change time FORD KUGA 2011 1.G Owner's Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 2011, Model line: KUGA, Model: FORD KUGA 2011 1.GPages: 2057

Page 1793 of 2057

Description

Item

CKP sensor

1

Tooth pitch

2

Flywheel ring gear

3

Reference mark

4

Voltage (sinusoidal-like signal curve)

5Description

Item

60-2 pulses per revolution of the

crankshaft

6

Tooth center

7

Reference mark

8

Tooth pitch

9

The acceleration of the flywheel at each power

stroke results in a change in the CKP signal.

During the power stroke, the combustion pressure

acting on the piston causes an acceleration of the

crankshaft and thus also of the flywheel. This is

apparent in the voltage curve from slightly higher

frequencies and amplitudes of the CKP signal.

Calculation of the ignition angle

Since propagation of the flame front in the air/fuel

mixture always takes the same amount of time, the

ignition of the air/fuel mixture has to take place

earlier or later depending on the engine speed.

The higher the speed, the earlier ignition must

occur. This ensures that maximum combustion

pressure is achieved immediately after Top Dead

Center and that maximum combustion pressure

acts on the piston.

When starting the engine, ignition timing is

determined by the CMP purely from the ignition

map and information on camshaft position (CKP

sensors) and crankshaft position (PCM sensor).

As soon as the engine is running, the following

data are used as a basis for calculating the ignition

angle:

• the engine speed,

• the engine load,

• the coolant temperature and

• the KS signal.

The ignition angle has a major impact on engine

operation. It affects

• engine performance

• exhaust emissions

• fuel consumption,

• combustion knock behavior and

• engine temperature.

The higher the engine load, i.e. the torque demand,

the richer the air/fuel mixture, the longer the

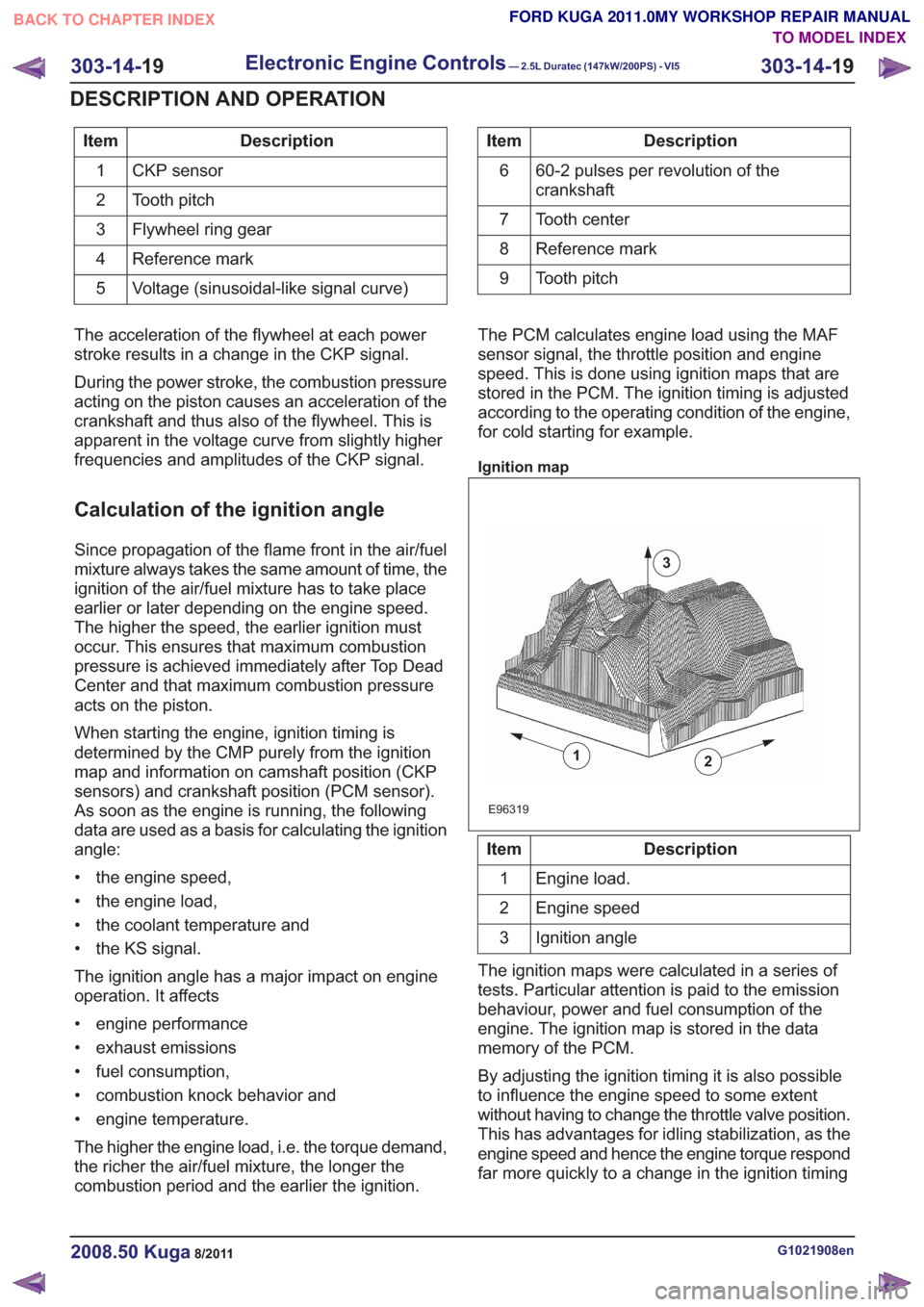

combustion period and the earlier the ignition. The PCM calculates engine load using the MAF

sensor signal, the throttle position and engine

speed. This is done using ignition maps that are

stored in the PCM. The ignition timing is adjusted

according to the operating condition of the engine,

for cold starting for example.

Ignition map

2

E96319

1

3

Description

Item

Engine load.

1

Engine speed

2

Ignition angle

3

The ignition maps were calculated in a series of

tests. Particular attention is paid to the emission

behaviour, power and fuel consumption of the

engine. The ignition map is stored in the data

memory of the PCM.

By adjusting the ignition timing it is also possible

to influence the engine speed to some extent

without having to change the throttle valve position.

This has advantages for idling stabilization, as the

engine speed and hence the engine torque respond

far more quickly to a change in the ignition timing

G1021908en2008.50 Kuga8/2011

303-14- 19

Electronic Engine Controls— 2.5L Duratec (147kW/200PS) - VI5303-14-

19

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1797 of 2057

Calculation of valve timing adjustment

angle

The 2.5L Duratec (VI5) engine has two camshaft

adjustment units which work independently of each

other.

One camshaft adjustment solenoid is installed for

each intake camshaft and exhaust camshaft.

This allows the PCM to continuously adjust the

intake and exhaust-side camshaft adjustments

independently of one another. The timing is

adjusted by the PCM using curves; adjustment is

primarily done as a function of engine load and

engine speed.

In this way the engine performance is increased

and internal exhaust gas recirculation is realized.

The advantages of camshaft adjustment are as

follows:

• Higher torque and improved torquecharacteristics

• Reduced fuel consumption

• Improved emissions performance

The camshaft adjustment solenoids are actuated

by the PWM by means of a PCM signal.

Continuous adjustment of the camshafts by the

PCM is achieved by means of the camshaft

adjustment solenoids, the camshaft adjustment

units and two CMP sensors. A defined quantity of

engine is oil is supplied to or drained from the

adjustment units via the camshaft adjustment

solenoids. The existing EOP (engine oil pressure)

is taken into account in the process. In this way

the valve timings are adjusted according to the

operating condition of the engine. The camshaft

adjusters work according to the vane-cell principle.

On starting the engine, both camshafts are

mechanically locked in their starting positions. The

intake camshaft is in the maximum late position

and the exhaust camshaft in the maximum early

position.

Control is divided into four main areas:

• Low engine speed and low load

• Partial load

• Low engine speed and high load

• High engine speed and high load

At low engine speed and low load, the exhaust

valves open early and the intake valves open late.

The result is reduced fuel consumption and more

uniform idling. In the partial load range, the exhaust valves and

the intake valves open late. The late opening of

the exhaust valves results in a good utilization of

the expanding gases in the cylinder. Closing the

exhaust valves after Top Dead Center allows

internal exhaust gas recirculation through aspiration

of exhaust gases into the combustion chamber.

Moreover, the intake valves close after Bottom

Dead Centre, allowing the fresh air/fuel mixture

and exhaust gases to flow back into the intake

tract. The result is reduced fuel consumption and

low emissions.

At low engine speed and high engine load, the

exhaust valves open late and the intake valves

open early. Due to the resulting valve opening

overlap at Top Dead Centre, the pulsating gas

column within the combustion chamber is utilized

to achieve better charging of the combustion

chamber. The result is increased torque at lower

RPM.

At high engine speeds and high engine load, the

exhaust valves open early and the intake valves

close late. Because a rapid gas exchange must be

achieved at high engine speeds, the early opening

of the exhaust valves achieves better expulsion of

the exhaust gas and the late closing of the intake

valves improves cylinder charge efficiency.

Optimum power output is achieved.

Many other camshaft positions are possible in

addition to these settings.

In order to avoid a malfunction in the camshaft

adjustment units at excessively low ambient or

engine-oil temperatures, they are activated by the

PCM with a time delay via the camshaft adjustment

solenoids. The PCM receives the information

required for this from the ECT sensor and the

outside air temperature sensor.

When idling and during deceleration, the camshaft

adjustment solenoids are activated repeatedly by

the PCM in order to remove any dirt which may be

on the bore holes and ring grooves.

Boost pressure control

Optimum regulation is achieved by means of an

electronically-controlled solenoid valve, the boost

control solenoid valve.

Refer to:

Turbocharger (303-04 Fuel Charging and

Controls - Turbocharger - 2.5L Duratec

(147kW/200PS) - VI5, Description and

Operation).

G1021908en2008.50 Kuga8/2011

303-14- 23

Electronic Engine Controls— 2.5L Duratec (147kW/200PS) - VI5303-14-

23

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1840 of 2057

E77584

NOTE:Due to static charging, measurements

inside the transaxle using a multimeter are

prohibited.

Stored DTCs in the engine management system

may affect transmission control. As a result, faults

in the transmission control system and engine

management system must be rectified in

accordance with the symptom-based diagnosis in

FordEtis IDS.

Applications of IDS Standard include:

• Resetting the counter for fluid change intervals.

• Programming the selector lever position 'N'.

• Resetting the values learned by the TCM.

Resetting the counter for fluid change

intervals.

This function must be performed if the transmission

fluid has been changed or a new automatic

transaxle has been installed with the previous TCM.

This function resets the values stored for the

pollution level of the transmission fluid.

Programming the 'N' position of the TR

sensor

This function must be executed if

• the TCM with integrated TR sensor is renewed,

• a new automatic transaxle is installed with the previous TCM.

• the selector lever cable or the selector mechanism assembly is renewed

• TR have been set due to a fault in the selector lever assembly or in the DTC (diagnostic trouble

code) sensor.

The TCM learns and stores the voltage value in

the 'N' position when this function is executed.

Resetting the values learned by the TCM

This function must be executed if

• a new automatic transaxle is installed with the previous TCM.

• a component of the automatic transaxle has been renewed.

G1163604en2008.50 Kuga8/2011

307-01- 19

Automatic Transmission/Transaxle

— Vehicles With:

5-Speed Automatic Transaxle - AW55 AWD

307-01- 19

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1847 of 2057

E112322

The TCM adapts the gear changing to ensure that

the correct gear is selected for the style of driving,

the engine load, driver requirements, vehicle speed

etc. This leads to lower fuel consumption together

with improved comfort through smoother gear

changes and lower noise levels.

The TCM receives information on the driver's

desired transmission range and type of driving

mode. In contrast to a transmission which is only

controlled hydraulically, the control module can

calculate the best times to shift gear and activate

torque converter lockup by using the signals from

the sensors in the transmission and the engine

management system.

The control module enables small changes in the

operating conditions to be made and adapts thevarious transmission functions to ensure that the

correct gear is always selected in relation to the

type of driving mode.

The TCM has adaptive capabilities. This ensures

smooth gear changes throughout the whole service

life of the transmission.

To exactly determine the activation points of the

gear shifts and torque converter lockup on the

basis of the type of driving mode chosen, the TCM

receives the following information:

• Transmission range chosen (TR sensor).

• Type of driving mode chosen

(normal/sport/select-shift).

• Transmission input shaft speed (TSS sensor).

• Transmission output shaft speed (OSS sensor).

• Transmission fluid temperature (TFT sensor).

• The engine speed and the torque as well as the throttle plate opening - from the PCM via the

CAN data bus.

• Actuation of the accelerator pedal - from the PCM via the CAN data bus.

• Coolant temperature - from the PCM via the CAN data bus.

• Vehicle speed - from the ABS via the CAN data bus.

• Actuation of the brake pedal - from the ABS via the CAN data bus.

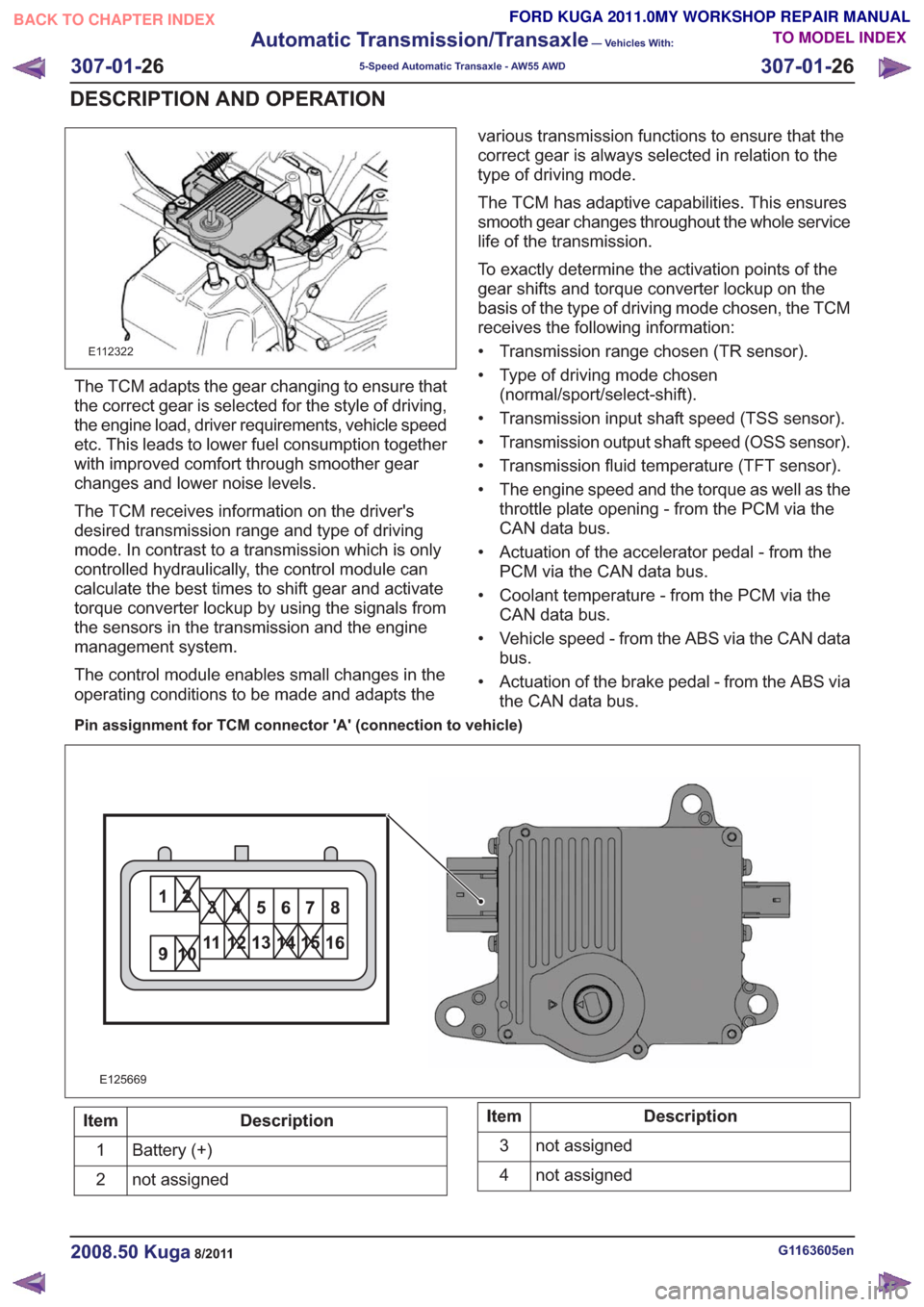

Pin assignment for TCM connector 'A' (connection to vehicle)

11

E125669

Description

Item

Battery (+)

1

not assigned

2Description

Item

not assigned

3

not assigned

4

G1163605en2008.50 Kuga8/2011

307-01- 26

Automatic Transmission/Transaxle

— Vehicles With:

5-Speed Automatic Transaxle - AW55 AWD

307-01- 26

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1849 of 2057

21

22 20 19

15 14 13

161718 12

876

9

10

11 5

3

42121

22 20 19

15 14 13

161718 12

876

9

10

11 5

3

421

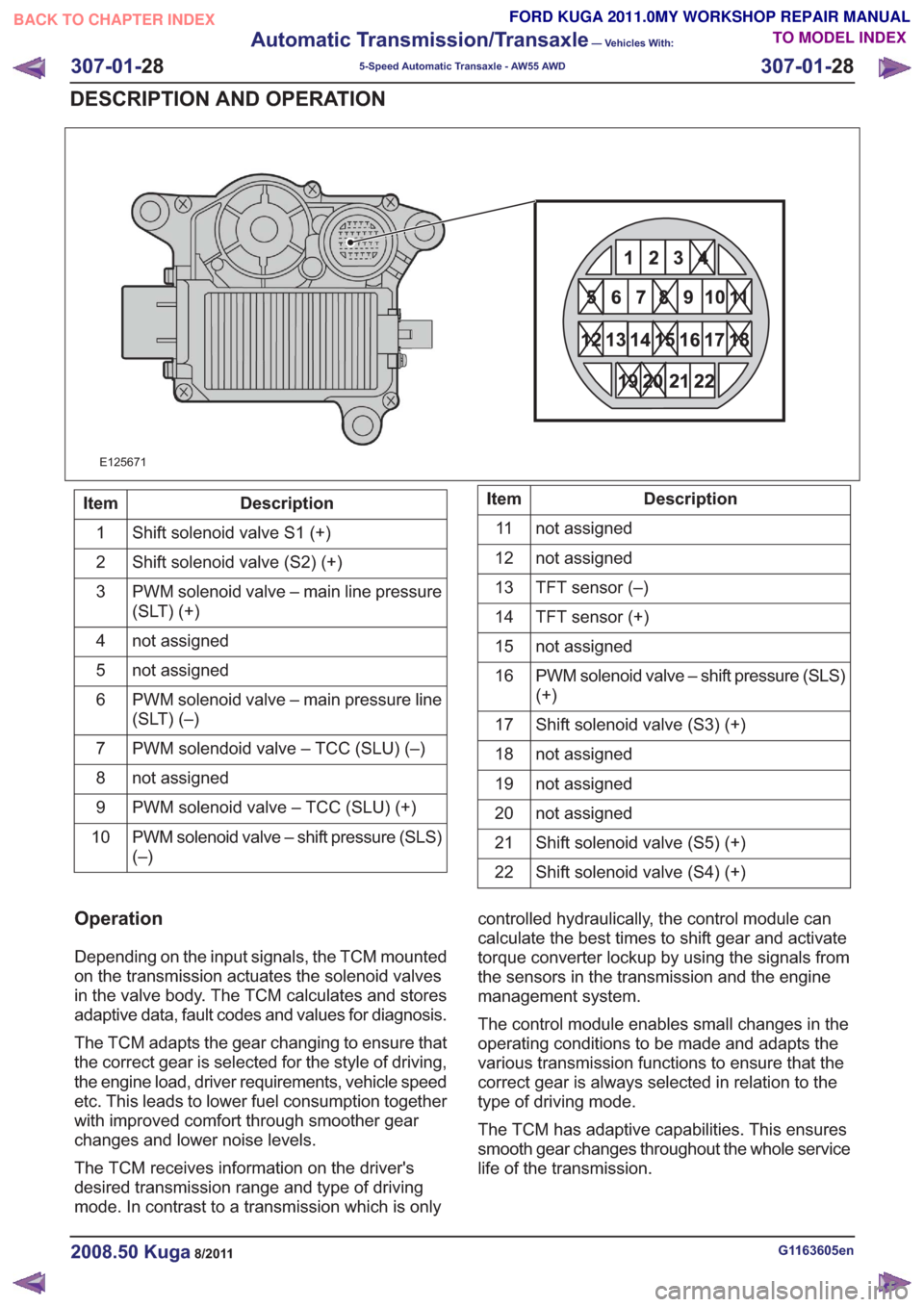

E125671

Description

Item

Shift solenoid valve S1 (+)

1

Shift solenoid valve (S2) (+)

2

PWM solenoid valve – main line pressure

(SLT) (+)

3

not assigned

4

not assigned

5

PWM solenoid valve – main pressure line

(SLT) (–)

6

PWM solendoid valve – TCC (SLU) (–)

7

not assigned

8

PWM solenoid valve – TCC (SLU) (+)

9

PWM solenoid valve – shift pressure (SLS)

(–)

10Description

Item

not assigned

11

not assigned

12

TFT sensor (–)

13

TFT sensor (+)

14

not assigned

15

PWM solenoid valve – shift pressure (SLS)

(+)

16

Shift solenoid valve (S3) (+)

17

not assigned

18

not assigned

19

not assigned

20

Shift solenoid valve (S5) (+)

21

Shift solenoid valve (S4) (+)

22

Operation

Depending on the input signals, the TCM mounted

on the transmission actuates the solenoid valves

in the valve body. The TCM calculates and stores

adaptive data, fault codes and values for diagnosis.

The TCM adapts the gear changing to ensure that

the correct gear is selected for the style of driving,

the engine load, driver requirements, vehicle speed

etc. This leads to lower fuel consumption together

with improved comfort through smoother gear

changes and lower noise levels.

The TCM receives information on the driver's

desired transmission range and type of driving

mode. In contrast to a transmission which is only controlled hydraulically, the control module can

calculate the best times to shift gear and activate

torque converter lockup by using the signals from

the sensors in the transmission and the engine

management system.

The control module enables small changes in the

operating conditions to be made and adapts the

various transmission functions to ensure that the

correct gear is always selected in relation to the

type of driving mode.

The TCM has adaptive capabilities. This ensures

smooth gear changes throughout the whole service

life of the transmission.

G1163605en2008.50 Kuga8/2011

307-01-

28

Automatic Transmission/Transaxle

— Vehicles With:

5-Speed Automatic Transaxle - AW55 AWD

307-01- 28

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1865 of 2057

Description

Item

ABS5

Cruise control

6

Select-shift switch module

7

PCM

8

Selector lever lock

9

PWM solenoid valve – shift pressure (SLS)

10

PWM solenoid valve for main line pressure

(SLT)

11

PWM- solenoid valve – TCC (SLU)

12Description

Item

Shift solenoid S1 (open when dormant)

13

Shift solenoid S2 (closed when dormant)

14

Shift solenoid S3 (closed when dormant)

15

Shift solenoid S4 (open when dormant)

16

Shift solenoid S5 (closed when dormant)

17

The TSS sensor

18

The OSS sensor

19

The TFT sensor

20

TR sensor in TCM

21

Input signals

Hard wired

• Item 18: ISS (input shaft speed) sensor

– Supplies information on the transmissioninput shaft speed. Used for calculations, for

instance the shift process, checking the

torque converter lockup and for diagnosis of

the hydraulic/mechanical operations in the

transmission.

• Item 19: OSS sensor – Supplies information on the transmissionoutput shaft speed. Used for calculations, for

instance the vehicle speed and for diagnosis

of the hydraulic/mechanical operations in the

transmission.

• Item 20: TFT sensor – Supplies information on the transmission fluidtemperature. This information is used to

adjust the shift times and the fluid pressure.

• Item 21: TR sensor – Supplies the TCM with the information on thechosen transmission range. Starting is only

possible when the selector lever is in the P

or N position. The sensor is a permanent

magnet which creates a magnetic field over

the different Hall sensors and in this way

creates a specific voltage for each shift

operation.

Via the LIN data bus

• Item 7: Selector lever module (select-shift module)

– Indicates that the selector lever is locked inposition P and supplies information on the

sport mode status. Also transmits a control

signal during select-shift gear changes and

supplies information on the fault status in the selector lever module, so that the fault codes

in the module can be stored as required.

Via the CAN data bus

• Item 4: PCM – Stop light switch ON/OFF, is used by theTCC.

– Coolant temperature, used for diagnosis of the transmission temperature sensor and for

activating the catalytic converter.

– Engine speed >400 rpm = engine running. Used for starting the transmission fluid

pressure and diagnosis functions.

– Engine rpm. Used for checking the torque converter slip and the pressure build-up,

which have an effect on the shift comfort.

– Kickdown. If the accelerator pedal is pressed down and the throttle plate is wide open, the

PCM transmits a kickdown signal to the TCM.

– Current engine speed, used to check the line pressure of the transmission.

– Throttle plate opening, used to calculate the gear changes. During sport mode and

kickdown.

– Accelerator pedal position, used to calculate the shift threshold timings.

• Item 5: ABS module – Supplies information on the vehicle speedand also on the difference in speed between

the left-hand and right-hand wheels. Prevents

changing up if the speed difference is greater

than 40 km/h, to protect the differential in the

transmission.

• Item 6: Vehicle speed control system – Is used to calculate the acceleration,depending on the position of the resume and

set buttons.

G1163605en2008.50 Kuga8/2011

307-01- 44

Automatic Transmission/Transaxle

— Vehicles With:

5-Speed Automatic Transaxle - AW55 AWD

307-01- 44

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 2007 of 2057

Description

Item

PCM

8

Throttle body

Comments:Contains the TP (throttle position) sensor

9

The APP (accelerator pedal position)

sensor.

10Description

Item

CPP (clutch pedal position) switch

Comments:Vehicles with manual transaxle.

11

BPP (brake pedal position) switch

12

Reverse gear solenoid

Comments:Vehicles with manual transaxle.

13

System Operation

Speed Control

Cruise control is integrated into PCM and

intervenes in engine management to automatically

keep to the target speed selected by the driver.

When the system is active, the vehicle can be

accelerated or decelerated without the accelerator

pedal being pressed. Cruise control is operated

using the control switch units on the steering wheel.

The PCM controls the throttle to achieve this. The

ABS module supplies the VSS signal for this.

On vehicles with automatic transmission, the TCM

receives a notification via the CAN (controller area

network) bus that cruise control is active. The TCM

then controls the transmission based on special

engine maps.

Cruise control recognizes three operating modes:

• "OFF": Control is switched off.

• "STANDBY": Control is switched on but not

active. The speed of the vehicle is not regulated

by the cruise control.

• "ACTIVE": Control is switched on and active. Cruise control adjusts the vehicle speed to the

stored or desired target speed.

Every time the engine is started, cruise control is

in the "OFF" mode. In this mode, only the "ON"

button is operable.

Cruise control is initially set to "STANDBY" mode

when the "ON" button is pressed. The green cruise

control indicator lamp in the instrument cluster

lights up. There is no target speed saved.

Cruise control can only be set to "STANDBY" mode

under the following conditions:

• Engine speed is between idle speed and maximum permissible speed. Cruise control can only be changed into "ACTIVE"

mode under the following conditions:

• 2nd - 6th gear engaged.

• Engine speed between idle speed and maximum

permissible speed.

• Vehicle speed at least 40 km/h.

Pressing the "SET+" or "SET-" button activates

cruise control ("ACTIVE" mode). The green "Cruise

control" indicator lamp in the instrument cluster

lights up. The current vehicle speed is saved as

the target.

In "ACTIVE" mode the "OFF", "SET+", "SET-" and

"RES" buttons are active. If the "RES" button is

pressed again, control is suspended. The "RES"

button has a dual function and is used to resume

and suspend the cruise control.

Tapping the "SET+" button (for less than 640 ms)

increases the target speed by 1 km/h at a time.

Holding down the "SET+" button (for longer than

640 ms) increases the target speed until the button

is released. If the button is not released, cruise

control accelerates the vehicle up to the maximum

permissible vehicle speed (200 km/h) or up to the

vehicle's maximum speed (whichever speed is

lower). Tapping the "SET-" button (for less than

640 ms) reduces the target speed by 1 km/h at a

time. When the the "SET-" button is held down, the

control reduces the target speed until the button is

released. If the "SET-" button is held down until

the minimum speed of 40 km/h is reached, cruise

control switches to "STANDBY" mode.

Cruise control is put into "STANDBY" mode when

the "RES" button is pressed. Control to the stored

target speed can be started again by pressing the

"RES" button again. If the "SET+" or "SET-" button

is pressed while the "RES" function is being

performed (control to saved target speed), cruise

G1044191en2008.50 Kuga8/2011

310-03- 4

Speed Control

310-03- 4

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 2037 of 2057

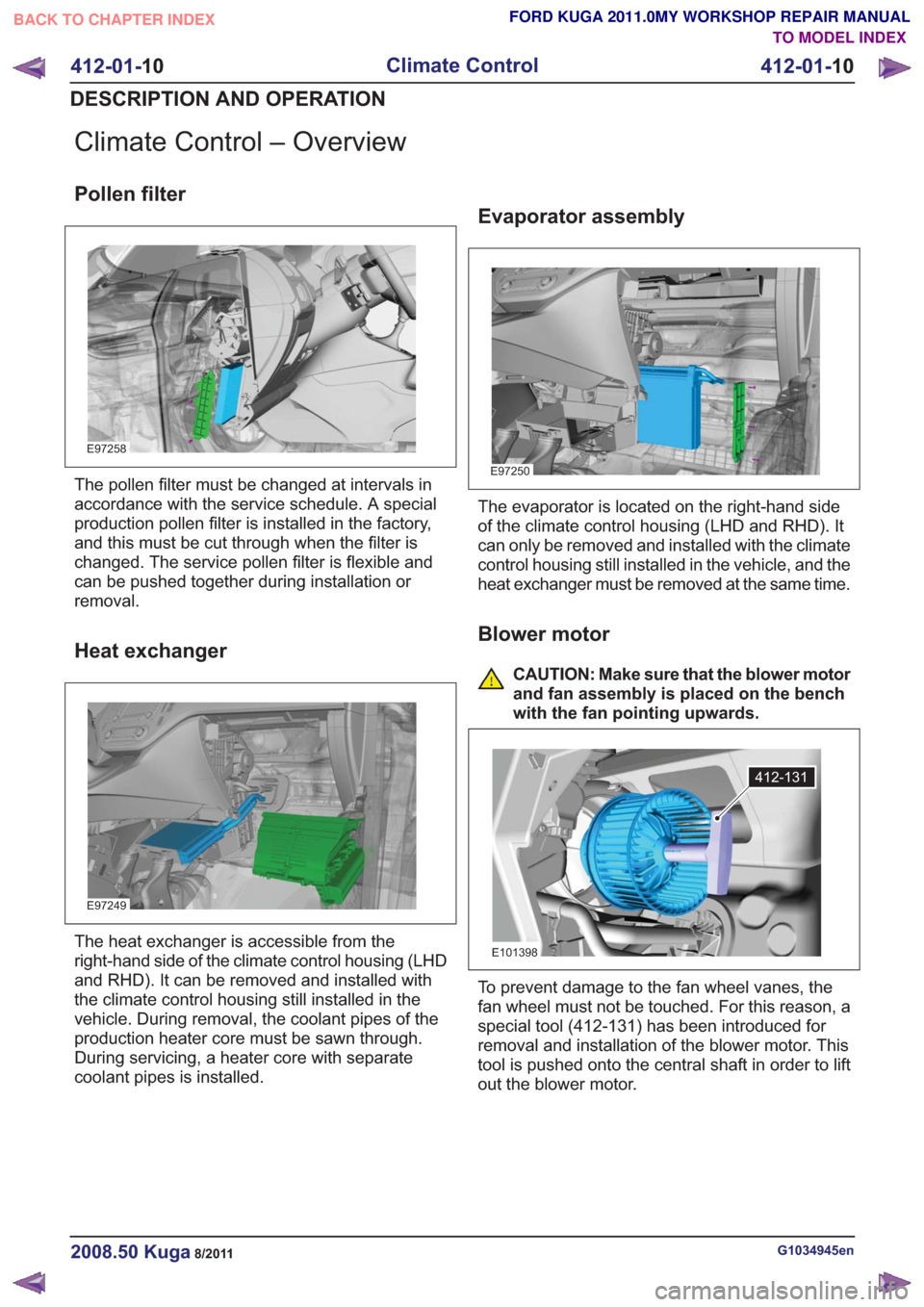

Climate Control – Overview

Pollen filter

E97258

The pollen filter must be changed at intervals in

accordance with the service schedule. A special

production pollen filter is installed in the factory,

and this must be cut through when the filter is

changed. The service pollen filter is flexible and

can be pushed together during installation or

removal.

Heat exchanger

E97249

The heat exchanger is accessible from the

right-hand side of the climate control housing (LHD

and RHD). It can be removed and installed with

the climate control housing still installed in the

vehicle. During removal, the coolant pipes of the

production heater core must be sawn through.

During servicing, a heater core with separate

coolant pipes is installed.

Evaporator assembly

E97250

The evaporator is located on the right-hand side

of the climate control housing (LHD and RHD). It

can only be removed and installed with the climate

control housing still installed in the vehicle, and the

heat exchanger must be removed at the same time.

Blower motor

CAUTION: Make sure that the blower motor

and fan assembly is placed on the bench

with the fan pointing upwards.

412-131

E101398

To prevent damage to the fan wheel vanes, the

fan wheel must not be touched. For this reason, a

special tool (412-131) has been introduced for

removal and installation of the blower motor. This

tool is pushed onto the central shaft in order to lift

out the blower motor.

G1034945en2008.50 Kuga8/2011

412-01-10

Climate Control

412-01- 10

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL