Turbocharger FORD KUGA 2011 1.G Owner's Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2011, Model line: KUGA, Model: FORD KUGA 2011 1.GPages: 2057

Page 1763 of 2057

Engine Emission Control

Inspection and Verification

1. Verify the customer concern.

2. Visually inspect for obvious signs of mechanicaldamage.

Visual Inspection Chart

Electrical

Mechanical

– Electricalconnector(s)

– Wiring harness

– Fuse(s)

– Relay

– Powertain control module (PCM)

– Hose(s)/hose joints

– Gasket(s)

– Positive crankcase

ventilation (PCV)

valve

– PCV crankcase vent oil separator

– Turbocharger 3. If an obvious cause for an observed or reported

concern is found, correct the cause (if possible)

before proceeding to the next step.

4. If the cause is not visually evident, verify the symptom and refer to the Symptom Chart.

Symptom Chart

Action

Possible Sources

Symptom

• CLEAN or INSTALL new PCVcomponents as necessary.

TEST the system for normal

operation.

• Blocked PCV crankcase vent

oil separator.

• Blocked PCV hose.

• Excessive crankcase pressure

• Worn or damaged enginecomponents.

REFER to: Engine(303-00

Engine System - General

Information, Diagnosis and

Testing).

• Engine.

• CLEAN or INSTALL a newcrankcase vent oil separator.

TEST the system for normal

operation.

• Crankcase vent oil separator.

• Oil in the air intake system

• Worn or damagedturbocharger.

REFER to: Turbocharger (303-

04 Fuel Charging and

Controls - Turbocharger -

2.5L Duratec (147kW/200PS)

- VI5, Diagnosis and Testing).

• Turbocharger.

G1183446en2008.50 Kuga8/2011

303-08-

4

Engine Emission Control— 2.5L Duratec (147kW/200PS) - VI5303-08-

4

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1766 of 2057

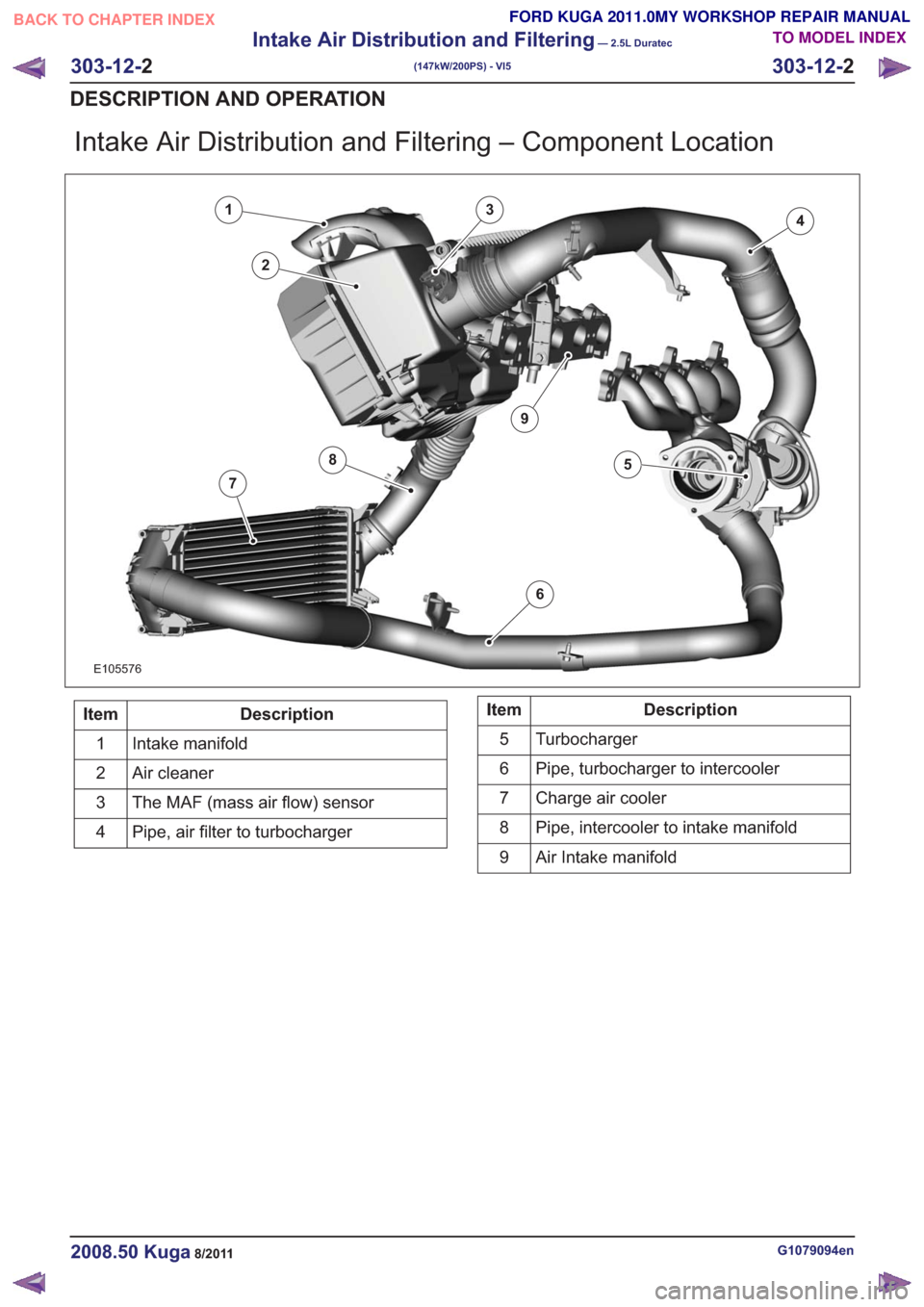

Intake Air Distribution and Filtering – Component Location

E105576

1

2

34

5

6

7

8

9

Description

Item

Intake manifold

1

Air cleaner

2

The MAF (mass air flow) sensor

3

Pipe, air filter to turbocharger

4Description

Item

Turbocharger

5

Pipe, turbocharger to intercooler

6

Charge air cooler

7

Pipe, intercooler to intake manifold

8

Air Intake manifold

9

G1079094en2008.50 Kuga8/2011

303-12- 2

Intake Air Distribution and Filtering

— 2.5L Duratec

(147kW/200PS) - VI5

303-12- 2

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1768 of 2057

Intake Air Distribution and Filtering

Inspection and Verification

1. Verify the customer concern.

2. Visually inspect for obvious signs of mechanicalor electrical damage.

Visual Inspection Chart

Electrical

Mechanical

– Mass air flow (MAF)sensor

– Manifold absolute pressure (MAP)

sensor

– Electrical connector(s)

– Air cleaner element

– Air cleaner intake

pipe

– Air cleaner outlet pipe

– Charge air cooler

– Charge air cooler intake pipe

– Charge air cooler outlet pipe 3. If an obvious cause for an observed or reported

concern is found, correct the cause (if possible)

before proceeding to the next step.

4. If the cause is not visually evident, verify the symptom and refer to the Symptom Chart.

Symptom Chart

Action

Possible Sources

Symptom

• CHECK the pipe(s) for securityand leaks to atmosphere.

INSTALL new intake air

components as necessary.

TEST the system for normal

operation.

• Detached air cleaner pipe(s).

• Detached turbocharger pipe(s).

• Detached charge air cooler

pipe(s).

• Excessive intake air noise

• REFER to:Engine Emission

Control (303-08 Engine

Emission Control - 2.5L

Duratec (147kW/200PS) -

VI5, Diagnosis and Testing).

• Blocked or damaged PCV

pipe(s)/hose(s).

• Blocked or damaged crankcase vent oil separator.

• Oil in the air intake system

• REFER to:Turbocharger(303-

04 Fuel Charging and

Controls - Turbocharger -

2.5L Duratec (147kW/200PS)

- VI5, Diagnosis and Testing).

• Turbocharger.

• CHECK the air intake pipesplash shield for correct install-

ation and alignment.

REPAIR/INSTALL the air intake

pipe splash shield as neces-

sary. TEST the system for

normal operation.

• Air intake pipe splash shield.

• Water in the air cleaner

G1183447en2008.50 Kuga8/2011

303-12- 4

Intake Air Distribution and Filtering

— 2.5L Duratec

(147kW/200PS) - VI5

303-12- 4

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1769 of 2057

Action

Possible Sources

Symptom

• CHECK the air cleaner drainfor blockage. TEST the system

for normal operation.

• Blocked air cleaner drain.

• INSPECT the air cleaner forsigns of blockage. INSTALL a

new air cleaner element as

necessary.

• Air cleaner element blocked.

• Engine lacks power

• INSPECT the charge air coolerpipes for damage. INSTALL a

new charge air cooler pipe(s)

as necessary.

• Charge air cooler pipe(s).

• INSPECT the charge air coolerfor blockage. INSTALL a new

charge air cooler as necessary.

REFER to: Charge Air Cooler

(303-12 Intake Air Distribution

and Filtering - 2.5L Duratec

(147kW/200PS) - VI5,

Removal and Installation).

• Charge air cooler blocked.

• REFER to:Fuel Charging and

Controls (303-04 Fuel Char-

ging and Controls - 2.5L

Duratec (147kW/200PS) -

VI5, Diagnosis and Testing).

• Fuel charging and controls.

• REFER to:Turbocharger(303-

04 Fuel Charging and

Controls - Turbocharger -

2.5L Duratec (147kW/200PS)

- VI5, Diagnosis and Testing).

• Turbocharger.

• REFER to:Engine(303-00

Engine System - General

Information, Diagnosis and

Testing).

• Engine.

G1183447en2008.50 Kuga8/2011

303-12-

5

Intake Air Distribution and Filtering

— 2.5L Duratec

(147kW/200PS) - VI5

303-12- 5

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1790 of 2057

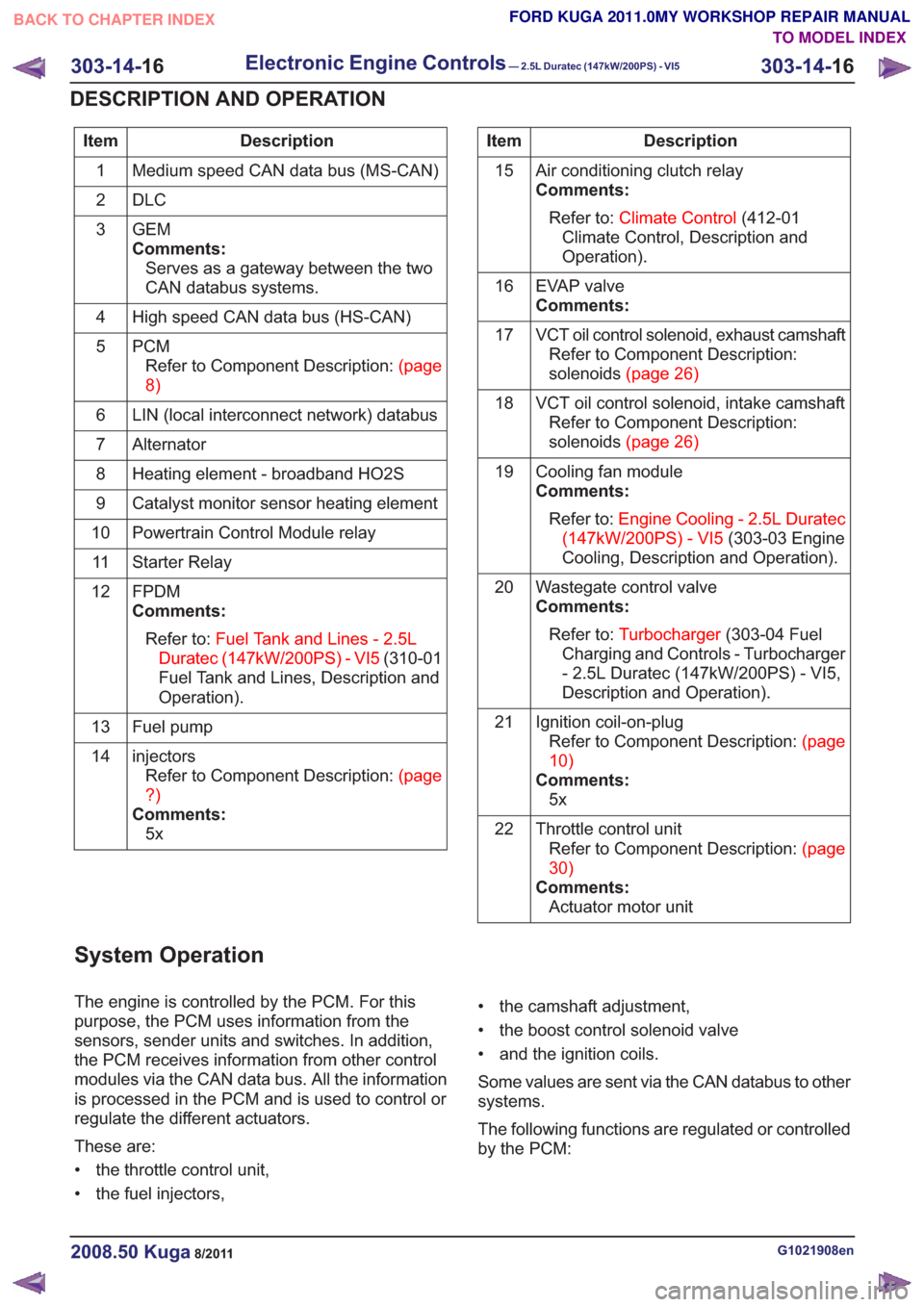

Description

Item

Medium speed CAN data bus (MS-CAN)

1

DLC

2

GEM

Comments:Serves as a gateway between the two

CAN databus systems.

3

High speed CAN data bus (HS-CAN)

4

PCMRefertoComponentDescription:(page

8)

5

LIN (local interconnect network) databus

6

Alternator

7

Heating element - broadband HO2S

8

Catalyst monitor sensor heating element

9

Powertrain Control Module relay

10

Starter Relay

11

FPDM

Comments:Refer to: Fuel Tank and Lines - 2.5L

Duratec (147kW/200PS) - VI5 (310-01

Fuel Tank and Lines, Description and

Operation).

12

Fuel pump

13

injectorsRefertoComponentDescription:(page

?)

Comments: 5x

14Description

Item

Air conditioning clutch relay

Comments:Refer to: Climate Control (412-01

Climate Control, Description and

Operation).

15

EVAP valve

Comments:

16

VCT oil control solenoid, exhaust camshaftRefer to Component Description:

solenoids(page26)

17

VCT oil control solenoid, intake camshaftRefer to Component Description:

solenoids(page26)

18

Cooling fan module

Comments:Refer to: Engine Cooling - 2.5L Duratec

(147kW/200PS) - VI5 (303-03 Engine

Cooling, Description and Operation).

19

Wastegate control valve

Comments:Refer to: Turbocharger (303-04 Fuel

Charging and Controls - Turbocharger

- 2.5L Duratec (147kW/200PS) - VI5,

Description and Operation).

20

Ignition coil-on-plugRefertoComponentDescription:(page

10)

Comments: 5x

21

Throttle control unitRefertoComponentDescription:(page

30)

Comments: Actuator motor unit

22

System Operation

The engine is controlled by the PCM. For this

purpose, the PCM uses information from the

sensors, sender units and switches. In addition,

the PCM receives information from other control

modules via the CAN data bus. All the information

is processed in the PCM and is used to control or

regulate the different actuators.

These are:

• the throttle control unit,

• the fuel injectors, • the camshaft adjustment,

• the boost control solenoid valve

• and the ignition coils.

Some values are sent via the CAN databus to other

systems.

The following functions are regulated or controlled

by the PCM:

G1021908en2008.50 Kuga8/2011

303-14-

16

Electronic Engine Controls— 2.5L Duratec (147kW/200PS) - VI5303-14-

16

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1797 of 2057

Calculation of valve timing adjustment

angle

The 2.5L Duratec (VI5) engine has two camshaft

adjustment units which work independently of each

other.

One camshaft adjustment solenoid is installed for

each intake camshaft and exhaust camshaft.

This allows the PCM to continuously adjust the

intake and exhaust-side camshaft adjustments

independently of one another. The timing is

adjusted by the PCM using curves; adjustment is

primarily done as a function of engine load and

engine speed.

In this way the engine performance is increased

and internal exhaust gas recirculation is realized.

The advantages of camshaft adjustment are as

follows:

• Higher torque and improved torquecharacteristics

• Reduced fuel consumption

• Improved emissions performance

The camshaft adjustment solenoids are actuated

by the PWM by means of a PCM signal.

Continuous adjustment of the camshafts by the

PCM is achieved by means of the camshaft

adjustment solenoids, the camshaft adjustment

units and two CMP sensors. A defined quantity of

engine is oil is supplied to or drained from the

adjustment units via the camshaft adjustment

solenoids. The existing EOP (engine oil pressure)

is taken into account in the process. In this way

the valve timings are adjusted according to the

operating condition of the engine. The camshaft

adjusters work according to the vane-cell principle.

On starting the engine, both camshafts are

mechanically locked in their starting positions. The

intake camshaft is in the maximum late position

and the exhaust camshaft in the maximum early

position.

Control is divided into four main areas:

• Low engine speed and low load

• Partial load

• Low engine speed and high load

• High engine speed and high load

At low engine speed and low load, the exhaust

valves open early and the intake valves open late.

The result is reduced fuel consumption and more

uniform idling. In the partial load range, the exhaust valves and

the intake valves open late. The late opening of

the exhaust valves results in a good utilization of

the expanding gases in the cylinder. Closing the

exhaust valves after Top Dead Center allows

internal exhaust gas recirculation through aspiration

of exhaust gases into the combustion chamber.

Moreover, the intake valves close after Bottom

Dead Centre, allowing the fresh air/fuel mixture

and exhaust gases to flow back into the intake

tract. The result is reduced fuel consumption and

low emissions.

At low engine speed and high engine load, the

exhaust valves open late and the intake valves

open early. Due to the resulting valve opening

overlap at Top Dead Centre, the pulsating gas

column within the combustion chamber is utilized

to achieve better charging of the combustion

chamber. The result is increased torque at lower

RPM.

At high engine speeds and high engine load, the

exhaust valves open early and the intake valves

close late. Because a rapid gas exchange must be

achieved at high engine speeds, the early opening

of the exhaust valves achieves better expulsion of

the exhaust gas and the late closing of the intake

valves improves cylinder charge efficiency.

Optimum power output is achieved.

Many other camshaft positions are possible in

addition to these settings.

In order to avoid a malfunction in the camshaft

adjustment units at excessively low ambient or

engine-oil temperatures, they are activated by the

PCM with a time delay via the camshaft adjustment

solenoids. The PCM receives the information

required for this from the ECT sensor and the

outside air temperature sensor.

When idling and during deceleration, the camshaft

adjustment solenoids are activated repeatedly by

the PCM in order to remove any dirt which may be

on the bore holes and ring grooves.

Boost pressure control

Optimum regulation is achieved by means of an

electronically-controlled solenoid valve, the boost

control solenoid valve.

Refer to:

Turbocharger (303-04 Fuel Charging and

Controls - Turbocharger - 2.5L Duratec

(147kW/200PS) - VI5, Description and

Operation).

G1021908en2008.50 Kuga8/2011

303-14- 23

Electronic Engine Controls— 2.5L Duratec (147kW/200PS) - VI5303-14-

23

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL