change time FORD KUGA 2011 1.G Owner's Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2011, Model line: KUGA, Model: FORD KUGA 2011 1.GPages: 2057

Page 360 of 2057

Turn Signal and Hazard Lamps

Refer to Wiring Diagrams Section 417-01, for

schematic and connector information.

Special Tool(s) / General Equipment

Terminal Probe Kit

29-011AThe Ford approved diagnostic tool

Description of operation

A diagnosis of the generic electronic module (GEM)

can be performed with the Ford approved

diagnostic tool. Furthermore, an integrated service

mode enables testing of the input and output

signals without the need for further tools. To enable

activation of service mode:

• switch off the ignition,

• switch off all other electrical consumers,

• apply the handbrake,

• shift to neutral

• and close the doors.

Activating the service mode

Proceed as follows to activate the service mode:

• OPERATE the switch of the heated rear window

and HOLD IT THERE

• Turn on the ignition.

• RELEASE the switch of the heated rear window

A signal sounds and the turn signal lamps come

on to indicate that service mode has been

successfully activated.

NOTE: If the alarm is activated (in vehicles fitted

with an anti-theft alarm system), service mode

cannot be activated.

Inputs

SWITCH the windshield wiper switch to the "OFF"

position to test the input signals. The following is

a list of the switch signals to be tested, in no

particular order:

• Turn signals (right, left, hazard warning lights)

• Windshield wiper stage I • Windshield wiper stage II

• Windshield washer system

• Rear window wiper

• Rear window washer system

• Doors open/closed

• Remote control for central locking with double

locking

• Hood open/closed (in vehicles equipped with an anti-theft alarm system)

• Tailgate open/closed

• A/C request signal

• Heated windscreen (if fitted)

• Parking Brake

• Brake reservoir fluid level

• Speed control system

• Autolamps

• Low beam

• High beam

• Headlamp flasher

• Marker Lamps

• Reversing lamp

• Liftgate release

• Ignition switch, terminal 15 (turn key to 0 position, then turn key to II position.)

An acoustic signal sounds and the turn signal

lamps flash to indicate receipt of each input signal

by the generic electronic module.

Test the windshield wiper "intermittent mode" stage

input signal (only vehicles with adjustable

intermittent mode)

The windshield wiper switch must be switched to

"intermittent mode" in order to test the input signal.

The delay times of the input signals can then be

tested by operating the rotary switch. Each change

of the rotary switch position is indicated by an

acoustic signal and illumination of the turn signals.

Output signals

SWITCH the wiper switch to the "intermittent""

position to test the output signals. PRESSING the

heated rear window switch activates the output

signals in the following order:

a. Turn Indicator Left Hand

b. Turn Indicator Right Hand

c. High beam

d. Low beam G1055002en

2008.50 Kuga 8/2011 417-01-26

Exterior Lighting

417-01-26

DIAGNOSIS AND TESTINGTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL29011A

Page 361 of 2057

e.

Windshield wiper stage I

f. Windshield wiper stage II

g. Heated rear window

h. Heater blower motor

i. Headlamp washer system (vehicles with gas discharge headlamps)

j. Electric booster heater (if fitted)

k. Automatic headlamps (if equipped)

l. Alarm horn (vehicles with alarm system)

m. Rear window wiper

n. Rear heated window relay

When the heated rear window switch is pressed

again, the test of the relevant signal is terminated.

When the heated rear window switch is pressed

once more, the test for the next signal in the list is

started.

Ending the service mode

The GEM automatically ends service mode 20

seconds after the last input or at a driving speed

of over 7 km/h. However, service mode can be

manually ended at any time by proceeding as

follows:

• OPERATE the switch of the heated rear window

and HOLD IT THERE

• SWITCH OFF the ignition

• RELEASE the switch of the heated rear window

3 signals sound and the turn signal lamps illuminate

to indicate that service mode has ended.

Reset service mode

If, after completion of service mode, some functions

do not operate or do not operate properly, check

the following functions:

• Instrument cluster illumination, side lamps and license plate lamp in autolamps mode

• Rear wiper

• Headlamp Washers

• Electric booster heater

• Active anti-theft sounder

• Heated windshield

If one or more of the listed functions is not OK, it's

possible that the cause of the fault is due to not

exiting service mode properly. To reactivate the

functions correctly, perform the following steps:

1. SWITCH OFF the ignition

2. SWITCH OFF the switch for the windscreen wash/wipe system 3.

OPERATE the switch of the heated rear window

and HOLD IT THERE

4. Turn on the ignition.

5. RELEASE the heated rear window switch (an acoustic signal will sound if activation has been

performed correctly)

6. SWITCH the windscreen wash/wipe switch to the "Intermittent wipe" position

7. OPERATE the heated rear window switch 6 times (the main beam headlamps switch on and

off)

8. SWITCH OFF the switch for the windscreen wash/wipe system

9. OPERATE the switch of the heated rear window

and HOLD IT THERE

10. SWITCH OFF the ignition

11. RELEASE the heated rear window switch (three

acoustic signals will sound if activation has been

performed correctly)

After completion of the work, check all the

functions.

Inspection and Checking

NOTE: The generic electronic module (GEM) forms

part of the central junction box (CJB).

NOTE: If the generic electronic module (GEM) is

changed, the new one must be reconfigured. For

this purpose, the vehicle-specific data is read out

of the module to be replaced using the Ford

approved diagnostic tool and is transferred to the

new module.

NOTE: Before reading out the vehicle-specific data,

remake all the electrical connections which were

separated in the vehicle, so that communication

between the module and the Ford approved

diagnostic tool is ensured.

1. Verify the customer concern.

2. Visually inspect for obvious signs of electrical damage.

Visual Inspection Electrical

• Fuse(s)

• Lamp(s)

• Connector(s).

• Switches

• Wiring harness G1055002en

2008.50 Kuga 8/2011 417-01-27

Exterior Lighting

417-01-27

DIAGNOSIS AND TESTINGTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 376 of 2057

Daytime Running Lamps (DRL)

Refer to Wiring Diagrams Section 417-04, for

schematic and connector information.

Special Tool(s)

Terminal Probe Kit

29-011ADescription of operation

A diagnosis of the generic electronic module (GEM)

can be performed with the Ford approved

diagnostic tool. Furthermore, an integrated service

mode enables testing of the input and output

signals without the need for further tools. To enable

activation of service mode:

• switch off the ignition,

• switch off all other electrical consumers,

• apply the handbrake,

• shift to neutral

• and close the doors.

Activating the service mode

Proceed as follows to activate the service mode:

•

OPERATE the switch of the heated rear window

and HOLD IT THERE

• Turn on the ignition.

• RELEASE the switch of the heated rear window

A signal sounds and the turn signal lamps come

on to indicate that service mode has been

successfully activated.

NOTE: If the alarm is activated (in vehicles fitted

with an anti-theft alarm system), service mode

cannot be activated.

Inputs

SWITCH the windshield wiper switch to the "Off"

position to test the input signals. The following is

a list of the switch signals to be tested, in no

particular order:

• Turn signals (right, left, hazard warning lights)

• Windshield wiper stage I

• Windshield wiper stage II

• Windshield washer system • Rear window wiper

• Rear window washer system

• Doors open/closed

• Remote control for central locking with double

locking

• Hood open/closed (in vehicles equipped with an anti-theft alarm system)

• Tailgate open/closed

• A/C request signal

• Heated windscreen (if fitted)

• Parking Brake

• Brake reservoir fluid level

• Speed control system

• Autolamps

• dipped beam

• main beam

• headlamp flasher

• Marker Lamps

• Reversing lamp

• Liftgate release

• Ignition switch, terminal 15 (turn key to 0 position, then turn key to II position.)

An acoustic signal sounds and the turn signal

lamps flash to indicate receipt of each input signal

by the generic electronic module.

Test the windshield wiper "intermittent mode" stage

input signal (only vehicles with adjustable

intermittent mode)

The windshield wiper switch must be switched to

"intermittent mode" in order to test the input signal.

The delay times of the input signals can then be

tested by operating the rotary switch. Each change

of the rotary switch position is indicated by an

acoustic signal and illumination of the turn signals.

Output signals

SWITCH the wiper switch to the "intermittent""

position to test the output signals. PRESSING the

heated rear window switch activates the output

signals in the following order:

a. Turn Indicator Left Hand

b. Turn Indicator Right Hand

c. main beam

d. dipped beam

e. Windshield wiper stage I

f. Windshield wiper stage II G1055032en

2008.50 Kuga 8/2011 417-04-2

Daytime Running Lamps (DRL)

417-04-2

DIAGNOSIS AND TESTINGTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL29011A

Page 384 of 2057

must use the same language. This language is

called a protocol.

At present, Ford uses three different data bus

systems. Depending upon model and equipment

level, all three data bus systems are used. Each

of these data bus systems has its own protocol.

Data bus systems

ISO 9141 bus

The International Organisation for Standardisation

ISO 9141 bus. This consists of a single wire and

is used exclusively for communication between the

modules and the Ford diagnostic unit. The fault

memories of the various modules are read out via

the ISO 9141 bus.

Local Interconnect Network (LIN) bus

The LIN bus is a standard specifically designed for

cost-effective communication between intelligent

sensors and actuators in vehicles. The LIN control

unit subnet is used in every situation where the

bandwidth and versatility of CAN is not needed.

The LIN specification comprises the LIN protocol,

a standard format for describing a complete LIN

and the interface between an LIN and the

application. An LIN comprises a LIN master and

one or more LIN slaves. The LIN utilizes the

master/slave principle for the purpose of bus

access control. This has the significant advantage

that few resources (CPU performance, ROM, RAM)

are required for bus management in the slave

module. The master is implemented in a control

module or a gateway which has the necessary

resources. All communication is initiated by the

master. Consequently, a message always consists

of a header, which is generated by the master, and

a response from the slave. The data transfer rate

is in the region of up to 20 Kbit/s. The LIN master

knows the time sequence of all data which are to

be transmitted. These data are transmitted by the

corresponding LIN slaves (e.g. ultrasonic sensors)

if they are requested to do so by the LIN master.

LIN is a single-wire bus, i.e. the data are

transmitted in the cable via one wire. Usually the

same cable is also used to provide the supply

voltage. The ground connection of the supply

voltage also acts as the ground connection of the

data transmission. An LIN does not use a

terminating resistor.

Controller Area Network (CAN) bus

This consists of two twisted wires and operates

serially (data is transmitted sequentially). It is used

for communication between the modules

themselves and between the modules and the Ford

diagnostic unit. The modules are connected to the

data bus in parallel. New modules can be

incorporated easily, without modifying the other

wiring or modules. The transmitted data is received

by every module connected to the control unit

network (CAN). As each data packet has an

identifier (label), in which the priority of the

message is determined as well as the content

identification, each module can detect whether or

not the data is relevant for its own information

processing. This enables several modules to be

addressed with a particular data packet and

supplied with data simultaneously. For this

purpose, it is ensured that important data (for

example from the ABS) is transmitted first. The

other modules are only able to submit their data to

the data bus after the high-priority messages have

been received.

The advantages of the CAN bus are:

• Minimization of wiring requirements

•

High degree of error protection (fault / fail-proof)

• Robustness

• Good extendibility

• Prioritization of messages

• Inexpensive

• Automatic repetition of faulty messages

• Independent system monitoring and the ability to disconnect faulty modules from the data bus

automatically

Due to the increased number of modules and the

resulting continued increase in data transfer, two

different CAN bus systems are used. Essentially,

they only differ in terms of their data transmission

rates and application areas.

To be able to distinguish between the individual

CAN bus systems, the CAN bus system with the

high transfer speed is called the high speed CAN

bus (HS-CAN). The data are transmitted at a baud

rate of 500 kB/s.

The CAN bus system with the medium transfer

speed is called the medium speed CAN bus

(MS-CAN) and is mainly used for communication

in the comfort electronics or the multimedia system.

The data are transmitted at a baud rate of 125 kB/s.

An interface (gateway) is used to exchange data

between the HS-CAN and the MS-CAN. This

provides the connection between the three CAN

databus systems and is installed in the GEM and

in the electronic instrument cluster. The number of

modules which are connected to the three databus G1030779en

2008.50 Kuga 8/2011 418-00-7

Module Communications Network

418-00-7

DESCRIPTION AND OPERATIONTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 453 of 2057

• Reversing lamp

• Liftgate release

• Folding liftgate release

• Ignition switch, terminal 15 (turn key to 0

position, then turn key to II position.)

An acoustic signal sounds and the turn signal

lamps flash to indicate receipt of each input signal

by the generic electronic module.

Test the windshield wiper "intermittent mode"

stage input signal (only vehicles with adjustable

intermittent mode):

The windshield wiper switch must be switched to

"intermittent mode" in order to test the input signal.

The delay times of the input signals can then be

tested by operating the rotary switch. Each change

of the rotary switch position is indicated by an

acoustic signal and illumination of the turn signals.

Output signals

SWITCH the wiper switch to the "Intermittent"

position to test the output signals. PRESSING the

heated rear window switch activates the output

signals in the following order:

• Left-hand turn signal

• Right-hand turn signal

• Main beam

• Dipped beam

• Windshield wiper stage I

• Windshield wiper stage II

• Heated rear window

• Heater blower motor

• Headlamp washer system (vehicles with HID headlamps)

• Electric booster heater (if fitted)

• Autolamps (if fitted)

• Alarm horn (vehicles with alarm system)

• Rear window wiper

• Heated rear window relay

When the heated rear window switch is pressed

again, the test of the relevant signal is terminated.

When the heated rear window switch is pressed

once more, the test for the next signal in the list is

started.

Ending the service mode

The GEM automatically ends service mode 20

seconds after the last input or at a driving speed

of over 7km/h. However, service mode can be

manually ended at any time by proceeding as

follows: •

OPERATE the switch of the heated rear window

and HOLD IT THERE

• Switch off the ignition.

• RELEASE the switch of the heated rear window

3 signals sound and the turn signal lamps illuminate

to indicate that service mode has ended.

Resetting service mode

If, after completion of service mode, some functions

do not operate or do not operate properly, check

the following functions:

• Instrument cluster illumination, side marker lamps (side lights) and licence plate lamp in

automatic headlamps mode

• Rear wiper

• Headlamp washer assembly

• Electric booster heater

• Alarm horn

• Heated windshield

If one or more of the listed functions is not OK, it's

possible that the cause of the fault is due to not

exiting service mode properly. To reactivate the

functions correctly, perform the following steps:

1. Switch off the ignition.

2. SWITCH OFF the switch for the windscreen wash/wipe system

3. OPERATE the switch of the heated rear window

and HOLD IT THERE

4. SWITCH ON the ignition.

5. RELEASE the heated rear window switch (an acoustic signal will sound if activation has been

performed correctly)

6. SWITCH the windscreen wash/wipe switch to the "Intermittent wipe" position

7. OPERATE the heated rear window switch 6 times (the main beam headlamps switch on and

off automatically)

8. SWITCH OFF the switch for the windscreen wash/wipe system

9. OPERATE the switch of the heated rear window

and HOLD IT THERE

10. Switch off the ignition.

11. RELEASE the heated rear window switch (three

acoustic signals will sound if activation has been

performed correctly)

After completion of the work, check all the

functions. G1030787en

2008.50 Kuga 8/2011 419-10-3

Multifunction Electronic Modules

419-10-3

DESCRIPTION AND OPERATIONTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 458 of 2057

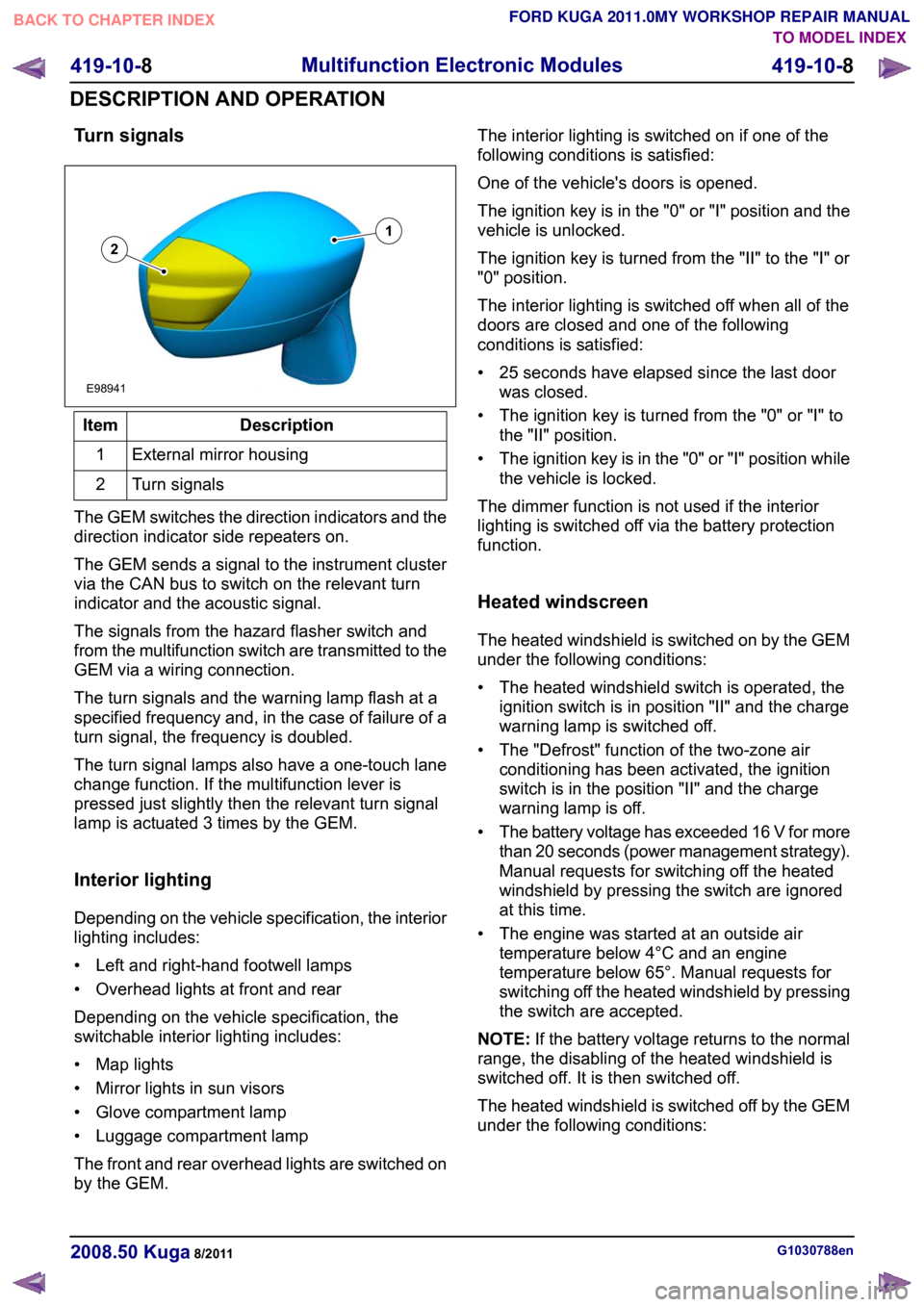

Turn signals

Description

Item

External mirror housing

1

Turn signals

2

The GEM switches the direction indicators and the

direction indicator side repeaters on.

The GEM sends a signal to the instrument cluster

via the CAN bus to switch on the relevant turn

indicator and the acoustic signal.

The signals from the hazard flasher switch and

from the multifunction switch are transmitted to the

GEM via a wiring connection.

The turn signals and the warning lamp flash at a

specified frequency and, in the case of failure of a

turn signal, the frequency is doubled.

The turn signal lamps also have a one-touch lane

change function. If the multifunction lever is

pressed just slightly then the relevant turn signal

lamp is actuated 3 times by the GEM.

Interior lighting

Depending on the vehicle specification, the interior

lighting includes:

• Left and right-hand footwell lamps

• Overhead lights at front and rear

Depending on the vehicle specification, the

switchable interior lighting includes:

• Map lights

• Mirror lights in sun visors

• Glove compartment lamp

• Luggage compartment lamp

The front and rear overhead lights are switched on

by the GEM. The interior lighting is switched on if one of the

following conditions is satisfied:

One of the vehicle's doors is opened.

The ignition key is in the "0" or "I" position and the

vehicle is unlocked.

The ignition key is turned from the "II" to the "I" or

"0" position.

The interior lighting is switched off when all of the

doors are closed and one of the following

conditions is satisfied:

• 25 seconds have elapsed since the last door

was closed.

• The ignition key is turned from the "0" or "I" to the "II" position.

• The ignition key is in the "0" or "I" position while the vehicle is locked.

The dimmer function is not used if the interior

lighting is switched off via the battery protection

function.

Heated windscreen

The heated windshield is switched on by the GEM

under the following conditions:

• The heated windshield switch is operated, the ignition switch is in position "II" and the charge

warning lamp is switched off.

• The "Defrost" function of the two-zone air conditioning has been activated, the ignition

switch is in the position "II" and the charge

warning lamp is off.

• The battery voltage has exceeded 16 V for more

than 20 seconds (power management strategy).

Manual requests for switching off the heated

windshield by pressing the switch are ignored

at this time.

• The engine was started at an outside air temperature below 4°C and an engine

temperature below 65°. Manual requests for

switching off the heated windshield by pressing

the switch are accepted.

NOTE: If the battery voltage returns to the normal

range, the disabling of the heated windshield is

switched off. It is then switched off.

The heated windshield is switched off by the GEM

under the following conditions: G1030788en

2008.50 Kuga 8/2011 419-10-8

Multifunction Electronic Modules

419-10-8

DESCRIPTION AND OPERATIONTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL12E98941

Page 461 of 2057

Generic Electronic Module (GEM)

Refer to Wiring Diagrams Section 419-10, for

schematic and connector information.

Special Tool(s) / General Equipment

Terminal Probe Kit

418-S035Digital multimeter

Ford approved diagnostic tool

Description of operation

A diagnosis of the generic electronic module (GEM)

can be performed with the Ford approved

diagnostic tool. Furthermore, an integrated service

mode enables testing of the input and output

signals without the need for further tools. To enable

activation of service mode:

• Switch off the ignition

• Switch off all other electrical consumers

• Apply the handbrake

• Shift to neutral

• Close the doors.

Activate service mode

Proceed as follows to activate service mode:

• PRESS and HOLD the switch of the heated rear

window

• SWITCH ON the ignition.

• RELEASE the switch of the heated rear window

A signal sounds and the turn signal lamps

illuminate to indicate that service mode has been

successfully activated.

NOTE: If the alarm is armed (in vehicles fitted with

an anti-theft alarm system), service mode cannot

be activated.

Input signals

SWITCH the windshield wiper switch to the "Off"

position to test the input signals. The following is

a list of the switch signals to be tested, in no

particular order: • Turn signals (right, left, hazard warning lights)

• Windshield wiper stage I

• Windshield wiper stage II

• Windshield washer system

• Rear window wiper

• Rear window washer system

• Doors open/closed

• Door key cylinder set/reset switch

• Remote control for central locking with double

locking

• Hood up/down (in vehicles fitted with anti-theft alarm system)

• Tailgate open/closed

• Mini liftgate open/closed

• Manual A/C request signal

• Manual AUX heater request signal

• Heated windshield (if fitted)

• Parking brake

• Brake fluid level

• Cruise control system

• Autolamps

• Dipped beam

• Main beam

• Headlamp flasher

• Side lights

• Reversing lamp

• Tailgate release

• Mini liftgate release

• Interior scanning system

• Ignition switch, terminal 15 (turn key to 0 position, then turn key to II position.)

An acoustic signal sounds and the turn signal

lamps flash to indicate receipt of each input signal

by the generic electronic module.

Test the windshield wiper "intermittent mode" stage

input signal (only vehicles with adjustable

intermittent mode)

The windshield wiper switch must be switched to

"intermittent mode" in order to test the input signal.

The delay times of the input signals can then be

tested by operating the rotary switch. Each change

of the rotary switch position is indicated by an

acoustic signal and illumination of the turn signals. G1055084en

2008.50 Kuga 8/2011 419-10-11

Multifunction Electronic Modules

419-10-11

DIAGNOSIS AND TESTINGTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL29011A

Page 1233 of 2057

Wheels and Tires

Inspection and Verification

Visual Inspection Chart

MechanicalWheel(s)Tire(s)

Tire pressure(s) * Wheel nuts

Wheel studs

* Vehicles equipped with a tire deflation detection system (DDS) must be inspected for correct operation using the Ford approved diagnostic tool.

To maximize tire performance, inspect the tires for

signs of incorrect inflation and uneven wear which

may indicate a need for balancing, rotation or

suspension alignment. Tires should also be

checked frequently for cuts, stone bruises,

abrasions, blisters and for objects that may have

become embedded in the tread. More frequent

inspections are recommended when rapid or

extreme temperature changes occur or when road

surfaces are rough or occasionally littered with

foreign material.

As a further visible check of tire condition, tread

wear indicators are molded into the bottom of the

tread grooves. When these indicator bands become

visible, new tires must be installed.

Tire Wear Diagnosis

Uneven wear is usually caused by either excessive

camber or excessive toe on tires.

Sometimes incorrect toe settings or worn struts will

cause severe `cupping' or `scalloped' tire wear on

non-driven wheels.

Severely incorrect toe settings will also cause other

unusual wear patterns.

Tire Vibration Diagnosis

A tire vibration diagnostic procedure always begins

with a road test. The road test and customer

interview (if available) will provide much of the

information needed to find the source of a vibration. During the road test, drive the vehicle on a road

that is smooth and free of undulations. If vibration

is apparent, note and record the following:

– the speed at which the vibration occurs.

– what type of vibration occurs in each speed

range.

– mechanical or audible

– how the vibration is affected by changes in the following:

– engine torque

– vehicle speed

– engine speed

– type of vibration - sensitivity: – torque sensitive

– vehicle speed sensitive

– engine speed sensitive

The following explanations help isolate the source

of the vibration.

Torque Sensitive

This means that the condition can be improved or

made worse by accelerating, decelerating,

coasting, maintaining a steady vehicle speed or

applying engine torque.

Vehicle Speed Sensitive

This means that the vibration always occurs at the

same vehicle speed and is not affected by engine

torque, engine speed or the transmission gear

selected.

G1061329en2008.50 Kuga8/2011

204-04- 6

Wheels and Tires

204-04- 6

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1429 of 2057

HCU to check for sudden actuation of the brakes.

With the brake pedal pressed, the ABS module

triggers emergency braking if the rate of increase

of hydraulic pressure exceeds the predetermined

limit.

If the brake pedal is pressed so hard that the ABS

becomes active on the front wheels then the ABS

control unit increases the pressure to the rear

wheel brakes up to the ABS intervention threshold.

EBA operation continues until the driver releases

the brake pedal sufficiently for the hydraulic

pressure in the HCU to drop below a threshold

value stored in the ABS module.

Trailer stability control:If the vehicle is ordered

with a trailer coupling then the Trailer Stability

Control function is integrated in the ESP. The ESP

detects snaking when driving with a trailer and

reduces the speed of the vehicle and trailer through

adapted braking and, if necessary, by also reducing

the engine output until the snaking movement of

the trailer is corrected.

Roll-over protection: The ESP dynamically

determines the tipping tendency of the vehicle and

works in conjunction with the EBA system to

prevent the vehicle from tipping over during

dynamic maneuvers like lane changing or while

negotiating bends.

Emergency brake light: The emergency brake

light automatically switches on the hazard flasher

system to warn drivers of other vehicles that

emergency braking is being initiated. Based on a

defined delay value, the ABS/ESP module sends

a signal to the generic electronic module (GEM)

via the CAN data bus. The GEM activates the

hazard flasher system, that then flashes 7 times.

Prerequisites for activation of the emergency brake

light are:

• The speed is higher than 50 km/h.

• The brake pedal is being actuated.

• The deceleration is greater than 9 m/s².

To prevent activation on snow or ice, for example,

the following prerequisites must be met:

• The speed is higher than 50 km/h.

• The brake pedal is being actuated.

• ABS regulation takes place.

• The deceleration is greater than 6 m/s².

Tire pressure monitoring system: The tire

pressure monitoring system used in the Kuga is

able to detect loss of air in a tire at an early stage

and warn the driver. Because it can only compare

the behaviour of the tyres with each other, it is not possible to draw conclusions about the absolute

tyre pressure. It is also not possible to monitor the

spare tyre pressure. In order for the system to

operate correctly, the tyre pressures must be

regularly checked and corrected and the system

subsequently initialised (see below).

The tire pressure monitoring system used here,

depending on the equipment level, is built into the

anti-lock braking system (ABS) as an extra function

and therefore does not have its own sensors.

The ABS module measures the loss of pressure

in the tyres by calculation using the wheel speed

sensors of the ABS system. If a tyre loses

pressure, its diameter decreases and the speed of

the wheel therefore increases. If the ABS module

detects such a loss in pressure, it sends a signal

to the instrument cluster via the CAN bus and a

warning message is displayed in the message

centre. The warning threshold depends among

other things on the dimension of the tyres being

used, the vehicle operating conditions and the

status at the last initialisation. Since neither the

absolute tyre pressure nor the position of the tyre

is known, the pressure of all the tyres must be

checked and the system re-initialised after a tyre

pressure warning. If necessary, the cause of the

loss of pressure must be investigated.

Regular tyre pressure checks are still necessary.

The system must be initialised after a tyre is

changed, winter or summer tyres fitted, the

pressures corrected or adjusted to suit the vehicle

load. This can be done by the driver using the

driver information system. For further information,

see: Owner’s Manual.

Component Description

Opto-electronic steering wheel rotation

sensor

E80158

G1001304en2008.50 Kuga8/2011

206-09B-

11

Anti-Lock Control - Stability Assist

206-09B- 11

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1674 of 2057

Engine Cooling — 2.5L Duratec (147kW/200PS) - VI5 – Overview

Auxiliary coolant pump

An electrically operated auxiliary coolant pump is

installed on vehicles with a trailer coupling and/or

additional heating. The auxiliary coolant pump

ensures that the coolant is circulated when the

coolant pump (which is driven by the engine) is not

running.

The additional heating uses the auxiliary coolant

pump to circulate hot coolant through the heat

exchanger and the engine.

On vehicles with a trailer coupling the auxiliary

coolant pump is switched on for 6 minutes by the

PCM (powertrain control module) if the coolant

temperature exceeds 106°C when the engine is

switched off. This prevents the coolant circuit from

overheating. This could happen particularly if the

engine is switched off after towing a heavy trailer

up a steep hill before there has been sufficient time

for cooling.

G1088220en2008.50 Kuga8/2011

303-03-3

Engine Cooling

303-03- 3

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL