100 FORD KUGA 2011 1.G Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2011, Model line: KUGA, Model: FORD KUGA 2011 1.GPages: 2057

Page 2018 of 2057

Air Conditioning (A/C) System Recovery, Evacuation and Charging

General EquipmentAir Conditioning Service Unit

Automatic Calibration Halogen Leak Detector

Electronic Leak Detector

Refrigerant Identification Equipment

UV Leak Detector

1. Refer to: Air Conditioning (A/C) System Health

and Safety Precautions (100-00 General

Information, Description and Operation).

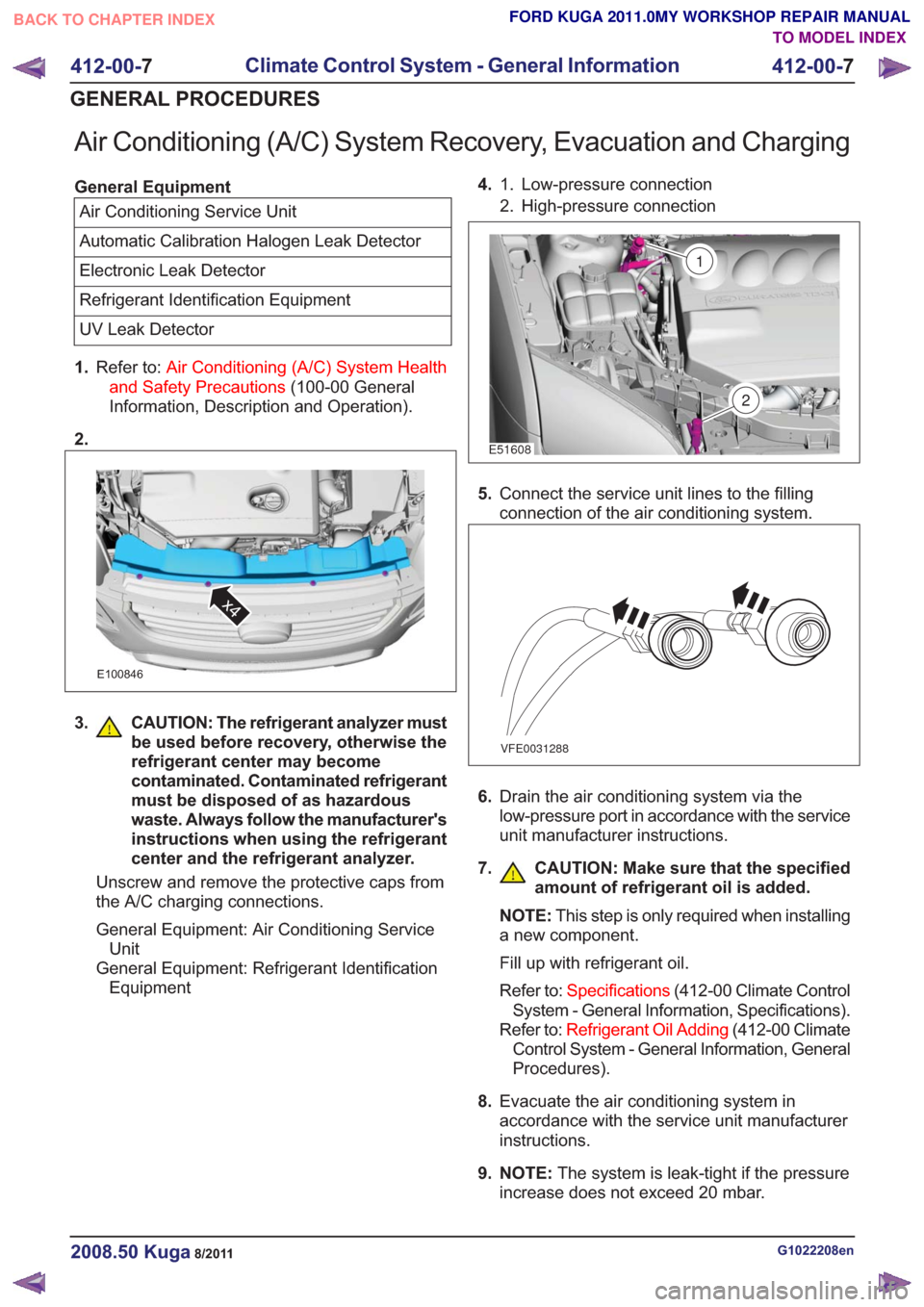

2.

E100846

x4

3. CAUTION: The refrigerant analyzer must be used before recovery, otherwise the

refrigerant center may become

contaminated. Contaminated refrigerant

must be disposed of as hazardous

waste. Always follow the manufacturer's

instructions when using the refrigerant

center and the refrigerant analyzer.

Unscrew and remove the protective caps from

the A/C charging connections.

General Equipment: Air Conditioning Service Unit

General Equipment: Refrigerant Identification Equipment 4.

Low-pressure connection

1.

2. High-pressure connection

2

E51608

1

5. Connect the service unit lines to the filling

connection of the air conditioning system.

VFE0031288

6.Drain the air conditioning system via the

low-pressure port in accordance with the service

unit manufacturer instructions.

7. CAUTION: Make sure that the specified amount of refrigerant oil is added.

NOTE:This step is only required when installing

a new component.

Fill up with refrigerant oil.

Refer to: Specifications (412-00 Climate Control

System - General Information, Specifications).

Refer to: Refrigerant Oil Adding (412-00 Climate

Control System - General Information, General

Procedures).

8. Evacuate the air conditioning system in

accordance with the service unit manufacturer

instructions.

9. NOTE: The system is leak-tight if the pressure

increase does not exceed 20 mbar.

G1022208en2008.50 Kuga8/2011

412-00- 7

Climate Control System - General Information

412-00- 7

GENERAL PROCEDURES

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 2020 of 2057

Spring Lock Coupling

Special Tool(s)412-026

Disconnect Tool, Spring Lock

Coupling (3/8" red)

23023A

412-027

Disconnect Tool, Spring Lock

Coupling (1/2" blue)

34001

412-038

Disconnect Tool, Spring Lock

Coupling (5/8" black)

34003

412-069

Disconnect Tool, Spring Lock

Coupling (3/4" white)

34002

Materials

Specification

Name

WSH-M1C231-B /

6U7J-M1C231-AA

Compressor Oil - Air

Conditioning 1.

Refer to: Air Conditioning (A/C) System Health

and Safety Precautions (100-00 General

Information, Description and Operation).

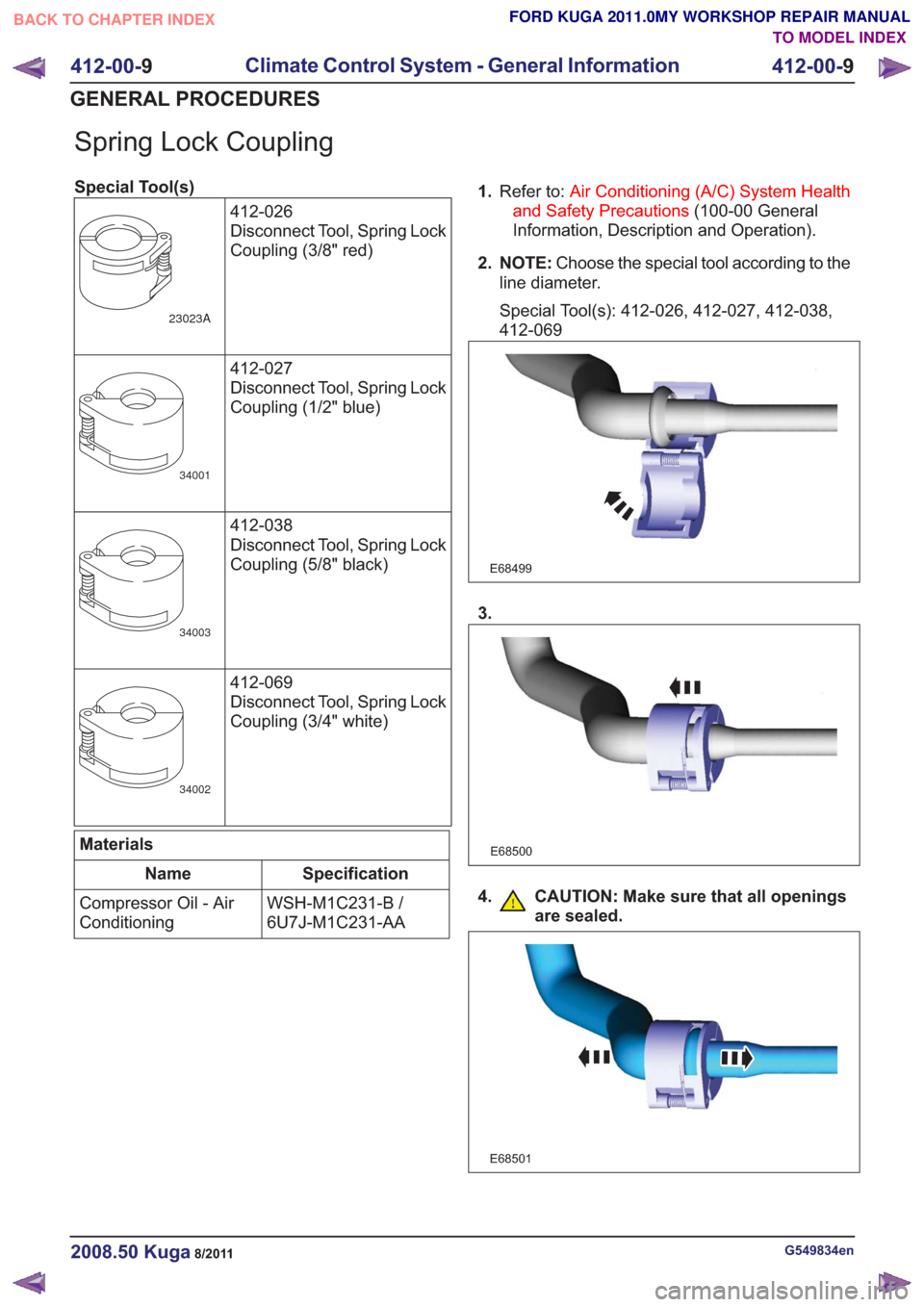

2. NOTE: Choose the special tool according to the

line diameter.

Special Tool(s): 412-026, 412-027, 412-038,

412-069

E68499

3.

E68500

4. CAUTION: Make sure that all openings are sealed.

E68501

G549834en2008.50 Kuga8/2011

412-00- 9

Climate Control System - General Information

412-00- 9

GENERAL PROCEDURES

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 2025 of 2057

Electronic Leak Detection

1.Refer to: Air Conditioning (A/C) System Health

and Safety Precautions (100-00 General

Information, Description and Operation).

2. WARNINGS:

Before starting leak detection, make

sure that the area where it is to be done

is well ventilated. If the surrounding air

is contaminated with refrigerant gas, the

leak detector will indicate this gas all

the time. Odors from other chemicals

such as antifreeze, diesel fuel, disc

brake cleaner, or other cleaning

solvents can cause the same problem.

Prevent air movement while performing

leak detection.

The refrigerant identification equipment

must be used before attaching the

manifold gauge set. Otherwise the

manifold gauge set may become

contaminated. Contaminated refrigerant

must be disposed of as special waste.

Follow the manufacturer's instructions

when working with the service unit.

NOTE: At 24°C with the engine switched off,

both manifold gauges should show 4.1 to 5.5

bar.

Attach the manifold gauge set to the service

gauge port valves.

3. For the leak test, close the manual valves on

the gauge set.

4. If little or no pressure is indicated, charge the

system with approx. 300g of refrigerant. Refer

to: Air Conditioning System - Evacuate and

Refill.

5. Use the R-134a Automatic Calibration Halogen

Leak Detector to leak test the refrigerant system.

Follow the instructions included with leak

detector for handling and operation techniques.

6. If any leak is found, extract the refrigerant under

suction. Refer to: Air Conditioning System -

Evacuate and Refill.

G549836en2008.50 Kuga8/2011

412-00- 14

Climate Control System - General Information

412-00- 14

GENERAL PROCEDURES

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 2026 of 2057

Fluorescent Dye Leak Detection

General EquipmentUV Leak Detector

1. Refer to: Air Conditioning (A/C) System Health

and Safety Precautions (100-00 General

Information, Description and Operation).

2. NOTE: Some vehicles may have signs of

refrigerant oil at the spring lock couplers. The

cause of this may be a procedure used in

production before installation of the fittings in

order to assist their assembly. When a spring

lock coupler is suspected of leaking, always

wipe the fitting clean and verify the leak with

R-134a Automatic Calibration Halogen Leak

Detector.

NOTE: The exact location of leaks can be

pinpointed by the bright yellow - green glow of

the tracer dye. Since more than one leak can

exist, always inspect each component.

• Locate the leaks. Check all components, fittings and lines of the A/C system for leaks.

General Equipment: UV Leak Detector

3. After the leak is found and rectified, remove any

traces of dye with a general purpose solvent.

4. Check the repair by operating the system for

some minutes and inspecting with the UV lamp

again.

G1065493en2008.50 Kuga8/2011

412-00- 15

Climate Control System - General Information

412-00- 15

GENERAL PROCEDURES

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 2050 of 2057

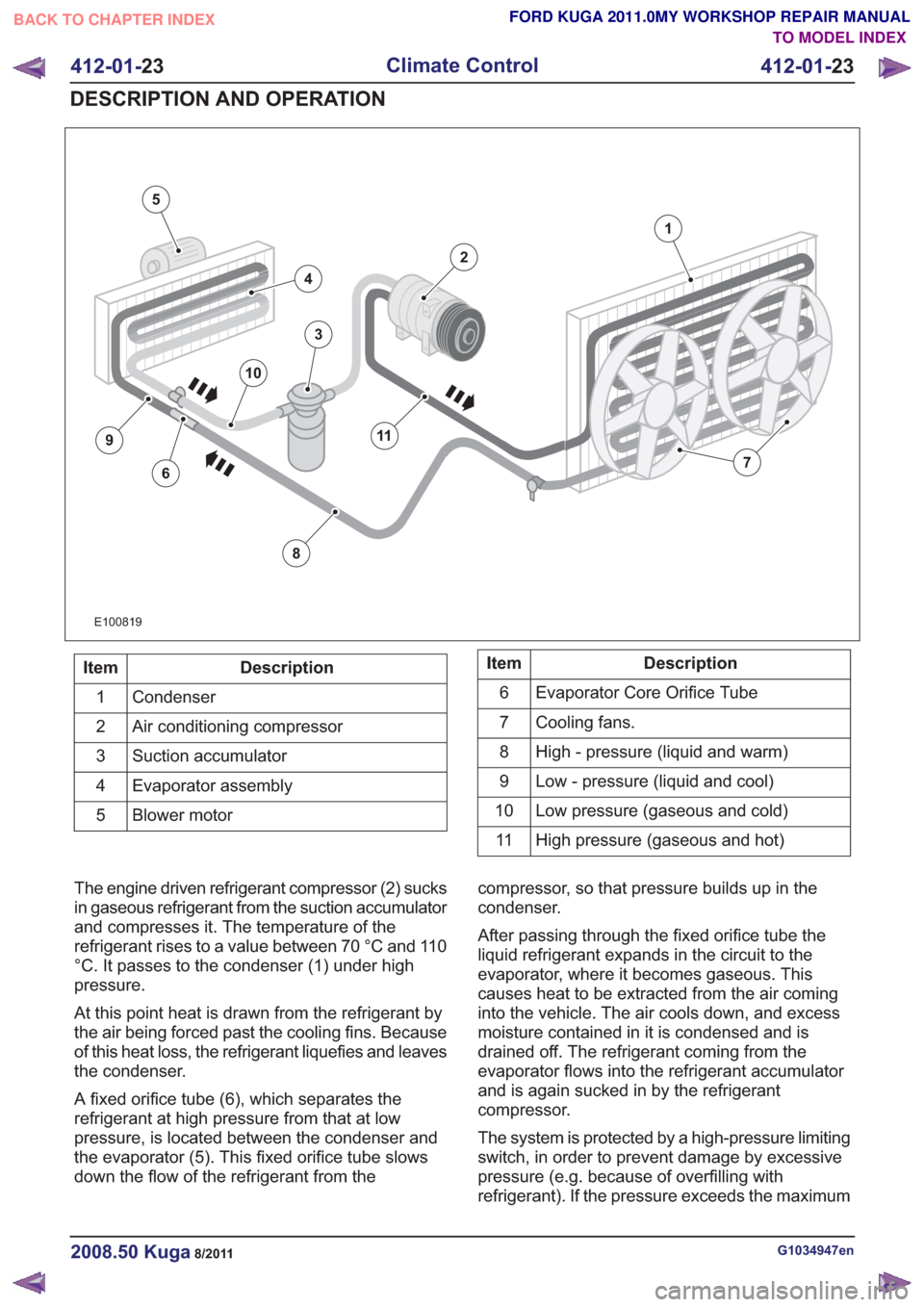

1

2

3

5

4

67

8

9

10

11

E100819

Description

Item

Condenser

1

Air conditioning compressor

2

Suction accumulator

3

Evaporator assembly

4

Blower motor

5Description

Item

Evaporator Core Orifice Tube

6

Cooling fans.

7

High - pressure (liquid and warm)

8

Low - pressure (liquid and cool)

9

Low pressure (gaseous and cold)

10

High pressure (gaseous and hot)

11

The engine driven refrigerant compressor (2) sucks

in gaseous refrigerant from the suction accumulator

and compresses it. The temperature of the

refrigerant rises to a value between 70 °C and 110

°C. It passes to the condenser (1) under high

pressure.

At this point heat is drawn from the refrigerant by

the air being forced past the cooling fins. Because

of this heat loss, the refrigerant liquefies and leaves

the condenser.

A fixed orifice tube (6), which separates the

refrigerant at high pressure from that at low

pressure, is located between the condenser and

the evaporator (5). This fixed orifice tube slows

down the flow of the refrigerant from the compressor, so that pressure builds up in the

condenser.

After passing through the fixed orifice tube the

liquid refrigerant expands in the circuit to the

evaporator, where it becomes gaseous. This

causes heat to be extracted from the air coming

into the vehicle. The air cools down, and excess

moisture contained in it is condensed and is

drained off. The refrigerant coming from the

evaporator flows into the refrigerant accumulator

and is again sucked in by the refrigerant

compressor.

The system is protected by a high-pressure limiting

switch, in order to prevent damage by excessive

pressure (e.g. because of overfilling with

refrigerant). If the pressure exceeds the maximum

G1034947en2008.50 Kuga8/2011

412-01-

23

Climate Control

412-01- 23

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 2051 of 2057

permitted, the high-pressure switch turns off the

refrigerant compressor.

The compressor on-off cycle is controlled by the

dual pressure switch depending on the pressure

in the refrigerant accumulator. The dual pressure

switch turns the refrigerant compressor off

permanently if the pressure falls below a permitted

value (e.g. if there is a leak).

Component Description

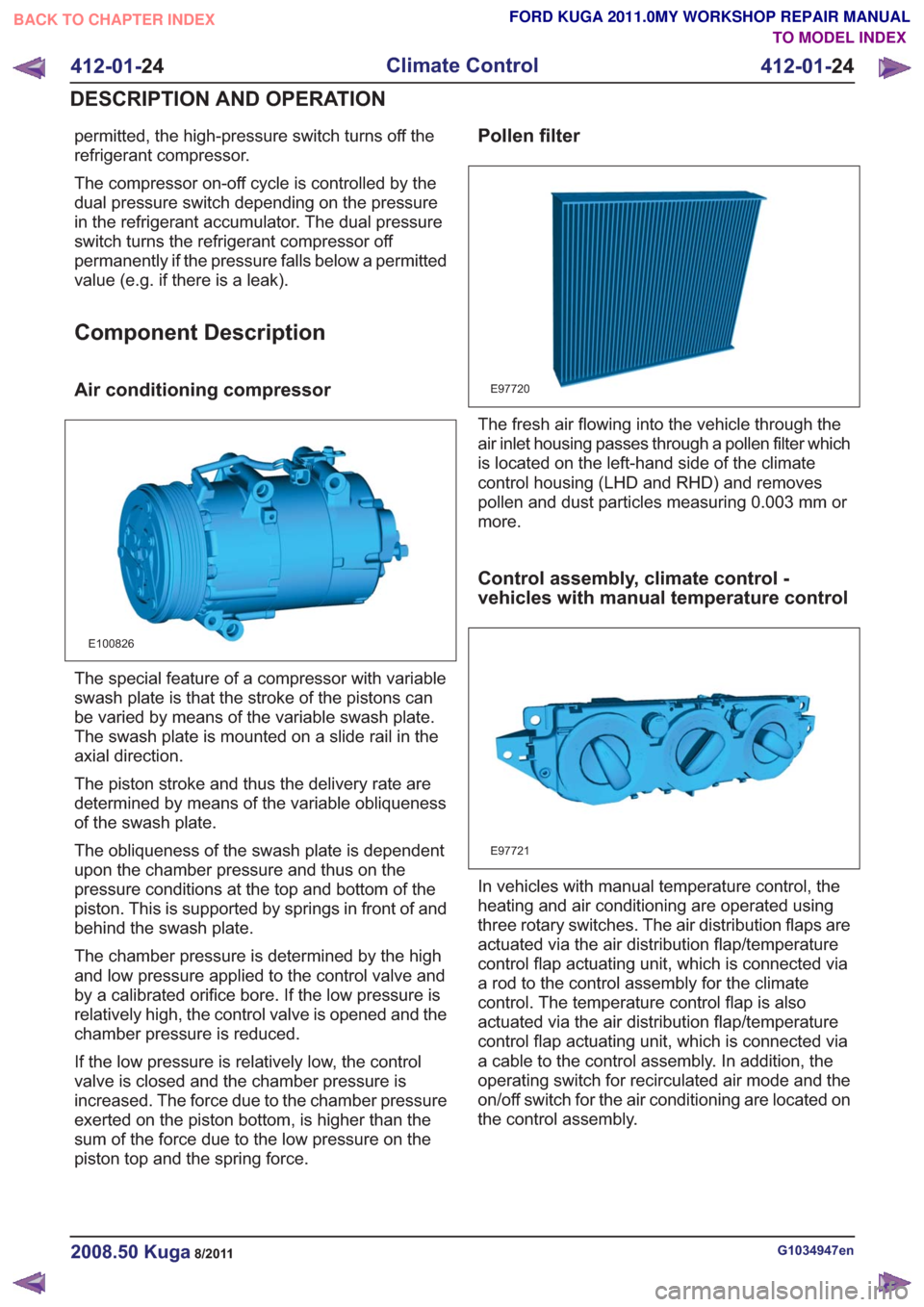

Air conditioning compressor

E100826

The special feature of a compressor with variable

swash plate is that the stroke of the pistons can

be varied by means of the variable swash plate.

The swash plate is mounted on a slide rail in the

axial direction.

The piston stroke and thus the delivery rate are

determined by means of the variable obliqueness

of the swash plate.

The obliqueness of the swash plate is dependent

upon the chamber pressure and thus on the

pressure conditions at the top and bottom of the

piston. This is supported by springs in front of and

behind the swash plate.

The chamber pressure is determined by the high

and low pressure applied to the control valve and

by a calibrated orifice bore. If the low pressure is

relatively high, the control valve is opened and the

chamber pressure is reduced.

If the low pressure is relatively low, the control

valve is closed and the chamber pressure is

increased. The force due to the chamber pressure

exerted on the piston bottom, is higher than the

sum of the force due to the low pressure on the

piston top and the spring force.

Pollen filter

E97720

The fresh air flowing into the vehicle through the

air inlet housing passes through a pollen filter which

is located on the left-hand side of the climate

control housing (LHD and RHD) and removes

pollen and dust particles measuring 0.003 mm or

more.

Control assembly, climate control -

vehicles with manual temperature control

E97721

In vehicles with manual temperature control, the

heating and air conditioning are operated using

three rotary switches. The air distribution flaps are

actuated via the air distribution flap/temperature

control flap actuating unit, which is connected via

a rod to the control assembly for the climate

control. The temperature control flap is also

actuated via the air distribution flap/temperature

control flap actuating unit, which is connected via

a cable to the control assembly. In addition, the

operating switch for recirculated air mode and the

on/off switch for the air conditioning are located on

the control assembly.

G1034947en2008.50 Kuga8/2011

412-01-24

Climate Control

412-01- 24

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 2053 of 2057

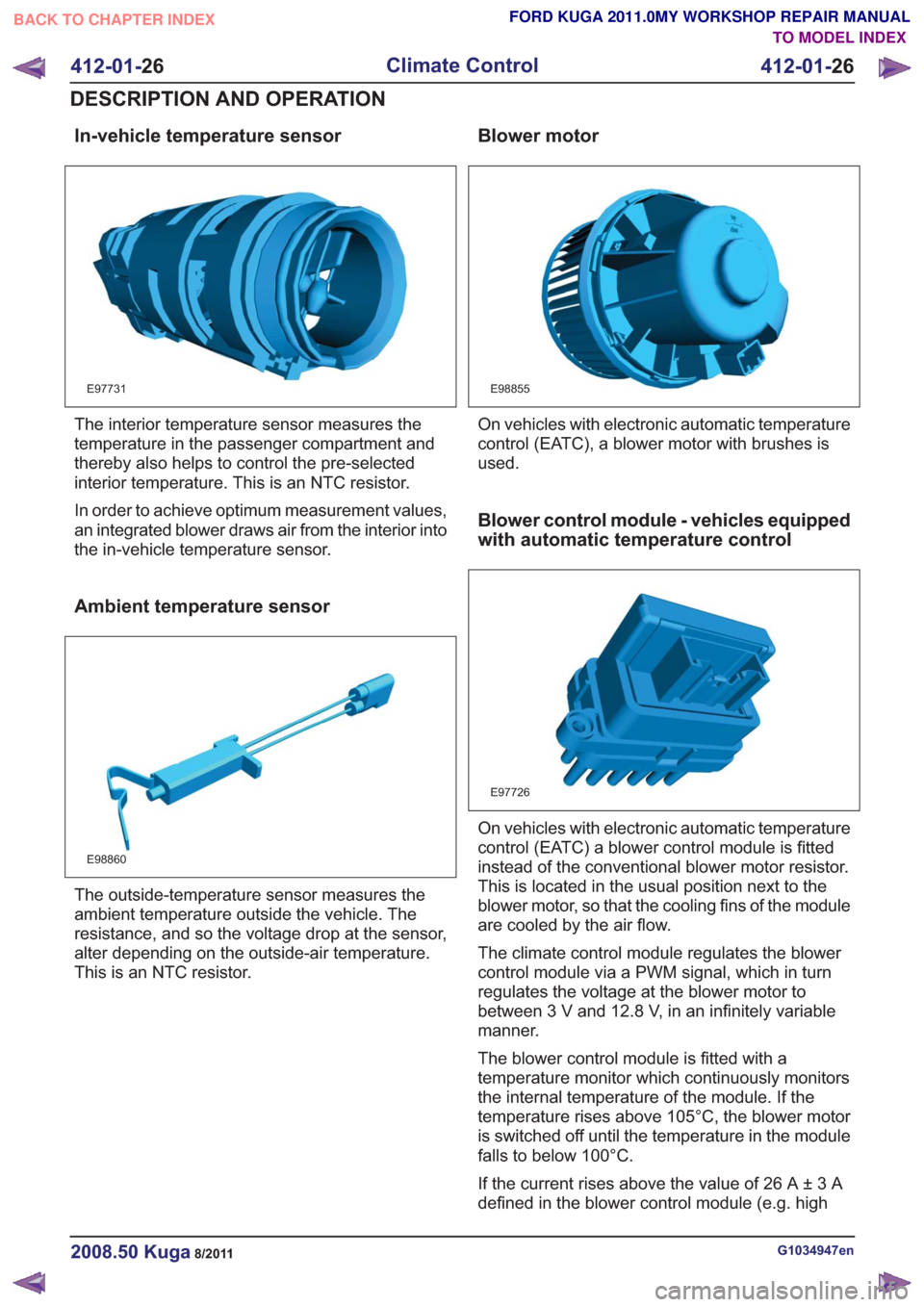

In-vehicle temperature sensor

E97731

The interior temperature sensor measures the

temperature in the passenger compartment and

thereby also helps to control the pre-selected

interior temperature. This is an NTC resistor.

In order to achieve optimum measurement values,

an integrated blower draws air from the interior into

the in-vehicle temperature sensor.

Ambient temperature sensor

E98860

The outside-temperature sensor measures the

ambient temperature outside the vehicle. The

resistance, and so the voltage drop at the sensor,

alter depending on the outside-air temperature.

This is an NTC resistor.

Blower motor

E98855

On vehicles with electronic automatic temperature

control (EATC), a blower motor with brushes is

used.

Blower control module - vehicles equipped

with automatic temperature control

E97726

On vehicles with electronic automatic temperature

control (EATC) a blower control module is fitted

instead of the conventional blower motor resistor.

This is located in the usual position next to the

blower motor, so that the cooling fins of the module

are cooled by the air flow.

The climate control module regulates the blower

control module via a PWM signal, which in turn

regulates the voltage at the blower motor to

between 3 V and 12.8 V, in an infinitely variable

manner.

The blower control module is fitted with a

temperature monitor which continuously monitors

the internal temperature of the module. If the

temperature rises above 105°C, the blower motor

is switched off until the temperature in the module

falls to below 100°C.

If the current rises above the value of 26 A ± 3 A

defined in the blower control module (e.g. high

G1034947en2008.50 Kuga8/2011

412-01-26

Climate Control

412-01- 26

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 2056 of 2057

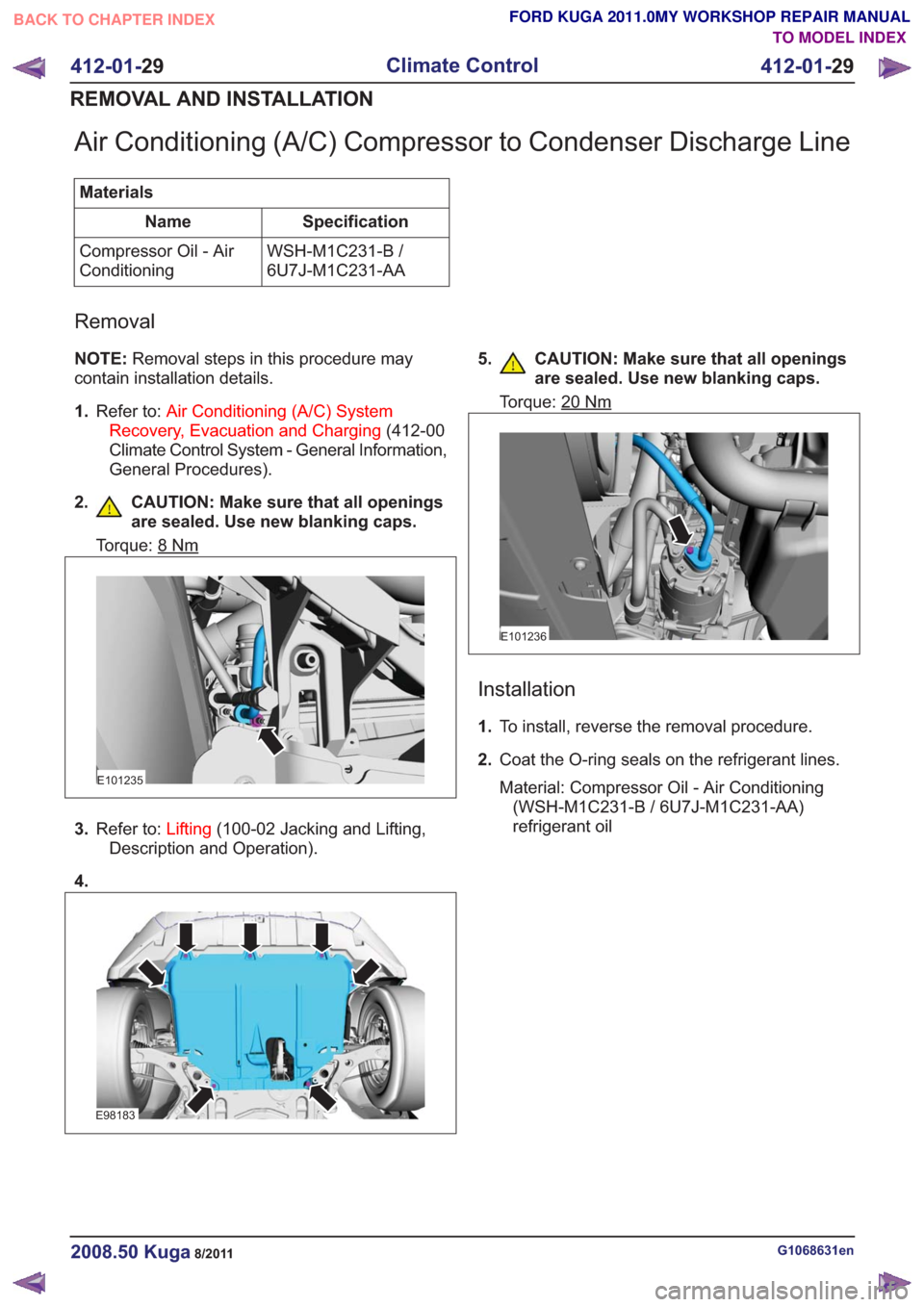

Air Conditioning (A/C) Compressor to Condenser Discharge Line

MaterialsSpecification

Name

WSH-M1C231-B /

6U7J-M1C231-AA

Compressor Oil - Air

Conditioning

Removal

NOTE:

Removal steps in this procedure may

contain installation details.

1. Refer to: Air Conditioning (A/C) System

Recovery, Evacuation and Charging (412-00

Climate Control System - General Information,

General Procedures).

2. CAUTION: Make sure that all openings are sealed. Use new blanking caps.

Torque: 8Nm

E101235

3.Refer to: Lifting(100-02 Jacking and Lifting,

Description and Operation).

4.

E98183

5. CAUTION: Make sure that all openings are sealed. Use new blanking caps.

Torque: 20Nm

E101236

Installation

1.To install, reverse the removal procedure.

2. Coat the O-ring seals on the refrigerant lines.

Material: Compressor Oil - Air Conditioning

(WSH-M1C231-B / 6U7J-M1C231-AA)

refrigerant oil

G1068631en2008.50 Kuga8/2011

412-01- 29

Climate Control

412-01- 29

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 2057 of 2057

Air Conditioning (A/C) Compressor to Condenser Discharge Line— 2.5L Duratec (147kW/200PS) - VI5

Materials

Specification

Name

WSH-M1C231-B /

6U7J-M1C231-AA

Compressor Oil - Air

Conditioning

Removal

NOTE:

Removal steps in this procedure may

contain installation details.

1. Refer to: Air Conditioning (A/C) System

Recovery, Evacuation and Charging (412-00

Climate Control System - General Information,

General Procedures).

2. CAUTION: Make sure that all openings are sealed.

Torque: 8Nm

E112729

3.Refer to: Lifting(100-02 Jacking and Lifting,

Description and Operation).

4.

E98183

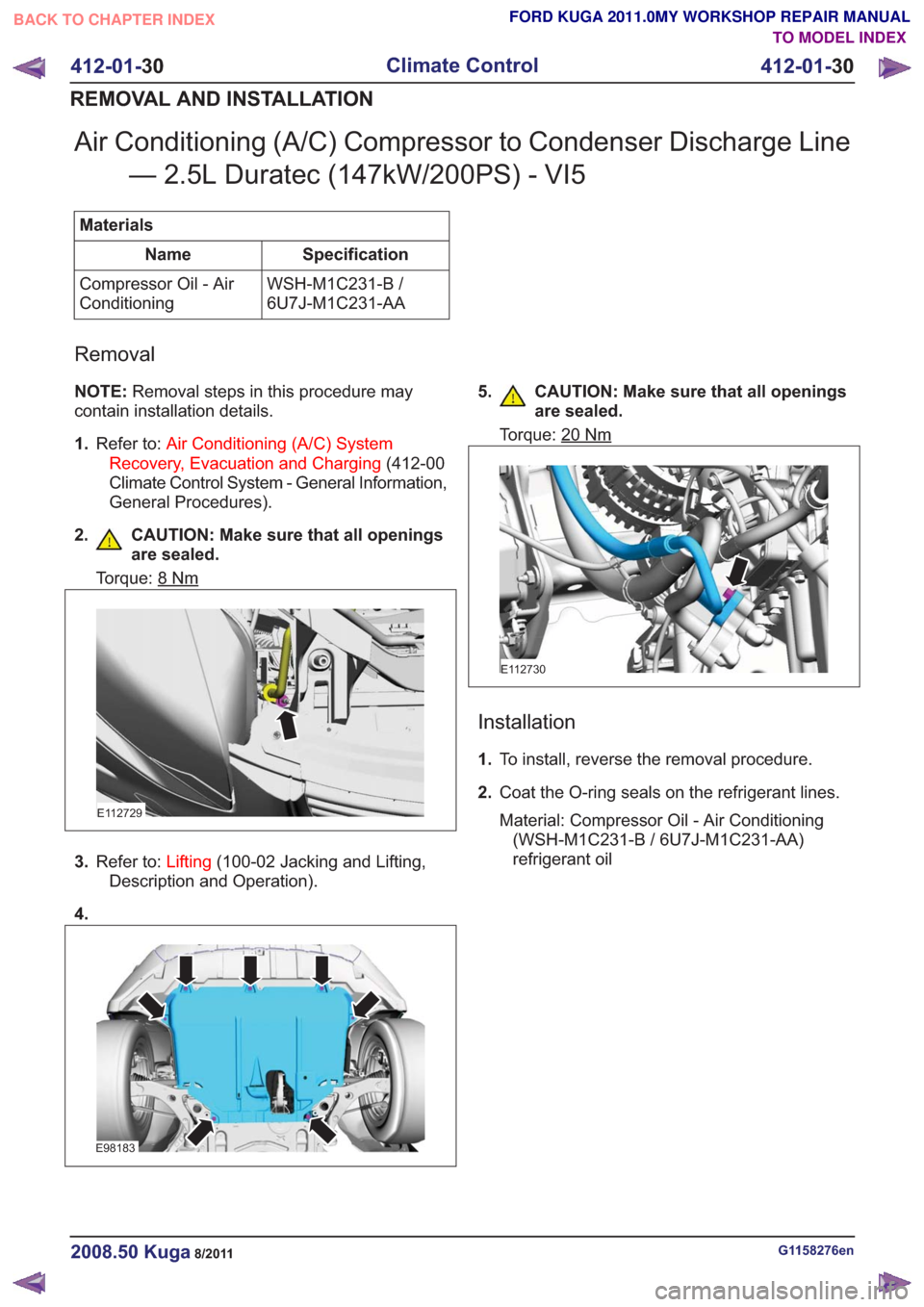

5. CAUTION: Make sure that all openings are sealed.

Torque: 20Nm

E112730

Installation

1.To install, reverse the removal procedure.

2. Coat the O-ring seals on the refrigerant lines.

Material: Compressor Oil - Air Conditioning

(WSH-M1C231-B / 6U7J-M1C231-AA)

refrigerant oil

G1158276en2008.50 Kuga8/2011

412-01- 30

Climate Control

412-01- 30

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL