exhaust FORD KUGA 2011 1.G User Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 2011, Model line: KUGA, Model: FORD KUGA 2011 1.GPages: 2057

Page 92 of 2057

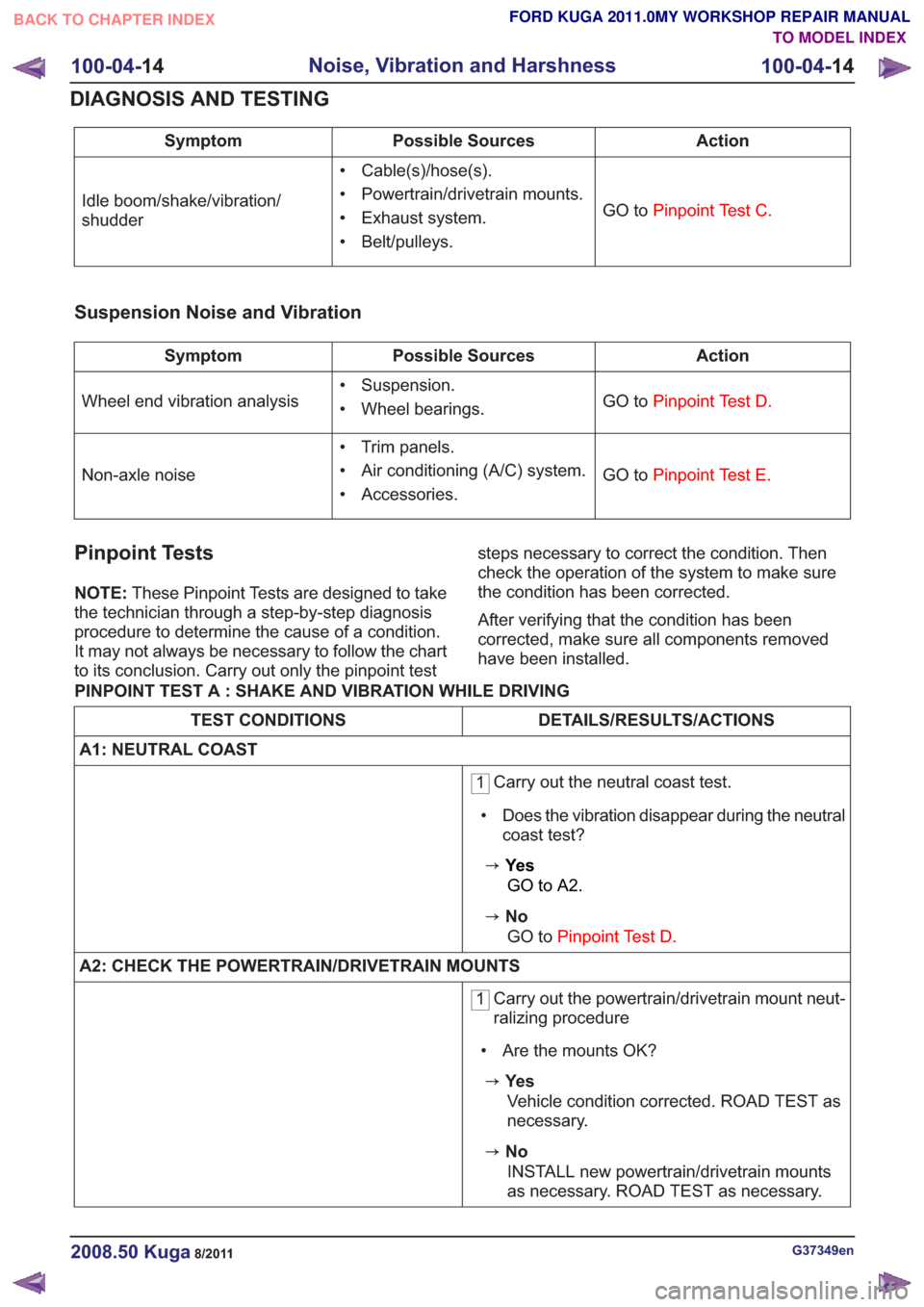

Action

Possible Sources

Symptom

GO toPinpoint Test C.

• Cable(s)/hose(s).

• Powertrain/drivetrain mounts.

• Exhaust system.

• Belt/pulleys.

Idle boom/shake/vibration/

shudder

Suspension Noise and Vibration

Action

Possible Sources

Symptom

GO toPinpoint Test D.

• Suspension.

• Wheel bearings.

Wheel end vibration analysis

GO toPinpoint Test E.

• Trim panels.

• Air conditioning (A/C) system.

• Accessories.

Non-axle noise

Pinpoint Tests

NOTE:

These Pinpoint Tests are designed to take

the technician through a step-by-step diagnosis

procedure to determine the cause of a condition.

It may not always be necessary to follow the chart

to its conclusion. Carry out only the pinpoint test steps necessary to correct the condition. Then

check the operation of the system to make sure

the condition has been corrected.

After verifying that the condition has been

corrected, make sure all components removed

have been installed.

PINPOINT TEST A : SHAKE AND VIBRATION WHILE DRIVING

DETAILS/RESULTS/ACTIONS

TEST CONDITIONS

A1: NEUTRAL COAST

1 Carry out the neutral coast test.

• Does the vibration disappear during the neutral coast test?

zYe s

GO to A2.

zNoGO to Pinpoint Test D.

A2: CHECK THE POWERTRAIN/DRIVETRAIN MOUNTS

1 Carry out the powertrain/drivetrain mount neut-

ralizing procedure

• Are the mounts OK?

zYe s Vehicle condition corrected. ROAD TEST as

necessary.

zNoINSTALL new powertrain/drivetrain mounts

as necessary. ROAD TEST as necessary.

G37349en2008.50 Kuga8/2011

100-04- 14

Noise, Vibration and Harshness

100-04- 14

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 93 of 2057

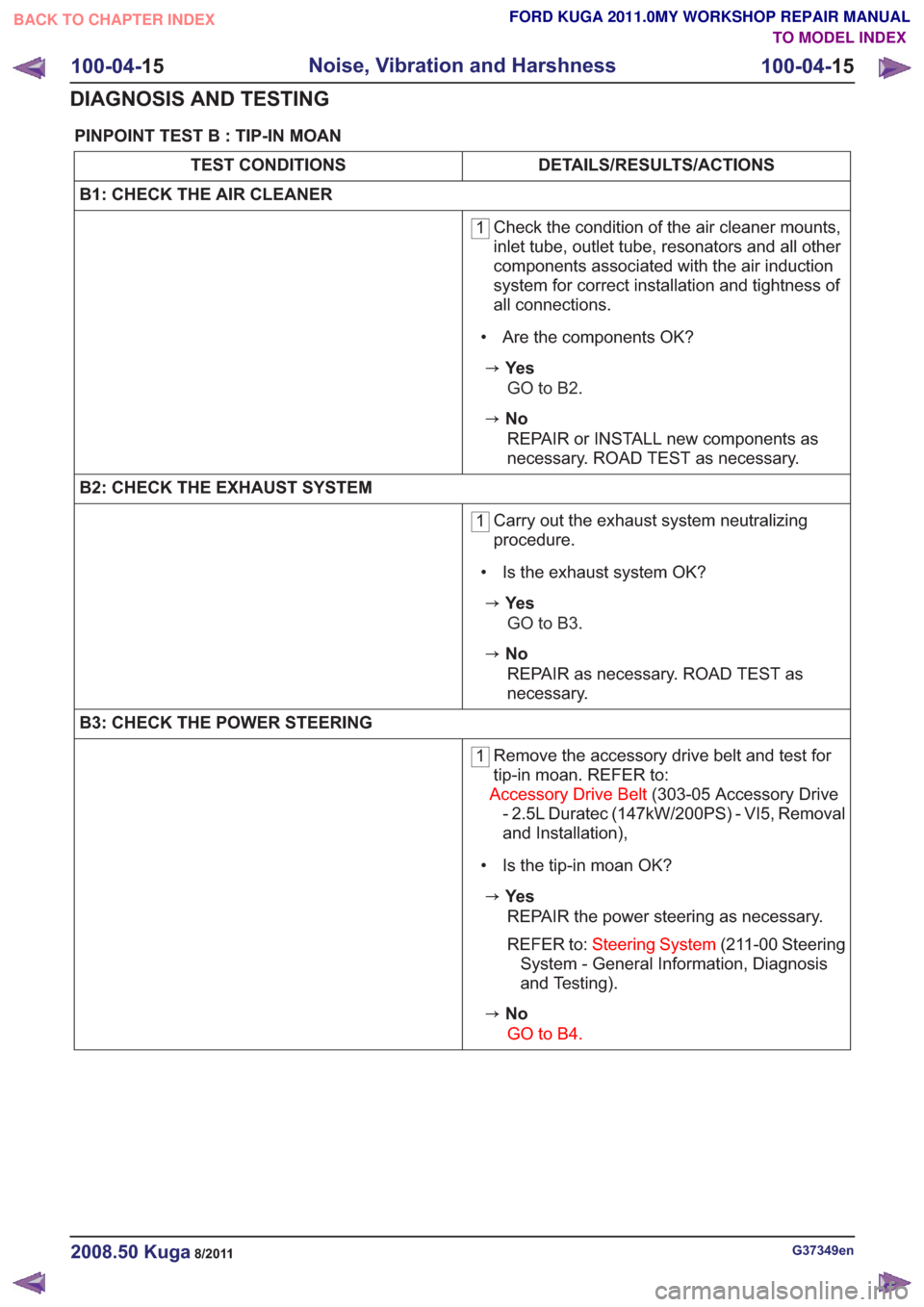

PINPOINT TEST B : TIP-IN MOAN

DETAILS/RESULTS/ACTIONS

TEST CONDITIONS

B1: CHECK THE AIR CLEANER

1 Check the condition of the air cleaner mounts,

inlet tube, outlet tube, resonators and all other

components associated with the air induction

system for correct installation and tightness of

all connections.

• Are the components OK?

zYe s GO to B2.

zNoREPAIR or INSTALL new components as

necessary. ROAD TEST as necessary.

B2: CHECK THE EXHAUST SYSTEM

1 Carry out the exhaust system neutralizing

procedure.

• Is the exhaust system OK?

zYe s GO to B3.

zNoREPAIR as necessary. ROAD TEST as

necessary.

B3: CHECK THE POWER STEERING

1 Remove the accessory drive belt and test for

tip-in moan. REFER to:

Accessory Drive Belt (303-05 Accessory Drive

- 2.5L Duratec (147kW/200PS) - VI5, Removal

and Installation),

• Is the tip-in moan OK?

zYe s REPAIR the power steering as necessary.

REFER to: Steering System (211-00 Steering

System - General Information, Diagnosis

and Testing).

zNo

GO to B4.

G37349en2008.50 Kuga8/2011

100-04- 15

Noise, Vibration and Harshness

100-04- 15

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 95 of 2057

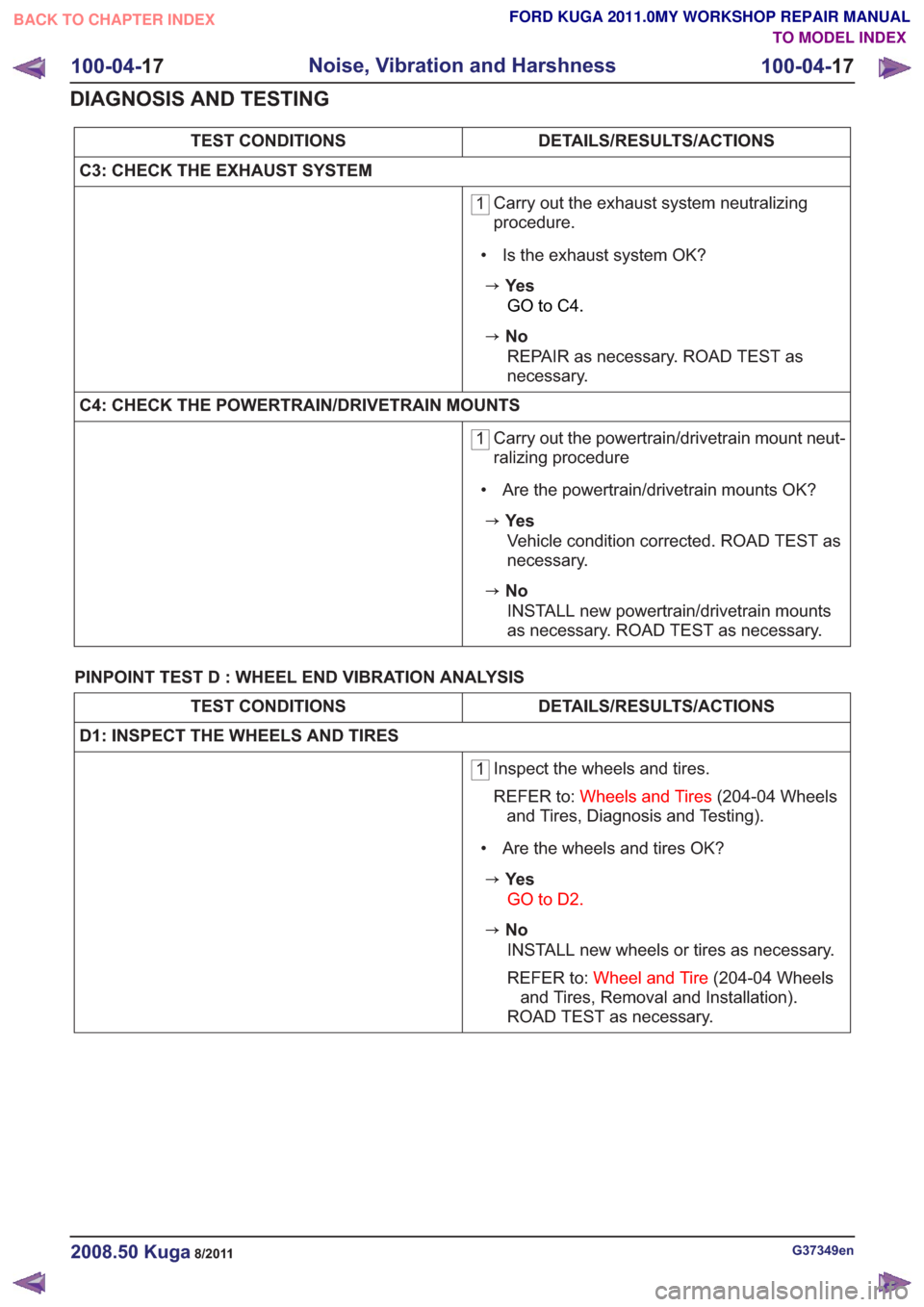

DETAILS/RESULTS/ACTIONS

TEST CONDITIONS

C3: CHECK THE EXHAUST SYSTEM

1 Carry out the exhaust system neutralizing

procedure.

• Is the exhaust system OK?

zYe s GO to C4 .

zNo

REPAIR as necessary. ROAD TEST as

necessary.

C4: CHECK THE POWERTRAIN/DRIVETRAIN MOUNTS

1 Carry out the powertrain/drivetrain mount neut-

ralizing procedure

• Are the powertrain/drivetrain mounts OK?

zYe s Vehicle condition corrected. ROAD TEST as

necessary.

zNoINSTALL new powertrain/drivetrain mounts

as necessary. ROAD TEST as necessary.

PINPOINT TEST D : WHEEL END VIBRATION ANALYSIS

DETAILS/RESULTS/ACTIONS

TEST CONDITIONS

D1: INSPECT THE WHEELS AND TIRES

1 Inspect the wheels and tires.

REFER to:

Wheels and Tires (204-04 Wheels

and Tires, Diagnosis and Testing).

• Are the wheels and tires OK?

zYe s GO to D2 .

zNo

INSTALL new wheels or tires as necessary.

REFER to: Wheel and Tire (204-04 Wheels

and Tires, Removal and Installation).

ROAD TEST as necessary.

G37349en2008.50 Kuga8/2011

100-04- 17

Noise, Vibration and Harshness

100-04- 17

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 156 of 2057

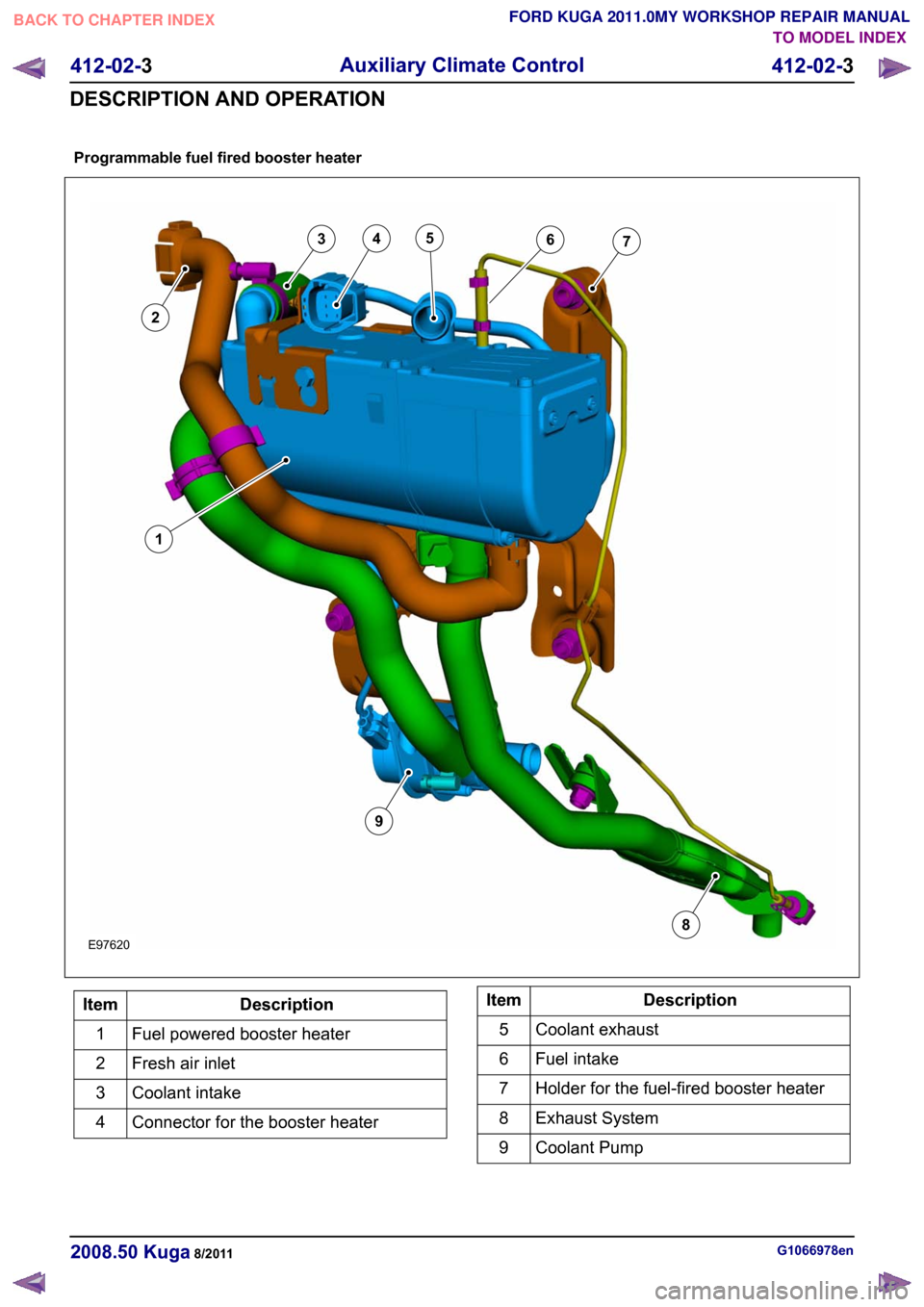

Programmable fuel fired booster heater

Description

Item

Fuel powered booster heater

1

Fresh air inlet

2

Coolant intake

3

Connector for the booster heater

4 Description

Item

Coolant exhaust

5

Fuel intake

6

Holder for the fuel-fired booster heater

7

Exhaust System

8

Coolant Pump

9 G1066978en

2008.50 Kuga 8/2011 412-02-3

Auxiliary Climate Control

412-02-3

DESCRIPTION AND OPERATIONTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL269835471E97620

Page 1186 of 2057

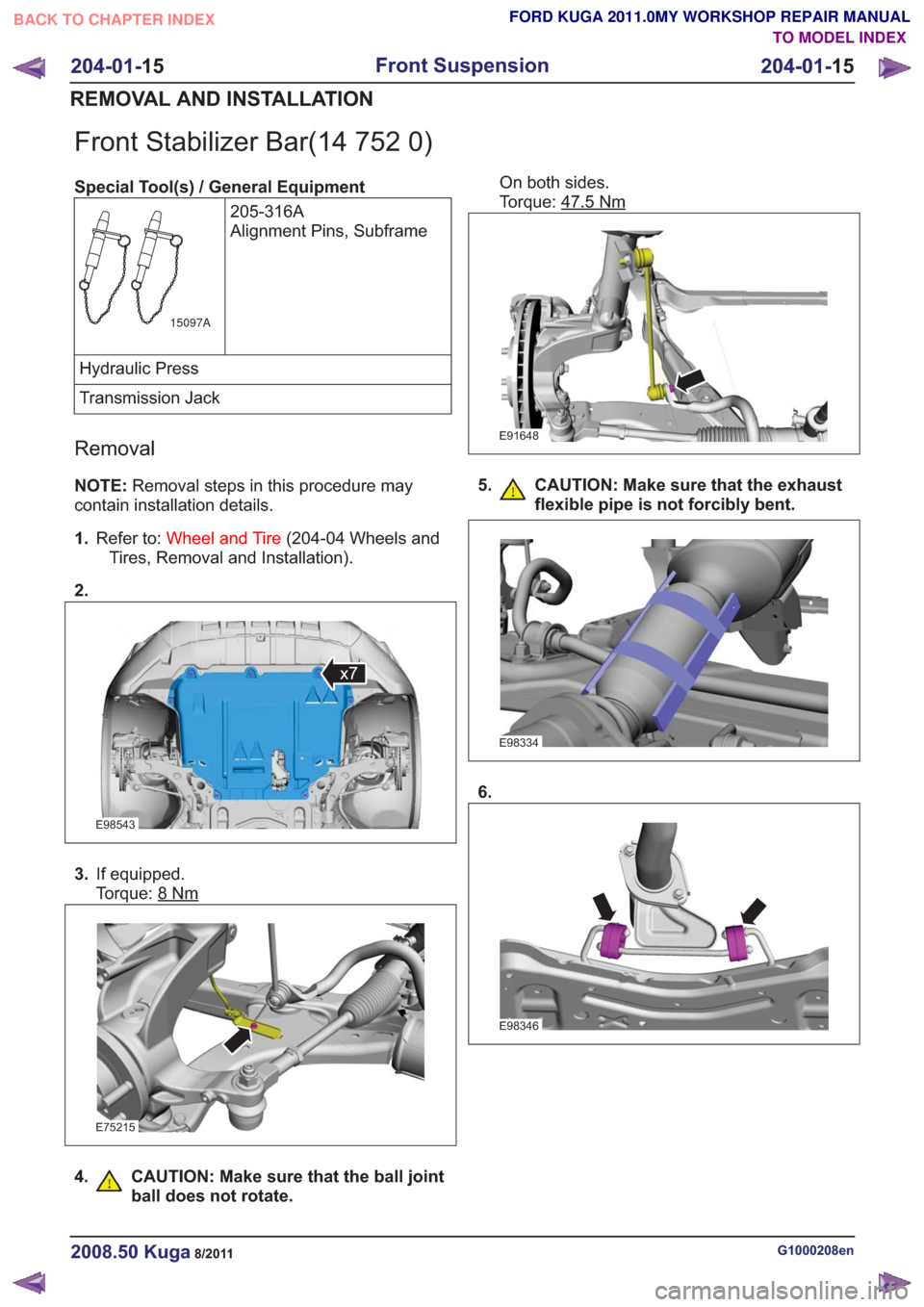

Front Stabilizer Bar(14 752 0)

Special Tool(s) / General Equipment205-316A

Alignment Pins, Subframe

15097A

Hydraulic Press

Transmission Jack

Removal

NOTE:Removal steps in this procedure may

contain installation details.

1. Refer to: Wheel and Tire (204-04 Wheels and

Tires, Removal and Installation).

2.

E98543

x7

3. If equipped.

Torque: 8

Nm

E75215

4. CAUTION: Make sure that the ball joint

ball does not rotate.

On both sides.

Torque: 47.5

Nm

E91648

5. CAUTION: Make sure that the exhaustflexible pipe is not forcibly bent.

E98334

6.

E98346

G1000208en2008.50 Kuga8/2011

204-01- 15

Front Suspension

204-01- 15

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1353 of 2057

DETAILS/RESULTS/ACTIONS

TEST CONDITIONS

F2: CHECK FOR BRAKE PEDAL BINDING

1 Check the brake pedal for free operation.

• Did the brake pedal operate freely?

zYe s INSTALL a new brake booster. TEST the

system for normal operation.

zNoINSTALL new brake pedal bushings. TEST

the system for normal operation.

Component Tests

Hydraulic Leak Check

NOTE: There is a common clutch and brake fluid

reservoir, therefore it is possible that a clutch leak

can lead to reduction in the reservoir level.

It is possible that all evidence of fluid leakage may

have washed off if the vehicle has been operated

in rain or snow, as brake fluid is water-soluble.

Refill the system, bleed then apply the brakes

several times. Examine the system to verify that

the reservoir fluid level is actually dropping. Locate

and repair the external leak. If the fluid level drops

and no external leak can be found, check for a

brake master cylinder bore end seal leak.

Brake System Check

Brake Pedal Reserve Check

Where a low brake pedal or the feel of a

bottomed-out condition exists, check for brake

pedal reserve.

1. Operate the engine at idle with the transaxle in the NEUTRAL position.

2. Apply the brake pedal lightly three or four times.

3. Allow 15 seconds for the vacuum to replenish the brake booster.

NOTE: This increased resistance may feel like

something has bottomed out.

4. Apply the brake pedal until it stops moving downward or an increased resistance to the

pedal travel occurs. 5. Hold the brake pedal in the applied position and

raise the engine speed to approximately 2000

rpm.

NOTE: The additional movement of the brake pedal

is the result of the increased engine manifold

vacuum which exerts more force on the brake

booster during engine rundown. This means that

additional stroke is available in the brake master

cylinder and the brake system is not bottoming out.

6. Release the accelerator pedal and observe that the brake pedal moves downward as the engine

returns to idle speed.

Brake Booster Functional Test

Inspect all hoses and connections. All unused

vacuum connectors should be capped. Hoses and

their connections should be correctly secured and

in good condition with no holes and no collapsed

areas. Inspect the check valve on the brake booster

for damage.

Brake Booster Operation Check

1. Check the hydraulic brake system for leaks orlow fluid.

2. With the transaxle in the NEUTRAL position, stop the engine and apply the parking brake.

Apply the brake pedal several times to exhaust

all the vacuum in the system.

3. With the engine turned off and the vacuum in the system exhausted, apply the brake pedal

and hold it down. Start the engine. If the vacuum

system is operating, the brake pedal will tend

to move downward under constant foot

pressure. If no motion is felt, the vacuum

booster system is not functioning.

G1058975en2008.50 Kuga8/2011

206-00- 17

Brake System - General Information

206-00- 17

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1483 of 2057

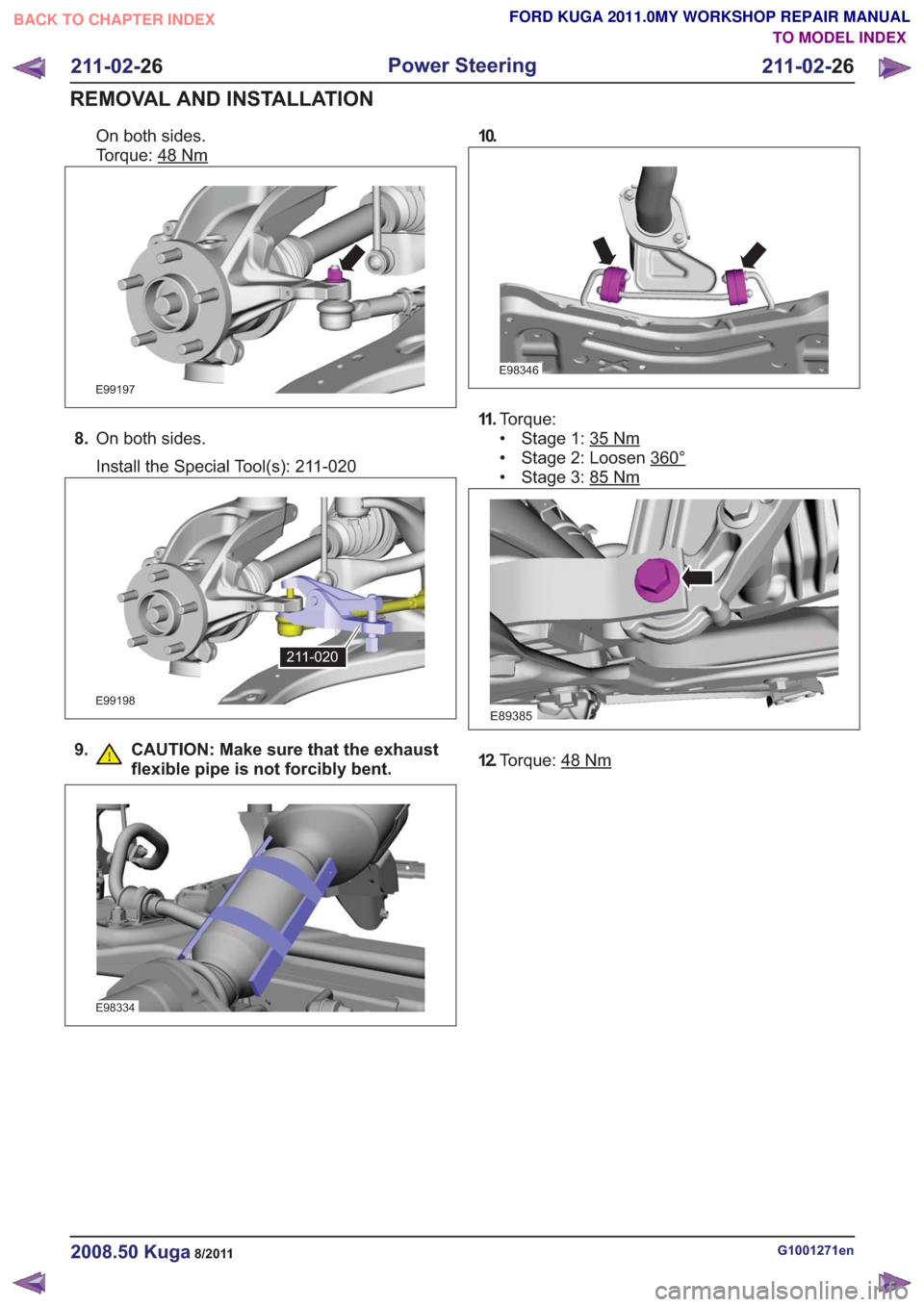

On both sides.

Torque: 48

Nm

E99197

8.On both sides.

Install the Special Tool(s): 211-020

E99198

211-020

9. CAUTION: Make sure that the exhaust

flexible pipe is not forcibly bent.

E98334

10.

E98346

11 .Torque:

• Stage 1: 35

Nm

• Stage 2: Loosen 360°

• Stage 3: 85Nm

E89385

12.Torque: 48Nm

G1001271en2008.50 Kuga8/2011

211-02- 26

Power Steering

211-02- 26

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1522 of 2057

Action

Possible Sources

Symptom

• CHECK the timing belt/timingchain and sprockets/pulleys.

INSTALL new components as

necessary. Engine - 2.5L

Duratec-ST (VI5) -

REFER to: Timing Belt (303-01

Engine - 2.5L Duratec

(147kW/200PS) - VI5,

Removal and Installation).

Engine - 2.0L Duratorq-TDCi

(DW) Diesel -

• Broken or damaged timing

belt/timing chain or

pulley/sprocket.

• CHECK the fuel system.Engine - 2.5L Duratec-ST (VI5)

-

REFER to: Fuel Charging and

Controls (303-04 Fuel Char-

ging and Controls - 2.5L

Duratec (147kW/200PS) -

VI5, Diagnosis and Testing).

Engine - 2.0L Duratorq-TDCi

(DW) Diesel -

• Fuel system.

• Very poor power output or fuel

consumption too high or engine

running rough.

• CHECK the intake air system.Engine - 2.5L Duratec-ST (VI5)

-

REFER to: Intake Air Distribu-

tion and Filtering (303-12

Intake Air Distribution and

Filtering - 2.5L Duratec

(147kW/200PS) - VI5,

Diagnosis and Testing).

Engine - 2.0L Duratorq-TDCi

(DW) Diesel -

• Engine intake air system.

• CHECK the exhaust system.

• Exhaust system blocked.

• CHECK the engine manage-ment system. Engine - 2.5L

Duratec-ST (VI5) -

REFER to: Electronic Engine

Controls (303-14 Electronic

Engine Controls - 2.5L

Duratec (147kW/200PS) -

VI5, Diagnosis and Testing).

Engine - 2.0L Duratorq-TDCi

(DW) Diesel -

• Engine management system.

G1055128en2008.50 Kuga8/2011

303-00-

6

Engine System - General Information

303-00- 6

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1528 of 2057

TIE44583

5. Remove the glow plug relay.

6. Lower the vehicle.

7. Remove the cowl panel grille.REFER to: Cowl Panel Grille (501-02 Front End

Body Panels, Removal and Installation).

E50527

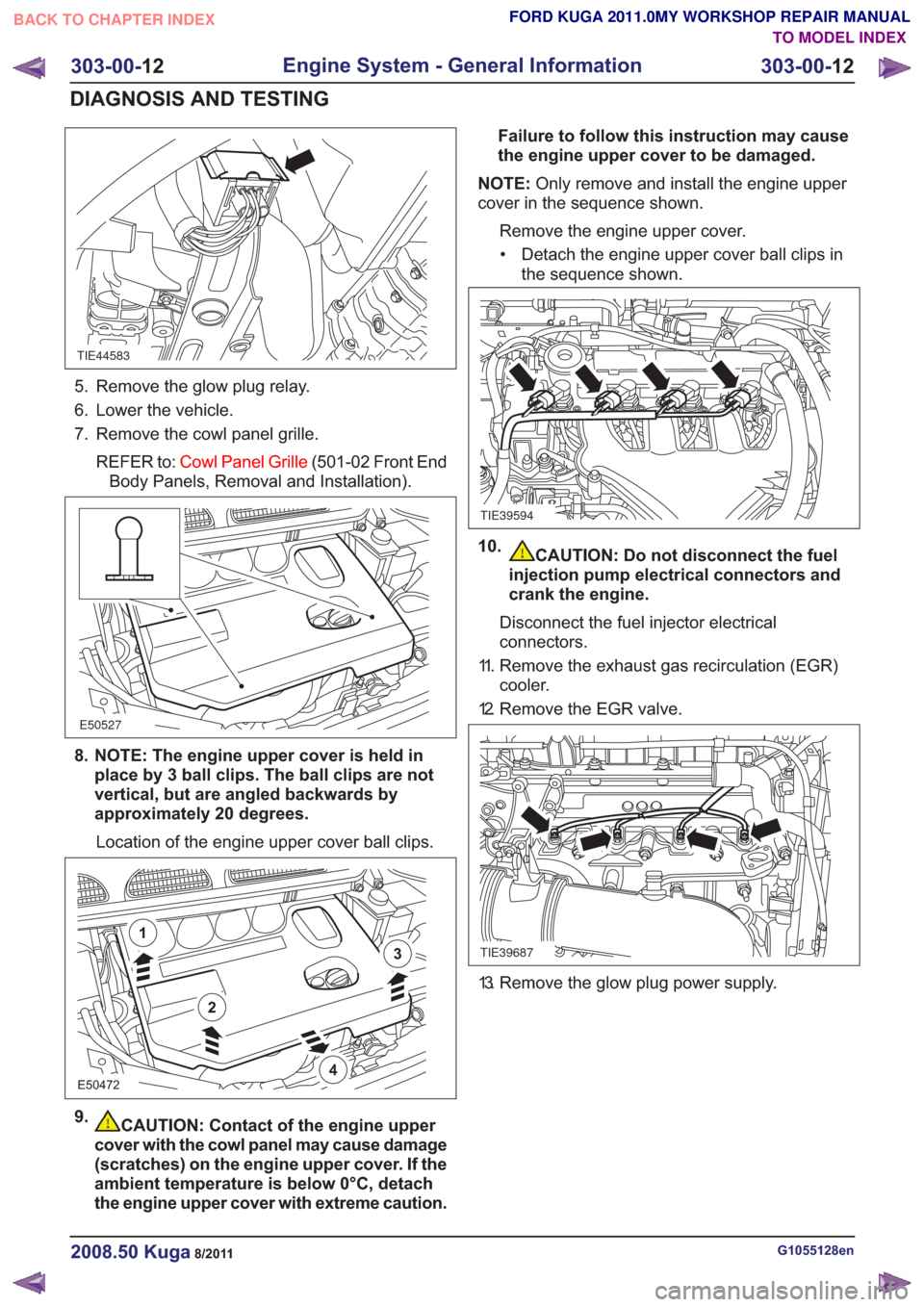

8. NOTE: The engine upper cover is held in place by 3 ball clips. The ball clips are not

vertical, but are angled backwards by

approximately 20 degrees.

Location of the engine upper cover ball clips.

E50472

2

1

3

4

9.CAUTION: Contact of the engine upper

cover with the cowl panel may cause damage

(scratches) on the engine upper cover. If the

ambient temperature is below 0°C, detach

the engine upper cover with extreme caution. Failure to follow this instruction may cause

the engine upper cover to be damaged.

NOTE: Only remove and install the engine upper

cover in the sequence shown.

Remove the engine upper cover.• Detach the engine upper cover ball clips in the sequence shown.

TIE39594

10.CAUTION: Do not disconnect the fuel

injection pump electrical connectors and

crank the engine.

Disconnect the fuel injector electrical

connectors.

11. Remove the exhaust gas recirculation (EGR) cooler.

12. Remove the EGR valve.

TIE39687

13. Remove the glow plug power supply.

G1055128en2008.50 Kuga8/2011

303-00- 12

Engine System - General Information

303-00- 12

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1534 of 2057

SECTION 303-01 Engine— 2.5L Duratec (147kW/200PS) - VI5

VEHICLE APPLICATION:2008.50 Kuga

PA G E

CONTENTS

SPECIFICATIONS

303-01-3

Specifications ........................................................................\

..............................................

303-01-3

Engine Data ........................................................................\

............................................

303-01-3

Engine Oil ........................................................................\

...............................................

303-01-3

Engine Oil Capacity ........................................................................\

................................

303-01-3

Oil Pressure ........................................................................\

............................................

303-01-4

Valve Clearance ........................................................................\

......................................

303-01-4

Crankshaft Main Bearing Selection ........................................................................\

........

DESCRIPTION AND OPERATION 303-01-6

Engine (Component Location) ........................................................................\

....................

303-01-9

Engine (Overview) ........................................................................\

......................................

303-01-9

General ........................................................................\

.......................................................

303-01-10

Cylinder head ........................................................................\

.............................................

303-01-14

Cylinder block ........................................................................\

.............................................

303-01-16

Engine (System Operation and Component Description) ...................................................

303-01-16

System Operation ........................................................................\

.......................................

303-01-17

Variable camshaft timing ........................................................................\

.........................

GENERAL PROCEDURES 303-01-19

Valve Clearance Adjustment ........................................................................\

.......................

REMOVAL AND INSTALLATION 303-01-20

(21 183 0)

Intake Manifold ........................................................................\

.......................

303-01-22

(21 467 0)

Crankshaft Front Seal ........................................................................\

.............

303-01-23

(21 238 0)

Valve Stem Seals ........................................................................\

...................

303-01-25

(21 304 0)

Timing Belt ........................................................................\

..............................

303-01-31

(21 284 0)

Camshafts ........................................................................\

..............................

303-01-36

(21 288 0)

Camshaft Seal ........................................................................\

........................

303-01-45

(21 154 0)

Oil Pan ........................................................................\

....................................

303-01-48

(21 714 0)

Oil Pump ........................................................................\

.................................

303-01-49

(21 187 0)

Exhaust Manifold ........................................................................\

....................

303-01-50

(21 163 0)

Cylinder Head ........................................................................\

.........................

303-01-56

(21 468 4)

Crankshaft Rear Seal ........................................................................\

.............

303-01-58

(21 764 0)

Oil Cooler ........................................................................\

................................

REMOVAL

303-01-59

(21

132 0;

21 132 6;

21 132 7)

Engine — Vehicles With: 5-Speed Automatic Transaxle (AW55)

...................

303-01-78

(21 139 4)

Engine Accessories ........................................................................\

................

303-01-1

Engine— 2.5L Duratec (147kW/200PS) - VI5303-01-

1

.

TO MODEL INDEX

BACK TO CHAPTER INDEX

PAGE 1 OF 2 FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL