front FORD KUGA 2011 1.G Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2011, Model line: KUGA, Model: FORD KUGA 2011 1.GPages: 2057

Page 1671 of 2057

67.Install the following items:

1. Refer to: Battery(414-01 Battery, Mounting

and Cables, Removal and Installation).

2. Refer to: Cowl Panel Grille (501-02 Front

End Body Panels, Removal and

Installation).

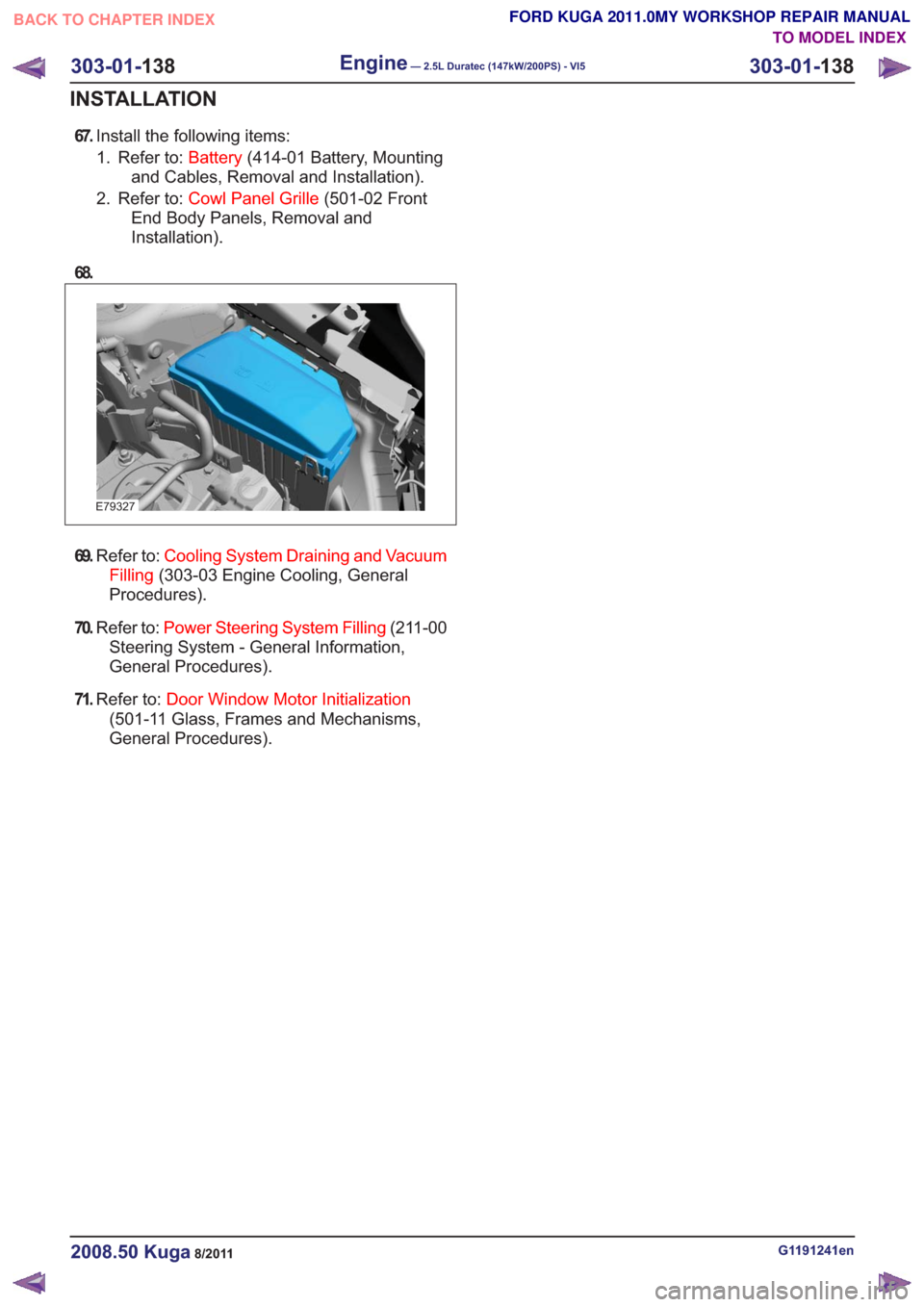

68.

E79327

69. Refer to: Cooling System Draining and Vacuum

Filling (303-03 Engine Cooling, General

Procedures).

70. Refer to: Power Steering System Filling (211-00

Steering System - General Information,

General Procedures).

71. Refer to: Door Window Motor Initialization

(501-11 Glass, Frames and Mechanisms,

General Procedures).

G1191241en2008.50 Kuga8/2011

303-01- 138

Engine— 2.5L Duratec (147kW/200PS) - VI5303-01-

138

INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1681 of 2057

Coolant Pump — 2.5L Duratec (147kW/200PS) - VI5(24 404 0)

General EquipmentTrolley Jack

Removal

NOTE: Removal steps in this procedure may

contain installation details.

1. Drain the cooling system.

Refer to: Cooling System Draining and Vacuum

Filling (303-03 Engine Cooling, General

Procedures).

2. Remove the timing belt.

Refer to: Timing Belt (303-01 Engine - 2.5L

Duratec (147kW/200PS) - VI5, Removal and

Installation).

3. CAUTION: Use a wooden block to protect the oil pan when supporting the

engine.

Position the trolley jack with the wooden block

under the oil pan. Raise the trolley jack until the

front of the engine is free from load and the

coolant pump bolts can be accessed.

General Equipment: Trolley Jack

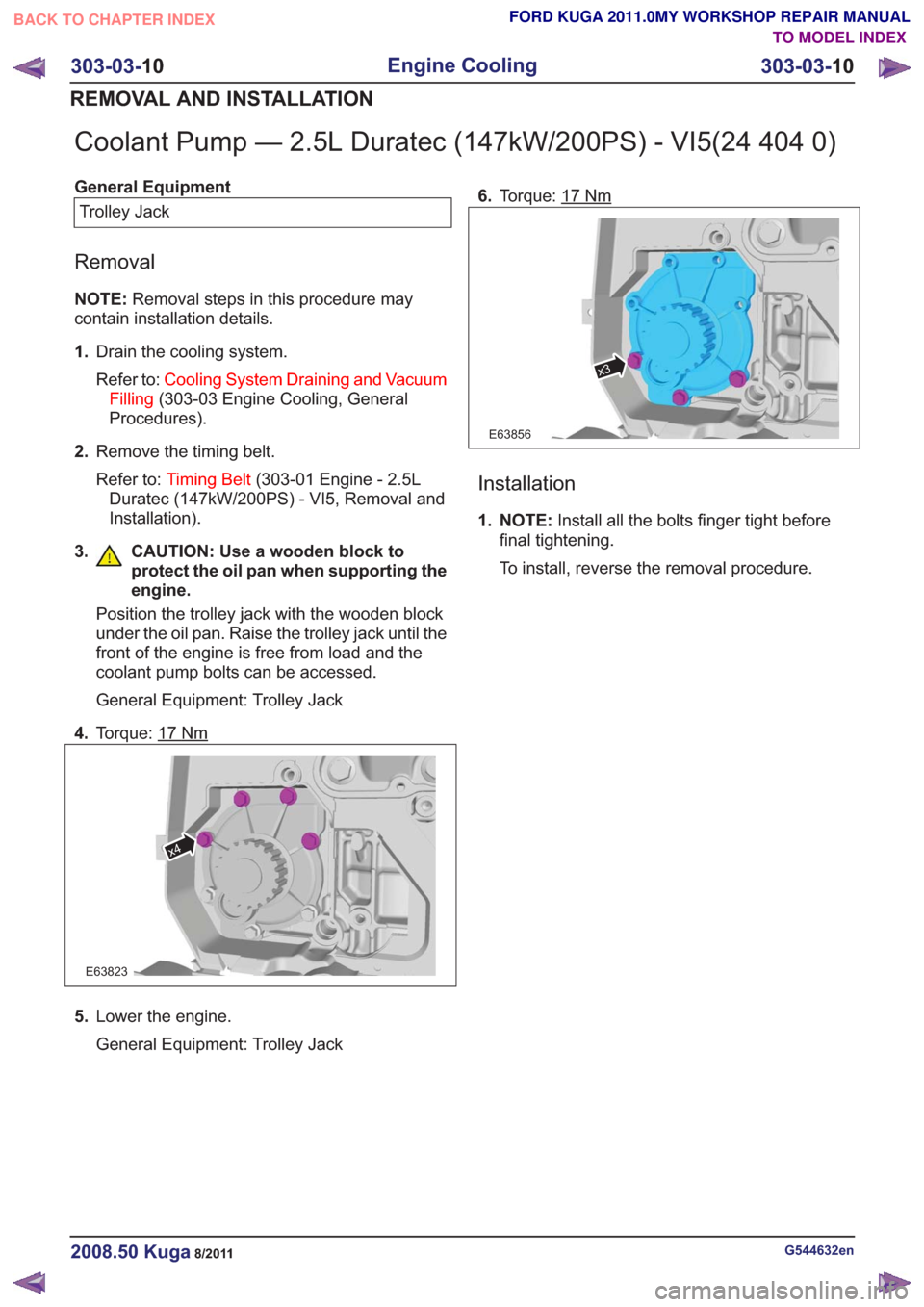

4. Torque: 17

Nm

E63823

x4

5.Lower the engine.

General Equipment: Trolley Jack 6.

Torque: 17

Nm

x3

E63856

Installation

1. NOTE: Install all the bolts finger tight before

final tightening.

To install, reverse the removal procedure.

G544632en2008.50 Kuga8/2011

303-03- 10

Engine Cooling

303-03- 10

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1727 of 2057

Turbocharger(23 612 0)

General EquipmentCable Ties

Hose Clamp Remover/Installer

Materials

Specification

Name

SA-M1C9107-A / YS5J-

M1C9107-AA

Grease KS-PS

Removal

NOTE:

Removal steps in this procedure may

contain installation details.

1. Refer to: Battery Disconnect and Connect

(414-01 Battery, Mounting and Cables,

General Procedures).

2. Refer to: Cooling System Draining and Vacuum

Filling (303-03 Engine Cooling, General

Procedures).

3. Refer to: Cowl Panel Grille (501-02 Front End

Body Panels, Removal and Installation).

4.

E65070

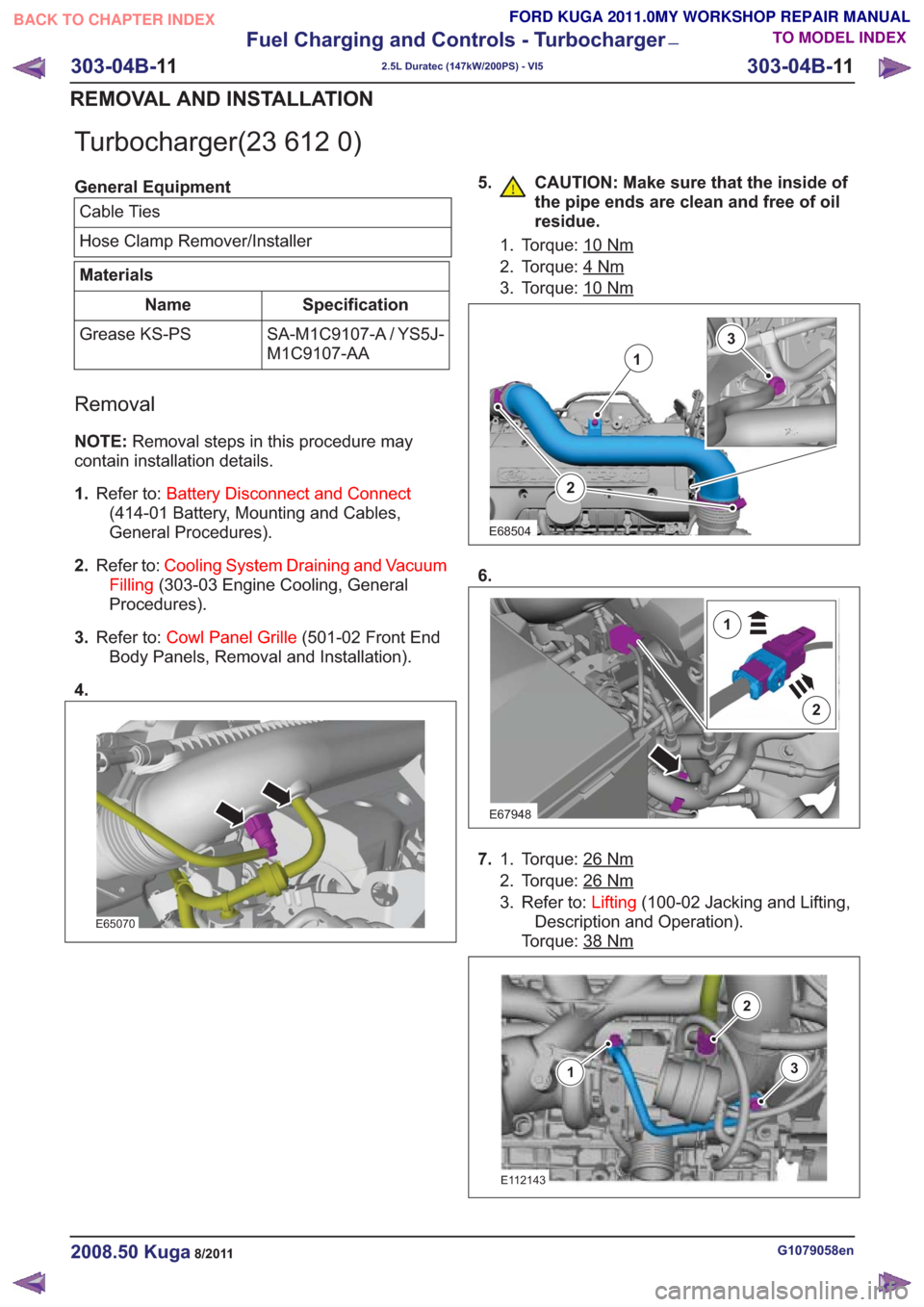

5. CAUTION: Make sure that the inside of the pipe ends are clean and free of oil

residue.

1. Torque: 10Nm

2. Torque: 4Nm

3. Torque: 10Nm

2

1

3

E68504

6.

E67948

2

1

7.Torque: 26Nm1.

2. Torque: 26

Nm

3. Refer to: Lifting(100-02 Jacking and Lifting,

Description and Operation).

Torque: 38

Nm

E112143

3

2

1

G1079058en2008.50 Kuga8/2011

303-04B- 11

Fuel Charging and Controls - Turbocharger

—

2.5L Duratec (147kW/200PS) - VI5

303-04B- 11

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1743 of 2057

Air Conditioning (A/C) Compressor Belt(21 567 0)

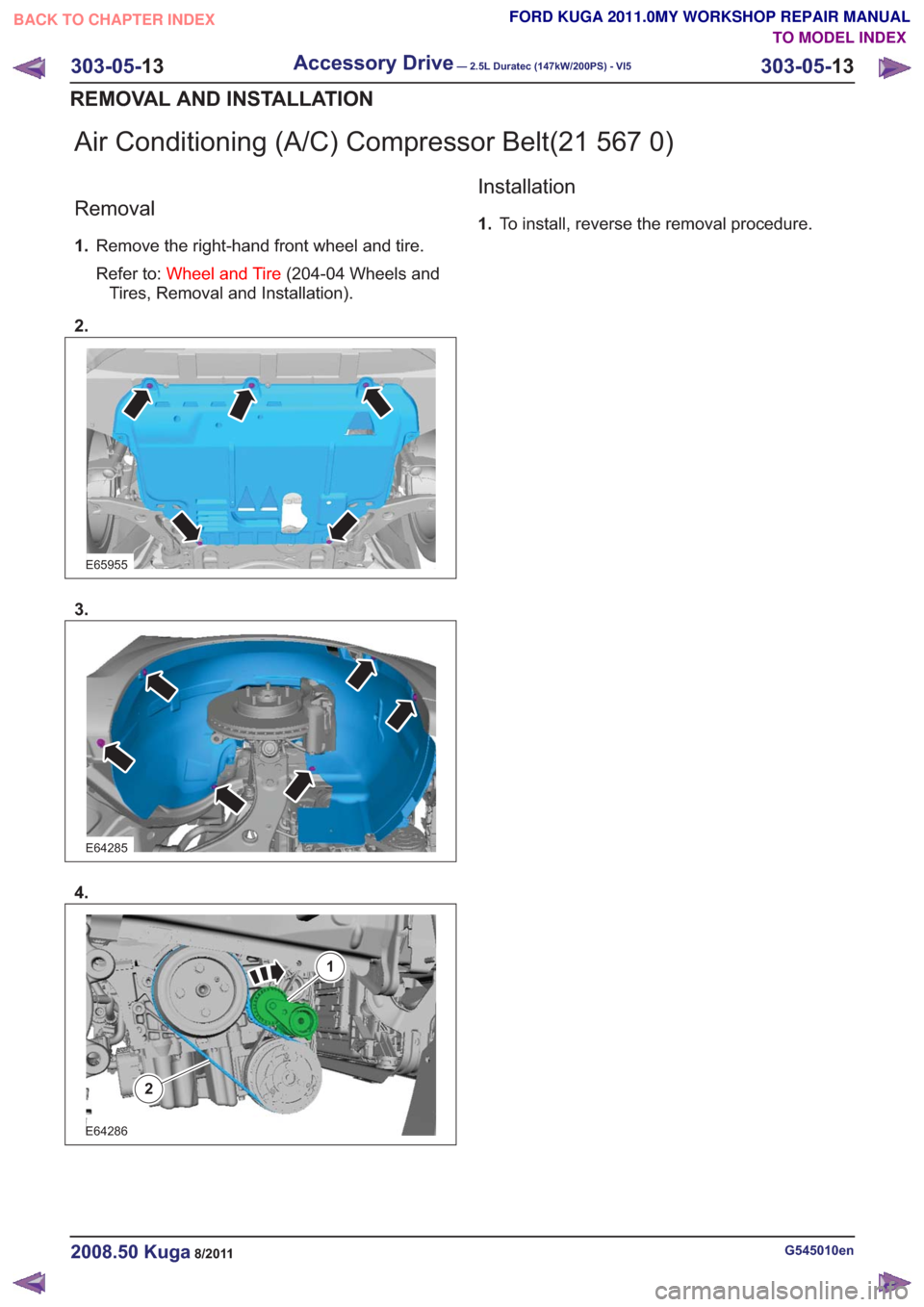

Removal

1.Remove the right-hand front wheel and tire.

Refer to: Wheel and Tire (204-04 Wheels and

Tires, Removal and Installation).

2.

E65955

3.

E64285

4.

E64286

2

1

Installation

1. To install, reverse the removal procedure.

G545010en2008.50 Kuga8/2011

303-05- 13

Accessory Drive— 2.5L Duratec (147kW/200PS) - VI5303-05-

13

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1793 of 2057

Description

Item

CKP sensor

1

Tooth pitch

2

Flywheel ring gear

3

Reference mark

4

Voltage (sinusoidal-like signal curve)

5Description

Item

60-2 pulses per revolution of the

crankshaft

6

Tooth center

7

Reference mark

8

Tooth pitch

9

The acceleration of the flywheel at each power

stroke results in a change in the CKP signal.

During the power stroke, the combustion pressure

acting on the piston causes an acceleration of the

crankshaft and thus also of the flywheel. This is

apparent in the voltage curve from slightly higher

frequencies and amplitudes of the CKP signal.

Calculation of the ignition angle

Since propagation of the flame front in the air/fuel

mixture always takes the same amount of time, the

ignition of the air/fuel mixture has to take place

earlier or later depending on the engine speed.

The higher the speed, the earlier ignition must

occur. This ensures that maximum combustion

pressure is achieved immediately after Top Dead

Center and that maximum combustion pressure

acts on the piston.

When starting the engine, ignition timing is

determined by the CMP purely from the ignition

map and information on camshaft position (CKP

sensors) and crankshaft position (PCM sensor).

As soon as the engine is running, the following

data are used as a basis for calculating the ignition

angle:

• the engine speed,

• the engine load,

• the coolant temperature and

• the KS signal.

The ignition angle has a major impact on engine

operation. It affects

• engine performance

• exhaust emissions

• fuel consumption,

• combustion knock behavior and

• engine temperature.

The higher the engine load, i.e. the torque demand,

the richer the air/fuel mixture, the longer the

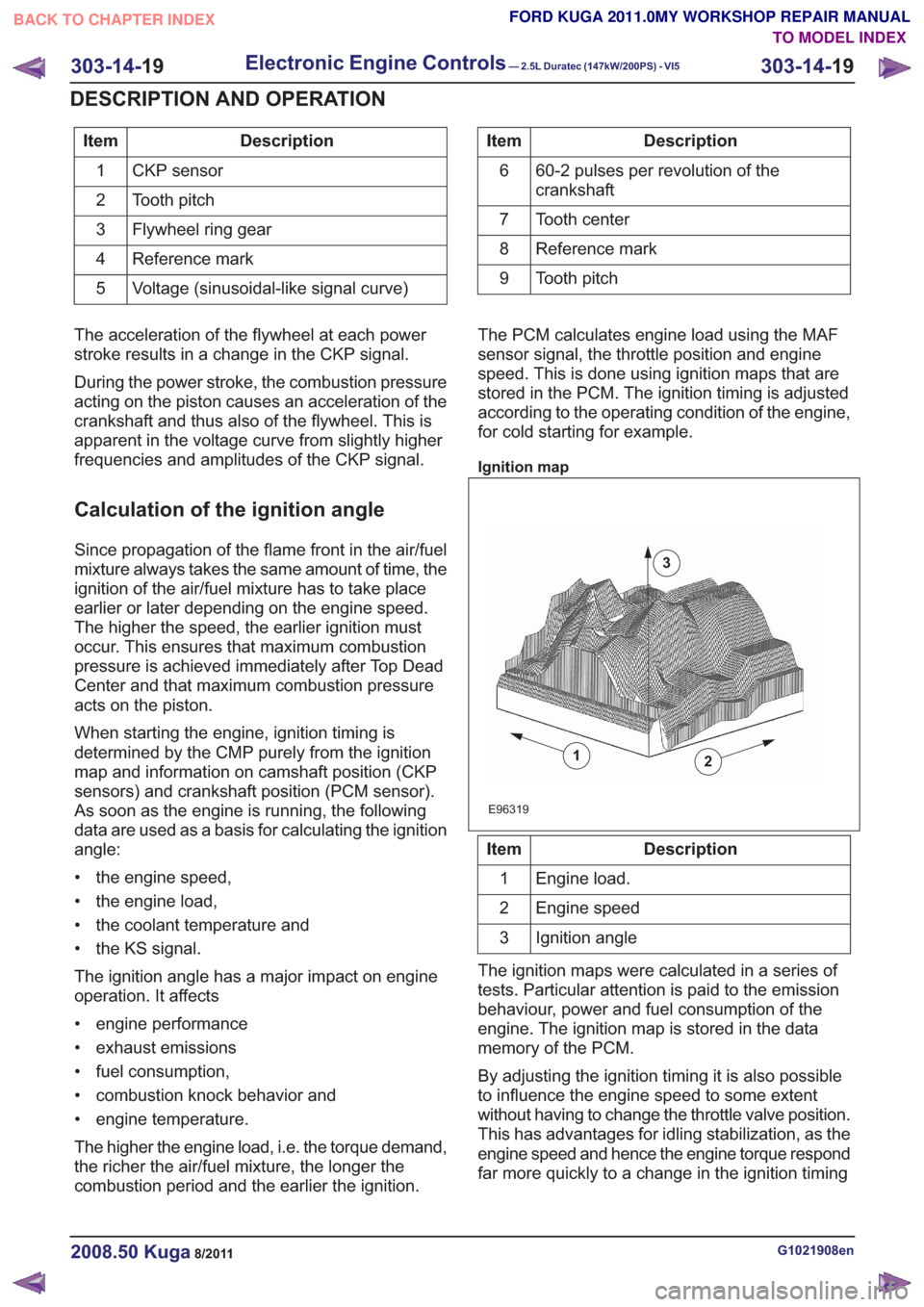

combustion period and the earlier the ignition. The PCM calculates engine load using the MAF

sensor signal, the throttle position and engine

speed. This is done using ignition maps that are

stored in the PCM. The ignition timing is adjusted

according to the operating condition of the engine,

for cold starting for example.

Ignition map

2

E96319

1

3

Description

Item

Engine load.

1

Engine speed

2

Ignition angle

3

The ignition maps were calculated in a series of

tests. Particular attention is paid to the emission

behaviour, power and fuel consumption of the

engine. The ignition map is stored in the data

memory of the PCM.

By adjusting the ignition timing it is also possible

to influence the engine speed to some extent

without having to change the throttle valve position.

This has advantages for idling stabilization, as the

engine speed and hence the engine torque respond

far more quickly to a change in the ignition timing

G1021908en2008.50 Kuga8/2011

303-14- 19

Electronic Engine Controls— 2.5L Duratec (147kW/200PS) - VI5303-14-

19

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1794 of 2057

than to a change in the throttle valve position. The

ignition timing also changes much more quickly.

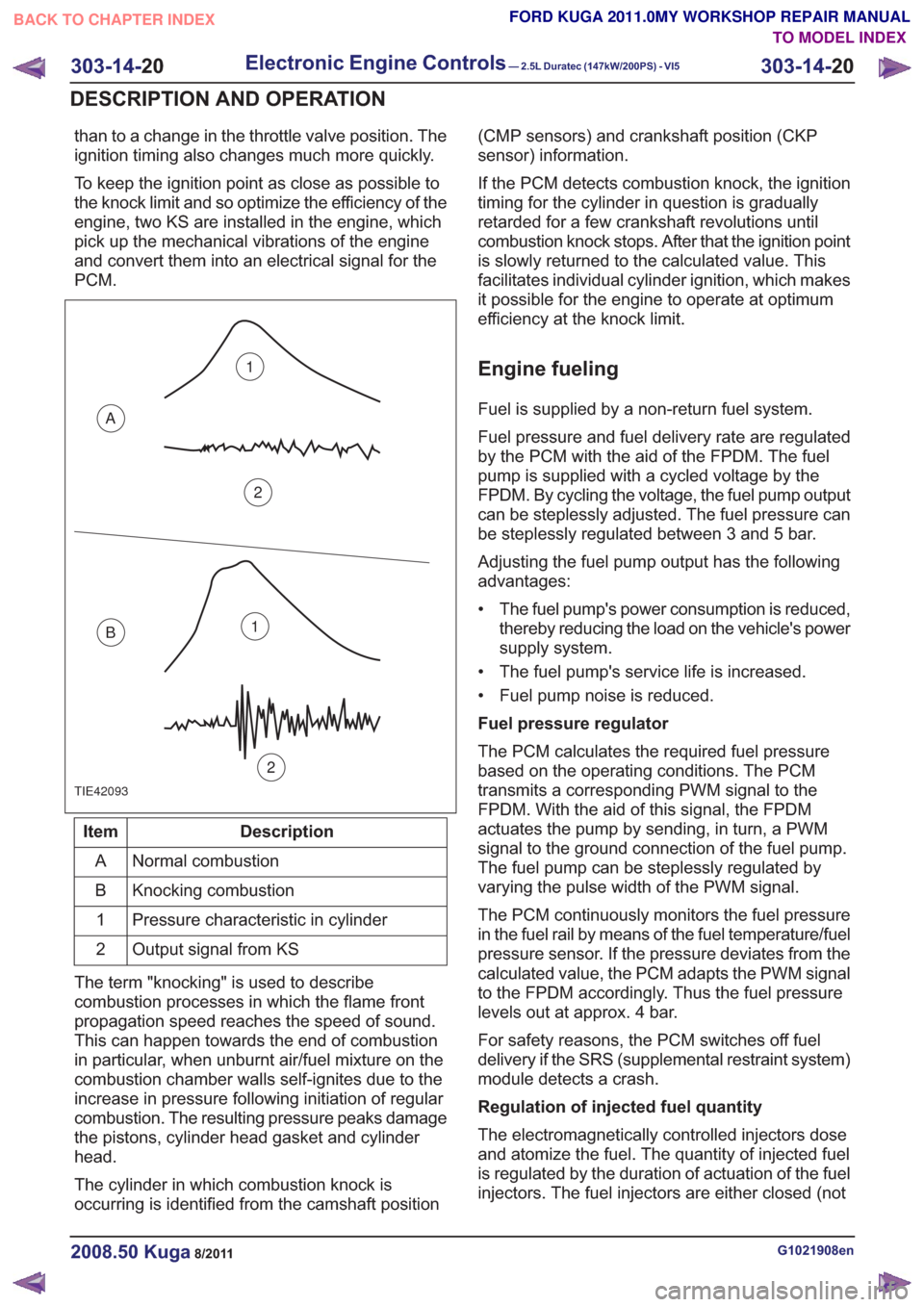

To keep the ignition point as close as possible to

the knock limit and so optimize the efficiency of the

engine, two KS are installed in the engine, which

pick up the mechanical vibrations of the engine

and convert them into an electrical signal for the

PCM.

TIE42093

1

2

A

B1

2

Description

Item

Normal combustion

A

Knocking combustion

B

Pressure characteristic in cylinder

1

Output signal from KS

2

The term "knocking" is used to describe

combustion processes in which the flame front

propagation speed reaches the speed of sound.

This can happen towards the end of combustion

in particular, when unburnt air/fuel mixture on the

combustion chamber walls self-ignites due to the

increase in pressure following initiation of regular

combustion. The resulting pressure peaks damage

the pistons, cylinder head gasket and cylinder

head.

The cylinder in which combustion knock is

occurring is identified from the camshaft position (CMP sensors) and crankshaft position (CKP

sensor) information.

If the PCM detects combustion knock, the ignition

timing for the cylinder in question is gradually

retarded for a few crankshaft revolutions until

combustion knock stops. After that the ignition point

is slowly returned to the calculated value. This

facilitates individual cylinder ignition, which makes

it possible for the engine to operate at optimum

efficiency at the knock limit.

Engine fueling

Fuel is supplied by a non-return fuel system.

Fuel pressure and fuel delivery rate are regulated

by the PCM with the aid of the FPDM. The fuel

pump is supplied with a cycled voltage by the

FPDM. By cycling the voltage, the fuel pump output

can be steplessly adjusted. The fuel pressure can

be steplessly regulated between 3 and 5 bar.

Adjusting the fuel pump output has the following

advantages:

• The fuel pump's power consumption is reduced,

thereby reducing the load on the vehicle's power

supply system.

• The fuel pump's service life is increased.

• Fuel pump noise is reduced.

Fuel pressure regulator

The PCM calculates the required fuel pressure

based on the operating conditions. The PCM

transmits a corresponding PWM signal to the

FPDM. With the aid of this signal, the FPDM

actuates the pump by sending, in turn, a PWM

signal to the ground connection of the fuel pump.

The fuel pump can be steplessly regulated by

varying the pulse width of the PWM signal.

The PCM continuously monitors the fuel pressure

in the fuel rail by means of the fuel temperature/fuel

pressure sensor. If the pressure deviates from the

calculated value, the PCM adapts the PWM signal

to the FPDM accordingly. Thus the fuel pressure

levels out at approx. 4 bar.

For safety reasons, the PCM switches off fuel

delivery if the SRS (supplemental restraint system)

module detects a crash.

Regulation of injected fuel quantity

The electromagnetically controlled injectors dose

and atomize the fuel. The quantity of injected fuel

is regulated by the duration of actuation of the fuel

injectors. The fuel injectors are either closed (not

G1021908en2008.50 Kuga8/2011

303-14- 20

Electronic Engine Controls— 2.5L Duratec (147kW/200PS) - VI5303-14-

20

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1795 of 2057

actuated) or opened (actuated). Each cylinder has

its own injector. The injection is accurately dosed

and takes place at a time determined by the PCM.

Injection takes place immediately in front of the

intake valves of the cylinder. The injectors are

actuated ground side via end-stages integrated

into the PCM and using the signal calculated by

the engine management system. Power is supplied

via the Powertrain Control Module relay in the BJB.

The injected fuel quantity depends on the opening

time, the fuel pressure and the diameter of the

nozzle holes.

The fuel metering is determined via open or

closed-loop control.

The open control loop differs from the closed

control loop in that the lambda control is

deactivated.

The PCM switches from closed to open-loop control

if the HO2S cools down to below 600°C or fails, as

well as when accelerating, coasting and at full load.

Regulation of injected fuel quantity via the PCM

involves:

• controlling the fuel pump,

• calculating the required quantity of fuel forengine starting,

• observance of the desired air/fuel ratio,

• calculating air mass,

• and calculating the fuel quantity for the different operating states and corresponding fuel

adjustment measures.

Open loop control

Open loop control is used primarily for fuel

injection, as long as the signals of the HO2S are

not involved in the calculation of the PCM.

The two most important reasons that make it

absolutely essential to run the engine without

lambda control (open-loop control) are the following

operating conditions:

• Cold engine (starting, warm-up phase)

• Full-load operation (WOT (wide open throttle))

Under these operating conditions the engine needs

a rich air/fuel mixture with lambda values below λ

= 1 in order to achieve optimum running or

optimum performance.

It is possible to keep this unregulated range very

small by using a broadband HO2S.

Closed-loop control

Closed loop control ensures strict control of

exhaust emissions in conjunction with the TWC (three-way catalytic converter) and economical fuel

consumption. With closed loop control, the signals

from the HO2S are analyzed by the PCM and the

engine always runs in the optimum range of λ = 1.

In addition to the normal HO2S, the signal from the

monitoring sensor for the catalytic converter is also

included in the control. The lambda control is

optimized on the basis of this data.

Certain factors such as wear, component

tolerances or more minor defects such as air leaks

in the intake system are compensated for by

lambda control. If the deviation occurs for a longer

period of time, this is recorded by the adaptive

(self-learning) function of lambda control. In this

instance, the entire map is shifted by the

corresponding amount, to enable control to

commence once again from the virtual baseline.

These adaptive settings are stored in the PCM and

are also used in open-loop control conditions.

If the adaptive value is too high or too low, an error

is stored in the fault memory of the PCM.

Oxygen sensor (HO2S) and catalyst monitor

sensor

A broadband HO2S is used as the HO2S. The

HO2S is located in front of the TWC. The catalyst

monitor sensor is located in the center of the TWC

so that it can detect any deterioration in the

cleaning performance of the TWC more quickly.

The HO2S measures the residual amount of

oxygen in the exhaust before the TWC.

The catalyst monitor sensor measures the amount

of oxygen in the exhaust gas after or in the TWC.

Both the HO2S and the catalyst monitor sensor

transmit these data to the PCM.

The broadband HO2S works at temperatures of

between 650°C and 900 °C. If the temperature

rises above 1000°C, the oxygen sensor will be

irreparably damaged.

To reach optimum operating temperature as quickly

as possible, an electrically-heated oxygen sensor

is installed. The heating also serves to maintain a

suitable operating temperature while coasting, for

example, when no hot gases are flowing past the

oxygen sensor.

The heating element in the HO2S is a PTC

(positive temperature coefficient) resistor. The

heating element is supplied with battery voltage as

soon as the Powertrain Control Module relay

engages. The HO2S is earthed via the PCM. As

the heating current is high when the element is

cold, it is limited via PWM in the PCM until a certain

G1021908en2008.50 Kuga8/2011

303-14-

21

Electronic Engine Controls— 2.5L Duratec (147kW/200PS) - VI5303-14-

21

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1828 of 2057

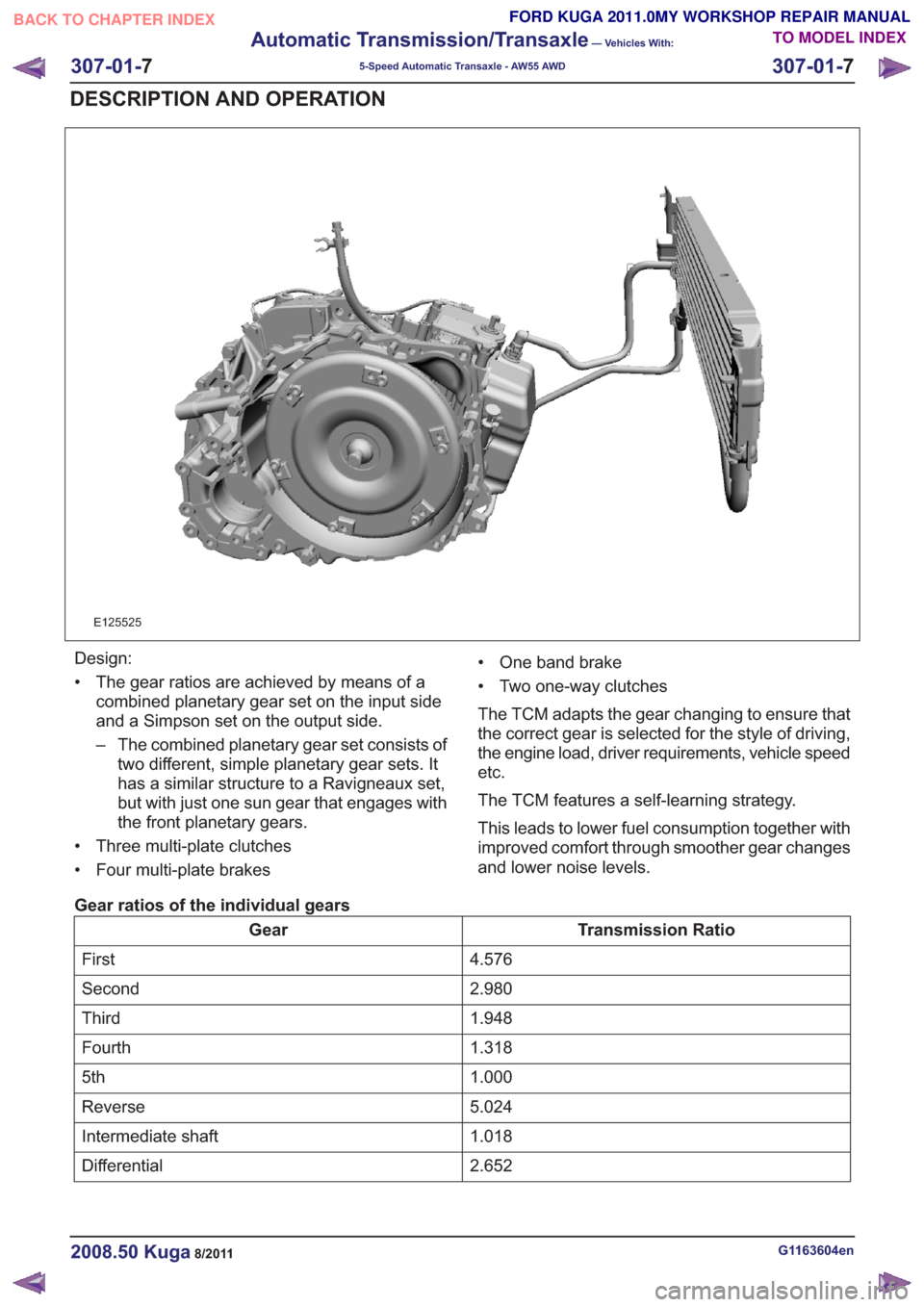

E125525

Design:

• The gear ratios are achieved by means of acombined planetary gear set on the input side

and a Simpson set on the output side.

– The combined planetary gear set consists oftwo different, simple planetary gear sets. It

has a similar structure to a Ravigneaux set,

but with just one sun gear that engages with

the front planetary gears.

• Three multi-plate clutches

• Four multi-plate brakes • One band brake

• Two one-way clutches

The TCM adapts the gear changing to ensure that

the correct gear is selected for the style of driving,

the engine load, driver requirements, vehicle speed

etc.

The TCM features a self-learning strategy.

This leads to lower fuel consumption together with

improved comfort through smoother gear changes

and lower noise levels.

Gear ratios of the individual gears

Transmission Ratio

Gear

4.576

First

2.980

Second

1.948

Third

1.318

Fourth

1.000

5th

5.024

Reverse

1.018

Intermediate shaft

2.652

Differential

G1163604en2008.50 Kuga8/2011

307-01- 7

Automatic Transmission/Transaxle

— Vehicles With:

5-Speed Automatic Transaxle - AW55 AWD

307-01- 7

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1832 of 2057

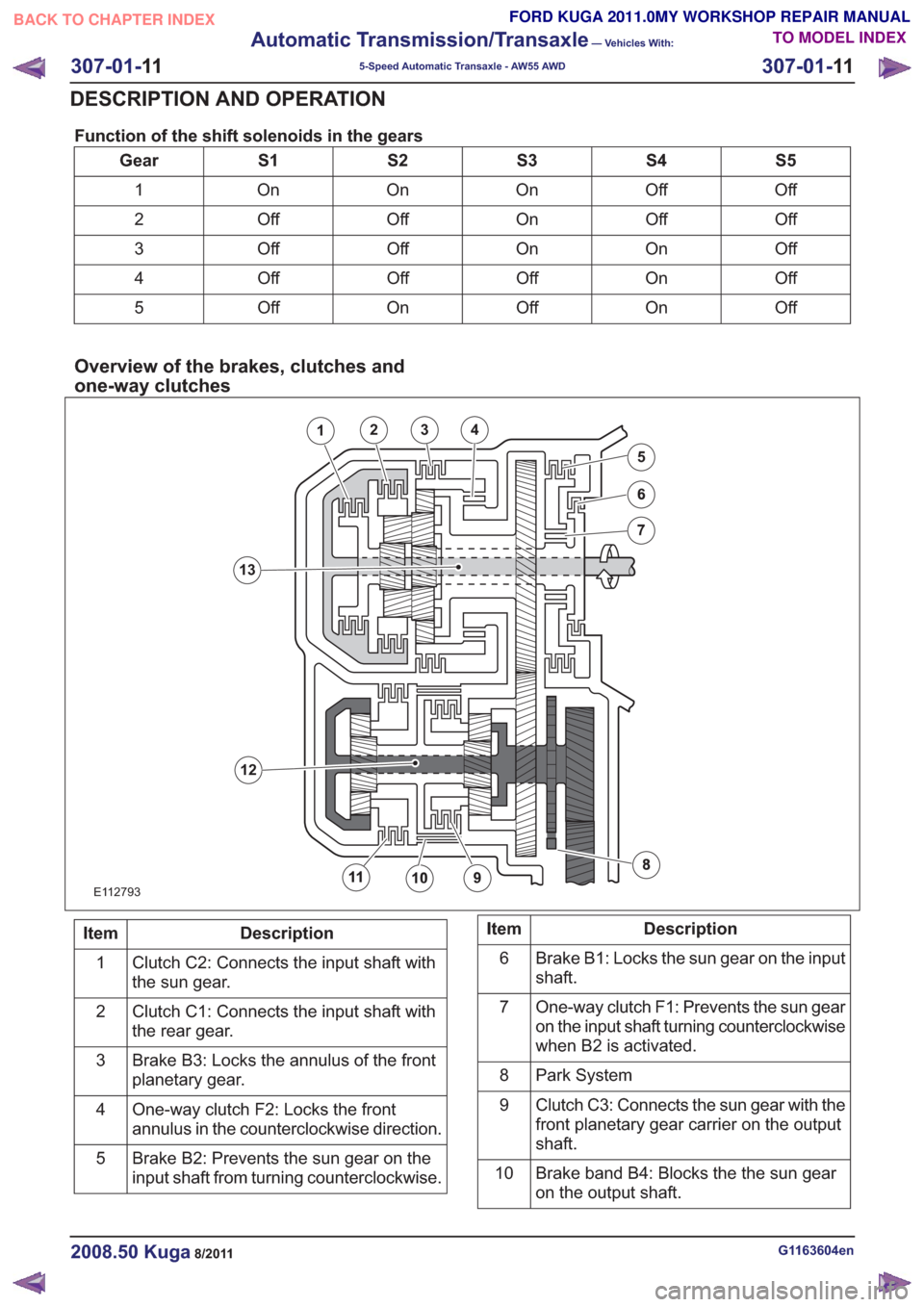

Function of the shift solenoids in the gears

S5

S4

S3

S2

S1

Gear

Off

Off

On

On

On

1

Off

Off

On

Off

Off

2

Off

On

On

Off

Off

3

Off

On

Off

Off

Off

4

Off

On

Off

On

Off

5

Overview of the brakes, clutches and

one-way clutches

E112793

1234

5

12

13

Description

Item

Clutch C2: Connects the input shaft with

the sun gear.

1

Clutch C1: Connects the input shaft with

the rear gear.

2

Brake B3: Locks the annulus of the front

planetary gear.

3

One-way clutch F2: Locks the front

annulus in the counterclockwise direction.

4

Brake B2: Prevents the sun gear on the

input shaft from turning counterclockwise.

5Description

Item

Brake B1: Locks the sun gear on the input

shaft.

6

One-way clutch F1: Prevents the sun gear

on the input shaft turning counterclockwise

when B2 is activated.

7

Park System

8

Clutch C3: Connects the sun gear with the

front planetary gear carrier on the output

shaft.

9

Brake band B4: Blocks the the sun gear

on the output shaft.

10

G1163604en2008.50 Kuga8/2011

307-01-

11

Automatic Transmission/Transaxle

— Vehicles With:

5-Speed Automatic Transaxle - AW55 AWD

307-01- 11

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1853 of 2057

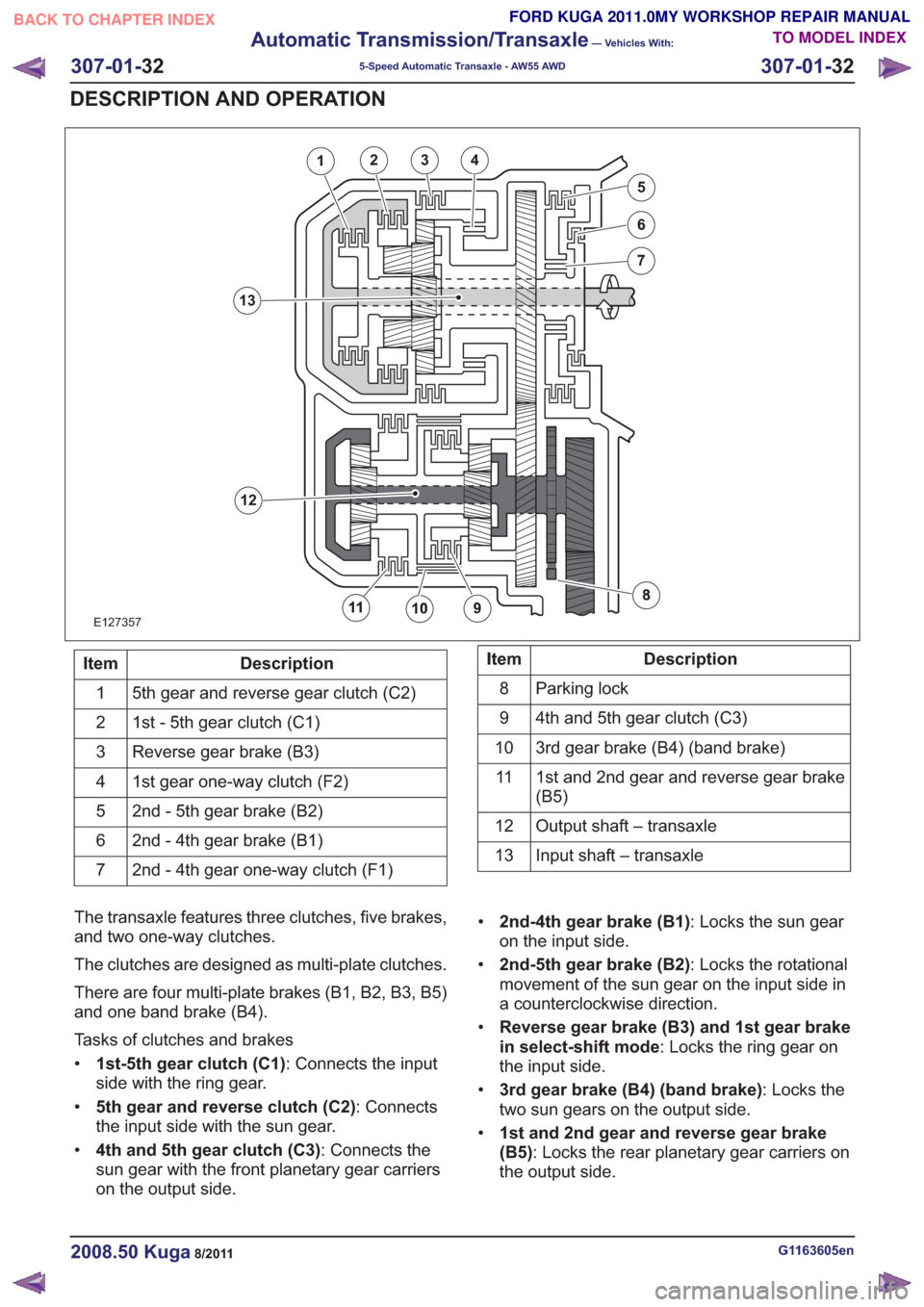

E127357

1234

5

12

13

Description

Item

5th gear and reverse gear clutch (C2)

1

1st - 5th gear clutch (C1)

2

Reverse gear brake (B3)

3

1st gear one-way clutch (F2)

4

2nd - 5th gear brake (B2)

5

2nd - 4th gear brake (B1)

6

2nd - 4th gear one-way clutch (F1)

7Description

Item

Parking lock

8

4th and 5th gear clutch (C3)

9

3rd gear brake (B4) (band brake)

10

1st and 2nd gear and reverse gear brake

(B5)

11

Output shaft – transaxle

12

Input shaft – transaxle

13

The transaxle features three clutches, five brakes,

and two one-way clutches.

The clutches are designed as multi-plate clutches.

There are four multi-plate brakes (B1, B2, B3, B5)

and one band brake (B4).

Tasks of clutches and brakes

• 1st-5th gear clutch (C1) : Connects the input

side with the ring gear.

• 5th gear and reverse clutch (C2) : Connects

the input side with the sun gear.

• 4th and 5th gear clutch (C3) : Connects the

sun gear with the front planetary gear carriers

on the output side. •

2nd-4th gear brake (B1) : Locks the sun gear

on the input side.

• 2nd-5th gear brake (B2) : Locks the rotational

movement of the sun gear on the input side in

a counterclockwise direction.

• Reverse gear brake (B3) and 1st gear brake

in select-shift mode : Locks the ring gear on

the input side.

• 3rd gear brake (B4) (band brake) : Locks the

two sun gears on the output side.

• 1st and 2nd gear and reverse gear brake

(B5) : Locks the rear planetary gear carriers on

the output side.

G1163605en2008.50 Kuga8/2011

307-01- 32

Automatic Transmission/Transaxle

— Vehicles With:

5-Speed Automatic Transaxle - AW55 AWD

307-01- 32

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL