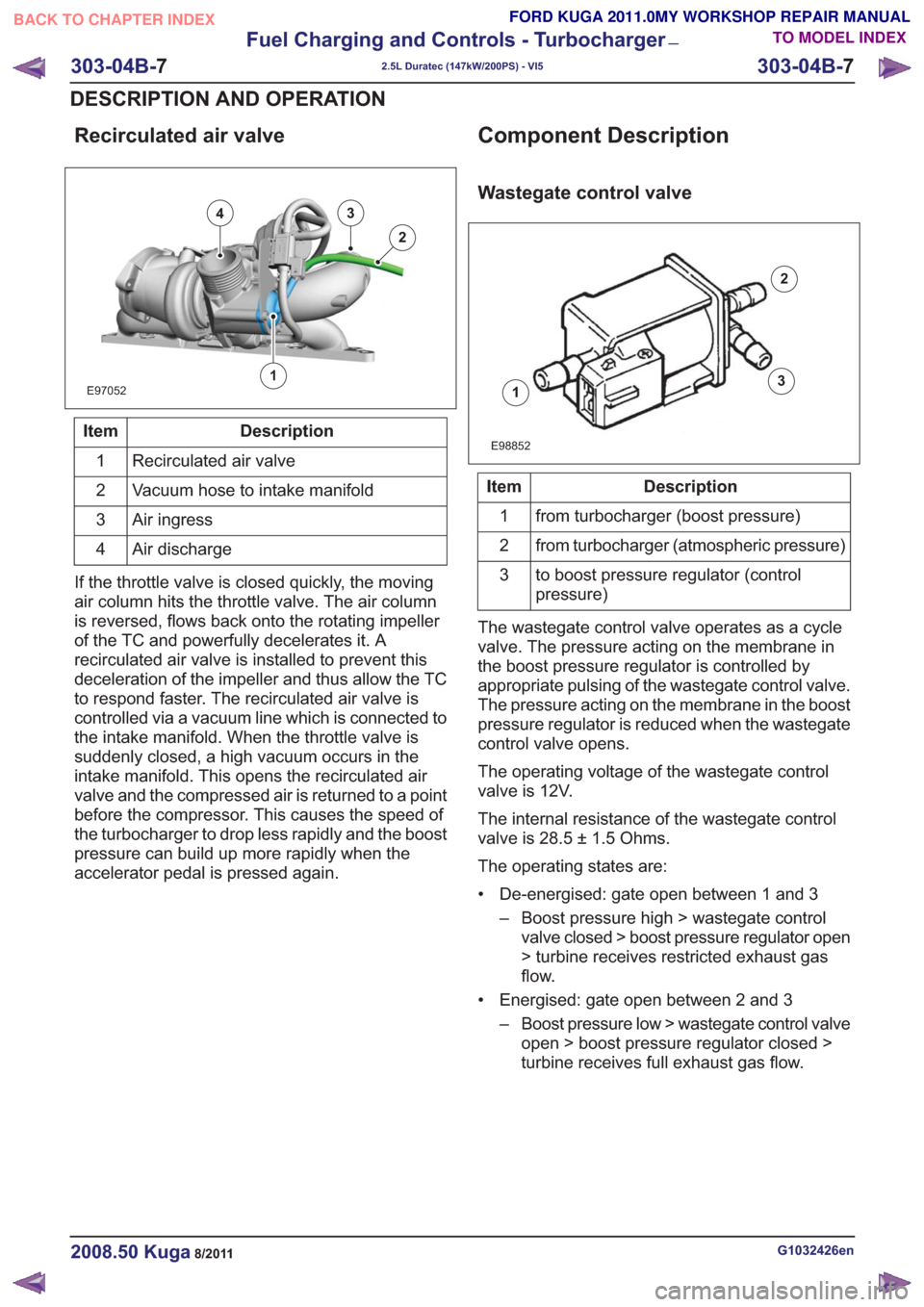

Recirculated air valve

E97052

43

2

1

Description

Item

Recirculated air valve

1

Vacuum hose to intake manifold

2

Air ingress

3

Air discharge

4

If the throttle valve is closed quickly, the moving

air column hits the throttle valve. The air column

is reversed, flows back onto the rotating impeller

of the TC and powerfully decelerates it. A

recirculated air valve is installed to prevent this

deceleration of the impeller and thus allow the TC

to respond faster. The recirculated air valve is

controlled via a vacuum line which is connected to

the intake manifold. When the throttle valve is

suddenly closed, a high vacuum occurs in the

intake manifold. This opens the recirculated air

valve and the compressed air is returned to a point

before the compressor. This causes the speed of

the turbocharger to drop less rapidly and the boost

pressure can build up more rapidly when the

accelerator pedal is pressed again.

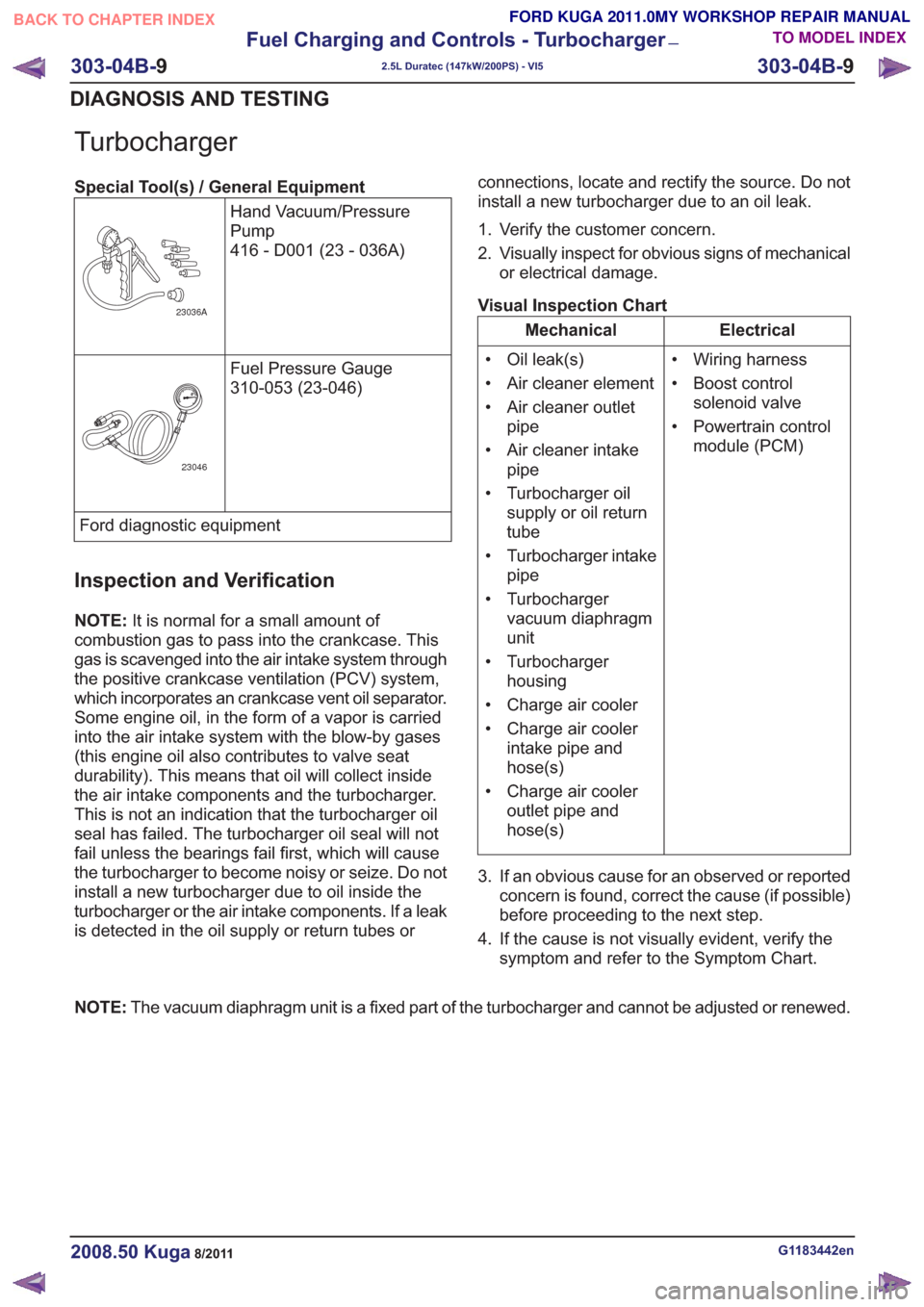

Component Description

Wastegate control valve

1

2

3

E98852

Description

Item

from turbocharger (boost pressure)

1

from turbocharger (atmospheric pressure)

2

to boost pressure regulator (control

pressure)

3

The wastegate control valve operates as a cycle

valve. The pressure acting on the membrane in

the boost pressure regulator is controlled by

appropriate pulsing of the wastegate control valve.

The pressure acting on the membrane in the boost

pressure regulator is reduced when the wastegate

control valve opens.

The operating voltage of the wastegate control

valve is 12V.

The internal resistance of the wastegate control

valve is 28.5 ± 1.5 Ohms.

The operating states are:

• De-energised: gate open between 1 and 3 – Boost pressure high > wastegate controlvalve closed > boost pressure regulator open

> turbine receives restricted exhaust gas

flow.

• Energised: gate open between 2 and 3 – Boost pressure low > wastegate control valveopen > boost pressure regulator closed >

turbine receives full exhaust gas flow.

G1032426en2008.50 Kuga8/2011

303-04B- 7

Fuel Charging and Controls - Turbocharger

—

2.5L Duratec (147kW/200PS) - VI5

303-04B- 7

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1725 of 2057

Turbocharger

Special Tool(s) / General EquipmentHand Vacuum/Pressure

Pump

416 - D001 (23 - 036A)

23036A

Fuel Pressure Gauge

310-053 (23-046)

23046

Ford diagnostic equipment

Inspection and Verification

NOTE:It is normal for a small amount of

combustion gas to pass into the crankcase. This

gas is scavenged into the air intake system through

the positive crankcase ventilation (PCV) system,

which incorporates an crankcase vent oil separator.

Some engine oil, in the form of a vapor is carried

into the air intake system with the blow-by gases

(this engine oil also contributes to valve seat

durability). This means that oil will collect inside

the air intake components and the turbocharger.

This is not an indication that the turbocharger oil

seal has failed. The turbocharger oil seal will not

fail unless the bearings fail first, which will cause

the turbocharger to become noisy or seize. Do not

install a new turbocharger due to oil inside the

turbocharger or the air intake components. If a leak

is detected in the oil supply or return tubes or connections, locate and rectify the source. Do not

install a new turbocharger due to an oil leak.

1. Verify the customer concern.

2. Visually inspect for obvious signs of mechanical

or electrical damage.

Visual Inspection Chart

Electrical

Mechanical

• Wiring harness

• Boost controlsolenoid valve

• Powertrain control module (PCM)

• Oil leak(s)

• Air cleaner element

• Air cleaner outlet

pipe

• Air cleaner intake pipe

• Turbocharger oil supply or oil return

tube

• Turbocharger intake pipe

• Turbocharger vacuum diaphragm

unit

• Turbocharger housing

• Charge air cooler

• Charge air cooler intake pipe and

hose(s)

• Charge air cooler outlet pipe and

hose(s)

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible)

before proceeding to the next step.

4. If the cause is not visually evident, verify the symptom and refer to the Symptom Chart.

NOTE: The vacuum diaphragm unit is a fixed part of the turbocharger and cannot be adjusted or renewed.

G1183442en2008.50 Kuga8/2011

303-04B- 9

Fuel Charging and Controls - Turbocharger

—

2.5L Duratec (147kW/200PS) - VI5

303-04B- 9

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1734 of 2057

Accessory Drive

Inspection and Verification

1. Verify the customer concern.

2. Visually inspect for obvious signs of mechanicaldamage.

Visual Inspection Chart

Mechanical

– Damaged or contaminated accessory drive belt or air conditioning (A/C) compressor belt

– Damaged or contaminated pulley(s)

– Incorrect accessory drive belt or A/C compressor belt

– Incorrect fitment of the accessory drive belt or A/C compressor belt

– Accessory drive belt tensioner

– Accessory drive belt idler pulley

– Generator

– A/C compressor

– A/C compressor belt tensioner

– Pulley(s)

– Loose hardware

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible)

before proceeding to the next step.

Accessory Drive Belt Concerns

CAUTION: Do not lubricate the accessory

drive belt, accessory drive belt tensioner(s)

or idler pulley(s) as potential damage to

the accessory drive belt material

construction, accessory drive belt

tensioner damping mechanism, accessory

drive belt tensioner pulley bearing and idler

pulley(s) bearing may occur.

NOTE: All the diagnosis and testing information

contained within this procedure can be used for

the accessory drive belt and the A/C compressor

belt.

Cracking

Accessory drive belts are made from rubber which

hardens with time and can develop cracks. As the

accessory drive belt runs on the back of some of

the pulleys, the cracks are opened up. Small cracks

are not considered to be a failure of the accessory drive belt. Only if the crack is deep enough to reach

the bottom of the groove to expose the cord or any

chunks are found to be missing from the accessory

drive belt, is the accessory drive belt condition

considered to be unacceptable.

1. Check the accessory drive belt for cracks. If the

damage exceeds the acceptable limit, install a

new accessory drive belt.

REFER to: Accessory Drive Belt (303-05

Accessory Drive - 2.5L Duratec

(147kW/200PS) - VI5, Removal and

Installation).

and/or

REFER to: Air Conditioning (A/C) Compressor

Belt (303-05 Accessory Drive - 2.5L Duratec

(147kW/200PS) - VI5, Removal and

Installation).

Chunking

Chunking describes the condition where long

lengths of rubber become detached from the ribs

of the accessory drive belt. This is considered to

be a failure of the accessory drive belt.

MPZ9632071

2. Check the accessory drive belt for damage. If any chunks are found to be missing, install a

new accessory drive belt.

REFER to: Accessory Drive Belt (303-05

Accessory Drive - 2.5L Duratec

(147kW/200PS) - VI5, Removal and

Installation).

and/or

REFER to: Air Conditioning (A/C) Compressor

Belt (303-05 Accessory Drive - 2.5L Duratec

(147kW/200PS) - VI5, Removal and

Installation).

G1183443en2008.50 Kuga8/2011

303-05- 4

Accessory Drive— 2.5L Duratec (147kW/200PS) - VI5303-05-

4

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1735 of 2057

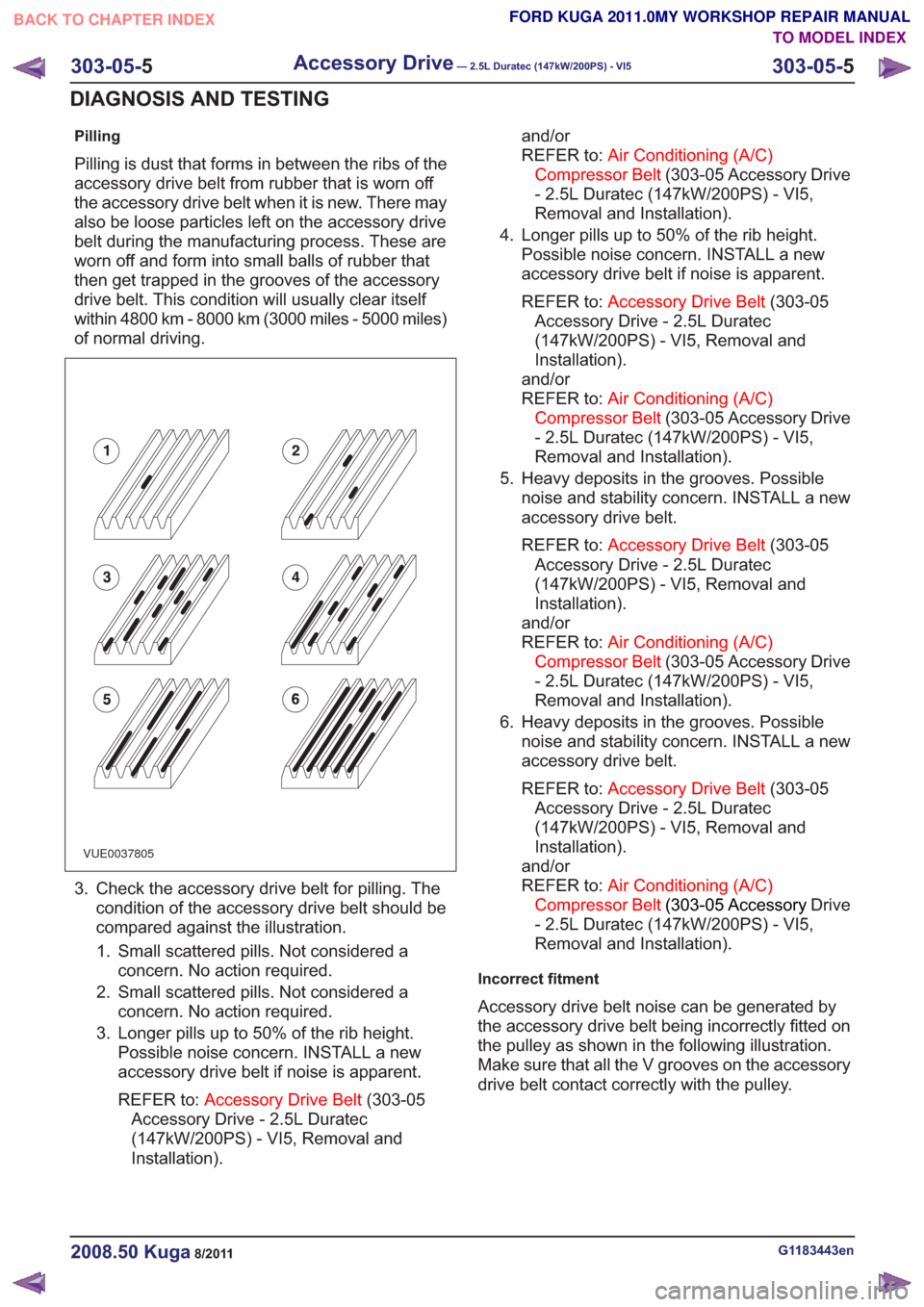

Pilling

Pilling is dust that forms in between the ribs of the

accessory drive belt from rubber that is worn off

the accessory drive belt when it is new. There may

also be loose particles left on the accessory drive

belt during the manufacturing process. These are

worn off and form into small balls of rubber that

then get trapped in the grooves of the accessory

drive belt. This condition will usually clear itself

within 4800 km - 8000 km (3000 miles - 5000 miles)

of normal driving.

VUE0037805

3. Check the accessory drive belt for pilling. Thecondition of the accessory drive belt should be

compared against the illustration.

1. Small scattered pills. Not considered a concern. No action required.

2. Small scattered pills. Not considered a concern. No action required.

3. Longer pills up to 50% of the rib height. Possible noise concern. INSTALL a new

accessory drive belt if noise is apparent.

REFER to: Accessory Drive Belt (303-05

Accessory Drive - 2.5L Duratec

(147kW/200PS) - VI5, Removal and

Installation). and/or

REFER to:

Air Conditioning (A/C)

Compressor Belt (303-05 Accessory Drive

- 2.5L Duratec (147kW/200PS) - VI5,

Removal and Installation).

4. Longer pills up to 50% of the rib height. Possible noise concern. INSTALL a new

accessory drive belt if noise is apparent.

REFER to: Accessory Drive Belt (303-05

Accessory Drive - 2.5L Duratec

(147kW/200PS) - VI5, Removal and

Installation).

and/or

REFER to: Air Conditioning (A/C)

Compressor Belt (303-05 Accessory Drive

- 2.5L Duratec (147kW/200PS) - VI5,

Removal and Installation).

5. Heavy deposits in the grooves. Possible noise and stability concern. INSTALL a new

accessory drive belt.

REFER to: Accessory Drive Belt (303-05

Accessory Drive - 2.5L Duratec

(147kW/200PS) - VI5, Removal and

Installation).

and/or

REFER to: Air Conditioning (A/C)

Compressor Belt (303-05 Accessory Drive

- 2.5L Duratec (147kW/200PS) - VI5,

Removal and Installation).

6. Heavy deposits in the grooves. Possible noise and stability concern. INSTALL a new

accessory drive belt.

REFER to: Accessory Drive Belt (303-05

Accessory Drive - 2.5L Duratec

(147kW/200PS) - VI5, Removal and

Installation).

and/or

REFER to: Air Conditioning (A/C)

Compressor Belt (303-05 AccessoryDrive

- 2.5L Duratec (147kW/200PS) - VI5,

Removal and Installation).

Incorrect fitment

Accessory drive belt noise can be generated by

the accessory drive belt being incorrectly fitted on

the pulley as shown in the following illustration.

Make sure that all the V grooves on the accessory

drive belt contact correctly with the pulley.

G1183443en2008.50 Kuga8/2011

303-05- 5

Accessory Drive— 2.5L Duratec (147kW/200PS) - VI5303-05-

5

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1737 of 2057

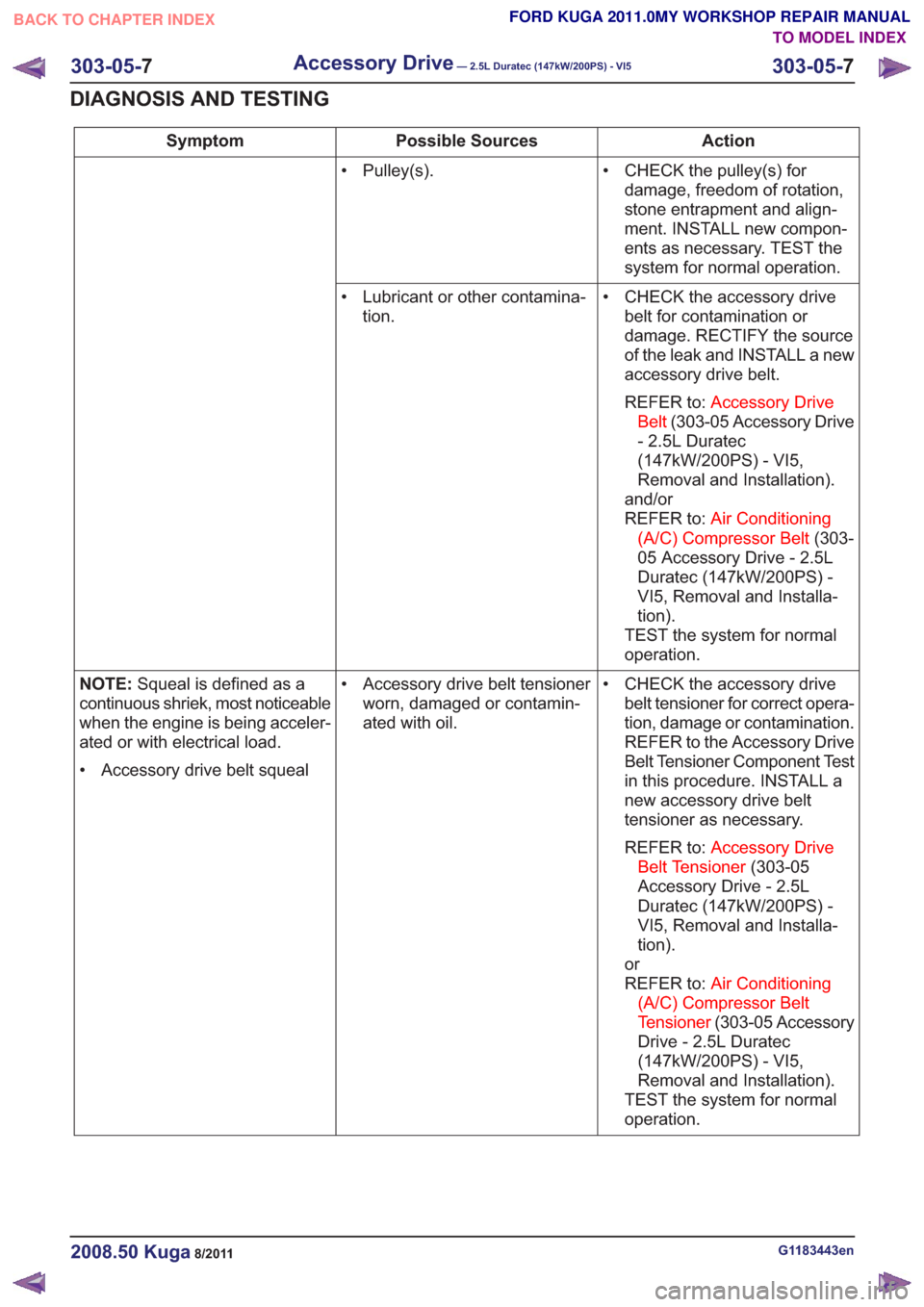

Action

Possible Sources

Symptom

• CHECK the pulley(s) fordamage, freedom of rotation,

stone entrapment and align-

ment. INSTALL new compon-

ents as necessary. TEST the

system for normal operation.

• Pulley(s).

• CHECK the accessory drivebelt for contamination or

damage. RECTIFY the source

of the leak and INSTALL a new

accessory drive belt.

REFER to: Accessory Drive

Belt (303-05 Accessory Drive

- 2.5L Duratec

(147kW/200PS) - VI5,

Removal and Installation).

and/or

REFER to: Air Conditioning

(A/C) Compressor Belt (303-

05 Accessory Drive - 2.5L

Duratec (147kW/200PS) -

VI5, Removal and Installa-

tion).

TEST the system for normal

operation.

• Lubricant or other contamina-

tion.

• CHECK the accessory drivebelt tensioner for correct opera-

tion, damage or contamination.

REFER to the Accessory Drive

Belt Tensioner Component Test

in this procedure. INSTALL a

new accessory drive belt

tensioner as necessary.

REFER to: Accessory Drive

Belt Tensioner (303-05

Accessory Drive - 2.5L

Duratec (147kW/200PS) -

VI5, Removal and Installa-

tion).

or

REFER to: Air Conditioning

(A/C) Compressor Belt

Tensioner (303-05 Accessory

Drive - 2.5L Duratec

(147kW/200PS) - VI5,

Removal and Installation).

TEST the system for normal

operation.

• Accessory drive belt tensioner

worn, damaged or contamin-

ated with oil.

NOTE:

Squeal is defined as a

continuous shriek, most noticeable

when the engine is being acceler-

ated or with electrical load.

• Accessory drive belt squeal

G1183443en2008.50 Kuga8/2011

303-05- 7

Accessory Drive— 2.5L Duratec (147kW/200PS) - VI5303-05-

7

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1739 of 2057

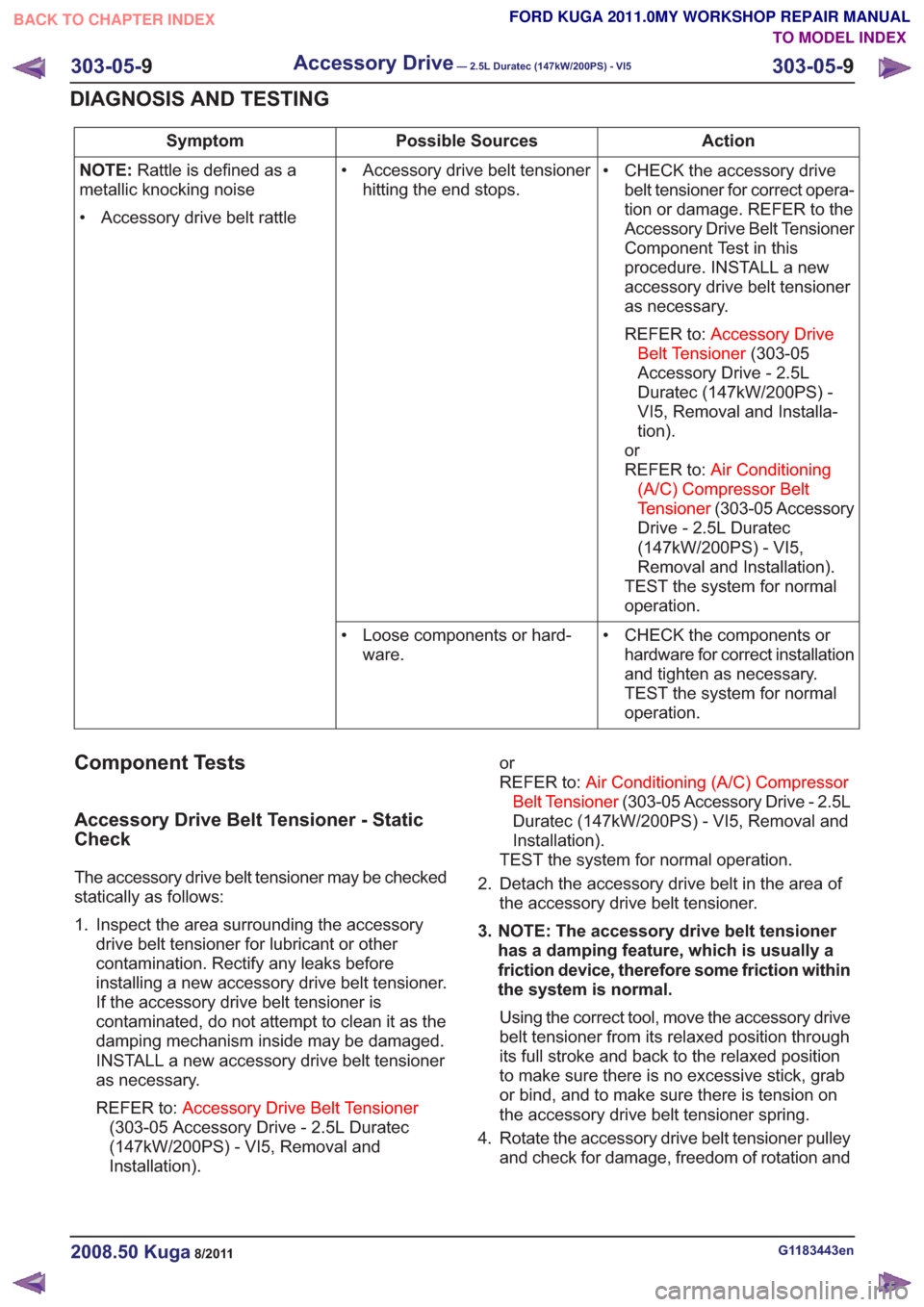

Action

Possible Sources

Symptom

• CHECK the accessory drivebelt tensioner for correct opera-

tion or damage. REFER to the

Accessory Drive Belt Tensioner

Component Test in this

procedure. INSTALL a new

accessory drive belt tensioner

as necessary.

REFER to: Accessory Drive

Belt Tensioner (303-05

Accessory Drive - 2.5L

Duratec (147kW/200PS) -

VI5, Removal and Installa-

tion).

or

REFER to: Air Conditioning

(A/C) Compressor Belt

Tensioner (303-05 Accessory

Drive - 2.5L Duratec

(147kW/200PS) - VI5,

Removal and Installation).

TEST the system for normal

operation.

• Accessory drive belt tensioner

hitting the end stops.

NOTE:

Rattle is defined as a

metallic knocking noise

• Accessory drive belt rattle

• CHECK the components orhardware for correct installation

and tighten as necessary.

TEST the system for normal

operation.

• Loose components or hard-

ware.

Component Tests

Accessory Drive Belt Tensioner - Static

Check

The accessory drive belt tensioner may be checked

statically as follows:

1. Inspect the area surrounding the accessorydrive belt tensioner for lubricant or other

contamination. Rectify any leaks before

installing a new accessory drive belt tensioner.

If the accessory drive belt tensioner is

contaminated, do not attempt to clean it as the

damping mechanism inside may be damaged.

INSTALL a new accessory drive belt tensioner

as necessary.

REFER to: Accessory Drive Belt Tensioner

(303-05 Accessory Drive - 2.5L Duratec

(147kW/200PS) - VI5, Removal and

Installation). or

REFER to:

Air Conditioning (A/C) Compressor

Belt Tensioner (303-05 Accessory Drive - 2.5L

Duratec (147kW/200PS) - VI5, Removal and

Installation).

TEST the system for normal operation.

2. Detach the accessory drive belt in the area of the accessory drive belt tensioner.

3. NOTE: The accessory drive belt tensioner has a damping feature, which is usually a

friction device, therefore some friction within

the system is normal.

Using the correct tool, move the accessory drive

belt tensioner from its relaxed position through

its full stroke and back to the relaxed position

to make sure there is no excessive stick, grab

or bind, and to make sure there is tension on

the accessory drive belt tensioner spring.

4. Rotate the accessory drive belt tensioner pulley and check for damage, freedom of rotation and

G1183443en2008.50 Kuga8/2011

303-05- 9

Accessory Drive— 2.5L Duratec (147kW/200PS) - VI5303-05-

9

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL