Wheel FORD KUGA 2011 1.G Owner's Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2011, Model line: KUGA, Model: FORD KUGA 2011 1.GPages: 2057

Page 100 of 2057

Suspension System

Special Tool(s)Alignment Pins, Subframe

205-316 (15-097A)

15097A

Inspection and Verification

1. Verify the customer concern.

2. Visually inspect for obvious signs of mechanicaldamage.

Visual Inspection Chart

Mechanical

Tire pressure(s) Wheel and tires

Mechanical

Wheel knuckles Tie-rod ends

Front suspension lower arm ball joints Front suspension lower arm bushings Front strut and spring assemblies

Front and rear stabilizer bar and connecting links Rear springs

Rear shock absorbers

Rear suspension lower arms

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible)

before proceeding to the next step.

4. If the cause is not visually evident, verify the symptom and refer to the Symptom Chart.

Symptom Chart

Symptom Chart

Action

Possible Sources

Symptom

• Vehicles without load levellingshock absorbers, CHECK for

abnormal loading, spring sag

or non-standard springs.

• Vehicles with load levelling shock absorbers, GO to

Pinpoint Test C.

• Vehicle attitude incorrect (front

or rear / left or right is high or

low).

• Drift left or right

• CHECK the steering system.REFER to: Steering System

(211-00 Steering System -

General Information,

Diagnosis and Testing).

• Steering gear or linkage worn

or damaged.

• CHECK the brake system.REFER to: Brake System (206-

00 Brake System - General

Information, Diagnosis and

Testing).

• Brake system.

• Using the special tool, CHECKthe front subframe alignment..

• Incorrect front crossmember

alignment.

• CHECK the wheel bearings.

• Worn front wheel bearings.

• GO toPinpoint Test A.

• Wheel and tires.

G1080717en2008.50 Kuga8/2011

204-00- 2

Suspension System - General Information

204-00- 2

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 187 of 2057

Description

Item

Instrument Cluster

1

PCM (powertrain control module)

2

EHPS (electro-hydraulic power steering)

control module

3

Audio unit

4

GEM (generic electronic module)

5

RCM (restraints control module)

6

PATS transceiver

7 Description

Item

Steering wheel lock module

8

Left-hand steering column switch

9

Fuel level sensor

10

Washer water level warning lamp switch

11

Accelerator pedal position sensor

12

CPP (clutch pedal position) sensor/BPP

(brake pedal position) sensor

13

Lighting control switch

14

System Operation

Instrument Cluster

The instrument cluster contains analog displays

as well as warning and control lamps for displaying

the system status; in addiiton, there is an LCD

indicator field for driver information.

The instrument cluster receives the following

signals from the PCM via the high speed CAN

(controller area network) Bus (HS-CAN):

• Vehicle speed – The PCM receives the necessary signalsfrom the ABS (anti-lock brake system) wheel

sensors from the ABS control unit on the

HS-CAN.

• Engine Coolant Temperature

• Engine oil pressure.

• Engine speed

The instrument cluster receives the following

signals from the GEM via the medium speed CAN

Bus (MS-CAN):

• Ambient temperature

• Brake fluid level

• Handbrake control

• Door latch control

• Liftgate latch control

• High beam control

• Headlamp flasher control

• Direction indicator control

The fuel level signal is sent by the two fuel level

sensors in the fuel pumps in the semitrailer tank,

which is wired to the instrument cluster. The

sensors are connected in series, and the total

resistance is determined from the two individual resistors. The instrument cluster converts the raw

fuel level signal into a damped fuel level value.

The odometer shows the total distance travelled

by the vehicle and is based on the same signal as

is processed for the daily mileage counter. The

value is recorded by the instrument cluster and

stored in a protected EEPROM (Electronically

Erasable Programmable Read Only Memory) area.

This area is a memory protected against

manipulation. If the instrument cluster detects an

error in this memory area, e.g. through damage,

the driver is notified with the "Odometer error"

message.

Message center

The message center is operated using the left-hand

switch on the steering column.

The SET/RESET button is activated to select a

submenu and change the settings. If signal tones

have been activated, a short acoustic signal will

sound each time a button is pressed.

By turning the rotary switch, the different menu

displays can be scrolled through or a setting

selected.

In this display, the navigation system can also

display direction and distance information.

In addition, safety and warning messages can be

displayed in this system, such as "Coolant

overheating", "Engine system error" or "Washer

fluid level too low". In addition to a safety message,

a general warning light (red/yellow) lights up.

G1030770en

2008.50 Kuga 8/2011 413-01-4

Instrument Cluster

413-01-4

DESCRIPTION AND OPERATIONTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 190 of 2057

Instrument Cluster

Refer to

Wiring Diagrams Section 413-01, for

schematic and connector information. General Equipment

The Ford approved diagnostic tool

Inspection and Verification

1. Verify the customer concern.

2. Visually inspect for obvious signs of mechanical

or electrical damage.

Visual Inspection Chart Electrical

Mechanical

– Fuse(s)

– Wiring harness

– Electricalconnector(s)

– Instrument cluster

– Light emitting diode(s) (LED)(s)

– Engine oil filter

– Engine oil level

–

Engine coolant level

– Oil pressure switch

– Engine coolant level

– Coolant thermostat

– Engine coolant temperature (ECT)

sensor

– Fuel gauge

– Collapsed or damaged fuel tank

– Recirculation hose

– Fuel tank filler pipe/hose

– Indicated fuel level

– Fuel lines

– Fuel tank filler cap

– Fuel filter (external to the fuel tank)

– Fuel tank

– Door adjustment

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible)

before proceeding to the next step.

4. NOTE: If none of the following warning indicators are operating correctly this may

indicate a concern with the central junction

box (CJB). If only one or two of the following

warning indicators are not operating

correctly this may indicate an instrument

cluster concern. Verify the following warning indicators are

working correctly:

• Charging.

• Turn signals.

• Headlamps.

5. If the cause is not visually evident, verify the symptom and refer to the diagnostic tab within

the Ford approved diagnostic tool.

Configuration of the Instrument Cluster

The instrument cluster is a programmable module,

which must be configured by selecting the

Programmable Module Installation Routine on the

Ford approved diagnostic tool.

NOTE: When the new instrument cluster has been

configured with the odometer value, its

configuration cannot be decreased or matched. A

new configuration will result in an increase in the

displayed odometer value by a minimum of two

units.

NOTE: The odometer value must be recorded from

the original instrument cluster before removal.

If the odometer value cannot be obtained from

the original instrument cluster (display failure)

the customer should supply the approximate

value.

The following features will need to be configured

when a new instrument cluster is installed:

• Anti-lock Brake System (ABS)

• All wheel drive

• Keyless vehicle entry

• Electronic power assisted steering

• Trip computer

• Voice control

• Parking aid

• Belt minder

• Safety belt not fastened

• Right hand drive

• Overspeed warning

• Reverse warning

• Turbocharger boost pressure

• Speed control

• Auxiliary heater

• Suspension control

• Washer fluid sensor G1054964en

2008.50 Kuga 8/2011 413-01-7

Instrument Cluster

413-01-7

DIAGNOSIS AND TESTINGTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 195 of 2057

Horn

Principles of Operation

The horn system consists of a relay, a steering

wheel switch and either one or two horns. The

horn(s) receives voltage from the switched side of

the relay, and the relay switch is controlled on its

ground side by the steering wheel switch.

The horn relay, is located in the Battery junction

box (BJB) and is supplied with a permanent voltage

from the battery.

The steering wheel horn switch shares the steering

wheel clockspring circuit with the air-bag circuit.

Each of these systems work completely

independent of each other.

Inspection and Verification

1. Verify the customer concern.

2.

Visually inspect for obvious signs of mechanical

or electrical damage.

Visual Inspection Chart Electrical

• Fuse(s)

• Wiring harness

• Electrical connector(s)

• Horn switch

• Horn

• Clockspring

• Horn relay

• BJB

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible)

before proceeding to the next step.

4. If the cause is not visually evident, verify the symptom and refer to the diagnostic tab within

the Ford approved diagnostic tool. G1055042en

2008.50 Kuga 8/2011 413-06-2

Horn

413-06-2

DIAGNOSIS AND TESTINGTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 304 of 2057

Description

Item

In-car entertainment

1

Genetic electronic module (GEM).

2

instrument cluster

3

ABS4

ABS sensor assembly

5

Rear LH mid/bass range speaker

6

Rear RH mid/bass range speaker

7

Rear LH tweeter

8 Description

Item

Rear RH tweeter

9

AUX port

10

Radio remote control.

11

FM/AM antenna

12

Front LH mid/bass speaker

13

Front RH mid/bass speaker

14

Front LH tweeter

15

Front RH tweeter

16

System Operation

In-car entertainment

The audio system is connected to the MS CAN

network and uses an internal amplifier which

directly drives the system speakers. It can only be

operated via the head unit and the radio remote

control. The head unit is connected to the vehicle

on the medium speed CAN bus. This allows the

unit to be interrogated for diagnostic purposes.

The automatic volume control (AVC) adjusts the

audio volume depending on the driving speed. The

audio device receives the necessary signals for

the ABS (anti-lock brake system) wheel sensors

from the instrument cluster on the MS-CAN. As

vehicle speed increases the audio level is adjusted

to compensate for extra road and vehicle noise.

Eight AVC settings are possible.

To choose the setting for automatic volume control,

press the MENU button until the AVC display

appears.

The required adjustment level is determined by the

Infotainment control unit based on the driving

speed signal. The vehicle speed signal is received

over the CAN. The signal is an average of the four

wheel speed sensor signals. Should an invalid

speed signal be received the AVC will not alter the

output volume.

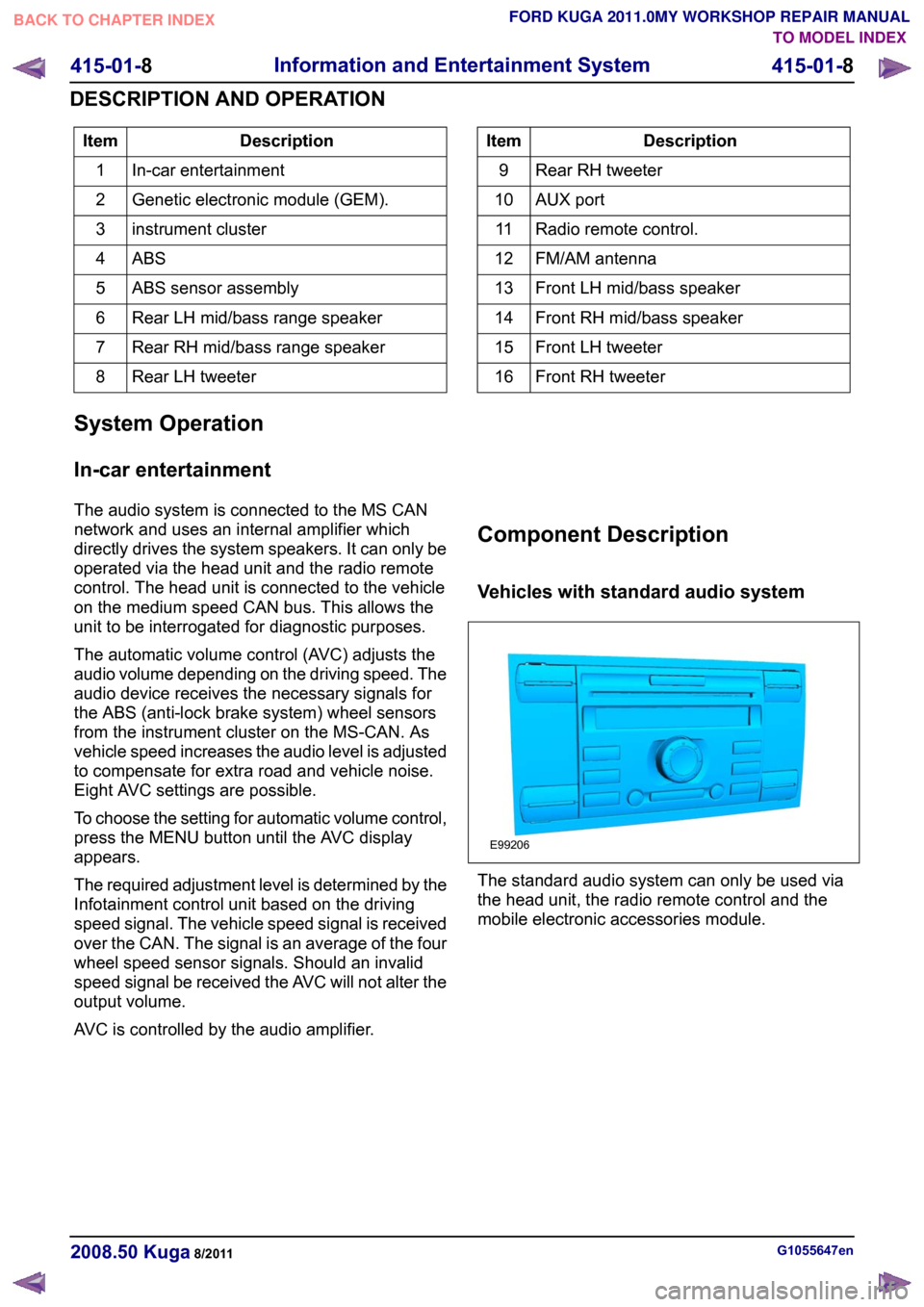

AVC is controlled by the audio amplifier. Component Description

Vehicles with standard audio system

The standard audio system can only be used via

the head unit, the radio remote control and the

mobile electronic accessories module.

G1055647en

2008.50 Kuga 8/2011 415-01-8

Information and Entertainment System

415-01-8

DESCRIPTION AND OPERATIONTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUALE99206

Page 364 of 2057

Headlamp Adjustment

General Equipment

Headlamp Beam Setter

All Vehicles

1. NOTE: Make sure that the tire pressures are to

specification and that the vehicle is unladen.

NOTE: Only use a damp cloth to clean the

headlamp lens to avoid any electrostatic

charging.

Ensure that the adjustment is made with the

suspension set up.

2. Place the vehicle on a level surface.

Vehicles with conventional headlamps

3. Repeatedly operate the headlamp leveling

switch and then set it to "0".

Vehicles with adaptive front lighting

4. Use the diagnostic tool to make certain that the

front wheels are in the straight ahead position.

Vehicles with gas discharge headlamps

5. Calibrate the headlamp leveling system using

the diagnostic tool.

All Vehicles

6. NOTE: Always follow the manufacturer's

instructions when handling the equipment.

Set the measuring screen of the beam setting

equipment to the correct headlamp adjustment

setting.

Refer to: Specifications (417-01 Exterior

Lighting, Specifications).

General Equipment: Headlamp Beam Setter

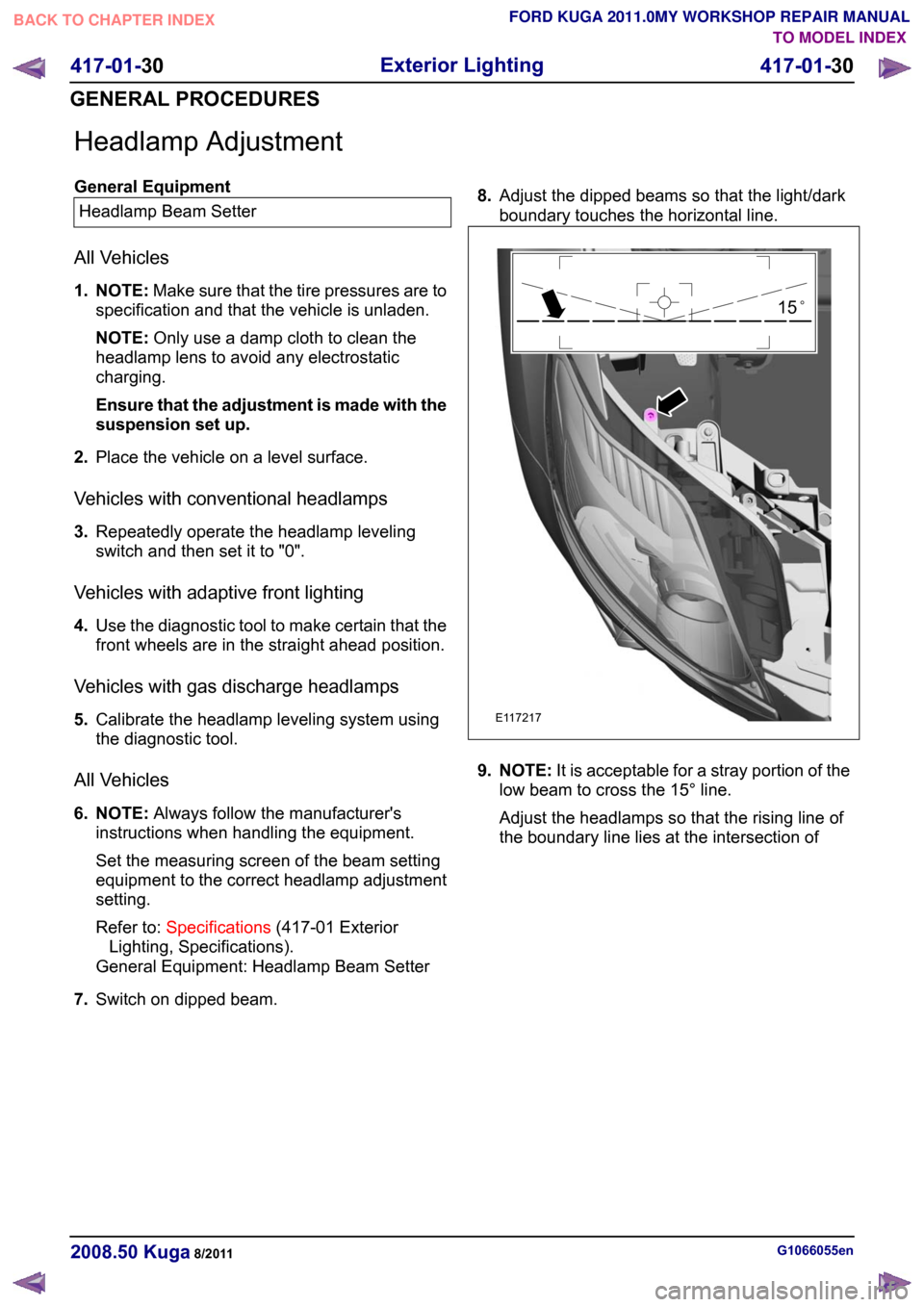

7. Switch on dipped beam. 8.

Adjust the dipped beams so that the light/dark

boundary touches the horizontal line. 9. NOTE:

It is acceptable for a stray portion of the

low beam to cross the 15° line.

Adjust the headlamps so that the rising line of

the boundary line lies at the intersection of G1066055en

2008.50 Kuga 8/2011 417-01-30

Exterior Lighting

417-01-30

GENERAL PROCEDURESTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUALE11721715

Page 380 of 2057

Description

Item

Reversing camera module (RVC)

10

Keyless vehicle module (KVM)

11

All-wheel drive control unit

12

RDM - Driver's side

13

RCM (restraints control module)

14

DDM (driver door module)

15

Instrument Cluster

16 Description

Item

High intensity discharge headlamp module

(optional)

17

ABS (anti-lock brake system) module or

electronic stability program module

18

PCM (powertrain control module)

19

The EATC (electronic automatic

temperature control) control module

20

Electrohydraulic power steering module

21 G1072290en

2008.50 Kuga 8/2011 418-00-3

Module Communications Network

418-00-3

DESCRIPTION AND OPERATIONTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 383 of 2057

Description

Item

Medium speed CAN (controller area

network) bus (MS-CAN)

A

High speed CAN bus (HS-CAN)

B

LIN (local interconnect network) bus

C

Terminating resistors

Drive

DLC (data link connector)

E

GEMRefer to Component Description: ABS

(page ?)

1

Fuel fired booster heater /programmable

fuel fired booster heater

2

The EATC control module

3

Reversing camera module (RVC)

4

Parking aid module (PAM)

5

DDM6

Front driver's side switch unit

7

Driver's side RDM

8

PDM (Passenger Door Module)

9

Passenger side RDM

10

Audio unit/navigation unit

11

CD changer

12 Description

Item

Navigation system module - vehicles

equipped with DVD navigation system with

touch screen (not communicating with the

diagnostic unit)

13

Navigation system display - vehicles

equipped with DVD navigation system with

touch screen (not communicating with the

diagnostic unit)

14

Control module for electronic auxiliary

equipment (BVC)

15

RCM16

Keyless vehicle module (KVM)

17

Instrument Cluster

18

PCM19

Fuel additive system module.

20

ABS module or electronic stability program

module

21

Yaw rate sensor/lateral acceleration

sensor

22

Headlamp Leveling Module

23

All-wheel drive control unit

24

Electrohydraulic power steering module

25

System Operation

General

In a communications network (data bus system),

various modules of different systems are connected

to one another via one or several lines.

The data bus system is used exclusively for

transmitting data between the connected modules,

as well as between the connected modules and

the Ford diagnostic unit.

In a data bus system, complete data blocks are

transmitted instead of single on/off pulses. In

addition to the actual information, these data blocks

also contain data regarding the address of the

module to be addressed, the size of the data block

and information for monitoring the content of each

individual data block.

Data bus systems offer various advantages: • Simplified data transmission between the

modules due to a standardized protocol

• Fewer sensors and connectors

• Improved diagnostic options

• Lower costs

The DLC is connected to the various data bus

systems and to the power supply via the standard

16-pin GEM. The signal for the module

programming is also transferred via the DLC.

In a data bus system, if there is a break in one or

both lines or there is a short to ground or to voltage,

then communication between the modules and

with the Ford diagnostic unit is disturbed or is no

longer possible at all.

In order to be able to establish communication with

one another, the modules of the individual systems G1030779en

2008.50 Kuga 8/2011 418-00-6

Module Communications Network

418-00-6

DESCRIPTION AND OPERATIONTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 388 of 2057

Module Configuration

Activation

1.

Install the most up-to-date software version in

the integrated diagnostic system (IDS).

2. In IDS, select the "Module reprogramming"

submenu in the "Module programming" menu

tool box and then follow the instructions.

3. Transfer a new software version (if available)

to the powertrain control module (PCM) using

IDS, if a module-reprogramming of the PCM

may be required in the case of engine running

concerns.

4. Following installation of a wheel/tire

combination, for which the tire-tread

circumference does not correspond to that of

standard tires, the tire size must be changed in

the PCM using IDS. Therefore select the

"Programmable parameters" submenu and enter

the corresponding tire size under the "tire size"

menu item. G1158256en

2008.50 Kuga 8/2011 418-01-2

Module Configuration

418-01-2

GENERAL PROCEDURESTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 426 of 2057

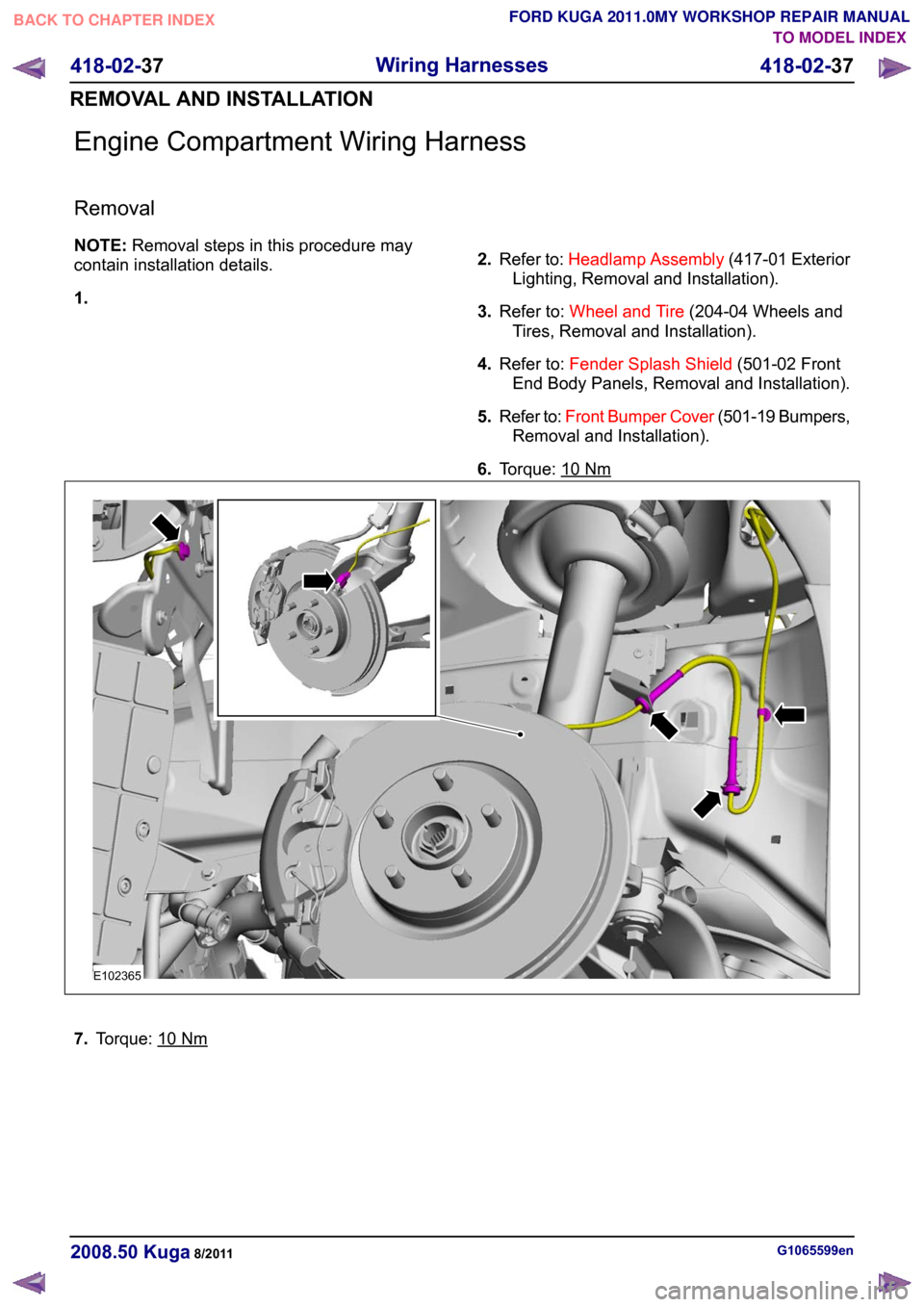

Engine Compartment Wiring Harness

Removal

NOTE:

Removal steps in this procedure may

contain installation details.

1. 2.

Refer to: Headlamp Assembly (417-01 Exterior

Lighting, Removal and Installation).

3. Refer to: Wheel and Tire (204-04 Wheels and

Tires, Removal and Installation).

4. Refer to: Fender Splash Shield (501-02 Front

End Body Panels, Removal and Installation).

5. Refer to: Front Bumper Cover (501-19 Bumpers,

Removal and Installation).

6. Torque: 10 Nm

7.

Torque: 10 Nm

G1065599en

2008.50 Kuga 8/2011 418-02-37

Wiring Harnesses

418-02-37

REMOVAL AND INSTALLATIONTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUALE102365