airbag off FORD KUGA 2011 1.G Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2011, Model line: KUGA, Model: FORD KUGA 2011 1.GPages: 2057

Page 74 of 2057

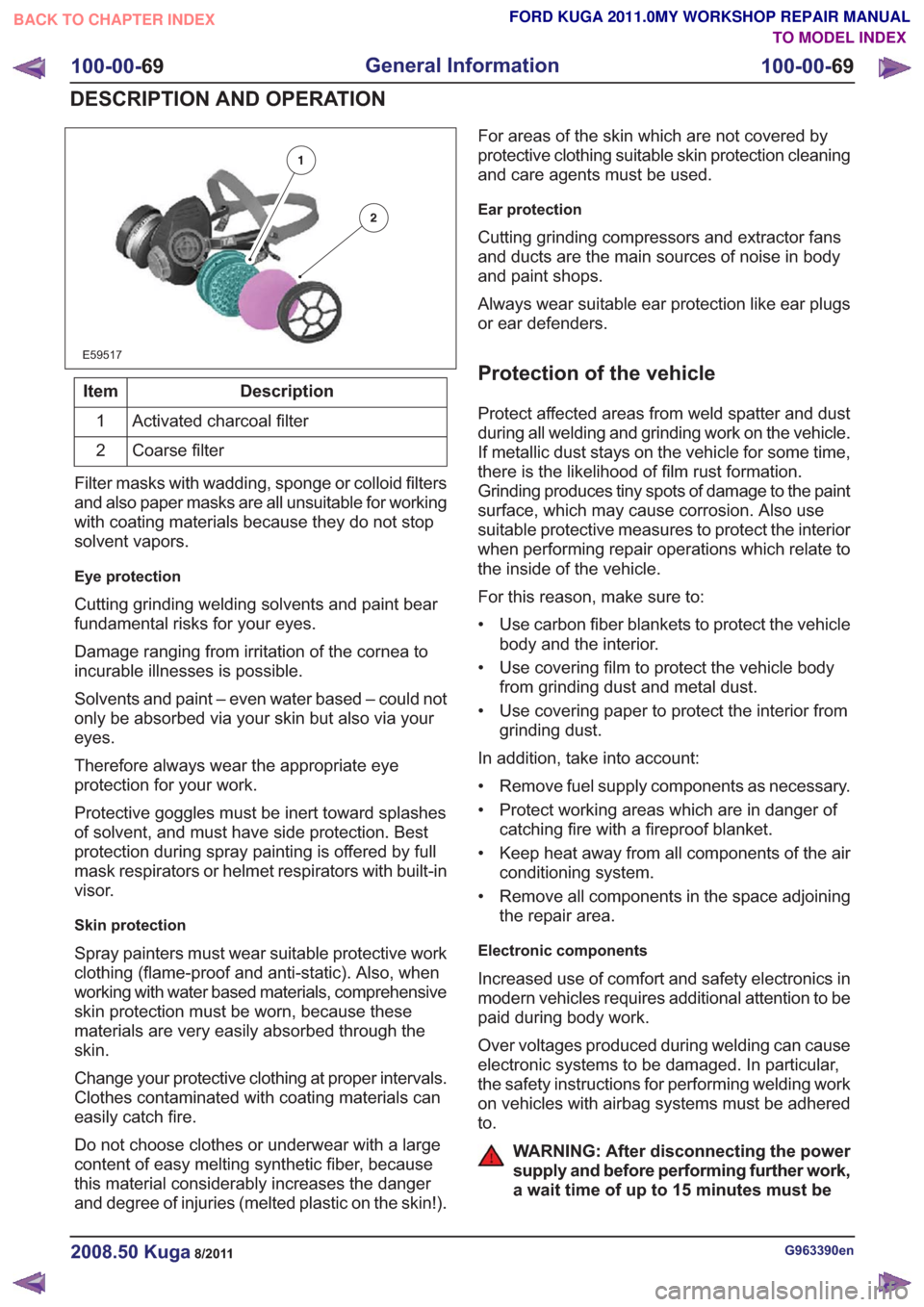

E59517

Description

Item

Activated charcoal filter

1

Coarse filter

2

Filter masks with wadding, sponge or colloid filters

and also paper masks are all unsuitable for working

with coating materials because they do not stop

solvent vapors.

Eye protection

Cutting grinding welding solvents and paint bear

fundamental risks for your eyes.

Damage ranging from irritation of the cornea to

incurable illnesses is possible.

Solvents and paint – even water based – could not

only be absorbed via your skin but also via your

eyes.

Therefore always wear the appropriate eye

protection for your work.

Protective goggles must be inert toward splashes

of solvent, and must have side protection. Best

protection during spray painting is offered by full

mask respirators or helmet respirators with built-in

visor.

Skin protection

Spray painters must wear suitable protective work

clothing (flame-proof and anti-static). Also, when

working with water based materials, comprehensive

skin protection must be worn, because these

materials are very easily absorbed through the

skin.

Change your protective clothing at proper intervals.

Clothes contaminated with coating materials can

easily catch fire.

Do not choose clothes or underwear with a large

content of easy melting synthetic fiber, because

this material considerably increases the danger

and degree of injuries (melted plastic on the skin!). For areas of the skin which are not covered by

protective clothing suitable skin protection cleaning

and care agents must be used.

Ear protection

Cutting grinding compressors and extractor fans

and ducts are the main sources of noise in body

and paint shops.

Always wear suitable ear protection like ear plugs

or ear defenders.

Protection of the vehicle

Protect affected areas from weld spatter and dust

during all welding and grinding work on the vehicle.

If metallic dust stays on the vehicle for some time,

there is the likelihood of film rust formation.

Grinding produces tiny spots of damage to the paint

surface, which may cause corrosion. Also use

suitable protective measures to protect the interior

when performing repair operations which relate to

the inside of the vehicle.

For this reason, make sure to:

• Use carbon fiber blankets to protect the vehicle

body and the interior.

• Use covering film to protect the vehicle body from grinding dust and metal dust.

• Use covering paper to protect the interior from grinding dust.

In addition, take into account:

• Remove fuel supply components as necessary.

• Protect working areas which are in danger of catching fire with a fireproof blanket.

• Keep heat away from all components of the air conditioning system.

• Remove all components in the space adjoining the repair area.

Electronic components

Increased use of comfort and safety electronics in

modern vehicles requires additional attention to be

paid during body work.

Over voltages produced during welding can cause

electronic systems to be damaged. In particular,

the safety instructions for performing welding work

on vehicles with airbag systems must be adhered

to.

WARNING: After disconnecting the power

supply and before performing further work,

a wait time of up to 15 minutes must be

G963390en2008.50 Kuga8/2011

100-00- 69

General Information

100-00- 69

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 167 of 2057

reprogrammed. However, if the engine hasn't been

run since the last programmed start, the fuel-fired

booster heater will not start up the second time so

as to prevent the battery from being discharged.

The length of time required to pre-heat the vehicle

is calculated in the control unit of the fuel-fired

booster heater and is based on two temperature

values:

• Ambient air temperature: this message is taken

from the GEM via the CAN bus.

• Coolant temperature: this is determined via an internal sensor in the fuel-fired booster heater.

The maximum heating time is 30 minutes at an

outside air temperature of -10 °C or lower. The

heating time decreases proportionally with

increasing ambient temperature until the ambient

temperature is between +15 °C and +20 °C. Then

the minimum heating time is 10 minutes. The

parking heater is deactivated at temperatures

above +20 °C.

The sequence for a programmed start of the

booster heater is as follows:

• Two minutes before the start of the maximum heating time the driver information

system/instrument cluster sends an activation

message to the fuel-fired booster heater via the

CAN bus.

• The fuel-fired booster heater calculates the required heating time and, if necessary, sends

a delay request on the CAN bus.

• At the calculated time, the fuel-fired booster heater starts up. The conditions for start-up are:

engine not running and amount of fuel in the

fuel tank is above 14% of maximum.

• When the coolant temperature reaches +30 °C, the control unit of the fuel-fired booster heater

sends a request to switch on the passenger

compartment blower.

• Eight minutes after the programmed switch-off time, the booster heater stops heating mode

and starts a run-on operation to clean the

system's spark plugs.

• Ten minutes after the switch-off time, the post-cleaning operation is complete. The

additional ten minutes run-on time provides

some leeway in case the driver is late arriving.

After a programmed start-up of the booster heater

it is switched off again after the heating time has

elapsed (or if the fuel level in the fuel tank drops

below 8%). The booster heater stops within 2 minutes of the engine starting. This leaves enough

time to check whether the switch-on conditions for

boost heat mode have been met, thus preventing

the booster heater from having to switch off and

switch back on again. The heater can be switched

off manually at any time from the menu.

Whilst the fuel-fired booster heater is in additional

heating mode and/or parking heating mode, the

instrument cluster receives a fuel consumption

signal; this is used to re-calculate the vehicle's

remaining range and fuel consumption data.

Emergency shutoff

In the event of an accident in which the airbags

are deployed, the control unit of the fuel-fired

booster heater receives a message on the CAN

bus from the restraints control module (RCM).

When this message is received, the booster heater

system switches off immediately.

The booster heater control module deactivates the

system and does not respond to further messages

on the CAN bus. The booster heater control module

needs to be activated with WDS.

Component Description

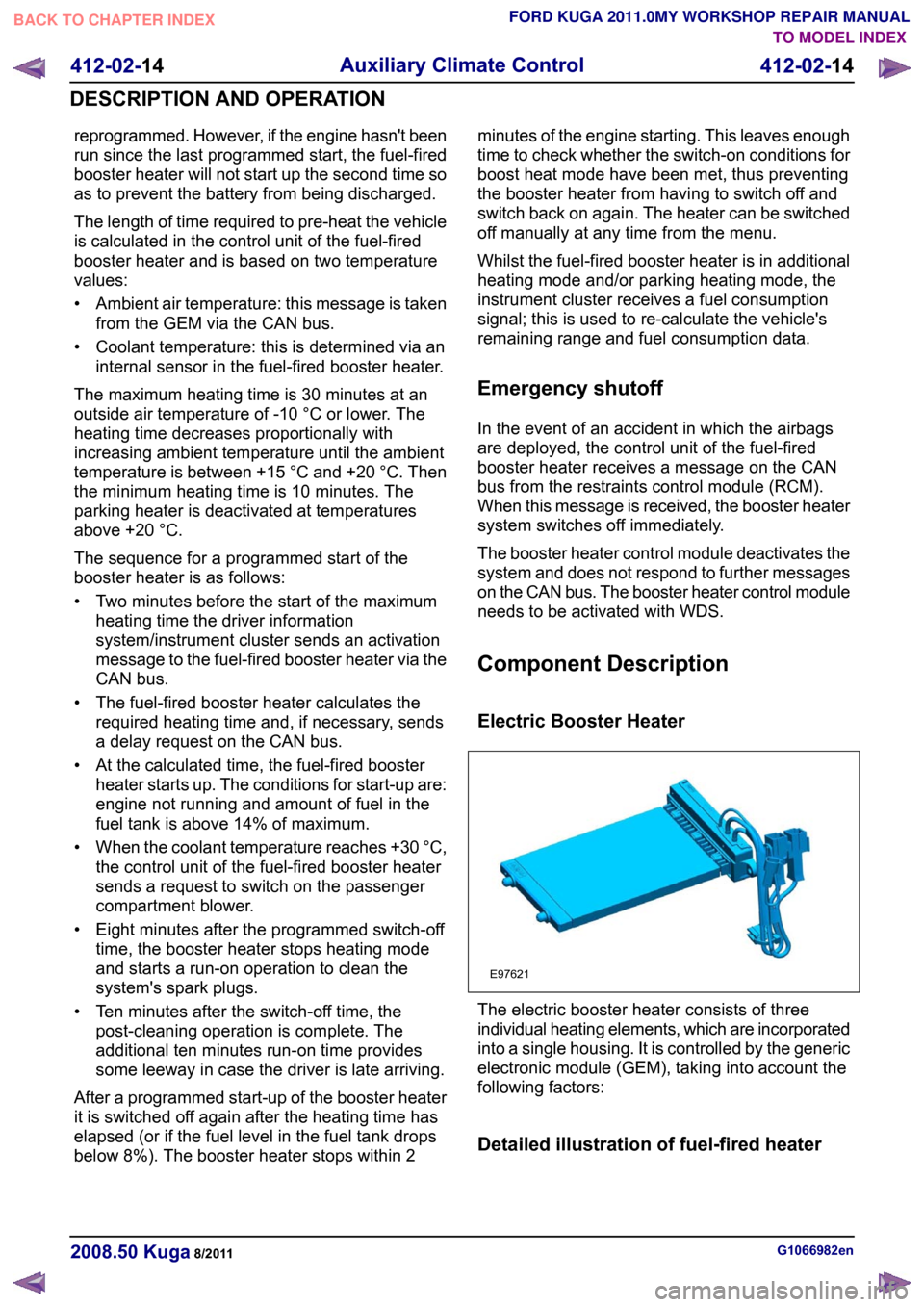

Electric Booster Heater

The electric booster heater consists of three

individual heating elements, which are incorporated

into a single housing. It is controlled by the generic

electronic module (GEM), taking into account the

following factors:

Detailed illustration of fuel-fired heater

G1066982en

2008.50 Kuga 8/2011 412-02-14

Auxiliary Climate Control

412-02-14

DESCRIPTION AND OPERATIONTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUALE97621