exhaust FORD KUGA 2011 1.G Owner's Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2011, Model line: KUGA, Model: FORD KUGA 2011 1.GPages: 2057

Page 1537 of 2057

Bar

Description

4.8

Oil pressure relief valve opening pressure

Valve Clearance

mm

Description

0.17 - 0.23

Valve clearance (engine cold), intake

0.36 - 0.43

Valve clearance (engine cold), exhaust

Valves

mm

Description

101.93 - 102.07

Intake valve lenght

5.87 - 6.01

Intake valve shaft diameter

0.05 - 0.07

Intake valve guide clearance

101.43 - 101.57

Exhaust valve lenght

5.87 - 6.01

Exhaust valve shaft diameter

0.05 - 0.07

Exhaust valve guide clearance

Valve Seats

degree

Description

45.33 - 45.67

Intake valve seat angle

45.33 - 45.67

Exhaust valve seat angle

Cylinder Head

mm

Description

149.25 - 149.55

Cylinder head height

0.05

Maximum mating face distortion (lengthwise)

0.02

Maximum mating face distortion (crosswise)

0.30

Maximum face milling

Camshafts

mm

Description

8.68

Intake camshaft lobe lift

9.05

Exhaust camshaft lobe lift

Crankshaft

mm

Description

0.08 - 0.19

Crankshaft axial clearance

Crankshaft Main Bearing Selection

Code - Cylinder block

Code - Cylinder block

Code - Cylinder block

C

B

A

Crankshaft

main bearing carrier

Cylinder

block

Crankshaft

main bearing carrier

Cylinder

block

Crankshaft

main bearing carrier

Cylinder

block

Crankshaft

main bearing

for:

G1079019en2008.50 Kuga8/2011

303-01-

4

Engine— 2.5L Duratec (147kW/200PS) - VI5303-01-

4

SPECIFICATIONS

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1539 of 2057

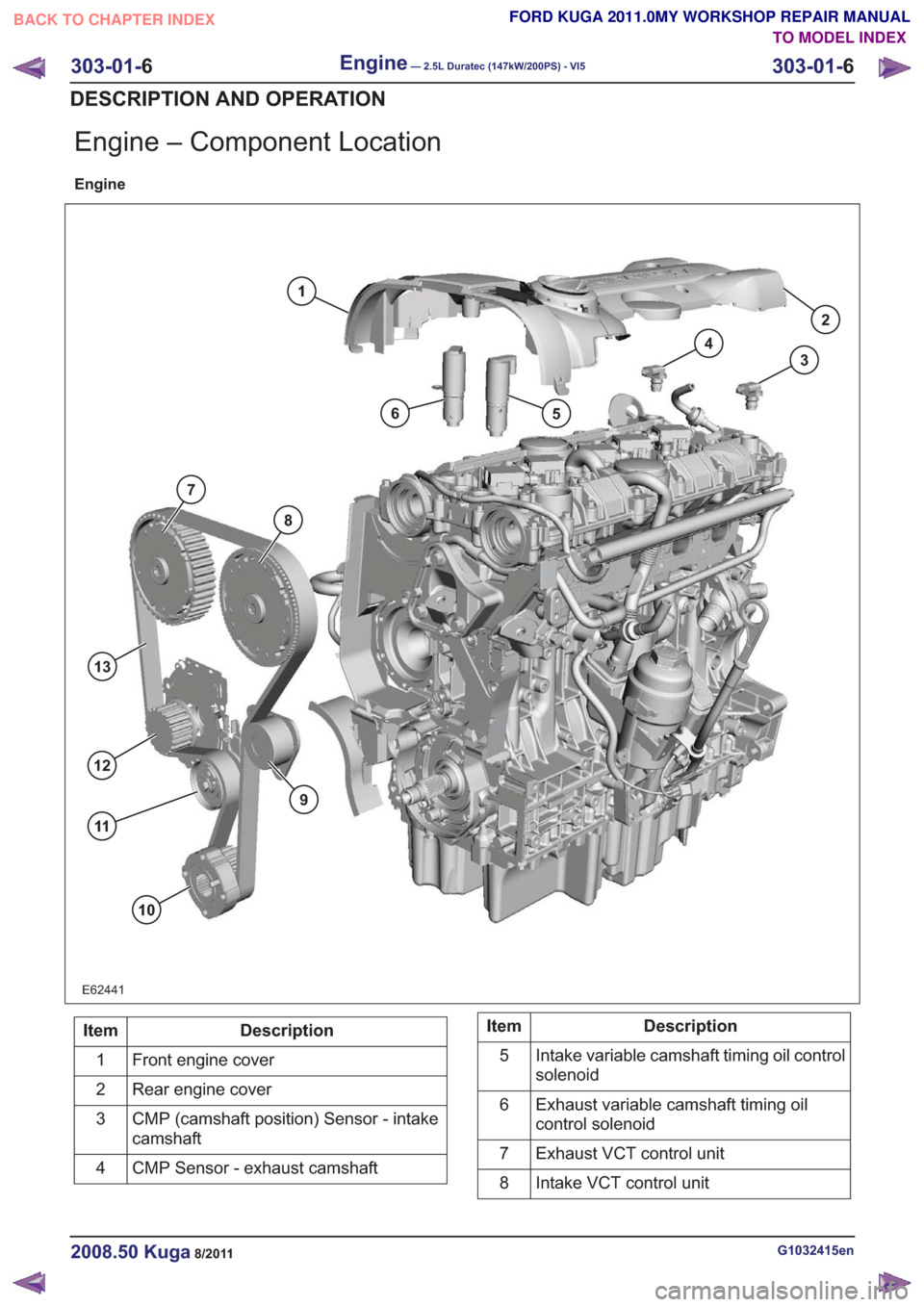

Engine – Component Location

Engine

E62441

1

65

4

3

2

9

10

13

12

11

8

7

Description

Item

Front engine cover

1

Rear engine cover

2

CMP (camshaft position) Sensor - intake

camshaft

3

CMP Sensor - exhaust camshaft

4Description

Item

Intake variable camshaft timing oil control

solenoid

5

Exhaust variable camshaft timing oil

control solenoid

6

Exhaust VCT control unit

7

Intake VCT control unit

8

G1032415en2008.50 Kuga8/2011

303-01- 6

Engine— 2.5L Duratec (147kW/200PS) - VI5303-01-

6

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1543 of 2057

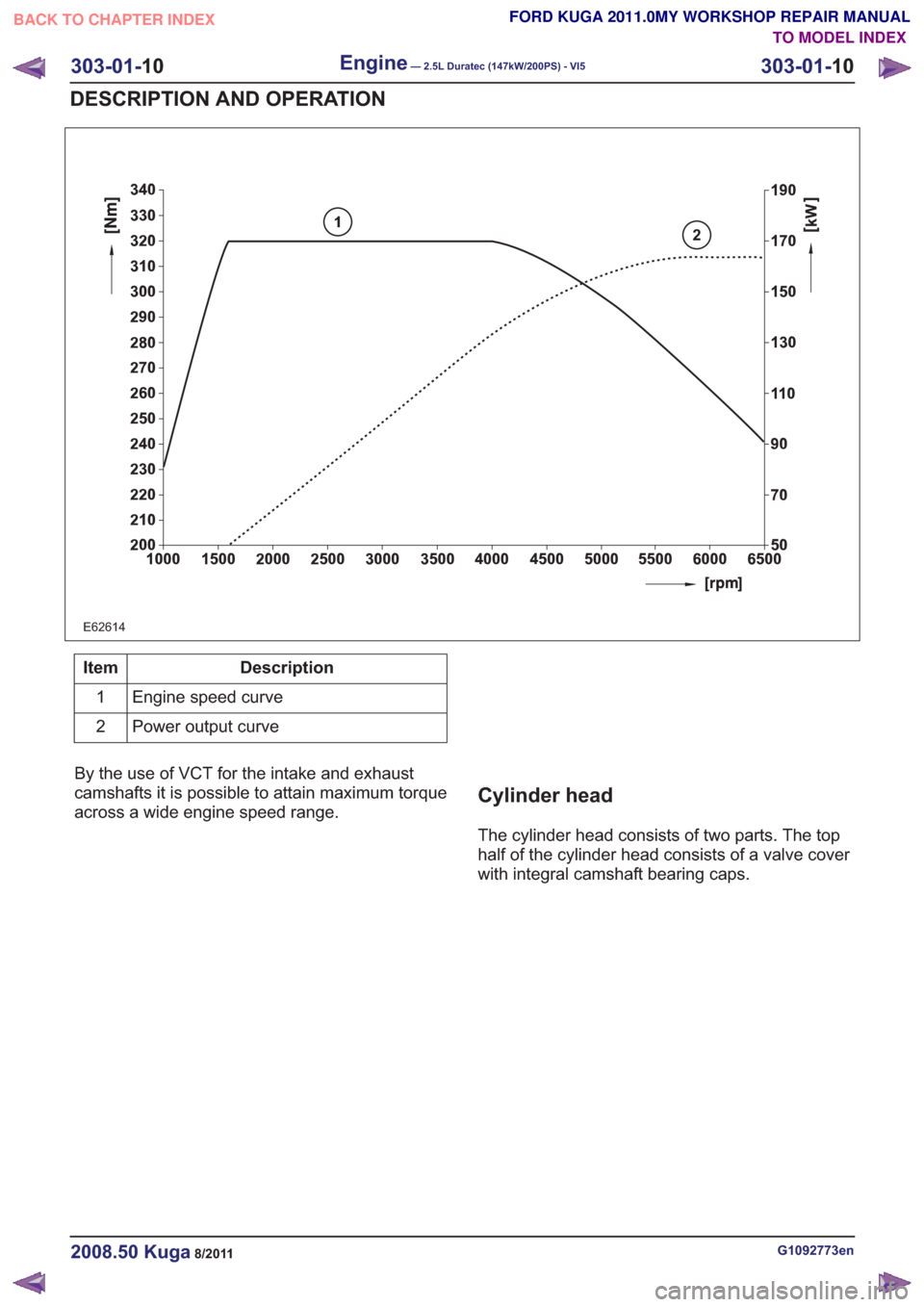

2

E62614

1

Description

Item

Engine speed curve

1

Power output curve

2

By the use of VCT for the intake and exhaust

camshafts it is possible to attain maximum torque

across a wide engine speed range.

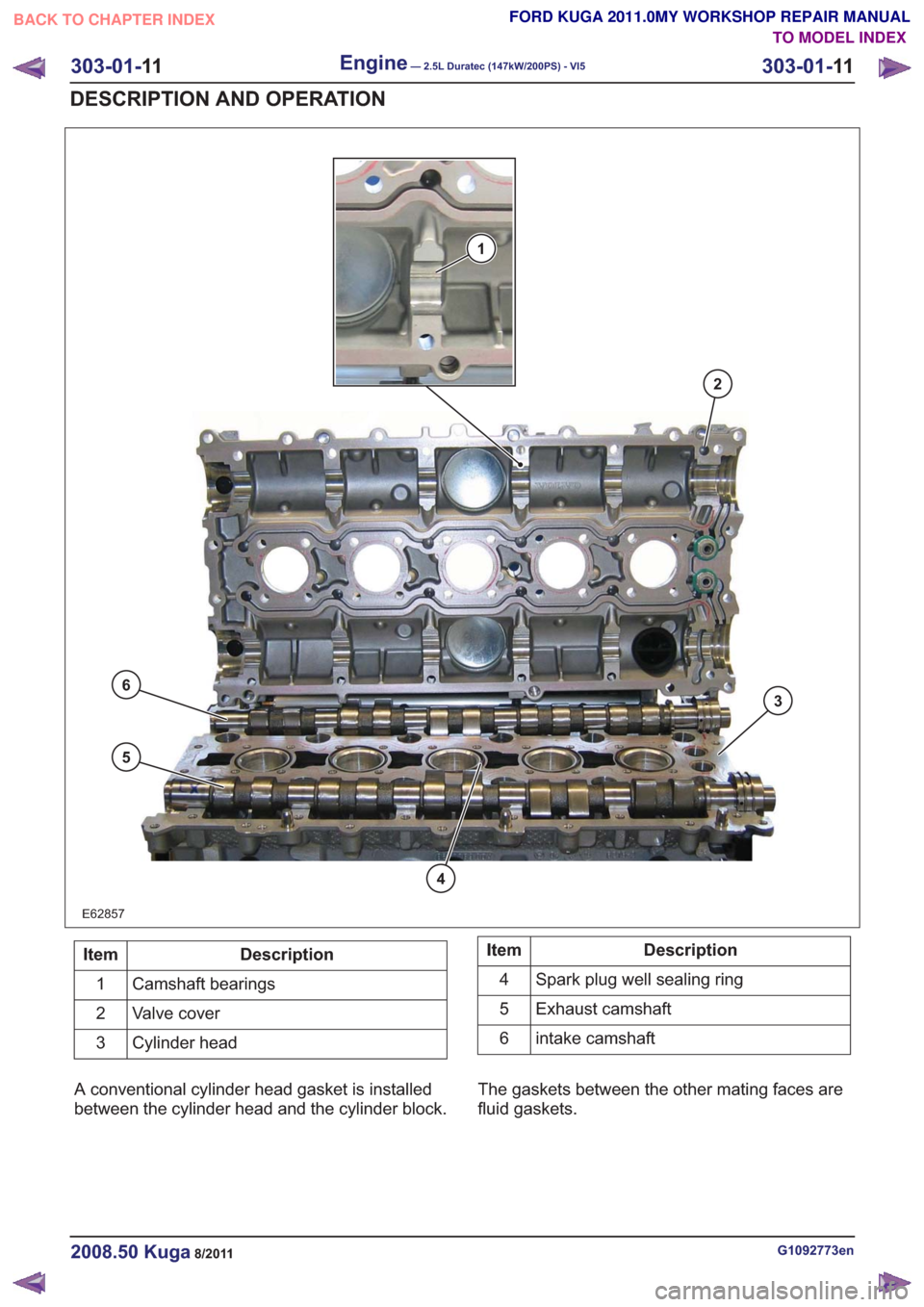

Cylinder head

The cylinder head consists of two parts. The top

half of the cylinder head consists of a valve cover

with integral camshaft bearing caps.

G1092773en2008.50 Kuga8/2011

303-01- 10

Engine— 2.5L Duratec (147kW/200PS) - VI5303-01-

10

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1544 of 2057

E62857

1

2

3

6

5

4

Description

Item

Camshaft bearings

1

Valve cover

2

Cylinder head

3Description

Item

Spark plug well sealing ring

4

Exhaust camshaft

5

intake camshaft

6

A conventional cylinder head gasket is installed

between the cylinder head and the cylinder block. The gaskets between the other mating faces are

fluid gaskets.

G1092773en2008.50 Kuga8/2011

303-01-

11

Engine— 2.5L Duratec (147kW/200PS) - VI5303-01-

11

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1546 of 2057

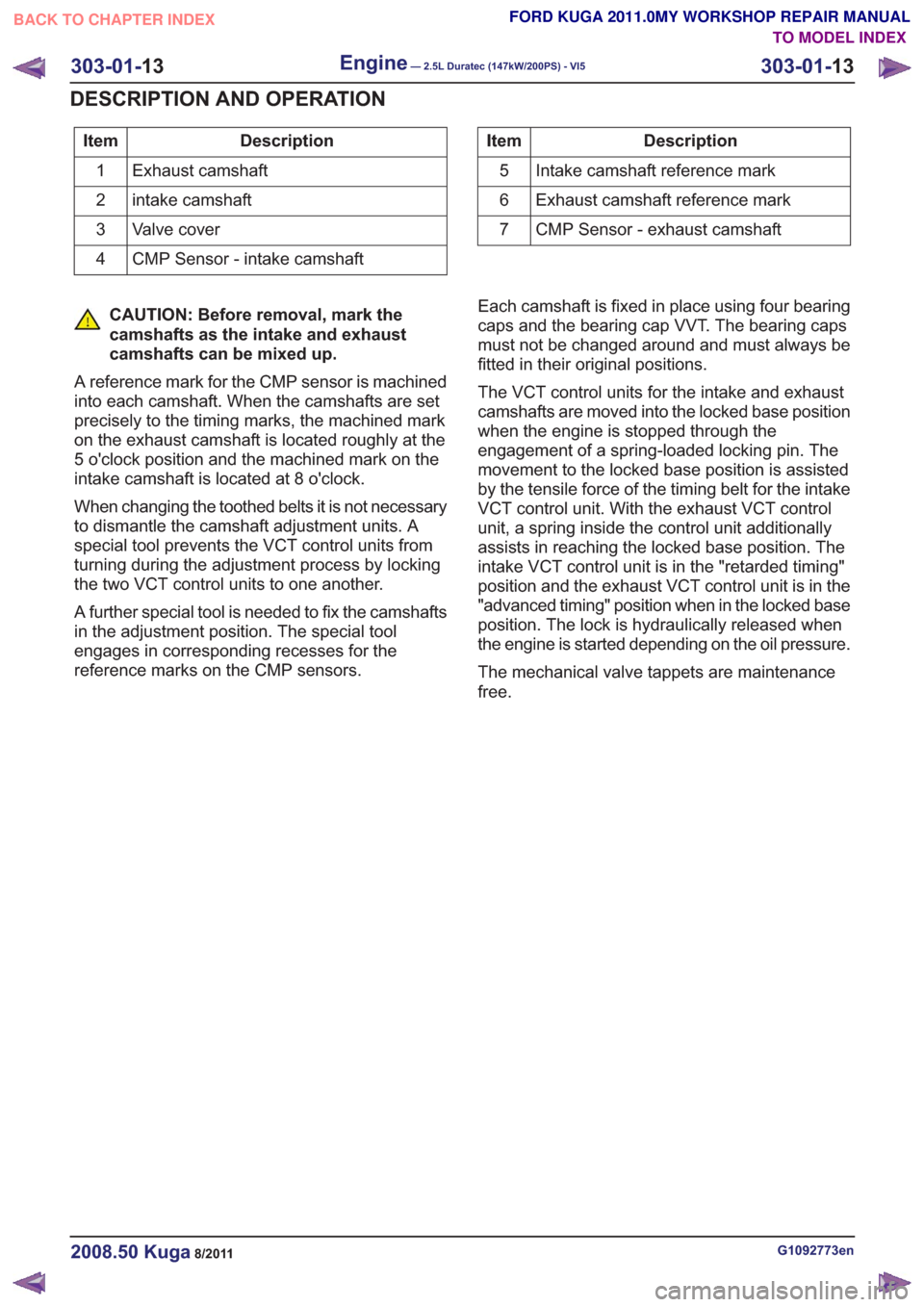

Description

Item

Exhaust camshaft

1

intake camshaft

2

Valve cover

3

CMP Sensor - intake camshaft

4Description

Item

Intake camshaft reference mark

5

Exhaust camshaft reference mark

6

CMP Sensor - exhaust camshaft

7

CAUTION: Before removal, mark the

camshafts as the intake and exhaust

camshafts can be mixed up.

A reference mark for the CMP sensor is machined

into each camshaft. When the camshafts are set

precisely to the timing marks, the machined mark

on the exhaust camshaft is located roughly at the

5 o'clock position and the machined mark on the

intake camshaft is located at 8 o'clock.

When changing the toothed belts it is not necessary

to dismantle the camshaft adjustment units. A

special tool prevents the VCT control units from

turning during the adjustment process by locking

the two VCT control units to one another.

A further special tool is needed to fix the camshafts

in the adjustment position. The special tool

engages in corresponding recesses for the

reference marks on the CMP sensors. Each camshaft is fixed in place using four bearing

caps and the bearing cap VVT. The bearing caps

must not be changed around and must always be

fitted in their original positions.

The VCT control units for the intake and exhaust

camshafts are moved into the locked base position

when the engine is stopped through the

engagement of a spring-loaded locking pin. The

movement to the locked base position is assisted

by the tensile force of the timing belt for the intake

VCT control unit. With the exhaust VCT control

unit, a spring inside the control unit additionally

assists in reaching the locked base position. The

intake VCT control unit is in the "retarded timing"

position and the exhaust VCT control unit is in the

"advanced timing" position when in the locked base

position. The lock is hydraulically released when

the engine is started depending on the oil pressure.

The mechanical valve tappets are maintenance

free.

G1092773en2008.50 Kuga8/2011

303-01-

13

Engine— 2.5L Duratec (147kW/200PS) - VI5303-01-

13

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1547 of 2057

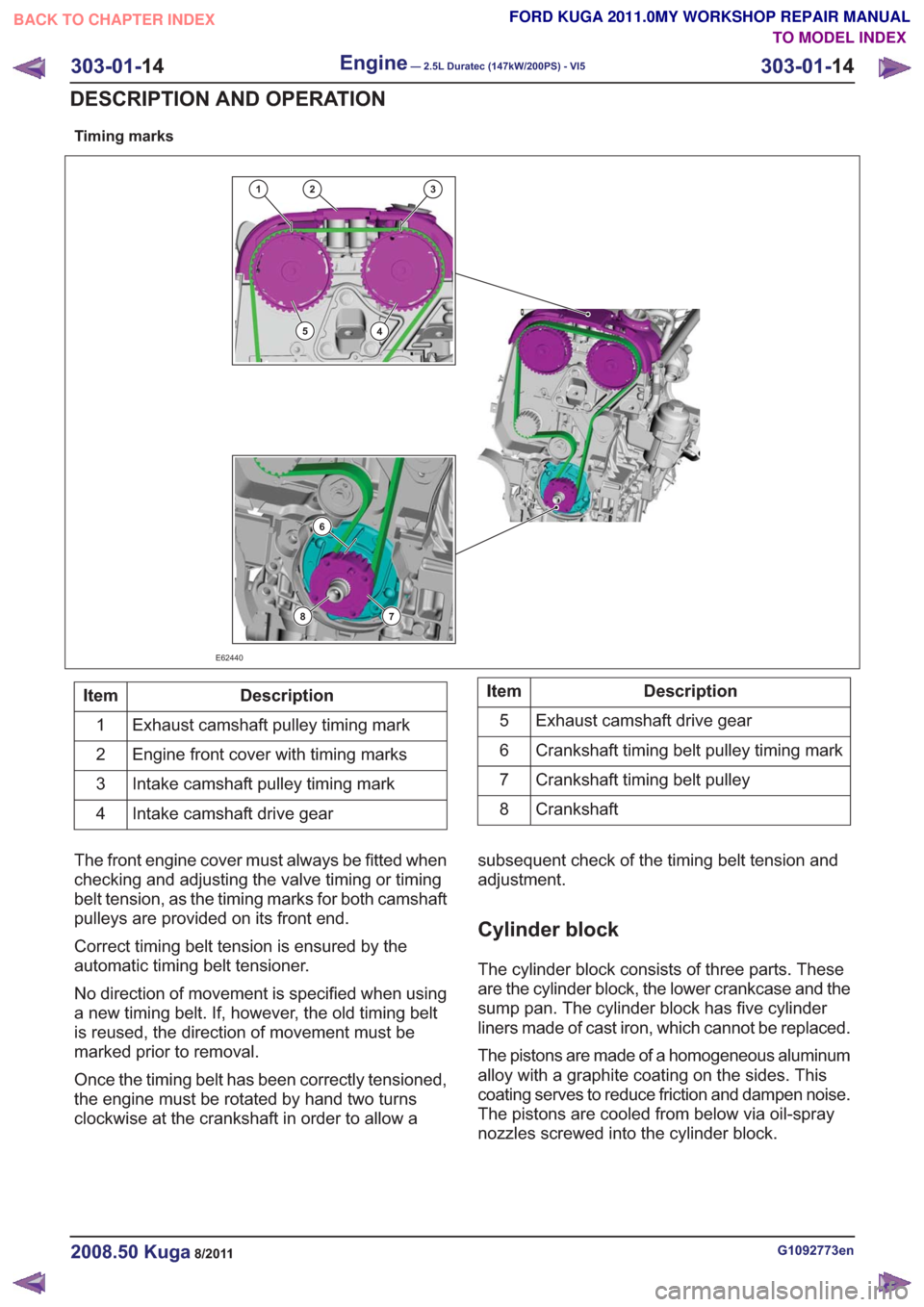

Timing marks

132

45

6

78

E62440

Description

Item

Exhaust camshaft pulley timing mark

1

Engine front cover with timing marks

2

Intake camshaft pulley timing mark

3

Intake camshaft drive gear

4Description

Item

Exhaust camshaft drive gear

5

Crankshaft timing belt pulley timing mark

6

Crankshaft timing belt pulley

7

Crankshaft

8

The front engine cover must always be fitted when

checking and adjusting the valve timing or timing

belt tension, as the timing marks for both camshaft

pulleys are provided on its front end.

Correct timing belt tension is ensured by the

automatic timing belt tensioner.

No direction of movement is specified when using

a new timing belt. If, however, the old timing belt

is reused, the direction of movement must be

marked prior to removal.

Once the timing belt has been correctly tensioned,

the engine must be rotated by hand two turns

clockwise at the crankshaft in order to allow a subsequent check of the timing belt tension and

adjustment.

Cylinder block

The cylinder block consists of three parts. These

are the cylinder block, the lower crankcase and the

sump pan. The cylinder block has five cylinder

liners made of cast iron, which cannot be replaced.

The pistons are made of a homogeneous aluminum

alloy with a graphite coating on the sides. This

coating serves to reduce friction and dampen noise.

The pistons are cooled from below via oil-spray

nozzles screwed into the cylinder block.

G1092773en2008.50 Kuga8/2011

303-01-

14

Engine— 2.5L Duratec (147kW/200PS) - VI5303-01-

14

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1549 of 2057

Engine – System Operation and Component Description

System Operation

The variable camshaft timing occurs

electro-hydraulically and individually for both

camshafts.

The camshaft adjusters work according to the vane

cell principle and have an adjustment range of 52°

crank angle on the intake side and 47° crank angle

on the exhaust side. On starting the engine and

during idling, both camshafts are mechanically

locked in their starting positions. The exhaust

camshaft is in the early position and the intake

camshaft is in the late position. The camshaftadjuster on the exhaust side has a torsion spring

which compensates the camshaft drive torque.

This ensures that the assembly can return to the

starting position under all operating conditions and

when the engine is turned off.

Internal exhaust gas recirculation can be realized

through continuous adjustment of the timings. This

results in better fuel consumption and more

favorable combustion temperatures which produce

less pollutants. This means that pollutant level IV

can be adhered to with a 3-way catalytic converter.

The variable timings also make it possible to

optimize performance with wide open throttle.

G1032416en2008.50 Kuga8/2011

303-01-

16

Engine— 2.5L Duratec (147kW/200PS) - VI5303-01-

16

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1552 of 2057

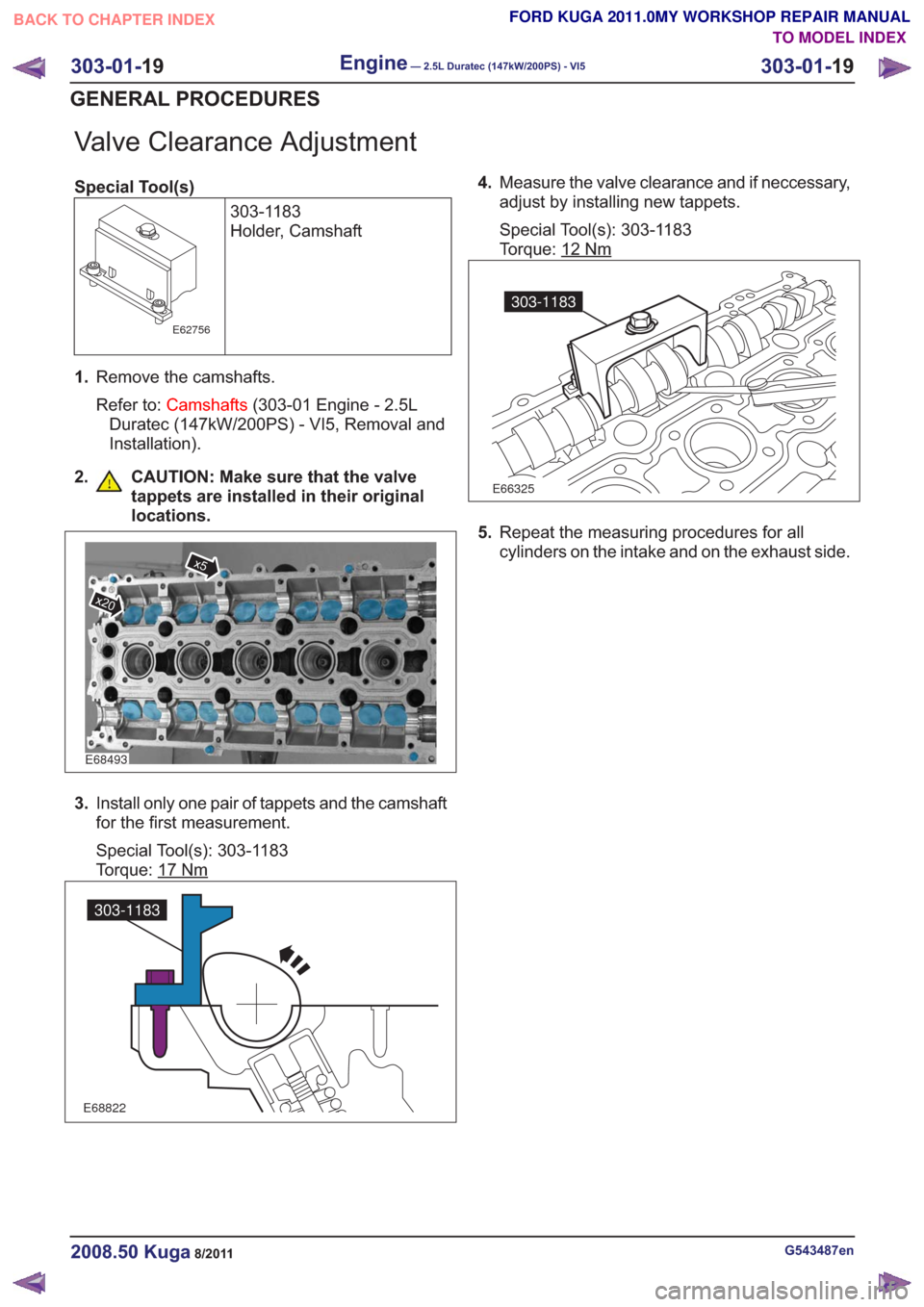

Valve Clearance Adjustment

Special Tool(s)303-1183

Holder, Camshaft

E62756

1.Remove the camshafts.

Refer to: Camshafts (303-01 Engine - 2.5L

Duratec (147kW/200PS) - VI5, Removal and

Installation).

2. CAUTION: Make sure that the valve tappets are installed in their original

locations.

E68493

x20

x5

3.Install only one pair of tappets and the camshaft

for the first measurement.

Special Tool(s): 303-1183

Torque: 17

Nm

E68822

303-1183

4.Measure the valve clearance and if neccessary,

adjust by installing new tappets.

Special Tool(s): 303-1183

Torque: 12

Nm

E66325

303-1183

5.Repeat the measuring procedures for all

cylinders on the intake and on the exhaust side.

G543487en2008.50 Kuga8/2011

303-01- 19

Engine— 2.5L Duratec (147kW/200PS) - VI5303-01-

19

GENERAL PROCEDURES

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1582 of 2057

Exhaust Manifold(21 187 0)

Removal

1.Refer to: Turbocharger (303-04 Fuel Charging

and Controls - Turbocharger - 2.5L Duratec

(147kW/200PS) - VI5, Removal and

Installation).

Installation

1. Refer to: Turbocharger (303-04 Fuel Charging

and Controls - Turbocharger - 2.5L Duratec

(147kW/200PS) - VI5, Removal and

Installation).

G1079021en2008.50 Kuga8/2011

303-01- 49

Engine— 2.5L Duratec (147kW/200PS) - VI5303-01-

49

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1583 of 2057

Cylinder Head(21 163 0)

General EquipmentFluid Container

Tire Lever

Materials

Specification

Name

WSS-M2C913-C

Engine Oil - 5W-30

SA-M1C9107-A / YS5J-

M1C9107-AA

Grease KS-PS

Removal

NOTE:

Removal steps in this procedure may

contain installation details.

1. Refer to: Cooling System Draining and Vacuum

Filling (303-03 Engine Cooling, General

Procedures).

2. Refer to: Fuel System Pressure Release

(310-00 Fuel System - General Information,

General Procedures).

3. Refer to: Battery Disconnect and Connect

(414-01 Battery, Mounting and Cables,

General Procedures).

4. Refer to: Air Cleaner (303-12 Intake Air

Distribution and Filtering - 2.5L Duratec

(147kW/200PS) - VI5, Removal and

Installation).

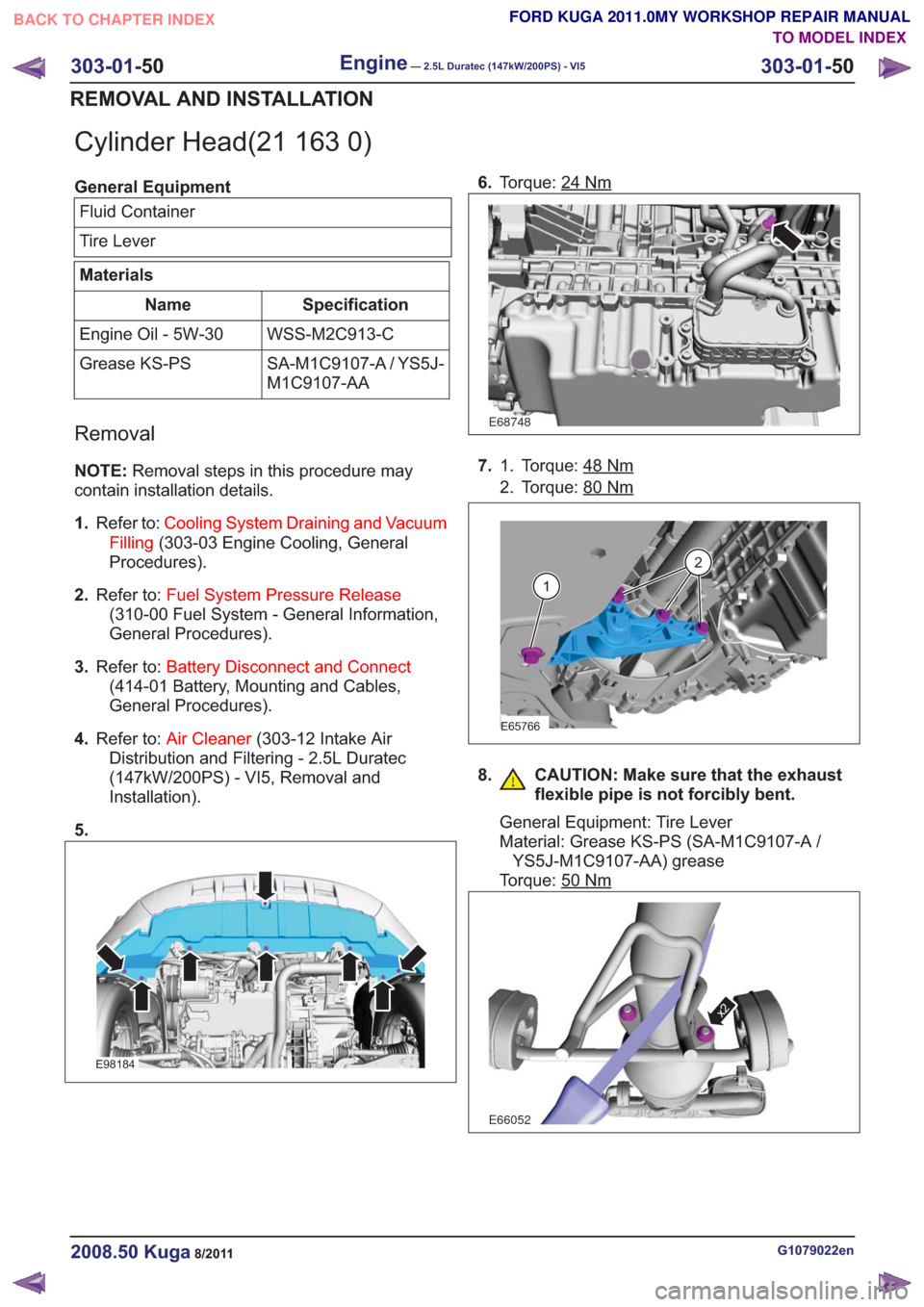

5.

E98184

6. Torque: 24Nm

E68748

7. Torque: 48Nm1.

2. Torque: 80

Nm

E65766

1

2

8. CAUTION: Make sure that the exhaust

flexible pipe is not forcibly bent.

General Equipment: Tire Lever

Material: Grease KS-PS (SA-M1C9107-A /YS5J-M1C9107-AA) grease

Torque: 50

Nm

E66052

x2

G1079022en2008.50 Kuga8/2011

303-01- 50

Engine— 2.5L Duratec (147kW/200PS) - VI5303-01-

50

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL